#open source 3d printed robot

Explore tagged Tumblr posts

Text

Top Open-Source 3D-Printed Robot Projects | Petoi LLC

OpenBot is a 3D-printed robot designed by Intel. The robot uses your smartphone and can navigate autonomously. It can also track and follow people using the Mobilenet SSD detection model that computes the output bounding box and class of an object from an input image. The performance of OpenBot may be limited as the robot uses a smartphone as its CPU.

#3D-Printed Robot Projects#3d printed robot projects#robot 3d print#open source 3d printed robot#open source robot 3d print

0 notes

Text

Source list for Fulfilled virgin

hello everyone. I published the first version of a new zine few weeks ago at Helsinki zine fest. In the spirit of everything I do, I forgot to add my sources when I printed the piece, so I have it here. peace and love. you can also consider this a teaser for the project. I will hopefully open internal shipping for an edited version of this lil passion project next month :3

"Bishōjo Games: ‘Techno-Intimacy’ and the Virtually Human in Japan" - Patrick W. Galbrait (Short text which digs deep into emotions and relationships formed around dating visual novels)

Japan’s emerging emotional tech - Daniel White, Patrick W Galbraith (similar as previous)

The Moe Manifesto - Patrick W. Galbrait (Interview collection of big names in turn of the milenium moe and otaku culture)

Relational artifacts with children and elders: the complexities of cybercompanionship - Sherry Turkle (this was the holly grail for me. extremely interesting read on the relationships children and the elderly built with pet robots)

Varieties of Tulpa Experiences: The Hypnotic Nature of Human Sociality, Personhood, and Interphenomenality - Samuel Veissiere

The affective and affectless bodies of monster toon porn - Susanna Paasonen (about the simultaneous pull and distance consuming porn is, i love paasonen)

Also big love toward artificialnightsky for his research on Toru Honda. Love is dead, long live the otaku.

Wikipedia: Train man, Akihiko Kondo, Tsutomu Miyazaki, AIBO

News articles:

The man who married a hologram in Japan can no longer communicate with his virtual wife

Porn-induced erectile dysfunction is not real.

Consuming 2D and 3D hentai does not lessen interest in real women.

"Porn addiction" isn't real.

#I'm trying to get back here. it's been an intense summer and year. not much time for myself. but trying to change that finally.#thank you all for support for my stuff <3

20 notes

·

View notes

Text

FLUID, an open-source, 3D-printed robot, offers an affordable and customizable solution for automated material synthesis, making advanced research accessible to more scientists. A team of researchers led by Professor Keisuke Takahashi at the Faculty of Science, Hokkaido University, have created FLUID (Flowing Liquid Utilizing Interactive Device), an open-source robotic system constructed using a 3D printer and off-the-shelf electronic components. To demonstrate FLUID's capabilities, the team used the robot to automate the co-precipitation of cobalt and nickel, creating binary materials with precision and efficiency. "By adopting open source, utilizing a 3D printer, and taking advantage of commonly-available electronics, it became possible to construct a functional robot that is customized to a particular set of needs at a fraction of the costs typically associated with commercially-available robots," said Mikael Kuwahara, the lead author of the study.

Read more.

#Materials Science#Science#3D printing#Electronics#Reactions#Materials synthesis#Hokkaido University#Liquids

9 notes

·

View notes

Text

“Radiating Kindness (Oil)”, 2023, Oil on linen

“Bold Glamour”, 2023, Digital print on linen

For AI Paintings, Matthew Stone‘s 2023 exhibition at The Hole’s Lower East Side location, he explored new ways of using the latest technology while expanding on techniques used in his previous digital creations.

Details from The Hole about this exhibition-

Two LED screens form the center of this show, displaying an unedited stream of novel AI outputs; a new painting every ten seconds. Corresponding in scale to the surrounding works on linen and functioning like smart canvases, these AI paintings transform endlessly and if you’re alone in the gallery, you will be the only person to ever see that version of the artwork.

Stone’s AI paintings—both the tangible on linen and the fleeting screenic pieces—are created through his training of a custom AI model on top of Stable Diffusion’s open source, deep learning, text-to-image model. By feeding it only his past artworks, Stone has created a self-reflexive new series of AI works that disintegrates the hegemony of the singular static masterpiece and problematizes the idea of ownership, or even what “the artwork” itself entails.

AI has become part of contemporary culture, used to solve real world problems and also create TikTok filters. It’s a tool and like a paintbrush it can be used skillfully or not. At the moment AI is throwing the art world into upheaval as artists explore its potential, galleries contend with its disruption of technique and presentation and collectors and museums feel the dissolution of authorship and ownership.

A second type of work makes its debut here, Radiating Kindness (Oil), a 3D printed, machine-assisted oil painting made in collaboration with ARTMATR labs in Red Hook, where MIT artists and engineers have come together to make innovative tools and tech. By leveraging AI, robotics, computer vision and painting scripts, their robot has created a traditional oil painting in three dimensions. You can see on the surface how the interplay between analog and digital mark making is eye-boggling.

The show also includes examples of Stone’s “traditional” technique, which is anything but: on the 13-foot wide linen painting, Irradiance, four nude figures dance over piles of strewn AI paintings. The figures in the foreground, reminiscent in choreography of Henri Matisse’s Dance (La Dance), 1910, are bodacious, athletic women, heavy and sexy like a Michelangelo marble while at the same time futuristic, weightless and splendid in impossible glass and metallic brush marks. Here Stone’s circular and sensitive approach is laid bare for the viewer, the references to art history, technology, culture, access and the pursuit for the intangible is almost overwhelming to grasp.

Stone’s approach points to the deeply interwoven nature of our offline and online lives today. He sees artists’ use of new technologies as necessary, with creatives deploying these tools in a manner that’s not motivated by big tech or financial gains, disrupting the algorithm by creating their own and exploring this new frontier without data-driven deliverables. Creating new context and room for human subjectivities and emotion in the shift from analog to digital that arguably has already occurred.

Below, in an interview for The Standard, he discusses using AI for this work further-

When working with AI, do you sometimes feel overwhelmed or do you always feel in control? I have never felt fully in control while making art and I’ve always been back and forth between wanting to be and understanding the transformative and creative power of just letting go. The most exciting moments in my creative process have often been unexpected mistakes. Those happy mistakes have revealed something that can then be consciously amplified. Using AI creates lots of unexpected outcomes very fast. So as someone who likes accidents in this context of image making, it’s a good way to become accident-prone.

Do you consider AI as just another digital tool? Or does it feel more like a collaboration? In other words, do you sometimes feel AI might develop its own taste, point of view, conscience? It’s a digital tool and I try to resist the urge to anthropomorphize it. But it’s difficult because it feels like such a paradigm shift and also sometimes like dreaming. I think that culturally speaking, we are moving in a direction that assigns these qualities of perceived sentience to AI even when more mundane actions are at play. It’s not clear to me how we will tell if AI has achieved general intelligence, but I think most people will assume it to be the case long before it actually happens, assuming that it does.

#Matthew Stone#The Hole#AI#AI Model#Painting#The Hole Gallery#AI Painting#ARTMATR#Art#NYC Art Shows#Art Show#Digital Art#Flashback#Henri Matisse#Mixed Media Art#Stable Diffusion#The Standard#FKA twigs#Flashback Friday#FBF

3 notes

·

View notes

Text

Top 5 Factors to Consider Before Buying an Electric Motor

Electric motors are the heart of modern machinery, powering everything from household appliances and HVAC systems to industrial equipment and electric vehicles. With a wide variety of types, sizes, and applications, choosing the right electric motor is critical to ensuring optimal performance, efficiency, and long-term reliability.

Whether you're an engineer selecting a motor for an industrial process or a buyer sourcing for a product design, making an informed decision can significantly impact your project’s success. Here are the top five factors you must consider before buying an electric motor.

1. Power and Torque Requirements

The first and most essential consideration is understanding the power and torque your application requires. Power is usually specified in kilowatts (kW) or horsepower (HP), while torque determines the motor’s ability to rotate a load.

To make the right selection:

Calculate the load the motor will drive and the required operating speed (RPM).

Use the torque = (Power × 9550) / RPM formula for sizing.

Avoid underpowered motors, which can overheat and fail prematurely, or overpowered motors, which waste energy and increase operational costs.

Understanding the duty cycle (how often and how long the motor will run) is also crucial when evaluating performance needs.

2. Type of Electric Motor

Different motors serve different functions. Choosing the right type of electric motor ensures that your equipment operates efficiently and effectively.

Common types include:

AC Motors (Synchronous and Induction): Widely used in industrial and household applications.

DC Motors: Ideal for applications needing variable speed control or high torque at low RPMs.

Stepper Motors: Used for precise movement control in robotics and 3D printing.

Brushless DC (BLDC) Motors: Common in electric vehicles and high-efficiency systems.

Each type has unique advantages and limitations based on speed control, torque characteristics, and maintenance needs.

3. Energy Efficiency and Operating Costs

In today’s energy-conscious world, motor efficiency is a major consideration. Motors account for a significant portion of industrial energy consumption, and inefficient models can increase your electricity bill over time.

When evaluating efficiency:

Look for motors rated under IE2, IE3, or IE4 standards (International Efficiency classes).

Consider Variable Frequency Drives (VFDs) to adjust speed and reduce energy waste in variable load applications.

High-efficiency motors may have a higher upfront cost but offer long-term savings through reduced energy consumption.

Also, check for government incentives or regulatory requirements for using energy-efficient motors in your region.

4. Mounting and Size Constraints

Physical dimensions and mounting configuration are often overlooked, yet crucial. The motor must fit into your equipment or designated space, and the mounting method should match your installation requirements.

Key factors to assess include:

Frame size and shaft dimensions.

Mounting type (foot-mounted, flange-mounted, face-mounted).

Enclosure type (open, drip-proof, or totally enclosed fan-cooled) based on the operating environment.

Ensure that the motor’s dimensions and mounting style are compatible with your mechanical system to avoid costly modifications.

5. Environmental Conditions and Protection Needs

The environment in which the motor operates greatly affects its durability and performance. Exposure to dust, moisture, chemicals, or high temperatures may require specialized features.

Consider:

IP rating (Ingress Protection) for dust and water resistance.

Ambient temperature and altitude where the motor will be used.

Whether the motor needs explosion-proof or corrosion-resistant features for hazardous locations.

Choosing a motor built for your environment will increase lifespan, reduce maintenance, and ensure safety and compliance.

Conclusion

Selecting the right electric motor involves more than just picking a power rating off a catalog. By taking the time to consider these five key factors—power and torque, motor type, energy efficiency, physical fit, and environmental suitability—you ensure better performance, energy savings, and reliability for your application.

With electric motors playing such a critical role in industrial and commercial operations, making an informed choice is an investment in both productivity and sustainability.

0 notes

Text

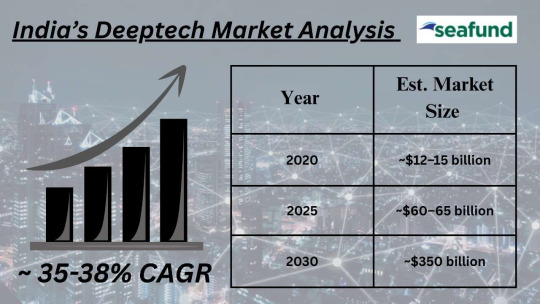

The Rise of Deeptech Startups in India: How Deeptech Funding is Shaping the Future of Innovation

India’s Deeptech Ecosystem: Startups, Investments, and Strategic Growth The Indian deeptech ecosystem has emerged as a powerhouse of innovation, driven by advancements in artificial intelligence, semiconductor design, space technology, and robotics. Over the past three months, the sector has witnessed significant funding inflows, strategic government interventions, and breakthroughs in research commercialization. Startups are leveraging cutting-edge technologies to address both domestic and global challenges, supported by a gro wing network of venture capital firms and policy frameworks. This report examines the current state of deeptech in India, analyzing key sectors, investment trends, and the interplay between public and private stakeholders shaping the future of this dynamic landscape. Know More

Key Sectors Driving Deeptech Innovation

Artificial Intelligence and Multi-Agent Systems AI startups are moving beyond conventional SaaS solutions to build core, infrastructure-level innovations. Alchemyst AI, for instance, is creating multi-agent systems that can embed into enterprise processes. Its AI system, Maya, is designed to act as a digital co-worker in sales development teams, automating complex tasks while enabling more coordinated workflows. Another rising player, Deceptive AI, is pushing the envelope on AGI with advanced capabilities in image synthesis and semantic segmentation, targeting use cases in fashion, media, and design. India’s AI sector is steadily evolving from end-user applications toward fundamental research and systems development with practical, cross-sector deployment potential.

Semiconductor and Hardware Innovation Hardware innovation in India is gaining ground. Mindgrove Technologies reached a key milestone by taping out a 28nm Secure-IoT chip earlier this year. Built using the open-source Shakti core from IIT Madras, this chip has applications in automotive electronics and consumer devices, offering a homegrown alternative to imported components. Government programs such as the Design Linked Incentive (DLI) are playing a critical role by supporting fabless startups and covering R&D costs. Meanwhile, Agnikul Cosmos has demonstrated engineering ingenuity by launching the first rocket powered by a single-piece 3D-printed engine—an achievement that speaks volumes about India’s growing stature in aerospace and additive manufacturing. Read More

Quantum Computing and Robotics Startups in quantum computing are beginning to explore solutions in optimization and cryptographic security, though most applications are still in the lab phase. Robotics, on the other hand, is seeing more immediate commercialization. Sedeman Mechatronics, a venture incubated at IIT Bombay, recently filed for an IPO to raise between ₹800–1,000 crore, aiming to scale its industrial automation systems. Its work in precision manufacturing is especially aligned with national goals like “Make in India” and the growing interest in dual-use technologies that can support both civilian and defense sectors. Explore

Government Initiatives and Policy Support

₹10,000 Crore Fund of Funds for Deeptech A major push came in April 2025 when Commerce Minister Piyush Goyal announced a ₹10,000 crore Fund of Funds to channel long-term capital into early-stage deeptech ventures. Administered by Small Industries Development Bank of India (SIDBI), the scheme focuses on startups working in AI, quantum computing, robotics, and biotech. The initial allocation of ₹2,000 crore is aimed at supporting ventures navigating the difficult transition from lab research to market readiness. This scheme adds to existing initiatives like the Indian Semiconductor Mission (ISM), which backs fabless innovation through grants and collaborative infrastructure.

Academic-Industry Collaboration Institutions such as IIT Madras and IIT Bombay continue to play an outsized role in pushing new ideas from research labs into commercial ecosystems. The Shakti processor project, which powered Mindgrove’s chip, is a prime example of academic innovation meeting market demand. The National Deep Tech Startup Policy (NDTSP) is also expected to ease IP licensing processes and promote closer ties between universities and startups. Over half of India’s deeptech ventures originate from academic environments, making these institutional linkages essential for sustained progress.

Investment Trends and Venture Capital Activity

Surge in Early-Stage Funding Deeptech investments reached $324 million across 35 deals in the first four months of 2025, doubling from $156 million in the same period in 2024. Notable deals include:

Netradyne raised $90 million for its AI-driven fleet management platform.

SpotDraft secured $54 million to expand its AI-based contract management solutions.

Tonbo Imaging garnered $21 million for advanced thermal imaging systems used in defense and automotive sectors.

Generalist funds like Peak XV Partners (formerly Sequoia India) and Blume Ventures are increasingly backing deeptech, diversifying from their traditional SaaS focus. Sector-specific funds like Seafund continue to lead early-stage rounds, with a portfolio emphasizing AI, IoT, and healthcare technologies.

Public Market Momentum The IPO pipeline reflects growing maturity, with MTAR Technologies and Tata Technologies emerging as top gainers in the deeptech sector, posting returns of 2.3% and 1.4%, respectively. Conversely, Olectra Greentech saw a 6.6% decline, highlighting volatility in clean-tech segments amid subsidy revisions.

Seafund’s Role in Shaping the Future of Deeptech Startups in India Seafund, a Bengaluru-based venture capital firm, is at the forefront of supporting India’s deeptech revolution. With a Rs 250 crore Fund II, Seafund plans to invest in 18-20 deeptech startups by FY27, focusing on areas like AI SaaS, mobility, sustainability, semiconductors, and clean energy.

Investment Strategy Seafund’s approach includes:

Early-Stage Focus: Investing from pre-seed to pre-Series A rounds, enabling startups to develop and refine their technologies.

Strategic Support: Providing mentorship, market access, and growth strategies to help startups scale effectively.

Sustainability Commitment: Allocating 20% of its corpus to clean energy and mobility startups, reflecting a commitment to sustainable innovation.

Portfolio Highlights Seafund has already invested in several deeptech startups:

RedWings: Specializes in drone logistics, aiming to revolutionize delivery systems.

Docker Vision: Utilizes AI-driven computer imaging to enhance port operations by accelerating the mobility of shipping containers and assessing their conditions in real-time.

Swapp Design: Develops modular battery swapping solutions using autonomous robots, facilitating efficient energy management for electric vehicles.

Simactricals: Focuses on wireless EV charging technologies, aiming to simplify and expedite the charging process for electric vehicles.

CalligoTech: Develops POSIT-based accelerator hardware for high-precision, low-power HPC solutions seamlessly integrated into enterprise systems.

TakeMe2Space: Builds affordable, radiation-shielded LEO satellites with onboard compute capabilities to power next-gen space-based AI applications.

These investments reflect Seafund’s commitment to fostering innovation in critical areas of deeptech, positioning India as a leader in technological advancements. Read More

Future Outlook and Strategic Recommendations

Projected Growth and Global Leadership Inc42 forecasts a 40% CAGR for India’s deeptech sector through 2027, driven by advancements in AI, quantum computing, and space tech. By 2030, the ecosystem is expected to contribute $350 billion to GDP, with startups transitioning from “lab-to-market” at unprecedented scale. Key drivers include:

Increased participation from generalist funds at Series A and beyond.

Expansion of design-linked incentives for semiconductor startups.

Growth in cross-border partnerships, particularly with Japan and the EU in robotics and IoT.

Policy Interventions for Sustained Growth

Accelerate Fund Disbursements: Simplify approval processes for the Fund of Funds to ensure timely access to capital.

Strengthen IP Frameworks: Introduce fast-track patent approvals and tax breaks for IP-driven startups.

Enhance Corporate Engagement: Mandate PSUs (Public Sector Undertakings) to allocate 5% of procurement budgets to deeptech solutions.

India’s deeptech ecosystem stands at an inflection point, buoyed by technological breakthroughs, strategic funding, and policy tailwinds. While challenges like funding gaps and adoption barriers persist, the convergence of academic excellence, entrepreneurial vigor, and global demand positions the country as a future leader in frontier technologies. The next decade will hinge on translating innovation into economic impact, ensuring that deeptech becomes a cornerstone of India’s $10 trillion GDP ambition.

FAQs:

What makes deeptech startups different from regular tech startups? Deeptech startups in India focus on building solutions grounded in advanced scientific research or engineering innovation. Unlike typical tech startups that often rely on existing platforms or business model tweaks, deeptech ventures tackle fundamental problems using technologies like AI, robotics, quantum computing, or space tech—usually requiring longer development timelines and more R&D funding.

Why is deeptech funding on the rise in India now? The sharp rise in deeptech funding—up 78% in 2024—is driven by global demand for advanced technologies, India’s skilled engineering talent pool, and supportive policies. There’s growing investor confidence that Indian startups can build globally competitive solutions in AI, semiconductors, and clean energy, pushing capital into this high-impact sector.

Which deeptech sectors are currently showing the most potential in India? Key areas seeing strong traction include artificial intelligence, which attracted 87% of all deeptech funding in 2024, as well as space tech, quantum computing, robotics, and semiconductors. These fields not only offer commercial potential but also strategic importance for India’s technological self-reliance and global positioning.

What challenges are holding back the growth of deeptech startups in India? The biggest hurdles include a shortage of deeptech talent, long development cycles, and regulatory complexity. Deeptech ventures also face difficulties in accessing early-stage capital due to the technical risk and slower path to profitability, making targeted government and ecosystem support crucial.

Have insights or bold ideas? Drop your thoughts, and let’s shape the next wave of innovation together!

Lets Connect!!

#Keywords#venture capital company#investment in startups#funding for startups#private equity venture capital#capital venture investors#stages of venture capital financing#venture capital investment#venture capital investors#venture capital firm#venture capital firms in india#leading venture capital firms#india alternatives investment advisors#best venture capital firms in india#early stage venture capital firms#venture capital investors in india#early stage investors#seed investors in bangalore#invest in startups bangalore#business investors in kerala#funders in bangalore#startup investment fund#seed investors in delhi#private equity firms investing in aviation#venture investment partners#venture management services#defense venture capital firms#popular venture capital firms#funding for startups in india#early stage funding for startups

0 notes

Text

When Tech Meets Green. How Innovation is Driving Sustainable Change

Beneath the surface of our climate crisis lies an unexpected ally: technology. Far from being part of the problem, smart technological solutions are quietly revolutionizing how businesses approach environmental challenges. What was once considered futuristic is now helping companies reduce waste, conserve resources, and operate more responsibly — often while improving their bottom line.

Eric Hannelius, CEO of Pepper Pay, observes this transformation daily: “We’re seeing fintech solutions that make sustainable choices easier for both businesses and consumers. From carbon footprint calculators embedded in banking apps to rewards for eco-friendly purchases, technology is removing the friction from doing good.”

The Invisible Revolution in Resource Management.

Modern sensors and AI are turning waste reduction into a science. Smart buildings now adjust lighting and temperature in real-time based on occupancy. Agricultural drones precisely target water and fertilizers only where needed. Even garbage trucks are getting smarter — some cities use AI-powered routing to optimize collection routes, reducing emissions by up to 40%.

The beauty lies in how these solutions often pay for themselves. A textile manufacturer recently installed water-recycling technology that cut their utility costs by a third while reducing consumption. “The best sustainability tech doesn’t ask businesses to choose between planet and profit,” notes Eric Hannelius. “It delivers both.”

Energy’s Digital Transformation.

Renewable energy gets most of the attention, but the unsung hero is the digital infrastructure making it viable. Advanced battery storage systems solve the intermittency problem of solar and wind. Microgrid technologies allow businesses to generate and share clean energy locally. Even something as simple as real-time energy monitoring dashboards can lead to significant reductions when employees see the immediate impact of turning off unused equipment.

Pepper Pay’s offices recently implemented an intelligent energy system that adjusts based on weather forecasts and staff schedules. “It was eye-opening,” Eric Hannelius recalls. “We assumed our energy use was efficient until the data showed us where we were wasting power without realizing it.”

The Circular Economy Goes High-Tech.

Technology is breathing new life into the idea of “reduce, reuse, recycle.” Blockchain tracks materials through complex supply chains, ensuring responsible sourcing. 3D printing enables localized manufacturing with less waste. Apps that facilitate product repairs and resale are keeping goods in use longer.

One electronics company has pioneered a program where customers return old devices, which are then refurbished using AI-assisted diagnostics and robotic disassembly. The result? Higher customer loyalty and a steady supply of affordable renewed products.

The Human Factor.

What makes these technological solutions truly effective is how they engage people. Gamified apps that reward sustainable behaviors. Visualization tools that make abstract concepts like carbon footprints tangible. Collaborative platforms that help communities share resources rather than over-consume.

Eric Hannelius points to an interesting trend: “The most successful sustainability tech meets people where they are. Our payment systems now gently nudge businesses toward greener suppliers by highlighting sustainable options — not mandating, but making the better choice slightly easier.”

The frontier keeps expanding. Researchers are developing AI that can design inherently sustainable products from the molecular level up. Startups are testing how IoT devices can give everyday objects a “green rating.” The next wave may involve technologies we can’t yet imagine.

One thing is certain: the marriage of technology and sustainability is just beginning. As Eric Hannelius puts it: “Real progress happens when innovation serves both human needs and planetary health. The tools we’re developing today aren’t just changing how we do business — they’re reshaping what business means in an ecological age.”

For companies willing to embrace these possibilities, technology offers a powerful path to operating responsibly while staying competitive. The future belongs to those who see environmental challenges not as obstacles, but as opportunities to innovate.

0 notes

Text

How to Address the Skilled-Labor Shortage in 2025: A Comprehensive Guide for Australia’s Built Environment Stakeholders

Introduction

Australia’s construction industry is facing a critical skilled labor shortage that threatens project timelines, budgets, and long-term growth. As demand for infrastructure, residential, and commercial projects soars, stakeholders across the built environment — from builders and property developers to government agencies and real estate investors — must collaborate to bridge the gap. This guide offers actionable, strategies to tackle the construction talent shortage, improve workforce resilience, and secure a sustainable pipeline of skilled professionals for 2025 and beyond.

1. Strengthen Apprenticeship Programs & Upskilling Initiatives

Why It Matters: Structured pathways attract new entrants and retain existing workers.

Partner with TAFEs and RTOs to co-develop modular courses tailored to on-site needs, addressing demand for electrical engineering consultants near me and fire engineering consultants near me.

Offer flexible micro-certificates in areas like steel framing, BIM coordination, and green-build techniques.

Launch site-based bootcamps focusing on digital skills: BIM, drone surveys, prefabrication methods.

Provide clear career ladders and mentorship to reduce turnover in skilled trades and among engineering consulting companies.

2. Expand the Talent Pool Through Diversity & Inclusion

Why It Matters: Tapping underrepresented groups eases pressure on the existing labor market.

Create targeted campaigns highlighting career benefits for women, veterans, and immigrants, showcasing roles in mechanical engineering firms Australia and Electrical Engineering Companies Australia.

Host virtual job fairs and “open site days” to showcase modern construction roles.

Collaborate with industry associations to secure grants and subsidies for diversity hires.

3. Leverage Technology & Prefabrication to Boost Productivity

Why It Matters: Automation and off-site construction reduce reliance on manual labor.

Adopt BIM integration for real-time clash detection and resource planning.

Implement prefabrication lines for repetitive modules (bathrooms, façade panels).

Trial robotic bricklaying and 3D concrete printing on low-risk projects.

Use AI-driven scheduling tools to optimize crew deployment and minimize idle time.

4. Streamline Immigration Pathways for International Talent

Why It Matters: Fast-tracking skilled migrants offers immediate relief.

Advocate for a dedicated Skilled Trades Visa category with simplified validation of overseas credentials.

Partner with migration agents and state governments to pilot regional relocation incentives.

Offer relocation support packages, including housing stipends and orientation programs.

5. Enhance Retention with Competitive Packages & Culture

Why It Matters: Keeping your best workers reduces recruitment costs and preserves institutional knowledge.

Benchmark salary and award rates quarterly to ensure competitiveness.

Introduce loyalty bonuses, training allowances, and profit-share schemes.

Foster a safety-first culture and celebrate achievements with site awards.

Use pulse surveys and exit interviews to identify pain points and improve conditions.

6. Foster Industry Collaboration & Government Engagement

Why It Matters: Collective action accelerates systemic change.

Join or form regional skills councils to align training with upcoming major projects.

Lobby for co-funded training grants and apprenticeships in infrastructure budgets.

Share best practices through roundtables, whitepapers, and case studies.

Frequently Asked Questions (FAQs)

Q1: What is the quickest way to fill labor gaps on high-priority projects? A: Short-term solutions include reassigning multi-skilled crews, fast-track upskilling bootcamps, and sourcing skilled migrants under a skilled visa construction program. Prioritize roles where delays cause the biggest bottlenecks.

Q2: How can small subcontractors compete for talent? A: Emphasize flexible hours, project variety, and niche skill development. Highlight partnerships with leading electrical engineering consultants near me, fire engineering consultants near me, or hydraulic engineering services Perth to bolster credibility.

Q3: Are prefab and automation cost-effective for mid-sized projects? A: Yes — modular units can reduce on-site labor by up to 30% and decrease material waste. Initial setup costs are offset by streamlined workflows and faster handover times.

Conclusion

Addressing Australia’s skilled labor shortage demands a strategic blend of training, diversity, technology, immigration reform, retention, and collaboration. By implementing these construction workforce solutions, stakeholders can future-proof operations, control costs, and deliver landmark projects on time. Begin today by evaluating which strategies align best with your organization’s goals and take decisive steps to build a robust, skilled workforce for 2025.

For personalized consulting and tailored workforce development plans, contact Decobu at decobu.com.au.

#hydraulic engineering services#mechanical engineering services#fire engineering services#electrical engineering services#engineering

0 notes

Text

🛠️ Build the Sky: Aasma Aerospace's DIY Drone Kit for Innovators, Students & Tinkerers

At Aasma Aerospace, we’re redefining what it means to learn, innovate, and fly. With drones transforming everything from disaster response to precision agriculture, we believe it’s time that the power of flight lands in the hands of creators and learners across the country.

Introducing the Aasma DIY Drone Kit — a complete build-it-yourself drone experience tailored for tech enthusiasts, students, educators, and early-stage UAV innovators.

Whether you're in a classroom, a lab, or your backyard workshop, this kit is your personal launchpad into the world of aerial robotics and smart systems.

🎯 Why We Built the Aasma DIY Drone Kit

In India, there's a growing hunger for hands-on STEM experiences that go beyond the textbook. The Aasma DIY Drone Kit is designed to:

Bridge the gap between theory and practical application

Inspire the next generation of aerospace engineers

Provide an affordable testbed for experimentation and research

Empower local drone ecosystem development through maker culture

This kit is not just a toy — it's a real, functioning UAV platform that helps you understand how drones work, and more importantly, how they can be adapted to solve real-world problems.

📦 What Comes in the Kit?

Each Aasma DIY Drone Kit is a carefully engineered and field-tested package that gives you everything you need to get airborne.ComponentDetailsFrame (PLA+)Lightweight, durable, and locally 3D-printed at Aasma LabsBrushless MotorsFour high-efficiency BLDC motors with ESCs for flight stabilizationPropellersBalanced propeller set for thrust and torque efficiencyLi-Po BatteryRechargeable 3S/4S battery for extended flight timeFlight ControllerPre-configured with open-source firmware (e.g., ArduPilot or Betaflight)Transmitter & Receiver6+ channel radio control system with failsafe optionsGPS Module (optional)Real-time global positioning for autonomous flightsCamera Module (optional)Capture aerial footage or stream FPV videoAssembly GuidebookFull-color manual with diagrams, QR-coded video tutorials, and safety tips

🧪 Learn by Doing: Skills You’ll Gain

The DIY Drone Kit is designed to be modular, educational, and upgradeable, ensuring that learners gain core competencies in:

✈️ Aerodynamics and flight stability

⚡ Power system design and Li-Po safety

🔌 Wiring, soldering, and electronic integration

🧠 Sensor fusion and flight controller tuning

🧭 GPS navigation, waypoint control, and return-to-home protocols

🧑💻 Intro to Python/C++ coding for autonomous flight

🎓 Who Is This For?

Target GroupUse CaseSchool/College StudentsBuild science fair projects, robotics competitions, or capstone prototypesSTEM EducatorsUse in aerospace labs, technical workshops, and classroom experimentsMakers & HobbyistsExperiment with drone upgrades, payloads, or autonomous featuresStartups & FoundersRapidly prototype UAV-based solutions (e.g., delivery, surveillance)

Our kit is designed for all skill levels — from first-time builders to experienced engineers — and comes with mentorship support for institutions and clubs.

💡 What Makes Aasma’s DIY Drone Kit Unique?

✅ Made in India — Designed, sourced, and assembled by Indian engineers for Indian learners ✅ Modular Architecture — Supports future upgrades (camera, GPS, autopilot modules) ✅ STEM-Aligned Curriculum — Developed in consultation with educators and UAV pilots ✅ 3D-Printed Frame — Lightweight and crash-resistant PLA+ design for easy prototyping ✅ Support Community — Access to Aasma’s builders forum, Discord community, and helpdesk

🏆 Certified Learning, Real Recognition

All Aasma DIY Drone Kit users receive:

📜 Certificate of Completion (issued after successful build + flight test)

🔬 Access to Aasma’s exclusive UAV Bootcamp

🌐 Opportunities to showcase projects in national-level drone challenges and events

🧑🏫 Discounts for schools, colleges, and government skill programs under NEP/Atal Tinkering Lab initiatives

💰 Pricing & Packages

Package TypeInclusionsPrice (INR)Basic KitFrame, motors, FC, battery, manual control setup₹6,999Advanced Kit+ GPS, Camera module, FPV, expanded tutorials₹11,999Institution Pack5x Advanced Kits + workshop + trainer supportOn Request

📦 Bulk orders available for schools, ed-tech startups, and state tech missions 🎯 Early bird offer: Flat 15% off for first 100 customers — use code: AASMA15

📍 How to Get Started?

Ready to build your first drone?

Visit our website: www.aasmaaerospace.in

Choose your kit (Basic or Advanced)

Place your order & get doorstep delivery

Access our exclusive video portal and e-guide

Share your build using #AasmaDIYDrone and join our growing community

🚀 Drone Today, Mission Tomorrow

The Aasma DIY Drone Kit is more than a product — it’s a platform. A platform to learn, experiment, fail, fix, and fly. It’s your first step toward becoming a drone innovator, aerospace engineer, or aerial problem solver.

We’re not just selling parts. We’re delivering the spark of innovation — one flight at a time.

Follow Us Instagram | LinkedIn | YouTube | Discord 📩 For collaborations or academic tie-ups, email: [email protected]

Aasma Aerospace — Empowering India’s Skyborne Thinkers

1 note

·

View note

Text

Revolutionizing Wire Manufacturing: The Latest Advancements in Wire Machines

The wire manufacturing industry is undergoing a transformative revolution, driven by cutting-edge technologies that enhance precision, efficiency, and sustainability. From AI-powered automation to advanced material innovations, modern wire machines are reshaping production processes across industries like automotive, telecommunications, aerospace, and energy. This blog explores the latest advancements in wire manufacturing machinery, highlighting how these innovations are setting new standards for quality, speed, and environmental responsibility.

Wire Machine Manufacturers

1. Intelligent Automation and AI Integration

Modern wire machines now leverage Artificial Intelligence (AI) and machine learning to optimize production in real time. Key advancements include:

Predictive Maintenance: AI analyzes sensor data (vibration, temperature, speed) to predict equipment failures, reducing downtime and maintenance costs.

Automated Quality Control: Computer vision detects defects (e.g., uneven winding, surface flaws) with higher accuracy than manual inspections.

Dynamic Tension Control: AI adjusts wire tension in real time, ensuring consistency for delicate materials like fiber optics.

These innovations minimize human error and maximize throughput, making wire production faster and more reliable.

2. High-Speed Precision and Advanced Handling

Next-gen wire machines achieve unprecedented speed and accuracy through:

Laser-Guided Positioning: Ensures precise cutting and welding for intricate designs (e.g., multi-strand power cables).

Servo-Driven Feeding Systems: Reduce wire breaks and improve material handling efficiency.

Multi-Axis Winding: Machines like Showmark’s Multi-Axis Take-Up Systems enable complex winding patterns for aerospace and medical applications.

Such technologies are critical for industries demanding ultra-fine tolerances, such as EV wiring harnesses or high-voltage power grids.

Wire Machinery Manufacturers

3. Sustainable Manufacturing Practices

The push for eco-friendly production has led to:

Energy-Efficient Machines: Regenerative braking systems and smart cooling reduce power consumption.

Material Optimization: Advanced extrusion and drawing techniques minimize scrap (e.g., crosshead extrusion for uniform coatings).

Recycled Materials: Manufacturers increasingly use recycled copper/aluminum and biodegradable insulation.

These steps align with global sustainability goals while cutting operational costs.

4. Smart Manufacturing and IoT Connectivity

Industry 4.0 integration enables:

Real-Time Monitoring: IoT sensors track production metrics (tension, speed) via cloud platforms for remote oversight.

Adaptive Production Lines: AI adjusts settings dynamically to meet custom demands (e.g., rapid switchovers between wire gauges).

AR-Assisted Maintenance: Technicians use augmented reality for troubleshooting and training.

Such interconnected systems enhance agility in responding to market shifts.

5. Customizable and Modular Designs

Flexibility is now a cornerstone of wire machinery:

Modular Systems: Machines like the ARTOS CR.11 allow quick reconfiguration for diverse wire harnesses (automotive, aerospace).

Open Architecture: Supports third-party tool integration for specialized tasks 8.

Programmable Take-Up Units: Enable recipe storage for repeatable precision in medical or fiber-optic wire production.

Wire Machine Manufacturers

The Future Outlook

The wire manufacturing sector is poised for further disruption with trends like:

3D-Printed Cable Components: Rapid prototyping of connectors/spacers.

Smart Cables: Embedded sensors for real-time load/temperature monitoring.

Advanced Robotics: AI-driven robots for complex assembly tasks.

By embracing these innovations, manufacturers can achieve higher productivity, lower costs, and greener operations—ushering in a new era of industrial excellence.

For deeper insights, explore the sources cited or contact industry leaders like Showmark or MSS Machinery.

0 notes

Text

How to Build a High-Tech STEM Lab in West Bengal on a Budget?

Introduction: Innovation Without Breaking the Bank

Imagine a school in Kolkata where students build robots, develop AI models, and conduct science experiments—all within a cutting-edge STEM lab. But what if your school lacks the financial resources to invest in advanced technology? The good news is that setting up a high-tech STEM lab in West Bengal on a budget is possible with the right planning, funding, and strategic partnerships.

A well-equipped STEM (Science, Technology, Engineering, and Mathematics) lab prepares students for future careers, enhances problem-solving skills, and fosters innovation. The key is to make smart investments in technology, leverage free resources, and explore funding options.

Why Every School Needs STEM Lab in West Bengal

As India moves toward a technology-driven economy, students must be equipped with the skills necessary for emerging industries like artificial intelligence, robotics, and biotechnology. According to NASSCOM, STEM-based jobs will grow by 44% in the next five years, making it crucial for students to gain early exposure.

A STEM lab provides:

Hands-on Learning – Students apply theoretical knowledge to real-world problems. Creativity & Innovation – Encourages students to think critically and design solutions. Career Readiness – Prepares students for tech-driven careers in India and abroad. Enhanced Competition Performance – Equips students for national and international science, robotics, and coding contests.

Step-by-Step Guide to Setting Up a Budget-Friendly STEM Lab in West Bengal

1. Leverage Free & Open-Source Software

Instead of investing in expensive proprietary tools, use:

Scratch & Blockly – Visual programming platforms for beginners.

Arduino IDE & Tinkercad – Electronics and circuit simulation tools.

GeoGebra – Interactive mathematics software.

Google Science Journal – A free app for conducting and recording experiments.

These platforms offer high-quality learning experiences at zero cost while making STEM education accessible to all students.

2. Apply for Government & CSR Funding

Several initiatives provide funding to schools in West Bengal to support STEM education:

Atal Tinkering Labs (ATL) by NITI Aayog – Schools can apply for grants of ₹20 lakh to set up a STEM lab.

State Government STEM Initiatives – Various state-level programs support digital learning.

Corporate CSR Programs – Companies like TCS, Infosys, and Reliance fund STEM education under CSR.

Many schools in Kolkata, Siliguri, and Durgapur have already received government support to develop STEM labs. Your school can apply today!

3. Partner with Universities & Startups

Collaborate with IIT Kharagpur, Jadavpur University, and IEM Kolkata for mentorship, resources, and lab visits.

Partner with tech startups and innovation hubs for cost-effective STEM training programs.

Invite local entrepreneurs and industry experts for guest lectures on AI, robotics, and machine learning.

These partnerships enhance the learning experience without requiring huge investments.

4. Use DIY & Low-Cost STEM Kits

If high-end equipment is out of budget, opt for:

Raspberry Pi & Arduino Kits – Affordable microcontrollers for coding and robotics.

Everyday Science Experiments – Use household materials for physics and chemistry projects.

3D Printing on a Budget – Schools can collaborate with nearby institutions to access 3D printers.

Encouraging students to build their own projects fosters creativity while keeping costs low.

5. Explore Crowdfunding & Community Support

If traditional funding isn’t available, try:

Crowdfunding platforms like Milaap & Ketto to raise funds from the community.

Alumni & Parent Contributions – Former students and parents can help sponsor lab equipment.

Local Business Sponsorships – Approach companies in Kolkata and surrounding areas for STEM funding.

Many schools have successfully raised funds through community-driven initiatives.

Success Stories: Schools with STEM Labs in West Bengal

Several schools in Kolkata, Howrah, Siliguri, and Durgapur have successfully implemented STEM labs despite financial constraints:

Kolkata Public School – Used Atal Tinkering Lab grants to develop an AI and robotics lab. Durgapur Model School – Partnered with a local university for free workshops. Siliguri Science Academy – Raised funds through a crowdfunding campaign to buy 3D printers.

These schools proved that STEM labs are achievable on a budget and have seen increased student engagement, better competition results, and higher interest in technology careers.

Take the First Step Toward a STEM Lab Today!

A lack of funds should not hold your school back from empowering students with world-class STEM education. By leveraging free resources, applying for grants, and seeking partnerships, you can build an innovation hub without exceeding your budget.

Want expert guidance on setting up a STEM lab in West Bengal? Contact us today to explore affordable options and funding opportunities!

0 notes

Text

Exploring Growing Manufacturing Industry | Manufacturing Products

The manufacturing industry is one of the backbones of the global economy. Over the years, it has evolved from traditional methods to cutting-edge technological innovations that produce a wide array of products. In recent years, the industry has seen significant growth, driven by advancements in automation, artificial intelligence, and sustainable practices. This growth is shaping the future of consumer goods, machinery, and even everyday items we rely on.

1. The Growth of the Manufacturing Industry: The manufacturing sector has experienced significant transformation in recent decades. As demand for various products continues to rise globally, manufacturers are adapting through improved production methods, smarter technologies, and better resource management.

Technological Advancements: From AI and robotics to 3D printing and the Internet of Things (IoT), these technologies are revolutionizing how products are designed, created, and distributed.

Automation and Smart Factories: Automation has significantly improved production efficiency and safety. Smart factories equipped with IoT devices and artificial intelligence can monitor production lines in real time, reducing waste and increasing output.

2. Key Trends Driving Growth in the Industry:

Sustainability and Green Manufacturing: With a growing focus on reducing environmental impact, many manufacturers are turning to eco-friendly processes, using renewable energy sources, and recycling materials in production.

Globalization: The global supply chain has made manufacturing products in one country for worldwide consumption common. Countries like China, India, and Vietnam have become central manufacturing hubs.

Customization and Personalization: Consumers are seeking more personalized products, and manufacturing has evolved to meet this demand through flexible, small-batch production lines.

3. Manufacturing Products: A Diverse Range Manufacturing produces a vast variety of products that touch nearly every aspect of daily life. These range from high-tech gadgets to construction materials, automotive components, and clothing. Here are a few industries where manufacturing is booming:

Electronics and Consumer Goods: The tech industry has seen rapid growth, with companies manufacturing everything from smartphones to wearables and smart home devices.

Automotive Industry: The shift to electric vehicles (EVs) and advancements in autonomous driving technology have opened new avenues for growth in the automotive sector.

Medical Devices: Manufacturing plays a crucial role in creating innovative medical tools, from life-saving equipment to diagnostic devices, with increased demand driven by global health needs.

Construction and Infrastructure: The demand for materials like cement, steel, and machinery continues to surge, especially in developing economies.

4. Challenges Facing the Manufacturing Sector: While the manufacturing industry continues to grow, it faces challenges that must be addressed for sustainable success. Some of these include:

Supply Chain Disruptions: Global events like the COVID-19 pandemic have shown how fragile supply chains can be, affecting manufacturing timelines and costs.

Labor Shortage: As automation increases, some jobs in manufacturing are being replaced by robots, but this has led to concerns about labor shortages in skilled jobs.

Cost of Raw Materials: Fluctuating raw material prices can impact profitability, especially for industries reliant on metals, plastics, and energy.

5. The Future of Manufacturing: The future of the manufacturing industry looks bright, driven by technological innovation and a focus on sustainability. As smart factories become more prevalent, there will likely be a greater push toward Industry 4.0, which integrates physical production with digital systems. In addition, the shift toward electric and sustainable products will continue to fuel growth in certain manufacturing sectors.

Conclusion:

The manufacturing industry is far from static; it is continuously evolving to meet the demands of consumers and the economy. With a focus on technological advancements, sustainability, and adapting to new market demands, the manufacturing sector will remain a pivotal part of the global economy. As we look to the future, the industry’s innovations promise to create even more advanced products that will shape the way we live, work, and connect.

CTA: Have questions about the manufacturing industry, or would you like to learn more about specific manufacturing innovations? Contact us – we're here to help and would love to assist with any inquiries you may have!

For more information: https://www.shreeramenterpriseltd.in/

#manufacturers#manufacturers products#Chemical industry#Textile industry#Export hub#Industrial machinery#Shree Ram Enterprise#Shree Ram Enterprise Limited#Shree Ram

0 notes

Text

Steel Fabrication Market Size Revenue, Growth, Restraints, Trends, Company Profiles, Analysis & Forecast Till 2032

The Steel Fabrication Market is an integral part of the global industrial landscape, shaping industries from construction to automotive, aerospace, energy, and beyond. Steel, with its high strength-to-weight ratio, recyclability, and versatility, has long been a cornerstone material in infrastructure and manufacturing projects. Steel fabrication, which involves cutting, bending, and assembling steel into specific products or structures, is a complex and evolving sector influenced by economic trends, technological advancements, and shifting customer demands.

The Steel Fabrication Market Size was valued at USD 20.66 Billion in 2023. The Steel Fabrication industry is projected to grow from USD 21.34 Billion in 2024 to USD 27.67 Billion by 2032, exhibiting a compound annual growth rate (CAGR) of 3.30% during the forecast period (2024 - 2032)

Market Overview

Steel fabrication plays a pivotal role in the global economy, facilitating the creation of products used in buildings, bridges, ships, vehicles, and industrial machinery. The market for fabricated steel has grown in recent years due to increasing investments in infrastructure development, industrial expansion, and energy projects. According to industry estimates, the steel fabrication market is expected to grow at a compound annual growth rate (CAGR) of 5–7% during the forecast period from 2024 to 2030.

Key Market Drivers

1. Infrastructure and Construction Boom

The global infrastructure and construction industry is one of the largest consumers of fabricated steel. Urbanization and population growth in emerging economies like India, China, and Southeast Asian nations have triggered significant investments in roads, bridges, railways, and commercial buildings. In developed regions, the push for green infrastructure and smart cities is further driving the demand for fabricated steel components.

2. Renewable Energy Projects

The shift towards renewable energy sources such as wind, solar, and hydropower has opened new avenues for steel fabricators. Steel is widely used in constructing wind turbine towers, solar panel frames, and hydropower plants due to its durability and strength. As global energy policies increasingly favor renewable sources, the demand for fabricated steel in energy projects is expected to soar.

3. Automotive and Aerospace Sectors

Steel fabricators are critical suppliers to the automotive and aerospace industries. High-performance steel alloys are essential for producing lightweight yet robust components that improve fuel efficiency and reduce carbon emissions. As electric vehicles (EVs) and advanced aerospace technologies gain momentum, the steel fabrication market will continue to expand.

4. Industrialization in Emerging Markets

Rapid industrialization in regions such as Africa, the Middle East, and South Asia is bolstering the demand for fabricated steel. Factories, warehouses, and manufacturing facilities require custom steel structures and machinery, driving market growth.

Technological Trends

Technological advancements are revolutionizing the steel fabrication market, improving productivity, precision, and sustainability. Key trends include:

1. Automation and Robotics

The integration of robotics and automated machinery is enhancing the efficiency of steel fabrication processes. Automation minimizes human error, reduces production time, and lowers costs, making it a game-changer for fabricators.

2. 3D Printing in Metal Fabrication

Additive manufacturing, or 3D printing, is gaining traction in steel fabrication. This technology allows for the creation of complex, customized designs with minimal waste, making it ideal for producing intricate components for industries like aerospace and healthcare.

3. Digital Twins and IoT

Digital twin technology and the Internet of Things (IoT) enable real-time monitoring and predictive maintenance of steel fabrication equipment. These innovations improve operational efficiency and reduce downtime, enhancing competitiveness.

4. Advanced Steel Alloys

The development of advanced high-strength steel (AHSS) and corrosion-resistant alloys is expanding the applications of steel fabrication. These materials are particularly valuable in harsh environments, such as offshore oil rigs and coastal infrastructure.

Challenges in the Market

Despite its promising outlook, the steel fabrication market faces several challenges:

1. Fluctuating Raw Material Prices

The cost of steel and other raw materials is subject to global supply-demand dynamics, geopolitical factors, and economic conditions. Volatility in prices can squeeze profit margins for fabricators.

2. Environmental Regulations

The steel industry is one of the largest emitters of carbon dioxide (CO2). Stricter environmental regulations and the push for sustainable practices compel fabricators to invest in cleaner technologies, which may increase operational costs.

3. Labor Shortages

The steel fabrication industry often struggles to attract skilled labor due to the demanding nature of the work. The aging workforce in developed markets further exacerbates this issue.

4. Competition from Alternatives

Materials like aluminum, composites, and carbon fiber are increasingly competing with steel in applications where weight reduction is critical, posing a threat to market growth.

Opportunities for Growth

Despite these challenges, the steel fabrication market is poised for growth, driven by emerging opportunities:

1. Green Steel Initiatives

The rise of green steel—produced using hydrogen or electric arc furnaces powered by renewable energy—presents a significant opportunity for sustainable growth. Companies adopting eco-friendly practices are likely to gain a competitive edge.

2. Modular Construction

Modular construction, which involves prefabricating building components offsite, is gaining popularity for its efficiency and cost-effectiveness. Steel fabricators are uniquely positioned to capitalize on this trend.

3. Expansion into New Markets

Emerging economies with untapped potential offer lucrative opportunities for steel fabricators. Strategic partnerships and localized production can help companies penetrate these markets effectively.

4. Diversification of Offerings

Fabricators can diversify their product portfolios to include high-value components, such as precision-engineered parts for the medical or electronics industries, to enhance profitability.

MRFR recognizes the following Steel Fabrication Companies - BASF SE (Germany),OCP Group S.A. (Morocco),The Mosaic Company (US),Nouryon (Netherland),PVS Chemicals Inc (US),Aurubis (Germany),Ineos Enterprises Limited (UK),Oriental Carbon & Chemicals Ltd. (India),Amal Ltd. (India),Dexo Fine Chem Pvt. Ltd. (India)

The steel fabrication market is set to evolve rapidly in the coming years. While challenges such as environmental regulations and raw material price volatility persist, advancements in technology and sustainable practices are paving the way for innovation and growth. Companies that embrace automation, invest in green steel production, and diversify their offerings will be well-positioned to thrive in this dynamic landscape.

As global industries continue to rely on steel for their structural and functional needs, the steel fabrication market will remain a critical pillar of the industrial economy. By staying ahead of emerging trends and challenges, the sector can ensure a resilient and sustainable future

Related Reports

Steel Market - https://www.marketresearchfuture.com/reports/steel-market-5465 Green Steel Market - https://www.marketresearchfuture.com/reports/green-steel-market-11286 APAC Steel Market - https://www.marketresearchfuture.com/reports/apac-steel-market-12449 Aerospace Steel Market - https://www.marketresearchfuture.com/reports/aerospace-steel-market-20690 Iron Steel Market - https://www.marketresearchfuture.com/reports/iron-steel-market-11958 India Iron Steel Market - https://www.marketresearchfuture.com/reports/india-iron-steel-market-21393 Flat Steel Market - https://www.marketresearchfuture.com/reports/flat-steel-market-1885 Stainless Steel Market - https://www.marketresearchfuture.com/reports/stainless-steel-market-16145 Carbon Steel Market - https://www.marketresearchfuture.com/reports/carbon-steel-market-10298

0 notes

Text

The 3D Printing Revolution: When the Printer Built Itself (Almost)

Remember when 3D printers were the exclusive toys of giant corporations? Back then, the idea of bringing one into your garage was about as likely as building a rocket ship in your backyard. But then came RepRap, the brainchild of a daring professor named Adrian Bowyer. His radical idea? A 3D printer that could... print itself!

Imagine the scene: Bowyer, probably wearing a slightly bewildered expression, watching his first RepRap printer, lovingly named "Darwin," slowly extrude its own plastic parts. It was like witnessing a robot giving birth to a smaller, slightly less impressive robot. Did he print a tiny screwdriver first? A miniature teacup? No, of course not. He printed more printer parts, because priorities.

RepRap wasn't just about self-replication; it was about democratizing 3D printing. By open-sourcing the designs, Bowyer unleashed a wave of tinkering and collaboration. Suddenly, hobbyists were building their own printers in garages, basements, and even, I kid you not, on kitchen tables. The internet buzzed with discussions about filament types, failed prints, and the occasional triumphant post of a perfectly printed gear.

The impact of RepRap is undeniable. It sparked a global movement, fueling the rise of affordable desktop printers that are now commonplace. From personalized gadgets to life-saving medical implants, 3D printing is transforming industries. So, the next time you marvel at a 3D-printed creation, remember the quirky professor and his self-replicating dream. It may not have been perfectly self-sufficient (who needs a self-printing teacup anyway?), but it revolutionized how we create.

0 notes

Text

Robotic Invention Ideas

Robotics has completely changed industries around the world, spurring innovation in everything from agriculture to healthcare. Ideas for robotics inventions lead to countless opportunities, enabling developers to create solutions that solve practical issues and boost productivity.

Personal Assistant Robots

Imagine a robot that can make your coffee in the morning, remind you of critical duties, and handle your daily schedule with ease. Robotic personal assistants are growing in popularity because they can help with household management, senior care, and busy professionals. Voice recognition, artificial intelligence (AI), and Internet of Things (IoT) technology can all be combined by inventors to produce a very customized and engaging experience.

Autonomous Delivery Robots

Autonomous delivery robots offer a novel approach to effective and frictionless distribution in light of the growth of e-commerce and online meal delivery. With GPS systems, obstacle recognition, and temperature-controlled compartments to guarantee the safe delivery of goods or meals, these robots can maneuver through streets or offices.

Agricultural Robotics

Significant progress has been made in agricultural robotics, which has helped to solve the labor crisis and boost output. Autonomous drones for crop monitoring, robotic harvesters, and precision weeding robots are some examples of invention concepts in this field. These methods can guarantee higher yields, limit waste, and need less human labor.

Healthcare Assistance Robots

By helping with surgery, rehabilitation, and elder care, healthcare robots are revolutionizing patient care. An AI-powered diagnostic bot, a surgical robot with precise movements, and a robot made to assist patients with mobility issues are examples of robotic inventions in this field. These innovations can provide high-quality care while reducing the workload for medical personnel.

Educational Robots for Kids

Children are increasingly being taught STEM (science, technology, engineering, and mathematics) principles through the use of educational robots. Interactive bots that gamify education, AI-powered tutors for individualized learning, and programmable kits that let children construct and program their own robots are some examples of educational robot concepts.

Tips for Turning Robotic Ideas into Reality

Research is the first step. Learn about the needs of your target audience and look into current technology to find any holes that can be filled.

Learn the Basics of Robotics: Arm yourself with an understanding of AI, mechanics, and code. For novices, platforms such as Arduino and Raspberry Pi are great.

Prototype Your Idea: To make a functional prototype, use open-source software, inexpensive hardware, and 3D printing.

Work Together with Experts: To improve your idea and launch it, join forces with engineers, designers, and marketers.

Seek Funding: To finance your robotic device, seek innovation awards or use crowdfunding websites.

Ideas for robotic inventions aim to solve issues, enhance lives, and make the world wiser and more sustainable, not only to build futuristic devices. You may contribute to the next significant advancement in robotics by fusing technical know-how, creativity, and a forward-looking outlook. Begin your exploration now to bring your creative concepts to life!

To know more, click here.

0 notes

Text

3d-Printed Accessories for Petoi Bittle/Bittle X Robot Dogs

Did you know that with Petoi Bittle/Bittle X, there are multiple 3D-printed accessories that you can create to use and interact with your Petoi DIY robot dogs? From Beetle horns to Fox heads, and Bittle stands to Lego Covers, you can use our free open-source 3D-printed accessory designs as you build your DIY Robot Dog!

Read This Article Here:

0 notes