#pallet wrapping machine

Text

Technoplat 3000 is a high-performance, highly automated wrapping machine for an end-of-line packaging

youtube

#stretch wrapping machine#pallet wrapping machine#automatic pallet wrapping machine#stretch wrapper#Technoplat 3000#Youtube

0 notes

Link

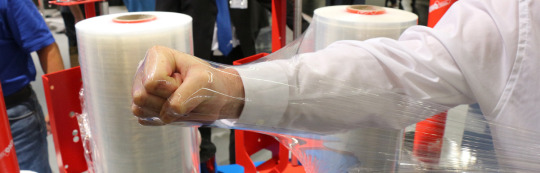

Using a pallet wrap machine can greatly benefit your wrapping process, saving time and labor while reducing costs and increasing workplace safety. In comparison to manual stretching, machines can stretch up to 300%, making the wrapping process more efficient and cost-effective.

Gateway Packaging provides reliable semi-automatic and automatic wrap machines that can boost productivity while also saving money.

Business Website - https://www.gatewaypackaging.com.au/

Business Email - [email protected]

Phone Number - 1800 003 310

#pallet wrap#pallet wrapping machine#pallet wrapper#pallet wrap machine#gateway packaging#packaging machines

0 notes

Link

#Pallet Wrapping Machine Manufacturer#Pallet Wrapping Machine#Stretch Wrapping Machine#Stretch Wrapping Machine Manufacturer

0 notes

Text

Why Use High Performance Stretch Film

In the world of logistics and supply chain management, efficiency is the name of the game. But pallet wrap might not be the first thing that comes to mind when you are thinking about how to optimize your operation. Enter high performance stretch film…

The right stretch film can often be the key to unlocking improvements. However, the challenge lies in finding the delicate balance between reducing the thickness of your pallet wrap and maintaining adequate load containment.

High performance stretch film is an innovative category of pallet wrap that has a much lower thickness than traditional film but provides a high level of performance. Traditionally, thicker stretch films were considered essential to provide sufficient strength and stability for wrapping pallets. However, advances in technology have paved the way for thinner performance films.

High performance pallet wrap enables businesses to wrap more pallets with less film without sacrificing effective load containment.

One of the primary advantages of reducing thickness in stretch wrap is the potential for significant cost savings. Thinner films, when applied to pallets in the right way, can reduce the overall amount of material required to wrap a pallet. In turn, this helps cut the amount of money you spend on purchasing stretch films.

With the right application process, it can also reduce the number of wraps around the pallet. This speeds up the wrapping process and reduces the time taken to wrap each pallet.

Using a high-performance stretch film with a lower thickness can positively impact your sustainability goals. Compared to a conventional film, using a high-performance pallet wrap can remove tons of plastic from a supply chain.

Whilst cost savings and sustainability are compelling reasons to explore using a high-performance film, ensuring that load containment is not compromised is critical. The primary purpose of stretch wrap is to secure and protect palletized loads during transportation and storage.

Striking the right balance between thickness reduction and load containment is imperative in reducing product damage, maintaining pallet integrity in the supply chain, and reducing incidents of health and safety breaches.

This is why pairing the right high-performance film with the right application method is important. The type of pallet wrapping machine used to apply material plays a pivotal role in achieving the delicate balance required for effective thickness reduction.

Call us at 813 242 6995 or [email protected] to discuss and test our range of high-performance stretch films.

#stretch film pricing#pricing news#stretch film#resin pricing#coreless film#quickpakinc#free pallet wrapper#quick pak inc#free machine#high performance stretch film#amtopp#loadstar pallet wrap

2 notes

·

View notes

Text

#India Packaging Machinery Market Report by Machine Type (Filling Machines#FFS (Form#Fill and Seal) Machines#Cartoning Machines#Palletizing Machines#Labeling Machines#Wrapping Machines#Cleaning and Sterilizing Machines#and Others)#Technology (General Packaging#Modified Atmosphere Packaging#Vacuum Packaging)#End Use (Food#Beverages#Pharmaceutical and Personal Care#Chemicals#and Region 2024-2032#India Packaging Machinery Market Report

0 notes

Text

Transform your packaging process with our cutting-edge Wrapping Machine Manufacturers in Coimbatore, efficiency and precision redefined. Kindly contact us www.wrappingmachinemanufacturers.com

Mobile Number : +91 9843332104

Website : wrappingmachinemanufacturers.com

Address : No.62 Tankstreet C V Patty Ashok Nagar, SNS Rajalakshmi College Of Arts And Science, Saravanampatti, Coimbatore-641006

#Wrapping Machine Manufacturers in Coimbatore#Pallet Wrapping Machine in Coimbatore#Steel Strapping Tool in Coimbatore

0 notes

Text

The PR ROBO 600 is a robotic pallet stretch wrapping machine with CE certification. This robotic machine has a PLC control board and LCD for ease of use.

It has a height sensor for detecting pallet height and automatically adjusting for it. The battery charger and indicator facilitate power efficiency and energy saving in the machine's operation.

0 notes

Text

Printed Stretch Film for box wrapping

In the world of packaging, the presentation of a product can make all the difference. Printed stretch film for box wrapping offers a unique and effective way to enhance your brand's image and make a lasting impression on customers.

One of the key benefits of printed stretch film is its ability to showcase your brand identity. Whether you choose to display your logo, company colors, or a custom design, the printed stretch film allows you to create a cohesive and professional look for your packaging.

Additionally, printed stretch film can serve as a powerful marketing tool. By featuring your brand message or promotional offers directly on the film, you can effectively communicate with customers and generate interest in your products.

Moreover, the printed stretch film provides practical benefits as well. It offers the same protective qualities as standard stretch film, helping to secure and protect your products during shipping and storage. The printed design also acts as a deterrent against tampering, ensuring the integrity of your products.

Overall, printed stretch film for box wrapping offers a versatile and cost-effective solution for enhancing your brand's visibility and impact. With its ability to combine practicality with aesthetics, printed stretch film is a valuable addition to any packaging strategy.

0 notes

Text

Printed Stretch Film for box wrapping

In the world of packaging, the presentation of a product can make all the difference. Printed stretch film for box wrapping offers a unique and effective way to enhance your brand's image and make a lasting impression on customers.

One of the key benefits of printed stretch film is its ability to showcase your brand identity. Whether you choose to display your logo, company colors, or a custom design, the printed stretch film allows you to create a cohesive and professional look for your packaging.

Additionally, printed stretch film can serve as a powerful marketing tool. By featuring your brand message or promotional offers directly on the film, you can effectively communicate with customers and generate interest in your products.

Moreover, the printed stretch film provides practical benefits as well. It offers the same protective qualities as standard stretch film, helping to secure and protect your products during shipping and storage. The printed design also acts as a deterrent against tampering, ensuring the integrity of your products.

Overall, printed stretch film for box wrapping offers a versatile and cost-effective solution for enhancing your brand's visibility and impact. With its ability to combine practicality with aesthetics, printed stretch film is a valuable addition to any packaging strategy.

0 notes

Text

5 Benefits of Using a Stretch Film Wrapping Machine in Dublin

In the vibrant business landscape of Dublin, efficiency and innovation are key drivers for success. For businesses involved in packaging and logistics, investing in the right equipment can make a significant impact. One such tool gaining prominence is the stretch film-wrapping machine. Here are five benefits of using a stretch film-wrapping machine in the dynamic city of Dublin.

I. Enhanced Product Stability During Transportation

Dublin's bustling streets and busy transportation networks demand robust packaging solutions. A stretch film wrapping machine ensures that palletized goods are securely wrapped, minimizing the risk of load shifting during transit. This enhanced stability not only prevents damage to products but also contributes to a smoother and more reliable supply chain.

II. Time Efficiency in Packaging Operations

In a city where time is of the essence, streamlining packaging processes is crucial. A stretch film wrapping machine automates the wrapping task, significantly reducing the time required for packaging. This time efficiency allows businesses in Dublin to enhance overall operational productivity and meet tight deadlines with ease.

III. Cost Savings through Material Efficiency

Stretch film wrapping machines are designed to optimize the use of packaging materials. By precisely stretching and wrapping the film around pallets, these machines reduce material wastage. This not only leads to cost savings but also aligns with sustainability goals, a factor of increasing importance in Dublin's environmentally conscious business environment.

IV. Versatility in Wrapping Applications

Dublin's diverse industries require packaging solutions that can adapt to various product types and sizes. Stretch film wrapping machines offer versatility in wrapping applications, accommodating different shapes and dimensions of palletized goods. This adaptability makes them suitable for a wide range of industries, from manufacturing to retail.

V. Improved Worker Safety and Ergonomics

Ensuring a safe working environment is paramount in Dublin's business culture. Stretch film wrapping machines contribute to improved worker safety by automating the wrapping process. This reduces the need for manual labor in repetitive and physically demanding tasks, minimizing the risk of workplace injuries and enhancing overall employee well-being.

#automatic pallet wrapper#pallet stretch wrap#machine packaging companies#packaging machine#packaging machine suppliers#packaging and machinery#packaging machinery equipment#stretch film wrapping machine dublin

0 notes

Text

#shrink wrap#pallet wrap#wrapping pallets#machine wrap#hand pallet wrap#pallet bags#wrap bundling film#clear wrap

0 notes

Text

Best Pallet Wrapping Machines Supplier in Dubai

Discover the premier supplier of top-quality pallet wrapping machines in the vibrant city of Dubai. Triveni Packaging Trading Co. LLC specialize in providing state-of-the-art solutions for all your pallet wrapping needs. With a commitment to excellence and a reputation for reliability, we offer a wide range of cutting-edge pallet wrapping machines designed to streamline your packaging processes and enhance the efficiency of your operations.Contact us today to explore how our solutions can revolutionize your packaging operations.

0 notes

Text

The Importance of Efficient End of Line Packaging

In today's competitive business landscape, efficiency and productivity are key factors that can make or break a company's success. When it comes to packaging, the end of the line process holds immense importance. Efficient end of line packaging can make a significant impact on your company's actions, satisfaction of customers, and complete effectiveness. In this blog, let us explore how Nichrome has helped industries across with our efficient end of line packaging and how it can benefit businesses across various industries.

With Nichrome’s end of line packaging comes the following benefits:

1. Streamlined Operations: Nichrome’s End of Line Packaging ensures a smooth and streamlined packaging process. It involves activities such as case sealing, palletizing, and labeling, which contribute to the final stage of product packaging. By optimizing these processes your businesses can reduce bottlenecks, eliminate unnecessary manual labor, and enhance overall operational efficiency.

2. Enhanced Productivity: Our end of line packaging directly impacts productivity. We have a proven track record of well-designed packaging lines, equipped with automated packaging systems and advanced machinery, that can handle higher volumes of products in less time. This leads to increased productivity, allowing businesses to meet customer demands, fulfill orders promptly, and achieve higher output with fewer resources.

3. Budget-Friendly: Our budget-friendly end of line packaging has helped businesses grow sufficiently by saving a handsome amount. Automation and integrated packaging solutions by Nichrome have aided many businesses to reduce their reliance on manual labor, leading to lower labor costs and enhanced cost efficiency. Additionally, streamlined operations reduce waste, minimize product damage, and optimize material usage, resulting in reduced operational costs.

4. Improved Product Protection: Proper end of line packaging ensures the safety and protection of products during storage and transportation. By using advanced packaging solutions such as case sealing machines and palletizers, businesses can secure products in sturdy containers, reducing the risk of damage and preserving product quality. This, in turn, enhances customer satisfaction and minimizes product returns or replacements.

5. Labeling and Traceability: It also plays a crucial role in guaranteeing conformity with your industry regulations and standards. Our designated labeling and traceability packaging systems enable your businesses to track and trace products throughout the supply chain, assisting quality control, recall management, and adherence to legal requirements.

6. Brand Reputation and Customer Satisfaction: Nichrome’s end of line packaging optimistically ensures to improve your brand’s reputation and customer satisfaction. Well-packaged products not only give a professional and appealing look but also reach your customers in pristine condition. This fosters positive brand perception, builds customer trust, and enhances the overall customer experience.

To achieve competent end of line packaging, businesses can leverage advanced & integrated packaging solutions. Nichrome, a top packaging machine manufacturer, offers a wide range of automated end of line packaging solutions such as case sealers, palletizers, carton packing machine, shrink wrapping machine for bottles, automatic case erector, carton box packing machine, automatic carton box packing machine, stretch wrap machine and labeling machines. These highly upgraded machines are designed to streamline the packaging process, increase productivity, and ensure the highest quality packaging for various industries.

Nichrome End of Line Packaging

Nichrome provides comprehensive end of line packaging solutions, including palletization, for both bags and cases. Our customized solutions cater to the unique needs of businesses, ensuring efficient and streamlined operations. We are the pioneers in providing comprehensive end of line packaging solutions to cater the unique needs of businesses, ensuring efficient and streamlined operations.

Our end of line packaging offers customized packaging solutions including:

➔ Automatic Pallet Dispensing

➔ Collation using Pick & Place (Robotic / Gantry)

➔ Palletizer (Robotic / Gantry)

➔ Multiple Line Configuration Integration

➔ Stretch Wrapping

In conclusion, Nichrome’s end of line packaging is crucial for businesses looking to optimize their operations, cost reduction, and deliver high-quality products to customers. By investing in advanced packaging technologies and leveraging the expertise of reliable manufacturers like Nichrome, businesses can unlock the benefits of efficient end of line packaging and gain a competitive edge in the market.

#Packaging#palletizers#end of line packaging solutions#shrink wrapping machine for bottles#automatic carton box packing machine#integrated packaging solutions

0 notes

Text

Reel Stretch Wrapping is specially designed for packing paper, film, foil, and similar materials manufactured in reels through a Paper wrapping Machine, Paper Packaging Machine, or Paper Roll Packing Machine.

#automatic stretch film wrapping machine#box stretch wrapping machine#box wrapping machine#manual stretch wrapping machine#pallet stretch wrapping machine#portable stretch wrap machine#reel stretch wrapping machine#Semi Automatic Reel#stretch film wrapping machine india#stretch wrap machine#stretch wrapping machine manual#stretch wrapping machine manufacturers#stretch wrapping machine price

0 notes

Text

Every Type of Packaging Dispenser

Quick Pak Inc has a vast amount of industrial packaging dispensers for every kind of material. We have cutters, dispensers and racks used for holding, dispensing and cutting paper, corrugated, poly, Pe foam, strapping, cord, stretch wrap, tape, kraft paper, wrapping paper, plastic films, bubble wrap, foil, PVC cling film and many other packaging materials.

If you have a packaging material that needs to be held, dispensed, cut, we have the dispenser for you.

Have a look at some of the dispensers we have available:

Bubble & Foam Dispensers

Corrugated Dispensers

Kraft Paper Dispensers

Pallet Wrap Dispensers

Poly Cover Dispensers

Tape Dispensers

If you need something custom made, we can do that. If you need more information on our vast range of packaging dispensers call us at 813 242 6995 or reach out to [email protected]

#dispensers#poly#tape#stretch wrap dispensers#quick pak inc#pricing news#youtube#stretch film pricing#stretch film#free pallet wrapper#coreless film#resin pricing#free machine#quickpakinc

0 notes

Video

youtube

Economic pallet wrapper. The E-Wrap 1000A pallet wrapper is the latest ISGPACK novelty with the best quality/price ratio on the market. This model manages to cover all standard work applications, thanks to the 6 work recipes that can be customized by the operator.

For more details on the product click on the link:

https://www.isg-pack.com/prodotto/avvolgipallet-economico-e-wrap-1000a/

#Wrapping machine#stretch wrapping machine#wrapping#imballaggio#Packaging#packagings#Packaging solutions#packaging machine#isgpack#economic pallet wrapper#avvolgipallet

0 notes