#motor vibration conveyor

Text

Streamlining Transport: Iron Ore Conveyor Systems in Industrial Operations

In the realm of industrial operations, the efficient transport of materials is paramount. Iron ore, a crucial raw material in various industries such as steel manufacturing and construction, requires reliable and efficient transportation methods to move it from mines to processing facilities and eventually to end-users. Among the arsenal of transport solutions, conveyor systems have emerged as indispensable assets, offering unparalleled efficiency and reliability in handling iron ore. Let's explore how iron ore conveyor systems streamline transport and enhance productivity in industrial operations.

Efficient Material Handling:

Iron ore conveyor systems play a pivotal role in material handling, facilitating the seamless movement of bulk materials from one location to another. These conveyor systems utilize belts or chains to transport iron ore efficiently over long distances, minimizing manual labor and maximizing throughput. By eliminating the need for multiple handling steps and reducing the risk of spillage or contamination, conveyor systems optimize material handling processes, enhancing overall efficiency in industrial operations.

Reliable Performance:

Conveyor systems designed for transporting iron ore are engineered for reliability and durability, ensuring consistent performance even in harsh operating environments. These systems are equipped with robust components such as heavy-duty belts, rugged rollers, and sturdy frames, capable of withstanding the abrasive nature of iron ore and the rigors of continuous operation. With minimal maintenance requirements and long service life, iron ore conveyor systems provide reliable and uninterrupted transport, minimizing downtime and maximizing productivity in industrial settings.

Versatility and Adaptability:

Iron ore conveyor systems offer versatility and adaptability to meet the specific needs and requirements of diverse industrial applications. Whether transporting raw iron ore from mines to processing plants or transferring processed materials between production stages, conveyor systems can be customized to accommodate varying loads, inclines, and distances. With adjustable speed controls and automated monitoring systems, conveyor systems provide flexibility and precision in material transport, ensuring optimal performance across different operating conditions.

Safety and Environmental Benefits:

Conveyor systems contribute to a safer working environment by reducing the risk of accidents and injuries associated with manual material handling and heavy machinery operations. By automating the transport of iron ore, conveyor systems minimize worker exposure to hazardous conditions and mitigate the potential for workplace accidents. Additionally, conveyor systems offer environmental benefits by reducing energy consumption, emissions, and noise pollution compared to traditional transport methods such as trucks or trains, aligning with sustainability initiatives and regulatory requirements.

For More:

Contact:0488 199 079

Email: [email protected]

Timings: Mon-Fri: 8:30am–5pm

Visit us: https://www.hudsolutions.com.au/

0 notes

Note

hiii, i was wondering if you’d be willing to do a continuing of your rose the hat one shot, maybe where reader pays off her debt? ;) or literally anything with rose / rebecca, i’m sooo obsessed with her and ur fic made me go feral it was amazing !!

[Hi Anon! I originally didn’t consider making a second part to the fic, (I just like the vagueness of one shots), but I am happy to write a second story involving similar themes. We’ll call it a multiverse addition. :3 Thank you for the request!]

Belligerent Collector

Rose the Hat x Fem! Reader

NSFW 18+- MINORS WHO INTERACT CAN AND WILL BE BLOCKED.

Summary: A chance meeting at a supermarket with a specialized clairvoyant brings Rose more than she could ask for. A little too much. [Shifting POVs].

Warnings: Depictions of straight sex between Rose and Crow (oral M and F receiving/giving, 69), one slap (R receiving), choking, depictions of attempted SA, overly emotional for a smut fic, lesbian smut (oral R receiving, strap on use, strap sucking R giving, forced deepthroating, Rose uses a set of vibrating panties to get off), a wee bit dub-con for good measure

A/N: Author pushes her writing boundaries in the name of character authenticity!!! No I’ve never had straight sex, no I don’t want to have straight sex, but boy oh boy, Rose has and will continue to fuck our little corvid boy, and you bet the mattress has some stories to tell. (I promise it ties in!!! It’s very brief!!!).

Word Count: 5.6k

Waking up in a foreign environment had always felt strange. Waking up in a foreign environment in a dream, only to wake once more in reality made realities blend together. Were you really in the rundown motor home of your Grandma’s in Dallas or were you in the divinely furnished home of some elite posing as a trailer park beauty? Then memories… Oh fuck, the memories.

“Rosie, the kid is barely even a kid, not worth eating at this point.” Crow lamented.

“Oh, for fucks sake, she’s not a kid, she’s an adult, let’s just call her that.” Rose spit back, crossing her arms over her bra covered breasts.

“Okay, fine. The adult-kid, this little overgrown shrimp, can see us coming from miles away. We wouldn’t even know about her if you hadn’t brushed her hand in a supermarket.”

Rose rolled her eyes, or more so you felt the motion of her rolling her eyes. These were her memories after all, and you were living them through her eyes.

“The rube brushed my hand, and she brushed right through my train of thought. She skimmed my mind, Crow! She skimmed my mind!”

Rose felt many things in this particular memory. Anger, a sense of deep humiliation, or more so violation. Rose felt that she had been violated by the little bitch child, a half-adult. The little half-ling had brushed her hand reaching for a lane divider for the conveyor belt of the grocery store, and had managed to skim her mind doing so. Like it hadn’t even been a forethought. She read the inner monologue of Rose the motherfucking Hat like it was as simple as brushing her hand in the first place!

“I want her dead.” Rose blurted. “Not just because she’s a little steamier than normal for her age, but because she read my mind. And now she knows who I am, she knows what I do, and she’s an adult, Crow!”

“-And since she’s an adult she has the authority and the ability to cause more problems than a kid, blah, blah, blah, I get it!” Crow cut her off.

Through Rose’s eyes, the bare-chested man was neither handsome nor appealing. He was a fucking vermin. One that had been latching on to Rose like an overgrown calf, sucking her dry; patience, charity, her damned sex drive all dried up like a desert.

“Out.”

The memory ended there, and with it came a brief reprieve, but brief. Another one of Rose’s memories slammed right into your head, the intensity of it hitting you hard. The last memory had been triggered by the touch of the sheets under your fingertips. This memory by the weight your body exerted on the mattress.

I need to breathe, oh fuck I need to breathe-

“Rosie baby, you taste so fucking good.” Crow moaned, sliding up, his dick sliding out of Rose’s mouth.

Rose sputtered, taking in mouthfuls of air. She laughed once she could, wiggling her hips enticingly. A mouth came down on her open entrance once more, tongue rolling wet circles over it; the way she liked it best. It was a 69, Rose was on the bottom because they were trying something new. Rose opened her mouth again, breathing in deep before guiding Crow’s hips down again.

The angle forced her to deepthroat him in his entirety, without exerting too much pressure on her uvula. She felt him licking and kissing her open pussy, moaning into her as she swirled her tongue at the base of his dick. It was the closest to breath play Rose was willing to go, and even as tears streamed down her cheeks, jaw aching at the stretch and gag reflex struggling against her higher will, it was fun.

The memory was ripped away, and you shot up as fast as you could, desperately trying to get away from the unwelcome memories that kept springing upon you. Never before in your life had someone's memories been so vibrant, so stubborn to be heard. You felt humiliation, no, violation. These mental images springing upon you without warning, without a trigger other than touch were akin to being violated. Usually you had more control over your abilities, you didn't have the ability to so easily peruse someone's mind, but with Rose it was like you weren't even trying. Well you weren't. Clairvoyance was an entirely conscious effort, at least it always had been. But Rose? Her mind and memories jumped open. It wasn't like a book sliding off a shelf, or a book falling open, no. It was like the books were violently flying off the shelves, ripping themselves open and shoving your face into them.

"Didn't I tell you to get out already?" Rose sighed, setting the book down she'd been reading.

Andy appeared, worrying her lip like a frightened child. Well... Hadn't she been a teen? Rose couldn't remember, age was pointless anyways. Whether she was 32 or 15, she'd look young with a fresh batch of steam in her.

"But.. I thought-"

"It was a one-time thing. My man is coming home today, and I'm not in the mood to pull apart a cat fight." Rose huffed.

This was the morning after she'd turned Andy, the night after she'd eaten the little blonde's pussy again and again until the young woman's body gave up on pleasure entirely. And waking up after that power trip, that victory for the Knot, it put things into perspective. But regardless, she was being a little too harsh on the newcomer.

"Put your clothes on, and come over here."

The blonde wasn't special, like Rose thought. A glorified pillow princess. And the blonde did have an ability that would benefit the Knot, but Rose was hungry now. She'd given Andy her own damn steam, her own life force. Sure, it had been fun, but not fulfilling.

"Why?" Andy whispered, sliding into Rose's open arms.

Rose groaned, sliding her hat over her head. She had her pair of two day old panties on, nothing else. She looked good, as always, but she was tired.

"Because it just can't. It was fun, it was something we could share, but I'm not available. I can get away with one night, one little welcome for the newbie, but I can't justify more than that to my Crow Daddy." Rose sympathetically explained. "You'll find another, there's plenty of youngins in the Knot still. Silent Sarry, for one."

Andy stared down at her feet. Rose watched her large brown eyes fill up with tears. Then she jerked her head, willing them away. A tough cookie, Rose thought. She'd get over this.

"Can I hug you goodbye, at least?" Andy whispered, looking at the floor still.

Rose chuckled at this, pulling the girl in for a gentle hug, followed by the softest kiss she was capable of giving.

"There. Now chin up, go have breakfast with the others. You're True now, you're family."

As Andy gently closed the door behind her, Rose let out a soft sigh, drawing patterns over the floor with her toe.

You dropped to your knees, clutching your head. It was painful, exerting this much energy into viewing her memories, even if it was completely against your will. You'd been in and out of consciousness for... You couldn't be sure. Time had lost all meaning. You were bombarded by memories until your body succumbed to exhaustion, only to wake up and be subjected to more memories. Rose's memories.

You knew her better than yourself at this point.

"Ah, you're actually conscio-"

Rose carried the little rube to her trailer, smirking as the girl twitched spasmodically.

"Bit off more than you can chew there, huh? Too greedy? Viewed too many memories at once?" Rose taunted, watching the young woman as she continued to twitch, her eyes wildly fluttering as her eyeballs roved around beneath her closed eyelids.

"God, she's like the dying." Barry the Chunk commented.

Rose laughed at that. Her fingers were frozen in twisted shapes, like the claw of the arthritic hands of the elderly. It was nothing like Grandpa Flick's nasty rheumatoid arthritis, but it was comparable.

"Well, that's what happens when someone gets too big for her britches." Rose smirked, hauling the girl right atop her bed. "She'll stay here under my watch until she can maintain conscious-

"Oh god, make it stop!" you cried out, clutching your head as it throbbed dangerously.

You were so tired, so hungry, and thirsty beyond belief. Nothing about this place was welcoming enough to allow you even a split second of rest and relaxation. Out of the corner of your eye, a ring covered hand came forward, reaching out to touch you.

"Don't touch me!" you shouted, voice dry and ragged.

Rose raised an eyebrow, looking at you quizzically. It was one of the few times you'd seen her. And unlike the mirrored effect you were used to viewing her in, the only perspective of herself she had, you were looking at her in the present, through your eyes.

"So now you're calling the shots? Oh, well excuse me." Rose let out an annoyed laugh.

You were scared to breathe, waiting for another memory to suddenly implode over you, but none came.

"I just... I'm tired. And if I move, if I shift my weight over the damn floor I might get another memory."

Rose cocked a brow.

"Get another memory? What, you can sense the memory of objects?"

You hesitantly nodded. Rose let out an intrigued sniff, but that's the only reaction she gave. You had been in her head long enough to understand what her different mannerisms meant. It gave you an advantage, being able to read her so.

"So... You've been reliving whose memories?" Rose asked, brow raised in that calculating critique.

Stern, that's what she was. This was Rose being stern.

"Yours. Only yours."

Rose's nose twitched in immediate disgust and disgraced anger.

"Not by choice," you butted in, trying to calm the storm before it began to brew much farther, "I keep passing out from exhaustion because I can't figure out how to stop viewing the memories. I'm tired, I've had enough of your thoughts and memories and..."

You cut yourself off. The next words out of your mouth would have been 'hedonistic escapades', or worse, 'sexcapades'. Rose eyed you dangerously, neither really believing or listening to your plight.

"Too big for my britches, crude violator, shrimp, halfling, rube, bitch-child," you listed, "I know. And I know too much. I don't want to know, I-"

You cut yourself off, pausing before you reenacted Irina Spalko's inversed lament. This could be something out of an Indiana Jones movie, you supposed. Rose had the special, magical hat after all.

"So, what. I don't care if you do or don't want to read my thoughts-"

"Memories-"

The slap that landed across your cheeks stung, and for the first time since meeting Rose, you were stunned. Slapping someone wasn't something the woman did. She was zealously cruel, calculatingly wicked, manipulating, hateful, over-indulgent and sadistic, but the woman didn't hit people. To lose herself in such a motion would surely seem overdone, by her standards.

"Shut your mouth." Rose seethed.

It was anger. Pure, unbridled, raging fury that caused her hands to shake. You'd never gotten a memory from Rose where she was so angry. Her trailer wasn't a place where she let negative emotions hang about, and that's why it was her safe place.

"You have the audacity to interrupt me when I'm speaking to you? You've been leaching off of me for weeks while I tracked you, reading not just my thoughts, but re-living my memories, and you have the fucking gall to interrupt me?" Rose spit, hands reaching up and choking, squeezing your windpipe.

It was an ego wound, you realized. She was bitter because her ego was being trodden all over by someone who'd been in her head for as long as you had. It was simple, in essence. You knew her. Intimately. More intimately than anyone else. In all of Rose's glory and power, you were interrupting her like any other individual regardless of the fact that you knew her. Knew what she could do, knew what she was.

"I don't even want your steam anymore, I just want to watch you die."

Your stomach lurched, and a memory slammed so violently into your skull that it didn't have somewhere else to go. You grabbed onto Rose's wrists, pulling her down the rabbit hole with you.

"Fucking Rube!" Malte wheezed, hands clinging to Rose's wrists.

Rose was shaking, her hands were shaking. The man beneath her wiggled like a squirrel caught in a trap, his eyes bulging violently, the whites of them rolling wildly. Rose was scared shitless, squeezing harder on instinct, even as the man beneath her slapped at her arms, trying to pull the young teen's hands off him.

He'd tried to rape her. He'd lured her into a street corner, promising her cash if she hiked up her skirts for him. She'd agreed to do so, she needed the money to feed her family. But she'd misheard him, or more accurately, had misunderstood him. The English these American foreigners spoke didn't cling to her Irish tongue easily. That and the structure of the English language was hard. It didn't match up with her native tongue. Combined with a day working in the filthy factories of Jersey had rubbed her hands and mind raw, so "Lift your skirt" meant to quite literally lift your skirt, no other motive or hidden arrangement. She was tall for a fourteen-year-old girl, but he had been stronger. Malte, the son of the factory owner, descended from Dutch immigrants who settled in Delaware, well before it was called Delaware had his eye on her. And he'd shoved her up against the brick wall of the factory, pawing at the front of his trousers, trying to bury himself between her legs as she tried to politely get him to stop.

But Rose was tired. And there was no direct translation for 'no' in her native language, and she couldn't remember the English word for it, so all her words were mixes of jumbled Irish phrases, none of which he interpreted correctly until she struck him between the legs.

His mouth was starting to froth. And the more pressure she exerted on his neck, the more afraid she got. If she killed him, oh god, if she killed him she could ruin her own life, the life of her family. They'd starve, they'd have nothing left to eat. She reached for the first strewn article of clothing she could grab. A top hat, the expensive satin lined kind, one that could fetch enough food for her family if she sold it. Food, eat, live long, stay young... Eat well, live long, stay young...

<------------->

Rose was crying. Sobbing like a fourteen-year-old child all over again. And the body underneath her was seizing, twitching and letting out garbled sounds. Rose grabbed the body, hugging it to her chest with possessive neediness. She needed physical contact, she needed that reassurance. The memory viewing had ended there, but Rose's memories filled in afterwards. She'd run home, falling into her overburdened mother's arms, sobbing and whimpering like her infant brother, still latched on her mother's breast. Her father had been furious, her mother scared. They were all scared in the perpetual twilight of Rose's memory.

Malte had never pressed charges. Whether it was pride or some other vice that compelled him to stay silent about the assault, he never did speak a word of it to anyone. But Rose found that her hours were cut back, her position was regularly filled before she had made it to her station. She looked for other work, worrying over the little bump that grew inside her mother. Worrying about food, about money, about the things that they needed to stay alive, let alone stock up to build their American dream.

"Tá brón orm." she sobbed into the girl's hair. "I'm sorry." she repeated.

Because Rose wasn't holding the rube girl anymore, she was holding a mirror of her younger self.

<------------>

Waking up for the upteenth time was more exhausting than being awake itself. Your head swum with too many thoughts, the mind's way of catching up after being unconscious. Someone was petting your hair, little strokes and teases that pulled at your scalp menacingly.

"We have a debt." Rose murmured. "My people are hungry, and they're going to go hungry because you're not on the menu any longer."

Her words rolled over your head in weary waves, peddling meanings over the valleys of your brain until they slowly sunk in, stringing together cohesive ideas once more.

"And why does that mean I have a debt with you?"

Rose gave the hairs at your scalp a tug, raising an eyebrow as she looked at you seriously.

"Because what I say goes, honey pie."

You closed your eyes, nodding in defeat. The light hurt, everything hurt.

"Got any more memories to view? I have millions, my mind is a cathedral."

You fought back the urge to mouth the words along with her. You knew her little cliches too well.

"I don't think so. The last memory was pushing others out of the way until it could be seen."

The logic behind that theory was imbued with a hidden clarity that had come from somewhere in your unconscious mind. The memories would stop jumping in front of your eyes again.

"Okay, well, you owe me. I'm keeping you alive because you're useful. Clairvoyance is a gift, we don't have a lot of True with such wide sensors as you."

Leaning forward felt like the next best thing with your head throbbing so violently. A soft little 'mmph' left your lips as you did so.

"You're not listening..." Rose said in sing-song fashion.

"Brain hurts."

Rose snorted at this.

"So eloquent. Truly, you should write novels with your linguistic prowess."

You let out another grunt in response.

"Its like talking to a caveman." Rose muttered.

She brought a cup of something to your lips. Tea. You drank it, not really caring that it was lukewarm and half full. It was liquid.

"Not picky. I'll add that to your list of positives."

You eyed her wearily.

"And let me guess, all the negatives include the fantasies of me you can't have because I know you too well."

Rose cocked an eyebrow, momentarily stunned.

"Well. I do have plans for you in the physical department. Crow and I are fizzling out, it might be time to break in a new lover."

She said it so confidently, in a fashion that made it almost unbearably flirtatious.

"You're wondering how good my head game is."

Rose laughed, a stunned kind of bark that caused her chest to jiggle, the swell of her breasts unencumbered beneath her t-shirt.

"Oh god, you're hysterical. I mean yes, but you make me sound so blunt. So, collected." Rose snickered. "I can be blunt, and I certainly try to be..."

Rose trailed off, eyeing you carefully.

"Kiss me."

It was a command that cut through your tired brain. She caught your head as you leaned in, pressing her lips against yours, one hand tangled in your hair, the other resting on your back. Rose pulled away after the short kiss, seemingly a little vexed by something.

"How much... How much experience do you have? You kiss like a petrified boy."

You blushed profusely, even though embarrassment in your exhausted state was difficult to even feel.

"I'm tired. Not in the mood."

Rose sighed, nodding at that statement.

"Fine. We'll nurse you back to health before the turn, get you all spick and span. But right before then... You and I are going to sort out this little debt situation we have going on. And then we'll see if you survive the turn."

The thought made your stomach queasy. You were between hell and a hard place. Become like her or die.

"What if I'd prefer being on the menu?"

"Not a lesbo?" Rose teased.

"Not a child eater."

Rose rolled her eyes, leaning in closer as she gripped your hips tight. She kissed your neck chastely.

"Eat well, live long, stay young."

You found yourself looking up at the ceiling, almost willing another memory to intrude, an excuse to pull away from this aggravating situation, but nothing.

"I'd like the luxury of just being normal."

Rose laughed at this, a genuine laugh.

"Whoever told you reading minds was normal. God, you're positively hysterical. I want to make a miniature you and stick her in my hat."

You crossed your arms, perusing the trailer for any signs of food, like a mouse. A little mouse caught in the cat's trap.

"I'll feed you, but first you need to give me a proper kiss." Rose whispered, breath tickling your earlobe.

As if you had anything on your mind other than food. Rose was pushing at your boundaries, playing with you and molding you into a state somewhere between desperate and stubbornly defiant. You leaned in, but you paused. You were coming on too strong. This needed to be natural, not forced. But it was forced, that was the paradox. Leaning in again, slowly, you met her grey eyes, taking a deep breath in. Your hands you drew up to her face, thumbs gently rubbing over the hollow of her cheeks. Rose leaned in, eyeing you with predatory intent.

"Good." she whispered. "You're getting somewhere."

You leaned in even further, pressing a teasing kiss to the corner of her lip, catching her gaze with hers. It was a game of both movement and eye-lines. Each of you would rove your eyes up and down the other, trying to catch the opponent in the act, making that split second of contact before drawing away to brush noses, to shift grip slightly. You weren't kissing yet, no, this was all about will. Who could tempt the other into making the first move.

"I believe I asked you to give me a kiss." Rose whispered, growing a bit bored of the game.

The softest brush of your lips over hers, making that eye-contact.

"Is that what you want?" you asked.

Rose's eyebrow quirked, and then she leaned in, pressing her lips to yours in response. The kiss wasn't as soft as you would have made it had you been administering the kiss. Rose kept you steady with a hand on your hip, a hand in your hair, her mouth occupied with yours. You forced yourself to be more engaged, even with how hungry and weak you felt. She tasted of mint tea, an undercurrent of something sour clinging to the edge of your tastebuds. It was the product of your clairvoyance, surely. Rose didn't taste quite right, a fact that lingered in the peripherals of your thoughts as you leaned into the kiss. She pulled away after a moment, seemingly amused.

"You're so chaste with your kisses. Or perhaps neat is the correct word. It's entertaining to see you so careful and focused."

Rose leaned back, dropping her hands. She easily maneuvered you out of her way, walking towards a fridge on the side of her camper. She wasn't wearing any pants, just too tight lacy panties. Her long legs were on full display, bare feet padding across her wooden floors. Her motions were all so elegantly careless, like she didn't much care what kind of gesture she made, so much as things landed in their respective places.

"Eggs alright with you?" she sighed.

"Yes, thank you."

Rose hummed in reply, starting up her gas powered stove top. She cracked open three eggs, reaching into the fridge for chives, cheddar cheese and bacon bits. It smelled good.

"You're pale, drink this."

A glass of orange juice appeared in front of you, and Rose looked down at you with some amusement.

"Like a startled lamb, freezing up in front of a newcomer." she laughed.

You drank the juice, grateful for the liquid. You weren't really paying attention to where your eyes rested as you drank, you were too tired to focus on much else other than the motion of your throat as you drank down the juice.

"I look that good do I?" Rose teased, grabbing your chin and angling it up.

You'd been staring at her upper thighs. Being so tall, Rose's legs filled much of your central and peripheral vision as you spaced out. The couch was low to the ground, and her stance gave a clear view of her inner thighs and the patch of dark hair that clung around her bikini line.

"Sorry, spaced out." you blushed, face going hot with the weight of your embarrassment.

Rose chuckled, squishing your face in soft teasing. She took the glass out of your hand, returning to the stove top. She came back with three eggs piled with cheese, chives and bacon. An American breakfast classic. You ate quickly, and the miserable tightness of your stomach gradually subsided.

"Perhaps you'd like to lay down on the bed and take a nap." Rose suggested.

You nearly choked on your bite of egg. The memory and the feeling of being forcefully deepthroated through Rose's eyes still clung to the back of your mind.

"Uhh, no. Not the bed. Couch is fine."

Rose cocked an eyebrow, taking away the plate of food you were still working on.

"Why? My hedonistic escapades still haunt you?" Rose threw your earlier internal monologue right back at you. "My sexcapades?"

You looked up at her in pure disbelief and jaded embarrassment. Rose wore a shit eating grin, leaning in as she grabbed your chin.

"Poor thing, thought you were the only one with the ability to skim someone's foremost thoughts, huh?" Rose cooed. "Maybe that's what we'll do.. Re-enact that little fixation of yours, get it out of your system."

You found yourself shaking your head and stuttering, hands searching for something to grab onto.

"Mhm, oh you're getting all flustered just thinking about it." Rose grinned cruelly, pulling you up to her feet. "What a perfect way to settle our debt, huh? We'll re-enact one of the memories you collected."

This time, you ardently shook your head, getting over your momentary bout of shyness.

"No, I didn't have control over what I was seeing, I didn't want to-"

"Shush, honey pie." Rose cut you off, pushing you to sit on the bed. "It'll be fun, we'll go slow-ish."

Rose stretched, settling on the bed beside you. She dusted off her hat, gingerly setting it off to the side. Hands looped around your waist, drawing you in.

"You'll like it, I promise." Rose whispered, leaning in to nip at your jaw and ear.

As she placed little love bites over your face and neck, her hands massaged slow patterns on your waist and back. You let out a soft sigh, leaning into her little nips and kisses.

"There you go, warming up to me perfectly." Rose cooed. "Touch me."

Your hands obeyed, cupping her lower face and neck. She placed a slow kiss in the crook between your jaw and neck, opening her lips to suck softly at the skin there. A soft moan broke out of your throat, to which Rose replied with her own throaty hum. One of your legs crept up to straddle her, and a hand from your waist quickly caught your leg, aiding the motion.

"Oh, good girl." Rose whispered. "Warming up nicely."

You smiled shyly, brushing your nose against hers. Her lips caught yours in a kiss, her tongue sliding out to caress your lip. You met her tongue with yours the longer the kiss went on, teasing her with your tongue. Rose's hands slid down your back, taking handfuls of your ass and massaging slowly. You moaned immediately, allowing Rose to slip her tongue into your mouth. Your hands were in her hair, playing with the half-braided strands that clung to the base of her scalp.

"Ready for more?" Rose rasped, one hand gripping your rear, the other drawing patterns down your spine.

"Yes." you found yourself saying.

Rose pulled off her top, freeing her breasts entirely. She brought your hands to them, biting her lip playfully.

"Touch, squeeze."

You did as she asked, to which she rewarded you with a sinfully teasing kiss.

"Lay down, top off."

You did as directed, pulling off your shirt, and the loose sports bra she'd found you in. Rose rummaged around in a drawer near the bedside for a moment, grabbing several Items. You watched as she slipped off her underwear, pulling a plain looking black set over her thighs again. A remote, which she clicked just twice. Rose bit her lip immediately, wiggling her hips a few times. A fake dick, a harness. You blushed as you realized just what she was going to do.

"I've never... I can't suck dick." you blurted out.

Rose laughed, sliding the harness over her hips.

"Too bad. You're gonna. And if you leave teeth marks on my nice silicone cock I'll throttle you."

Rose settled between your thighs, dragging your leggings and underwear down in one motion. She spread your thighs, eyeing the glistening folds of your inner labia. Taking a moment to gather saliva in her mouth, Rose leaned down, spitting on your red, erected clit.

"There's something you can focus on while I stretch your throat."

Rose crawled over you in a traditional 69, slapping the silicone dick on your chin.

"Open."

You could see the soft blur of the panties as they vibrated, producing a noticeable wet spot on the black fabric. Opening your mouth as wide as you could, you were careful not to graze the silicone with your teeth. The saliva Rose had placed on your clit slowly began to drip down and cool, producing a maddening sensation. Leaning forward all the way, Rose propped herself up on her elbows, holding your thighs open.

"Breathe through your nose, deep breath, now relax."

Rose pushed her hips down, forcing the silicone past your molars, past your uvula and down into the hollow space of your throat. You gagged, grabbing at her hips and thighs, desperately trying to push away the weight on your head that bore down. Rose laughed as she heard you gag and choke, letting up after fifteen seconds. You sputtered, nose running and eyes blurry with tears.

"Catch your breath, I'll give you fifteen."

Fifteen seconds felt more like five, and the silicone was back down, further this time. You couldn't breathe through your nose, and the burn of your lungs mixed with the stretch of your throat was both terrifying and maddeningly difficult to get away from. Rose let up after a moment, and you were quick to breathe in through your nose, filling your lungs as rapidly as you could, exhaling shortly thereafter. The next time, you breathed in through your nose as the dick slid down your throat, forcing the muscles of your throat to relax. Rose hummed in approval, pressing a soft kiss to your clit.

"Good girl. Now I'm going to rock. If you absolutely cannot manage to get any air in, two taps to my hips, got it?"

Rose didn't wait for you to make any sort of noise or gesture in understanding, she just undulated her hips slowly. You exhaled with every thrust out, inhaling as she thrust in. Your lungs slowly began to accommodate the lack of air, your throat muscles relaxing. Rose kissed your clit again, humming carefully as she rolled her tongue in slow circles over your clit. You found yourself getting the hang of things, more focused on the sensations between your legs than the burn of your throat. Rose's own stimulation was heightened by the pull and stretch of the vibrating panties that shifted with every movement of her hips. You moaned as she licked down into your entrance, and Rose let out a breathy hum in response.

Her mouth settled at your entrance, licking and probing gently. You gripped her hips, helping to support her thrusts. Overtime, your nose brushed her clothed clit as the base of the strap met your lips, adding direct pressure to the vibrating panties. Rose moaned loudly at this sensation, fervently kissing and licking your open pussy. Your lower abdominal muscles coiled rapidly, and by the way Rose was growing sloppy with her thrusts, she must have also been close.

Warm tingles slid up your spine as you climaxed, and your moans were muffled by the strap. Rose slipped the silicone dick out of your mouth, allowing you to gasp and moan through your orgasm without threat of suffocation. Still relatively aware, you had the forethought to find her clit through the panties and rub circles over the vibrating fabric. Rose let out a series of breathy whimpers, pushing her hips back into your thumb until she too climaxed. In need of a place to rest her weary hips, Rose sat back, resting on your face. A mouthful of panty-clad pussy and an eye-full of ass was all you knew for a good fifteen seconds.

"Fine then." Rose sighed, sliding off of you after you tapped the side of her ass twice.

Rose looked down, eyeing your puffy, tear and snot covered face. She smirked, reaching for something on her bedside table. A polaroid camera, one that had to be from the 90s. She snapped a photo of your frazzled state, taking out the photo produced and grabbing a pen.

"What shall we name this one? 'Belligerent collector', perhaps."

Rose gave an evil grin, sliding off the vibrating panties and casting them aside. She swung one of her legs over your face, angling her still wet core over your mouth. Another snap of the camera, capturing your mortified eyes as your mouth was obscured by her vulva.

"And this one we'll title 'debt settled'."

<------------->

#rebecca ferguson x reader#rose the hat x reader#rose the hat x you#rebecca ferguson x you#rose the hat smut#rose the hat doctor sleep#doctor sleep#rose the hat#rebecca ferguson#wlw#lesbian#lesbian smut#rose the hat x you smut

108 notes

·

View notes

Text

Mesin Press Batako Listrik Semi Otomatis Berkualitas

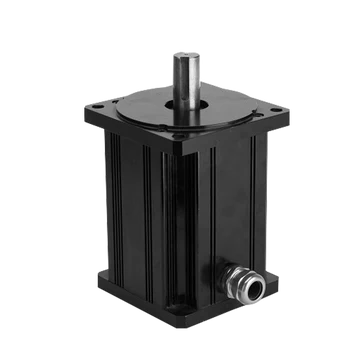

Mesin Press Batako Listrik

Mesin press batako listrik adalah peralatan industri yang digunakan untuk memproduksi batako atau blok beton dengan menggunakan tenaga listrik. Proses pembuatan batako ini melibatkan penggunaan cetakan yang diisi dengan campuran beton atau material bahan bangunan lainnya. Mesin press batako listrik ini membantu meningkatkan efisiensi dan produktivitas dalam pembuatan batako, karena dapat menghasilkan blok-blok beton dengan cepat dan konsisten.

Berikut adalah beberapa fitur umum yang biasanya dimiliki oleh mesin press batako listrik:

Tenaga Listrik: Mesin ini dioperasikan menggunakan sumber daya listrik, yang membuatnya lebih mudah digunakan dan mengurangi ketergantungan pada tenaga manusia.

Cetakan Berbagai Ukuran: Mesin press batako listrik biasanya dilengkapi dengan cetakan yang dapat diganti-ganti, sehingga memungkinkan produksi berbagai ukuran batako atau blok beton sesuai kebutuhan.

Sistem Hidrolik atau Pneumatik: Banyak mesin press batako menggunakan sistem hidrolik atau pneumatik untuk memberikan tekanan yang diperlukan pada campuran beton di dalam cetakan. Ini membantu dalam mencapai kepadatan yang diinginkan pada batako.

Pemrosesan Cepat: Mesin ini dirancang untuk memproses material dengan cepat, meningkatkan output produksi dan efisiensi waktu.

Kontrol Otomatis: Beberapa mesin dilengkapi dengan kontrol otomatis yang memungkinkan pengaturan dan pengendalian yang lebih mudah terhadap proses pembuatan batako.

Daya Tahan dan Ketahanan: Mesin press batako listrik umumnya dibangun dengan material yang kokoh dan tahan lama untuk menanggung beban kerja yang berat.

Portabilitas: Beberapa model mungkin dirancang dengan pertimbangan portabilitas sehingga dapat dipindahkan dengan relatif mudah di lokasi konstruksi yang berbeda.

Sebelum membeli atau menggunakan mesin press batako listrik, pastikan untuk memahami spesifikasi, kapasitas produksi, dan fitur keselamatan. Selain itu, perlu juga mematuhi pedoman keamanan kerja dan petunjuk pengoperasian yang disediakan oleh produsen untuk memastikan penggunaan yang aman dan efektif.

Kelengkapan Mesin Press Batako Listrik

Mesin press batako listrik umumnya dilengkapi dengan berbagai komponen dan fitur yang memungkinkan proses pembuatan batako berjalan dengan efisien. Berikut adalah beberapa kelengkapan yang seringkali ada pada mesin press batako listrik:

Struktur Utama: Bagian utama mesin yang mendukung dan memuat komponen-komponen lainnya. Struktur ini harus kokoh dan tahan lama untuk menanggung beban kerja.

Motor Listrik: Mesin press batako ditenagai oleh motor listrik yang menyediakan tenaga untuk proses pemadatan campuran beton dalam cetakan.

Cetakan: Cetakan adalah salah satu komponen kunci yang digunakan untuk membentuk batako. Mesin biasanya dilengkapi dengan cetakan yang dapat diganti-ganti, memungkinkan produksi berbagai ukuran dan bentuk batako.

Sistem Hidrolik atau Pneumatik: Banyak mesin press batako menggunakan sistem hidrolik atau pneumatik untuk memberikan tekanan yang diperlukan pada campuran beton di dalam cetakan. Sistem ini membantu mencapai kepadatan yang diinginkan pada batako.

Papan Kontrol: Papan kontrol adalah antarmuka pengguna yang memungkinkan operator mengatur dan mengontrol berbagai parameter, seperti tekanan, waktu pemadatan, dan lain-lain.

Rel Pengangkut Bahan: Beberapa mesin dilengkapi dengan rel atau conveyor untuk memudahkan pengisian campuran beton ke dalam cetakan, meningkatkan efisiensi dan kecepatan proses.

Sistem Penggoyang (Vibration System): Untuk meningkatkan kepadatan dan kekuatan batako, mesin sering dilengkapi dengan sistem getar yang dapat diatur. Sistem ini membantu menghilangkan kelebihan udara dari campuran beton dan memastikan distribusi yang merata.

Sensor dan Pemantauan: Beberapa mesin dilengkapi dengan sensor dan sistem pemantauan untuk memastikan bahwa proses pembuatan batako berjalan dengan benar dan memberikan hasil yang konsisten.

Peralatan Keselamatan: Ini meliputi fitur-fitur keselamatan seperti tombol darurat, sistem pengaman, dan pelindung lainnya untuk melindungi operator selama pengoperasian.

Panduan Pengguna dan Dokumentasi: Informasi mengenai penggunaan, perawatan, dan keselamatan biasanya disediakan dalam panduan pengguna atau dokumentasi dari produsen.

Sebelum menggunakan mesin press batako listrik, pastikan untuk membaca petunjuk penggunaan, memahami cara merawatnya, dan selalu mengikuti prosedur keselamatan yang telah ditetapkan.

Temukan dan cari kami di:

WEBSITE : https://jauramesin.com/

Youtube : https://www.youtube.com/@juaramesin/

IG : https://www.instagram.com/juaramesin/

Twitter : https://twitter.com/JuaraMesin/

FB : https://web.facebook.com/juaramesin

Call/Whatapp : 085 707 300 536 (admin Muhyi)

Terima kasih atas kunjungan anda di situs Juara Mesin produsen Mesin cetak batako dan paving, mesin bata ringan, mixer, conveyer dan mesin stone clusher pemecah batu serta mesin pelengkap lainnya.

#mesinpressbatakolistrik#mesincetakbatakohydrolik#mesincetakbatakosemiotomatis#mesincetakbatakootomatis#mesinpavingblockhidrolik#mesincetakpavingblocksemiotomatis#mesincetakpavinghydrolik#mesinpavingblock#mesinpavingotomatis#juaramesin

2 notes

·

View notes

Text

An Easy Guide To Conveyor System Design

So, you're aware that moving your product or material requires an efficient conveyor system. But, how can you tell if a conveyor is efficient? Also, how can you be confident that a machine already designed would work for your company? The easiest option is to hire a professional to design a bespoke system that fits your application perfectly.

The design of a conveyor system need not be complicated; even with a simple design, your automation line's efficiency can be enhanced.

Conveyor Systems

In addition to transporting products from A to B, a conveyor system has additional uses, such as sorting, chilling, and screening. A high-quality conveyor is an asset to any company, whether you're in the recycling, bulk processing, or metal casting industries.

Design of a Belt Conveyor

The following parts comprise a basic transfer belt conveyor system: a drive and tension mechanism for the flat belt, a transmission chain, a mechanism to place the work, and a system of sensors to detect work and manage the drive.

An essential part of any conveyor system is the mechanism for adjusting the belt tension. Here, the belt is held in place by the pulleys, and the bearing holders are placed on a roller plate. The belt alignment is maintained by the adjustment mechanism, which consists of a bracket for an adjusting screw and a block for positional adjustments. Driving the belt pulley is a chain-driven power transmission mechanism that transfers torque from the gearhead induction motor. A transfer conveyor belt's typical speed is slow and steady.

Building a Vibratory Conveyor

Using vibration, a vibratory conveyor system facilitates the transfer of items from one place to another. Conveyors typically have a smooth metal trough as their surface, which makes them more durable and suitable for transporting hot products.

There is a wide range of customization options for vibratory conveyors. The material is moved in the desired direction by vibrating the trough, which is connected to a network of reactor springs and an angled driving connection. It is possible to categorize vibrating conveyors according to their design and the tasks they perform.

Considerations for Conveyor Design

The following requirements must be considered during the design phase of your conveyor system:

· Rate of Performance

· Maximum limit on load capacity

· Expressing Rapidity

· Trough size

· Material

· Driving site

· Removable liner or replaceable trough

Obtaining the most effective conveyor system for your requirements requires careful consideration of these characteristics.

Different Sorts of Conveyors

A few examples of conveyor systems are vibratory, belt, roller, powered roller, magnetic, apron, and bucket. More options are available as well. When choosing a conveyor system, you need to think about the product or material you're moving because it will tell you what kind of system will keep your goods safe. Additionally, consider the features your system requires from the products or materials.

Is feeding or conveying necessary for your conveyor system?

Describe the setting in which you intend to implement this system.

Is it a building?

Is it a factory?

The great outdoors?

It is important to inform the manufacturer of any potential environmental factors that could affect the design of your system, such as humidity, temperature, and the presence of any dangerous or combustible chemicals in the region.

Simply put, a belt system transports goods by belts. Assuming the weights are manageable, the belt is looped between two pulleys and rests on rollers or a metal slider pan. Motors with reduction gears that allow for constant or variable speed supply the power for belt conveyor systems. Rubber, leather, plastic, cloth, and metal are just some materials used for belt conveyors, which can be employed horizontally or at an angle. Every product's unique characteristics dictate the material type chosen for transportation.

One advantage of conveyor systems is their adaptability. Vibratory conveyors come in various lengths and incorporate techniques to suit different applications. Depending on the application, vibratory conveyors can regulate the temperature and coat or dry the products as they move through the process. Vibration spiral conveyors can do the same job of raising or lowering goods.

Design Hints for Conveyors

Follow these guidelines regardless of whether you're using a belt, roller, overhead, or chute conveyor system:

1. First and foremost, safety must be prioritized.

You would like conveyor systems not to contribute to the ambient noise because they are typically situated in already active areas. Putting up a flat-stroke vibratory conveyor of an aging chain conveyor is one approach. Flat-stroke patterns and troughs that deaden noise achieve a silent and smooth material flow.

2. Make efficient use of the available area

When used properly, conveyors may efficiently use otherwise unused space, making them invaluable assets for tasks like loading and unloading products. Conveyors with a vibratory spiral design not only reduce floor space but also chill materials as they move them.

3. Remain straightforward.

Robots and other highly automated systems have their uses, but they can sometimes be prohibitively expensive and difficult to use.

4. Get setup and troubleshooting down to a minimum.

By integrating with a monitoring program, conveyors may frequently offer pre-programmed routines, significantly reducing maintenance and troubleshooting time.

5. Set your budget.

Before making a purchase, compare the prices of new, retrofitted, or refurbished conveyors to ensure you get the best deal.

In the end!

By keeping the aforementioned ideas and principles intact, no matter how you construct your conveyor, you can ensure the most efficient system for your product or material. However, it is pivotal to determine the nature of your industry before selecting a suitable conveyor design.

#This Summer#Guest Author#Guest Blogger#Guest Contributor#Guest Post#Guest Writer#Best Ways To Prevent The Most Common Plumbing Problems#Plumbing Problems#broken pipes#leaking pipes#clogged toilets#garbage disposals#prevent drains from clogging#plumber in tinley park#tinley park plumbers#plumber in orland park#orland park plumbers#plumber in homer glen#homer glen plumbers#plumber in frankfort#frankfort plumbers#plumber in mokena#mokena plumbers#plumber in lemont#lemont plumbers#plumber in new lenox#new lenox plumbers#plumber in oak forest#oak forest plumbers#plumber in homewood

0 notes

Text

Motor Replacement in San Diego: Ensuring Smooth Operation and Longevity

Motor replacement in San Diego is a critical service for maintaining the efficiency and longevity of various machines and systems. Whether it's for industrial machinery, automotive engines, or home appliances, replacing a motor can be a significant step towards ensuring that equipment runs smoothly and reliably. This article explores the importance of motor replacement, the signs that indicate a need for it, and the benefits it brings, especially in a bustling city like San Diego.

Why Motor Replacement is Crucial

Motors are the heart of any mechanical system. They convert electrical energy into mechanical power, driving everything from conveyor belts in factories to the compressors in refrigerators. Over time, motors can wear out or become less efficient due to factors like overuse, inadequate maintenance, or environmental conditions. In industrial settings, a failing motor can lead to decreased production efficiency and increased operational costs. In personal vehicles or home appliances, it can mean the difference between functionality and costly breakdowns.

Signs You Need Motor Replacement

Identifying the need for motor replacement before a complete failure occurs can save time, money, and stress. Here are some common signs that it might be time to consider replacing a motor:

Excessive Noise or Vibration: Unusual sounds or vibrations from a motor can indicate worn-out bearings, misalignment, or internal damage.

Overheating: Motors that overheat frequently despite proper use and ventilation may have internal issues that hinder performance.

Increased Energy Consumption: If a motor is drawing more power than usual, it could be struggling to perform its tasks, which can be a sign of wear or damage.

Consistent Performance Issues: Issues such as failing to start, experiencing frequent surges, or delivering inconsistent power are clear indicators that a motor might need replacing.

Choosing the Right Replacement Motor

When it comes to motor replacement in San Diego, selecting the right motor is essential for ensuring optimal performance and energy efficiency. Consider the following factors:

Type of Motor: Ensure the replacement motor matches the type required for the application, whether it’s an AC or DC motor, a stepper motor for precision tasks, or a powerful induction motor for heavy-duty operations.

Power Ratings and Size: The motor’s power output should align with the needs of the application to avoid underperformance or excessive energy consumption.

Efficiency Ratings: High-efficiency motors can reduce energy costs significantly, making them a worthwhile investment, especially in settings where motors run continuously.

Benefits of Timely Motor Replacement

Replacing a motor at the right time can lead to several benefits:

Reduced Energy Costs: Newer, more efficient motors require less energy to operate, which can lead to lower electricity bills.

Improved Performance: A new motor can restore equipment to its optimal performance, ensuring reliability and consistency in operations.

Longer Equipment Lifespan: Replacing a motor can extend the overall life of the machine it powers, delaying the need for complete equipment replacement.

Enhanced Safety: Old or failing motors can pose safety risks. New motors come with improved safety features and comply with current standards.

Finding Motor Replacement Services in San Diego

San Diego offers a variety of options for motor replacement services. When selecting a service provider, consider their reputation, the brands they carry, and their expertise in your specific type of motor. It’s also beneficial to choose providers who offer warranties and follow-up services to ensure that your new motor continues to operate efficiently.

Conclusion

Motor replacement is a crucial aspect of maintaining the operational integrity of machines and systems. In San Diego, where industries range from biotechnology to manufacturing, ensuring that your motors are in top condition is essential for business continuity and efficiency. By understanding when and why to replace motors, and choosing the right equipment and service provider, you can ensure that your operations remain smooth and cost-effective.

#spring replacement in san diego#garage door screen installation#gate installation san diego#door installation san diego#gate repair san diego#spring repair san diego

0 notes

Text

Exploring Force Springs and Slip Ring Induction Motors

In the realm of physics and engineering, force springs and slip ring induction motors represent important concepts and technologies that play pivotal roles in various applications, from mechanical systems to electrical machinery. Let's delve into the principles, functionalities, and applications of force springs and slip ring induction motors.

Force Springs:

Force springs, also known as mechanical springs, are elastic devices designed to store and release mechanical energy when subjected to external forces. They exhibit the fundamental properties of elasticity, providing resistance and exerting a force in response to deformation. Here are key aspects related to force springs:

Types of Force Springs: Force springs come in various types, including compression springs, tension springs, torsion springs, and leaf springs, each designed to withstand specific types of loads and deformations.

Functionality: The primary function of force springs is to absorb and store mechanical energy when compressed, stretched, or twisted, and release this energy when the applied force is removed.

Applications: Force springs find widespread applications in mechanical systems such as automotive suspensions, industrial machinery, consumer products (e.g., mattresses, door hinges), and aerospace components. They play crucial roles in damping vibrations, supporting loads, and maintaining stability.

Material Selection: Force springs are typically made from materials such as steel alloys, stainless steel, or non-ferrous metals, chosen for their strength, durability, and resilience to repeated loading cycles.

Design Considerations: Factors such as spring rate (stiffness), maximum load capacity, deflection range, and fatigue life are critical considerations in force spring design to ensure optimal performance and longevity.

Slip Ring Induction Motors:

Slip ring induction motors (also known as wound rotor induction motors) are a type of AC (alternating current) electric motor designed for applications requiring high starting torque and speed control. They differ from standard squirrel cage induction motors by incorporating slip rings and external resistors in the rotor circuit. Here's an overview of slip ring induction motors:

Principle of Operation: Slip ring induction motors operate on the principle of electromagnetic induction, where alternating current in the stator windings generates a rotating magnetic field. The rotor windings are connected to slip rings, allowing external resistance to be inserted into the rotor circuit.

Starting Characteristics: Slip ring induction motors exhibit high starting torque due to the ability to control rotor resistance. By inserting resistors into the rotor circuit during startup, motor speed and torque can be adjusted.

Speed Control: Slip ring motors offer speed control by varying the resistance in the rotor circuit. This feature makes them suitable for applications such as cranes, elevators, and conveyors requiring adjustable speed operation.

Applications: Slip ring induction motors are used in heavy industrial applications where high starting torque and speed control are essential, such as mining equipment, pumps, compressors, and large fans.

Advantages and Considerations: While slip ring induction motors offer advantages in torque control and speed adjustment, they require additional maintenance due to the presence of slip rings and brushes, compared to the maintenance-free operation of squirrel cage motors.

Conclusion

Force springs and slip ring induction motors represent essential components and technologies in mechanical and electrical engineering, respectively. Understanding their principles of operation, functionalities, and applications is crucial for designing and implementing efficient and reliable systems in various industries. By leveraging the capabilities of force springs and slip ring induction motors, engineers and designers can optimize performance, enhance control, and meet specific requirements in a wide range of mechanical and electrical applications.

0 notes

Text

BEI 924-01063-001 Industrial Encoder H25: Optimize Operations with High-Quality Precision

The Bei 924-01063-001 Industrial Encoder H25 is a robust and versatile device designed to provide accurate feedback in industrial automation systems. As an encoder, its primary function is to convert mechanical motion into electrical signals, enabling precise control and monitoring of machinery and equipment.

In the world of industrial automation, precision and reliability are paramount. And when it comes to precise motion control and feedback systems, the Bei 924-01063-001 Industrial Encoder H25 stands out as a trusted solution. In this guide, we'll delve into what makes this encoder special, its key features, applications, and why it's a crucial component in various industries.

Features of the Bei 924-01063-001 Industrial Encoder H25

High Precision: The H25 encoder boasts exceptional accuracy, allowing it to detect even the slightest movements with precision. This level of accuracy is essential for tasks requiring tight tolerances and fine control.

Durable Construction: Built to withstand harsh industrial environments, the H25 encoder features a rugged construction that ensures reliable performance even in demanding conditions. Its robust design protects it from dust, moisture, vibration, and temperature variations, ensuring longevity and reliability.

Versatile Compatibility: The H25 encoder is compatible with a wide range of industrial equipment and control systems, making it a versatile solution for various applications. Whether used in manufacturing, robotics, or motion control systems, the H25 encoder seamlessly integrates into existing setups, providing accurate feedback and control.

Incremental and Absolute Modes: The H25 encoder supports both incremental and absolute encoding modes, offering flexibility in how motion is tracked and monitored. Incremental encoding provides real-time feedback on movement, while absolute encoding offers precise position information, allowing for accurate positioning and motion control.

Easy Installation and Setup: Installing and configuring the H25 encoder is straightforward, thanks to its user-friendly design and intuitive setup process. With minimal effort, users can quickly integrate the encoder into their systems and start benefiting from its precise feedback capabilities.

Applications of the Bei 924-01063-001 Industrial Encoder H25

Manufacturing: In manufacturing environments, the H25 encoder plays a vital role in controlling conveyor systems, robotic arms, CNC machines, and other equipment requiring precise motion control. Its high precision and durability make it well-suited for tasks such as positioning, speed control, and synchronization.

Robotics: In robotic applications, the H25 encoder provides accurate feedback on joint positions, enabling robots to perform precise movements and tasks with efficiency and reliability. Whether used in industrial robots, automated guided vehicles (AGVs), or collaborative robots (cobots), the H25 encoder ensures optimal performance and safety.

Motion Control Systems: Motion control systems rely on encoders like the H25 to accurately track and control the movement of motors, actuators, and other components. From servo drives to linear motion systems, the H25 encoder enhances the performance and accuracy of motion control applications across various industries.

Packaging and Material Handling: In packaging and material handling applications, the H25 encoder facilitates precise control of conveyors, sorting systems, and packaging machines. Its high precision and reliability ensure smooth operation and efficient handling of goods, contributing to increased productivity and throughput.

Renewable Energy: The H25 encoder finds applications in renewable energy systems such as wind turbines and solar trackers, where it helps optimize the performance and efficiency of power generation equipment. By accurately tracking the position and movement of turbine blades or solar panels, the H25 encoder ensures maximum energy capture and output.

Benefits of Using the Bei 924-01063-001 Industrial Encoder H25

Improved Precision: With its high accuracy and resolution, the H25 encoder enables finer control and positioning accuracy, resulting in improved product quality and consistency.

Enhanced Reliability: The rugged construction and robust design of the H25 encoder ensure reliable performance in challenging industrial environments, minimizing downtime and maintenance costs.

Versatile Performance: From precise motion control to position feedback, the H25 encoder offers versatile performance across a wide range of applications, making it a valuable asset in diverse industrial settings.

Easy Integration: With its compatibility with standard interfaces and protocols, the H25 encoder can be seamlessly integrated into existing systems without the need for extensive modifications or programming.

Cost-Effective Solution: Despite its advanced features and capabilities, the H25 encoder provides excellent value for money, offering reliable performance and longevity at a competitive price point.

Why Choose the Bei 924-01063-001 Industrial Encoder H25?

Reliability: Built to withstand harsh industrial environments, the H25 encoder offers reliable performance even in the most demanding conditions.

Accuracy: With its high-resolution sensing technology, it provides precise position feedback, ensuring accurate motion control and positioning.

Versatility: The H25 encoder's multiple output options and wide operating temperature range make it suitable for a wide range of industrial applications.

Ease of Integration: Its simple installation and standard electrical connections make it easy to integrate into existing systems, minimizing downtime and installation costs.

BEI 924-01063-001 Industrial Encoder H25 is a powerhouse of performance and reliability, making it the encoder of choice for industrial automation applications. With its advanced features, rugged construction, and versatile design, it provides unparalleled precision and durability in the most demanding environments. Whether you're in manufacturing, material handling, automotive, renewable energy, or packaging, the H25 encoder is sure to exceed your expectations and deliver superior results.

0 notes

Text

Efficient Solutions: Explore Our Belt Conveyors for Sale Today

In today's fast-paced industrial landscape, efficiency is key to success. Businesses across various sectors rely on streamlined processes to maintain competitiveness and meet the demands of a dynamic market. At our company, we understand the critical role that efficient material handling plays in driving productivity and profitability. That's why we offer a wide range of belt conveyors for sale, designed to optimize material transport and streamline operations in diverse industries.

Our belt conveyors are engineered with precision and durability in mind, ensuring reliable performance even in the most demanding environments. Whether you're in mining, manufacturing, agriculture, or logistics, our conveyors are built to meet your specific needs and exceed your expectations.

Optimized Efficiency:

Our belt conveyors are equipped with advanced features to maximize efficiency in material handling processes. Variable speed controls allow for precise adjustment of conveyor speed, optimizing throughput and minimizing energy consumption. Additionally, automated sorting systems enable seamless integration with downstream processes, ensuring smooth material flow and minimizing bottlenecks.

Customization Options:

We understand that every business is unique, with its own set of challenges and requirements. That's why we offer customizable belt conveyor solutions tailored to your specific needs. From adjustable heights and inclines to varying belt widths and lengths, we work closely with our clients to design conveyor systems that seamlessly integrate into their operations and deliver maximum value.

Reliability and Durability:

When it comes to material handling, reliability is paramount. Our belt conveyors are built to withstand the rigors of daily operation, with robust construction and high-quality components. Whether you're transporting bulk materials, heavy loads, or delicate products, you can trust our conveyors to deliver consistent performance day in and day out.

For More:

Contact:0488 199 079

Email: [email protected]

Timings: Mon-Fri: 8:30am–5pm

Visit us: https://www.hudsolutions.com.au/

For More:Contact:0488 199 079Email: [email protected]: Mon-Fri: 8:30am–5pmVisit us: https://www.hudsolutions.com.au/

0 notes

Text

What are the locations on industrial equipment where ACF materials can be applied?

ACF artificial cartilage material has a wide range of applications in the industrial field, and its unique vibration and noise damping properties make it play an important role in many key locations of equipment and machines. The following are some of the locations where ACF materials can be applied in industrial fields or equipment:

Equipment base and support structure: The equipment base and support structure are the main transmission path of vibration. By using shock pads, shock absorbers or support structures made of ACF materials in these locations, the vibration of the equipment can be effectively reduced and the stability of the equipment can be improved.

Rotating parts and bearings: For high-speed rotating parts, such as motors, pumps, fans, etc., the vibration and noise generated by their rotation have a great impact on the performance and life of the equipment. The use of ACF material in the base or bearing of these parts to make a shock absorbing ring can effectively reduce vibration and noise and improve the operating efficiency of the equipment.

Precision instruments and equipment: For equipment that requires high-precision operation, such as semiconductor manufacturing equipment and optical instruments, any small vibration may affect the performance of the equipment. Using ACF material as a vibration damping element in these equipments ensures that the equipments operate in a stable environment and improves the quality of the products.

Robotic arms and conveyor belts: In automated production lines, vibration in robotic arms and conveyor belts can affect product positioning and transfer accuracy. By applying ACF materials to these components, vibration can be reduced and the line can operate more efficiently.

Automotive and aerospace components: ACF materials are also widely used in the automotive and aerospace fields, such as vibration-damping supports for automotive engines, turbine blade supports for aviation engines, and so on.

Bridges and building structures: In bridges, high-rise buildings and other structures, the use of ACF materials as a shock-absorbing element can reduce vibration caused by earthquakes or wind loads, and improve the stability and safety of the structure.

It should be noted that the specific application location and parameters of ACF materials can be determined and adjusted according to the structure, vibration characteristics and performance requirements of the equipment. In the actual application, the overall design of the equipment, the working environment, service life and other factors need to be considered to ensure that ACF materials can play the best vibration damping, noise reduction, sealing, lightweight effect.

400-6543-699

www.acf.com

0 notes

Text

Rotary Four Head and Six Head ROPP Capping Machine

Shiv Shakti Machtech operates as a Manufacturer, Exporter, and Supplier of Rotary Four Head and Six Head ROPP Capping Machines.

Shiv Shakti Machtech manufactures Rotary Four Head and Six Head ROPP Capping Machines, offering precision and efficiency in the bottling and packaging industry.

The Rotary Four Head and Six Head ROPP Capping Machine exemplifies Shiv Shakti Machtech's dedication to innovation and excellence in bottle capping technology.

Product Specification:

Automation Grade: Automatic

Capacity: 80 bottles per minute (BPM)

Driven Type: Electric

Brand: Shiv Shakti Machtech

Direction Of Movement: Left to Right

Electrical Specification Cap Feeding Vibrator: Vibrating Bowl

Electrical Specification Main Motor: 2 HP

Phase: 1 Phase

Change parts required: Additional cost for different cap sizes

I Deal In: New Only

Country of Origin: Made in India

Machine Features:

Feed Conveyor System: Ensures smooth and consistent bottle feeding to the capping station, minimizing disruptions.

Bottle Gripper Assembly: Holds bottles securely during capping, ensuring precise positioning for a quality cap seal.

Four and Six Capping Heads: Equipped with specialized ROPP capping mechanisms, swiftly and accurately securing caps onto bottle necks.

Torque Adjustment System: Allows customization of cap tightness to meet product requirements, maintaining freshness and integrity.

Control Panel: User-friendly interface for adjusting settings and monitoring production in real time, enhancing operational control.

Safety Features: Emergency stop buttons and sensor-based safeguards prioritize operator and machine safety during operation.

Applications:

Ideal for various industries requiring efficient and precise bottle capping, ensuring product integrity and production efficiency.

Shiv Shakti Machtech is Supplier of Rotary Four Head and Six Head ROPP Capping Machine in Ahmedabad, Gujarat, India and including locations like

Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chandigarh, Chhattisgarh, Dadra and Nagar Haveli, Daman and Diu, Delhi, Goa, Gujarat, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Ladakh, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Nagaland, Odisha, Puducherry, Punjab,

Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, West Bengal.

For further details, please feel free to contact us.

Read the full article

#Ahmedabad#AndhraPradesh#ArunachalPradesh#Assam#Bihar#Chandigarh#Chhattisgarh#DadraandNagarHaveli#DamanandDiu#Delhi#Exporter#Goa#Gujarat#Haryana#HimachalPradesh#India#JammuandKashmir#Jharkhand#Karnataka#Kerala#Ladakh#MadhyaPradesh#Maharashtra#Manipur#Manufacturer#Meghalaya#Nagaland#Odisha#Puducherry#Punjab

1 note

·

View note

Text

Fully Automatic Concrete Block Making Machine in Karnataka

Company Overview:

Robexo Industries is a manufacturer and supplier in Karnataka, India, specializing in Fully Automatic Concrete Block Making Machine.

Since 2015, the company has been producing construction machinery that meets international standards.

Manufacturers utilize a fully automatic concrete block making machine as specialized equipment to produce concrete blocks in large quantities with high efficiency and precision.

It operates on an automated system for accurate positioning, feeding, and molding of concrete blocks.

Components include a hopper, conveyor belt, mixer, molding machine, palletizer, and stacking unit.

Process:

Mixing: The machine mixes concrete ingredients like cement, sand, and water in precise proportions.

Molding: It molds the concrete mixture into blocks of desired shape and size.

Curing: Blocks are cured to allow concrete to harden and gain strength.

Palletizing: The palletizer stacks cured blocks on wooden pallets for transportation and storage.

Benefits:

Increased production capacity, reduced labor costs, and improved product quality.

Can produce various types of concrete blocks, including hollow blocks, solid blocks, interlocking blocks, and paving stones.

Product Specification:

Height of Finished Products: 50-200 mm

Pallet Size: 950 x 730 mm

Production Area: 910 x 690 mm

Cycle Time: 15-20 S (as per mold)

Vibration Force: 70 KN

Overall Dimension: 8200 (L) x 4600 (W) x 2800 mm (H)

Total Weight: 10.5 T

Motor Frequency: 5-60 Hz

Application:

Various industries and sectors utilize the machine, including construction, infrastructure development, landscaping, urban development, and more, for residential, commercial, and industrial projects requiring concrete blocks.

Geographical Coverage in Karnataka:

Robexo Industries provides Fully Automatic Concrete Block Making Machine in various cities of Karnataka, including Badami, Belagavi, Chamarajanagar, Bhadravati, Bidar, Hassan, Bagalkot, Chikkamagaluru, Kalaburagi, Kolar, Ballari, Bangalore Rural, Dakshina Kannada, Haveri, Kodagu, Bengaluru, Davangere, Halebid, Hubballi-Dharwad, Madikeri, Mandya, Mangaluru, Chitradurga, Vijayapura, Gadag, Tumakuru, Mysuru, Raichur, Shivamogga, Shravanabelagola, Shrirangapattana, Ramanagara, and Kittur.

For detailed information and inquiries, please feel free to contact us.

Read the full article

#Badami#Bagalkot#Ballari#BangaloreRural#Belagavi#Bengaluru#Bhadravati#Bidar#Chamarajanagar#Chikkamagaluru#Chitradurga#DakshinaKannada#Davangere#Exporter#FullyAutomaticConcreteBlockMakingMachine#FullyAutomaticConcreteBlockMakingMachineinKarnataka#Gadag#Halebid#Hassan#Haveri#Hubballi-Dharwad#India#Kalaburagi#Karnataka#Kittu#Kodagu#Kolar#Madikeri#Mandya#Mangaluru

0 notes

Text

Exploring the Power and Efficiency of Brushless DC Motors: Revolutionizing Industry in Australia

Brushless DC motors, or BLDC motors, are a type of electric motor that uses electronic commutation instead of brushes and commutators. This means they have less friction, noise, maintenance, and higher efficiency than conventional brushed motors. Brushless DC motors are widely used in applications that require high speed, high torque, and precise control, such as robotics, electric vehicles, appliances, and industrial automation systems.

But what makes BLDC motors so powerful and efficient? How do they work, and what are their advantages? In this blog post, we will explore the basics of BLDC motors, their benefits, and their applications in various industries in Australia.

How do BLDC motors work?

BLDC motors consist of two main parts: the rotor and the stator. The rotor is the rotating part that has permanent magnets attached to it. The stator is the stationary part that has coils of wire wound around it.

The coils are connected to an electronic controller that switches the current to the coils based on the position of the rotor. It creates a magnetic field that rotates in space and attracts the rotor magnets, causing the rotor to spin.

The electronic controller also adjusts the motor's speed and torque by varying the current pulses' frequency and amplitude. The controller can also receive feedback from sensors that monitor the speed and position of the rotor, allowing for more precise and responsive control.

What are the benefits of BLDC motors?

Brushless DC motors have many advantages over brushed motors, such as:

Higher efficiency: BLDC motors can convert up to 90% of the electrical energy into mechanical energy, compared to 75% for brushed motors. It means they consume less power and generate less heat, reducing operating costs and extending the motor's lifespan.

Higher power-to-weight ratio: BLDC motors can deliver more power with less weight and size, thanks to their compact design and high-performance magnets. This makes them ideal for applications that require high power density and low inertia, such as drones, electric bikes, and medical devices.

Higher speed and torque: BLDC motors can operate up to 100,000 rpm and produce high torque even at low speeds. This enables them to accelerate and decelerate quickly and to handle variable loads and sudden changes in demand, such as in CNC machines, pumps, and fans.