Text

If you are looking for a reliable and professional metal fabrication company in Canada, look no further than Tecoustics. We offer a wide range of services, including Mig Welding, Tig Welding, Forming and Bending, Metal Laser Cutting, Mechanized Plasma Cutting, and Oxy-Acetylene Cutting. Whether you need laser cutters for metal, laser cutting of metal, or laser for cutting metal, we have the equipment and expertise to handle any project.

#mig welding#tig welding#laser cutters for metal#laser cutting services#oxy-acetylene cutting#mechanized plasma cutting#laser cutting steel

3 notes

·

View notes

Text

Must brush floor with hand broom. Must collect tiny metal balls.

#Welding scraps#I’m in an auto class#I was cutting part of a riding lawnmower#it was an Oxy acetylene welder

4 notes

·

View notes

Text

ever wondered what tools dean is using to build the ma'lak box (aka his own coffin </3) in 14.11 damaged goods?? detailed notes with images

explanations under the images <3

starting off. what he's using to mark up his measurements is soapstone! it's soft & smooth to touch and works a bit like chalk. comes in these little quarter-inch x half-inch sticks.

to cut, he's using an oxy acetylene torch (I personally haven't used these but will update cause i think we're getting to them in a few weeks)

he carves the symbol into the box with a plasma torch of some kind (idk which cause i've only ever used one to cut with)

this tool is an angle grinder. I'm not sure what blade is on it right now but it looks just like a grinding one (to clean up the edge probably) but you could put a cutting blade or wire brush or etc on too.

the metal he's working with is mild (low-carbon) steel (most common kind pretty much). you can tell by the pattern of the spark spray. it's hard to get a good screen cap but it's got the characteristic long orange tails with spindly star sparks

they never show the exact kind of welding equipment he's using but presumably it's oxy acetylene or plasma as well. though donna's shop is pretty fucking stocked so it could be stick, flux-core, MIG, TIG, among others. this is him examining what's called a T-joint.

he wears the goggles for the oxy cutting and the mask for both the plasma cutting and the welding. I dont know which specific kinds these are for sure. but the mask looks like the kind where you have position the welding tools & then flip the mask down by snapping your neck without losing your spot with the tools then it's all dark until the arc of the welding lights up but if you slip, it goes dark again. its hard!!!

he's doing pretty well with safety/PPE as far as i can tell but he should be wearing ear protection with the angle grinder (& not be building himself a coffin to be dropped into the ocean in & be trapped with an evil archangel for eternity. that's an extreme safety hazard!!!)

anyway i'm no expert so please correct me if i'm wrong! thanks for reading! here's the twitter version too.

#dean winchester#smart boy dean#info dump#welding#ma'lak box#supernatural#spn#14.11#damaged goods#PPE

7 notes

·

View notes

Text

Last Monday of the Week 2023-09-04

Bean power springs eternal

Listening: Started The Magnus Archives because I remember everyone loving those years ago. First few episodes so far, it's good! I kind of wish it was a full radio drama because the stories are well done but the framing device works. The one about the guy who got given the mysterious coffin was great.

A lot of these stories have me imagining them drawn in the style of Abby Howard's horror stuff, like The Door in the Kitchen or The Portrait of Sal Pullman:

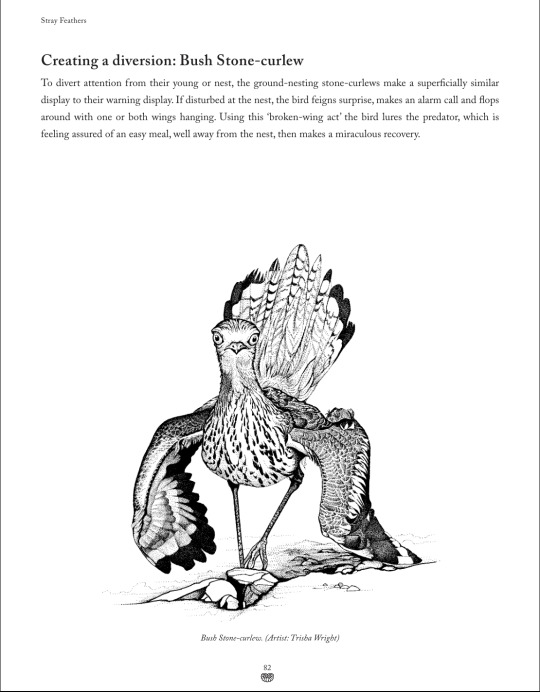

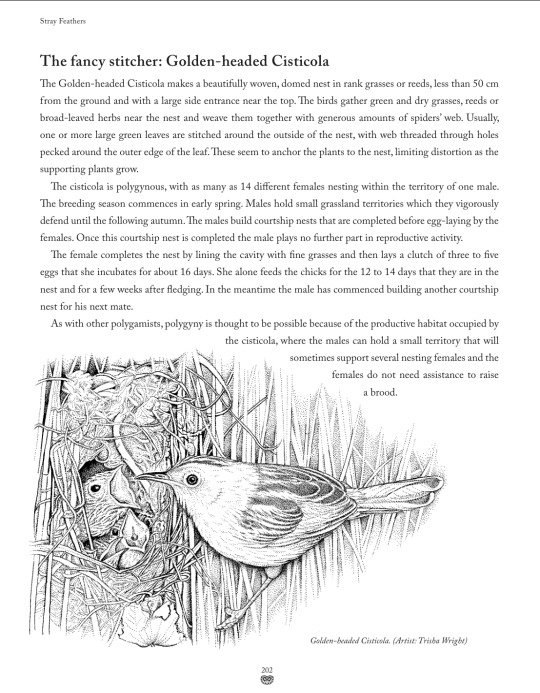

Reading: Stray Feathers: Reflections on the Structure, Behaviour and Evolution of Birds, a collection of mostly one-page notes on Australian birds published by the CSIRO. Mostly flipping through it to fulfil some questions I had about feathers but it's quite engaging and I'm probably going to end up reading the whole thing. Wonderful illustrations.

Playing: Still at Breath of the Wild, spent a while tooling around in the southern part of the map, found one of the other springs and stumbled into the Lightning Dragon. Probably going to finally head into the desert soon and check out that Divine Beast.

Watching: Got slightly obsessed with this youtube series where a guy cooks several recipes focussed on a single ingredient, starting when he had half a caterer's bag of potatoes left over from another video. Really well shot food and also interesting, some cool ideas.

In particular the Garlic and Onion ones look... really good.

youtube

youtube

Making: Not much, although my sealed bags arrived today so I can start printing again, I have some designs lined up. I guess I made roti for the first time which involved seasoning a cast iron pan, a thing I've never done before. My parents only piece of cast iron is a thawa that is literally a piece of plate cast iron you'd find in like, a bridge section, that one of my uncles cut and bent with an oxy-acetylene torch, and it had been used several hundred times before I was born so the concept of intentionally seasoning cast iron has never come up.

Tools and Equipment: I've been using gpu-screen-recorder to do replays of Breath of the Wild.

You could just use OBS or whatever but GPU-screen-recorder implements recording and encoding all on the GPU, dramatically reducing CPU overhead and resulting in an extremely efficient replay system. It's basically an open source version of the driver-level video recorders AMD and Nvidia include in their software suites. It is kind of prototype software, it's not quite ready for mainstream, but it's a handy thing and you can get it to spit raw video if you want to incorporate it into a larger workflow.

10 notes

·

View notes

Text

Mastering Welding Fabrication: A Breakdown of Essential Techniques

Welding fabrication is a vital process in manufacturing, construction, and repair industries. It involves the joining of metals through various welding techniques to create durable, robust, and high-quality structures or components. Whether it’s constructing buildings, bridges, or machinery, welding plays an essential role in almost every sector. There are numerous welding methods, each suited for different applications and materials. Understanding the types of welding fabrication helps in choosing the appropriate method for specific projects, ensuring quality, safety, and cost-effectiveness.

In this article, we’ll explore some of the most common types of welding fabrication, their applications, and their advantages and disadvantages.

1. Arc Welding

Arc welding is one of the most widely used welding processes in the industry. It works by using an electric arc to create heat, which melts the metal at the joint between two workpieces. Once cooled, the metals are fused together, forming a strong bond.

Types of Arc Welding:

Shielded Metal Arc Welding (SMAW): Also known as stick welding, this method uses a consumable electrode coated in flux. When the electrode melts, it creates a weld, and the flux coating burns off, creating a protective gas shield to prevent contamination. SMAW is versatile and can be used on various metals like steel, iron, and aluminum, making it suitable for heavy-duty tasks like building construction and shipbuilding.

Gas Metal Arc Welding (GMAW): Commonly known as MIG welding, this method uses a continuous wire feed as an electrode. The welding area is shielded from contamination by an external gas, such as argon or carbon dioxide. MIG welding is favored for its speed and ease of use and is typically employed in automotive and manufacturing industries.

Gas Tungsten Arc Welding (GTAW): Also called TIG welding, this method uses a non-consumable tungsten electrode and a shielding gas, typically argon, to protect the weld from contamination. TIG welding is known for producing high-quality, precise welds and is often used for welding thin materials like stainless steel and aluminum.

Flux-Cored Arc Welding (FCAW): Similar to MIG welding, FCAW uses a continuous wire feed, but the wire is flux-cored, eliminating the need for external shielding gas in some applications. It’s commonly used for outdoor or heavy-duty work, such as construction and shipbuilding.

2. Oxy-Fuel Welding

Oxy-fuel welding, also known as gas welding, is one of the oldest forms of welding. It uses a combination of oxygen and a fuel gas, typically acetylene, to produce a flame that melts the metal at the joint. This method is suitable for welding ferrous and non-ferrous metals and is widely used in small-scale fabrication and repair work.

Advantages:

Portable and inexpensive equipment.

Versatile, can also be used for cutting metals.

Disadvantages:

Slow welding process.

Limited to thin materials, not suitable for heavy-duty tasks.

3. Resistance Welding

Resistance welding is a process where heat is generated through the resistance of the materials being joined to the flow of electric current. The pressure is applied to fuse the materials together, making it a fast and efficient method for mass production.

Types of Resistance Welding:

Spot Welding: One of the most common types of resistance welding, spot welding is typically used to join two metal sheets by applying pressure and heat to localized areas (or “spots”). It’s widely used in the automotive industry to fabricate car bodies and other sheet metal products.

Seam Welding: Seam welding is similar to spot welding but involves a continuous weld along a seam, making it ideal for applications that require leak-tight seals, such as fuel tanks and pipes.

4. Plasma Arc Welding

Plasma arc welding (PAW) is a precision welding process that uses a high-velocity jet of ionized gas (plasma) to melt and fuse metals. It is similar to TIG welding but provides more control and higher precision, making it ideal for applications that require intricate and detailed welds, such as aerospace and medical device manufacturing.

Advantages:

High level of precision and control.

Suitable for thin materials and complex shapes.

Disadvantages:

Requires specialized equipment and highly skilled operators.

Slower process compared to other welding methods.

5. Electron Beam Welding

Electron beam welding (EBW) is a high-energy welding process that uses a focused beam of electrons to melt and join materials. It’s performed in a vacuum to prevent electron scattering, resulting in extremely precise and high-quality welds. EBW is used in industries like aerospace, automotive, and electronics, where precision is critical.

Advantages:

Produces clean, high-quality welds with minimal distortion.

Suitable for thick materials and deep welds.

Disadvantages:

Expensive equipment and setup.

Limited to applications that can be performed in a vacuum.

6. Laser Beam Welding

Laser beam welding (LBW) uses a concentrated laser beam to melt and join materials. This method is highly accurate and fast, making it ideal for automated welding processes in industries like automotive and electronics manufacturing. It can weld thin materials with minimal heat input, reducing distortion.

Advantages:

High welding speed and precision.

Minimal heat-affected zone.

Disadvantages:

High initial equipment cost.

Limited to thin materials.

7. Ultrasonic Welding

Ultrasonic welding is a solid-state welding process that uses high-frequency ultrasonic vibrations to create frictional heat between the materials being joined. This method is commonly used for plastics but can also be used for metals. It’s widely applied in the electronics, automotive, and medical industries for welding components without using external heat or adhesives.

Advantages:

Fast, clean, and precise.

Ideal for materials sensitive to heat.

Disadvantages:

Limited to small, thin components.

Requires specialized equipment.

8. Orbital Welding

Orbital welding is a specialized form of automated welding, typically used for joining pipes or tubes. The process involves a welding head that rotates around the stationary pipe, allowing for a continuous and precise weld. Orbital welding is primarily used in industries where high-quality, repeatable welds are essential, such as aerospace, pharmaceuticals, nuclear, and semiconductor manufacturing.

Advantages:

Produces highly consistent and precise welds.

Ideal for clean environments and industries with stringent standards, like pharmaceuticals and semiconductors.

Disadvantages:

Requires specialized, expensive equipment.

Setup can be complex and time-consuming.

Conclusion

Welding fabrication is a diverse and essential process in various industries, each method offering unique advantages suited to specific applications. Whether it’s the simplicity and versatility of arc welding, the precision of TIG or laser welding, or the speed of resistance welding, the right technique depends on factors like material type, joint design, and project scale.

Understanding these different types of welding fabrication through expert training courses allows manufacturers, engineers, and fabricators to choose the most appropriate method, ensuring that their projects are efficient, durable, and cost-effective.

#orbital welding training#orbital welding technology#welding technology#welding types#orbital welding courses

0 notes

Text

Discover the Benefits of HTS-2000 Brazing Rods

If you’re searching for a superior brazing solution, look no further than HTS-2000 brazing rods. These second-generation fluxless rods offer unmatched performance for all your metal repair needs. Here's why HTS-2000 stands out and why it should be your top choice.

Why Choose HTS-2000 Brazing Rods?

Buy HTS 2000 Brazing Rods because theseare renowned for their advanced technology and exceptional quality. Unlike older brazing rods, which often use a mix of three alloys, HTS-2000 is composed of nine alloys. This innovative formulation makes it more flexible, stronger, and effective. With an elongation of 10% in 2 inches, HTS-2000 is three times more flexible than its predecessors, allowing it to handle stresses and strains better.

Key Features and Benefits

1. Superior Strength and Flexibility

One of the standout features of HTS-2000 is its impressive tensile strength of up to 45,900 PSI. Because of this, it is more robust than the metal it is repairing. The high elongation rate of 10% ensures that the repairs are not only strong but also flexible, reducing the risk of fractures under stress.

2. No Flux Required

Buy HTS 2000 Brazing Rods as they do not require flux, simplifying the brazing process. This cuts down on preparation time and removes the need for extra cleaning brushes. The rods easily penetrate impurities beneath the metal's surface, creating a robust metal-to-metal bond.

3. Low-Temperature Operation

Operating at a working temperature between 717 and 737 degrees Fahrenheit, HTS-2000 brazing rods are suitable for use with common heat sources such as propane, butane, or oxy-acetylene torches. This low temperature is over 500 degrees below the melting point of aluminum, making it ideal for delicate repairs without risking damage to surrounding materials.

4. Durable and Corrosion-Resistant

Repairs made with HTS-2000 are highly durable and resistant to corrosion. The joints created with these rods can last for over a decade in severe conditions. According to evaluations, HTS-2000 joints are stronger and more long-lasting than those created using other conventional brazing rods or heli-arc machines.

How to Use HTS-2000 Brazing Rods

Step 1: Prepare the Surface

Clean the area to be repaired using a file, grinder, or wire brush. HTS-2000 does not require a special cleaning brush, making the preparation straightforward.

Step 2: Heat the Metal

The work surface should be heated to the HTS-2000 brazing rod's melting point. Avoid placing the rod directly in the flame. Instead, focus on heating the base metal to ensure proper bonding.

Step 3: Apply the Rod

For thin aluminum or threaded parts, tin the housing with the rod itself once the appropriate temperature is reached. Apply the rod to the area using a tinning brush for other uses. Proceed with your build-up for optimal results.

Step 4: Cool Naturally

Allow the repair to cool naturally after completing the brazing. For metals up to 1/4 inch thick, propane is usually sufficient. For thicker metals or quicker results, use mapp gas or oxy-acetylene with a Rosebud tip.

Buy HTS 2000 Brazing Rods as they offer an advanced solution for metal repairs, providing superior strength, flexibility, and ease of use. Their unique formulation and low-temperature operation make them a top choice for anyone needing reliable and durable repairs. Experience the difference with HTS-2000 and see why it’s the best brazing rod available.

#HTS 2000 Brazing Rods#HTS 2000 Rods#HTS 2000 Brazing Material#HTS 2000 Welding Rods#HTS 2000 Alloy Rods#HTS 2000 Brazing Filler Metal#HTS 2000 Soldering Rods#HTS 2000 Rods for Repair#HTS 2000 Rods for Automotive#HTS 2000 Welding Supplies

0 notes

Text

THE ESSENTIAL GUIDE TO STRUCTURAL STEEL FABRICATION AND DURABILITY

Steel fabrication creates buildings and goods from steel sheets and plates. Steel fabrication comprises cutting, bending, and welding to desired forms and sizes from the best Structural steel fabrication companies in UAE. Steel fabrication helps the world’s largest steel sector succeed. Structural steel Fabricators in UAE use laser cutters, plasma cutters, oxy-acetylene torches, and welding machines. CNC machines, which can manufacture accurate geometries, are used for most industrial metal manufacturing. Fabricating buildings, bridges, and other infrastructure with steel is one of its largest uses. Equipment and machines are made with it.

What are the benefits of steel fabrication?

Steel fabricators make robust, durable items for construction, transportation, and aerospace. The main benefits of steel fabrication are: Strength: Steel is robust and has been used for millennia to build bridges and sculptures. Steel is stronger than other materials, thus these thinner components can handle more weight without breaking or warping. Durability: Steel is durable and wear-resistant, making it ideal for scaffolding. Steel materials are stable since they don’t rust or corrode and can withstand water and sunlight.

Read more:https://baraqsteel.com/structuralsteel.html

0 notes

Text

Gas vs. Electric Welding Equipment: Which is Better?

Welding is a crucial process in many industries, from construction to automotive manufacturing. But when it comes to choosing the right equipment, the debate often centers around gas versus electric welding. Both have their merits, but which one is truly better? In this article, we will explore the differences, advantages, and disadvantages of gas and electric welding equipment to help you make an informed decision.

Introduction: Why the Choice Matters

Choosing between gas and electric welding equipment is not just a matter of preference; it can significantly impact your work's quality, efficiency, and cost. Have you ever wondered why some professionals swear by their TIG Welder machine while others prefer a MIG Welder machine? What factors should you consider when selecting your welding equipment? Let’s dive into the specifics.

Understanding gas welding equipment

How Does Gas Welding Work?

Gas welding, also known as oxy-fuel welding, uses a flame produced by burning a fuel gas (usually acetylene) with oxygen. This flame melts the base metal and allows the welder to join the materials.

Advantages of gas welding

Portability: Gas welding equipment is typically more portable than electric setups, making it ideal for fieldwork.

Versatility: It can be used for welding, cutting, and heating.

Cost: Initial costs are generally lower compared to electric welding machines.

Disadvantages of Gaswelding

Safety risks: handling flammable gases poses a safety risk.

Slower Process: Gas welding is often slower compared to electric methods.

Precision: Not as precise as some electric welding techniques.

Understanding Electric Welding Equipment

How does electric welding work?

Electric welding uses an electric arc to generate the heat needed to melt and join metals. Common types of electric welding include MIG (metal inert gas) and TIG (tungsten inert gas) welding.

Advantages of Electric Welding

Speed: Electric welding is generally faster than gas welding.

Precision: Techniques like TIG welding offer high precision, ideal for detailed work.

Safety: Generally safer as it does not involve flammable gases.

Disadvantages of Electric Welding

Cost: higher initial investment for the equipment.

Power Dependency: requires a stable power source, limiting portability.

Complexity: Can be more complex to set up and operate.

Comparing TIG and MIG Welder Machines

TIG Welder Machine

Precision: TIG welding is known for its precision and control, making it suitable for thin materials and detailed work.

Clean Welds: Produces clean, high-quality welds with minimal spatter.

Skill Level: requires a higher skill level to operate effectively.

MIG Welder Machine

Speed: MIG welding is faster, making it ideal for larger projects.

Ease of Use: Easier to learn and operate, suitable for beginners.

Versatility: Can be used on a variety of materials and thicknesses.

Factors to Consider When Choosing Welding Equipment

Project Requirements

Material: The type of material you are welding (e.g., aluminum, steel) can dictate the best equipment choice.

Thickness: Thicker materials may require the higher power output of electric welders.

Environment

Location: For fieldwork, portability may be more important, favoring gas welding.

Power Availability: If power supply is unreliable, gas welding might be the better option.

Budget

Initial Costs: Electric welding equipment usually has higher upfront costs.

Operating Costs: Consider the long-term operating costs, including maintenance and consumables.

Conclusion: Making the Right Choice

So, which is better: gas or electric welding equipment? The answer depends on your specific needs and circumstances. If portability and versatility are your top priorities, gas welding might be the way to go. However, if you value speed, precision, and safety, electric welding could be the better choice. Ultimately, understanding the differences and considering your project's unique requirements will help you make the best decision. Whether you’re in a welding supply store eyeing a new TIG Welder machine or debating the merits of a MIG Welder machine, having the right information can make all the difference.

What are your thoughts on gas versus electric welding? Do you have a preference or any experiences to share? Let’s continue the conversation and find the best solutions together.

0 notes

Text

Here's How To Use Our Pipe Cutting Machine to Ensure Your Safety

If you are in the market for precision oriented pipe cutting machines in UAE, you have come to the right place. It is very important to buy highly accurate machines and instruments for pipe cutting because they matter a lot in how the job is completed. Gas cutting instruments are mainly used for cutting, welding and bevelling using the basic concepts of oxy-fuel welding. This process is done by joining metals by applying heat from a gas flame. Cutting is the opposite of welding, of course, and in this process too, the oxy-fuel cutting process is used. In this, workers use acetylene and oxygen to preheat the metal and then use oxygen to cut away the part of the metal.

The products here are excellent for pipe cutting, and plumbers and welders have multiple uses for the various models. The welding supplies in UAE are crafted according to brand requirements and serve myriad purposes. The blog details the process of pipe cutting machines in UAE, and tips on how you can use yours safely.

0 notes

Text

Analyzing the Impact of Industrial Uses on Acetylene Price Chart

Acetylene or Ethyne (C2H2) is a colourless gas that has a faint garlicky odour. It is one of the simplest and widely known members of the hydrocarbon series containing one or more pairs of carbon atoms linked to triple bonds called the acetylenic series, or alkynes. It is a terminal acetylenic compound which is produced using calcium carbide and has traces of phosphine. The gas is easily combustible and burns with a sooty flame. Acetylene Price chart, including India Acetylene price, USA Acetylene price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

It is lighter than air in weight and has the respective boiling and melting point of -84.7°C and −80.8 °C. The top Acetylene importers are China, and its top exporters are India and Italy.

Key Details About the Acetylene Price Trend:

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the Acetylene price in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

Request for Real-Time Acetylene Prices: https://www.procurementresource.com/resource-center/acetylene-price-trends/pricerequest

Industrial Uses Impacting Acetylene Price Trend:

Acetylene, a versatile hydrocarbon gas, finds extensive application across various industries, including metal fabrication, chemical synthesis, and welding. Understanding the relationship between industrial uses and acetylene price trends is crucial for stakeholders to anticipate market dynamics and make informed decisions. In this analysis, we delve into the industrial uses impacting acetylene price trends, elucidating key factors driving price fluctuations and future outlooks for the acetylene market.

Industrial Uses of Acetylene

Metal Fabrication

Acetylene serves as a primary fuel gas in oxy-acetylene welding and cutting processes employed in metal fabrication and construction industries. It provides high flame temperature and localized heating, making it ideal for cutting, brazing, and welding ferrous and non-ferrous metals. The demand for acetylene in metal fabrication is influenced by construction activities, infrastructure development, and manufacturing trends, driving seasonal and cyclical fluctuations in acetylene prices.

Chemical Synthesis

Acetylene is a crucial feedstock in chemical synthesis processes, serving as a precursor for various organic compounds, including vinyl acetate monomer (VAM), acrylic acid, and polyvinyl chloride (PVC). Chemical industries utilize acetylene in the production of plastics, solvents, pharmaceuticals, and specialty chemicals. The demand for acetylene in chemical synthesis is influenced by factors such as technological advancements, market demand for downstream products, and regulatory standards, impacting price dynamics.

Specialty Gas Applications

Acetylene finds niche applications in specialty gas mixtures used in analytical laboratories, semiconductor manufacturing, and medical applications. Its unique properties, such as high reactivity and flame stability, make it suitable for gas chromatography, semiconductor etching, and medical gas formulations. The demand for high-purity acetylene in specialty gas applications is driven by advancements in analytical techniques, semiconductor fabrication processes, and healthcare technologies, affecting price trends in niche markets.

Factors Influencing Price Trends

Feedstock Costs

The price of acetylene is closely tied to the cost of its primary feedstock, calcium carbide, which is produced by reacting coke and limestone in an electric arc furnace. Fluctuations in coke and limestone prices, influenced by factors such as energy costs, mining activities, and environmental regulations, impact the overall cost structure of calcium carbide production and, consequently, acetylene prices. Additionally, changes in electricity prices and availability affect the economics of calcium carbide production and acetylene pricing.

Supply-Demand Dynamics

Supply-demand dynamics play a significant role in determining acetylene prices, with supply shortages or surpluses exerting upward or downward pressure on prices, respectively. Production capacity expansions, plant shutdowns, and unplanned outages in acetylene manufacturing facilities can disrupt supply chains and lead to price volatility. Changes in demand from industrial sectors, seasonal variations, and market uncertainties influence market dynamics and affect pricing trends.

Regulatory Environment

Regulatory standards and environmental regulations governing acetylene production, storage, and transportation impact production costs and market dynamics. Compliance with safety regulations, emission standards, and workplace safety guidelines necessitates investments in infrastructure, technology upgrades, and regulatory compliance measures, affecting operating costs for acetylene producers. Additionally, changes in regulatory frameworks, such as carbon pricing mechanisms and emission trading schemes, may influence the long-term sustainability and competitiveness of acetylene production.

Future Outlook

Emerging Applications

The future outlook for acetylene is shaped by emerging applications in sectors such as additive manufacturing, renewable energy, and carbon capture and utilization (CCU). Innovations in 3D printing technologies, hydrogen production, and carbon sequestration present new opportunities for acetylene utilization and market expansion. Moreover, advancements in gas storage and distribution systems, coupled with the transition towards cleaner energy sources, may drive demand for acetylene in niche applications and sustainable technologies.

Technological Advancements

Technological advancements, such as alternative production methods, gas purification technologies, and process optimization techniques, are expected to enhance the efficiency and sustainability of acetylene production. Research efforts towards electrochemical acetylene synthesis, biomass-derived feedstocks, and carbon-neutral production pathways offer potential solutions to mitigate feedstock dependency and reduce environmental footprint. Integration of digitalization, automation, and artificial intelligence (AI) in acetylene production processes may improve productivity, safety, and cost competitiveness in the future.

Key Players:

BASF SE

Gulf Cryo

Linde

Praxair Technology Inc.

SINOPEC

Chengdu Xinju Chemical Co. Ltd.

Conclusion

In conclusion, the industrial uses of acetylene play a pivotal role in shaping price trends and market dynamics in the acetylene industry. Understanding the interplay between industrial applications, feedstock costs, supply-demand dynamics, and regulatory environment is essential for stakeholders to anticipate market fluctuations and make informed decisions. Proactive risk management, strategic partnerships, and technological innovations are key strategies to navigate challenges and capitalize on emerging opportunities in the dynamic acetylene market.

Contact Us:

Company Name: Procurement Resource Contact Person: Leo Frank Email: [email protected] Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

0 notes

Text

The Evolution of Welding: From Ancient Craft to Modern Innovation

Introduction:

Welding is a time-honored craft that has evolved over millennia, from its humble beginnings in ancient times to the sophisticated processes and techniques used in modern industry. In this article, we embark on a journey through history to explore the evolution of welding, tracing its development from primitive methods to cutting-edge innovations that have revolutionized manufacturing and construction.

Ancient Welding Techniques:

The origins of welding can be traced back to ancient civilizations, where early humans discovered methods to join metal pieces together using heat and pressure.

Ancient Egyptians, Greeks, and Romans practiced forge welding, heating metal pieces in a forge and hammering them together to form a solid bond.

Other ancient welding undercut techniques included brazing and soldering, which involved melting a filler metal to join metal surfaces without melting the base metal.

Medieval Craftsmanship:

During the Middle Ages, welding techniques continued to evolve as craftsmen refined their skills and expanded their knowledge of metallurgy.

Blacksmiths played a crucial role in medieval society, forging iron and steel components for weapons, armor, tools, and architectural structures.

Welding methods such as forge welding and lap welding were widely used in the construction of medieval castles, cathedrals, and fortifications, demonstrating the durability and versatility of welded metal joints.

Industrial Revolution Innovations:

The Industrial Revolution in the 18th and 19th centuries brought significant advancements in welding technology, driven by the demands of industrialization and mass production.

The invention of the oxy-fuel welding process by Edmund Davy in the early 19th century revolutionized metal joining by using a combination of oxygen and acetylene gases to produce a high-temperature flame for welding and cutting.

The introduction of electric arc welding by Nikolai Benardos and Stanisław Olszewski in the late 19th century further accelerated the industrialization process, enabling faster and more efficient metal fabrication for construction, manufacturing, and infrastructure projects.

Technological Revolution:

The 20th century witnessed rapid advancements in welding technology, fueled by innovations in materials science, metallurgy, and engineering.

Developments such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW) expanded the capabilities of welding, allowing for greater precision, control, and versatility in joining various metals and alloys.

Automation and robotics revolutionized welding processes in the latter half of the 20th century, introducing computer-controlled systems for welding automation, robotic welding arms, and advanced welding sensors for quality control and monitoring.

Modern Innovation and Future Prospects:

In the 21st century, welding continues to evolve with advancements in additive manufacturing (3D printing), laser welding, friction stir welding, and other cutting-edge technologies.

Additive manufacturing processes such as selective laser melting (SLM) and electron beam melting (EBM) enable the production of complex metal parts with intricate geometries and customized properties, revolutionizing the manufacturing industry.

As industries embrace digitalization and Industry 4.0 principles, welding is poised to play a central role in smart manufacturing systems, interconnected production networks, and sustainable fabrication processes.

Conclusion:

The evolution of welding from ancient craftsmanship to modern innovation is a testament to human ingenuity, perseverance, and adaptability. From the primitive methods of forge welding to the sophisticated technologies of the 21st century, welding has continuously pushed the boundaries of what is possible in metal fabrication and construction. As we look to the future, the legacy of welding innovation serves as a foundation for continued progress, driving advancements in manufacturing, infrastructure development, and technological innovation across industries.

0 notes

Text

Oxygen gas regulator

NINGBO DSW INDUSTRY CO., LTD established in 2004 year, is a global leader in research & development and manufacturing in the welding fields.

Our major products are oxy-fuel cutting and welding equipment such as oxy-acetylene and oxy-fuel welding and cutting equipment, cutting torches, cutting tips, welding nozzles, heating torches, gas regulators, cutting and welding outfits.

For over 10 Years, DSW has been exported to more than 50 countries,listed as long-term strategic partner due to its reliability and accumulated experience.

The medical oxygen regulator is an essential device that is securely attached to an oxygen cylinder to carefully control and regulate the flow of oxygen to the patient. This device plays a crucial role in ensuring that the pressure of the oxygen coming from the cylinder is adjusted to a safe and appropriate level that meets the specific needs of the patient. By carefully regulating the flow of oxygen, the medical oxygen regulator guarantees that the patient receives the precise amount of oxygen required at the prescribed rate for effective treatment.

In healthcare settings such as hospitals, clinics, and other medical facilities, oxygen regulators are widely used to administer oxygen therapy to patients with various respiratory conditions or other medical needs. The DSW-86 pressure gauge is an integral component of the oxygen regulator, providing a clear indication of the pressure level within the gas cylinder to ensure that the oxygen flow is maintained at the correct level.

0 notes

Text

https://www.advancemarketanalytics.com/reports/61827-global-flame-cutting-machines-market

Flame Cutting Machines Market Growth Prospect: Is the tide Turning?

Advance Market Analytics released a new market study on Global Flame Cutting Machines Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Flame Cutting Machines Forecast till 2029*.

Flame cutting is a thermal cutting process that uses oxygen and a fuel source to create a flame with enough energy to melt and sever material. The process is a thermo-chemical Process requiring a source of intense heat, referred to as “Preheatâ€, and pure oxygen. There are various types of flame cutting machines available for different cutting applications in different industries such as automotive, aerospace, etc. CNC machines are the most widely used machines in advanced countries like China, Japan, Korea, etc. for cutting of the metal sheet for applications ranging from airplane parts to domestic household products.

Key Players included in the Research Coverage of Flame Cutting Machines Market are:

Messer Group (Germany), Koike Group (Japan), Mass Cutting Systems (India), BUG-O SYSTEMS (United States), ARCBRO Ltd. (China), Soitaab Impianti S.r.l. (Italy), SteelTailor (China), Technocrats Plasma Systems Private Limited (India), Th. Wortelboer B.V. (Netherlands), Shanghai Huawei Welding & Cutting Machine (China),

What's Trending in Market: Fully Integrated Oxy-Fuel Cutting System with Cutting Torch, Ignition, Height Sensing and Lifter All in One Package

Challenges: Reduction in Cutting Speed owing to Improper Connections, Bad Hoses, or Leaks Stringent Government Regulation for Safety of Labours

Opportunities: Fast-growing industries like automotive have fuelled the growth opportunities of sheet metalworking in numerous applications in car bodies, airplane wings, medical tables, roofs for buildings and many other things. Automatic and Cost-Effective Machine to Produce High-Quality Products at much Cheaper Rates

Market Growth Drivers: An increasing number of applications in the automotive and aerospace industry owing to high precision, accuracy, and reliability, is the key driving factor for the growth of the market. Growing Number of Manufacturing and Production Activities for High Volume Production in Emerging Economies Low Equipment Cost and No Power Supplies Needed

The Global Flame Cutting Machines Market segments and Market Data Break Down by Type (Manual Flame Cutting Machines, Semi-automatic Flame Cutting Machines, Automatic Flame Cutting Machines, CNC Flame Cutting Machines, Imitation Shape Flame Cutting Machines), Application (Metal Cutting, Glass & Ceramics Cutting, Others), End-User (Automotive, Aerospace & Defence, Construction, Marine, Electronics, Others), Fuel Type (Acetylene, MAPP, Propylene, Propane, Natural Gas)

Get inside Scoop of the report, request for free sample @: https://www.advancemarketanalytics.com/sample-report/61827-global-flame-cutting-machines-market

To comprehend Global Flame Cutting Machines market dynamics in the world mainly, the worldwide Flame Cutting Machines market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas.

• North America: United States, Canada, and Mexico.

• South & Central America: Argentina, Chile, Colombia and Brazil.

• Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa.

• Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia.

• Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia.

0 notes

Text

Pipe Beveling Cutting Machine (Motorized)

The Pipe Beveling Cutting Machine from SPM Equipment motorized is fast, accurate, and versatile. A single operator can position the band and beveling machine easily a few times. The Pipe Beveling Cutting Machine Motorized head is constructed of cast aluminum. Our pipe beveling cutting crawler is lightweight, and its compact design allows for easy one-person setup and operation in Russia, USA, UAE, Australia, and Malaysia.

1 note

·

View note

Text

Top CNC Plasma cutting machine manufacturer in India - Pusaanindia

A CNC flame cutting machine, also known as a CNC oxy-fuel cutting machine, is a type of industrial cutting tool used for cutting through thick metal plates or sheets. It utilizes a combination of fuel gases and oxygen to create a controlled flame that melts and removes the metal in the cutting path.

This machine is used for facilitating the process of plasma cutting, which uses an accelerated jet of hot plasma to cut through electrically conducting materials. Furthermore, it is a well-liked option for applications in both large-scale enterprises and tiny hobbyist shops due to its fast speed and accuracy cut.

Additionally, it is put through a variety of quality tests with expert supervision. Additionally, a variety of metals are cut using a CNC plasma cutting machine of the gantry type. Computers run plasma CNC machines, which use programmed instructions to make materials that adhere to exact requirements. The cutting torch is the standard tool used in plasma cutting machines to cut metal plates, sheets, bolts, pipes, etc.CNC plasma cutter machines have a system that can move the path of plasma torch by computer. Pusaan Automation PVT LTD is the best gantry type CNC Plasma cutting machine manufacturer in India. In the industrial world, our plasma cutting machine is highly regarded. Compared to a fibre laser cutting machine, a plasma cutter can easily cut materials that are the same thickness or thicker. When compared to other dealers and manufacturers, the price of the Gantry type CNC plasma cutting machine is reasonable. For more information about the Bench type machine and Portable CNC plasma cutting machine.

Here's an overview of how a CNC flame cutting machine typically operates:

Material Preparation: The metal sheet or plate to be cut is placed on a cutting table or platform. It is securely clamped or held in place to ensure stability during the cutting process.

Gas Supply: The machine has gas supply systems to provide the necessary fuel gases, typically acetylene or propane, and oxygen. These gases are mixed in precise ratios to create a combustible flame.

Ignition and Preheating: The CNC flame cutting machine has torches or burners that ignite the fuel gas and oxygen mixture. The torches are positioned above the material, and the preheating process begins. The preheating flame raises the temperature of the metal along the cutting path.

CNC Control: The machine is equipped with a computer numerical control (CNC) system that controls the movement of the cutting torch. The operator programs the desired cutting path into the CNC system or imports a pre-designed cutting pattern.

CNC flame cutting machines are commonly used for cutting thick metal plates, typically over 1 inch (25 mm) in thickness. They are suitable for materials like carbon steel, stainless steel, and aluminum. However, the heat-affected zone produced by flame cutting is larger compared to other cutting methods, which may require additional post-cutting operations for surface finishing.

It's important to note that as of my knowledge cutoff in September 2021, CNC flame cutting machines were widely used. However, there may be more advanced cutting technologies available at present.

CNC plasma cutting machines are widely used in India for their versatility and ability to cut through various types of metals. These machines utilize a plasma torch that generates a high-temperature plasma arc to melt and sever the metal.

When considering purchasing a CNC plasma cutting machine in India, it's essential to assess the specific requirements of your application, such as the material type, thickness, and cutting speed needed. Additionally, consider factors like after-sales support, warranty, training, and service availability from the manufacturer or supplier.

To make an informed decision, it's recommended to reach out to multiple suppliers, compare their offerings, and request quotations based on your specific requirements. This will help you determine the most suitable CNC plasma cutting machine that meets your needs and budget in India.

#CNC plasma cutting machine in India#CNC plasma cutting machine#CNC Plasma cutting machine manufacturer

1 note

·

View note

Text

8 Different Types Of Metal Cutting Tools And Their Uses

It is possible to be confused about how to choose the right metal cutting machine for you. This guideline will be worth reading to find out what kinds of metal cutting tools you may get available. Also, you will learn about how to use these tools.

Metal cutting is a process that allows you to cut metal in your desired shapes and sizes, also remove unnecessary objects off of the metal workpiece.

Metal cutting tools are instruments used to cut different types of metals. These tools are mostly used for shaping and cutting metal. The tools are used differently in accordance with their style. Whether you really want to learn more details on tools, you've to browse around https://www.sundicuttingtools.com/products/full-solid-cbn-inserts/ website.

This article will cover the different types of tools for cutting metal that are on the market and how they are best used.

Many different types of metal cutting tools

Different cutting instruments are being used to cut metals. Some of them are very useful and do their job well. This is a list of the most effective metal cutting tools.

The Saw

The blade of the saw is toothed, and it will cut through plastic wood or metal depending on what type of tool it is.

They are used by DIYers and metalworkers in order to cut through metal. For this kind of cutting, there are quite a number of saws you'll need included in your toolbox.

Cold Saw

Cold saws can slice through almost anything, starting with the stainless steel to tin, nickel, brass, titanium, copper, aluminum, lead, zinc to alloy steel, and carbon steel. Cold saws produce fewer sparks and less noise.

The circular saw generates no heat and cuts smoothly without friction. The result is a cold saw. The coolant allows for precise cutting, minimal discoloration and dust free production. The price is worth it if you do work with metal on a regular basis.

Hacksaw

Hacksaws are C-shaped saw that has a small blade. It is possible to adjust the frame with different blades. It is an excellent and affordable option for small metal cutting jobs.

Metal Circular Saw

Metal-cutting blades are used for the circular saw that makes it a "metal circular saw". It can cut straight up to 3/8 inches. Mild steel is an excellent quality thickness for mild steel. By using a circular saw, you can cut metal sheeting, roofing metals such as corrugated steel the majority of other metals. When cutting roofing be sure to hold it in the correct direction if necessary.

Install a blade in your saw. Mark the areas you want to cut. After that, cut in accordance with the plan. In order to speed up the process cutting large amounts of material in the same time using a knife made from ferrous metal. It's a fantastic tool for easy and straight cuts.

Band Saws

Band saws are excellent for cutting large quantities. It can be used to cut layers of thick material in curves. This tool can be used to cut unusual shapes.

It is a uninterrupted metal band that runs along the sharp-toothed blade to cut tube-like metal and flat material.

Oxy-Acetylene Torch

This tool produces flames at a high temperature. This tool is a torch which mixes acetylene, the gas derived from hydrocarbons, along with oxygen. The torch is able to cut through metals so thick that a normal saw cannot.

Another great feature is that this tool is very noisy compared to other saws or metal cutting tools. This tool is much more quickly.

Tin Snips

Tin snips are like an apron. When you need to cut various sheet metals, the kit you'll need is a pair of Tin cutting snips. The handheld tool is not that expensive.

This tool is great for cutting curvatures, straight lines or even circles, in soft metals. It's also convenient for cutting metal roofing, sheets of sheet metal, gutters and studs, while leaving an even edge.

Metalworkers make use of tin snips cut sheet metals for car bodies. Professional metalworkers cut corrugated metal using tin snips. You'll have to hold the tin snips as an axe. Keep the blades of the tool open wide, and then cut long and smooth. Cut until the work is completed.

Metal Air Shears

They are perfect for cutting large pieces of steel or even strips. Additionally, it is possible to rotate the head to make an exact cut. They produce better cuts and lesser spark.

It is easy to replace the blade. The blade can be cut in straight or curly lines. You can do both with an air shears. They can provide a different option to the tin snips but it will give a faster and more efficient result. It can be hand powered or electrically. Look for an item with handles that are insulated.

Angle Grinder with Cutoff Wheel

Angle grinders can be utilized to fabricate metal, such as cutting, grinding and finishing. They can also remove the surface, polish it, and take away burrs. It typically operates on electric power, either via a cord or battery. It is possible to cut through metals using an iron cutoff wheel.

Angle grinders can also be used to grind, sharpen and cut metal, in addition to removing the rust. An angle grinder is an excellent tool for seasoned DIYers and metalworkers.

0 notes