#plywood-packaging-boxes

Link

Newel Packaging is leading Nail less plywood box manufacturers in india. We also manufacture Wooden Packing Boxes Supply in India. Contact us for Nail less plywood box, wooden packaging boxes, wooden packing boxes, plywood packaging boxes, indsutrial heavy machine packaging boxes, industrial wooden export packaging boxes in India

#wooden-packaging-boxes-manufacturer -sangli-kolhapur#plywood-packaging-boxes-manufacturer-in-india#Nail-less-plywood-box-manufacturers-in-india#wooden-packing-boxes#wooden-packaging-boxes-manufacturer#plywood-packaging-boxes

0 notes

Text

PLYWOOD PACKAGING BOX MANUFACTURER

Custom Plywood Boxes

When it comes to packaging solutions that seamlessly blend strength, durability, and eco-friendliness, look no further than Ficus Pax’s range of custom plywood boxes. As a leading manufacturer in Bangalore, we specialize in crafting high-quality plywood packaging boxes that not only protect your goods but also elevate your brand’s image. In this article, we’ll delve into the numerous benefits and features of opting for plywood packing boxes, addressing common questions and concerns along the way.

Benefits And Features Of Packaging Plywood Boxes

Unmatched Strength and Durability: Plywood is renowned for its exceptional strength-to-weight ratio, making it an ideal choice for packaging heavy or delicate items. Our plywood packaging boxes provide robust protection against impacts, ensuring your products reach their destination unscathed.

Customizability: At Ficus Pax, we understand that one size doesn’t fit all. That’s why we offer customizable plywood boxes tailored to your specific requirements. Whether you need a standard size or a bespoke design, we have the expertise to deliver packaging solutions that align perfectly with your needs.

Eco-Friendly Solution: Sustainability is at the core of our manufacturing process. Our plywood packaging boxes are crafted from renewable and biodegradable materials, minimizing environmental impact without compromising on quality. By choosing Ficus Pax, you’re not just investing in superior packaging; you’re also contributing to a greener future.

Moisture Resistance: Unlike traditional cardboard boxes, plywood offers inherent resistance to moisture, preventing damage from humidity or damp conditions. This feature is particularly beneficial for long-distance shipping or storage in varying climates.

Enhanced Brand Image: Your packaging speaks volumes about your brand. With our custom plywood boxes, you can make a lasting impression on your customers. Add your logo, branding elements, or custom designs to create packaging that reflects your brand’s identity and values.

FAQs

How strong is a plywood box?

Plywood boxes are incredibly strong due to their cross-grain construction, offering robust protection for your goods during transit.

Which is better plywood packing box or pinewood box?

Plywood boxes generally offer higher strength-to-weight ratio and greater moisture resistance compared to pinewood boxes, making them an ideal choice for durable and eco-friendly packaging solutions.

#manufacturer#material#packaging#packing solutions#supplier#plywood#plywood box#plywood boxes#storage

1 note

·

View note

Text

TW — mentions of suicidal ideation and suicide attempt

simon is out on sick leave, his mental health has gotten worse since johnny died. “can’t have you in service if you’re not 100%, riley.” price gruffly remarks as he signs simon’s papers, eyes looking up through thick eyebrows at si, who is angrily glancing away.

sick leave is torture. simon feels lost, no anchor to tether him down to earth. without work, he is nothing. without johnny, he’s ….. nothing.

he spends all day rotting away in bed, his thumb rasping against a battered old photograph of him and johnny on holiday in mallorca. johnny with a gorgeous tan, and simon all pink. no, he doesn’t get an impeccable bronze. that man BURNS.

the corners of simon’s lips twitch as he glances at johnny in the photo, admiring how handsome he truly was. he would give anything to see him again.

and then it gets hard to get anything but dying out of his head. if he dies, then maybe he can see johnny again. they can finally be together again. right?

the capt drops off a small bundle of johnny’s stuff at simon’s apartment, and then a small package is delivered in the post from mrs mactavish, johnny’s mom. various bits and bobs, some of johnny’s tshirts, his favourite cap, some sketchbooks.

his dog tags.

simon’s surprised to find them; he thought that they would be put in johnny’s urn or something. but clearly his mom thought otherwise, she must’ve known how much johnny adored simon. he would have moved heaven and earth for that mancunian.

still, suicide ghosts every waking moment of simon’s life. he glances at johnny’s dog tags besides his bed, chewing his chapped lips as he entertains the idea more. and again when he’s walking around the shops, glancing at various means of killing himself. his thumb rasps against the cold metal of johnny’s tags from within his jacket pocket as his free hand extends to read the packet of rat poison. might be a bit too painful, and apparently it stinks to the high heavens.

simon puts the box of rat poison back, continuing to walk around the shop, thumb still stroking against the dog tags as he continues to glance around the store. he can’t take painkillers, there’s a limit to two boxes per person. so, he settles on visiting the hardware store, and buys a bundle of sturdy rope. even grabs some plywood and metal brackets. “makin’ a swing for the little’un.” he mumbles to the cashier, flashing an uneasy yet somewhat believable smile to her as he fishes out some loose bank notes from his jean pockets. he’s not big on wallets.

for almost a week, simon sits on the edge of his bed staring at the bundle of rope next to a chair from his kitchen. he knows its the only way out, so why is it so terrifying? just do it, riley. do it.

he scrawls out demented ramblings on some loose leaf paper, barely readable chicken scratch to captain price, gaz and to mrs mactavish. “i’ll always be grateful for you for bringing my johnny boy into the world.” is somewhat legible in the letter written to her.

he neatly leaves the letters at the foot of his bed, taking a deep breath as he reaches into his pocket for johnny’s dog tags. for a moment, simon admires them in the dim lighting of his bedroom, watching as the thin metal clinks together. sergeant john mactavish.

as the tags slowly slip over simon’s head, the ball chain momentarily getting caught on a wry piece of scruffy blonde hair, they finally join with simon’s own tags on his chest as he stands on the kitchen chair. for a moment, his hand reaches out against his wardrobe to steady his balance. he slips the noose around his neck, heart thumping against his rib cage ferociously. do it, simon. do it.

simon’s trying his best to still his breathing, taking deep breaths as he tries to dull the nagging thoughts, against his instincts to not do this.

“tae fuck d’yae ‘hink yer daein?!”

simon falls back against his wardrobe out of shock, eyes wide with horror as he glances in the direction of that all too familar voice, that voice that immediately drowns out every single thought that was screaming at simon to kill himself.

it’s johnny.

he’s effervescent, an angelic silhouette of his mortal self. a halo of warm light, blue, ghosts around his form.

simon’s mouth is agape, eyes still wide as his body freezes. immediately, he tears the noose off of his head, damn near stumbling off the chair to get a closer look of the spectacle in front of him.

“johnny? but… you’re…”

“dead? aye, sherlock. i am.” the silhouette retorts sarcastically, flashing ghostly pearly whites in a lopsided grin, one that’s terrifying just like johnny’s signature grin. simon backs against the wardrobe, his breathing uneven and scant as he begins to panic. this isn’t normal, this isn’t right.

the mass of energy and light shaped like johnny notices this panic in simon, and seems to frown. it slowly moves towards him, a hand reaching out to touch simon’s shoulder. it’s hauntingly cold, and it makes simon recoil with horror. the spectre frowns even more, retracting its hand.

this can’t be johnny.

because johnny’s dead.

#elexaria writes#simon ghost riley#john soap mactavish#simon riley#soap mactavish#ghoap#ghoap au#ghoap angst

138 notes

·

View notes

Text

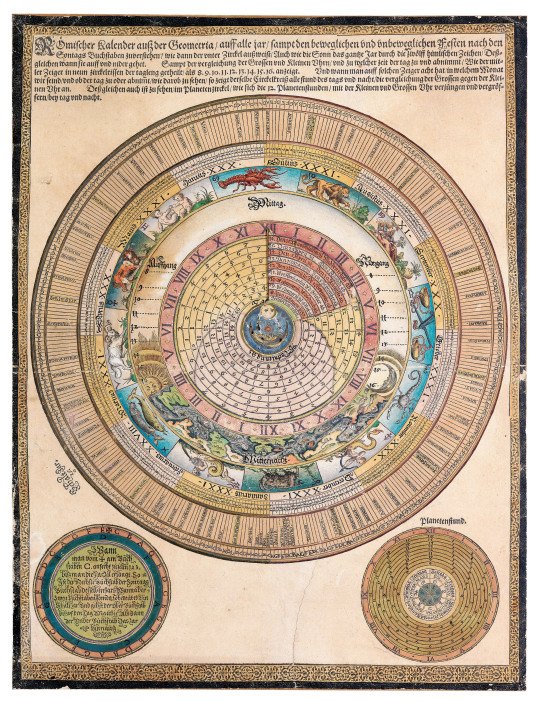

We’re getting into the holiday spirit and unboxing our last packages before the break. We were delighted to receive this carefully boxed shipment from Daniel Crouch Rare Books bearing a very special item: an exceptionally deluxe 16th-century wall calendar with volvelle, finely-detailed coloring and gold highlights. Pictured here, hard at work, are Michael Pasternak of our Technical Services’ End-Processing team and Early Books and Manuscripts curatorial team, John Overholt and Sara Powell. Sound on for full plywood ASMR.

204 notes

·

View notes

Note

APPA!!! *rattles you by your shoulders so hard* You can't post a snippet of such an awesome wip and expect me to be sane!! I'm already in love with what I assume is deity x human sacrifice au and I can't wait to read it! Ahhhh *chomps furiously on plywood* I guess this is one of my fave AUs because I also have like 2 such stories in my head lol

Ahhh sorry for the ramble! Love your writing! I'm sending a big care package of the softest plushies, blankies, sweets and pastries, bathbombs, scented candles and a box of gemstones your way (a huge heart shaped rhodonite included) 💜💜💜💜💜💜💜💜

Wait it was a rhodonite right?

Dear anon, I'm so sorry for saving your lovely ask like a squirrel saves acorns for the winter. I so rarely get asks about my writing anymore (even back when I was somewhat active here) so I felt I needed to wring out every drop of dopamine I could from this one.

Yes, it's a deity x human sacrifice au. We'll see if anything ever becomes of it. I have a bunch written so I might just post that at some point since it seems to interest you. 😊

I'm using this ask to ramble about myself a bit. Writing has been hard lately. I'm still unemployed, but due to everything getting more and more expensive I'm actually actively trying to job hunt now and it's so tough. Rejection after rejection from jobs I don't even want that much (but need since I gotta feed my kid) hasn't been very kind on my mental health. This all coinciding with a noticeable drop in interaction with the stuff I've posted makes the evil trolls in my head rejoice. It's hard not to feel worthless. I'm doing my best to combat the dark feelings. I know where they can lead and I have no desire to fall into that deep depression again.

(To make matters worse, I've been winding down my depression meds for the past 6-ish months and I took my last one about a week ago. I was not prepared for the withdrawal being this hard.)

I want to get back into writing. It makes me happy, and there haven't been that many things making me happy lately. (Except my friends, you know who you are. I love you and you mean more to mean than you can understand. 💜)

P.S. yes, it was a rhodonite ❤️

#lovely anon#random ask box love#late reply#fave#sorry to be so morose#it might just be the seasonal depression knocking on my door#appa's rambles

8 notes

·

View notes

Text

🔥 Oval Large Outdoor Sphere Stainless Steel Red Painted Sculpture

👉 Description: Stainless Steel Sculpture

👉 Product size: L=200 cm

👉 Finishing: Painted

👉 Material: Stainless Steel

👉 Packaging: Plywood box/Steel frame

📌Link product: https://www.067sculpture.com/product/detail/Red-Painted-Metal-Sculpture-Oval-Large-Outdoor-Sphere-Modern-Garden-Art-Sculptures.html

-----

067 GROUP - 067 Sculpture

🏢 38 Lakeside road Ha Dinh, Ha Dinh Ward, Thanh Xuan District, Hanoi City, Vietnam.

☎️ 024 66 733 777 - 024 66 739 777

📞 0768 067 067 - 0778 067 067

🌐 https://www.067sculpture.com

1 note

·

View note

Text

Custom decorative garden panels aluminum laser cut coated waterproof guardrail fence

Detailed description of the production process

Our production process begins with heating the aluminum material. After the aluminum material is heated to a certain temperature, we will seize the opportunity to shape it while it is still high temperature. This step is crucial because it ensures that the aluminum material can remain flexible enough when it is molded into the desired shape.

Aluminum goes through a series of precision machining processes. In these processes, the aluminum material is finely polished and adjusted to ensure that its surface is smooth and flawless. During the machining process, the aluminum material is gradually cooled down until it reaches the required hardness standard. This process requires precise control so that the material can achieve the best mechanical properties and durability.

According to the specific requirements of customers, we will precisely cut and grind the aluminum material to ensure that each section of aluminum bar meets the size specifications required by customers. Once the cutting and grinding process is complete, we proceed to the next step of surface treatment, including dyeing, spraying and, if necessary, welding. These steps are designed to enhance the appearance and durability of the product, but also to meet the individual needs of the customer.

After all the production steps have been completed, the final packaging of the products is carried out to ensure that they are safely and undamaged packed and ready to be shipped to the customer. We use different packaging methods to protect our products and ensure that they are not damaged during transportation.

Packaging options include

Packaging in accordance with shipping requirements ensures that the product can withstand the moisture and pressure that may be encountered during long sea transportation.

The use of felt and plastic film packaging, plus full carton, this packaging method is suitable for heavier or larger products.

On the basis of felt and plastic film packaging, the outer reinforced carton and placed in a LCL plywood box, such packaging is suitable for products requiring additional protection.

We also offer custom packaging services, which can add additional packaging protection measures according to the specific requirements of our customers.

Mode of transport description

We offer our customers a variety of transport options so that they can choose the most suitable transport option according to their needs and budget. While we personally prefer to use sea freight as it is generally more economical and suitable for large volume shipments, we also understand that different customers may have different shipping preferences. Therefore, if you have specific transport requirements, we are more than happy to arrange the transport according to your instructions. Whether it is by land, air or other special logistics needs, we will do our best to meet your requirements and ensure that your products can be safely and timely to the destination.

1 note

·

View note

Text

Protective packaging Services in Gurugram | Benz Packaging

BENZ Packaging provides heavy machinery packaging services in Gurugram, with over 45 years of experience, offers comprehensive solutions for industrial packaging. Protective packaging Services in Gurugram – BENZ Packaging · Transportation & Logistics · 09899144488. [email protected]. Benz Protective VCI packaging provides super protection for all of your metal surfaces and hidden parts. Click on www.benz-packaging.com and get to know more. Heavy Machinery Packing · Protective Packaging · Plywood Box Packing · Delhi NCR Gurgaon · Component Packing. FMCG & Retail Sector. BENZ Packaging partners with FMCG and Retail businesses, offering eye-catching and sustainable packaging solutions. BENZ Packaging has been leading the way in Corrosion Prevention Technology for more than 30 years, with over 4000 satisfied and regular customers

0 notes

Text

Adhesive Products Business Startup: Key Insights and Advice

The adhesive products sector represents a dynamic industry, riding the wave of global trends like sustainable living, rapid industrialization, and increased focus on infrastructure and construction. With an expansive array of applications spanning from automotive to packaging, and textiles to furniture, adhesive products offer a promising avenue for investors. visite pur website https://entrepreneurblog.in/

This article will explore some of the best manufacturing business ideas in the adhesive product sector, emphasizing why startups should invest in this industry, given the current market size, trends, and future opportunities.

Epoxy Resin Based Primer (Putty):

Reasons to Invest:

High Durability: Epoxy resins provide a hard and durable surface, making them ideal for industrial coatings, flooring, and marine applications.

Growth in Construction: With an increased focus on infrastructure and the construction industry, the demand for high-quality primers, such as epoxy-based ones, is set to rise.

Leather Binder (Resin Based):

Reasons to Invest:

Thriving Leather Industry: The leather industry is booming globally, requiring quality binders for leather processing and finishing.

Sustainability: Resin-based binders are more sustainable than traditional chemical binders, offering eco-friendliness as an added advantage.

Pigment Binders for Textile Printing:

Reasons to Invest:

Fashion Trends: With fashion’s ever-changing dynamics, the demand for unique textile prints is evergreen.

Technical Advancements: Innovations in textile machinery and digital printing necessitate advanced pigment binders.

BOPP Adhesive Tapes:

Reasons to Invest:

Packaging Growth: Biaxially oriented polypropylene (BOPP) tapes are essential for packaging. With e-commerce and retail industries growing, so is the demand for BOPP tapes.

Versatility: These tapes have applications ranging from packaging to stationery.

Pressure Sensitive Adhesives for BOPP Tapes (Acrylic Based):

Reasons to Invest:

Strong Adhesion: Acrylic-based adhesives are renowned for their strong bonding properties, making them a top choice.

Broad Applications: These adhesives are also used in labels, decals, and graphics, expanding their market reach.

Guar Gum:

Reasons to Invest:

Food Industry: Guar gum is a popular thickening agent in the food industry, particularly in bakery products and sauces.

Oil & Gas: It’s used in hydraulic fracturing in the petroleum industry, further increasing its demand.

Adhesive (Fevicol Type):

Reasons to Invest:

Furniture Boom: With a growing real estate industry and urbanization trends, there’s a rise in furniture manufacturing, requiring such adhesives.

Craft and DIY: The craft and DIY sector also heavily rely on such adhesives, ensuring steady demand.

Urea Formaldehyde Resin (Powder):

Reasons to Invest:

Wood Industry: Predominantly used as an adhesive in the wood industry, its demand will grow with the timber and furniture sectors.

Durability: It offers resistance to moisture, making it perfect for plywood and particleboard.

Alkyl Resin from Cotton Seed Oil:

Reasons to Invest:

Green Revolution: Derived from renewable sources, these resins offer a sustainable alternative to synthetic ones.

Diverse Applications: They serve various sectors like paints, inks, and rubber.

Corrugated Carton Boxes Gum Powder (Tamarind Kernel Powder Base):

Reasons to Invest:

Packaging Needs: The increasing need for packaging solutions ensures the demand for corrugated boxes and, subsequently, their adhesive needs.

Natural Base: Being based on tamarind kernel powder, it’s eco-friendly and sustainable.

Market Analysis & Trends

The international adhesives market dimension was valued at USD 50 billion in 2019 and is forecasted to sign up a CAGR of over 5% between 2020 and 2026. The vital chauffeurs consist of:

Sustainability: With global emphasis changing in the direction of lasting items, adhesive manufacturers are working towards environmentally friendly options, leading to ingenious products.

Rapid Industrialization: As markets grow, their sticky needs expand, using opportunities in locations like vehicle, building, and product packaging.

Technological Advancements: With development in chemical research, brand-new adhesive items with much better residential or commercial properties and applications are frequently emerging.

Detailed Market Analysis

As we dig much deeper into the adhesive industry, different elements arise that represent its vastness and capacity.

Global Perspective:

Geographically, the Asia-Pacific region controlled the sticky market in 2019, with China, India, and Japan as the frontrunners. The region’s rise in production tasks, infrastructure development, and raising non reusable earnings are leading to greater usage of glue products. Europe complies with the Asia-Pacific, with Germany being the main contributor as a result of its robust vehicle industry. North America, with the U.S. at its core, likewise provides a substantial share, driven by its sophisticated manufacturing industries and surging construction industry.

Segment Analysis:

Different types of adhesives cater to varied applications:

Reactive & Others: This segment held a dominant share in 2019. Products like epoxies, urethanes, and acrylics fall under this category. They’re pivotal in applications demanding high strength and durability.

Hot Melts: These are gaining traction due to their quick-setting nature. Predominantly used in packaging, bookbinding, and the footwear industry.

Water-Based: These are eco-friendly, catering to the rising demand for sustainable solutions. They have applications in packaging, construction, and woodworking.

Raw Material Analysis:

Synthetic: Derived from petroleum feedstock, synthetic adhesives like vinyl acetate are prominent due to their cost-effectiveness.

Natural: Obtained from organic sources like plants and animals. Products such as starch, dextrin, and casein glues are in this category. The drive towards sustainability is making natural adhesives a focal point of research and innovation.

End-Use Trends:

Packaging: With the e-commerce boom, there’s an undeniable demand for adhesive solutions in packaging. Furthermore, the food and beverage industry requires specialized adhesive solutions.

Construction: Urbanization and infrastructure projects globally ensure that adhesives for tiles, wallpapers, and insulation materials are always in demand.

Automotive: Modern vehicle assembly requires adhesives for various parts, from interiors to the engine assembly.

Emerging Trends:

Bio-Based Adhesives: With environmental concerns, there’s an increasing shift towards bio-based adhesive solutions. Algae, soy protein, and lignin are now being explored as potential adhesive sources.

Smart Adhesives: Research is underway to develop adhesives that can change their stickiness or cure when exposed to particular stimuli, such as light or specific temperatures.

Opportunities and Challenges:

Opportunities:

Green Building Standards: With more countries adopting green building standards, there’s a rising demand for eco-friendly adhesive solutions.

Technological Advancements: Innovations will lead to the discovery of adhesives with better durability, resistance, and applicability.

Challenges:

Volatility in Raw Material Prices: The fluctuating costs of petroleum-based feedstock impact the pricing of synthetic adhesives.

Environmental Concerns: Some adhesive manufacturing processes are pollutant-heavy, drawing criticism and demands for cleaner production methods.

Strategies for Startups in the Adhesive Sector:

Invest in R&D: The adhesive industry thrives on innovation. Investing in research ensures the development of superior products.

Diversification: Tapping into various adhesive segments ensures stability. For instance, if one sector faces a slump, another might be booming.

Eco-Friendly Focus: With the world shifting towards sustainability, developing green adhesive solutions can offer a competitive edge.

Global Outreach: While some regions might face market saturation, others, especially in the developing world, offer untapped potential.

Consumer Awareness: Educating the end-user about the advantages of a particular adhesive can lead to brand loyalty and preference.

Case Studies:

Eco-Friendly Shift:

Company: A European adhesive manufacturer.

Challenge: Facing criticism for its environmentally-unfriendly production processes.

Solution: The Company invested in R&D and shifted to water-based adhesives, reducing its carbon footprint and tapping into the eco-friendly adhesive market.

Innovation-Driven Growth:

Company: An Asian adhesive startup.

Challenge: Competing against established giants in the adhesive industry.

Solution: The startup developed a unique adhesive that could bond dissimilar materials, like glass to wood, effectively. Their niche product ensured they stood out and captured a significant market share.

Understanding the Adhesive Landscape:

The adhesive landscape is considerable, and to navigate it successfully, it is crucial to recognize its details, from historic evolution to future forecasts.

Historical Context:

Adhesives aren’t a contemporary development. Old people utilized all-natural compounds like tree sap, beeswax, and tar as binding agents. Over centuries, this art evolved. The 20th century saw a major shift with the introduction of artificial adhesives. Modern adhesives are the end result of hundreds of years of advancement, from nature-based to laboratory-engineered products.

Advancements in Adhesive Technologies:

Nano-technology in Adhesives:

The mixture of nanotechnology has been advanced. Nanoparticles modify the adhesive’s physical properties, boosting its thermal security, peel strength, and even supplying conductivity. For example, adding silica nanoparticles to epoxy resins can dramatically enhance its mechanical strength.

Structural Adhesives:

These are employed where load-bearing joints are required. Developing from simple binding representatives, modern-day architectural adhesives, especially in fields like automotive and aerospace, are expected to bear significant weights and withstand environmental difficulties.

Economic Factors Impacting the Adhesive Sector:

Economic dynamics globally play a vital role in determining the health of the adhesive industry.

Global Economy: A booming global economy leads to increased manufacturing and construction activities, directly propelling the adhesive market.

Trade Relations: Open trade policies and cordial international relations can significantly boost the adhesive market, especially if manufacturing hubs are involved.

Regional Economic Health: Economic health in areas like the Asia-Pacific can have a disproportionate impact on the adhesive industry due to the concentration of manufacturing units.

Adhesive Manufacturing Process:

To genuinely appreciate the nuances of adhesive production, understanding its manufacturing process is pivotal.

Raw Material Procurement: Depending on the adhesive type, raw materials can range from natural substances like tamarind and guar gum to synthetic elements derived from petroleum.

Synthesis: Raw materials undergo chemical reactions to form adhesive substances. For instance, in the production of epoxy resins, epichlorohydrin reacts with bisphenol-A.

Formulation: Additives, fillers, and other ingredients are introduced to give the adhesive its final properties.

Packaging: The finished product is then packed, ready for distribution.

Regulatory Framework & Environmental Considerations:

The adhesive industry is governed by several regulations, especially due to environmental and health concerns.

Volatile Organic Compounds (VOCs): Many adhesives release VOCs, leading to air pollution. Regulations in many countries limit VOC emissions, pushing companies to develop low-VOC or VOC-free products.

Sustainable Production: Emphasis on sustainable manufacturing processes is leading to the adoption of green technologies in adhesive production.

Challenges in Adhesive Manufacturing:

While the adhesive sector is lucrative, it’s not without challenges.

Environmental Impact: Many adhesive manufacturing processes are non-environmentally friendly. Transitioning to greener methods requires R&D investments.

Raw Material Scarcity: With depleting natural resources, sourcing raw materials, especially for synthetic adhesives, might become challenging.

Importance of Branding & Marketing in the Adhesive Sector:

In a competitive market, branding and marketing become essential.

Branding: Strong branding ensures customer trust and loyalty. Many end-users rely on brand reputation when choosing adhesives, especially for critical applications.

Marketing: Effective marketing strategies ensure that the product reaches its target audience. Digital marketing, given its wide reach, has become particularly crucial.

Case Studies in Innovation:

Sustainable Adhesive Production:

Company: A U.S.-based adhesive manufacturer.

Challenge: Facing backlash for its high environmental footprint.

Solution: The Company shifted to a water-based adhesive manufacturing process, drastically reducing its carbon emissions. This move, apart from being environmentally beneficial, also became a significant marketing point, attracting environmentally-conscious clients.

Overcoming Raw Material Challenges:

Company: A startup in South America.

Challenge: High costs and scarcity of synthetic raw materials.

Solution: The startup turned to local resources, utilizing plant-based materials to produce adhesives. Not only did this bring down costs, but it also resulted in unique adhesive products that stood out in the market.

Emerging Markets & Future Potential:

Areas like Africa and parts of Southeast Asia, while currently not dominant players in the sticky industry, hold considerable possibility. Quick urbanization, paired with raising manufacturing tasks, makes these regions potential future hubs for the glue field. Moreover, with global emphasis on sustainability, there is large capacity in the development and marketing of eco-friendly adhesives. Firms that can innovate and generate environment-friendly adhesive solutions will likely dominate the future market.

Conclusion:

The sticky field, while currently large, is still advancing. It presents myriad chances for those going to innovate and adjust. With sustainability as the brand-new rule, there’s uncharted region waiting to be explored in environment-friendly sticky options.

#project consultancy#business consultant#free business advisor in India#business consulting services#small business consultant#business advisory services near me#business model sample#project consulting firms#top ten consulting firms#big 10 consulting firms

0 notes

Text

Corrugated Types Used in the Packaging Sector

Because cardboard may be used in many ways daily, many varieties are available on the market. Cardboard may have good thermodynamic qualities and be a material that is both lightweight and very strong, depending on its thickness, shape, and form.

This post will examine the most popular varieties of cardboard box manufacturers sector and discuss their widespread usage and dependability.

Also Read: Suppliers of Carton Boxes and Their Impact on Contemporary Packaging

Different Cardboard Box Types

The several kinds of boxes and the terms used interchangeably in the packing business to describe them—rigid boxes, folding cartons, set-up boxes, corrugated boxes, cardboard boxes, paperboard boxes, and so forth—confound many people. There are three main box types in the packaging industry. They are all made of paper pulp in varying thicknesses.

Fundamental Kinds of Boxes

Carton Folding

Among the most common box types seen in stores are folding cartons, also called paperboard cartons or paper packaging boxes. This is a folding carton; it resembles a milk or cereal box.

Stiff Boxes

Since they do not fold or collapse, rigid boxes—also called set-up boxes—are more resilient than folding cartons. They are often (though not always) used to luxury goods that are thought to be of superior quality. They are also used when the contents need extra support since they are hefty. A stiff box may be compared to the packaging of an iPhone.

Plywood Boxes

When relocating, brown cardboard boxes called corrugated boxes—also called corrugated board, mixed board, or corrugated fiberboard—are often used to pack and store belongings.

Honeycomb box manufacturers typically consist of three layers. A curved or fluted layer sits between two smooth exterior surfaces. The longevity of this paper product is found in its perforated layer.

Various Cardboard Packaging Types

Your needs will determine how many different kinds of cardboard packaging you need. The following list includes many types of cardboard packaging:

One-Faced Board

The single-face board is the most prevalent kind of cardboard packaging that you will encounter. This is only corrugated cardboard minus the second piece on the opposite side of the fluted layer. It is common practice to pack items in a single box in this manner to ensure that they do not break or clash while in transportation.

Single-Wall Board

This is the typical corrugated cardboard for shipping boxes and other cardboard packaging. It features one line of fluting in the centre and two flat walls. This cardboard may be robust even with only one flute layer, so boxes often utilise it.

Double-Wall Board

Naturally, the double-wall board adds fluting between the two outermost layers. Doing this strengthens the board, giving the items kept within even more protection.

Conclusion

Making the best choices for package design requires understanding the function of cardboard in packaging.

#corrugated box supplier#carton box supplier#corrugated packaging manufacturer#corrugated box manufacturers

0 notes

Text

NAILLESS BOXES: A SUSTAINABLE PACKAGING SOLUTION

Nail less Boxes: A Sustainable Packaging Solution

Are you in search of an innovative and eco-friendly packaging solution? Look no further than Ficus Pax, as we introduce our revolutionary nail-less E-1 grade plywood packaging boxes. These boxes are meticulously crafted from high-quality wood and reinforced with steel corners, offering a new level of convenience, reliability, and sustainability in packaging.

At Ficus Pax, we understand the importance of sustainable practices in today’s world. That’s why our nail-less boxes are designed to minimize environmental impact without compromising on durability. By eliminating the need for nails, we reduce waste and make recycling easier, contributing to a greener future.

Our boxes are not only environmentally friendly but also highly functional. The precision craftsmanship ensures that each box is sturdy and reliable, providing optimal protection for your valuable goods during shipping. The steel corners add an extra layer of reinforcement, ensuring that your items remain intact even in the most demanding transportation conditions.

Benefits & Uses of Nail less Boxes

Ficus Pax pioneers the innovation of nail-less packaging solutions, offering unparalleled benefits in safeguarding your valuable goods across diverse industries. Nail-less boxes redefine convenience and durability, ensuring optimal protection during storage and transit.

Key Advantages:

Collapsible & Customizable: Our E-1 grade plywood nail-less boxes boast collapsible features, simplifying storage and transportation. Tailored to your product’s size and weight specifications, these boxes can be assembled and dismantled effortlessly, eliminating the need for on-site carpenters or nails.

Enhanced Durability: Crafted with a fusion of wood and reinforced steel corners, these boxes ensure superior strength and resilience. Their ability to withstand challenging weather conditions and prolonged storage safeguards your goods effectively.

Eco-friendly & Reusable: Utilizing plywood, these boxes remain exempt from ISPM 15 certification. This eco-friendly approach aligns with sustainable practices, while their reusability for up to 5 years underscores their cost-efficiency.

Versatile Applications: From safeguarding sensitive electronics to transporting heavy machinery, nail-less plywood boxes offer a versatile packaging solution for various industries. Their adaptability to diverse product types underscores their universal utility.

FAQs

What sets nail-less plywood boxes apart from traditional packaging?

Nail-less boxes offer unparalleled convenience and sustainability, eliminating the need for nails and skilled labor during assembly, making them collapsible and reusable.

Can these boxes be customized for specific products?

Absolutely! Ficus Pax provides tailored solutions, ensuring these boxes match your product’s size, weight, and transportation needs.

Are these boxes compliant with international shipping standards?

Yes, our nail-less E-1 grade plywood boxes comply with export requirements and, being entirely plywood, are exempt from ISPM 15 certification.

#manufacturer#material#packaging#packing solutions#supplier#trendingnow#box#boxes#box set#storage#product design#packaging design#logo

2 notes

·

View notes

Text

Explore the Versatility of Plywood by Discovering its Use in Several Applications

The need for the sustainable and affordable development is making people choose Plywood for different types of construction these days. The first thing that comes in mind when people hear about plywood is furniture. But with the help of this blog, we will help you explore the versatility of plywood in the best way. At present, plywood is available at most places, but due to their high demand, prices are quite high at most places. But if you buy from the right brand like Ristal Laminates, you will not face the problem in price. Plywood in Noida, Uttar Pradesh at best price is available for different types of uses. But before you buy one, let’s explore where all you can utilize this material.

Roofing and Flooring – Plywood being one of the sturdy construction materials is being used in several construction applications. Roofing, sheathing, and flooring are some of the common construction applications where plywood is used. It offers a strong base along with the long lasting durability. The smoothness of plywood surface makes it apt for formwork and flooring applications. Also, due to the availability of plywood in Noida, Uttar Pradesh at best price, it is considered budget-friendly to use in all these construction applications.

Automotive Sector – Automobiles are not only made of metals but there are several items in an automobile that are made of plywood. Some of them include dashboards, seat structures, door panels, and a few more. The robustness of plywood makes it suitable to use in the manufacturing of these components.

Marine Applications – Another industry where plywood is highly used is marine industry. We know that many people feel that wood is not sustainable when it is about using it in water. But the availability of BWP and BWR grade plywood has made it possible to manufacture several marine industry components using it. These grades of plywood offer excellent resistivity to water and that is why they are being used for building boats, ships, and the interior wood components used in them like decks and hulls. Though not every plywood manufacturer offers water resistant plywood but Ristal Laminates is known for offering both BWP and BWR grade plywood.

Packaging Industry – The strength of plywood makes it suitable for building shipping boxes and crates. These boxes are roughly used in the cargo & shipping industry and that is why they need to be sturdy for long lasting use. Plywood not only offers the rigidity for constructing these boxes but the availability of plywood in Noida, Uttar Pradesh at best price makes it an affordable material for such applications.

Other than these applications, plywood is also used in manufacturing sports equipment, aerospace industry, interior designing sector, and many more. We know that price matters a lot when investing in Plywood that is why we recommend going for a brand like Ristal Laminates. Here, you will get plywood at best prices and for almost every application.

0 notes

Text

Design: The first step is to design the puzzle, which includes choosing the image to be used, determining the number and size of puzzle pieces, and creating a template or blueprint for the puzzle.

Printing: Once the design is finalized, the image is printed onto paper or cardstock. This printed image will serve as the guide for cutting the wooden puzzle pieces.

Mounting: The printed image is then mounted onto a thin sheet of wood, typically made from plywood or MDF (medium-density fiberboard). The wood is then cut into individual puzzle pieces using a laser cutting machine or a saw.

Sanding: After the pieces are cut, they are sanded to ensure that they have smooth edges and are free of any rough spots or splinters.

Sorting: The pieces are then sorted and placed into bags or boxes, according to their shape and size. This is typically done by hand.

Packaging: Finally, the puzzle pieces are packaged, typically in a box made from the same type of wood used to make the puzzle pieces. The box is often adorned with the same image as the puzzle, and may include a picture of the completed puzzle as a reference for the puzzler.

Overall, the production process of wooden jigsaw puzzles requires a combination of skilled craftsmanship and modern technology to create a high-quality product that is both aesthetically pleasing and enjoyable to solve.

0 notes

Text

Li’l Boxes are the experts in turning timber and plywood into visually attractive brand activations. From smaller, individual timber boxes for product display packaging for the grocery, floral, retail, wine industries, to large-scale point-of-sale boxed displays for temporary or permanent retail environments, we deliver long-term value for our clients’ businesses. Whether you are after a product display for retail, or a physical fit-out for your space, we create a bespoke solution for your needs. We are experts in creating custom-made solutions from simple materials, with intelligent design and high-tech machinery. The outcome is user-friendly, clever activations for your brand and business.

Li'l Boxes

10-14 Clyde St, Wingfield SA 5013

0882506781

https://lilboxes.com.au/

Facebook

Instagram

Google Maps

1 note

·

View note

Text

Unlocking Efficiency and Sustainability with ISPM15 Custom-Made Pallets

The logistics and supply chain industry functions efficiently mainly due to the presence of custom made pallets from wood and plastic. Companies that manufacture these custom made pallets follow every law and regulation related to their production, and one guideline that they can't afford to skip is ISPM 15. Everything made from wood for overseas transportation has to be manufactured in compliance with the ISPM 15 guidelines. In this blog post, we go through some common questions related to ISPM 15 and what impact these regulations put on custom made pallets.

WHAT IS ISPM 15?

ISPM stands for International Standards For Phytosanitary Measures – Publication Number 15. This publication has guidelines for regulating wood packaging materials in international trade and transportation.

WHY WAS 'ISPM' DEVELOPED?

According to the vendors of pallet bed frames and wholesale timber pallets, ISPM 15 was developed to address the problem of pests transport from one country to another through wooden pallets and other products. These guidelines were intended to regulate the movement of timber packaging and pallets, pallet bed frames, dunnages, wooden boxes and so on in international trade.

WHAT IS INCLUDED IN ISPM 15?

ISPM 15 has all the guidelines related to regulating the movement of wooden packaging products across the globe. It also describes phytosanitary measures to reduce the risks of deadly pests and virus transport in other countries.

WHO DEVELOPED AND ENDORSED ISPM 15

The United Nations Food And Agriculture Organisation played an instrumental role in developing ISPM 15 rules and guidelines. This organisation is responsible for addressing plant current time through the International Plant Protection Convention.

WHAT DOES ISPM 15 APPLY ON?

ISPM 15 applies to every wooden product used for packaging, transporting, and storing goods and products. This means that wooden pallets, wooden crates, custom made pallets, wooden boxes, wooden dunnages, wooden drums, wooden pallet collars etc., all have to comply with ISPM 15 regulations.

Apart from these, several other products also have to comply with ISPM 15, like –

Wood packaging made entirely from thin wood (6 mm or less in thickness)

Wood packaging made wholly of processed wood such as plywood, particle board, oriented strand board or veneer

Veneer peeler core

Barrels for wine and spirit that have been heated

Wooden gift boxes for wine, cigars and other commodities

Sawdust, wood shavings and wood wool

Wood components attached to freight vehicles and containers.

0 notes

Text

nailless boxes manufacturers in india

Newel Packaging is one of the leading Nail less Plywood Boxes Manufacturers, Suppliers in India. Contact us for Nail less Wooden Boxes, Collapsible wood plywood packaging boxes, Nailess Packaging Boxes, Nailess Boxes Manufacturer, Supplier, Exporter

#nailless boxes suppliers in india#nail less boxes in india#nail less packaging boxes in india#wooden crates manufacturers in india

1 note

·

View note