#optical rotary encoders

Photo

Optical rotary encoders can revolutionize your business facilities. Made by experts, these rotary encoders have integral bearings for separate coupling. Not only this, but they have a solid shaft. To know more about magnetic rotary encoders, visit the website today.

0 notes

Text

Roomba Silver (models 4150, 415) by iRobot, Bedford, MA (2005). This model has a distinctive silver finish, and was sold via Amazon.com and Target. It’s one of the first models to sport the two-tone swivel caster wheel. This passive caster located at the front of the Roomba provides a third point of support in addition to the two drive wheels. This half black & half white caster is also a rotary encoder, with an optical sensor detecting the alternating contrast as it rotates. This detects if the Roomba is stuck or beached, when the drive wheels are spinning, but the Roomba isn't moving.

20 notes

·

View notes

Note

immgonna cry im soo gladyou are my friend you knowthhh your so sssmaaaaaart!!! and you know robots so well and you know about like creatures and stuff and plants and its so awesome your so good and then you are also just so so nice and its awesomeeeeeeee 😭😭😭 what the helllll

STOP ITTTTT YUORE TOO NICE TO ME SONIC WAGHGHGHGG I AM HUGGING YOU AND HIGH FIVING YOU AND FIST BUMPING YOU

since you mentioned Stuff lemme infodump for good measure because i enjoy sharing facts

creature fact: dragonflies are the most successful predators on the planet, succeeding in 95% of their prey captures. also, some dimorphic species have evolved multiple forms that appear deceptively like males to avoid harassment. they also see much faster than we do, perceiving around 200 images per second - nearly 80% of a dragonfly's brain is dedicated to sight alone.

plant fact: welwitschia mirabilis, also called the tree tumbo, can live to be 2,000 years old as suggested by carbon dating. it's unique for only having two permanent leaves which can grow to a length of 6 to 13ft. eventually it can reach 6ft tall and 24ft wide. it's also thought to be a relic of the jurassic period and is sometimes called a living fossil. pretty cool. they also look like theyre chronically dead. google it you’ll see what i mean

robot fact: roombas are built with rotary encoders on their wheels which detect the rate at which they’re spinning, so they can tell if they’re slipping or trapped. there’s also a rotary encoder on the front of most models that detects the black and white of the caster’s wheel - its optical sensors detect the change in colour as it rotates, so the roomba can tell if it’s stuck i.e. if the wheels are spinning but the unit isn’t moving.

5 notes

·

View notes

Text

Grayhill specializes in designing and manufacturing intuitive interfaces, offering a range of standard products such as touch encoders, optical encoders, joysticks, rotary switches, keypads, pushbuttons, and CAN bus vehicle controls. These products, featuring finely tuned haptics, can be customized to suit specific requirements.

The company's engineers excel in integrating various interface technologies, including displays, touch technology, and motion sensing, into ergonomic panels and product shells, and creating holistic and intuitive solutions for human interface.

Reach out to us with your requirements today.

0 notes

Video

encoder rotary #JogPendants #Drawwiresensor #cncmachineencoder #angularencoder #positionencoder

encoder rotary, Jog Pendants, Draw wire sensor, cnc machine encoder, angular encoder, position encoder Changchun Rongde Optics Co., Ltd. www.roundssencoder.com [email protected]

0 notes

Text

Brushless DC Motors Working Principle and Applications

Brushless DC motors (BLDC) are a type of electric motor that operate on direct current (DC) power and use electronic commutation to switch the current direction in the armature windings. They have many advantages over traditional brushed DC motors, such as higher efficiency, longer lifespan, and lower maintenance requirements. They are widely used in various applications, such as electric vehicles, industrial automation, robotics, and power generation. This blog post will explain the basic structure, working principle, and applications of BLDC motors.

Structure of Brushless DC Motors

A Brushless DC motors consists of two main parts: the stator and the rotor. The stator is the stationary part of the motor that contains the armature windings. The armature windings are arranged in a sequence of coils that produce a uniform magnetic field when energized. The rotor is the rotating part of the motor that contains permanent magnets. The permanent magnets are attached to the rotor in a specific pattern that determines the number of poles of the motor. The rotor rotates around the stator due to the interaction of the magnetic fields.

The BLDC motor also requires a controller and a sensor to control the commutation of the armature current. The controller is an electronic circuit that switches the current in the armature windings according to the position of the rotor. The sensor is a device that detects the position of the rotor and sends a signal to the controller. The sensor can be either a Hall sensor or a rotary encoder. The Hall sensor is a magnetic sensor that detects the change of the magnetic field due to the rotation of the permanent magnets. The rotary encoder is an optical or mechanical sensor that detects the angular position of the rotor.

Working Principle of Brushless DC Motors

The working principle of a Brushless DC motors is based on the Lorentz force law, which states that a current-carrying conductor placed in a magnetic field experiences a force. The direction of the force is perpendicular to both the current and the magnetic field. In a BLDC motor, the current-carrying conductors are the armature windings, and the permanent magnets produce the magnetic field. The force acting on the armature windings causes them to rotate around the stator.

The commutation of the armature current is done electronically by the controller and the sensor. The controller switches the current in the armature windings in a specific sequence that ensures that the magnetic field of the stator is always perpendicular to the magnetic field of the rotor. This creates a maximum torque and a smooth rotation. The sensor provides feedback to the controller about the position of the rotor, so that the controller can switch the current at the right time.

Applications of Brushless DC Motors

BLDC motors are suitable for applications that require high efficiency, precision, and reliability. Some of the common applications of BLDC motors are:

Electric vehicles: BLDC motors are used to power electric vehicles, such as electric bikes, scooters, cars, and buses. They offer high performance, low noise, and long battery life.

Industrial automation: BLDC motors are used to drive various machines and equipment in industrial automation, such as conveyor belts, pumps, fans, and robots. They offer high speed, accuracy, and durability.

Robotics: BLDC motors are used to control the movement and operation of robots, such as humanoid robots, service robots, and drones. They offer high torque, responsiveness, and flexibility.

Power generation: BLDC motors are used to generate electricity from renewable sources, such as wind, solar, and hydro. They offer high efficiency, low maintenance, and environmental friendliness.

EMPPL is a company that specializes in providing high-quality Brushless DC motors for various applications. EMPPL offers a wide range of BLDC motors, such as brushless motors, brushless outrunner motors, brushless inrunner motors, and brushless hub motors. EMPPL also offers custom-made BLDC motors according to the customer’s specifications and requirements. EMPPL is your trusted partner for all your BLDC motor needs. You can visit their website here to learn more about their products and services.

0 notes

Text

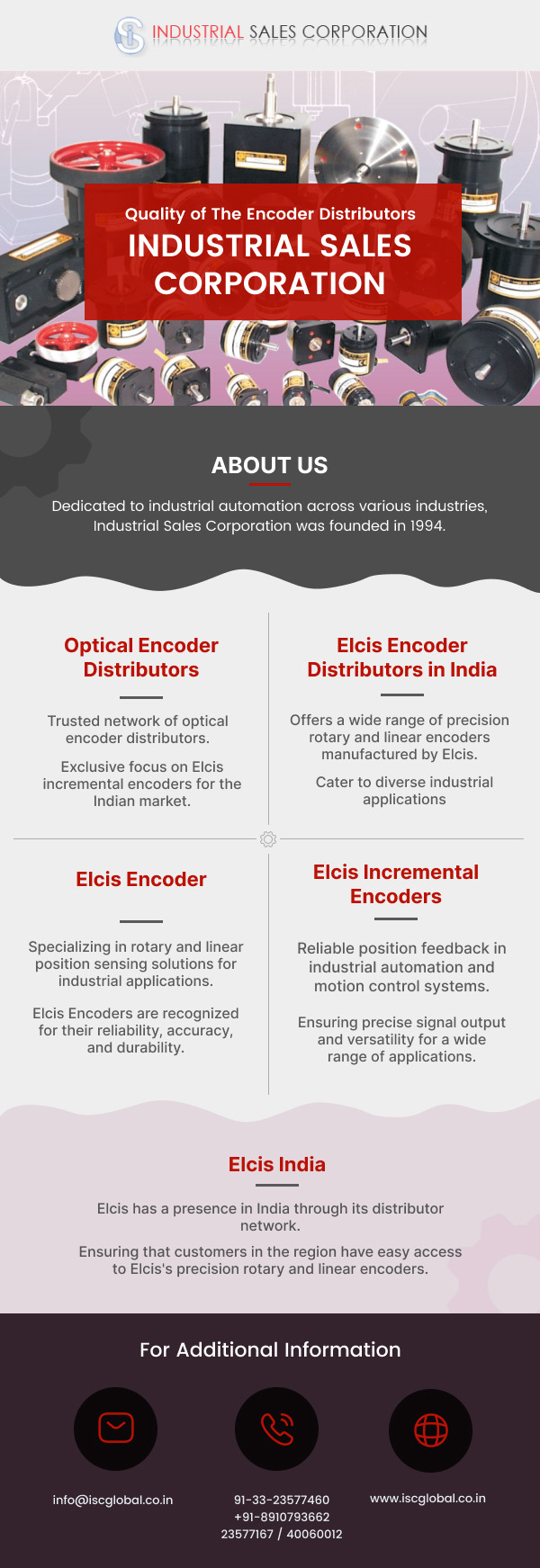

Quality of The Encoder Distributors: Industrial Sales Corporation

About Us

Dedicated to industrial automation across various industries, Industrial Sales Corporation was founded in 1994.

Optical Encoder Distributors

Trusted network of optical encoder distributors.

Exclusive focus on Elcis incremental encoders for the Indian market.

Elcis Encoder Distributors in India

Offers a wide range of precision rotary and linear encoders manufactured by Elcis.

Cater to diverse industrial applications

Elcis Encoder

Specializing in rotary and linear position sensing solutions for industrial applications.

Elcis Encoders are recognized for their reliability, accuracy, and durability.

Elcis Incremental Encoders

Reliable position feedback in industrial automation and motion control systems.

Ensuring precise signal output and versatility for a wide range of applications.

Elcis India

Elcis has a presence in India through its distributor network.

Ensuring that customers in the region have easy access to Elcis's precision rotary and linear encoders.

For additional information:

Tel/Fax: 91-33-23577460 / +91-8910793662 /23577167 / 40060012

Email: [email protected]

Website: http://iscglobal.co.in

0 notes

Text

Encoders Market to amass significant gains by 2025

Encoders are devices or components used in various fields, including electronics, computing, communications, robotics, and automation. They are designed to convert physical or analog input signals into digital output signals for processing, measurement, or control purposes. Encoders play a crucial role in translating real-world data into a format that can be understood and utilized by electronic systems. Here are a few types of encoders:

For Download Sample Link : https://www.globmarketreports.com/request-sample/258207

Rotary Encoders: Rotary encoders are used to measure the position, speed, or angular displacement of a rotating object or shaft. They typically consist of a rotating disk with patterns or slots and a sensor that detects changes in the patterns as the disk rotates. Rotary encoders can be absolute (providing a unique digital code for each position) or incremental (providing relative changes in position or speed).

Linear Encoders: Linear encoders measure linear motion or position along a straight path. They are commonly used in applications such as machine tools, coordinate measuring machines, and robotics. Linear encoders can be optical, magnetic, or capacitive, depending on the technology used to detect and convert the linear displacement into digital signals.

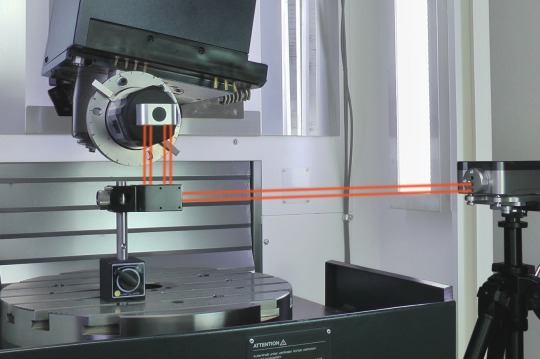

Optical Encoders: Optical encoders use light and photodetectors to convert motion or position into digital signals. They typically consist of a light-emitting diode (LED), a codewheel or scale with patterns, and photodetectors to detect changes in the light patterns as the scale moves. Optical encoders offer high resolution, accuracy, and reliability.

Magnetic Encoders: Magnetic encoders use magnetic fields and sensors to detect changes in position or motion. They are often used in environments where dust, dirt, or liquids can affect the performance of other types of encoders. Magnetic encoders can be absolute or incremental and provide robust operation in challenging conditions.

Digital Encoders: Digital encoders convert analog signals into digital format. They are commonly used in audio and video applications for encoding analog signals into digital signals for processing, storage, or transmission. Digital encoders use various coding schemes, such as pulse code modulation (PCM), to represent analog signals digitally.

Encoder-Decoder (Codec): In the context of audio and video processing, an encoder-decoder, also known as a codec, is a device or software that converts analog or digital audio/video signals into a compressed digital format for efficient storage, transmission, or streaming. Codecs are widely used in applications such as video conferencing, multimedia streaming, and digital broadcasting.

Encoders are essential components in numerous systems and applications, providing accurate and reliable measurement, control, and data processing capabilities. The choice of encoder depends on the specific requirements of the application, such as resolution, accuracy, environmental conditions, and cost considerations.

0 notes

Text

Potentiometer Position Sensors Market Size, Share, Trends, Growth, Industry Analysis, Key Players, Revenue, Future Development & Forecast 2023-2032

The potentiometer position sensors market refers to the industry that involves the manufacturing, distribution, and sales of potentiometer-based position sensors. Potentiometers, also known as pots, are variable resistors that are commonly used as position sensors to measure the position or movement of various mechanical components in different applications.

Potentiometer position sensors typically consist of a resistive element and a sliding contact or wiper that moves along the resistive track. As the wiper position changes, the resistance of the potentiometer changes, allowing for position sensing and measurement. These sensors are widely used in various industries such as automotive, aerospace, industrial automation, robotics, and consumer electronics.

The market for potentiometer position sensors is driven by the increasing demand for accurate and reliable position sensing in various applications. These sensors offer advantages such as simplicity, cost-effectiveness, and ease of integration, making them a popular choice in many industries. Additionally, the growing adoption of automation and robotics in industries further fuels the demand for potentiometer position sensors.

Factors such as technological advancements, miniaturization of sensors, and the development of contactless potentiometer position sensors are expected to drive market growth. Contactless potentiometers use non-contacting methods such as magnetic, capacitive, or optical principles to measure position, eliminating issues related to wear and tear of mechanical components.

However, the potentiometer position sensors market faces competition from alternative position sensing technologies such as optical encoders, Hall effect sensors, and inductive sensors. These technologies offer advantages such as higher accuracy, longer lifespan, and resistance to environmental factors, which may limit the growth of the potentiometer position sensors market in certain applications.

Overall, the potentiometer position sensors market is expected to continue growing as industries seek reliable and cost-effective position sensing solutions. The market is characterized by ongoing technological advancements, increasing automation, and the need for precise position measurement in various sectors.

I recommend referring to our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into the humidity sensors market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to the humidity sensors market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in the market.

Remember to look for recent reports to ensure you have the most current and relevant information.

Click Here, To Get Free Sample Report : https://stringentdatalytics.com/sample-request/potentiometer-position-sensors-market/723/

Market Segmentations:

Global Potentiometer Position Sensors Market: By Company

• SIKO

• ASM Sensor

• Honeywell

• BEI SENSORS

• NOVOTECHNIK

• ATEK SENSOR

• OPKON Optik Electronic

• MICRO-EPSILON

Global Potentiometer Position Sensors Market: By Type

• Potentiometer Rotary Position Sensors

• Potentiometer Linear Position Sensors

Global Potentiometer Position Sensors Market: By Application

• Aerospace & Defense

• Automotive

• Food & Beverage

• Pharmaceuticals

• Others

Global Potentiometer Position Sensors Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Potentiometer Position Sensors market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details : https://stringentdatalytics.com/reports/potentiometer-position-sensors-market/723/

Reasons to Purchase Potentiometer Position Sensors Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behavior: these research studies can offer insightful information about customer behavior, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organization’s useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy development, and business planning.

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/potentiometer-position-sensors-market/723/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs.

Contact US:

Stringent Datalytics

Contact No - 91-9763384149

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Potentiometer Position Sensors Market#global Potentiometer Position Sensors Market report#global market insights#global research market report#global market report

0 notes

Text

Revolutionizing Motion Control: The Power of Optical Encoders

Optical encoders are devices used to convert physical motion into digital signals. They consist of a rotating disc, which has evenly spaced lines or slots etched into it. As the disc rotates, a light source shines on the disc, and a sensor detects the changes in light intensity caused by the lines or slots passing by. These changes in light intensity are then converted into digital signals, which can be used to determine the position, speed, and direction of the rotating disc.

One of the primary benefits of optical encoders is their high accuracy and precision. They can detect even small changes in position or speed, making them ideal for use in a wide range of applications, from robotics to precision manufacturing. Additionally, they are highly reliable, with a long lifespan and minimal maintenance requirements.

Optical encoders come in various forms, including linear and rotary encoders. Linear encoders are used to measure linear motion, such as the movement of a linear stage or conveyor belt, while rotary encoders are used to measure rotational motion, such as the speed and position of a motor shaft. They can also be absolute or incremental, with absolute encoders providing a unique position code for every point in a rotation, and incremental encoders providing a signal that indicates the amount and direction of rotation since the last signal.

Overall, optical encoders are a versatile and essential component in many applications requiring precise position or motion control. Their high accuracy, reliability, and variety of forms make them a popular choice among engineers and manufacturers in a wide range of industries.

Read More: https://thetechnologynews-24.blogspot.com/2023/04/precision-tracking-benefits-of-optical.html

0 notes

Text

IndMALL Automation

Discover an array of products at your fingertips, from proximity sensors, photoelectric sensors, and rotary encoders to limit switches, fiber optic sensors, and temperature controllers. Our selection also includes safety scanners, Turck proximity Sensor, vision sensors, PLCs, HMIs, drives, ultrasonic sensors, distance sensors, measuring sensors, panel meters, safety light curtains, safety rope switches, safety mats, safety door switches, pulse meters, timers, counters, distributor blocks, IO-Links, RFID, acceleration sensors, cables, and connectors, and much more.

0 notes

Text

A brief note on the sensors created by the sensor manufacturers in Pune

Sensors are valuable tools that are often used in our day to day lives. They are often used in electronics and in computing technology. The sensor basically functions as a device which can detect any changes within the environment. They can also respond to some kind of output produced by another system. The role of a sensor is to convert some physical phenomenon or signal into a quantifiable digital signal or analog voltage. This is then converted into some kind of human-readable display and/or transmitted for the purpose of reading or additional processing. The input that is detected by the sensor from its immediate physical environment can vary in its form. Some of the most common forms of input here include motion, light, heat, pressure, moisture or any other type of environmental phenomena. This leads the sensor to create an output in its response. This output is mostly a signal and it can be read with the help of a human-readable display machine.

A sensor device helps to detect and read the signal from its immediate environment which is transmitted electronically. A common example of sensor is a microphone as it helps to convert the sound energy into an electrical signal which can be further amplified, recorded, transmitted and reproduced. These days when computers and computing technology is used at almost all aspects of human lives, the sensors have become an essential component for all things related to internet of things (IoT). Through the use of sensors, it is possible to give rise to a huge ecosystem of connected devices that seamlessly collect, share and process data regarding the environment in which they operate and the users that interact with these devices. This in turn helps the companies owning the devices to monitor, control and manage the devices with greater accuracy and efficiency. The IoT sensors are extensively used in automobiles, in the airplanes, in homes, in the field, in various industrial settings as well as in other locations. The use of sensors makes it possible to create a connection between the physical domain and the logical world.

Such factors really make the sensors a quintessential component for computing infrastructure which in turn can assist in analyze and act on the data that has been collected with the help of the sensors. Over the years, many different types of sensors have been designed and produced and they all have specific user cases of their own. Some of the most well known types of sensors that you can find in the market include thermocouples, thermistors and RTDs, all of which are used to measure temperature. Other types of sensors include the load cells that can help in measuring load and weight; strain gages for measuring the strain on some object, such as tension, pressure and weight; accelerometers for measuring shock and vibration; LVDT sensors for measuring the displacement in distance; Microphones to capture the sound waves; current transducers that can help in measuring the AC current or DC current; optical sensors for detecting light, replace conventional sensors and transmission of data; voltage transformers to measure the high voltage potentials; camera sensors for capturing single as well as continuous 2D images, positioning sensors for GPS purposes and digital sensors for rotary and linear encoding as well as position measurements.

When you need to get specific types of sensors for your operations, you need to contact a company of sensor manufacturers in Pune that can get you the products you are looking for. This will not only help you to ensure complete accuracy of your procedure but also ensure the best output in the process.

0 notes

Text

Types of different motors and classification

A motor that is designed to rotate at high speeds, most commonly used in applications such as CNC milling machines. Like all motors, spindle motors can and will break suffering many of the same failure modes as other types of motors.

Servo Motor

Servo implies an error sensing feedback control which is utilized to correct the performance of a system. It also requires a generally sophisticated controller, often a dedicated module designed particularly for use with servomotors. Servo motors are DC motors that allow for precise control of the angular position. They are DC motors whose speed is slowly lowered by the gears. The servo motors usually have a revolution cut off from 90° to 180°. A few servo motors also have a revolution cutoff of 360° or more. But servo motors do not rotate constantly. Their rotation is limited between the fixed angles.

Motor 3 cv

Features of motor 3 cv

Electric single-phase motor 3 CV 1400 rpm. Cast alluminium alloy carter. Steel C-40 shaft. Cage rotor with cast alluminium cover. Radial bidirectional blades fan. Reversible direction of rotation. Motor shaft Ø 28 mm.

Motor Encoder

An encoder motor a rotary encoder mounted to an electric motor that provides closed loop feedback signals by tracking the speed and/or position of a motor shaft. There are a wide variety of motor encoder configurations available such as incremental or absolute, optical or magnetic, shafted or hub/hollow shaft, among others.

Motor de refrigeração

Features of motor de refrigeração

This RC engine radiator is specially designed for 540 550 engines of RC model cars.

RC radiators with temperature sensors are equipped with 5–10V dual cooling fans to protect your engine.

When the engine temperature reaches 40℃, the thermal sensor will accurately detect the temperature rise, and the dual cooling fan will automatically turn on to cool the engine.

0 notes

Text

Different types of motors and their use

What is motor?

A motor that is designed to rotate at high speeds, most commonly used in applications such as CNC milling machines. Like all motors, spindle motors can and will break suffering many of the same failure modes as other types of motors.

Motor 3 cv

Features of motor 3 cv

Electric single-phase motor 3 CV 1400 rpm. Cast alluminium alloy carter. Steel C-40 shaft. Cage rotor with cast alluminium cover. Radial bidirectional blades fan. Reversible direction of rotation. Motor shaft Ø 28 mm.

Motor Encoder

An encoder motor a rotary encoder mounted to an electric motor that provides closed loop feedback signals by tracking the speed and/or position of a motor shaft. There are a wide variety of motor encoder configurations available such as incremental or absolute, optical or magnetic, shafted or hub/hollow shaft, among others.

Servo Motor

Servo implies an error sensing feedback control which is utilized to correct the performance of a system. It also requires a generally sophisticated controller, often a dedicated module designed particularly for use with servomotors. Servo motors are DC motors that allow for precise control of the angular position. They are DC motors whose speed is slowly lowered by the gears. The servo motors usually have a revolution cut off from 90° to 180°. A few servo motors also have a revolution cutoff of 360° or more. But servo motors do not rotate constantly. Their rotation is limited between the fixed angles.

Motor de refrigeração

Features of motor de refrigeração

This RC engine radiator is specially designed for 540 550 engines of RC model cars.

RC radiators with temperature sensors are equipped with 5–10V dual cooling fans to protect your engine.

When the engine temperature reaches 40℃, the thermal sensor will accurately detect the temperature rise, and the dual cooling fan will automatically turn on to cool the engine.

0 notes

Link

0 notes

Text

Everything To Know About Incremental Shaft Encoders

Having a proper idea about the incremental shaft encoders is very important before starting work with such components. With a proper idea of the components, one would know how it works and where would be it’s ideal usage. Here it must be kept in mind that the incremental encoders fall undr the group of rotary shaft encoders. Hence, it can easily collect data and even offer feedback depending on the object rotation of a device.

What Are The Encoder Types?

Most of us might be aware of the fact that encoders are usually classified into four types, such as optical to magnetic, and mechanical to electromagnetic. All these types of encoders are usually available with the magnetic encoder distributors.

Shaft Encoders: Incremental

As we are well-aware of the fact that Rotary Encoders are often stated as Shaft Encoders. Also, Rotary Shaft Encoders are often referred to as Incremental Shaft Encoders. They can be used in a wide range of applications. But their main task is that they can easily measure speed, distance, and even the position.

However, one should keep in mind that the incremental encoders are able to offer information related to angle, position, as well as, on the rotation counts. The resolution gets defined as per the number of lines or even the pulses for every rotation. It must be kept in mind that the current position can be established by the control unit by taking help of the pulses.

Why Is It Referred To As Shaft Encoder?

In case, you are wondering why an incremental encoder is called as a shaft encoder then this post is right for you. For this style of encoder, the disk is usually mounted on the rotating shaft. The disk consists of a pattern of opaque as well as transparent sectors. As and when the disk starts tobrotate, the patterns will interrupt the light that gets emitted upon the photo detector. Thus, generating a pulse signal output.

Working Principle

Before consulting any magnetic encoder distributors for getting hold of any type of encoders, having an idea regarding the working principle of the encoders is important. For instance, the incremental encoder works as and when there is a change in the position of the shaft’s angular position into digital signal via the optical disk.

Hopefully, once you have a proper idea of the incremental shaft encoders, working with the component would be very easy one. But make sure the incremental encoder should meet the application device.

0 notes