#stainless steel machine screws

Text

Precision Fastening High-Quality Machine Screws

Find high-quality machine screws for accurate and decent fastening in various applications. Ideal for manufacturing, assembly, and repair projects. Buy now!

0 notes

Text

Usha Precision

We are renowned manufacturer & supplier of a wide range of industrial flat head rivets as well as round head rivets, Our various types of solid metal rivets are made using superior quality material which is tested before the production process.

#Micro Rivets#Micro Screws#Steel Rivets#Stainless Steel Rivets#Metal Rivets#ss rivet#stainless steel dowel pins#stainless steel dowels#precision turned components#machined parts#stainless steel#metal parts manufacturing

0 notes

Text

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

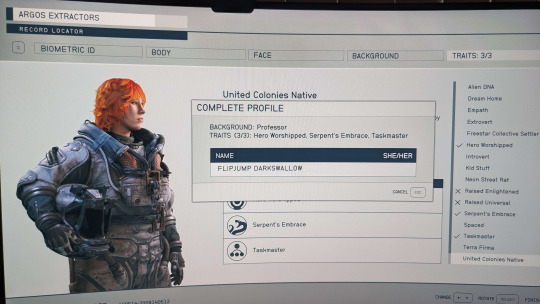

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

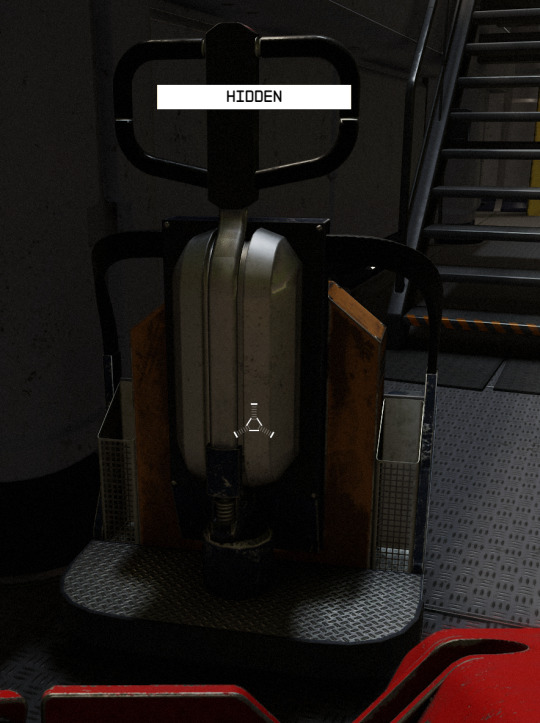

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Note

I OWN THAT SEWING MACHINE??

How did you get working?

mostly i just cleaned it out and oiled it and it worked!! the good news is these machines are fairly bulletproof, so it doesn't take a lot to get them working again

your first step should be to plug in the serial number into this website -- this will tell you exactly what model of guy you have, so you'll be able to look up instructions and check if you've got missing parts. (or if you've got the original instruction manual you can use that!)

the things you will probably need to replace are the belt (leather treadle belts have a tendency to turn brittle with age) and the needle (old needles tend to also be brittle and possibly rusty, which is Not Great for fabric). helpfully, singer model 15s use the same standard needle shape as nearly all modern sewing machines, so you can stick just about any modern needle in there. a new treadle belt, as well as replacements for any missing or damaged parts, can be had from the internet -- there are a ton of vintage sewing machine parts sellers on ebay. (you'll need to cut the new treadle belt to length and possibly rosin it; i had to tighten mine two or three times before it was driving the machine nicely.)

and then, of course, Everything Needs To Be Cleaned. you'll want a bottle of sewing machine oil, a jug of cleaning vinegar, dish soap, and an ultrasonic cleaner (incredibly handy general household tool, $25ish on amazon). also large amounts of q-tips and paper towels, and various sizes of flat-head screwdrivers. possibly also a dremel tool. (if the machine needs a surface cleaning, wipe it down GENTLY with sewing machine oil -- many harsher cleaning substances will damage the shellac or the pretty gold decals.)

stuff i took off my machine to clean:

throat plate + slidey bit next to it

hook and bobbin case, and the circular track thing the hook slides back and forth in (i don't know what this is called)

side plate and thread tension assembly

needle holder and thread guide

presser foot and its thumb screw

round plate on the back and its thumb screw (i could've gotten away without cleaning this but i wanted it to be Shiny)

(also: take pictures while you disassemble everything so you remember how it goes back together!!)

an ultrasonic cleaner bath with vinegar will remove rust (you may have to run it a few times); an ultrasonic cleaner bath with warm soapy water will remove dirt and gunk (ancient thread dust + ancient sewing machine oil = horrible black gunk). the parts WILL NOT be stainless steel, so you WILL need to dry them off after they come out of the bath; don't leave them on a wet paper towel or they'll rust again. (i made this mistake about three or four separate times and i wanted to kick my own ass every time. for parts that are hard to dry with paper towels + q-tips, you might want to use a solder reflow station or hairdryer (the poor man's solder reflow station) to dry them.) it's also good to wipe stuff down with a very light coating of sewing machine oil just for a little extra rust protection. for stuff you want to be Extra Shiny, like the throat plate, you can use the dremel tool and a wire brush or a fine grit sanding attachment and get it nice and polished :)

But Watch Out -- some of the screws may be VERY stiff and you definitely don't want to strip the heads. if a screw is just not budging, try drenching it in sewing machine oil (in such a way that the oil will run down into the threads) and waiting half an hour or so.

while all the plates and stuff are going through the ultrasonic cleaner, it's time to clean and lubricate the inside! (and the treadle. the treadle might also be stiff. pro tip: take the belt off while you're working on lubricating the treadle so you can make sure it runs smooth without the sewing machine.) there should be little holes for oil everywhere you're supposed to oil (including the underside! with the belt off the machine should fold out of the treadle table so you can access these bits), but you can oil other areas of metal-on-metal movement too if it seems like they need it. the basic control loop here is oil something -> spin the hand wheel a bit and listen carefully for squeaking or other Bad Noises -> oil something (etc.) until it's all running smooth. if there is gunk on any of the moving parts (or dead spiders. apparently spiders LOVE to go inside of model 15s and die there) apply q-tips until they're clean. or a paper towel + vinegar for bits that are rusty.

and then you put it back together and try it out!! (AND SEND ME PICTURES I WANNA SEEEEE)

#the trashcan speaks#sewing machine go brrr#also be careful not to lose any of the tiny ass bobbin case screws :/ :/ :/

11 notes

·

View notes

Text

OK, I have two overall things to say about Gundam SEED: Destiny (I’ve been sick, binging this nominally staved off extreme boredom; spoilers to follow).

Number 1: Arthur Trine is doing his best, damnit, and I hope he got a cup of tea and a sit down once everything was over.

Number 2: what an incredibly frustrating show.

In many ways it is leaps and bounds ahead of its predecessor, freed from literally repeating the same set-pieces of the original Gundam to tell a story that, honestly, has something approaching a meaningful point. Chairman Durandal is a compelling antagonist and the way he and Teen!Le Cookset gradually break the series’ pseudo-protagonist to their perspective is narratively interesting. The underlying message in what he does -- about how those in power pick out enemies that will best serve their ends and present themselves as the reasonable ones -- is definitely worth exploring. And the show even manages to address the Gundam-overload issues from SEED, by more clearly delineating the point of each machine and staggering them a bit more competently.

However. It inherits the problem of its length exceeding its content, leading to more stock-footage abuse and, far less forgivably, *three* clips shows, only one of which (the last, focused on Meer) has any actual merit. It also continues SEED’s determination to screw over every single female character who isn’t Lacus. For the record, I *like* Lacus: she’s a nice execution of someone having a ‘typical’ presentation wrapped around a core of stainless steel conviction, which is something I always enjoy in fiction. However, Cagalli in particular is an utter waste of potential, not being allowed to mature, gain focus, or make a single bloody decision without Kira or Athrun’s input, to the point where it’s actively aggravating to watch.

This is where we hit the limits of the genre and demographic, of course, and once again makes me appreciate literally every female character in IBO because Gundam generally is so very *not good* at this. (Obviously G-Witch is ahead again on the score, thankfully, but IBO is probably the best-case scenario within the ‘fiction aimed at boys’ problems that plague its predecessors.)

Shinn is similarly annoying. It’s not a bad thing he’s abrasive and the endpoint was always going to be him winding up a broken, weeping wreck because he’s too stupid to recognise anything beyond his own feelings. But his trauma flashbacks hit parodic very early and he’s far too irritating to be worth sitting through his screen-time. Like Kira, only the problem is the presence of personality rather than its total fucking absence.

My biggest complaint, however, is reserved for the variety of ways SEED:Destiny buggers up its good ideas. I’d have liked it a lot more if ‘Logos’ hadn’t actually been a thing. ‘Shadowy conspiracy doing [bad thing] from the shadows in the name of profit’ is the kind of message that gets slung around a lot in real life with no justification whatsoever and it really doesn’t help counter the people who do that if you hinge your plot on ‘no the Illuminati actually do have a giant laser on the moon.’ The cleverer and more cutting twist would have been to reveal there was no actual group called Logos and while the people Durandal named might have had interests in common, he was really just lumping them together for his own convenience.

You know. As scapegoats. Like the way this goes in reality, with the matters that this show is sticking its oar in and trying to Say Something about.

But no, because once more, this is a story interested in emotional reactions and personal epiphanies over any sort of systemic question because, well . . . that’s typical, isn’t it? Frustrating but not unexpected. Eureka Seven does nearly everything SEED/SEED:Destiny attempts better and that is hardly the first case of that happening with a Gundam show. Possibly this is just galling me more than usual because there are so many [swerves around the obvious pun] traces of a more interesting story here.

Oh well. Mu steadily getting his memories back was fun and I shall be taking the final epilogue to mean he, Murrue and Andrew settled down to a life of coffee-fueled polyamory. Yzak yeeting himself on to the right side of the final battle through sheer indignation was actually kind of funny. And I will give it credit, this did feel like one of the more meaningful ‘final battles to destroy a giant super-weapon’ out of the many, many times Gundam has done that (including in SEED, for gods’ sake). If nothing else, I appreciate the chutzpah of having Durandal rock up in an off-brand Death Star, right down to a recoloured Emperor’s chair.

Whatdyouknow. I actually did have something to say about this one. I think that just leaves Victory for main series I haven’t watched (I finished G Fighter; it was joyfully ridiculous). That probably won’t be changing any time soon. Ranking wise . . . SEED:Destiny probably sits around equal with 00 for me.

#gundam seed#gundam seed destiny#more rambling#kind of a review?#mostly more snark#I didn't even rant about the combining suit did I?#it's daft#not so much the replacement parts aspect#but the combination dance#every time it heads out#JUST SHOOT IT WHILE IT'S COMING TOGETHER#even the one (1) attempt to justify its utility was stupid#since that cave was clearly big enough for a whole mobile suit despite the dialogue#anyway#look at me getting annoyed with fiction aimed a teenagers#again

8 notes

·

View notes

Text

Shaping the Future: The Rise of Stainless Steel Components Manufacturers in India

In recent years, India has emerged as a powerhouse in the manufacturing sector, particularly in the production of stainless steel components. This surge can be attributed to various factors, including technological advancements, evolving market demands, and a skilled workforce. Stainless steel components play a crucial role in numerous industries, including automotive, construction, and aerospace, due to their durability, corrosion resistance, and aesthetic appeal.

One of the key drivers behind the growth of stainless steel components manufacturing in India is the country's abundant availability of raw materials, particularly stainless steel. With the government's emphasis on initiatives like "Make in India," there has been a significant push to boost domestic manufacturing and reduce dependency on imports. This has led to the establishment of numerous stainless steel component manufacturing units across the country, catering to both domestic and international markets.

Amidst this growth, companies like Meck Industries have played a pivotal role in shaping the landscape of stainless steel component manufacturing in India. Established in 1990, Meck Industries has carved a niche for itself as a leading provider of precision turned parts. Specializing in CNC machining and automatic screw machines, Meck Industries has earned a reputation for its commitment to quality, reliability, and innovation.

With a state-of-the-art facility located in G.I.D.C. Makarpura, Vadodara, Meck Industries is well-equipped to meet the diverse needs of its clientele. The company's skilled workforce, coupled with its investment in cutting-edge technology, has enabled it to deliver superior stainless steel components to various industries, including electrical, automotive, and sheet metal.

Moreover, Meck Industries' dedication to customer satisfaction and continuous improvement has been instrumental in driving its growth and success. By adhering to stringent quality standards and embracing innovative manufacturing processes, Meck Industries has positioned itself as a trusted partner for stainless steel component requirements, both domestically and internationally.

Looking ahead, Meck Industries remains committed to pushing the boundaries of excellence in stainless steel component manufacturing. With a focus on leveraging technology, fostering innovation, and expanding its global footprint, Meck Industries is poised to continue shaping the future of the industry and contributing to India's manufacturing prowess on the world stage.In conclusion, the rise of stainless steel components manufacturers in India, exemplified by companies like Meck Industries, underscores the country's growing dominance in the global manufacturing arena. With a blend of tradition, innovation, and excellence, Indian manufacturers are poised to lead the way in shaping the future of stainless steel component manufacturing worldwide.

1 note

·

View note

Text

MAKE, IT, COOK!

(Kiln repair)

Ended up doing a little maintenance on a kiln. The bricks had been so worn down at the top that ceramics placed too close to the top front were getting a draft, and weren't getting fully cooked. Lucky there was an organ donor nearby

They aren't the most complex machines in the world. It's not much different from a lightbulb on a timer, with a lot of insulation. The heating elements connect to relays, and the controller opens and closes the relays based on how fast you want to reach a temperature

These things are built in layers and can be ripped apart like a wedding cake. To retain the bricks, they just kinda sit there, and a stainless steel sheet is wrapped around with a hose clamp welded at the seam to tighten it. There's then 2 clamps to lock it to the other segments, and it's arranged to have 1 heating element per segment

To spiff it up, I put the bottom layer of the donor as the top layer, but used the steel sheet from the original to avoid unscrewing the hindge brackets from it. I had a feeling if those hindge screws came out, they were never going back in strong enough to resist that honker chonk of a spring. That thing is eager to kill someone

The lid from the donor was also taken by just unloading the spring and removing a spring cotter pin for a dowel

It actually decided to be a bitch when connecting the elements back to the controller, and kept cracking. It was a hell of a lot more brittle at room temperature than I thought (Tho if it's nichrome, I guess neither the nickle OR chromium does its malleability any favors). Anyways, a quick hit from a propane torch got the wire nice and bendy at red hot temps. (I didn't use a Bic™ lighter to bend it.... Well I did, but then I got a propane torch out, because fuck that) It's kinda important to double up on the wire at the terminals, so the terminal doesn't get melting temperatures hot

She cooks perfectly now and knocked the firing time from over 10 hours to 7 🔥

#mechanical engineering#repair#big oven#diy repair#she be spiffen now#material science#I used a Bic lighter for metal bending

4 notes

·

View notes

Text

Food-Grade Stainless Steel Tanks by Center Enamel: The Ultimate Storage Solution for the Food and Beverage Industry

When it comes to food and beverage storage, maintaining the highest standards of hygiene, safety, and quality is critical. Center Enamel, a leading manufacturer of storage solutions, offers food-grade stainless steel tanks specifically designed to meet the stringent requirements of the food and beverage industry. With decades of experience, Shijiazhuang Zhengzhong Technology Co., Ltd. is committed to delivering high-performance, reliable tanks that ensure product integrity and compliance with global food safety standards.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Food-Grade Stainless Steel Tanks?

Stainless steel is the material of choice for food-grade storage tanks due to its unmatched durability, corrosion resistance, and ability to maintain cleanliness. Center Enamel's food-grade stainless steel tanks offer numerous advantages:

Hygienic and Easy to Clean

Stainless steel is non-porous, which means it does not harbor bacteria, making it easy to clean and sanitize. This is crucial for the food and beverage industry, where contamination can compromise product safety and quality.

Corrosion Resistance

Our food-grade stainless steel tanks are made from high-quality 304 and 316L stainless steel, known for their excellent resistance to corrosion from acidic and alkaline substances. This ensures a long-lasting storage solution that protects the purity of food and beverage products.

Safe Material Composition

Stainless steel is inherently food-safe, with no risk of leaching harmful chemicals into the stored products. Our tanks are built to comply with NSF/ANSI standards, ensuring that they meet global food safety regulations.

Durability and Longevity

The robust construction of stainless steel ensures that our tanks can withstand extreme temperatures, pressures, and environmental conditions, providing reliable performance for years.

Applications of Food-Grade Stainless Steel Tanks

Center Enamel’s stainless steel tanks are suitable for a wide range of applications in the food and beverage industry, including:

Dairy Products

Our tanks are ideal for storing milk, yogurt, and other dairy products, ensuring they remain fresh and uncontaminated.

Beverages

Whether it’s juice, soft drinks, or alcoholic beverages, our stainless steel tanks provide a safe and hygienic storage solution.

Edible Oils

The non-reactive nature of stainless steel makes it perfect for storing cooking oils, preserving their quality and flavor.

Sauces and Condiments

Stainless steel tanks can store sauces, vinegar, and condiments without the risk of corrosion or contamination.

Customizable Design and Capacity

At Center Enamel, we understand that every operation has unique requirements. That’s why we offer a variety of customizable options for our food-grade stainless steel tanks, including:

Tank Size and Capacity: Whether you need a small storage tank or a large vessel, we can design tanks to meet your specific volume requirements.

Mixing and Agitation Systems: For industries requiring constant movement or mixing of liquids, we can incorporate agitators and mixing systems into our tanks.

Insulation: We offer insulation options to maintain precise temperature control for temperature-sensitive products.

Center Enamel: A Trusted Leader in Food-Grade Stainless Steel Tanks

With over 30 years of experience in manufacturing high-quality storage solutions, Center Enamel is a trusted supplier of food-grade stainless steel tanks to the global food and beverage industry. Our tanks are designed to meet the most stringent industry standards, providing our clients with peace of mind knowing their products are stored safely and securely.

We pride ourselves on our ability to customize our tanks to meet the specific needs of each client, ensuring that they receive the ideal solution for their food and beverage storage needs.

For companies in the food and beverage industry, ensuring that storage tanks meet the highest standards of hygiene, safety, and durability is crucial. Center Enamel’s food-grade stainless steel tanks provide an ideal solution, offering corrosion resistance, ease of cleaning, and compliance with international food safety standards. Whether you need a tank for dairy, beverages, oils, or sauces, our stainless steel tanks are designed to maintain the integrity of your products.

Choose Center Enamel for your next food-grade stainless steel tank project and experience unmatched quality and performance. Contact us today to learn more about our storage solutions and how we can help meet your specific needs.

0 notes

Text

Fixings and Fasteners: Essential Components for Secure and Durable Installations

In construction, manufacturing, and DIY projects, Fixings And Fasteners are essential components that ensure materials are securely attached, stable, and capable of withstanding stress over time. From securing heavy structural elements to holding smaller parts in place, the right choice of fixings and fasteners can make a significant difference in the safety, strength, and durability of an installation.

This guide will explore the different types of fixings and fasteners, their uses, and how to select the right ones for various applications.

What Are Fixings and Fasteners?

Fixings and fasteners are hardware devices used to join or secure materials together. They come in various forms, including screws, bolts, nails, rivets, anchors, and clips, each designed for specific tasks. These components can be used for permanent or temporary connections and are critical in ensuring that structures and assemblies hold up under mechanical forces such as tension, compression, and shear.

Types of Fixings and Fasteners

Screws

Screws are one of the most commonly used fasteners. They are designed to be driven into materials like wood, metal, or plastic with a twisting motion. Screws come in a wide range of types, such as wood screws, machine screws, and self-tapping screws, each suited to different materials and applications.

Common Applications: Furniture assembly, decking, and general construction.

Bolts and Nuts

Bolts are threaded fasteners typically used with nuts to secure two or more parts together. They are ideal for applications where high strength and durability are required. Bolts and nuts come in different sizes, grades, and materials, including steel, stainless steel, and brass.

Common Applications: Heavy machinery, automotive, structural steelwork, and construction.

Nails

Nails are used to fasten materials by driving them through one or more layers using a hammer or nail gun. Unlike screws or bolts, nails do not have threads, making them suitable for applications where high shear strength is needed.

Common Applications: Framing, roofing, and carpentry.

Anchors

Anchors are used to secure fasteners to surfaces like concrete, brick, or drywall, where screws or bolts alone would not be effective. There are several types of anchors, including wall plugs (also known as rawl plugs), toggle bolts, and concrete anchors.

Common Applications: Hanging heavy objects like shelves, fixtures, and cabinets on walls.

Rivets

Rivets are permanent fasteners used to join two or more materials by deforming the head after insertion. They are commonly used in applications where access to both sides of the material is limited.

Common Applications: Aircraft assembly, shipbuilding, and metalworking.

Washers

Washers are thin plates with a hole in the middle, used to distribute the load of a threaded fastener, like a screw or bolt. They help prevent the fastener from loosening and can protect the material surface from damage.

Common Applications: With screws and bolts in mechanical and structural installations.

Clips and Clamps

Clips and clamps are fasteners that hold objects together or secure cables and pipes in place. They are often used in scenarios where frequent disassembly or adjustment is necessary.

Common Applications: Cable management, piping systems, and automotive assembly.

Staples

Staples are U-shaped fasteners driven into materials using a staple gun or hammer. They are commonly used for attaching thin materials like fabric, paper, or insulation to wood or other surfaces.

Common Applications: Upholstery, packaging, and light construction.

Choosing the Right Fixings and Fasteners

Selecting the appropriate fixing or fastener for a project depends on several factors:

Material Type: Different materials require specific types of fasteners. For example, wood screws are designed for timber, while machine screws are suitable for metal or plastic.

Load Requirements: The strength and load-bearing capacity of the fastener should match the weight and mechanical forces it will need to withstand. Bolts and anchors are often used in high-load applications, while screws and nails are better for lighter tasks.

Environmental Conditions: In outdoor or corrosive environments, such as marine or chemical industries, materials like stainless steel or galvanized fasteners are preferred for their resistance to rust and wear.

Installation Method: Consider how the fastener will be installed. Some fasteners, like nails and staples, are hammered in, while others, like screws and bolts, require tools like screwdrivers or wrenches.

Permanent vs. Temporary: If the assembly needs to be frequently disassembled and reassembled, choose fasteners like screws, bolts, or clamps. For permanent installations, rivets or nails might be more appropriate.

Common Applications of Fixings and Fasteners

Construction: Fasteners such as screws, bolts, and nails are used to assemble structures, secure frameworks, and attach components like doors and windows.

Manufacturing: In industries such as automotive and aerospace, fasteners like bolts, rivets, and clips ensure the secure attachment of parts that undergo mechanical stress.

Home Improvement: From hanging shelves to assembling furniture, various fixings and fasteners are used in everyday home projects.

Electrical Installations: Fasteners like anchors, clips, and clamps are essential for securing wiring and electrical components in place.

Conclusion

Fixings and fasteners are fundamental to nearly every construction, manufacturing, and DIY project. Selecting the right type based on material, load, and environmental factors ensures that your installation is secure, durable, and safe. With the vast range of options available, understanding the specific requirements of your project will guide you in choosing the most appropriate fixing or fastener for the job.

0 notes

Text

#Brass Rivets#Hollow Rivets#Semi Tubular Rivets#Achse#Micro Rivets#Micro Screws#Steel Rivets#Stainless Steel Rivets#Metal Rivets#ss rivet#machined parts#stainless steel#metal parts manufacturing#stainless steel suppliers#metal manufacturing#stainless steel fabricators near me#stainless steel manufacturers

1 note

·

View note

Text

Introduction to Stainless Steel Screw Fasteners Manufacturing

Stainless steel screw fasteners are essential components in various industries due to their corrosion resistance and durability. The manufacturing process begins with selecting high-quality stainless steel alloys, which are then melted, cast, and formed into screws through methods like extrusion or machining. The screws undergo threading, heat treatment, and surface finishing to enhance their strength and appearance. Quality control checks ensure precision and reliability. These fasteners are widely used in construction, automotive, and aerospace applications for their superior performance.

0 notes

Text

#UKDEALS Rshuhx 150PCS M5 Cross Countersunk 304 Stainless Steel Machine Screws Bolts and Nuts Flat Head Phillips Screw Fastener Repair Tools Assortment Kit for Baby Crib Headboards Chairs Furniture https://www.bargainshouse.co.uk/?p=120992 https://www.bargainshouse.co.uk/?p=120992

0 notes

Text

Inline Flow Indicators, Sequence Valve, PP Pipe Clamp, Manufacturer

Manufacturer and Supplier of Inline Flow Indicators, Inline Flow Indicator, Sequence Valve, PP Pipe Clamp, Pressure Gauges, Industrial Valves, Mumbai, India.

Quick Release Coupling, Quick Release Couplings, Ball Valve, Ball Valves, Gemel Ball Valves, Industrial Ball Valves, Quick Coupling, Quick Couplings, Camlock Coupling, Camlock Couplings, Camlock Quick Coupling, Camlock Quick Couplings, Micro Hose, Micro Hose For High Pressure, Micro Hose For Pressure Fittings, Test Coupling, Test Couplings, Minipress Test Coupling, Minipress Test Couplings, Test Point Coupling, Test Point Couplings , Threaded Test Coupling, Threaded Test Couplings, Bulkhead Test Coupling, Bulkhead Test Couplings, Female Swivel Test Coupling, Female Swivel Test Couplings, Plug in Test Coupling, Plug in Test Couplings, Pressure Gauge Adaptors, Cartridge Valve, Cartridge Valves, Hydraulic Hoses, Hydraulics Hose, Hoses Crimped Hydraulic, Hydraulic Systems, Pneumatic Systems, Hydraulic Accessories, Hydraulic Couplings, Hydraulic Fitting, Hydraulic Fittings, SS304 Hydraulic Fittings, SS316 Hydraulic Fittings, CS Hydraulic Fittings, DIN 2353 Fittings, Pressure Gauge, Pressure Gauges, Industrial Valves, Coupling Valves, Hydraulic Components, Inline Valve, Inline Valves, Inline Flow Indicator, Inline Flow Indicators, Portable Hydraulic Crimping Machine, Portable Hydraulic Crimping Machines, Portable Hydraulic Instrument, Portable Hydraulic Instruments, Pressure Gauge Anti Shock Valve, Pressure Gauge Anti Shock Valves, Stainless Steel Hydraulic Components, High Pressure Check Valve, High Pressure Ball Valve, High Pressure Flow Control Valve, High Pressure Needle Valve, Non Return Valve, Gemels Italy Ball Valves, Holmbury Uk Couplings, Minipress Italy Couplings, Oleoweb Italy Valves, SS304 Csermeto Fittings, SS316 Csermeto Fittings, Flat Face Coupling, Quick Connect Disconnect Coupling, Screw Coupling 1000 Bar, Dust Cap, Test Point, Test Hose, Test Point Coupling, Test Point Hose, SAE Flange Ball Valve, Rotating Union, Hose Burst Check Valve, Compensated Load Control Valve, Compensated Flow Control Valve, Load Shuttle Ball Valve, End Stroke Valve, Single Acting Pilot Check Valve, Double Acting Pilot Check Valve, Double Cross Line Direct Acting Relief Valve, Single Cross Line Direct Acting Relief Valve, Sequence Valve, Single Counter Balance Valve, Dual Counter Balance Valve, Hand Pumps, Tube Clamp, Instrumentation Fittings, Lubrication Fittings, PP Pipe Clamp, Dowty Seal Copper Washer, Bonded Seal, Nut, Ferrule, asia, asian, india, indian, mumbai, maharashtra, industrial, industries, thane, navi mumbai, pune, nashik, aurangabad, ratnagiri, nagpur, ahmednagar, akola, amravati, chandrapur, dhule, jalgaon, raigad, sangli, satara, belgaum, kolhapur, belgaon.

0 notes

Text

Custom Micro Screw Manufacturers & Suppliers | Chuanghe Fastener

Among these essential components are micro screws, which play a crucial role in various applications, from electronics and medical devices to aerospace and automotive industries. As their name suggests, micro screws are miniature fasteners designed to hold together tiny parts with exceptional accuracy. Understanding the key players in this niche industry—micro screw manufacturers—can help you find the right supplier for your specific needs. This blog aims to provide an in-depth overview of micro screw manufacturers, exploring their roles, capabilities, and what to consider when choosing the right supplier for your projects.

What Are Micro Screws?

Micro screws are extremely small fasteners, typically with diameters ranging from 0.2 mm to 2.0 mm. They are engineered to provide secure fastening in applications where space is limited and precision is paramount. These screws come in various head types, thread forms, and materials, catering to diverse industry requirements.

The Importance of micro screw manufacturers

Micro screw manufacturers specialize in producing these tiny yet vital components with the utmost precision. The role of these manufacturers extends beyond mere production; they often engage in the design, engineering, and customization of screws to meet specific industry standards and application needs.

Key Features of Leading Micro Screw Manufacturers

Precision Engineering

Top micro screw manufacturers utilize advanced machinery and technology to achieve unparalleled precision. This includes CNC (Computer Numerical Control) machines, micro-threading equipment, and automated inspection systems to ensure each screw meets stringent quality standards.

Material Selection

Quality manufacturers offer a range of materials suited to various applications, including stainless steel, brass, titanium, and plastic. The choice of material affects not only the screw's durability but also its performance in different environments, such as high temperatures or corrosive conditions.

Customization Capabilities

Given the diverse applications for micro screws, leading manufacturers often provide customization services. This includes producing screws with specific thread patterns, lengths, or coatings to meet the unique requirements of a project or industry.

Quality Control

Rigorous quality control processes are essential in micro screw manufacturing. Reputable manufacturers conduct extensive testing and inspection to ensure each batch of screws adheres to international standards and performs reliably under various conditions.

Top Applications for Micro Screws

Electronics

In electronics, micro screws secure delicate components like circuit boards and connectors. Precision is critical to avoid damage to sensitive electronic parts and ensure the reliable operation of devices.

Medical Devices

Medical devices often require micro screws for assembling intricate instruments and implants. These screws must meet stringent hygiene and reliability standards, making precision and material choice vital.

Aerospace

The aerospace industry demands micro screws for their lightweight yet robust properties. These fasteners must withstand extreme conditions and contribute to the overall safety and performance of aerospace components.

Automotive

In the automotive sector, micro screws are used in various components, from dashboards to engine parts. They play a role in ensuring parts are securely fastened and function correctly.

Choosing the Right Micro Screw Manufacturer

Selecting the right micro screw manufacturer involves several considerations:

Industry Experience

Manufacturers with extensive experience in your specific industry are often better equipped to meet your needs and understand the nuances of your application.

Technical Support

A manufacturer that offers technical support can assist in optimizing your screw selection and customization, ensuring that you achieve the best performance for your application.

Reputation and Reviews

Researching a manufacturer’s reputation and reading reviews from other clients can provide insights into their reliability, quality of products, and customer service.

Lead Times and Delivery

Ensure that the manufacturer can meet your delivery timelines and has a track record of timely fulfillment, as delays can impact your project schedules.

Conclusion

Micro screw manufacturers are pivotal in providing the tiny yet critical components needed for modern technology and innovation. By understanding their capabilities and carefully selecting a supplier that meets your specific needs, you can ensure the reliability and performance of your products. Whether you require standard micro screws or custom solutions, partnering with a reputable manufacturer can significantly enhance the quality and success of your projects.

1 note

·

View note

Text

High-Quality S32750 Fasteners: Super Duplex Fasteners Manufacturer in India

Introduction to Super Duplex Fasteners

In the world of high-performance fasteners, Super Duplex stainless steel stands out for its remarkable combination of strength and corrosion resistance. Super Duplex Fasteners, crafted from Super Duplex stainless steel, are designed to handle the toughest industrial challenges. In India, manufacturers are providing high-quality Super Duplex Fasteners, including the notable Grade S32750, renowned for its superior performance in extreme environments.

About Super Duplex Fasteners

Super Duplex stainless steel is a category of stainless steel that combines both austenitic and ferritic structures. This unique composition provides Super Duplex Fasteners with exceptional mechanical properties, enhanced toughness, and superior resistance to corrosion and stress corrosion cracking. These fasteners are an ideal choice for applications exposed to harsh environments, such as offshore and chemical processing industries.

Super Duplex Fasteners Grade S32750

Grade S32750, also known as Super Duplex 2507, is a high-performance alloy that falls under the Super Duplex stainless steel category. It is particularly known for its excellent corrosion resistance in chloride-rich environments and its high yield strength. Grade S32750 is widely used in industries that demand durability and reliability under severe conditions.

Key Properties of Grade S32750:

Corrosion Resistance: Offers outstanding protection against pitting, crevice corrosion, and stress corrosion cracking.

High Strength: High yield and tensile strength, making it suitable for heavy-duty applications.

Toughness: Good impact toughness at both room temperature and cryogenic temperatures.

Specifications of Super Duplex Fasteners

When selecting Super Duplex Fasteners, understanding their specifications is important for ensuring they meet the requirements of your application. Here are the typical specifications for Super Duplex Fasteners, particularly those made from Grade S32750:

Material Grade: S32750

Type: Bolts, nuts, washers, screws, and studs

Standard Compliance: ASTM A182, ASTM A240, ASTM A276

Size Range: From M6 to M64 or 1/4" to 2" in diameter, depending on the application

Finish: Various finishes are available, including passivated, coated, or as-machined

Mechanical Properties:

Tensile Strength: Minimum 750 MPa

Yield Strength: Minimum 550 MPa

Elongation: Approximately 15% in 50 mm

Dimensions and Tolerances:

Bolts and Screws: Available in various diameters and lengths, often customized to meet specific application requirements.

Nuts: Standard and custom sizes, typically matching bolt specifications.

Washers: Various types including flat, spring, and locking washers, tailored to the application.

Standards and Certifications:

Conforms to ASTM A182, ASTM A320, ASTM A276, and other relevant international standards.

Certified for quality with ISO 9001 and ISO 14001 standards.

Applications of Super Duplex Fasteners

Super Duplex Fasteners are utilized in a wide range of applications due to their robust properties. Key applications include:

Offshore Platforms: For structural components exposed to seawater.

Chemical Processing Equipment: In environments where exposure to corrosive chemicals is prevalent.

Desalination Plants: Handling brine and other harsh conditions.

Marine Environments: For components exposed to saltwater.

Manufacturing Super Duplex Fasteners in India

India is home to several leading manufacturers of Super Duplex fasteners, leveraging advanced technology and stringent quality control measures to produce high-quality components. These manufacturers utilize state-of-the-art equipment for forging, machining, and testing, ensuring that their fasteners meet global standards.

Ananka Group stands out as a leading manufacturer of Super Duplex fasteners in India, renowned for its expertise in producing high-performance components. Utilizing advanced technology and rigorous quality control, Ananka Group ensures that its Super Duplex fasteners, particularly those made from grade S32750, meet global standards for strength and corrosion resistance.

By combining cutting-edge manufacturing processes with a deep understanding of industry needs, Ananka Group delivers reliable, durable fasteners that excel in demanding applications across various sectors.

Key Advantages of Indian Manufacturers:

Competitive Pricing: Affordable solutions that maintain top-notch quality.

Expertise: Skilled professionals with extensive experience in working with Super Duplex alloys.

Custom Solutions: Ability to manufacture fasteners to specific requirements and tolerances.

Timely Delivery: Efficient production processes ensure timely delivery for domestic and international clients.

Conclusion

Super Duplex Fasteners, particularly those made from Grade S32750, are engineered to withstand the most demanding conditions while providing superior strength and corrosion resistance. Indian manufacturers offer high-quality fasteners that meet international standards, ensuring reliability and performance in critical applications. Whether you’re in the offshore, chemical, or marine industry, choosing Super Duplex Fasteners can significantly enhance the durability and efficiency of your equipment.

Super Duplex fasteners, particularly those made from grade S32750, offer exceptional strength and corrosion resistance, making them indispensable in industries facing extreme conditions. Indian manufacturers are well-equipped to produce these high-performance fasteners, providing a valuable resource for global markets.

FAQs

1. What is the primary advantage of using Grade S32750 Super Duplex Fasteners?

Grade S32750 offers superior corrosion resistance and high strength, making it ideal for applications in harsh environments.

2. Are Super Duplex Fasteners more expensive than other types of fasteners?

Yes, due to their advanced properties and manufacturing processes, Super Duplex Fasteners are generally more expensive than standard fasteners.

3. Can Super Duplex Fasteners be used in high-temperature applications?

While they excel in corrosive environments, Super Duplex Fasteners are also suitable for applications with moderate temperature ranges. For extremely high temperatures, other materials might be preferred.

4. How can I ensure the quality of Super Duplex Fasteners?

Choose reputable manufacturers who comply with international standards and offer certifications for their products.

0 notes

Text

4 Ways a Vapor Glock Ported Barrel and Slide Will Boost Your Shooting Experience

NineX19’s Vapor Glock ported barrel and slide combos can and will substantially change your shooting experience.

Made for Glock 17 and 19 platforms (Generations 3, 4, and 5) these ported barrel and slide combos are CNC-machined in the United States from stress-relieved, heat-treated 416R stainless steel (the barrels), available in wear and corrosion-resistant nitrided finishes, and offer a precision, OEM-like fit.

But these are just specifications. One of these combos will substantially change your shooting experience, and greatly for the better. Here’s how.

Recoil Reduction

The most important aspect of these Vapor Glock ported barrel and slide combos is the ported, matched design.

Both the barrel and slide feature matched porting, that, in lieu of a compensator, redirects the manner in which gasses are ported near the muzzle.

This, in turn, substantially reduces felt recoil, without any other alterations needed to the gun, or in terms of the ammo you shoot.

This built-in recoil-reducing feature helps keep muzzle flip to a minimum, which in turn keeps your sights trained more closely on target, enabling faster, more accurate follow-up shots.

A Clearer Sight Picture

Now let’s talk about one of the downsides to some conventional compensators that port the gasses directly upwards as opposed to obliquely, off to the side.

While this conventional, “direct-up” configuration does directly counteract muzzle flip, it also clouds your sight picture with a burst of hot gas.

There is a reason that the ports on the Vapor barrel/slide combos are set off at an angle; this configuration splits the gasses around your sights and sight picture, keeping the picture clear for faster realignment and more rapid follow up shots.

Add Optics, Effortlessly

NineX19’s Vapor barrel and slide combos are “combat cut,” making them optic-ready for red dots and other sights that have an RMR-pattern footprint.

This eliminates any custom work associated with upgrading the slide to accommodate such optics, and as an added bonus, these slides feature rear sight index dimpling, in case you wanted to add screw-in iron sights.

Legal in States with Threaded Barrel Restrictions

There are, unfortunately, some states, in which threaded barrels are restricted. Some of these are Illinois, Connecticut, and Washington, although this post is not to serve as legal advice and there may be others.

With that said, since these barrels are integrally ported and therefore not threaded, they are legal in jurisdictions in which threaded barrels are restricted.

Want More Information on These Glock Ported Barrel and Slide Combos?

Need more specific information on these Vapor Glock ported barrel and slide combos before you determine if one is right for you?

You can learn more at NineX19. At the same website (link at the top of this article), you’ll also find Glock barrels (including threaded barrels) along with other Glock slides and parts for other popular handguns, including but not limited to the Sig P320 and P365.

Check out their website for more information and get in touch with them directly if you have specific questions.

For more information about Glock 19 Threaded Barrel and Glock 19 Magwell please visit:- NineX19, LLC

0 notes