Text

If you are looking for a reliable and professional metal fabrication company in Canada, look no further than Tecoustics. We offer a wide range of services, including Mig Welding, Tig Welding, Forming and Bending, Metal Laser Cutting, Mechanized Plasma Cutting, and Oxy-Acetylene Cutting. Whether you need laser cutters for metal, laser cutting of metal, or laser for cutting metal, we have the equipment and expertise to handle any project.

#mig welding#tig welding#laser cutters for metal#laser cutting services#oxy-acetylene cutting#mechanized plasma cutting#laser cutting steel

3 notes

·

View notes

Text

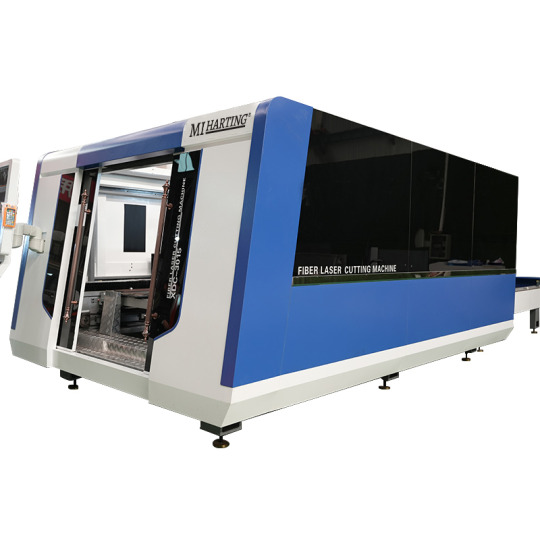

We are Direct Manufacturer & Supplier Of Fiber Laser Cutting Machines. Order Now . Email Us [email protected]

#Fiber Laser Cutting Machine#Laser Pipe Cutting Machine#Fiber Cutting Machine#Fiber Laser Cutter for Metal#Cnc Fiber Laser Cutting Machine Price#Fiber Optic Laser Cutting Machine#Co2 Fiber Laser#Fiber Laser Equipment#Fiber Laser Cutting Machine for Sale#Cnc Fiber Laser Cutting Machine

2 notes

·

View notes

Text

Hygrade Laser Profiling provides complete manufacturing solutions from start to finish. To complement our laser cutting, bending, and fabrication we also offer mass finishing services. This results in a streamlined process for our customers. || Address: 32 Harley Crescent, Condell Park, NSW 2200, Australia || Phone: +61 2 9791 1255 || Website: https://www.hygradelaser.com.au

0 notes

Text

Cutting-Edge Efficiency: Buy Fiber Laser Pipe Cutting Machines from Ci Laser, Delhi's Trusted Manufacturer!

Elevate your metal fabrication with the revolutionary power of fiber laser pipe cutting machines! At Ci Laser, Delhi's leading manufacturer, we offer premium machines to transform your productivity and precision. ✨

Why Choose Ci Laser for Your Fiber Laser Pipe Cutting Needs?

Unmatched Performance: Experience blazing-fast cutting speeds, high accuracy, and minimal burrs with our top-of-the-line machines.

Versatile Cutting: Effortlessly handle a wide range of pipe shapes and materials, from mild steel to stainless steel and aluminum.

Industry-Leading Expertise: Our experienced team provides expert guidance and support, ensuring you get the perfect machine for your needs.

Unwavering Reliability: Enjoy peace of mind with our robust machines and comprehensive warranty programs.️

Cost-Effective Solutions: Invest in machines that deliver a fast return on investment thanks to their efficiency and reduced operating costs.

But don't just take our word for it! See the difference Ci Laser's fiber laser pipe cutting machines can make:

Increased production output: Meet deadlines with ease and boost your profitability.

Enhanced product quality: Deliver flawless, burr-free cuts that impress your customers. ✨

Reduced material waste: Optimize material usage and minimize your environmental impact.

Streamlined operations: Simplify your workflow and free up valuable resources. ⏳

Ready to unlock the potential of fiber laser technology? Visit our website today: https://chiraginternationals.com/fiber-laser-cutting/fiber-laser-metal-pipe-cutting-machines

youtube

#fiberlaser #pipemetalcutting #metalfabrication #delhi #cilaser #trustedmanufacturer #efficiency #precision #versatility #reliability #costeffective #production #quality #waste #operations #linkinbio

#laser#lasercutting#lasercutter#laser metal cutter#metal cutter#lasermarking#laserengraving#heavy metal#Youtube

0 notes

Text

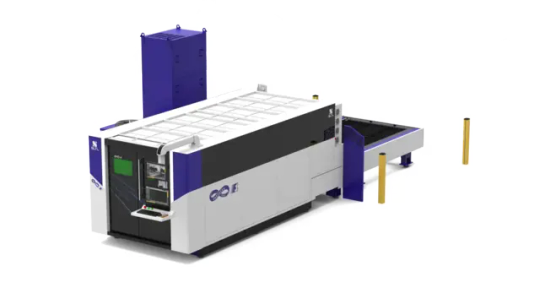

3015 Pipe and Sheet Laser Cutting Machine 2000w 3000w 4000w

Pipe and Sheet Laser Cutting Machine

A 3015 Pipe and Sheet Laser Cutting Machine is a type of laser cutter designed to cut both flat sheets and pipes or tubes. the size of the working area, with 3000mm x 1500mm being a common size for the cutting bed.The 3015 pipe and sheet laser cutting machine is equipped with a specialized rotary device that allows for the cutting of both flat sheets and cylindrical pipes or tubes. This versatility makes it suitable for a wide range of applications in industries such as metal fabrication, automotive, aerospace, and more.

The machine can efficiently cut flat sheets of various materials, including metals like steel, stainless steel, aluminum, and non-metals like acrylic, wood, and plastics. It provides precise and clean cuts, allowing for complex shapes and intricate designs to be achieved.

These machines often come with advanced software programs that allow for easy importation and manipulation of design files. The software can optimize cutting paths, reduce material waste, and increase efficiency. Additionally, some machines can be integrated into automated production lines for enhanced productivity.Laser cutting machines offer exceptional precision and accuracy, resulting in clean and smooth cuts without the need for additional finishing processes. This level of precision ensures tight tolerances and enables the production of high-quality parts and components.

Laser cutting machines can perform both cutting and engraving operations. Cutting involves the laser beam melting, burning, or vaporizing the material along a predefined path to create a clean, precise cut. Engraving, on the other hand, involves etching or marking the material’s surface with the laser beam to create text, logos, or intricate designs.Laser cutting is a non-contact process, which minimizes material waste compared to traditional cutting methods. The precision of laser cutting allows for tight nesting of parts, maximizing material usage and reducing costs.

The 3015 pipe and sheet laser cutting machine operates at high speeds, allowing for efficient production and quick turnaround times. It can handle complex cutting patterns and contours, optimizing productivity for both sheet and pipe cutting operations.

What Is a Laser Cutting Machine ?

The fiber laser cutting machine for sale, also known as the metal laser cutting machine or metal laser cutter, is the laser machine adopting fiber laser source to cut steel, carbon steel, stainless steel, copper, brass, aluminum, iron, galvanized steel, titanium and various alloys. It has wide applications in metal part, equipment, ship, and automotive manufacturing, advertising signs, sheet metal structure, kitchenware, metal furniture, custom metal fabrication, and other fields.

The fiber laser cutter, based on functions, falls into the laser cutting machine for metal sheet, fiber laser tube cutting machine, and sheet and tube laser cutting machine. Each model of the fiber laser machine has multiple specifications and configurations.

Based on the fiber laser power, we provide 1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W fiber laser cutting machine and other high power laser cutting machines to realize your metal cutting designs, ideas, and plans.

In addition, there are multiple worktable sizes available for the laser sheet cutting machine. For example, 1530 fiber laser cutting machine, 1540 laser sheet cutting machine, 2040 CNC fiber laser cutter, 1560 sheet metal laser cutter, 2040 fiber laser cutting machine , 2060 fiber laser cutter, etc. Feel free to contact us if you want to know more about the fiber laser cutting system or the laser cutting service.

Advantages of CNC fiber laser cutter?

1. Good beam quality. The waveguide structure of the fiber laser determines that it is easy to obtain a single transverse mode output. Besides, it is unlikely to be affected by external factors, which can achieve high brightness laser output.

2. High efficiency. The overall electro-optical efficiency of commercial fiber lasers is as high as 25%, which is conducive to cost reduction, energy-saving, and environmental protection.

3. Good heat dissipation. The CNC fiber laser uses thin rare earth element doped fibers as the gain medium, which has a very large surface area to volume ratio. This is conducive to heat dissipation. The water-cooling method for high-power fiber laser can avoid the loss of quality and efficiency caused by the heat effect.

4. Compact structure and high reliability. Since the fiber laser uses fine and flexible fiber as the gain medium, it helps to compress the size and save cost.

5. Maintenance free. There is no optical lens in the resonant cavity of the CNC fiber laser. So it has the advantages of adjustment-free, maintenance-free, and high stability, which is incomparable to traditional lasers.

Application of the fiber laser cutting machine

Fiber laser cutting machines can cut many kinds of metal plates and tubes. It is mainly suitable for cutting stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized plate, aluminized zinc plate, pickled plate, copper, silver, gold, and other metal plates and tubes.

The fiber laser cutting machine has wide application fields. For example, thin metal sheet processing, advertising signs, electric cabinets, mechanical parts, kitchenware, automobile, equipment, crafts, arts, electronic boards, medical equipment, instruments, tools, etc.

Why choose the fiber laser cutting machine?

High cutting accuracy.The positioning accuracy of the metal laser cutter reaches 0.03 mm, and the repeated positioning accuracy reaches 0.02 mm.

Narrow slit. The width of the slit is generally 0.10-0.20 mm.

Smooth cutting surface. There is no burr on the cutting surface, and the roughness of the cut surface is generally controlled within Ra6.5.

Fast cutting speed. The cutting speed of a fiber laser cutter can reach 60m/min. And the maximum running speed of a fiber laser metal sheet cutting machine can reach 140m/min.

Good cutting quality: Adopting non-contact cutting, there is basically no thermal deformation and damage of the workpiece. Besides, the cutting surface generally requires no further processing.

Flexible operation. The fiber laser cutting machine has good flexibility to cut any patterns. It can also cut various regular and irregular-shaped tubes and steel bars.

Long service life. A top-rated fiber laser has high photoelectric conversion rate and stable performance. The service life of the major parts of a fiber laser cutting machine could reach 100,000 hours.

Less maintenance. The laser of laser metal cutters for sale is transmitted by optical fibers instead of optical lenses. So there is no need to adjust the optical path and replace lenses frequently, which reduces many maintenance costs.

Strong adaptability. The laser cutting machine for metal sheet is capable of handling any harsh working environment. It also has strong adaptability to dust, vibration, impact, humidity, and temperature.

0 notes

Text

Optimizing Efficiency and Precision- A Guide to Consumables for CO2 Laser Cutting

GVK Metal Forms stands at the forefront of the metal fabrication industry, offering unparalleled expertise in utilizing high-quality consumables for CO2 laser cutting. With cutting-edge technology and a commitment to excellence, GVK Metal Forms ensures precise, efficient, and cost-effective metal fabrication solutions. Their skilled professionals use top-notch consumables for CO2 laser cutting processes, guaranteeing superior results for a wide range of applications. Trust GVK Metal Forms for all your metal fabrication needs, where quality meets innovation through advanced consumables for CO2 laser cutting.

Read more on:https://gvkmetalforms.in/spares-for-co2-laser/

0 notes

Text

Laser Cutting In Ghaziabad

Get the job done quickly and efficiently with our laser-cutting services! Our state-of-the-art laser cutters can cut through any material, from aluminum to steel, for precise cuts every time. We provide fast and reliable service that is tailored to your specific needs. Contact us today for more information about our laser-cutting services!

#laser cutting services near me#laser cutting near me#laser cut near me#acrylic cutting near me#acrylic laser cutting near me#acrylic cutter near me#laser cutting services in Noida#laser cutting services#mdf laser cutting near me#metal laser cutting near me#laser metal cutting near me#laser cutting in delhi#laser cutting in gurgram#laser cutting in ghaziabad#laser cutting in meerut#modular kitchen in greater noida

0 notes

Text

Beyond Limits: Unveiling the Might of High-Power Lasers on 40mm Metal Sheets

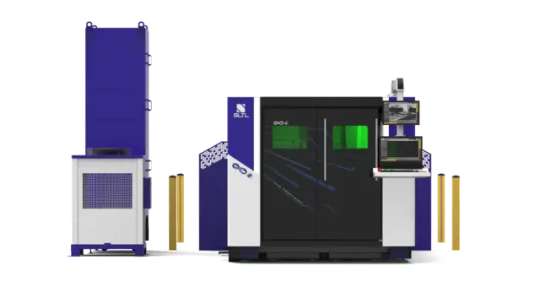

Exploring the Capabilities of up to 30KW Laser Cutting Machines and the Advantages of SLTL Infinity Metal Cutting Laser Machine

The world of metal fabrication is undergoing a transformative phase, powered by cutting-edge technology that pushes the boundaries of what was once considered impossible. We delve into the awe-inspiring domain of high-power lasers, where up to 30KW laser cutting machines take center stage. The spotlight is on the remarkable SLTL Infinity Metal Cutting Laser Machine, a marvel that defies limits and sets new standards in precision and efficiency.

1. Laser Precision: A Glimpse into the Future

The introduction of high-power lasers in metal cutting has been a game-changer, revolutionizing an industry that has long grappled with the challenges of cutting thick metal sheets. With the capability to slice through 40mm metal sheets like a hot knife through butter, the technology raises questions that intrigue and inspire.

2. The Power of 30KW Laser Cutting Machines

"30KW Laser Cutting: Redefining Metal Fabrication"

The 30KW laser cutting machines represent a monumental leap in the world of engineering. Imagine harnessing energy equivalent to the powerhouses that fuel entire cities, all focused onto a precise beam that can carve through metal with surgical precision. This level of power is not just about might; it's about rewriting the rules of metal fabrication.

3. The Star of the Show: SLTL Infinity Metal Cutting Laser Machine

"Infinite Potential: Unraveling the Features of SLTL Infinity"

Amidst the universe of high-power lasers, the SLTL Infinity Metal Cutting Laser Machine stands out as a testament to human ingenuity. Designed to handle the toughest challenges, its adaptive controls and state-of-the-art technology redefine what's achievable in metal cutting. The machine's versatility shines as it seamlessly transitions from intricate designs to slicing through 40mm metal sheets.

4. Advantages That Illuminate Possibilities

"Cutting through Advantages: Illuminating the Benefits of SLTL Infinity"

The advantages offered by the SLTL Infinity are a beacon for industries seeking innovation and efficiency. The machine's ability to maintain precision across varying metal types, reduced heat-affected zones, and minimal post-processing are advantages that not only streamline production but also raise the quality bar.

5. Beyond Metal Cutting: Expanding Horizons

"Expanding Boundaries: Beyond Metal Cutting with SLTL Infinity"

While the primary focus is metal cutting, the impact of the SLTL Infinity transcends this singular domain. It has the potential to shape industries that rely on intricate metalwork, from automotive to aerospace. The machine's capabilities become a catalyst for imagination and innovation, propelling industries into uncharted territory.

Conclusion: Carving a New Era in Metal Fabrication

As we conclude this journey through the realms of high-power lasers and the remarkable SLTL Infinity Metal Cutting Laser Machine, the answers to the questions posed at the beginning become evident. The boundaries of what can be achieved with metal cutting have expanded beyond our wildest dreams. The synergy of human ingenuity and technological prowess has birthed a new era where 40mm metal sheets are no longer obstacles but opportunities.

In the world of metal fabrication, limits are no longer barriers; they are merely indicators of what can be surpassed. As we embrace the capabilities of the SLTL Infinity, we are ushered into a future where innovation is boundless, and metal is shaped not just by machines, but by the audacity of human imagination.

In this journey of innovation, the SLTL Infinity Metal Cutting Laser Machine is not just a tool; it's an emblem of progress and a tribute to human determination to reach beyond the confines of what was once considered feasible.

#SLTL Infinity#cnc laser cutting machine#sheet cutting machine#metal cutting machine#fiber laser cutter

0 notes

Text

The Ultimate Laser Cutter Types Guide

Welcome to The Ultimate Guide to Laser Cutting Models! In modern manufacturing, laser cutting machines play a vital role. They revolutionize materials processing through their highly precise cutting and engraving capabilities. This guide will give you an in-depth look at the different types of laser cutting machines, including CO2 lasers, fiber lasers and semiconductor lasers, and their application areas in various industries. Whether you're a beginner or a professional, with this guide you'll gain a comprehensive understanding of how to choose the right laser cutter for your needs and stay on top of the latest innovations.

laser cutting machine:

A laser cutting machine is a precision tool that uses a high-powered laser beam to cut and engrave materials. It offers exceptional accuracy, speed, and versatility, making it ideal for various industries. The laser beam melts or vaporizes the material, creating precise cuts without the need for physical contact or excessive heat, resulting in clean edges and intricate designs.

Key components of laser cutting machine:

1.Laser: The laser source provides a concentrated beam of light, typically generated by using either a carbon dioxide (CO2) laser or a fiber laser. The laser emits a high-energy beam of coherent light used for cutting the material.

2.Optical system: This system includes mirrors and lenses that help direct and focus the laser beam onto the workpiece. It ensures precise and controlled delivery of the laser energy.

3.Control system: The control system comprises both hardware and software components responsible for controlling the overall operation of the laser cutting machine. It includes a controller, motion control system, interface, and software to program and control the cutting process.

4.Cutting bed: The cutting bed provides a stable and flat surface on which the workpiece is placed during the cutting process. It helps in positioning and securing the material and allows for efficient cutting.

5.Workpiece support: In some laser cutting machines, a workpiece support system is used to hold the material in place during cutting. It may use clamps, suction, or other methods to keep the workpiece stationary and prevent vibrations.

6.Assist gas system: An assist gas (commonly compressed air, nitrogen, or oxygen) is used to blow away molten metal or debris from the cut, improving the overall cutting quality. The assist gas system typically includes gas tanks, filters, and nozzles.

7.Exhaust system: The exhaust system is responsible for removing fumes, smoke, and particulates generated during the cutting process. It helps maintain a clean working environment and ensures the safety of the operator.

8.Cooling system: Laser cutting generates a significant amount of heat that needs to be dissipated. The cooling system, which usually includes a chiller or water cooling system, helps maintain optimal laser and machine temperature to prevent overheating.

9.Safety features: Laser cutting machines incorporate various safety features, such as emergency stop buttons, door interlocks, and protective enclosures, to ensure the operator's safety during operation.

Application & importance of laser cutting machine:

Laser cutting machines are used in various industries for precise and efficient material cutting. Their applications range from metal fabrication, such as cutting and shaping sheets, tubes, and profiles, to manufacturing sectors like automotive, aerospace, electronics, and furniture. The key importance of laser cutting machines lies in their high precision, versatility, speed, and ability to cut a wide range of materials with minimal heat-affected zones. They enable complex designs, eliminate the need for tooling, and offer increased productivity, making them essential tools for modern manufacturing processes.

Considerations for choosing a laser cutting machine:

When choosing a laser cutting machine, consider the following factors:

1.Power and cutting capabilities: Determine the required power level and cutting thickness to ensure the machine can handle your intended materials and cutting depth.

2.Bed size: Consider the maximum size of the workpiece you'll be cutting to ensure it fits on the machine's bed.

3.Laser type: Decide between CO2 or fiber lasers based on the materials you'll be cutting. CO2 lasers are versatile and can cut a wide range of materials, while fiber lasers excel at cutting metals.

4.Cutting speed and precision: Evaluate the machine's speed and accuracy to ensure it meets your production needs, especially if you have specific tolerances or a high-volume workload.

5.Support and service: Research the manufacturer's reputation for customer service and technical support, as well as the availability of spare parts and maintenance requirements.

6.Software compatibility: Check if the machine's software is compatible with the design software you use, allowing for seamless integration and efficient workflow.

7.Safety features: Look for safety mechanisms like protective enclosures, interlock systems, and emergency stop buttons to ensure the operator's safety.

8.Budget and cost of ownership: Consider the initial cost of the machine, as well as ongoing expenses like maintenance, replacement parts, and operational costs like electricity and gas.

9.User-friendly interface: Evaluate the ease of use and accessibility of the machine's interface, considering features like touchscreen controls and intuitive software.

10.Reviews and recommendations: Read customer reviews and seek recommendations from industry professionals to gain insights from those who have used the machine.

Working principle of laser cutting machine:

A laser cutting machine operates based on the principle of using a highly focused beam of light, known as a laser, to cut materials with precision and accuracy. Here is a detailed description of its working principle:

1.Laser Generation: The laser cutting machine starts by generating a laser beam using a laser resonator. This resonator contains a gas mixture, such as carbon dioxide (CO2), nitrogen (N2), and helium (He), which, when energized, produces a highly concentrated beam of light.

2.Beam Amplification: The laser beam is then amplified within the resonator by passing it through a series of mirrors and lenses. These optical devices intensify the laser's power, increasing its energy density and enabling high cutting speeds.

3.Beam Delivery System: The amplified laser beam is delivered from the resonator to the cutting head through a beam delivery system. This system typically consists of mirrors and fiber optics, which help guide and direct the laser beam to the desired cutting location.

4.Material Interaction: When the laser beam reaches the cutting head, it is focused into a small spot size, ranging from a few micrometers to a few millimeters, depending on the application. The focused laser beam is then directed onto the material to be cut, which could be metal, wood, plastic, or various other materials.

5.Material Absorption: The material being cut absorbs the energy of the laser beam. This energy is converted into heat, causing the material to melt, vaporize, or undergo a process known as thermal stress cracking. Different materials respond differently to the laser beam, and adjustments can be made to the beam's power and speed to optimize the cutting process for each material.

6.Cutting Process: As the laser beam interacts with the material, it moves along the desired cutting path. The focused laser beam acts as a high-energy heat source that effectively melts or vaporizes the material within a narrow region. As the laser continues to move, it creates a kerf (cutting groove) through the material, separating it into two distinct pieces.

7.Gas Assist and Removal: To improve the cutting process and remove molten material, a gas assist system is often used. This system blows a gas, typically compressed air or nitrogen, onto the cutting area, helping to remove debris and prevent the accumulation of molten material. Gas can also prevent oxidation reactions and enhance the edge quality of the cut.

8.CNC Control: Laser cutting machines are usually equipped with computer numeric control (CNC) systems. These systems use specialized software to precisely control the movement of the laser beam and the cutting head. The CNC system takes input from CAD/CAM software, allowing for highly accurate and complex cutting patterns.

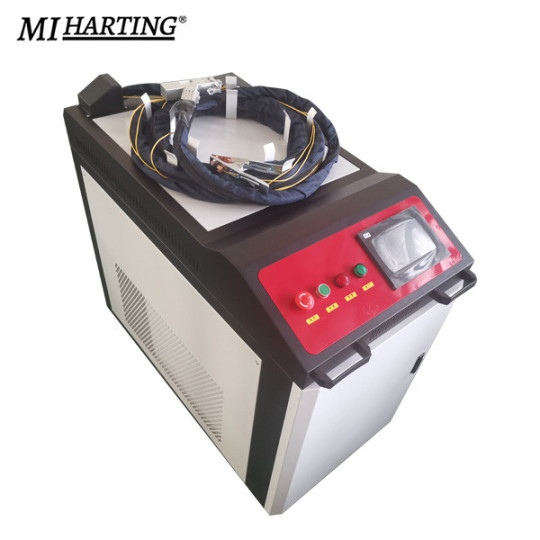

Advantages:

1.Portability: Handheld laser welding machines are compact and lightweight, making them easy to carry and operate in various locations. They offer flexibility and convenience for on-site welding tasks.

2.Precision: Laser welding technology provides high precision and accuracy, allowing for precise control of the welding process. It results in clean and aesthetically pleasing welds with minimal distortion.

3.Efficiency: Handheld laser welding machines have a fast welding speed and high deposition rates compared to traditional welding methods. They can significantly reduce welding time, increasing overall productivity.

4.Versatility: These machines can weld a wide range of materials, including stainless steel, aluminum, titanium, copper, and even dissimilar metals. They can be used in various industries, including automotive, aerospace, electronics, and jewelry.

Applications:

1.Automotive Industry: Handheld laser welding machines are used for repairs, modifications, and manufacturing processes in the automotive industry. They can weld car body parts, exhaust systems, fuel tanks, and more.

2.Jewelry Making: Precise and clean welds are essential in the jewelry industry. Handheld laser welding machines enable jewelers to perform intricate repairs, resizing, and creating complex designs.

3.Electronics Manufacturing: These machines find applications in electronics manufacturing, such as welding connectors, batteries, sensors, and printed circuit boards (PCBs).

4.Medical Equipment: Handheld laser welding machines are used in the production of medical devices, including implants, surgical tools, and dental equipment.

Precautions:

1.Eye Protection: Laser radiation can be harmful to the eyes. It is crucial to wear appropriate laser safety goggles or shields when operating a handheld laser welding machine.

2.Ventilation: Laser welding produces smoke, fumes, and vaporized metal particles. Adequate ventilation is necessary to maintain a safe working environment and prevent inhalation of hazardous substances.

3.Training and Certification: Proper training and certification are essential to operate a handheld laser welding machine safely and effectively. It is important to understand the equipment, its settings, and safety protocols.

4.Workpiece Preparation: Prior to welding, the workpieces should be properly cleaned and prepared to ensure quality welds. Any grease, dirt, or oxide layers should be removed for optimal welding results.

Advantages:

1.Versatility: A plate and tube integrated laser cutting machine combines the capabilities of both plate cutting and tube cutting into a single system. It offers versatility and flexibility to handle various cutting requirements.

2.Time and Cost Efficiency: Using a single machine for both plate and tube cutting eliminates the need for separate equipment, reducing investment costs and saving valuable floor space. It also streamlines the production process, increasing overall efficiency.

3.High Precision: Laser cutting technology provides high precision and accuracy, allowing for intricate and complex cutting patterns. It ensures clean and smooth cuts with minimal material wastage.

4.Automation and Productivity: Integrated laser cutting machines often come with advanced automation features such as robotic loading and unloading systems. This improves productivity by reducing manual labor and increasing uptime.

Applications:

1.Metal Fabrication: Plate and tube integrated laser cutting machines are widely used in the metal fabrication industry for cutting various materials like steel, stainless steel, aluminum, and brass. They can be used to create a wide range of products, including sheet metal parts, tubes, frames, and brackets.

2.Construction: These machines are employed in the construction industry for cutting metal components used in building structures, bridges, and infrastructure projects.

3.Automotive and Aerospace: Integrated laser cutting machines find applications in the automotive and aerospace sectors, where accurate and precise cutting is required to manufacture chassis, body panels, exhaust systems, and aircraft components.

4.Furniture Manufacturing: The ability to cut both plates and tubes makes these machines suitable for the furniture industry. They can be used to cut metal parts for chairs, tables, cabinets, and decorative elements.

Precautions:

1.Operator Safety: Laser cutting machines emit high-power laser beams that can be hazardous to the eyes and skin. Proper safety equipment, such as laser safety goggles and protective clothing, should be worn.

2.Ventilation: Laser cutting generates fumes, smoke, and particulate matter, which can be harmful if inhaled. Adequate ventilation systems should be in place to ensure a safe working environment.

3.Maintenance and Cleaning: Regular maintenance and cleaning of the machine are essential to maintain its performance and prolong its lifespan. This includes cleaning the lenses, checking the beam path, and ensuring proper alignment.

4.Material Handling: Care should be taken when handling and loading materials onto the machine. Sharp edges and heavy objects can pose hazards, so proper lifting techniques and equipment should be utilized.

Advantages:

1.Expanded Cutting Area: A large surround laser cutting machine offers a significantly larger cutting area compared to standard laser cutting machines. It allows for the processing of larger workpieces or multiple smaller pieces in a single operation, increasing production efficiency.

2.Flexibility: These machines can cut a wide range of materials, including various metals (steel, stainless steel, aluminum), plastics, wood, and more. They can be used in diverse industries such as automotive, aerospace, signage, furniture, and construction.

3.High Precision and Quality: Laser cutting technology provides excellent precision and accuracy, resulting in clean, smooth cuts without the need for secondary finishing operations. It ensures high-quality cuts with tight tolerances.

4.Automation and Efficiency: Large surround laser cutting machines often come with advanced automation features like robotic loading and unloading systems, automatic sheet feeding, and sorting capabilities. This reduces manual labor, increases productivity, and optimizes workflow.

Applications:

1.Sheet Metal Fabrication: Large surround laser cutting machines are commonly used in the sheet metal fabrication industry. They can cut large sheets of metal to create various products, including architectural components, machinery parts, enclosures, and decorative panels.

2.Automotive and Aerospace: These machines find applications in the automotive and aerospace sectors for cutting components like body panels, frame parts, brackets, and intricate designs.

3.Signage and Advertisement: Large surround laser cutting machines are employed in the manufacturing of large-scale signage, billboards, and advertising displays. They enable precise and detailed cutting of different materials, allowing for intricate designs and logos.

4.Furniture Manufacturing: The ability to process large workpieces makes these machines suitable for the furniture industry. They can cut wood, acrylic, and other materials used in furniture construction, providing intricate patterns and precise joints.

Precautions:

1.Safety Measures: Laser cutting machines emit high-power laser beams that can be hazardous to the eyes and skin. It is essential to implement proper safety measures such as using laser safety goggles, guarding the work area, and ensuring operator training on safe practices.

2.Ventilation and Extraction: Large surround laser cutting machines generate smoke, fumes, and debris during the cutting process. Adequate ventilation systems and exhaust extraction units should be in place to maintain a safe working environment and remove harmful substances.

3.Maintenance and Calibration: Regular maintenance, including cleaning and calibration of the machine, is necessary to ensure optimal performance and accuracy. Follow the manufacturer's guidelines for maintenance procedures and intervals.

4.Material Handling: Care should be taken when handling large and heavy materials on the machine to avoid accidents or damage. Ensure proper lifting equipment and techniques are used and follow safety protocols.

Advantages:

1.Compact Design: A single platform laser cutting machine is designed to occupy a relatively small footprint, making it suitable for small or limited workspace environments. It allows for efficient use of space and easy integration into existing production lines.

High Precision Cutting: These machines utilize laser technology that provides excellent precision and accuracy in cutting various materials. They can achieve intricate and detailed cuts with minimal material wastage.

2.Versatility: Single platform laser cutting machines are capable of cutting a wide range of materials, including metals (steel, stainless steel, aluminum), plastics, wood, leather, and more. This makes them applicable across different industries.

3.Cost Efficiency: Operating a single platform laser cutting machine can be cost-effective due to its relatively lower initial investment cost compared to larger industrial laser cutting systems. They require less space, consume less power, and have lower maintenance costs.

Applications:

1.Small-Scale Manufacturing: These machines are ideal for small-scale manufacturing operations, such as job shops, custom fabrication businesses, or small workshops. They can handle the production of small parts, prototypes, customized products, and personalized items.

2.Arts and Crafts: Single platform laser cutting machines are widely used in arts and crafts industries for engraving, etching, and cutting various materials like wood, acrylic, paper, fabric, and leather. They allow for intricate designs and precise cutting of artistic pieces.

3.Jewelry Making: Jewelers can utilize single platform laser cutting machines to precisely cut and shape materials like gold, silver, and precious stones. They enable the creation of intricate designs and custom jewelry pieces.

4.Electronics and PCB Manufacturing: These machines can be employed in electronics and printed circuit board (PCB) manufacturing processes for precision cutting and drilling of PCBs. They ensure accurate component placement and precise electrical connections.

Precautions:

1.Operator Safety: Laser cutting machines emit high-power laser beams, which can be dangerous to the eyes and skin. It is crucial to follow proper safety protocols, such as wearing laser safety goggles and protective clothing, to ensure operator safety.

2.Ventilation: Laser cutting produces smoke, fumes, and potentially harmful particles. Adequate ventilation systems should be in place to remove these byproducts and maintain a safe working environment.

3.Material Compatibility: Ensure that the materials being processed are suitable for laser cutting. Some materials may release toxic gases or produce harmful fumes when subjected to laser cutting, so it's important to verify material compatibility beforehand.

4.Maintenance: Regular maintenance is essential to keep the machine in good working condition. Follow the manufacturer's guidelines for cleaning, inspection, and lubrication schedules to prevent breakdowns and ensure optimal performance.

0 notes

Text

#CNC Laser Cutting#Laser Cutting#cnc machining#metal fabrication#metal fabricaters#Custom Cuts#CNC Laser Cutting in Delhi NCR#CNC Laser Cutting in Delhi#CNC Laser Cutting Delhi#Industrial Cutting#CNC technology#Laser Cutter#Creative Designs#Manufacturing Industry

1 note

·

View note

Text

youtube

1 note

·

View note

Video

youtube

hot sale 10% discount 2kw raycus fiber laser cutter equipment cut 12mm c...

#youtube#hot sale 10% discount 2kw raycus fiber laser cutter equipment cut 12mm carbon plate and metal tube starmacnc delllasercutter lasercuttingmac

0 notes

Text

How Does the Price of a Wood Laser Engraver Compare to Other Woodworking Tools?

Woodworking is a beloved craft that has been around for centuries. You don't have to be an expert woodworker to realize that having the right tools can make all the difference in the world.

In recent years, wood laser engraver have become increasingly popular, allowing woodworkers to create intricate designs and custom patterns with ease.

While some may assume that wood laser engravers are expensive compared to other woodworking tools, the truth is that they are actually quite reasonably priced.

The Cost of Woodworking Tools

The cost of woodworking tools varies from a few hundred dollars to several thousand.

Table saws, drill presses, and routers are just a few examples of common woodworking tools that can be quite expensive.

However, when compared to the cost of other power tools, wood laser engravers are quite affordable.

The Cost of Wood Laser Engravers

A machine that engraves wood typically costs between a few hundred dollars and several thousand dollars, depending on the brand, the power, and the size of the engraving bed.

Even though this may seem steep to some, it's important to consider the unique benefits that a wood laser engraver can offer.

For example, wood laser engravers can be used to create intricate designs and patterns on a wide range of materials, including basswood plywood, and can etch logos or text onto wood with precision.

Benefits of Wood Laser Engravers

Portable laser engravers are a great choice for woodworkers who want to create intricate designs on the go.

They are small enough to be easily transported yet powerful enough to handle most wood laser engraver parts. These machines are perfect for those who want to work on wood engraving projects in a variety of settings.

The best laser cutter engraving machines offer precise and accurate engraving capabilities. With a wood laser engraver, you can create detailed designs and custom patterns with ease.

Whether you're creating a custom piece of furniture, a personalized gift, or a unique decoration, a wood laser engraver is the perfect tool for the job.

Conclusion

Overall, the cost of a wood laser engraver is quite reasonable when compared to other woodworking tools. While the initial investment may be higher than some other tools, the benefits of a wood laser engraver are well worth it.

With a wood laser engraver, you can create intricate designs, etch logos or text, and customize your woodworking projects like never before.

No matter how experienced you are or how new you are, a wood laser engraving machine is a valuable investment that will help you take your woodworking projects to the next level.

0 notes

Text

Hygrade Laser Profiling provides complete manufacturing solutions from start to finish. To complement our laser cutting, bending, and fabrication we also offer mass finishing services. This results in a streamlined process for our customers. || Address: 32 Harley Crescent, Condell Park, NSW 2200, Australia || Phone: +61 2 9791 1255

0 notes

Text

#lasermarking#laserengraved#laserengraving#lasermetalcuttingmachine#laser metal cutter#lasercutter#lasercutting#laser

0 notes

Text

Laser Cutting: How Has This Innovation Improved the Manufacturing Industry Over Time?

Huxley Design will help you stay on the cutting edge of metal fabrication. Laser cutting is a fabrication process involving lasers' use to cut materials. A qualified company like Huxley can help you stay current with new fabrication techniques, machine builds, and training in welding. To know more about Custom Laser Cutting Utah click here!

#metal laser cutting utah#Cnc Laser Cutter Utah#The Laser Cutting Company Utah#laser cutting services utah

1 note

·

View note