#metal laser cutter company

Text

Top Reasons to Choose Huxley Designs Laser Cutting for Sheet Metal Fabrication Projects

Huxley Designs offers Sheet Metal Laser Cutting services for a wide range of fabrication needs. Our expert fabrication team will create your project on time, within budget, and with the highest standards of craftsmanship. We're here to help you get started. Give us a call at (801)-900-0633.

#metal laser cutting utah#Laser Cutting Utah#Custom Laser Cutting Utah#Cnc Laser Cutter Utah#The Laser Cutting Company Utah

2 notes

·

View notes

Text

to be fair, weaving and dyeing and all these things i do aren't super accessible either but i feel the barrier to, say, spin yarn with a drop spindle or use a frame loom aka a picture frame to weave something or naturally dye some yarn using some onion skins in your kitchen is less severe than that of trying to access a 3d printer or laser cutter or the knowledge to operate them or a computer that can run 3d modeling software without blue screening for most people, and environmental impact of working with wool and wood equipment is something that is more manageable than using petrochem plastic resin that will literally never decompose and all of this complex computerized equipment relies on rare metals that are mined in africa and latin america by companies that destroy local communities and the land and cause irreparable damage

this isn't to slam using any of these methods or processes for making things, i've used 3d printers and worked with plastic resins and likely will in the future, i use computers, i'm typing this on my phone, i play video games etc but like that's my point, this stuff is kind of inescapable and it's so entrenched in how many of us esp those of us in the first world function day to day. there is value in the idea of taking the time to disconnect from all of that for a while, in processes that have nothing to do with the hyper-online digital tech world, in alternate ways of making art and finding entertainment and in manufacturing goods, to lessen our consumption if we can, to slow things down if we have the chance to do so, but many people are resistant to that idea or dismiss it as boomer talk or being a luddite or they get overly defensive.

my point is that the current arts industry landscape doesn't value artists who choose to work with materials and processes that provide somewhat of a respite from all of this, it doesn't value traditional craft and it can't bc the way the global economy is structured under capitalism requires making more things constantly and faster and for cheaper, it all relies on forever increasing profit margins. it does not value craft because it does not value labour. and valuing craft, and valuing slow processes and the physical labour involved and thinking about environmental impacts and the lifespan of an object, is fundamentally linked to valuing the labour and lives of the working class, and of the working people of the global south, and the environment.

the same tech companies that exploit and outsource labour to underpaid and slave labour in the global south and exploit blue collar workers in the global north and destroy the environment are funding the arts across the world. so many textile designers and illustrators and graphic designers i know have worked for google and amazon and banks and all of these fast fashion retailers, that's where the money is. these companies all have arts divisions, their money gets invested in arts programming talking about AI and digital economies and they get them to make art about sustainability and diversity and using all of this cool new radical tech theyre making while they simultaneously poison rivers in the amazon and manufacture their clothes in collapsing warehouses in bangladesh and send death squads to terrorize people in central africa. it's all connected, none of this is new, individual solutions to these problems don't exist, etc etc etc and we are all implicated in this whether willfully or not.

but on a micro level i just wish that craft was valued more and there were more opportunities for craftspeople in the arts, that there were more spaces for people who don't have any interest in working with tech or digital art, and traditional craftspeople esp those in the global south have the time and space to labour humanely and that craft labour is valued, that slow work is valued, and not for profit reasons but because it's so fundamental to the human experience and its necessary that we reassess the role of craft and analogue processes if we are to actually address climate change and the impacts of mass manufacturing in its current form on people and the planet. but all of this is a symptom of a greater problem (capitalism, and imperialism which is the highest stage of capitalism), it doesn't exist in a vacuum.

137 notes

·

View notes

Text

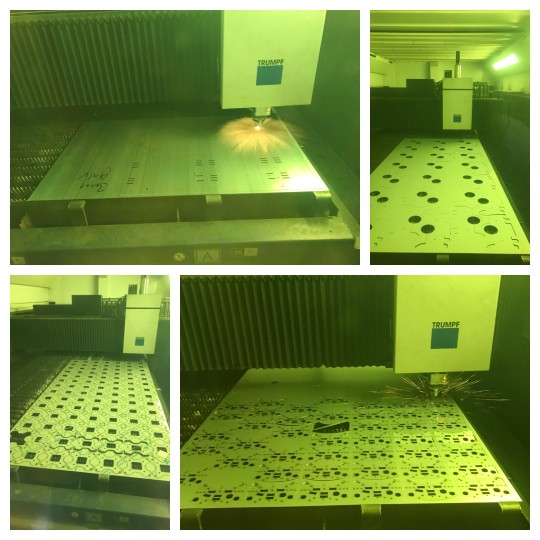

If you are looking for a reliable and professional metal fabrication company in Canada, look no further than Tecoustics. We offer a wide range of services, including Mig Welding, Tig Welding, Forming and Bending, Metal Laser Cutting, Mechanized Plasma Cutting, and Oxy-Acetylene Cutting. Whether you need laser cutters for metal, laser cutting of metal, or laser for cutting metal, we have the equipment and expertise to handle any project.

#mig welding#tig welding#laser cutters for metal#laser cutting services#oxy-acetylene cutting#mechanized plasma cutting#laser cutting steel

3 notes

·

View notes

Text

Laser cutting has revolutionized the sheet metal fabrication industry, offering precision, speed, and versatility like never before. Utilizing a highly focused beam of light, laser cutting can effortlessly slice through various materials, including sheet metal, with unparalleled accuracy and intricacy. For those in Hampshire, UK, seeking a reliable sheet metal company, V and F Sheet Metal stands out as a prime choice, particularly for laser cutting services.

V and F Sheet Metal boasts state-of-the-art laser cutting technology coupled with years of expertise, ensuring clients receive top-notch results tailored to their exact specifications. Their advanced equipment allows for intricate designs, intricate patterns, and precise cuts, catering to a wide range of industries and applications. Whether it's creating intricate prototypes, intricate parts for machinery, or intricate decorative elements, V and F Sheet Metal's laser cutting capabilities can meet the most demanding requirements with ease.

Moreover, V and F Sheet Metal's commitment to quality, reliability, and customer satisfaction sets them apart as a trusted partner for all sheet metal needs in Hampshire and beyond. Their skilled team of professionals works closely with clients throughout the process, from initial design to final production, ensuring seamless execution and superior outcomes.

In conclusion, when it comes to laser cutting sheet metal in Hampshire, UK, V and F Sheet Metal stands as a premier choice, offering cutting-edge technology, unparalleled precision, and unmatched expertise to bring any project to fruition with excellence.

0 notes

Text

New Fibre Laser Cutting Machines For Sale

World Machinery Company, your favorite place to obtain superior grades of fibre laser cutting machines. The current shipment of our newest inventory comprises cutting edge technology featuring fibre laser cutter models for sale. Aimed at speediness and performance, these robots are tailored for today's production environment.

Feel the difference of cutting materials fast and precisely with our fiber laser machines that only works with high quality. Regardless of your specific industry be it automotive, aerospace or metal fabrication, our state-of-the-art solutions will lead to results of the highest quality as they will help to streamline your production processes and allow high production outputs.

Browse around with us and check out the exceptional New Fibre Laser Cutting Machines For Sale that will take your process to a higher level. The World Machinery Company brand promises you excellency. Invest in quality in order to invest in the future of production.

0 notes

Text

Advantages and Disadvantages of Laser Cutting

The basic and regularly used method in the manufacture of metal is cutting. In the business, laser cutting is the preferred technology for completing these tasks due to its numerous benefits over alternative approaches.

At the same time, it does have a few downsides as well. So let’s explore those great qualities and disadvantages more closely.

Table of Contents hide

I What Are the Advantages of Laser Cutting?

II What Are the Disadvantages of Laser Cutting?

III What Are the Advantages of Laser Cutting?

Manufacturers choose laser cutting services because of the numerous benefits they provide. Flexibility, accuracy, repeatability, speed, economy, excellent quality, contactless cutting, adaptability, and automation opportunities are some of the benefits of laser cutting.

Up to a thickness of around 10 mm, laser cutting outperforms alternative thermal cutting techniques like plasma or flame cutting in terms of speed. However, the laser cutter's power ultimately determines the precise advantage point.

Automation

Up to a thickness of around 10 mm, laser cutting outperforms alternative thermal cutting techniques like plasma or flame cutting in terms of speed. However, the laser cutter's power ultimately determines the precise advantage point.

Many machines even come with feeding systems as well as follow-up conveyors. Such setups make for a higher-priced laser cutting machine.

Scale Your Manufacturing from Prototyping to Series

Personal account manager

Quality assurance

Payment terms for companies

On-time delivery by Fractory

Get a quote

Quality

A laser cutter leaves only a little burr when used properly. Frequently, it is not even required to take it out. The material, its thickness, and other elements all play a part.

A tiny heat-affected zone is an additional benefit. Parts with a narrower HAZ area are more consistent and dependable as the microstructure along the HAZ changes.

Contactless Cutting

In case of laser cutting, only the beam comes into contact with the material. Therefore, there is no mechanical friction that could wear tools.

Versatility

This is probably one of the most important aspects of laser cutting’s greatness. The versatility manifests itself in two ways.

Laser Cutting Acrylic

Laser cutting is suitable for a lot of different materials. Among them are different metals, acrylic, MDF, wood, paper, etc. One machine can be configured to perform different jobs. Of course, the ability to cut some of these materials depends on the power of your machine.

Many laser cutters are not for cutting only. Laser marking is another way to utilise these machines. And marking has a lot of applications when producing everyday products.

A standard laser cutting head cannot be used for welding and a laser welding head cannot meet the cutting speeds and quality needed for cutting. Some machines allow swapping the heads if a different operation is needed to perform, combi-heads are also being developed in the background but these haven’t taken off yet due to various limitations they have.

Lastly, the technology is suitable for a variety of profiles. Tube laser cutting can perform the process on anything from box sections to open channels.

What Are the Disadvantages of Laser Cutting?

Although used to produce parts in almost every industry, laser cutting does have it downsides. Namely, the need of expertise, limitations to metal thickness, costs and hazardous fumes are all things to consider before turning to laser cutting.

Need of Expertise

As we already said, a specialist operator is a must in order to make the most of a laser cutter’s potential. The right setup makes sure the cutting quality is up to the standard people are expecting from this technology.

Limitations to Metal Thickness

When compared to other thermal cutting techniques, laser cutting is not recommended for cutting extremely thick plates. The largest appropriate thickness will vary depending on the equipment and expertise that are available. Metal fabrication businesses typically use a laser to cut metal up to 15 or 20 mm thick.

Prices for laser cutting machines might approach £1,000,000. When considering waterjet or plasma cutters, the cost of a laser can be doubled. The initial investment is still very substantial, but over time the savings and increased efficiency more than offset it.

Perilous Odors

Laser cutting's ability to cut a variety of materials is one of its benefits. The thermal cutting process simultaneously melts the material, releasing harmful chemicals and gasses into the air.

This is especially valid for plastic cutting. Therefore, having a reliable ventilation system—which is frequently expensive—is essential for a safe workplace.

0 notes

Text

Unrivalled Quality and Versatility: Stainless Steel in Dandenong for Industrial Excellence

There is always a need for quality stainless steel in Dandenong as companies need a consistent supply of steel to maintain their industrial production. Stainless steel is required almost everywhere, regardless of whether a company manufactures large machinery or fasteners. The best steel suppliers provide a huge selection of steel goods to several industries, such as building and manufacturing. The best companies offer more than just steel; they also offer additional steel products like stainless steel that is folded and cut to size. Reliable steel suppliers are essential to businesses' ability to maintain manufacturing production, and reputable stainless-steel producers are essential to satisfying this need.

Let Us Look at a Few Steel Products Offered by Reputable Steel Suppliers:

Stainless steel rod and pipes are available in grades 304 and 316 from reputable suppliers. There are several applications for stainless steel rod in many industries, including construction. It is also necessary for stainless steel handrail fittings to be composed of different stainless-steel components, such as bends and pipes. These pipes are occasionally used for both aesthetic and functional reasons in places where fluids need to be transferred from one place to another.

Stainless steel plate & coil are widely used in many industries and are also offered by leading manufacturers in a range of thicknesses. Top firms use the best equipment and techniques, such, lasers, and plasma cutters, to make their goods according to specifications.

Stainless steel tubes are utilised for a number of things, such balustrades and pipelines in places where other metals can corrode. These tubes are very resistant to corrosion, and the coating may be selected to meet certain requirements.

In engineering, architecture, and construction applications, stainless steel angles are utilised to give structural support. Because of their resistance to corrosion, stainless steel angles are suitable for use in both indoor and outdoor environments.

The best steel suppliers may provide numerous additional steel components for a range of industrial uses. One must get in touch with reliable merchants in order to purchase the necessary stainless steel and other similar goods.

Source

0 notes

Text

Chamfering Your Way to Precision: A Guide to India's Mighty Metal Mavens

Introduction

Ah, the chamfering machine - the unsung hero of the metalworking world. This ingenious device transforms sharp, unforgiving edges into smooth, elegant bevels, chamfering machine india boosting both form and function. But fear not, metalworking novice! This guide, crafted with Indian ingenuity in mind, will equip you with the knowledge to navigate the exciting world of chamfering machines in India. Buckle up, for we're about to chamfer our way to metalworking mastery!

Choosing Your Chamfering Champion: What to Consider

Picking the perfect chamfering machine is like choosing your trusty steed. You wouldn't just grab any horse, would you? So, let's explore the key features to consider:

Material Muscle: What metals will you be working with? Steel, aluminum, or the occasional exotic alloy? Match your machine's capabilities to your material needs.

Power Play: Electric or pneumatic? Consider factors like portability, power requirements, and your budget. Remember, more watts don't always translate to better results!

Angle Alchemy: What bevel angles do you need? Some machines offer fixed angles, while others boast adjustable magic. Choose wisely, grasshopper!

Feature Fiesta: Does your ideal machine have fancy foot pedals, dust extraction systems, or laser guides? Prioritize features that'll make your chamfering dreams a reality.

Chamfering Like a Pro: Tips & Tricks from the Indian Gurus

Now that you've got your metallic mustang, let's learn to ride! Here are some chamfering wisdom nuggets from India's finest:

Sharpen Up: Blunt blades lead to tears (both metal and yours). Keep your cutters sharp for clean, precise cuts.

Clamp Down Tight: A secure workpiece is a happy workpiece. Use sturdy clamps to prevent movement and ensure accuracy.

Slow and Steady Wins the Race: Don't rush! Apply gentle, controlled pressure for optimal results. Patience is key, my friend.

Safety First, Always: Goggles, gloves, and proper ear protection are your chamfering companions. Safety is never an option, it's a mandate!

Frequently Asked Questions: Chamfering Demystified

Q: Which chamfering machine brands are popular in India?

A: Many Indian manufacturers and distributors offer excellent machines. Do your research and consider brands like BDS Machines, Bhavya Machine Tools, and Devendra Techno Industries.

Q: Can I rent a chamfering machine instead of buying one?

A: Absolutely! Rental options are available, especially for occasional use. Explore tool rental companies or directly contact manufacturers.

Q: Where can I find replacement parts and accessories?

A: Most manufacturers and distributors stock spare parts. Online retailers also offer a wide selection.

Conclusion: Your Chamfering Journey Begins Now!

With this knowledge in your arsenal, you're ready to conquer the world of chamfering machines! Remember, practice makes perfect, so unleash your inner metal maestro and create masterpieces that would make even the gods of metalworking jealous. Happy chamfering, India!

1 note

·

View note

Text

How to Choose the Right Laser Cutting Services?

Laser cutting Perth is a manufacturing technique used in various industrial applications. Unlike other cutting methods, it is more precise and less energy-intensive, especially when cutting steel and aluminium sheets.

Laser cutters are available in various sizes, shapes, and variable frequencies, making it challenging to choose the right one suitable to your purpose. Choosing an inappropriate cutting system could provide difficulties in the long run.

Things to Consider When Choosing the Right Laser Cutting Services

Laser-cutting service providers can assist you in creating prototypes for new products, exploring metal options, and customise designs for your work.

Here are some of the following factors you can consider for your project:

Material

It is essential to consider the type of material you want to cut, including its thickness and density. Laser cutting involves various types of materials, such as:

Paper

Wood

Acrylic

Metals

Plastics

However, not all laser-cutting companies can handle your thickness and density requirements. For instance, particular equipment can cut metals like stainless steel and non-ferrous metals but cannot process reflective materials like laser etching aluminium. Likewise, laser cutting is not advisable for cutting glass as this is reflective.

Proven Skills

A brief review of their prior work samples provides valuable insights into the shop's project capabilities and level of expertise. It's essential to ensure they've handled projects akin to your requirements and possess the necessary skills for tackling new challenges.

Their portfolio provides a window into the wide array of laser cutting projects they've undertaken, showcasing various project types.

Additionally, it offers a glimpse into their proficiency, with numerous examples highlighting specific skills. For instance, if your project demands expertise in crafting intricate patterns rather than primarily focusing on precision cuts, their portfolio should reflect such capabilities.

Good Communication

Stating a commitment to customer service is commendable, but it's crucial to assess the quality of communication with your potential laser-cutting partner.

They should not only be attentive to your requirements but also excel at asking pertinent questions. Proper communication plays a vital role in promoting the swift and precise completion of projects.

If you've invested the time to converse with previous clients, you should have gained insights into how the shop collaborates with customers and their responsiveness to changes.

Opting for a shop that leverages technology in this regard is equally important. They should facilitate the seamless transmission of drawings and updates via email or online platforms, ensuring convenience and efficiency.

Are you looking for a reputable laser-cutting services provider? You can consider Artcom Fabrication. Contact us at (08) 9331 6131 to know more about our services.

0 notes

Text

The Power of LD-4 Machines in Modern Industries

In the world of manufacturing and production, efficiency is key. One of the crucial advancements contributing to enhanced efficiency in various industries is the LD-4 machine. What exactly is an Ld 4 Machine, and why is it such a game-changer?

What is an LD-4 Machine?

An LD-4 machine falls into the category of laser devices used for cutting and engraving materials. These machines utilize a high-powered laser beam to precisely cut, engrave, or mark various materials like wood, plastic, glass, metal, and more.

How Does It Work?

Picture this: the LD-4 machine is like a high-tech artist. It takes instructions from a computer and translates them into precise movements of the laser beam. This beam, focused and powerful, acts like a super-accurate cutter or painter, following the patterns and designs dictated by the digital instructions.

Why Are LD-4 Machines Important?

1. Precision & Accuracy

LD-4 machines are incredibly precise. They can create intricate designs and cuts with minuscule tolerances, ensuring that the final product matches the digital design flawlessly. This precision is invaluable in industries where perfection is a must.

2. Versatility

These machines aren't limited to one material or one type of job. Whether it's cutting shapes out of wood, engraving intricate designs on glass, or marking serial numbers on metal, LD-4 machines can handle diverse tasks with finesse.

3. Efficiency & Speed

Imagine crafting a complex pattern manually – it could take hours or even days. LD-4 machines, however, can accomplish these tasks swiftly. What might have been a time-consuming process becomes remarkably faster, boosting productivity significantly.

4. Reduced Waste

Traditional cutting methods often produce a lot of waste material due to imprecise cuts or errors. LD-4 machines minimize this waste by executing cuts precisely as per the design, thus saving resources and reducing costs.

5. Automation & Consistency

By relying on computer-generated instructions, LD-4 machines ensure consistency across multiple products. Each item produced is an exact replica of the one before, eliminating human error and maintaining quality standards.

Applications of LD-4 Machines

LD-4 machines find applications across various industries:

Manufacturing: Used for precise cutting and shaping of materials in the production of parts and components.

Art & Design: Artists and designers utilize LD-4 machines for creating intricate and personalized pieces across different mediums.

Electronics: They play a vital role in manufacturing electronic components by accurately cutting and marking circuit boards and other materials.

Automotive: LD-4 machines aid in fabricating parts and components with high precision, contributing to the automotive industry's efficiency.

Future Prospects

As technology advances, LD-4 machines continue to evolve. With improvements in speed, accuracy, and the range of materials they can handle, these machines are becoming indispensable in various sectors.

Manufacturer Company: Kashdra Group

The LD-4 machine, a cutting-edge technology, owes its innovation and reliability to visionary manufacturing companies like Kashdra Group. Renowned for their commitment to precision engineering and cutting-edge solutions, Kashdra Group has been at the forefront of developing and refining these laser machines. Their dedication to research and development has led to advancements that have significantly enhanced the capabilities of LD-4 machines.

Through Kashdra Group's expertise, these machines have evolved to handle a wider array of materials and execute more complex tasks with unmatched accuracy. Their continuous efforts in refining this technology have not only revolutionized industries but have also set a benchmark for excellence in manufacturing across the globe.

Final Thoughts

The LD-4 machine might seem complex at first glance, but its impact is straightforward – it revolutionizes precision, speed, and efficiency in manufacturing and design. As industries evolve, these machines will remain at the forefront, shaping the future of production and creation.

In essence, LD-4 machines are like the artists of the modern industrial world, etching, cutting, and creating with unparalleled precision and speed, ultimately transforming the way we manufacture and craft our world.

0 notes

Text

Laser Cutting: How Has This Innovation Improved the Manufacturing Industry Over Time?

Huxley Design will help you stay on the cutting edge of metal fabrication. Laser cutting is a fabrication process involving lasers' use to cut materials. A qualified company like Huxley can help you stay current with new fabrication techniques, machine builds, and training in welding. To know more about Custom Laser Cutting Utah click here!

#metal laser cutting utah#Cnc Laser Cutter Utah#The Laser Cutting Company Utah#laser cutting services utah

1 note

·

View note

Text

The Green Cut: Sustainable Laser Cutting Practices in Canada

The world is waking up to the importance of sustainability, and the manufacturing industry is no exception. Laser cutting, a versatile and precise technology, is finding its place in this green revolution thanks to its inherent advantages and the innovative practices adopted by Canadian businesses. Let’s delve into the world of eco-conscious laser cutting in the Great White North.

Why Laser Cutting is Naturally Green

Compared to traditional manufacturing methods, laser cutting boasts several sustainability benefits:

Minimal material waste: Laser cutters use focused beams of light to cut materials, leaving behind clean edges with minimal waste. This reduces the need for raw materials and the generation of scrap.

Reduced energy consumption: Laser cutting machines are highly efficient, consuming less energy than traditional methods like stamping or drilling.

Lower emissions: Laser cutting doesn’t involve combustion or chemical processes, leading to significantly lower emissions of harmful pollutants.

Versatility for recycled materials: Lasers can cut a wide range of materials, including recycled wood, plastic, and metal, giving new life to waste materials.

Canadian Businesses Leading the Green Charge

Canadian laser cutting businesses are at the forefront of sustainable practices, implementing innovative approaches to minimize their environmental impact. Here are some inspiring examples:

Ecosave Laser Cutting (Toronto): This company uses solar panels to power its laser machines, significantly reducing its carbon footprint. They also source materials from local, sustainable suppliers and offer recycling programs for scrap materials.

West Coast Laser Cutting (Vancouver): This business specializes in cutting recycled wood and acrylic, giving waste materials a second chance at life. They also use water-based coolants in their machines, eliminating the need for harmful chemicals.

Green Fab Labs (Nationwide): These maker spaces offer laser cutting services alongside other tools and resources. They promote sustainability by encouraging users to choose recycled materials and offering workshops on eco-friendly design principles.

Beyond the Business: Tips for Greener Laser Cutting

Whether you’re a laser cutting business owner, an individual using a community maker space, or simply curious about the technology, there are steps you can take to ensure your laser cutting practices are as green as possible:

Choose recycled materials: Opt for recycled wood, plastic, and metal whenever possible. This reduces the demand for virgin materials and gives waste a new purpose.

Optimize your designs: Minimize material waste by carefully planning your cuts and nesting designs efficiently within the material sheet.

Explore alternative coolants: Look for water-based or vegetable-based coolants instead of traditional oil-based ones to reduce your reliance on fossil fuels.

Promote local sourcing: Support local suppliers of sustainable materials to minimize transportation emissions and support your community.

Spread the word: Educate others about the green benefits of laser cutting and encourage them to adopt sustainable practices.

The Future is Green: A Bright Outlook for Sustainable Laser Cutting

As technology advances and environmental awareness grows, the future of laser cutting is undoubtedly green. With continued innovation and dedication from businesses and individuals, laser cutting can become a powerful tool for sustainable manufacturing, leaving a lighter footprint on our planet while shaping a brighter future.

Remember, every green cut counts! By making conscious choices and supporting sustainable businesses, we can ensure that laser cutting continues to be a force for good in the Canadian manufacturing landscape. So, let’s join hands and make the green cut the standard for laser cutting across the country!

I hope this blog post has inspired you to think about the environmental impact of your laser cutting practices and encouraged you to explore ways to make them more sustainable. Together, we can make a difference!

Feel free to share your thoughts and experiences with sustainable laser cutting in the comments below. Let’s keep the conversation going and continue to build a greener future for laser cutting in Canada!

Contact us for more information.

0 notes

Text

The 4 Most Common Types of Precision CNC Machining

CNC machining is a catch-all term for a wide range of machining applications. The term “CNC” stands for Computer Numerical Controlled and refers to the machine’s programmable feature, which allows the machine to perform many functions with little human intervention. CNC machining is the process of creating a component with a CNC-controlled machine. A lot of CNC Manufacturers in India excel in providing you with these machines. The term refers to a group of subtractive manufacturing processes that involve removing material from a stock workpiece or bar to create a finished component part.

The 4 most common types of Precision CNC Machining are as follows:

CNC Lathes and Turning Machine:

During machining, CNC lathes and turning machines rotate materials. These machines use linear cutting tools to remove material around the revolving bar stock’s circle until the required diameter is reached. Internal and external components such as drilled holes and threads can be produced by a CNC lathe or a CNC turning machine. Screws, bolts, shafts, and poppets are examples of CNC machined components. Precision Components manufacturers may assist you with a CNC lathe and turning machine. A CNC lathe or a CNC turning machine can produce internal and external components such as drilled holes and threads.

2. CNC Milling Machines:

CNC milling machines are distinguished by their ability to rotate cutting tools while remaining stationary with the material workpiece/block. They can make a variety of shapes, such as face-milled features (shallow, flat surfaces and cavities in the workpiece) and peripheral-milled features (deep cavities such as slots and threads). CNC milling machine components are typically square or rectangular in shape and have a variety of features.

3. CNC Laser Machines:

CNC laser machines use a pointed router with a highly focused laser beam to cut, slice, or engrave materials precisely. The laser heats the material, causing it to melt or vaporize and leaving a cut in it. The material is typically in sheet form, and the laser beam moves back and forth across the material to create a precise cut. CNC laser engravers are frequently used to mark machined components. It can be difficult, for example, to machine a logo and company name into a CNC-turned or CNC-milled component.

4. CNC Plasma Cutting Machine:

CNC plasma cutters are also used to slice materials. They do it, however, with a computer-controlled high-powered plasma torch. Plasma torches operate similarly to hand-held gas welding torches but reach temperatures of 50,000°F. To form a cut, the plasma torch melts through the material. Precision CNC machining is used in the manufacturing industry to create CNC-machined components. Depending on the environment, material, lead time, volume, budget, and features, there is usually an optimal way to provide the desired output.

Supreme Metal Works is considered amongst the best steel components manufacturers. We are recognized as one of the renowned CNC Turned Component Manufacturers in Mumbai, India. Our diverse services include tube fitting which also happens to be our primary expertise. Quality and Customer satisfaction are what we assure you at Supreme Metal Works.

You can reach us on suprememetal.in

#cnc machined components manufacturer#manufacturers of tube fittings in india#ferrule fittings manufacturer in india#cnc machined components manufacturer in india

0 notes

Text

What are the Benefit of Fiber Laser Cutting Machine – Applications

Benefit of Fiber Laser Cutting Machine

We all know that fiber laser is now well accepted in the market, and also because of the excellent advantages of good beam quality and high conversion efficiency in the company, it is widely preferred in some finishing fields. A form of active choice for products in many industrial applications, fiber lasers currently make up close to 50% of the industrial field. As frequency conversion light sources, fiber lasers have many benefits over conventional gas and solid state lasers. In this post, we will discuss what is a fiber laser cutting machine, its characteristics, benefits, and uses. We will also discuss its features, advantages, and benefits.

What Is A Fiber Laser Cutting Machine?

A brand-new machine in the globe that produces high energy density laser beams is the fiber laser cutting machine. The work piece’s surface is targeted by the laser beam, which causes the area of ultra-fine focus to rapidly melt and evaporate as it moves through the CNC mechanical system. Automatic cutting through positional illumination. It has clear benefits over large volume gas lasers and solid-state lasers, and has increasingly taken on significance in industries such as high-precision laser processing, lidar systems, space technology, laser medicine, and others.

With clean and smooth edges, the optical fiber laser cutting machine can be utilised for both plane cutting and oblique cutting. It is appropriate for cutting metal plates with extreme precision. The original five axis laser can be swapped out for the manipulator at the same time for 3D cutting. It has a higher photoelectric conversion rate and uses less space and gas than a typical CO2 laser cutting machine. It is a cutting-edge technological product that also conserves energy and protects the environment.

Features Of CNC Fiber Laser Cutting Machine

1. The CNC fiber laser cutting machine has a high optical power conversion efficiency, with a conversion efficiency of above 30%. The lack of a water cooler requirement for the low power fiber laser significantly reduces operational power consumption, lowers operating expenses, and achieves the highest level of production efficiency.

2. The cost of operation and maintenance is the lowest when a laser cutting machine is in operation because it only requires electric power and does not require the production of additional laser gas.

3. The fiber laser cutting machine uses a redundancy and semiconductor modularization design. There is no start-up time and no optical lens in the resonator. Its features include adjustability, lack of maintenance, and excellent stability. They offer unmatched cost and maintenance time savings over conventional lasers.

4. The fiber laser cutter has the best cutting and welding capabilities, the best output beam quality, the highest power density, is favourable to the absorption of metal materials, and the lowest processing cost.

5. The entire machine’s optical transmission does not require a sophisticated light guide machine, such as a mirror. The optical system is easy to use, reliable, and requires little upkeep.

6. Because the cutting head has protective lenses, there is relatively little need for expensive consumables like focusing lenses.

7. Since light is produced via optical fiber, the mechanical system’s design is highly straightforward and simple to combine with robots or multi-dimensional workbenches.

8. Once the laser has been integrated into the shutter, the system can be divided into many machines, optical fiber division, multiple channels operating simultaneously, easy function expansion, simple update, and more.

9. The small volume, light weight, flexible position, and tiny area of the fiber laser cutting machine are benefits.

Applications of Fiber Laser Cutting Machines

The use of the fiber laser cutting machine includes a variety of manufacturing and processing sectors, including sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube accessories, automobiles, grain machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, lifts, home appliances, crafts, tool processing, decoration, advertising, metal processing, kitchenware processing, and others.

Materials For Fiber Laser Cutting:

Cutting of metal sheets and pipes in stainless steel, carbon steel, alloy steel, silicon steel, galvanised sheet, spring steel, aluminium, copper, silver, aluminium alloy, pickling sheet, gold, and other metals.

0 notes

Text

The Most Effective Reasons For People To Succeed In The Replacement Car Key Industry

Cost of Replacement Car Key

The cost of a replacement car keys can be very different according to the type of key used and vehicle. This article will examine three factors that impact the cost of replacement car keys:

Car dealerships usually charge more for remotes and key fobs than independent locksmiths or third-party service providers. This is due to the fact that they are able to take advantage of their reputation and convenience.

The kind of key

The type of key you have will determine how much it will cost to replace it. The most affordable options are keys that don't have chips, remotes or laser-cut keys. More advanced models, however, are much more expensive. Key fobs that can be integrated into smart keys require special programming and machines that are only available at dealerships.

Additionally, certain keys are harder to duplicate than others. For example, a laser cut key is designed to avoid duplicates by utilizing unique patterns within the key blade. This makes it difficult for someone with the aid of a grinder or laser cutter to make a duplicate.

The kind of vehicle you own will also impact the cost of a replacement key. Some newer cars use transponder chips that are embedded into the keys to enable and start the car. They are the most expensive to replace because they require special equipment and programming by locksmiths or dealers.

It is a good idea to have an extra car key in case you wish to avoid paying cost of replacing keys to your vehicle. It is important to keep in mind that this method is not 100% secure as lost keys could still occur even with the best planning.

The most common method of getting a spare is by registering your keys with the manufacturer, or by using the use of a key-fob replacement program. These programs typically will cover up to $400 in losses, which includes the cost of key and key fob replacement. They are available to car owners and leaseholders. People leasing their vehicles should consult with the leasing company first to confirm that they are able to benefit from the program. This is usually a simple process online. There are many options, so make sure to do your research to find the best one for you.

The kind of vehicle

The type of car you use is a major element in the cost of replacement car key. This is because different cars have different keys, and certain are more costly to replace than others. If your vehicle has a smart key, for instance, it will cost more to replace than if you are using an ordinary metal key. The VIN number can identify the type and make of vehicle you own. Then you can know the type of key you need.

Typically, newer cars require more complicated keys that use transponder chips and remote components. They are more difficult to duplicate than older models. This is why they are more expensive.

You must carefully consider your options as certain keys can only be replaced by a dealer or a locksmith. If you have an old key fob which is not too complicated, it might be cheaper to replace it by a locksmith instead of an individual dealer.

If you own a smart key with an integrated transponder, you will need to shell out more money to replace it. These are more expensive than standard key fobs and require the use of specially designed machinery to cut them. car key lost replacement costs more to make because of the added technology, but you'll also need a technician to program it.

Smart keys can be an excellent feature for your vehicle. They make driving easier and provide additional security. Some smart keys even start your vehicle. They allow you to lock and unlock the vehicle with a simple button press. It is essential to have a backup smart key in case you lose it.

Some of the key features available in a smart key include keyless entry as well as a proximity sensor and remote starter. You will need to have your key programmed by a professional to ensure that these features can't be tampered with. If you're looking to save money you can do it yourself following the instructions found in the owner's manual.

The technology

The loss of your car keys is a stressful experience, particularly if you are in an unfamiliar region. It also costs a lot of money to replace them, and many drivers don't have the extra cash lying around. Fortunately modern technology for car keys has made the process much easier and cheaper.

The first thing you have to do is acquire an additional key. There are several options available, and the cost will vary depending on the kind of key you've got. Basic metal keys are, for instance, the least expensive, whereas fobs can be more expensive. If you want to purchase a new one you must contact local dealerships, locksmiths or mechanics to get an estimate.

Modern car keys have a computer chip built in that communicates with the vehicle's system. This decreases the chance of theft, and also increases security. However, it is still possible for someone to create an unauthentic key. To protect yourself from this, the best option is to purchase an extended warranty for your vehicle.

In the past replacing lost keys required a costly trip to a dealer. The dealer would use a specific machine to cut the key and then connect it to a computer which electronically "paired it" with your vehicle. Locksmiths are now able to do the same job at a fraction the cost. They can utilize a small device called an EZ installer that connects to the standard diagnostic port on your car and connects the key with your vehicle's system.

Most people don't realize how important it is to have an extra key for their car. The most important thing you'd want is to be locked out of your car in the event of an emergency, and a spare key is the best way to avoid this situation. Getting a duplicate key can be much cheaper than you'd think, and it's definitely worth the peace of mind. Make sure to keep the keys in a safe location, as it's better to be prepared than to be caught unaware when you lose your car keys!

The location

In the past you could lose or misplace your car key was a minor issue. It was easy to replace your car's key at a local hardware shop or a locksmith. As automobiles have become more complex and technologically advanced, their keys have also grown to be complex electronic devices, which can be expensive to replace. This is why it's important to keep a spare key in your possession and keep it in a safe location, so that you can save yourself the cost and hassle of having your replacement car key.

The type of key you have will determine the cost to have it replaced. The type of key you have, whether it's a standard mechanical key, transponder key or a smart key will determine the amount it will cost to have it duplicated. A standard key is the most affordable. A transponder key or smart key is more expensive. Certain keys can only be replaced by a dealership and others can be created by a mechanic or locksmith.

In car key replacements near me to the type of key, the place the place you lose it will affect the cost to have it replaced. If you lose your keys in a remote area it might take longer to replace them than those that were lost in a city. This is due to the fact that a tow truck or locksmith may have to travel farther to reach you. The cost of replacing keys can also rise in bad weather.

If you lose your car keys If you lose your car keys, it's best to call your insurance company immediately. The majority of insurance companies will cover a minimum of the cost, depending on the coverage and terms of your policy. The cost of a key is often covered by an extra roadside assistance add-on, or a bumper-to-bumper extended warranty. Always verify your policy to be sure that you are not liable for the cost.

#car keys replacement cost#car key lost replacement#replacement car key cost#car key replacements near me#car replacement keys near me

0 notes

Text

What You Should Be Focusing On Enhancing Replacement Car Key

Cost of Replacement Car Key

The cost of a replacement car keys can be very different according to the type of key and the vehicle. This article will examine the three elements that impact the price.

Car dealerships usually charge more for key fobs and remotes than independent locksmiths or third-party service providers. This is because they are able to take advantage of their reputation and convenience.

The kind of key

The type of key you have will determine the amount it will cost to replace it. The cheapest options are basic keys that do not have a chip, remotes or laser-cut keys. More advanced models, however, are much more expensive. Key fobs that can be integrated into smart keys require specialized programming and machinery only available at dealerships.

In addition, some keys are harder to duplicate than others. Keys that are laser cut, for example they are designed to stop duplication using unique patterns on the blade. This makes it more difficult for a person with an abrasive or laser cutter to create a duplicate.

The type of car you drive will also influence the cost of the replacement key. Some newer vehicles use transponder chips embedded in keys to unlock the vehicle and start it. These are the most expensive replacements, since they require specialized equipment and programming by a locksmith or dealer.

It is a smart idea to keep an extra car key in case you're looking to avoid more expensive replacement costs for your vehicle keys. It is important to remember that this approach isn't foolproof as lost keys can still occur even with the best planning.

Most of the time you can obtain an extra key by making an application with the manufacturer. You can also utilize a key-fob program. These programs will cover up to $400 in expenses, which includes the cost of replacing keys as well as key fobs. Both car owners and leasing holders can avail of these programs. People leasing their vehicles should check with the leasing company first to confirm that they will be allowed to benefit from the program. It's usually an easy process online. There are many programs to choose from therefore it is essential to research and find the right one for you.

The kind of vehicle

The type of car you drive is a significant element in the cost of replacing your car keys. This is because different cars have different types of keys, and some are more expensive to replace than others. If your car has an electronic key, for example it will cost more to replace than if you have the standard metal key. The VIN number can reveal the model and make of vehicle you own. You can then determine the type of key you require.

car replacement keys require more sophisticated keys, which use transponder chip and remote parts. They are more difficult to duplicate than older models, which is the reason they are more expensive.

Some of these types of keys can only be replaced by a dealer or locksmith, so it is important to be aware of your options. If you have an old key fob that is not very complicated, it may be more affordable to replace it with a locksmith rather than an individual dealer.

However, if you have a smart key that has an integrated transponder, you will be required to pay more to replace it. They are more expensive than standard key fobs and require specialized machinery to cut. The key is more expensive due to the additional technology. You'll also have to engage a technician to program the key.

Smart keys can be a great feature for a vehicle. They make driving easier, but also provide added security. Some smart keys even start your vehicle. They allow you to lock and unlock the vehicle with a simple button press. It's important to have a backup key for your smart device in case you lose it.

Some of the key features you can find in a smart key include keyless entry as well as a proximity sensor and remote starter. To make sure that these features aren't compromised, you'll need to have the key programmed by an expert. Locksmiths have the tools needed to accomplish this, but should you wish to save money, you can attempt to do it yourself, following the steps in the owner's guide.

The technology

Car keys lost can be a very stressful experience, particularly if it happens in a remote location. It also costs quite a bit of money to replace them, and most drivers don't have the extra cash on hand. Modern technology for car keys makes the process much easier and less expensive.

The first step is to obtain a replacement key. There are a variety of choices available, and the cost will depend on the type of key you've got. Metal keys made of basic materials, for example, are the cheapest, whereas fobs can be more expensive. If you want to purchase a new one, you should contact local dealerships, locksmiths or mechanics for a quote.

Contrary to traditional car keys modern car keys are equipped with a computer chip that communicates with the vehicle's system. This reduces the likelihood of theft and improves security. However, it's still possible for someone to create a fake key. To protect yourself from this the most effective option is to purchase an extended warranty for your vehicle.

In the past the replacement of a lost key required a costly trip to a dealership. The dealer cut the key using a special machine and then hook it up to a computer that electronically "paired" it to your vehicle. Locksmiths are now able to do the same thing for a fraction the cost. They can utilize a device known as an EZ Installer that connects to your car's standard diagnostic port and connects your key to the car's security system.

Most people don't realize that it's important to have a spare car key. A spare key can prevent you from being locked out of your car in an emergency. Getting a duplicate key can be cheaper than you might think, and it's definitely worth the peace of mind. Just remember to keep the keys in a safe location, as it's better to be prepared rather than be caught off guard when you lose the keys to your car!

The location

It wasn't so long ago that misplacing, or even losing your car keys was thought of as an inconvenience of a minor nature. It was easy to replace your car keys at a local hardware store or a locksmith. As automobiles have become more sophisticated and technologically advanced and the keys that come with them have also evolved into complicated electronic devices that can be costly to replace. This is the reason it's essential to have a spare key available and keep it in a safe place, to save yourself the hassle and expense of getting your replacement car key.

The kind of key you own will determine the cost of having it replaced. The cost of replacing a key will depend on whether you have an electronic key, transponder or smart key. A traditional key is the least expensive, whereas the transponder or smart key is more expensive. In addition, certain types of keys can only be changed by a dealership while others are made by a locksmith or mechanic.

The location of the key will also affect the cost. If you lose your key in a remote location, it may take longer to be replaced than if you lost it in the city. This is because a tow vehicle or locksmith will need to travel farther to reach you. The cost of replacing keys may also increase in bad weather.

If you lose keys to your car It is best to contact your insurance company immediately. Most insurance companies will provide at least a portion of the cost, contingent on the coverage and conditions of your policy. Often the cost of the new key is covered by a roadside assistance extra add-on or a longer bumper-to-bumper warranty, so you should be sure to check your coverage to ensure that you aren't required to pay for the cost.

#car keys replacements#car replacement keys#key replacement car#replacement keys for cars#key car replacement

1 note

·

View note