#microporous board

Explore tagged Tumblr posts

Text

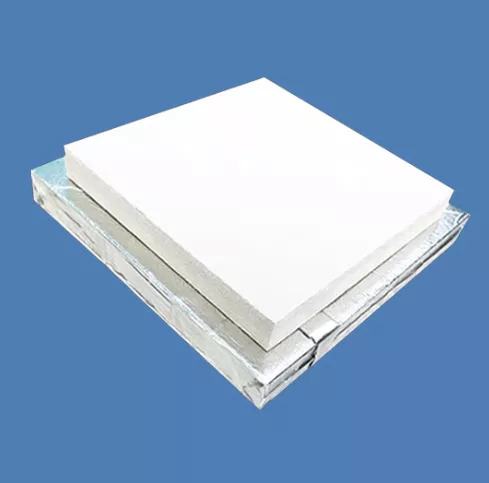

Exploring Minmetals East's Microporous Board in the Chemical Manufacturing Industry

Hello everyone! I am excited to share my experience with Minmetals East and their exceptional microporous board products. As I delve deeper into the chemical manufacturing and industrial materials sectors, I have found that Minmetals East stands out for its high-quality silica products and adhesives.

Their microporous board has proven to be a game-changer in construction materials and water treatment applications. The versatility and durability of their products are impressive, making them a top choice for various projects. I appreciate that their microporous boards are designed with sustainability in mind, contributing positively to environmental efforts.

If anyone has insights or experiences with Minmetals East's microporous board, I would love to hear your thoughts!

Best regards,

Sent from my device

#environmental efforts#industrial materials#silica products#microporous board#adhesives#water treatment#sustainability#chemical manufacturing

0 notes

Text

Innovating the Future: Minmetals East and Microporous Board Solutions

In the ever-evolving landscape of the Chemical Manufacturing and Industrial Materials sectors, Minmetals East stands out as a beacon of innovation and quality. Specializing in Silica Products and Adhesives, our company is committed to providing top-tier Construction Materials and effective Water Treatment solutions.

Our microporous boards are a testament to our dedication to excellence. These boards are designed to offer superior insulation, lightweight properties, and enhanced durability, making them ideal for a variety of applications in construction and beyond. With a focus on sustainability, our microporous boards are not only efficient but also environmentally friendly, ensuring a positive impact on the planet.

At Minmetals East, we believe in the power of collaboration and innovation. Our team of experts is constantly exploring new methods and technologies to enhance our product offerings and meet the diverse needs of our customers. We are proud to contribute to the advancement of industries while maintaining our commitment to quality and customer satisfaction.

Join us on this journey as we continue to lead the way in the Chemical Manufacturing, Industrial Materials, and Water Treatment industries with our cutting-edge microporous board solutions.

#microporous boards#innovation#construction materials#silica products#water treatment#customer satisfaction#insulation

0 notes

Text

Microporous Insulation Market Size, Share, Trends, Opportunities, Key Drivers and Growth Prospectus

Executive Summary Microporous Insulation Market:

This market research report is an utter outline of the global industry which is penned down so that an unskilled individual as well as professional can easily extrapolate the entire Microporous Insulation Market Market within few seconds. In this report; a meticulous investment analysis is given which forecasts forthcoming opportunities for the market players. Competitive analysis conducted in this report makes you aware about the moves of the key players in the market such as new product launches, expansions, agreements, joint ventures, partnerships, and acquisitions. The market study encompasses market drivers and restraints along with their impact on the demand over the forecast period.

It has most-detailed market segmentation, systematic analysis of major market players, trends in consumer and supply chain dynamics, and insights about new geographical markets. Besides, this report offers better market perspective in terms of product trends, marketing strategy, future products, new geographical markets, future events, sales strategies, customer actions or behaviours. Whether it is about renewing a business plan, preparing a presentation for a key client, or giving recommendations to an executive, this Microporous Insulation Market Market report will surely help you to a degree Quality and transparency has been strictly maintained while carrying out research studies to provide an exceptional market research report for a niche.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Microporous Insulation Market Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-microporous-insulation-market

Microporous Insulation Market Market Overview

**Segments**

- **By Product Type**: The global microporous insulation market can be segmented into rigid boards and panels, flexible panels, and flexible panels. Rigid boards and panels are expected to hold a significant share of the market due to their high strength and thermal efficiency. - **By Application**: The market can be segmented into industrial, energy & power, oil & gas, aerospace & defense, automotive, and others. The industrial segment is expected to dominate the market as microporous insulation finds extensive applications in various industrial processes. - **By End-Use Industry**: Based on end-use industry, the market can be segmented into construction, automotive, oil & gas, power generation, and others. The construction segment is projected to witness substantial growth due to the increasing demand for energy-efficient solutions in the construction sector.

**Market Players**

- **Promat International NV**: One of the key players in the global microporous insulation market, Promat International NV offers a wide range of products for different applications. - **Morgan Advanced Materials**: With a strong presence in the market, Morgan Advanced Materials is known for its innovative solutions in microporous insulation. - **Unifrax**: Unifrax is a leading player in the market, catering to diverse industries with its high-quality microporous insulation products. - **NICHIAS Corporation**: NICHIAS Corporation is a prominent name in the market, known for its advanced microporous insulation technologies. - **Isoleika S.L.**: Isoleika S.L. is a key player offering a comprehensive range of microporous insulation solutions for various industries.

The global microporous insulation market is witnessing significant growth, driven by the increasing demand for energy-efficient solutions in industries such as oil & gas, automotive, and construction. The market is characterized by the presence of well-established players competing on the basis of product innovation, quality, and pricing strategies. Rigid boards and panels segment is expected to witness strong growth due to their high strength and durability. Industrial applications of microporous insulation are expected to lead the market, supported by the growing focus on enhancing operational efficiency and reducing energy consumption. The construction segment is also poised for substantial growth as the construction industry increasingly adopts sustainable and energy-efficient building materials.

In terms of product type segmentation, the market is likely to see a continued preference for rigid boards and panels due to their superior thermal efficiency and durability characteristics. These products are well-suited for high-temperature applications and offer excellent insulation properties, making them a popular choice for various industries. Flexible panels also hold promise in niche applications where flexibility and ease of installation are paramount, driving their demand in specific market segments.

When it comes to application segmentation, the industrial sector is expected to maintain its dominance in the microporous insulation market. Industries such as manufacturing, processing, and utilities are increasingly adopting microporous insulation to enhance thermal management and achieve energy savings. The aerospace & defense sector, in particular, is likely to leverage microporous insulation for its lightweight and high-temperature performance benefits, supporting the growth of this application segment.

From an end-use industry perspective, the construction sector is poised for significant growth as the emphasis on sustainable building practices and energy-efficient solutions intensifies. Microporous insulation offers builders and developers a way to improve the thermal performance of structures while reducing energy consumption, aligning with global efforts to combat climate change. The automotive industry is another key end-use segment where microporous insulation is gaining traction, driven by the need for lightweight materials that can enhance vehicle efficiency and performance.

In terms of product segmentation, rigid boards and panels are expected to maintain a leading position in the market due to their robust thermal efficiency and durability, making them ideal for high-temperature applications. On the other hand, flexible panels offer flexibility and ease of installation, catering to specific market niches where such features are crucial. The versatility of microporous insulation products in addressing different industry requirements positions them as a preferred choice for a wide range of applications.

The industrial segment is anticipated to be a primary driver of market growth, with industries like manufacturing, processing, and utilities increasingly adopting microporous insulation to enhance thermal management and achieve energy savings. The aerospace & defense sector is also showing a growing interest in microporous insulation for its lightweight properties and high-temperature performance advantages. Moreover, the construction industry is emerging as a significant end-use sector for microporous insulation, as the focus on sustainable building practices and energy efficiency continues to rise globally.

As the market continues to evolve, market players are focusing on product differentiation, quality enhancement, and competitive pricing strategies to stay ahead in the competitive landscape. With a strong emphasis on research and development, these companies are poised to meet the changing demands of customers and capitalize on the expanding opportunities in the microporous insulation market. Overall, the future outlook for the global microporous insulation market remains positive, driven by the collective efforts of key players and the growing awareness of the importance of energy-efficient solutions across industries.

The Microporous Insulation Market Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-microporous-insulation-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Key Influence of this Microporous Insulation Market Market:

Comprehensive assessment of all opportunities and risk in this Microporous Insulation Market Market

This Microporous Insulation Market Marketrecent innovations and major events

Detailed study of business strategies for growth of the this Microporous Insulation Market Market leading players

Conclusive study about the growth plot of the Market for forthcoming years

In-depth understanding of this Microporous Insulation Market Market particular drivers, constraints and major micro markets

Favorable impression inside vital technological and market latest trends striking this Microporous Insulation Market Market

To provide historical and forecast revenue of the Microporous Insulation Market Marketsegments and sub-segments with respect to four main geographies and their countries- North America, Europe, Asia, and Rest of the World (ROW)

To provide country level analysis of the Microporous Insulation Market Market t with respect to the current market size and future prospective

Browse More Reports:

Global Bioethanol Market Global Automotive Safety System Market Global Double Glazing Glass Market Global Mint Essential Oil Market Global Engineering Plastic Compounds Market Global Corneal Analyzer Market Global Vehicle Pillar Market Global Research Department Explosive (RDX) Market Global Medical Foam Market Global Klinefelter Syndrome Treatment Market Global Oilseed and Grain seed Market Global Centrifugal Blood Pumps Market Global Innerspring Mattress Market Global Hydrolyzed Vegetable Protein Market Global Wireless Radio Frequency Identification (RFID) Reader Market Global Parkinson’s Disease Market Global Mediterranean Fever Treatment Market Global Activated Carbon Filters Market Global Bioplastics Packaging Market Global Aluminium Aerosol Cans Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag

Microporous Insulation Market Market Size, Microporous Insulation Market Market Share, Microporous Insulation Market Market Trend, Microporous Insulation Market Market Analysis, Microporous Insulation Market Market Report, Microporous Insulation Market Market Growth, Latest Developments in Microporous Insulation Market Market, Microporous Insulation Market Market Industry Analysis, Microporous Insulation Market Market Key Player, Microporous Insulation Market Market Demand Analysis

0 notes

Text

Anti-Mold And Anti-Bacterial Properties Of WPC Door Frames

As people's awareness of home health and environmental protection continues to improve, the choice of building materials also focuses more and more on functionality and safety. Among the many door frame materials, WPC (Wood Plastic Composite) door frames are gradually favored by the market for their unique properties. In addition to environmental protection, moisture, corrosion and other advantages, one of the most noteworthy features of the WPC door frame is its excellent anti-mold and anti-bacterial properties. In the humid, closed indoor space, this performance is particularly important, directly related to the cleanliness of the home environment and the health of the occupants.

Composition And Basic Characteristics Of WPC Door Frame Materials

WPC door frame is made of wood fibers or plant fibers and polymer plastics (such as PE, PVC) through high-temperature extrusion composite. This material has both the natural texture of wood and the stable structure of plastic, so while maintaining the sense of wood, it has good waterproof, moisture-proof, insect-resistant, not easy to deform and other characteristics.

Compared with the traditional solid wood or medium density board (MDF) door frame, WPC door frame has a longer service life in a humid environment, especially suitable for kitchens, bathrooms, basements and other areas with heavy moisture.

The Causes And Hazards Of Mold

Mold usually breeds in environments with high humidity and poor ventilation. Its spores spread in the air and grow and multiply rapidly when exposed to suitable temperature and moisture. Mold not only destroys the surface structure of the door frame and affects the aesthetics, but also may cause indoor air pollution, inducing allergies, asthma and other health problems, especially harmful to children and the elderly.

Once the traditional wooden door frame absorbs moisture, it is easy to become a “hotbed” of mold growth. The poor anti-mold materials often need to be frequently cleaned or even replaced, not only increase the maintenance cost, but also affect the home experience.

The Anti-Mold Performance Advantage Of WPC Door Frame

WPC door frame has natural anti-mold ability due to its unique structure and material properties:

1. Low water absorption structure: WPC material inside the closed microporous structure, not easy to absorb water, effectively blocking the source of moisture needed for mold growth.

2. Antibacterial components added: many high-end WPC products in the production process will add antibacterial agents, nano-silver and other antibacterial components, can actively kill or inhibit the reproduction of bacteria and fungi.

3. Dense surface without pores: WPC door frame surface is smooth and dense, not easy to hide dirt, greatly reducing the opportunity for bacteria and mold adhesion, even in the rainy and humid environment in the South, but also to keep clean and tidy.

4. Resistant to corrosion and deterioration: WPC will not rot, mildew or odor due to moisture, even if the long time in a humid environment does not affect the structural stability.

The Antibacterial Performance Of WPC Door Frame Embodiment

In terms of antimicrobial, WPC door frame also shows satisfactory effect, especially suitable for the environment that requires high hygiene conditions, such as medical places, mother and child space, school dormitories and so on. Its antimicrobial performance is mainly reflected in:

1. Active antimicrobial: WPC materials containing antimicrobial agents can effectively inhibit the reproduction of bacteria, such as Escherichia coli, Staphylococcus aureus and other common bacteria.

2. Long-term effective: different from the surface coating of antibacterial coating, the antibacterial component of WPC door frame is usually mixed in the material itself, which will not be invalidated by cleaning and friction in the process of using, and the antibacterial performance is durable and stable.

3. Safety and environmental protection: qualified WPC antimicrobial materials in line with RoHS, REACH and other environmental certification standards, harmless to the human body, does not release formaldehyde or other harmful substances.

Use And Maintenance Recommendations

Although the WPC door frame itself has good anti-mold and antibacterial properties, but reasonable use and maintenance will help to extend its service life and aesthetics:

Keep the room well ventilated and avoid long-term dampness and water accumulation;

Regularly wipe the surface of the door frame with a damp cloth, do not need to use corrosive cleaning agents;

Avoid heavy impact, so as not to damage the surface of the door frame protective layer;

If stains are found in the process of use, neutral cleaner can be used to clean gently.

Summarize

With its excellent anti-mold and anti-bacterial properties, WPC door frame shows strong competitiveness in modern home and commercial space. It not only meets people's pursuit of a healthy and environmentally friendly lifestyle, but also solves the problem that traditional door frames are easy to mold and difficult to clean in a humid environment. For consumers who pay attention to home quality and health, WPC door frame is undoubtedly a modern building material product worth choosing.

In today's increasingly focus on indoor air quality and micro-environmental safety, choosing WPC door frames is not only responsible for your family's health, but also a kind of upgrading of your future lifestyle.

0 notes

Text

Which type of material is used in muffle furnace?

1. Refractory Materials:

Refractory materials are the backbone of muffle furnaces, providing the necessary heat resistance and durability. Commonly used refractories include alumina, zirconia, and silicon carbide. Alumina is valued for its high melting point and thermal stability, making it ideal for furnaces operating at temperatures up to 1700°C. Zirconia is another excellent refractory material known for its low thermal conductivity and high resistance to thermal shock. Silicon carbide, with its exceptional thermal conductivity and ability to withstand temperatures up to 1600°C, is often used for muffle furnace linings and heating elements.

2. Insulation Materials:

Proper insulation is crucial to minimize heat loss and improve energy efficiency in muffle furnaces. Insulating materials such as ceramic fibers, insulating firebricks, and microporous boards are commonly used. Ceramic fibers offer low thermal conductivity and high-temperature stability, making them ideal for lining furnace walls. Insulating firebricks are lightweight and provide excellent thermal insulation, while microporous boards are known for their superior thermal performance and low thermal conductivity.

3. Heating Elements:

The heating elements in muffle furnaces are typically made from materials that can withstand high temperatures while providing consistent and efficient heating. Kanthal (iron-chromium-aluminum alloy) and Nichrome (nickel-chromium alloy) are widely used for heating elements due to their excellent electrical resistance and ability to operate at elevated temperatures. Molybdenum disilicide (MoSi2) is another material used in heating elements for furnaces requiring temperatures above 1800°C.

4. Structural Materials:

The external structure of muffle furnaces is usually constructed from stainless steel or mild steel, ensuring strength and durability. These materials provide structural support and protect the internal components from external environmental factors.

In summary, muffle furnaces rely on a combination of refractory materials, insulation, heating elements, and structural materials to achieve optimal performance and longevity. The careful selection and combination of these materials ensure the furnace can operate efficiently at high temperatures while maintaining safety and reliability.

Related Products:- High Temperature Furnace Muffle Furnace Programmable Furnace

For more Information:- Contact us:-+91–9278334734 Email:- [email protected] Address:- House №210, 1st Floor, Block-I, SDV Lakkarpur, Pole Factory, Faridabad, Haryana-121009, India.

#muffle furnace#muffle furnace manufacturer#muffle furnace manufacturer in india#muffle furnace supplier in india

0 notes

Text

0 notes

Text

HDI PCB & High Interconnect PCB Manufacturing--Hitech Circuits

What is a high density PCB board (HDI PCB)?

The HDI board is based on the traditional double panel as the core board, which is made by continuously accumulating. This circuit board made by a continuous layer is also called the Build-Up Multilayer (BUM). Compared with the traditional circuit board, the HDI circuit board has the advantages of "light, thin, short, small".

The electrical connection between HDI's plate layer is achieved by conductive pores, buried holes, and blind holes. Its structure is different from ordinary multi -layer circuit boards. A large number of blind holes are used in HDI boards. HDI PCB uses laser direct drilling, and standard PCB usually uses mechanical drilling, so the number of layers and high width ratio often decreases.

HDI includes the use of fine features or signal traces and spaces of 0.003” (75 µm) or less and laser-drilled blind or buried microvia technology. Microvias allow the use of micro-interconnects from one layer to another within a PCB utilizing a smaller pad diameter creating additional routing density or reducing form factor.

High-density interconnect (HDI) PCBs are characterized by finer lines, closer spaces, and more dense wiring, which allow for a faster connection while reducing the size and bulk of a project. These boards also feature blind and buried vias, laser ablated microvias, sequential lamination, and via in-pads. As a result, a HDI board can house the functionality of the previous boards used. HITECH CIRCUITS is an HDI PCB manufacturer and provider in Shenzhen, China supports HDI PCB prototype and mass production with less expensive price and quick-turn lead time. Customers from a variety of industries we serve have a common that have high expectations in quality, reliability and on-time delivery in HDI PCB production. Our quality is not afterthought, but built into each process from front-end to fabrication and shipping.

HDI PCB's Advantages

1. Reduce PCB cost: When the density of PCB increases beyond the eight-layer board, it will be manufactured in HDI, and the cost will be lower than that of traditional complicated press-forming process.

2. Better reliability: Due to the thin thickness and the aspect ratio of 1:1, the micropores have higher reliability when transmitting signals than ordinary through holes.

3. Improves thermal properties: The insulating dielectric material of the HDI board has a higher glass transition temperature (Tg) and therefore has better thermal properties.

4. Improve RF interference / electromagnetic interference / electrostatic discharge (RFI / EMI )

5. Increase design efficiency: Micro-hole technology allows the circuit to be arranged in the inner layer, so that the circuit designer has more design space, so the efficiency of the line design can be higher.

HDI PCB Manufacturing Process

The overall process for manufacturing HDI PCB is essentially the same as for fabricating other PCB board, with notable differences for PCB stack-up and hole drilling. Since HDI boards generally require smaller drill holes for vias, laser drilling is usually required. Although laser drills can produce smaller and more precise holes, they are limited by depth. Therefore, a limited number of layers can be drilled through at a time. For HDI boards, which are invariably multilayer and may contain buried and blind vias, multiple drilling processes may be required. This necessitates successive layer boding to achieve the desired stack-up or sequential lamination cycles. Not surprisingly, this can significantly increase PCB manufacturing time and cost. HDI PCB fabrication is an advanced technology and therefore requires expertise along with specialized equipment like laser drills, laser direct imaging (LDI) capability, and special clean room environments. In order to efficiently manufacture high-quality and reliable HDI PCB products, you must understand the HDI board manufacturing process and coordinate with your HDI PCB supplier to implement good DFM (Design for Manufacturability) for HDI layout design. Therefore, not all board factories have the ability to do the HDI, but Hitechpcb can, we will be here to support our customer needs. If you are looking for reliable high density interconnect PCB board partner from China, please don’t hesitate to contact us.

0 notes

Text

HDI PCB & High Interconnect PCB Manufacturing(from Hitech Circuits Co., Limited)

What is a high density PCB board (HDI PCB)?

The HDI board is based on the traditional double panel as the core board, which is made by continuously accumulating. This circuit board made by a continuous layer is also called the Build-Up Multilayer (BUM). Compared with the traditional circuit board, the HDI circuit board has the advantages of "light, thin, short, small".

The electrical connection between HDI's plate layer is achieved by conductive pores, buried holes, and blind holes. Its structure is different from ordinary multi -layer circuit boards. A large number of blind holes are used in HDI boards. HDI PCB uses laser direct drilling, and standard PCB usually uses mechanical drilling, so the number of layers and high width ratio often decreases.

HDI includes the use of fine features or signal traces and spaces of 0.003” (75 µm) or less and laser-drilled blind or buried microvia technology. Microvias allow the use of micro-interconnects from one layer to another within a PCB utilizing a smaller pad diameter creating additional routing density or reducing form factor.

High-density interconnect (HDI) PCBs are characterized by finer lines, closer spaces, and more dense wiring, which allow for a faster connection while reducing the size and bulk of a project. These boards also feature blind and buried vias, laser ablated microvias, sequential lamination, and via in-pads. As a result, a HDI board can house the functionality of the previous boards used. HITECH CIRCUITS is an HDI PCB manufacturer and provider in Shenzhen, China supports HDI PCB prototype and mass production with less expensive price and quick-turn lead time. Customers from a variety of industries we serve have a common that have high expectations in quality, reliability and on-time delivery in HDI PCB production. Our quality is not afterthought, but built into each process from front-end to fabrication and shipping.

HDI PCB's advantages

1. Reduce PCB cost: When the density of PCB increases beyond the eight-layer board, it will be manufactured in HDI, and the cost will be lower than that of traditional complicated press-forming process.

2. Better reliability: Due to the thin thickness and the aspect ratio of 1:1, the micropores have higher reliability when transmitting signals than ordinary through holes.

3. Improves thermal properties: The insulating dielectric material of the HDI board has a higher glass transition temperature (Tg) and therefore has better thermal properties.

4. Improve RF interference / electromagnetic interference / electrostatic discharge (RFI / EMI )

5. Increase design efficiency: Micro-hole technology allows the circuit to be arranged in the inner layer, so that the circuit designer has more design space, so the efficiency of the line design can be higher.

HDI PCB Manufacturing Process

The overall process for manufacturing HDI PCB is essentially the same as for fabricating other PCB board, with notable differences for PCB stack-up and hole drilling. Since HDI boards generally require smaller drill holes for vias, laser drilling is usually required. Although laser drills can produce smaller and more precise holes, they are limited by depth. Therefore, a limited number of layers can be drilled through at a time. For HDI boards, which are invariably multilayer and may contain buried and blind vias, multiple drilling processes may be required. This necessitates successive layer boding to achieve the desired stack-up or sequential lamination cycles. Not surprisingly, this can significantly increase PCB manufacturing time and cost. HDI PCB fabrication is an advanced technology and therefore requires expertise along with specialized equipment like laser drills, laser direct imaging (LDI) capability, and special clean room environments. In order to efficiently manufacture high-quality and reliable HDI PCB products, you must understand the HDI board manufacturing process and coordinate with your HDI PCB supplier to implement good DFM (Design for Manufacturability) for HDI layout design. Therefore, not all board factories have the ability to do the HDI, but Hitechpcb can, we will be here to support our customer needs.

-Consumer Driven Technology

The via - in - pad process supports

More technology on fewer layers, proving that bigger is not always better. Since the late 1980's we have seen video cameras using cartridges the size of a novel, shrink to fit in the palm of your hand. Mobile computing and work at home have further promoted technology to make the computer faster and lighter, allowing consumers to do remote work from anywhere.

HDI technology is the main reason for these changes. The products do more, weigh less, and their bodies are smaller. Professional equipment, mini components and thinner materials reduce the size of electronic equipment, while expanding technology, quality and speed.

-Via in Pad Process

The inspiration from the surface installation technology pushed the restrictions of BGA, COB and CSP to a smaller square surface inch. The via in pad can be placed in the surface of flat land through the cushion process. The via is plated and filled with conductive or non-conductive epoxy resin, and then close and plat it to make it almost invisible.

It sounds simple, but there are eight steps to complete this unique process. Professional equipment and well -trained technicians followed closely to achieve perfect hiding.

-Via Fill Types

There are many different types of via fill materials: non -conductive epoxy, epoxy, copper filling, filling and electrochemical coating. All this leads to via buried in a flat land, and the land will be fully solders as normal land. Vias and mricrovias are drilled, blind or buried, plated, and then hidden under the SMT land. Processing vias of this type of Vias requires special devices and takes time. The process time of multiple drill cycles and controlling deep drills has increased.

-Cost Effective HDI

Although the size of some consumer products is reduced, quality is still the most important factor for consumers. Use HDI technology during the design process, you can reduce the 8-layer through-hole PCB to a 4 layer HDI Microvia technology packed PCB. The elaborate HDI 4-layer PCB wiring function can achieve the same or better functions as standard 8-layer PCB.

Although the Microvia process has increased the cost of HDI PCB, the appropriate design and decrease of layers of counting reduces the cost of the ingredients of the material, and the layer count is large.

-Laser Drill Technology

The smallest micro-vias can provide more technologies on the surface of the plate. Using a beam with a diameter of 20 microns (1 mil), this high impact can be cut through metal and glass to produce tiny via hole. There are new products, such as uniform glass materials, and they are low -loss layer pressure plates and low -dielectric constants. These materials have high heat resistance, can be used for lead -free components, and allows smaller holes.

-Lamination & Materials For HDI PCB Boards

Advanced multilayer technology allows designers to add other layers to form a multilayer PCB. Use laser drills to produce holes in the inner layer, and can be coated when pressed, imaging and etching. The process of this increase is called sequential construction. Hitechpcb HDI PCB manufacturing uses solid -filled VIA can better heat management, connect stronger connection and improve the reliability of the board.

The copper of the resin coating is a assistant with poor pores, with longer drilling time and thinner. Hitechpcb has ultra low contours and ultra thin copper foil, and its surface is fixed on a tiny nodule. This material has chemically treated and started chemical treatment and startup of the most fine and high quality lines and spacing technology.

The dry resistance of the layer pressure plate still uses heating scroll method to apply resistance to core materials. It is now recommended to preheat the material to the required temperature before the layer pressure process of the HDI printing circuit board. The preheating of the material can better apply dry resistance to the surface of the layer pressure plate, pull less calories from the heat roll, and keep the stable export temperature of the layer made products consistent. The consistent entrance and exit temperature cause less air clips under the movie. This is essential for the breeding of fine lines and spacing.

-How difficult is the HDI Printed Circuits Board?

The manufacturing of the HDI PCB (High Denity PCB) is relatively difficult because it needs to use complex manufacturing technique and technology. The following is some difficulties made by HDI PCB:

Multi-layer plate lamination: HDI Printed Circuits Boards are usually composed of multi-layer boards, and multi-layer boards need to be laminated. Multi-layer plates need to control parameters such as temperature, time, pressure to ensure the control quality and thickness control between multi-layer boards.

Blind holes and buried holes: HDI Printed Circuits Boards need to create blind holes and buried holes, which requires technologies such as laser drilling and chemical corrosion to ensure the accuracy and quality of the hole.

Impedance control: HDI Printed Circuit Boards need to control impedance, which requires fine design of the layout and circuit of the circuit board, and uses special materials and processes to achieve impedance control.

Small track space manufacturing: HDI Printed Circuits Boards need to make very small spacing tracks (conductions), which requires high-precision manufacturing equipment and technologies to ensure the accuracy and quality of the circuits.

-The difference between HDI board and normal PCB

The HDI board is generally made of accumulation method. The more times the accumulation layer, the higher the technical grade of the board. Ordinary HDI boards are basically one accumulation. The high-end HDI uses two or more accumulated technologies, and at the same time, advanced PCB technology such as stacked holes, plating filling, and laser direct punching. When the density of PCB increases more than eight layers board, it is made by HDI, and its cost will be lower than the traditional complex compact process.

The electrical performance and signal of the HDI board are higher than that of traditional PCB. In addition, HDI boards have improved better for radio frequency interference, electromagnetic wave interference, electrostatic release, and thermal conduction. High density integration (HDI) technology can make terminal product design more miniaturized, while meeting higher standards for electronic performance and efficiency.

The HDI board uses a blind hole plating to perform secondary pressure, divided into one order, second order, third order, fourth, fifth order, etc. The first order is relatively simple, and the processes and processes are easy to control. The main problem of the second order is the issue of the place, and the other is the problem of punching and copper plating. There are many second order design. One is the wrong position of each order. When connecting the secondary neighborhood, it is connected to the middle layer through the wire. The method is equivalent to two first order HDI. The second is that the two order holes are overlapped. The second -order is realized by the superposition method. The processing is similar to the two first order, but there are many key points of the process. The third type is to punch perforation directly from the outer layer to the third layer (or N-2 layer). There are many different techniques from the front, and the difficulty of punching is even more difficult.

In PCB proofing, HDI costs high, so general PCB proofing manufacturers are unwilling to do it. HITECHPCB can be a HDI Blind PCB board that others are unwilling to do. At this stage, the HDI technology adopted by HITECH has exceeded the highest number of layers of 20 layers; the number of blind holes is 1st to 4th; the minimum pore diameter is 0.076mm, and the process is laser drilling.

HDI PCB Manufacturer & Assembly – One-stop services from China

-HDI (high-density interconnection board) is a compact circuit board designed for small capacity users. Compared with ordinary PCB, the most significant feature of HDI is that the wiring density is high.

HDI PCB Manufacturer & Assembly – One-stop service The HDI PCB is defined as a micro via with a hole diameter of 6 mils or less and a hole diameter of 0.25 mm or less. The contact density is above 130 points/square, and the wiring density is with a line width/pitch of 3 mil/3 mil or less. HDI PCB, the full name is High Density Interconnect PCB, it requires much higher wiring density with finer trace and spacing, smaller vias and higher connection pad density. Blind and buried vias’ design is one of their marked feature. HDI PCB board is widely used in Cell phone, tablet computer, digital camera mother board PCB, GPS, Automobile board, LCD module and other different area.

HDI PCB is the abbreviation for High Density Interconnect PCB or High Density PCB. An HDI PCB is defined as a printed circuit board with a higher wiring density per unit area than a conventional PCB. Hitech Circuits Co., Limited is a professional high density interconnect PCBs, HDI PCB board manufacturer, supplier and design company from China, if you are looking for reliable high density interconnect PCB board partner from China, please don’t hesitate to contact [email protected], from Cynthia.

1 note

·

View note

Text

Microporous Insulation Market Challenges, Key Vendors, Drivers, Trends and Forecast to 2031

According to a new report published by The Insight Partners, titled, " Microporous Insulation Market Forecast | Share and Size - 2031". The report provides a detailed analysis of the top investment pockets, top winning strategies, drivers & opportunities, Microporous Insulation market size & estimations, competitive landscape, and changing market trends.

The Microporous Insulation market report represents a detailed overview of the current market situation and forecasts till the Forecast Year. The study is perhaps a perfect mixture of qualitative and quantitative information highlighting key market developments, challenges, and competition the industry faces alongside gap analysis and new opportunities available and Microporous Insulation market trends. This report offers market size, recent trends, growth, share, development status, government policy, market dynamics, cost structure, and competitive landscape. The research report also includes the Microporous Insulation market growth potential in the given period of forecast.

This research is based on valid information sources that make it a credible asset. Through a range of quantitative methods and qualitative approaches, this research brings forward comprehensive insights on trends, drivers, and restrictions ahead of Microporous Insulation market players. PESTEL, Porter's five forces, and SWOT models are used for Microporous Insulation market analysis of the business environment across a range of categories, geographical regions, and applications.

Key companies in the Microporous Insulation market are- Elmelin Ltd., Jays Refractory Specialists Ltd, L`Auxiliaire D?Industrie Departement Distrisol, Nichias Corporation, Refractory Partners S.A., SILCA Insulation (SEA) Sdn Bhd, ThermoDyne, Tianjin Nanji Star (NJS) Insulating Material Co., Ltd., Unicorn Insulations Ltd., Unifrax

Market Analysis and Insights:

The report identifies emerging revenue pockets and opportunities for growth in the market. It analyses changes in market regulations and provides a strategic growth analysis, which can be used by businesses to develop effective growth strategies.

Overall, this report is an essential resource for businesses seeking to stay ahead of the competition in the Microporous Insulation market. With its comprehensive Microporous Insulation market analysis of recent developments and emerging trends, it provides valuable insights into the market that can be used to develop effective growth strategies and improve market positioning.

Market Drivers and Restraints:

The report provides valuable information on the production costs, supply chain dynamics, and raw materials that are essential to the Microporous Insulation market. The report identifies key market restraints, such as economic constraints in emerging countries and business market obstacles. By understanding these risks and challenges, businesses can develop strategies to mitigate them and achieve long-term success in this exciting and dynamic industry to increase their Microporous Insulation market share.

Market Segmentation:

The political and economic landscape of the Microporous Insulation market is analyzed in depth, providing a comprehensive understanding of the market's potential risks and opportunities. The report includes a detailed analysis of the competitive landscape of the market, identifying the top players and their Microporous Insulation market size, and evaluating their strategies and performance. The research report covers a wide range of topics, including market trends, technological advancements, and emerging opportunities, providing valuable insights for businesses looking to expand their presence in the market.On the Basis of Types this market is categorized further into-

Rigid boards and panels

Flexible panels

On the Basis of Application this market is categorized further into-

Industrial

Energy and power

Oil and gas

Aerospace and defense

Key regions Microporous Insulation Market Research Report:

North America (U.S., Canada, Mexico)

Europe (U.K., France, Germany, Spain, Italy, Central & Eastern Europe, CIS)

Asia Pacific (China, Japan, South Korea, ASEAN, India, Rest of Asia Pacific)

Latin America (Brazil, Rest of Latin America)

The Middle East and Africa (Turkey, GCC, Rest of the Middle East and Africa)

Rest of the World

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

0 notes

Text

Foldable Microporous Insulation Panels – Innovative Solution Brings Thermal Protection to a Convenience

In modern industry and construction, thermal protection is of paramount importance. However, traditional insulation materials have some limitations, such as bulky, heavy and inconvenient installation. In order to break through these limitations and provide a more convenient thermal protection solution, foldable microporous insulation panels have emerged. This innovative insulation opens up new possibilities for thermal protection.

1. What is a collapsible microporous insulation board? The foldable microporous insulation panel is an innovative product made of high-performance microporous insulation materials. Its unique feature lies in its foldable design, which makes the installation and transportation process more convenient. This insulation board is composed of multiple microporous insulation blocks, which are connected together by flexible connectors to form a foldable whole.

2. Main features: Collapsible microporous insulation panels have a number of impressive features that make them ideal for thermal protection:

2.1 Lightweight and flexible: Compared with traditional insulation materials, the foldable microporous insulation board has lighter weight and flexible structure. It can be folded and unfolded according to actual needs to adapt to different installation environments and requirements.

2.2 Excellent thermal insulation performance: Although light and flexible, the foldable microporous insulation board is not inferior in thermal insulation performance. Microporous insulation material can effectively insulate heat and reduce thermal energy transfer, thus providing reliable thermal protection.

2.3 Durable and reliable: The foldable microporous insulation board is made of high-quality materials and has excellent durability and anti-aging performance. It can maintain effective thermal insulation effect for a long time and is not easily affected by the external environment.

2.4 Easy installation: Due to the foldable design, it becomes easier and faster to install the foldable microporous insulation board. By unfolding and connecting individual microporous insulation blocks, the installation process can be completed quickly, saving time and labor costs.

https://www.wh-heat-insulation.com/foldable-microporous-insulation-panels.html

0 notes

Text

Greetings, tumblr. I warn you this isn't going to be much of a post for a whole raft of reasons:-

It's hotter than Satan's buttcrack outside and, consequently, inside my un-airconditioned first floor flat.

It's impossible for me to look soigné or remotely put together when I'm a sweaty, irritable mess.

There is a British Gas engineer currently boring holes in the outside walls of my flat with the aim of relocating my gas meter. The same thing is going on in my downstairs neighbours' flat. We have no say in this noisy, intrusive, cat-terrorising folderol. They've been threatening to do it for four years and we are literally the last house in the last street to be done. 'twas ever thus.

I had in fact written about two thirds of this original post and saved it as a draft. Tumblr since appears to have eaten that draft and washed it down with a nice Chianti. I have since lost the will to live.

My hair, as you can see, looked like crap when I took these pics.

The reason my hair looks like shite is because twelve days ago I had a cataract in my right eye removed and getting one's 'do done is not recommended for a couple of weeks after surgery.

Prior to surgery I had to take out my right contact lens and affect an eye-patch for a couple of weeks. I did not look piratical. Mainly because the size and positioning of my ears made the elastic intolerable after twenty minutes tops. Instead I had to make do with a Moorfields eyeshield stuffed with tissues and stuck to my face with Micropore. In 40ºC.

I'm hoping to get the left eye sorted late September/early October. A few weeks after that I'll find out whether I'll still need to wear contact lenses for distance and what prescription my new readers will be.

So, yeah, cataracts. Only partial but rubbish genetics on my paternal grandmother's side have resulted in those and an official diagnosis of Pathological Myopia along with a squint I didn't even know I had. The cataract/next-best-thing-to-blind double whammy has been causing me double vision and a blind spot in my right eye for years and the situation was becoming critical. I'd also experienced occular migraines during lockdown, though I think they were down to stress. But, in short, my eyesight was a shitshow and I'd gotten whiplash from the conflicting advice I've received by eye specialists the length and breadth of London. I'm relieved to say Moorfields cataract department got the last word. Thus far I'm optimistic. Three weeks ago I couldn't read the numbers on buses unless I was physically boarding one. Now I could probably see them from space.

But back to the main content of the post. Identically-cut Monki frock, gingham edition. Thus far they've offered this design in black, beige, light blue, orange, and lilac gingham. But there's a reason why the emerald green variation called to my heart.

Between the ages of 4 and 9 I attended a tiny private co-educational school. Admittedly this was many years ago but even then it was quaint and anachronistic. It was run by three sisters called Fowle and I had an elocution teacher who was older than God's dog and still wore long skirts and a bonnet. On Mondays we had to march, in single file, around the room we took dance classes in, in freshly whitened plimsoles to the strains of what later became the theme music to Monty Python's Flying Circus; this mysterious custom was known as Drill. We walked to the Headmistress's home for lunch every day, which was cooked by the kinder of her two sisters. That's how small the school was. It was also attended by kids of every conceivable nationality and ethnicity, and after it closed in the early 70s, the building subsequently became one of Erin Pizzey's shelters for women fleeing somestic violence.

As a sprog my summer school uniform featured a green gingham dress, which I always rather liked. But – get this – the size of the gingham squares increased proportionally with the age and height of the wearer. So, while my dresses had teeny tiny squares on them, the "seniors" had big ones on theirs. By the time I was of high school age and attending a different institution, sixth formers were no longer required to wear uniform, but as soon as I clocked this dress the exotic allure of achieving Big Green Square Status came rushing back and I knew I had to claim it.

Stay weird, tumblr. (And hydrated).

15 notes

·

View notes

Link

#Microporous Insulation Market#Microporous Insulation#Rigid boards & panels#flexible panels#machined parts#moldable products

0 notes

Text

The water absorption capacity can reach 6-10 times of its own dry weight

The bonded suction roller should be maintained in clean water if it is not used for a while.Brush Products Factory produces sponge suction roller. The general use temperature should not exceed 60℃, otherwise it will age and shorten the service life.

Sponge suction roller is a kind of microporous, and the micropores are connected with each other. Our factory can be customized according to the needs of users, according to the drawings or actual samples provided by the customers, and the delivery is timely and delivered to the door. ○Technical indicators of sponge suction roller:

The water absorption capacity can reach 6-10 times of its own dry weight. It requires a moisturizing state, so Store it in the sink. Sponge suction roller made of hydrophilic polymer PVA (polyvinyl alcohol), because the hydrophilic base material has finely connected pores so that it has good water absorption and water retention capacity, coupled with its unique softness

Can It is widely used in the cleaning, pressing, water absorption, and dehydration processes of printed boards, glass products, steel plates, aluminum plates and other panels.. Code: AQN Unit: mm Material: PU, PVA foamed sponge, PVC hose.

The normal use period is 5-8 months. It is ice scraper manufacturers very ideal to absorb water on the surface. It has good water absorption and good corrosion resistance

1 note

·

View note

Text

A-Level Playing Field

Nobody wanted my opinion on this, but it’s hard growing up poor.

1988. It’s that damp kind of evening outside, clouded by condensation on the single glazed windows, and the smoke from my Nan’s Benson and Hedges. We’ve just had tea – this is North, of course – and everything is accompanied by slices of springy bread heavily lacquered in ‘soft spread’. The gold foiled butter is, usually, saved for my grandad, who works at a fibreglass factory. It’s a very long way away (actually 3.7 miles) and he leaves on his bike every evening with three rounds of tinned ham sandwiches in his bag. Tonight, my mum is out until half nine, working in the care home in the next town, picking me up at ten-ish, depending on how fast she walks. My mum is 27. Five years out of a loveless marriage, living in a council house, she has no qualifications but is working for her City and Guilds and her English ‘O-Level’, GCSEs haven’t hit our vocabulary yet, and won’t until my second cousin Mark does his two years later.

Tonight is Thursday. Nan goes out on a Thursday, which means she will leave the house at half seven in a haze of Vitapoint, Elnett and Lily of the Valley, to play Bingo at the local club. I am being looked after by Alan, my mum’s younger brother, living at home, working in the Mill that overlooks the town below like a stern Victorian overseer. He’s always grumpy, stuck in a town that has no opportunities, and no visible exit. The eighties have been cruel to young, working-class men. The vehement cry of ‘get the fuck out’ hasn’t reached our town but will do in eight years time, on a wave of Britpop, New Labour, cigarettes, and alcohol.

My uncle looks to the television for nightly escape. Thursday is Blackadder, it’s Not The Nine O’Clock News, it’s Comic Strip, it’s A Bit of Fry and Laurie, it’s Red Dwarf, it’s shipwrecked and comatose, and me engrossed on the couch, not sipping mango juice, but milky tea (the North!), as my uncle laughs his head off in between cigarettes. My mum returns, smelling like TCP and the outside, with salty, vinegary chips, and we eat them as we walk the newly tarmacked paths under the orange street lights. I ask her what a goldfish shoal is. She tells me to shush.

I decided that weekend that I wanted to be funny. I mean I could make people laugh when I did my Cilla Black impression, so surely that was a start, and thank to Carry On films I was brilliant at ‘Infamy, Infamy!’, I knew this because my grandad (the cleverest man I knew) had told me so. Even though I was only in Junior One, I knew that you had to be taught how to be funny, that there was definitely some kind of class that you would have to take to learn it, because I had never really been a natural at anything; apart from whistling, which I did with gusto in shrill, high- pitched tones wherever I could.

I read a lot, especially the paper – particularly the Daily Mirror, which probably explains why I am always heavily weighted to the left, and not just because of my ineptitude in heels – and found out that Hugh Laurie, who is obviously the funniest man I have ever encountered, went to Cambridge and was in something called ‘The Footlights’. Then was it, I decided. I was going to go to Cambridge and join ‘The Footlights’ and be funny like Victoria Wood and Dawn French. I imagine ‘The Footlights’ to be a rag-tag theatrical group living on their wits, humour, and more importantly, Pot Noodles. I tell my Grandad that I want to go to Cambridge. He tells me not to be daft.

Now, when I think about it, wanting to go to Cambridge was not a preposterous idea for any child at the age of seven; you are at the start of your education journey. There is plenty of time to get better at things, to practice, to be coached, to improve yourself; but for a working-class girl, who would eventually be the first member of her family to go to university, I might as well have said that I wanted to fly to Mars on fairy wings. But, children who attend private schools are told from the age of four that Oxford or Cambridge are the end goals for their education, with any of the higher-performing Russell Group universities being something that they could settle for, at a push. I didn’t even know what a Russell Group University was until about three years ago, and why would I? For me, in my small artsy primary school with forty children across four year groups, a dismissive attitude towards formal English education, and a liberal fancy for devoting the whole of the summer term to the end of year show, this was not something that was even thought about. Oxford and Cambridge were places printed on the back of books, they weren’t places that you went to university. In fact, most of my primary school teachers hadn’t even been to university but received their qualifications at the local teacher training college; the only exception is a brown jumpered gentleman with a penchant for using cupboards as a disciplinary technique.

We’ll skip forward a few years later, and high school is a vigorous mixing bowl of talents, it takes until at least year nine before anyone even notices who I am amongst the squall of kids churning about in KS3. Dinner is pink sausage meat wrapped in a translucent puff pastry duvet, a treat even on the hottest days when the fat sticks to your lips; and the terms pass in a haze of cheap cider (the kind that tastes like sick), the floral pout of Cherry Lypsyl, and Chris Evans on the Radio One Breakfast Show; who is hastily snoozed every morning before I smell the lukewarm coffee my mum has left by my bed before she goes to work. At this point my mum is a newly qualified nurse at the hospice two towns over, her fingers raw from hand sanitiser, but with rolls of antiseptic scented micropore tape that I use for a cacophony of projects. She is on nights right now, spooning gravelly granules of instant coffee into a mug, blurry from sleep, I am cobbling together a mask out of old Cornflake packets, stuck together with nursing supplies and painted with nail varnish that went past its best around the same time as the Thompson Twins. It is 1995, and the country feels like it is on the cusp of something. I don’t know what, but I’m looking forward to the Year 2000 because I will be fully grown. Well, nineteen.

But what about Oxbridge? Well, for starters, if you attend a state school you have to be so immediately impressive to your teachers that they discuss you in the staffroom. It’s not enough to be good at one particular thing, you have to excel across the board. You have to be so amazingly shiny, that even the most jaded teacher in the school cannot fail to be dazzled by your brightness. For state school kids, Oxbridge is not something that they suggest to the average 10 A*-C kids, it’s not something that they even dangle in front of 10 A*-B kids who are pretty good. At state school, you have to be exceptional for your teachers to even consider you as a candidate, and then you have to achieve enough A*s in your GCSEs that you might as well open a Planetarium. Even then, all they can really do is say ‘I think you could go to Oxford or Cambridge, you know’, or flag you up to the local authority careers service as ‘potential Oxbridge’. There is no Oxford Fast Track programme in state schools, even for exceptional kids.

In a recent social media fracas, one lady proclaimed that if you gave kids a level playing field then poor kids would always triumph because they were more resilient - all those Crispy Pancakes, surely? But for children from a working-class background, we’re not even on the playing field yet; we have to borrow trainers with non-marking soles, scrape around for a quid for the bus. By the time we get to the playing field, we have already been running around for half the day trying to get there, we miss the warm-up because we were late and, honestly, by this point, we’re just knackered because we’ve had to work so much harder just to get there in the first place.

The warm-up is a given to those whose parents have been able to pay for their education – they even get complimentary orange slices for afterwards, just for extra pep and vigour. There are Oxbridge prep classes, extracurricular activities slanted towards the Oxbridge admissions interviews, and chances to take unpaid internships during the summer using family connections. It’s not just that though... it’s little things like knowing it’s pronounced ‘Barkshire’, not Berkshire, it’s when you use a napkin, it’s spending a week skiing at Courchevel. It’s olives.

In 1998, I don’t know any of these things and, even if I did, my accent with its flat vowels and its Lancashire intonation would give me away in a heartbeat, because I sound like I’ve fallen off a pit pony on my way back t’mill. Things change quickly though. My mum has a baby. A screaming, mewling little boy born during The Simpsons on a Friday evening in October. Now there is absolutely no money for luxuries, and when our TV gets nicked, we end up using the small portable from upstairs. My Nan lends me money here and there to get to college, but it only covers the bus fare, and the small endowment that I receive - supposedly to cover driving lessons - gets swallowed up with everyday things that seventeen-year olds shouldn’t have to pay for. I’m working for 4 hours a week in Woolies too, £3.10 p/h to stand around the toy department in a slippery polyester blouse the colour of synthetic mint ice cream, before skulking off to the bookshop to spend that money on things for college. Nothing fancy but, by this point, I am well on my way to being a ‘Funny Girl’, studying a raft of ‘arty-farty’ A-Levels and English thrown in for good measure. The Cambridge Footlights hardly crosses my mind anymore, because Oxford and Cambridge are reserved for the kids doing the hard sciences, maths, law, politics, things that you need a calculator for. You don’t get into Oxford with A-Levels in Theatre Studies, Media, and Performing Arts, despite what they tell you about diversity.

Oxford or Cambridge do not offer a typical British university experience, and how can teachers who have never passed through the rigorous and exhausting Oxbridge admissions procedure be expected to offer any kind of advantage to their gifted and talented students? If you are a working-class parent relying on underfunded, underpaid and overworked FE lecturers to help coach your child through this, then you are immediately on the backfoot compared to a child whose parents can afford private tutors, admissions booklets, and interview coaches. This is no reflection on sixth form teachers in FE establishments across the country, who do all they can to nurture the kids with Oxbridge potential, but when some classes haven’t received new textbooks for two years, where students are encouraged to photocopy their own materials to save costs, you can see where the class difference begins to draw attention to itself without the need for neon yellow highlighters.

My UCAS book arrived in September; an impressive, thinly papered tome with a glossy black and white cover, University Colleges and Admission Services stamped across it in orange. It smells like a cross between the Argos catalogue and a phone book, which I feel is rather apt given that it contains the codes of institutions and courses that will break me out of this godforsaken town: a cypher that I etch out on the application form in black biro.

London

Southampton

Buckinghamshire

Preston

Liverpool

Manchester.

I don’t want to go to any of the bottom three, of course, far too close to where I came from to be relevant. My second cousin Mark’s stint at Sheffield Hallam seemed to be an excuse for his mum to visit his ‘digs’ once a month with catering sized tins of Nescafe, and I would be lying if I said I wasn’t quite looking forward to edging the lid off with a knife and stabbing through that ridged foil. My mum writes a cheque out in her secondary modern handwriting, crossing her fingers that they won’t cash it until after payday.

The discrepancies between low-income working-class families and those with a better income also show here too - this can be something as simple as slow internet connection, not having a working laptop and doing work on smartphones, access to transport, costs for travel to visit universities. Things like this are not included when factoring in costs for students from low income. How can you visit all the different university campuses, with all the travel costs and maybe even overnight accommodation, when your parents can barely afford to keep the lights on? There was only one institution that I wanted to go to. London Institute, a glamourous collection of art colleges that included the London College of Fashion, Central St Martins, and, more importantly for me, The London College of Printing. The competition was fierce, but I was shortlisted for an interview in the capital with a former editor of the Daily Mirror. My house was showered in happy expletives that day. Even in 1999, tickets from Wigan to London were over £50 for a pre-booked return. My mum cashed in all of her Clubcard points for the ticket. But, just for me, because she hadn’t bought enough milk to cover the cost of two tickets. However, I must have impressed Tony Delano in that office in Clerkenwell, because he gave me an amazingly lowball offer meaning that my A-level results became a terribly graded self-fulfilling prophecy.

Oxford is different from usual universities in that there are colleges, thirty-nine in total. You might have seen them on University Challenge – Balliol, Trinity, Emmanuel, Brasenose – or from reading the Wikipedia pages of any of our last three Prime Ministers, including the incumbent Boris Johnson, who graduated with a 2:1 in 1987. That’s the other thing – you don’t study something at Oxford, you read it – you don’t start your studies, you matriculate, for which you need a robe. Now, I have been told by helpful and obstinate alumni via social media that Matriculation Robes are £25, ex-hire. However, I have also been told by a current Oxford student that the robe cost is £50 minimum, and no-one would dare wear a secondhand robe as ‘everyone would know’. It’s immediately singling yourself out as a Weasley in a room filled with Malfoys.

The accommodation costs are comparable to London prices; however, this does not cover the Christmas break, which means everything needs to be packed up and stored. Not only do you pay for the storage, but you pay for the boxes too. Much to my disappointment, no-one nips out for a Pot Noodle either, students are expected to dine ‘in hall’ (again, more cost!) where you can choose between an informal and a formal sitting – where your gown is required. I imagine for a working-class kid attending Oxford or Cambridge is very much like cosplaying on a Harry Potter set, but without the magic of a bottomless purse. There are balls too at the end of each term, formal affairs with ticket prices over £50. Again, said the former alumni, you don’t have to go! It’s not obligatory!

But let me tell you a harsh reality. Nothing ostracises a poor kid more than not being able to join in because they can’t afford it. Nothing. And we might have great friends who would all chip in and pay for our ticket, or lend us the money, but there is something very working-class about not wanting people to know that we can’t afford it. Surely we should not be asking these young adults who have studied and worked against all odds, to have a second class university experience because they know their parents won’t be able to help. You can’t even get a job to supplement your income either; the majority of colleges stipulate this, and as someone who had to work two term-time jobs at a much less prestigious university to live (even with the glorious student overdrafts of pre-austerity Britain), this really hit home at how much I would have struggled financially if I had gone to either of these institutions.

Recently my daughter applied for university. We get in the car and visit a university each week, driving miles up and down and across the country. We fight over choices and analyse each course based on employability, and whether or not she would like it. The process is completed in clicks and feels much more clinical than twenty years earlier, but rather than heading into unchartered waters, I have a map. It might be old and tattered, but I have a much better idea of where we are going now. My daughter believes that the meritocracy is a lie, and she tells me this in sharp, pointed tones as we receive her A-level results on a rainy Thursday morning. She goes to University in September and spends the autumn sending me videos of the Minster, or tutorials on how to swear in Japanese. She is only the second person in our family to continue on to higher education. I don’t just mean in her generation. I mean in total. We are the exception, not the rule.

One of the first questions someone at Oxford was asked by a fellow student last year was ‘private or state’, she replied ‘private’ and was met with a smile. There was no need to ask who the state school entrant was, as she queried the partridge and asparagus served for dinner – ‘this chicken is tough. Is that grass?’- and arrived for the formal sitting with her gown covering a denim skirt and shimmery top underneath. Private school teaches these things, no desperate faux pas for Isobel or Jeremy, whereas state schools do not have the resources or the knowledge to run classes on etiquette for the small number of their students that make it through the intense application procedures. This is not saying that low-income children should be discouraged – not at all – instead, it is saying that there is something inherently wrong with the system. At private school, you are disappointed if you don’t get into Oxbridge, whereas the state school child who gets in is an extraordinary anomaly talked about for years in hushed tones of reverence by the faculty.

And this is the issue with saying that children are on a level playing field, that everyone is measured on their own merit; because it is not true. For children on very low incomes, the odds are unfairly stacked against them, and the issues such as 2020’s disastrous A-Level results just add more bricks to an already near-insurmountable wall.

7 notes

·

View notes

Text

How Do Hand Warmers Work?

Each time the climate gets somewhat crisp, we figure out how to go out into the world with little or nothing covering our hands – just to rapidly recollect that it is so awkward to have cold digits. Furthermore, at whatever point that occurs, we end up going to similar devices a seemingly endless amount of time after year: hand warmers.

Just something happened to us: while we were grateful for the little ponders, we weren't totally certain how they functioned. Indeed, we comprehended that it had something to do with compound responses, yet that was about its degree. This year, as opposed to being left pondering, we volunteered to do a little examination with respect to how, precisely, hand warmers truly work. Also, we've refined it down into the accompanying preliminary – you know, just on the off chance that anybody out there was pondering only equivalent to click here.

Kinds Of Warmers

Before we begin, it's significant that not all hand warmers are made the same. Certainly, there are some that are more across the board than others, yet they don't all work the equivalent. Indeed, in our exploration, we found that there are five genuinely basic kinds of hand warmers and every one of them works a smidgen in an unexpected way. The advantage of this information is twofold: it permits us to recognize the dangers and awards of any one sort of hand hotter and it enables us to settle on an educated choice concerning which types we need to spend our cash on and which we'd preferably maintain a strategic distance from. The five most regular sorts of hand warmers are as per the following: air actuated, supersaturated arrangement, lighter fuel, battery-controlled, and charcoal. We've separated how each capacities, just as certain upsides and downsides in the accompanying segments.

Air-Activated

Presumably the most widely recognized of all hand warmers – and furthermore maybe the most intriguing – are the expendable air-actuated assortment. These are the sorts you see while holding up in the checkout line of supermarkets in the colder pieces of the world. And keeping in mind that they appear to be so ordinary, they're quite intriguing a result of the substance responses through which they work. These little parcels of warmth simply holding on to be released are loaded up with 4 fixings that makes them work: iron powder, The one other vital fixing is air (oxygen), but at the same time the impetus kicks the entire procedure off.

In all honesty, the warmth made by these hand warmers is really a result of another common response: rusting. What happens is, the point at which you expel the little microporous bundles – which permit the free progression of air through their structure – from their defensive bundling, the iron powder inside starts to rust, in this way making heat. Be that as it may, the powder and air blend isn't sufficient to do only it. The procedure of oxidation really requires water, also – which is housed inside the normally permeable actuated charcoal. The nearness of water likewise accomplishes something different: it goes about as a conductor that permits the warmth to be spread out more uniformly.

At that point, it's sodium chloride's turn. Salt – similarly it capacities in the preparing of food – enhances the general response, quickening the entire procedure. However, the expansion of salt additionally can possibly accelerate the response and its power by something over the top (we're talking genuine burning, flares and everything). What's more, that is the thing that vermiculite deals with. This hydrated magnesium aluminum silicate – got from the latin term for 'little worm' – goes about as a cover. This is on the grounds that, when presented to warm, it grows, retaining the abundance head as it does. It's additionally fireproof, artificially idle, scentless, and lightweight. It's as simple as that. The greatest drawback to this shrewd tad of science, notwithstanding, is that it's very a one-time thing.

Supersaturated Solution

The primary guideline behind supersaturated arrangement hand warmers isn't not at all like air-initiated dispensable ones, however for one significant theoretical contrast: they can be reused. The purpose behind this is because of the synthetic substances inside the gel filling of this assortment. The gel is involved a sodium acetic acid derivation blend – one fit for cooling to room temperature without taking shape. Inside every one of these parcels, there's a little malleable metal plate that can be bowed or "popped," severing minuscule bits of metal which launch nucleation – the initial phase in a thermodynamic reaction.In request to make these reusable, the arrangement must be turned around into a fluid. That procedure makes the gel arrangement solidify once again into strong sodium acetic acid derivation trihydrate – a side-effect of which is, obviously, heat.

When that response has happened, in any case, twisting the metal plate won't create any further response. So as to make these reusable, the arrangement must be turned around into a fluid. Fortunately, that procedure is exceptionally straightforward: simply put the parcels into bubbling water. The warmth will make the arrangement disintegrate and stay a fluid as it chills ease off to room temperature. At that point, basically pop the metal plate again and the warming procedure should rehash itself. In the end, the compound bonds will separate and the parcels won't keep on working, yet you ought to have the option to get a lot of utilization out of them before at that point.

Lighter Fuel