Text

The 4 Most Common Types of Precision CNC Machining

CNC machining is a catch-all term for a wide range of machining applications. The term “CNC” stands for Computer Numerical Controlled and refers to the machine’s programmable feature, which allows the machine to perform many functions with little human intervention. CNC machining is the process of creating a component with a CNC-controlled machine. A lot of CNC Manufacturers in India excel in providing you with these machines. The term refers to a group of subtractive manufacturing processes that involve removing material from a stock workpiece or bar to create a finished component part.

The 4 most common types of Precision CNC Machining are as follows:

CNC Lathes and Turning Machine:

During machining, CNC lathes and turning machines rotate materials. These machines use linear cutting tools to remove material around the revolving bar stock’s circle until the required diameter is reached. Internal and external components such as drilled holes and threads can be produced by a CNC lathe or a CNC turning machine. Screws, bolts, shafts, and poppets are examples of CNC machined components. Precision Components manufacturers may assist you with a CNC lathe and turning machine. A CNC lathe or a CNC turning machine can produce internal and external components such as drilled holes and threads.

2. CNC Milling Machines:

CNC milling machines are distinguished by their ability to rotate cutting tools while remaining stationary with the material workpiece/block. They can make a variety of shapes, such as face-milled features (shallow, flat surfaces and cavities in the workpiece) and peripheral-milled features (deep cavities such as slots and threads). CNC milling machine components are typically square or rectangular in shape and have a variety of features.

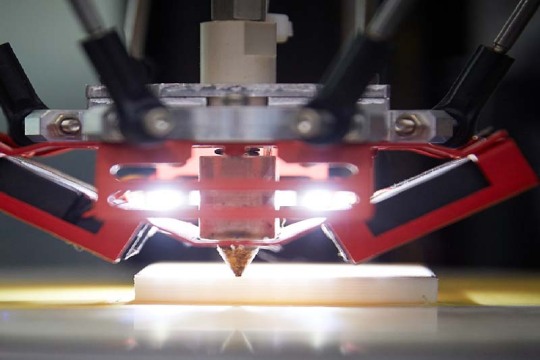

3. CNC Laser Machines:

CNC laser machines use a pointed router with a highly focused laser beam to cut, slice, or engrave materials precisely. The laser heats the material, causing it to melt or vaporize and leaving a cut in it. The material is typically in sheet form, and the laser beam moves back and forth across the material to create a precise cut. CNC laser engravers are frequently used to mark machined components. It can be difficult, for example, to machine a logo and company name into a CNC-turned or CNC-milled component.

4. CNC Plasma Cutting Machine:

CNC plasma cutters are also used to slice materials. They do it, however, with a computer-controlled high-powered plasma torch. Plasma torches operate similarly to hand-held gas welding torches but reach temperatures of 50,000°F. To form a cut, the plasma torch melts through the material. Precision CNC machining is used in the manufacturing industry to create CNC-machined components. Depending on the environment, material, lead time, volume, budget, and features, there is usually an optimal way to provide the desired output.

Supreme Metal Works is considered amongst the best steel components manufacturers. We are recognized as one of the renowned CNC Turned Component Manufacturers in Mumbai, India. Our diverse services include tube fitting which also happens to be our primary expertise. Quality and Customer satisfaction are what we assure you at Supreme Metal Works.

You can reach us on suprememetal.in

#cnc machined components manufacturer#manufacturers of tube fittings in india#ferrule fittings manufacturer in india#cnc machined components manufacturer in india

0 notes

Video

youtube

DY cast & forge a forging is a manufacturing company based on India & Se...

#youtube#www.dycastandforge.com#steelforging#Steel casting#steel machinery#Dy Impex manufactures Precision Machined components & Assemblies through the CNC VMC and Conventional Machines. And having the well known a

2 notes

·

View notes

Text

How CNC Machined Components Suppliers Support OEM CNC Machine Manufacturers in Precision Engineering

In the world of precision manufacturing, the collaboration between CNC machined components suppliers and OEM CNC machine manufacturers plays a crucial role in delivering high-quality, reliable parts for various industries. From automotive and aerospace to medical devices and electronics, the demand for expertly crafted components is ever-growing. By leveraging advanced technologies and customized solutions, both CNC suppliers and OEM manufacturers work together to meet the needs of a dynamic global market.

The Role of CNC Machined Components Suppliers

A CNC machined components supplier is a company that specializes in producing highly accurate parts and components using Computer Numerical Control (CNC) machines. These suppliers cater to industries that require intricate and precise components to ensure the optimal performance of their products. CNC machining involves automated cutting, milling, turning, and drilling processes that are controlled by pre-programmed software, allowing for high precision and repeatability.

The key advantage of working with a CNC machined components supplier is their ability to deliver parts with exact specifications, whether in small or large quantities. They use state-of-the-art CNC machines to ensure that every part meets the client’s required tolerances and quality standards. As industries increasingly demand customized and complex parts, CNC suppliers have risen to the challenge by adopting innovative machining techniques and technologies, providing tailored solutions that are critical to the success of many manufacturing processes.

How OEM CNC Machine Manufacturers Benefit

Original Equipment Manufacturers (OEMs) rely on precision parts and components to integrate into their larger systems or products. For OEM CNC machine manufacturers, these components are essential to their own manufacturing processes. OEMs often work with CNC machined components suppliers to source specific parts that meet their production needs, whether it’s for automotive engines, aerospace fuselages, or medical devices.

OEM manufacturers produce machinery and equipment that serve various industries, and the quality of their machines depends largely on the precision of the parts used. By partnering with reputable CNC suppliers, OEMs can ensure that their machines are equipped with the highest quality components. These components are integral to the performance, durability, and functionality of the OEM machinery, making them vital in meeting industry standards and client expectations.

The Symbiotic Relationship Between Suppliers and OEM Manufacturers

The collaboration between CNC machined components suppliers and OEM CNC machine manufacturers is essential for streamlining production processes. CNC suppliers provide the specialized components that OEMs need to build their machines, while OEM manufacturers depend on these high-quality parts to ensure the efficiency and precision of their products.

For CNC suppliers, working with OEM manufacturers allows them to cater to a wide range of industries, offering custom solutions and developing long-term partnerships. This collaboration also drives innovation, as both parties work closely to optimize designs, reduce lead times, and enhance the overall quality of the final product. In many cases, OEMs will partner with CNC suppliers from the design phase, allowing for a seamless integration of parts into the production process.

The Future of CNC and OEM Collaboration

The demand for precise and high-performing machines continues to rise as industries evolve, especially with the growing interest in automation and Industry 4.0 technologies. Both CNC machined components suppliers and OEM CNC machine manufacturers are adapting to these trends by incorporating smart technologies, robotics, and AI-driven processes to enhance the precision, efficiency, and scalability of their operations.

As industries like aerospace, automotive, and electronics push the boundaries of innovation, the collaboration between CNC suppliers and OEM manufacturers will remain pivotal. The continued advancement of CNC machining technology will ensure that both suppliers and OEMs can meet the demands of complex, high-performance parts in a fast-changing global market.

Conclusion

The partnership between CNC machined components suppliers and OEM CNC machine manufacturers is at the core of modern precision manufacturing. With advanced CNC technology and a commitment to quality, these suppliers provide the critical components that allow OEMs to build high-performing machines. This collaboration not only enhances production efficiency but also supports innovation across various industries, ensuring that both CNC suppliers and OEMs continue to drive progress in the field of manufacturing.

0 notes

Text

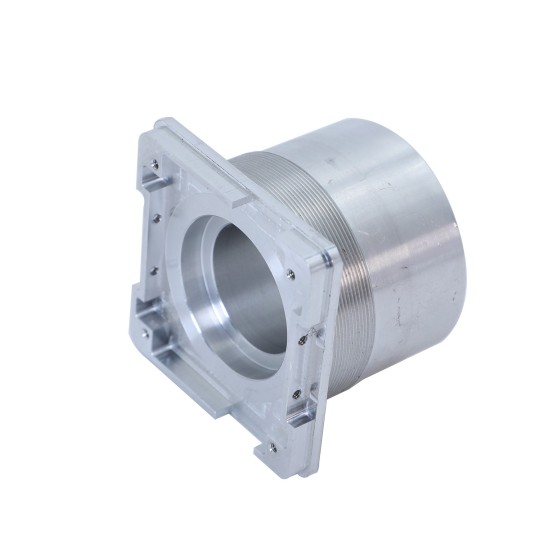

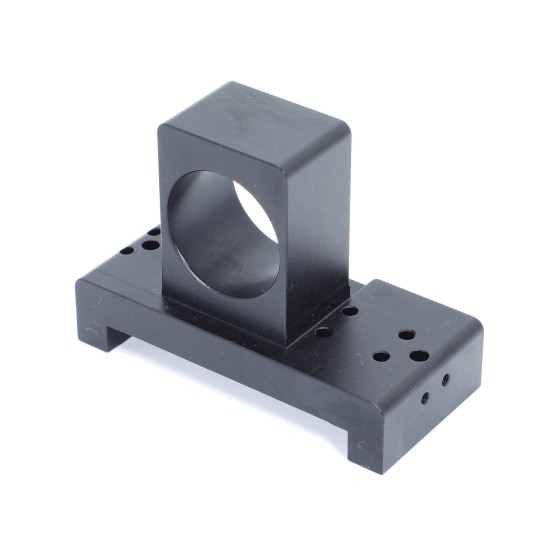

OEM CNC Machining Services Large Housing

Our OEM CNC Machining Services for Large Housing are designed to meet the demanding requirements of various industries. Leveraging advanced CNC technology, we provide precision machining solutions for large-scale components, ensuring high-quality finishes and exact tolerances. Whether you need prototypes or full production runs, our experienced team is equipped to deliver reliable and efficient machining services tailored to your specifications.

1 note

·

View note

Text

#cnc-machined-components-manufacturers#CNC-machining-parts-manufacturer#CNC-precision-machining-company#precision-CNC-machining#precision-CNC-machining-shops

0 notes

Text

Global Precision - leading CNC machined components manufacturers. Get high-quality CNC custom machined parts, and customized solutions for your needs.

#global precision#CNC machined components#CNC machined components manufacturers#CNC components manufacturer delhi

1 note

·

View note

Text

VMC Job Works Manufacturer in Ahmedabad

Searching for a VMC job works manufacturer in Ahmedabad? Scharf Precision Engineering is the best VMC job works manufacturer provide an excellent range of high quality VMC job works as per customer requirements.

#VMC Machined Components#VMC Job Works Manufacturer#VMC Machine Job Works#VMC CNC Job Work#VMC Machined Parts#VMC Machine Components#Ahmedabad

1 note

·

View note

Text

Unitritech Leading the Way in Aerospace Machined Components Manufacturing

In the highly specialized field of aerospace manufacturing, precision and reliability are paramount. Among the key players in this industry, Unitritech stands out as the premier manufacturer of aerospace machined components. With a steadfast commitment to quality, innovation, and customer satisfaction, Unitritech has earned its reputation as the best in the business.

Unitritech's expertise in producing high-precision machined components ensures that every part meets the stringent standards required for aerospace applications. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing for unparalleled accuracy and consistency. This dedication to excellence extends to their rigorous quality control processes, which guarantee that every component is meticulously inspected and tested before it reaches the customer.

One of the key factors that set Unitritech apart is their ability to handle complex and challenging projects. Whether it's producing intricate parts for commercial aircraft or custom components for military applications, Unitritech's skilled team of engineers and technicians possess the knowledge and experience to deliver exceptional results. Their innovative approach to problem-solving and continuous improvement ensures that they remain at the forefront of the industry.

In conclusion, Unitritech's commitment to precision, quality, and innovation makes them the best choice for aerospace machined components manufacturing. Their dedication to exceeding customer expectations and their proven track record of excellence solidify their position as industry leaders.

#High Precision Aerospace Machined Components#Advanced Aerospace Component Manufacturing#Custom Aerospace Machining Services#Leading Aerospace Machined Parts Supplier#Top Aerospace CNC Machining Company#Aerospace Precision Machining Experts#Quality Aerospace Manufacturing Solutions#Reliable Aerospace Machined Parts Manufacturer

0 notes

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

Precision CNC machining service for defence, automotive, medical, government, mining, aerospace, electronics and telecommunication industries.

#machinery#cnc machined components#electronic components#spareparts#manufacturer#factory#cnc machining#machining parts#precision machining#machinist

0 notes

Text

Brass CNC Turned Parts and Components Manufacturer in India

GK Metals is Jamnagar, India based manufacturer, supplier and exporter of high-quality customized brass CNC turned parts, brass CNC turned components and brass CNC machining parts with great precision & accuracy. Our CNC turned parts are made from brass, copper, bronze and stainless steel materials.

#brass cnc turned parts#brass cnc turned components#brass cnc machining parts#customized brass cnc turned parts#brass cnc turned parts manufacturers#brass cnc turned components manufacturers#brass#brass parts#brass components#gk metals

0 notes

Text

Behind the Scenes: Crafting Precision with CNC Machining

Discover how raw materials transform into intricate machine components.

Selecting the Right Materials

Choosing the right materials is crucial in CNC machining. We use steel, stainless steel, brass, and aluminum for various needs.

2. Material Procurement Process

We efficiently get our materials. They’re tested and inspected to ensure they meet our quality standards.

3. Quality Control at Every Stage

Quality matters to us. We constantly check our products during production to make sure they’re just right.

4. Surface Treatments and Finishes

Surface treatments are essential in making parts look and work great. See how finishes transform components.

5. Precision Measuring and Testing

We use modern equipment to measure and test our products accurately. It helps us ensure quality and precision

6. Crafting Components for Various Industries

Our CNC machined components serve many industries, like machines, molds, engineering, defense, and aerospace

If you have any inquiries about our manufacturing process, please feel free to visit our website.

#tube fittings manufacturer#cnc machined components manufacturer#ferrule fittings manufacturer in india#manufacturers of tube fittings in india#cnc machined components manufacturer in india

0 notes

Text

Custom Component Manufacturing

Custom Component Manufacturing by Norck! Elevate your projects with precision-engineered components tailored to your exact needs. Our expert team and advanced facilities ensure top-notch quality across various industries, from aerospace to automotive. Experience unmatched precision and reliability with Norck's custom component manufacturing services. Contact us today to bring your vision to life!

0 notes

Text

Elevating Precision: How a CNC Machined Components Supplier Drives Innovation

In today's technologically advanced world, precision and efficiency are paramount, especially in manufacturing. The role of a CNC machined components supplier has become indispensable, fostering innovation and ensuring the seamless production of high-quality parts. The synergy between a CNC machined components supplier and a CNC manufacturing company exemplifies the advancements and collaborative efforts that drive the industry forward.

The Backbone of Modern Manufacturing

A CNC machined components supplier specializes in producing parts with extreme precision using Computer Numerical Control (CNC) machinery. These suppliers provide critical components to various industries, including aerospace, automotive, medical, and electronics. The ability to produce intricate designs with tight tolerances makes CNC machined components suppliers the backbone of modern manufacturing.

The relationship between a CNC machined components supplier and a CNC manufacturing company is symbiotic. While the supplier focuses on producing high-quality parts, the manufacturing company integrates these components into their products, ensuring overall excellence and functionality.

Precision and Quality: The Hallmarks of CNC Machining

Precision is the cornerstone of CNC machining. A CNC machined components supplier utilizes advanced machinery and software to produce parts that meet exact specifications. This level of accuracy is crucial in industries where even the slightest deviation can lead to significant issues. For instance, in the aerospace industry, a minor flaw in a component can compromise safety and performance.

Quality control is another critical aspect that sets a reputable CNC machined components supplier apart. Rigorous inspection processes and adherence to industry standards ensure that each component meets the highest quality benchmarks. This commitment to quality not only enhances the supplier's reputation but also strengthens the CNC manufacturing company’s product reliability.

Innovation through Collaboration

The collaboration between a CNC machined components supplier and a CNC manufacturing company drives innovation. Suppliers often work closely with manufacturers to understand their specific needs and challenges. This collaborative approach leads to the development of custom solutions that address unique requirements, ultimately pushing the boundaries of what is possible in manufacturing.

For example, a CNC machined components supplier might develop a new alloy or machining technique that improves the durability and performance of a component. This innovation, in turn, allows the CNC manufacturing company to offer superior products to its customers, gaining a competitive edge in the market.

The Impact on Various Industries

The influence of CNC machined components suppliers extends across multiple industries. In the medical field, precision-machined components are essential for devices like surgical instruments and implants. The automotive industry relies on these suppliers for parts that ensure vehicle safety and performance. In electronics, CNC machined components are integral to producing devices with intricate and compact designs.

Future Prospects and Technological Advancements

As technology continues to evolve, the role of CNC machined components suppliers will only become more critical. The advent of Industry 4.0 and the Internet of Things (IoT) is driving further advancements in CNC machining. Suppliers are adopting smart manufacturing techniques, such as real-time monitoring and predictive maintenance, to enhance efficiency and reduce downtime.

Additionally, the integration of artificial intelligence (AI) and machine learning in CNC machining processes is set to revolutionize the industry. These technologies enable suppliers to optimize production, predict potential issues, and continuously improve the quality of their components.

Conclusion

In conclusion, the partnership between a CNC machined components supplier and a CNC manufacturing company is a testament to the power of collaboration and innovation. By prioritizing precision, quality, and continuous improvement, these entities play a crucial role in advancing modern manufacturing. As technological advancements continue to shape the industry, the contributions of CNC machined components suppliers will remain vital, driving progress and excellence across various sectors.

0 notes

Text

#stainless-steel-cnc-machining-services#prototype-machining-services#custom-cnc-aluminum-parts#cnc-machining#cnc-components-manufacturers#best-prototype-companies

0 notes

Text

Revolutionizing Precision by CNC Components Manufacturers

CNC (Computer Numerical Control) is a machining technology. Products are created by removing material from a so-called workpiece using various cutting tools. At the same time, the production process is automated by software – the tool or workpiece moves according to the code, and the machine operator performs only auxiliary operations, such as changing tools or setting the workpiece. CNC machining by CNC components manufacturers makes it possible to produce high-precision parts from a CAD (computer-aided design system) file with excellent physical and mechanical properties. Due to the high level of automation, CNC machining is competitive for single pieces & short runs, as well as for serial and mass production.

CNC manufacturing process

The CNC manufacturing process of a product can be broken down into four main steps:

1. An engineer designs a CAD model.

2. A technologist based on CAD/CAM software prepares a control program for the CNC machine.

3. The operator inserts the tool, and workpiece into the CNC machine and starts the control program.

4. The CNC machine performs all the processing operations – material removal.

CNC Machine Applications Industries

Aerospace

The aerospace industry encompasses all modes of air transport, from massive Airbus A380 aircraft that carry hundreds of passengers to spacecraft designed to fly to the International Space Station, the Moon, and even Mars. Aerospace technology is characterized by incredible precision that is difficult to achieve with conventional tools, which is why CNC machines by CNC-turned parts manufacturers were the perfect solution.

CNC in Aviation

The CNC machine plays a crucial role in the fast and accurate production of the parts that are used in the operation of every component of the aircraft. Such tools are used to create engine parts, cockpit equipment, aircraft skin, wings, and other parts.

CNC in the space industry

CNC is used at NASA, SpaceX, and Roscosmos enterprises to provide rockets with parts of any size and shape with incredibly high fitting accuracy. They produce spare parts for engines, computer equipment, parts for various systems, and spacecraft hulls.

Car

Car shop manager Rocky Helms has a lot of work to do. He oversees the workshop of the world-famous racing team Richard Childress Racing (RCR). The company's 24 employees work two shifts a day to produce the 170,000 parts needed to service the RCR.

The workshop itself occupies 7,000 square meters on a 210,000 square meter campus. Since its inception in 1969, RCR has played 17 championships and won more than 200 times in three NASCAR Major Series, including three Daytona 500 races (1998, 2007, 2018) and three Brickyard 400 races (1995, 2003, 2011).

To increase the production of cars and maintain maximum productivity in the workshop, the RCR is equipped with the latest material handling technologies, including the Roland MODELA MDX-540 benchtop mill.

According to Helms, the machine can do the work in 10 minutes that a person does in 10 hours. RCR uses Roland to mill engine and brake parts, wheel discs, and shock absorbers. The device is also used to create carbon fiber parts & to engrave identification numbers on parts.

Medical

In the space industry, it is customary to say: "There is no repair shop in space." The quality, precision, and reliability of each part must be impeccable because once it leaves the planet, it just has to work. The same applies to the medical field. If the prosthetic implant does not work properly, it affects the health and well-being of the patient. When the operation is complete, the part simply needs to function.

Global trends indicate that the need for medical implants will increase, as will the competition in the market. According to Seco Tools, about five major suppliers are vying for 85 percent of the orthopedic parts market, with more than 200 companies vying for the remaining 15 percent.

The manufacturing process of orthopedic implants includes cutting, grinding, 3D printing, and other operations on CNC devices by CNC machining parts factory. The machine performs roughing, finishing, milling, T-slot machining, chamfering, and deburring. The goal is to achieve the required surface finish, reducing the need for time-consuming manual processing. Five-axis milling and grinding machines provide advantages when working with complex shapes and contours of prosthetic implants. Thanks to CNC, the production time is significantly reduced & the accuracy is increased. Modern technology is capable of processing almost any material, including titanium and ceramics.

0 notes