#metric machine screws

Note

trying to find a punishment to discipline jisung when he acts out would be so difficult bc honestly that little masochist likes them too much. edging, overstimulation, bondage, spankings— he enjoys them all, to the point that it’s almost a reward to him sometimes, an incentive to misbehave. so the next time he starts being all bratty and insufferable to you with that familiar glint in his eyes, he’s practically begging for u to show him his place

…so u tie him up, strap him to a fucking machine + put a cockring on him, to make sure he won’t be able to cum despite the never-ending stimulation he has to endure, while u go attend to mundane tasks in another room so that his constant spill of moans falls on deaf ears <3

maybe he was teasingly flirting with other ppl to try make u jealous, and so u tell him before leaving that “this is what u wanted, isn’t it? to be fucked? here. if you’re gonna act like a slut, you should be ready to be treated like one”

it would rly be torture for him :(( his shaking body would tense up with every one of the machine’s unchanging rhythmic thrusts.. poor spoiled baby gets whiplash bc of how different it is from the way you fuck him; you’re usually so receptive to his requests to switch up ur speed or pace or hit one of his sweet spots according to how he wants it at that moment, so the cold, unfeeling piece of tech teasing his hole only makes him want you more </3 he misses being able to hold ur hand while u rail him, and the stimulation he’s subject to is both too much and not enough, continually bringing him up to the brink of his orgasm but failing to tip him over bc of the cockring. his length lying against his abdomen is so hard he’s aching, he’d try grind down on the machine to catch his orgasm but he’d eventually keel over in exhaustion when he realises it’s impossible :(( his volume, which is already shamelessly loud by default, would reach another level if u toyed with him like this, an uninterrupted soundtrack of broken moans filtering through the walls. it goes from blissful, sweet moans at the beginning as he enjoyed the metrical pleasure being given to him, to hiccups and sobs and pleas for more after being left on the edge so many times, slurring out promising that he’s learnt his lesson, just pls come back and look at him </3

u’d leave him like that until his flushed face is glistening with his tear-stains, sweat n drool. boy might even thrash so hard he breaks his ties or the whole machine apart 😭

maybe u even come back at one point and his face lights up like a christmas tree, his begging immediately going silent as ur long-awaited presence pacifies him, and he thinks ur finally surrendering to his pleas. he watches u walk in like u hung the stars in the sky, tear-filled shining doe eyes tracing ur body in awe as u take off ur panties, only to become increasingly confused when you still don’t pay him any mind and say nothing, ignoring his questions as you fasten his ties tighter again. you then put your discarded panties in his mouth to work as a gag and turn up the machine to the highest speed, muffling his cries when you exit the room again, leaving him alone and coming forced orgasms dry, over and over <3 until you decide he’s been through enough and return for real

he doesn’t see you coming in this time because his eyes are screwed so tightly shut and his smothered moans are still loud enough to drown out the sound of your footsteps, his own whimpers ringing in his ears like white noise. he doesn’t even register that you’ve turned off the machine and taken off the cockring until he feels your soft, grounding hands at his sides bringing him back to earth. even though his body is so weak, he’d reach out towards u with grabby hands in an instant. you kiss his tears away affectionately, and, if he’s still got energy left in him, you reward him for getting through his punishment so well with a real orgasm from whatever he’d like. otherwise, you go straight to a warm bubblebath and cleanse him of the sticky mess of fluids covering his skin.

he’s too fucked out to move, limbs like a rag doll’s, so u wash him down with a soapy cloth urself while you whisper praises and he lets out tiny satisfied hums. pretty thing would shyly apologise for being disobedient earlier and ask u to give him kissies to make him feel better ♡ (the anon who said he’d make rubber duckies kiss and say it’s u two after just finishing super rough n intense play before is so right btw)

😭 han 😭 ji 😭 sung 😭

— 🌸

😭 han 😭 ji 😭 sung 😭!!! my exact reaction while reading this delicious ask you really served us up a 5 star meal w this one

masochistic lil hannie is just so easy to please isn’t he!! it’s as hot as it is frustrating how he’ll take anything you give him so eagerly and even beg for more. i 100% agree he’d enjoy practically any punishment you try to dish out to him way too much, it’s more like positive reinforcement than anything else bc at the end of the day, he gets to feel good and he gets all your focus on him, exactly what your cute little attention whore wants so bad <3

strapping him to a fucking machine and putting a cockring on his dick is soo genius i love it 😽 he gets fucked senseless by a toy instead of you, can’t cum, and on top of that doesn’t even get the satisfaction of you at least watching him fall apart for you…it’s poor jisungie’s nightmare ): what’s the point of acting up if he doesn’t get ur attention out of it! he’d whine so loud when you tell him that if he wants to act like a slut he gets treated like one…the needy pout and big pleading gaze he fixes you with would be so hard to resist when he whimpers out that he wants to be your slut, he wants you to treat him like one, not anyone else or any toy

the visual of his flushed face covered in tears and sweat and saliva w his hair ruffled so cutely and his mouth full w your panties would be to die for ♡_♡ you grab his jaw and give it a lil squeeze so that he opens up obediently, only for you to scold him for being so fucking noisy and stuffing your underwear in his drooling mouth. he would moan so pathetically loud the moment it touches his tongue bc he’s so desperate for you that even the faint taste of you is enough to make him crazy

the grabby hands ㅠㅠ that’s so adorable…as much of a handful as hannie might be he still deserves to be treated so sweetly once all the brattiness has been railed out of his system and he’s back to ur sweet affectionate lil angel ♡

162 notes

·

View notes

Text

Hold on I'm gonna use some of my hardware store employee powers to advise you guys

- If you're just using it at home, get the cheap drill. You don't need the Dewalt. Drill is used for making holes, driver is used for putting stuff in those holes.

- That being said please please please don't use power tools you aren't familiar with without tutorials or having someone show you. Yes use PPE even if you think it is stupid. I have had customers who are highly experienced come in with missing fingers because a chop saw kicked back on them. Be. Careful. Use. Protective. Equipment. Unplug them or remove the battery when you are done or lock them or something OK.

- A small screwdriver set is extremely useful. SAE + Metric together is the best. Having a socket set at home will also save you so much headache. Try to use the proper sized driver and socket the first time because a stripped screw or bolt will be way worse than just finding the right tool.

- If you need a nut or a bolt or machine screw or whatever please bring in an example of what you want or the thing it's going to be screwed into or something. Bolts and machine screws have different thread patterns and so having it with you will make it way easier for you And the employee. Eyeballing it will not work if it has to thread into the hole or nut or whatever.

- When screwing in a nylon lock nut you will probably need a socket wrench and you need to put the part that lays flat on first. The bump faces outwards. Like a normal nut. Thread it on with your hands first then use the wrench and if you can't get it on with your hands then you are doing it the wrong way turn it around.

- If you have a snowblower yes get a sheer pin or butter bolt. Yes it's annoying when they break. But a 2$ pin is a lot less expensive than a new 200$ snowblower.

- Bolts and machine screws are not the same they have different uses. Try to stick with whatever your project calls for ok.

- Be yourself and have fun

8 notes

·

View notes

Text

Amphibia's Needed 4 seasons

When looking over Amphibia as a whole, it's easy to blame Disney for screwing over the show's quality in the third season, after getting pissed over true colors.

And there certainly is a lot to blame them for, as there is no doubt that they were responsible for the creators not being able to commit to exploring all the ideas they set up in the second season finale, and the tonal shift it promised.

However, there is also one other, massive problem with Amphibia that is not actually Disney's fault, instead being a result of how Amphibia was planned out from the start.

Namely that from day one(Literally, it was pitched this way) Amphibia was planned to be a 3 season long show.

In hindsight, this was actually terrible idea, as the overall structure of the series can tell you.

Season 1 had a very clear progression, with Anne and Sasha being stuck in the Valley and having to deal with it, befriending new people and making mistakes and growing from them.

Season 2 began in the aftermath of the Season 1 finale, and had the cast go on a journey, which ultimately led to the 3 girls being reunited, their various goals colliding, and the machinations of our villains coming to fruition, and everything all exploding in a glorious finale.

Both these seasons are clear stories, with a beginning and an end, and the steps in between given a full seasons worth of episodes to explore them in full.

But then we get into season 3.

Season 3 is 2 completely different stories, with each half having their own distinct beginning and ending, with their respective plots being very different from the other.

The first half deals with Anne and the Plantars on Earth, while the second half is all about the cast on Amphibia.

And the thing is, both of these two halfs beginnings and endings work. They're not perfect, but fundamentally this is how the story should be told.

The problem comes in between the biginnings and the endings of these respective stories.

Because neither half had even close to enough episodes to make their respective tales work out, even if Disney hadn't meddled all throughout season 3.

Season 3A is a slow affair, that takes it's time, and isn't close to covering Anne's emotional journey by the time it ends, something it wouldn't have been able to do in full, even if disney hadn't censored the creators plans.

Frankly speaking, season 3A plays like the creators didn't quite realize they only had so many episodes to tell their story with, and so took their time with stuff that by any metric should have been cut in favor of other stuff given their episode limitations.

And you can tell that it was only in the second half that they had suddenly realised, holy shit! We have SO MUCH we gotta do!

Commander Anne is rushed beyond belief, speed running Anne and Sasha's reunion, and only held together by the sheer strength of the bond between these two girls in spite of the sheer amount of stuff that has to be done in that entire episode really should have had 2-4 episodes all on their own.

But they couldnt do that. Because they only had half a season to tell the story of the return to Amphibia.

The rest of 3B is nowhere near as rushed as Commander Anne, but it is rushed, and it speeds along way too fast towards its finale, when the show desperately needed some time to breathe and relax. It even ended up cutting one fully planned and important episode(Sasha's origin story) along the way to the finale.

While Disney screwed over Amphibia, Amphibia NEEDED to split season 3 into two full seasons for the show to truly hit it's full potential.

And that was a mistake on the part of it's creator, who clearly made a huge blunder when planning this story out. Amphibia ISN'T a three part story. It's a 4 part story, where part 3 and 4 got smushed together to the detriment of the product.

30 notes

·

View notes

Note

Irish breakfast and coffee (imagine me taking very careful notes)?

irish breakfast: what country do you want to visit?

I've never been out of the US, so anywhere!! But especially England and Ireland, and of course, can't forget Canada. I would like to see a moose.

coffee: how do you take your coffee?

*sets up my 45 slide presentation* *cracks knuckles*

Ahem. So. For myself, I usually just do a standard black coffee either with a phin (Vietnamese coffee maker) or just a normal drip coffee maker, whichever is gonna be quicker.

For a regular drip coffee maker, I get out my trusty Walmart brand, medium body, cheap coffee and put two heaping tablespoons (apparently, the metric equivalent is a heaping 30ml). Just pop those bad boys into the filter, add about two cups or so (475ml) of water into your machine. Hit go, and viola. Coffee. If I'm feeling zesty (usually for an afternoon coffee) I'll put in a dash of milk (I measure by sounds i make, so like, a zzzoop! of milk) and two spoons of sugar.

tea ask game!

picture of phin and brief little tutorial under the cut bc lots of people don't know what it is and it's such a nifty little dude

ok so for this dude. I have one that make a cup of coffee. Like. Idk if it's actually the proper measurement of a cup, but it fills a decent sized mug. Put two heaping spoons of sweetened condensed milk into your chosen mug. Set aside.

I have Vietnamese coffee, which is kinda chocolatey and strong, and I put about two tablespoons ish into the phin. Basically until it hits the little ledge inside. Screw the filter on snug but not over the top, microwave (or kettle, I guess) your water until it's nice and hot. I do two minutes. Put phin onto your mug, then pour water into phin and cover with the cap. Let it brew right into your mug, and stir when it's done! It's super good especially if you like sweet coffee

#thanks Red<333#i hope you feel properly schooled on coffee#i ranted a little#but you asked for it soooo#can you tell I love coffee#tea ask game#willow talks

5 notes

·

View notes

Text

#UKDEALS XhjzgcTech Fasteners Set - 1680 Pcs Metric Hex Head Bolts M2-M5, Nuts & Washers - Black Machine Screw Socket Cap Screws https://www.bargainshouse.co.uk/?p=121650 https://www.bargainshouse.co.uk/?p=121650

0 notes

Text

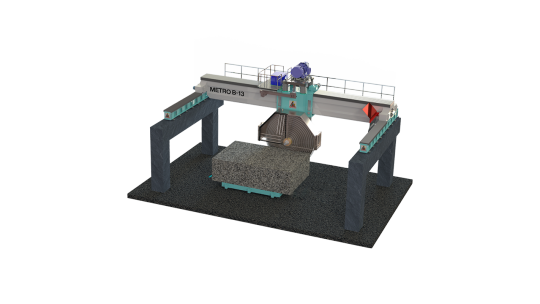

Why the Metro-B13 is a Game-Changer For Stone Industry

Overview of the METRO-B13 Multi Cutter Machine

The METRO-B13 Multi Cutter Machine, manufactured by Shri Bhagwati Machines Pvt. Ltd., is a cutting-edge solution for the stone processing industry. Based in Ajmer, Rajasthan, the company has established itself as a leader in manufacturing high-quality machinery tailored for granite and marble cutting. This weblog will delve into the intricate details of the METRO-B13, exploring its features, specifications, applications, and the company’s commitment to quality and innovation.

Importance of Stone Cutting Machines

Stone cutting machines play a crucial role in the construction and manufacturing sectors. They enhance productivity, ensure precision, and reduce waste, making them indispensable for businesses involved in stone processing. The METRO-B13 stands out in this competitive landscape, offering advanced features that cater to the needs of modern industries.

Technical Specifications

· Model Name/Number: METRO-B13

· Usage/Application: Industrial stone cutting

· Useful Cutting Block Size: 3657 mm x 2134 mm x 1220 mm

· Blade Diameter: Up to 3.0 meters

· Blade Mounting Provision: 5 blades

· Country of Origin: Made in India

Performance Metrics

The METRO-B13 is designed for high-performance cutting, capable of handling large granite blocks with precision. The ability to use multiple blades simultaneously significantly increases throughput, making it an ideal choice for large-scale operations.

Advanced Cutting Technology

The METRO-B13 incorporates several innovative features that enhance its functionality:

· Up-Down Hydraulic Motion System: This system allows for smooth and precise cutting, reducing errors and improving overall efficiency.

· High-Quality LM Bearings: These bearings minimize friction, ensuring longevity and reliability.

· Screw Less Column Design: This design enhances stability and reduces maintenance requirements.

· Accurate Slab Thickness Control: Achieved through an encoder, this feature ensures uniformity in slab thickness.

· Robust Structure: Built with reinforced concrete, the machine provides stability during operation.

Energy Efficiency

The METRO-B13 is designed to be energy-efficient, consuming less power while maximizing output. This not only reduces operational costs but also aligns with sustainable practices in manufacturing.

Automation and Control

The METRO-B13 is equipped with a fully automatic PLC-controlled system, making it easy to operate and maintain. This automation minimizes the need for manual intervention, allowing operators to focus on other critical tasks.

Maintenance Accessibility

The machine features a maintenance balcony that provides easy access to the power pack and other components. This design simplifies routine maintenance, ensuring that the machine remains in optimal working condition.

Industrial Applications

The METRO-B13 is primarily designed for cutting granite and is suitable for various industrial applications, including:

· Construction: Used for producing granite slabs for buildings, countertops, and flooring.

· Monuments: Ideal for creating intricate designs and memorials.

· Interior Design: Utilized for crafting custom stone features in homes and commercial spaces.

Versatility

The machine’s ability to switch between blade configurations (5 blades with a 3.0-meter blade set and 10 blades with a 2.4-meter blade set) allows it to adapt to different project requirements, making it a versatile choice for stone processors.

Shri Bhagwati Machines Pvt. Ltd.

Founded in 1995, Shri Bhagwati Machines Pvt. Ltd. has grown to become a prominent player in the machinery manufacturing sector. The company’s headquarters in Ajmer, Rajasthan, serves as the hub for its innovative designs and production processes.

Commitment to Quality

Shri Bhagwati Machines is dedicated to delivering high-quality products that meet international standards. The company invests in research and development to continuously improve its offerings, ensuring that customers receive the best possible machinery for their needs.

Customer Feedback

Customers have praised the METRO-B13 for its reliability and performance. Testimonials highlight its efficiency in cutting large granite blocks and the ease of operation provided by the automated system. Many users report significant improvements in productivity and reduced downtime due to the machine’s robust design.

Conclusion

The METRO-B13 Multi Cutter Machine by Shri Bhagwati Machines Pvt. Ltd. is a game-changer in the stone processing industry. Its innovative features, combined with the company’s commitment to quality and customer satisfaction, make it an excellent investment for businesses looking to enhance their cutting capabilities. For more information

Click here for detailed video of Metro-B13 Multicutter

https://www.bhagwatimachines.com

0 notes

Text

A Deep Dive into Gajjar Compressor’s Screw Compressor Manufacturing Process

Screw compressors are vital in various industrial applications, providing efficient and reliable performance. Gajjar Compressor, a leading manufacturer and exporter of screw compressors, has carved a niche for itself in the market through its dedication to quality and innovation. This blog will take you through an in-depth look at Gajjar Compressor’s screw compressor manufacturing process, shedding light on the meticulous steps and advanced technologies involved.

Understanding Screw Compressors

Screw compressors, also known as rotary screw compressors, operate on the principle of positive displacement. They use two intermeshing rotors (screws) to compress air or gas. This design offers several advantages, including continuous operation, high efficiency, and low maintenance. Screw compressors are widely used in industries such as manufacturing, automotive, food processing, and pharmaceuticals.

Gajjar Compressor’s Manufacturing Philosophy

Gajjar Compressor’s manufacturing philosophy revolves around quality, innovation, and customer satisfaction. The company invests heavily in research and development to stay ahead of technological advancements and industry trends. Their state-of-the-art manufacturing facilities are equipped with the latest machinery and tools, ensuring precision and efficiency in every step of the production process.

Design and Engineering

The manufacturing process begins with design and engineering. Gajjar Compressor‘s team of experienced engineers uses advanced computer-aided design (CAD) software to create detailed models and simulations of the screw compressors. This phase involves rigorous testing and optimization to ensure the design meets the required performance standards and efficiency metrics.

Material Selection

Selecting the right materials is crucial for the durability and performance of screw compressors. Gajjar Compressor uses high-grade materials that can withstand the demanding conditions in which these machines operate. Materials are chosen based on their mechanical properties, resistance to wear and tear, and compatibility with the compressed medium. Quality control checks are performed at this stage to ensure all materials meet the company’s stringent standards.

Precision Machining

Machining is a critical step in the manufacturing process, where raw materials are transformed into precise components. Gajjar Compressor employs advanced CNC (Computer Numerical Control) machines to achieve high levels of accuracy and consistency. These machines are capable of producing complex geometries required for screw rotors and other critical components. The precision machining process ensures that each part fits perfectly, contributing to the overall efficiency and reliability of the air compressor.

Rotor Manufacturing

The heart of any screw compressor is its rotors. Gajjar Compressor places significant emphasis on rotor manufacturing, as the performance of the entire system depends on these components. The rotors are machined to exact specifications, ensuring minimal clearances between them for maximum compression efficiency. Special coatings and surface treatments are applied to enhance the rotors’ durability and reduce friction during operation.

Assembly

Once all components are machined and inspected, the assembly process begins. Highly skilled technicians assemble the compressors in a controlled environment to prevent contamination. Precision alignment of the rotors is crucial at this stage to ensure smooth operation and minimize wear. The assembled compressors undergo a series of tests to verify their performance, efficiency, and compliance with industry standards.

Quality Control

Quality control is a cornerstone of Gajjar Compressor’s manufacturing process. The company follows stringent quality assurance protocols at every stage of production. Advanced testing equipment and techniques are used to check the dimensional accuracy, mechanical properties, and performance of each component. The final assembled compressors undergo rigorous testing under various operating conditions to ensure they meet or exceed the required specifications.

Testing and Validation

Before a screw compressor is deemed ready for shipment, it undergoes comprehensive testing and validation. Gajjar Compressor has dedicated testing facilities where compressors are subjected to real-world conditions to verify their performance and reliability. These tests include load testing, thermal analysis, and vibration analysis. The data collected during testing is used to fine-tune the compressors and ensure they deliver optimal performance in the field.

Innovation and Continuous Improvement

Gajjar Compressor is committed to continuous improvement and innovation. The company regularly reviews its manufacturing processes and incorporates feedback from customers and field data to enhance its products. This proactive approach ensures that Gajjar Compressor’s screw compressors remain at the forefront of technology and meet the evolving needs of various industries.

Environmental Responsibility

In addition to quality and innovation, Gajjar Compressor is dedicated to environmental responsibility. The company employs eco-friendly practices throughout its manufacturing process. This includes the use of energy-efficient machinery, recycling of materials, and minimizing waste. Gajjar Compressor also designs its screw compressors to be energy-efficient, helping customers reduce their carbon footprint and operating costs.

Customer Support and After-Sales Service

Gajjar Compressor’s commitment to customer satisfaction extends beyond the manufacturing process. The company offers comprehensive customer support and after-sales service to ensure the longevity and optimal performance of its screw compressors. This includes providing maintenance tips, troubleshooting assistance, and a readily available supply of spare parts. Gajjar Compressor’s global network of service centers ensures that customers receive timely support, regardless of their location.

Conclusion

Gajjar Compressor’s screw compressor manufacturing process is a testament to the company’s dedication to quality, innovation, and customer satisfaction. From design and engineering to assembly and testing, every step is meticulously planned and executed to deliver high-performance screw compressors that meet the diverse needs of various industries. By prioritizing continuous improvement and environmental responsibility, Gajjar Compressor has established itself as a trusted leader in the screw compressor market, providing reliable solutions to customers worldwide.

0 notes

Text

Handy Mechanic and Auto Tools for Every Garage

Having the right tools is crucial for both professional mechanics and auto enthusiasts who loves working on cars. Quality mechanic and auto tools can make your job easier, faster, and safer. From hobbyists to full-time experts, there are tools available for every skill level. With a little research and practice, anyone can use multi-functional tools effectively to get the most out of them. This blog post will walk you through the essential tools every American garage should have.

Lift Equipment and Jacks for Sturdy Support

When it comes to working on your vehicle, having reliable lift equipment and jacks is non-negotiable. These tools allow you to elevate your car safely, providing better access to the undercarriage for detailed repairs.

Floor Jacks: Floor jacks are essential for quickly lifting your vehicle. Look for a heavy-duty, hydraulic floor jack for maximum efficiency.

Jack Stands: Once your car is lifted, jack stands ensure it stays elevated, allowing you to work underneath the vehicle safely.

You can also find bottle jacks, motorcycle lifts and elevation equipment for heavy vehicles, depending on your project or interest.

Versatile Pneumatic Mechanic Tools and Air Compressors

Pneumatic mechanic tools, powered by air compressors, are a game-changer for any serious mechanic. They offer more power and precision than manual tools, making tasks easier and faster.

Air Compressors for Pneumatic Tools: A sturdy, high-capacity air compressor can power a variety of pneumatic tools such as impact wrenches, ratchets, and spray guns.

Pneumatic Auto Tools: From pneumatic wrenches to sanders, these tools provide the muscle needed for heavy-duty tasks. They are particularly useful for auto body repair and engine work.

Also called air tools, pneumatic tools are everyday essentials in many industries, from manufacturing plants to home garages. These tools come in different drive sizes to suit nuts, screws and bolts in a wide size range. Keyless tools last longer and are more efficient that keyed options. Whatever you choose, make sure you read the instruction manual thoroughly. Even seasoned pros follow manuals to make sure they use tools correctly to prevent mishaps and tool damage.

Auto Body Repair Tools – Set Vehicles Right

If you’re involved in auto body repair, having specialized tools is essential for achieving professional-quality results.

Dent Pullers: These are vital for removing dents without damaging the paint.

Body Hammers and Dollies: Used for shaping and smoothing metal surfaces, ensuring the car’s body looks flawless.

Rams, spreaders, and brake repair kits are other auto body repair tools that are always useful when working with vehicles.

Multi-Functional Mechanic Tool Sets

A comprehensive mechanic tool set is a must for any garage. These sets usually include a variety of sockets, wrenches, and screwdrivers that are useful for a multitude of tasks.

Socket Sets: Ensure you have both metric and SAE sockets for maximum versatility.

Wrench Sets: From open-end wrenches to adjustable wrenches, having a variety of options lets you tackle different bolt sizes and types.

These tool sets provide multiple size variants of each type of tool, letting you deal with all sizes of fasteners on automobiles or machines.

Resolve Issues Quickly with Auto Diagnostic Tools

Modern vehicles are equipped with complex electronic systems that require advanced diagnostic tools for troubleshooting.

OBD-II Scanners: These scanners can read diagnostic trouble codes (DTCs) from your vehicle’s computer, helping you identify and fix issues quickly.

Multimeters: Essential for measuring voltage, current, and resistance in various electrical components.

Ignition testers and battery testers are some of the other notable diagnostic tools for vehicles.

Repair Engines with Advanced Tools

Engine repairs are often the most complex and demanding tasks. These require specialized tools designed for engines precision and durability.

Torque Wrenches: Bolts are tightened to the manufacturer’s specifications with torque wrenches, preventing over-tightening or under-tightening.

Engine Hoists and Stands: These are crucial for removing and working on engines outside of the vehicle.

Find vacuum pumps, tuning kits and terminal repair tools to sort out a number of engine issues.

A Multitude of Hand Tools for Vehicles and Machinery

No garage is complete without a reliable set of mechanic hand tools. From pliers to hammers, these basic tools are indispensable for a variety of repairs.

Pliers: Needle-nose, slip-joint, and locking pliers each have their specific uses.

Wrenches: Each type of wrench is specialized to be effective in its specific application. Crowfoot wrenches are perfect for congested corners, while dog bone designs offers dual functionality of a wrench and socket. Crescents, plumbers’ wrenches and oil filter wrenches are the most widely used types.

Hammers: Ball peen hammers and rubber mallets are some of the most commonly used in auto repairs.

Every repair scenario could be unique and will need specific hand tools to work with precision. Pick hard-wearing ratchets, sockets and mechanic hand tools that are up to the task and will last for the long haul.

Own a Formidable Tool Collection for Wide-Ranging Applications

Having the right tools is essential for any mechanic or auto enthusiast. From lift equipment and jacks to pneumatic mechanic tools and air compressors, each tool plays a significant role in making repairs easier and more efficient. Don’t skimp on quality when it comes to your tools; investing in the best can save you time and money in the long run.

0 notes

Text

WHEELCHAIR SPOILER SOLAR TAILFINS WITH OPTIONAL TAIL LIGHT MOUNT

https://www.thingiverse.com/thing:6698928 Files for download

So, ever since I got my new wheelchair, it had this annoying habit that no matter how tight made the bolt to hold the headrest up, the first time someone would lean upon it, the headrest would go down. As my neck muscles are exceptionally weak due to a neuromuscular disease, this can be very dangerous as it makes it difficult to sit back up.

My new wheelchair also did not include tail lights, and since that extra feature, albeit important for safety is not considered a medical necessity, cost several hundred bucks. Instead, I opted for far cheaper bicycle lights. Unfortunately, the tail lights have a habit of needing to be charged every day if left them on.

Not satisfied with a simple fix, I spent three weeks of computer design, one burnt finger, multiple curse words, misprinted parts, and loss of my sanity to build solar powered tail fins that charge my tail lights and light up a plate with the words 'DarkRubyMoon.com' (Advertising my art and stuff website ) so long as are in direct sun.

Not everything fit together perfectly…the screws intended to hold the wings on…while perfectly positioned …still required some glue as I forgot that the bracket to mount the fins blocked access to some of the screws. I also updated the fins enlarging the access slot for the solar panels which I had to cut using a hot knife. It also turns out that I occupy a world with many klutzes as the fins were on my chair no less than 20 minutes before two people bumped into them breaking a bracket for which I am currently printing a stronger version as well as a set of less fancy smaller spoiler without solar panels to attach when around aforementioned klutzes. My first attempt to replicate the slot connection for the tail light connection was off by less than a millimeter. Rather than reprinting the part, I simply made an adapter to connect in that slot and attach to the tail light. You may opt to correct this error rather than printing extra parts. Also, the first 'licence plate' backing failed to print the connection bracket and the cover originally failed to print correctly. Rather then reprinting the entire thing, I printed another cover with mounting bracket attached. Both versions are included along but you only need to print one.

The bracket that helps support the headrest uses a higher print density and the bars of the wheelchairs headrest bracket are sandwiched in-between. Bolts through the C bracket above and below each bar of the headrest help support the headrest from moving.

For Tail lights and solar fins, will need…

* M2 x 6mm /8mm /10mm /12mm /16mm /20mm, Phillips Pan Head Machine Screws, Metric Screws Bolts Washers Nuts Kit, 304 Stainless Steel

* USB 2.0 Adapter, Dual USB Female Jack Y Splitter Charger Cable (2 Pack)

*1.65W Solar Charger, 5.5V 300mA USB Portable Solar Panel, Waterproof Solar Phone Charger 2

*77 Pieces Black M8 x 30/35 /40/45 /50 mm Button Head Socket Cap Screws Nuts Washers Assortment Kit, 10.9 Grade Alloy Steel

*Bicycle Turn Signals Tail Lights USB Charging Brake Taillights with Wireless Remote Control High Brightness LED Beads Base Bracket Bike Rear Lights for Nighttime Cycling

*Flexible USB LED Lights Strip Ribbon

Assembly …

The cbracket sandwiches over headrest poles. Use M8 screws and bolts with washers to mount spacer fin bracket on top and bottom. Use the spacer bar and lock space to grip headrest bars securing with more M8 screws and bolts.

For fins, secure solar panels with glue. I used a hand held 3d printing pen. Insert fin connection before mounting wings. Secure in foil fin mount using M2 screws where possible and glue. Use fin connector to attach to spacer fin.

For optional license plate, run wires through top opening from usb splitter and one female usb end out each side. Optionally change text on plate. Connect LED light strip inside. I used packing tape on interior under the letters and coated it with red transparent hot glue. Then sealed and glued box closed with lights and wires inside. Using the plate connector , connect to lower spacer fin bracket. Bolt plate connectorB to plate connector, then to lighted plate vers2 (licence plate backing )

PLEASE NOTE; THIS IS NOT INTENDED AS A MEDICAL DEVICE. USE AT YOUR OWN RISK. NOT LIABLE FOR ANY INJURIES CAUSED BY THIS DEVICE, ITS USE.

Copyright © Eric Ovelgone DarkRubyMoon Be sure to check out my artwork on all sorts of fantastic items from T-shirts and prints to clocks and more at my DarkRubyMoon stores following web locations. Main Website: http://DarkRubyMoon.com * DarkRubyMoon Store CafePress: http://www.cafepress.com/darkrubymoon * DarkRubyMoon Store Zazzle: http://www.zazzle.com/darkrubymoon * DarkRubyMoon Store I DO NOT GIVE ANY COMPANY, PROGRAMMERS, OR PROGRAMS INCLUDING ARTIFICIAL INTELLIGENT DATA COLLECTION DEVICES THE RIGHT TO GATHER, USE, TRAIN FROM OR SOURCE ANY OF MY IMAGES, TEXT, OR USE ANY OF MY WORKS OUTSIDE OF MY EXPLICIT CONSENT. ANY USE WITHOUT MY CONSENT AND COMPENSATION IS THEFT AND WILL BE TREATED AS SUCH.

1 note

·

View note

Text

Why Choose the Seppa Solutions Rinser Filler Capper Machine for Your Business?

We at Seppa Solutions recognize how vital efficiency and dependability are to the day-to-day operations of your company. With its unparalleled speed and accuracy in packaging solutions, our Rinser Filler Capper (RFC) Machine is destined to transform your production line. Our RFC Machine redefines automation and quality control for food, beverage, pharmaceutical, and cosmetics businesses.

Unparalleled Technology and Innovation

Advanced Rinser Technology

Modern rinser machine, included in the Seppa Solutions RFC Machine, guarantees that containers are thoroughly cleaned before filling. With configurable settings for various bottle kinds and sizes, our equipment ensures hygienic compliance while reducing maintenance downtime.

Precision Filling Capabilities

Our RFC Machine, equipped with precision fillers, provides precise measurements with each cycle. This accuracy is essential for preserving product quality and cutting waste, which will maximize your manufacturing expenses. Our equipment meets the highest industry standards by ensuring exact filling amounts, whether you're bottling pharmaceutical liquids, juices, sauces, or water.

Reliable Capping Mechanism

The capping process in our RFC Machine is designed to be reliable and efficient. Our adaptable capping system suits several closure types, from screw caps to press-on caps, without sacrificing seal integrity. This function is crucial for maintaining consumer happiness, adhering to regulations, prolonging the shelf life of products, and preventing leakage.

Key Features of Seppa Solutions RFC Machine

Modular Design for Scalability

Our RFC Machine is developed in a modular manner, allowing for seamless integration into existing manufacturing lines. You can modify our machine to match your unique throughput needs without compromising the effectiveness of your workflow, regardless of your size as a startup or established company.

User-Friendly Interface

Our user interface makes it easy to navigate complicated machinery. Operators may track production metrics, monitor and modify machine settings, and quickly detect problems. The design that prioritizes the needs of the user minimizes training time and increases operational productivity.

Robust Construction for Durability

The Seppa Solutions rinser filler capper machine is constructed with tough materials and precision engineering to sustain prolonged operation in harsh settings. Its longevity maximizes your return on investment over the machine's lifecycle by reducing maintenance expenses and downtime.

Industry Applications and Benefits

Beverage Industry

Speed to market and product quality are critical in the highly competitive beverage sector. You can confidently satisfy customer demand with our RFC Machine, which speeds up production cycles while maintaining consistency in taste and appearance.

Food Industry

From sauces to dressings, our rinser filler capper machine keeps products fresh and improves shelf life by securely capping and filling them precisely. This capacity is critical for maintaining flavor characteristics and adhering to severe food safety rules.

Pharmaceutical and Cosmetics

Accurate dosage and strict adherence to cleanliness regulations are requirements in the pharmaceutical and cosmetics manufacturing industries. The cGMP-compliant Seppa Solutions RFC Machine provides accurate filling and sterile rinsing to protect product integrity and regulatory compliance.

At Seppa Solutions, we're dedicated to using our cutting-edge Rinser Filler Capper Machine to improve your business's operational effectiveness and product quality. Whether you value speed, precision, or dependability, our RFC Machine outperforms expectations in a wide range of industries, setting a new standard for automated packaging solutions.

#rfcmachine#rinser machine#rinser filler capper machine manufacturer#rinser filler capper machine#filler capper#filler capper machine#filler machine#non contact filling#non contact filler#non contact filling machinery#non contact filling machine#rfc machine manufacturer#rfc machine

0 notes

Text

I've been playing a lot of Opus Magnum lately. For those unfamiliar, it is a puzzle engineering/programming game where you make little machines that assemble alchemical molecules. Imagine if Factorio was just the conveyor belts and arms and the gameplay was dunking on all your friends with leaderboard metrics.

Opus Magnum is a very technical game that asks you to problem solve in an open-ended manner. It is viciously complex and trains you to break down problems into steps you already know how to work on. A shape that looks insurmountable at first can be analyzed and meticulously tackled one step at a time.

This is to say, this morning, when I wanted to make waffles, I pulled out the dirty waffle iron and thought, "I bet there is a way to clean this." There were some easily accessible screws on the hot plates. Ah! Clearly these can be removed for washing! Wait, now I have to disconnect the wiring from the heater coil on the top half. I know how to do thus, just tackle one step at a time...

It was only after I had disassembled the entire waffle iron down to its base components that I realized it would probably have been easier to just hand-wash the whole thing in the sink.

1 note

·

View note

Text

Precision Fastening High-Quality Machine Screws

Find high-quality machine screws for accurate and decent fastening in various applications. Ideal for manufacturing, assembly, and repair projects. Buy now!

0 notes

Text

Hastelloy B3 FastenersManufacturers In India

INTRODUCTION:-

Shasan Piping Solution is one of the preeminent Manufacturers and Suppliers of Hastelloy B3 Fasteners. We give the entire level of attach in different points of view, sizes, types and determinations.

Our offered Fasteners have momentous security from hydrochloric shocking at all concentrations and temperatures. Hastelloy B3 Fasteners are made by utilizing ideal quality unrefined substances.

DESCRIPTION:-

These things are utilized in diminishing acids affiliations and Fasteners tofastenersher of warming stuff. Hastelloy B3 Secure are Fasteners produced using mix containing nickel and molybdenum as base part containing chromium and advancements of cobalt and tungsten.

Our offered Fasteners are typical for exceptional hydrochloric harming, sulfuric acids, hydrobromic shocking, acidic deplorable, phosphoric harming, and formic harming. These gets offer mind blowing strength and heartiness in any acidic and decreasing media.

BENEFITS:-

Hastelloy B3 Fasteners pushes smooth overseeing through welding gear and diminished tip in contact tips. We are a proactive association that offers Hastelloy B3 Fasteners and other quality things that meet and beat client unequivocal necessities and as such assurance all out satisfaction.

We give a huge level of materials like Hastelloy B3 Fasteners. Our offered Fasteners show extraordinary security from pitting, opening disintegrating and stress use breaking in any chloride containing conditions.

SPECIFICATION:-

Specifications

ASTM B574 / ASME SB574

Fasteners size

Bolt / Screw Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Nuts Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Washers Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Machine Screws Size : M1.6 – M12 Self Tapping Screw Size : No.2 – No. 14

Fasteners Length

3 mm to 200 mm

Fastener Threads

UNF, BSW, BSF, METRIC, UNC or as required

Standard of High Nickel Alloy Fasteners

DIN : DIN 934, DIN 931, DIN 970, DIN 933 UTS : UNEF, NPT, UNC, UNS, UNF, NPTF ISO : JIS standards, ISO 4033, ISO 4032, ANSI – American National Standards Institute ASME B18.5 ANSI B 28.2.4 1M as per defined in ASME B16.5 standard Stud Bolt length ANSI B 18.2.4 2M as per defined in ASME B18.2.2 Hex nuts

Dimensions

DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3

PRODUCT OVERVIEW:-

Shasan Piping Solution trusts in serving the most adroit thought of things by utilizing imaginative social event strategies. We supply these Fasteners to our clients at really reasonable costs. We have done current stuff for social event wide degrees of things by picking the astounding thought of crude substance.

We have picked gifted arranged specialists and qualified workers that produce Hastelloy B3 Fasteners. Our specialists screen each time of the party development to guarantee twisting free creation.

CONCLUSION:-

Our offered Fasteners go through different damaging and non-disastrous tests to insist the quality and execution. These tests are performed under the serious oversight of our quality educated trained professionals. Also, we have encountered laborers who attempt to foster things quality as well.

For safe and wickedness free new development and transportation of thing, we utilize reasonable pressing material. Shasan Piping Solution Association offers secure entry alliance. We endeavor to convey the things on time. We utilize a steady system for transport to keep away from harms. We other than offer bundling and transportation choices as shown by basics of our regarded clients.

CONTACT US:-+91 22-6651 8642

EMAIL ID: [email protected]

WEBSITE: https://www.shasanpiping.com/hastelloy-b3-fasteners-manufacturers-exporters-suppliers-stockists.html

0 notes

Text

"Why don't Americans switch to metric" well yeah it would be hypothetically nice right, except the wrenches and the screw taping machines and the instruction manuals and the tooling for pretty much everything everywhere is already in imperial and like. Do you know how ungodly resource intensive that would be to replace.

0 notes

Text

Delta Scroll saw

I bought a scroll saw from the Hackspace where it was surplus equipment. There were two in an auction, both quite old and litlle used. I won one of them for £15 and chose the Delta model since it was the heavier and had a dust blower.

The model is 40-430, single speed. There is a manual for it on-line https://www.manualslib.com/manual/590720/Delta-40-530.html

The machine takes pinless blades of which I already had a few. Pinless blades are finer and come in greater variety than pined blades, which are faster to change. There is a custom tool for blade changing, with a long 4mm Allen key attached to a bar which slots into a hole on the blade holder, setting the key in the right position and locking the hinged holder. It was missing and its fiddly to change blades without, so I need to make a substitute.

Surprisingly the blower works - online advice says the bellows is usually perished.The connecting tube is stiff and should realy be replaced.

At first the machine was very rattley until I realized the the three bolts put though the holes in base were only needed if the machine was going to be permanently fixed to a bench. Much better without and its heavy enough to be stable although it would be better with rubber feet.

Once I'd attached a blade and got the tensioning right, I turned it on and it cut fine and true.

The saw was very dusty and hadn't been used in a while. I took it apart, happy to find all fittings were metric.

A few jobs to do:

free up the table so it tilts

lubricate the pivot bolts

remove the rusty table, sand and polish with wax

(x)replace gnarled cover screws

(x)replace worn blade holder socket head bolts

make the blade change tool with long hex 4mm tool (x) and 5mm threaded (x) bar with 3D-printed spacers

add rubber feet 12mm hole eg https://www.ebay.co.uk/itm/133246278952

x Bits ordered 28/01 £12.50

Blade change tool

I designed a spacer in OpenSCAD to align the long Allen key and a threaded guide bar with M5 nuts to hold it in place. Took a few iterations to get the sizing right but it works fine with three spacers, using lock nuts to fix the spacers in place. The OpenSCAD and STL files are on Thingiverse https://www.thingiverse.com/thing:6460819

Anti-vibration feet

Commercial mounts are surprisingly expensive so I made my own. I had a lot of large tap washers in stock so I made up a stack of one dished and two flat washers below the base, two more flat washers and a metal washer above the base, held together with an M8 coach bolt and nut. This works very well and the saw runs pretty quitely now.

The table

I sanded and oiled the table and it's much improved. Car polish is recommended so I'll do that.

Tilt lock handle

Now that the table has been freed up, the locking mechanism comes into play. It is an M6 bolt with a handle moulded onto it, but the moulding has failed so it can't be fully tightened. Fortunately, it also takes a 3mm Allen key and doesnt need to be adjusted quickly.

Looking better

1 note

·

View note

Text

Right Angle Gearbox | SMD Gearbox

In the industrial automation world, where making efficient use of space is crucial, the choice of components can make a significant impact. This is where SMD right-angle gearboxes come into play. They are popular for its Adjustable backlash for suitable low load and intermitted motion with high load carrying capacity and high Rigidity. This is an easiest Right-Angle gearhead in the market to geo-metrically integrate into your machine

SRAS Series: - The SMD Right angle with Shaft end is the most commonly used Gearbox this comes with a shaft end. The shaft output serves as a direct link for power transmission, providing a versatile connection point. This makes the SRAS gearbox suitable for various applications where precise torque delivery and controlled rotational movement are required and this gearbox can be coupled with another gearbox like SMD Hollow Rotary.

SRAC Series: - This Gearbox is equipped with Clamp Style Output where the application can be directly mounted. The clamping end output simplifies the installation process, making it suitable for applications like turntables and other setups where direct mounting is preferred. The gearbox's robust construction ensures stability and reliability, contributing to the overall efficiency of the machinery it serves.

SRAH Series: - This gearbox features a unique design with a hollow shaft, allowing for the insertion of a long shaft or ball screw, enhancing its flexibility in motion transfer applications. The hollow shaft design enables seamless integration with various components, making it suitable for applications.

To know more please visit https://www.smdgearbox.com/90-degree-gear-reducer.html or you can contact us on following details.

Mail ID- [email protected]

Contact No- +886 933510083 / 91 7030669818

#smdgearbox#servogearbox#90degreegearreducer#90degreegearbox#gearboxsupplier#rightanglebevelgearbox#gearboxmanufacturers#rightanglereducer#rightanglegearbox

0 notes