#pneumatic screwdriver

Text

Revolutionizing Efficiency: The Pneumatic Screwdriver’s Impact on Industrial Productivity”

Introduction:

In the fast-paced world of industrial manufacturing, the quest for efficiency and speed is never-ending. One of the tools that has played a crucial role in achieving these goals is the pneumatic screwdriver. This innovative device has transformed assembly lines and construction sites, providing a powerful and reliable solution to the challenges of fastening screws. In this article, we will explore the features, benefits, and the significant impact of pneumatic screwdrivers on industrial productivity.

Understanding Pneumatic Screwdrivers:

A pneumatic screwdriver, also known as an air screwdriver, operates using compressed air as its power source. This distinguishes it from traditional electric screwdrivers. Compressed air, supplied through hoses connected to an air compressor, powers the internal mechanism of the screwdriver, generating the torque needed to drive screws efficiently.

Features and Components:

Pneumatic screwdrivers are designed with precision and durability in mind. They consist of several key components, including an air motor, clutch mechanism, and adjustable torque settings. The air motor converts compressed air into rotational energy, while the clutch mechanism ensures that the tool stops applying force once a certain torque level is reached, preventing over-tightening.

The adjustable torque settings are a crucial feature, allowing users to customize the tool’s performance based on the specific requirements of the task at hand. This adaptability is especially valuable in industries where a variety of screws with different torque specifications are used.

Benefits of Pneumatic Screwdrivers:

High Torque and Speed: Pneumatic screwdrivers deliver impressive torque and speed, making them ideal for applications where efficiency and precision are paramount. The high rotational speed ensures quick and accurate screw fastening, reducing assembly times and increasing overall productivity.

Lightweight and Ergonomic Design: Unlike some electric screwdrivers, pneumatic models are often more compact and lightweight. This ergonomic design contributes to reduced operator fatigue during prolonged use, enhancing worker comfort and safety.

Durability and Reliability: Pneumatic screwdrivers are known for their durability and reliability. The absence of complex electrical components makes them less prone to malfunctions, and their robust construction ensures a long operational lifespan. This reliability is a significant factor in maintaining continuous production in industrial settings.

Cost-Effective: In many cases, pneumatic screwdrivers are more cost-effective than their electric counterparts. The initial investment may be lower, and ongoing maintenance costs are often minimal. Additionally, the efficiency gains translate to cost savings in terms of labor and time.

Impact on Industrial Productivity:

The introduction and widespread adoption of pneumatic screwdrivers have had a profound impact on industrial productivity. Assembly lines that once faced bottlenecks due to slow and inefficient screw fastening processes are now able to operate at higher speeds with improved precision.

Increased Throughput: Pneumatic screwdrivers significantly contribute to increased throughput on assembly lines. The combination of high torque and speed allows for rapid and accurate screw fastening, enabling manufacturers to produce more units in less time.

Consistent Quality: The adjustable torque settings on pneumatic screwdrivers ensure consistent and reliable fastening. This is critical in industries where product quality is of utmost importance. By preventing over-tightening or under-tightening, these tools contribute to the production of high-quality goods.

Time and Cost Savings: The efficiency gains achieved with pneumatic screwdrivers result in notable time and cost savings. Reduced assembly times mean lower labor costs, and the durability of these tools minimizes the need for frequent replacements or repairs, further contributing to overall cost-effectiveness.

Conclusion:

In conclusion, the pneumatic screwdriver stands as a testament to the constant evolution of industrial tools aimed at enhancing efficiency and productivity. Its high torque, speed, durability, and cost-effectiveness have made it an indispensable asset in various manufacturing and construction settings. As industries continue to seek ways to optimize their processes, the pneumatic screwdriver remains a key player in driving progress and innovation.

0 notes

Text

Discover the Hidden Secret Behind the Explosive Performance of Shinano Pneumatic Tools

Are you searching for top-notch air tools that deliver exceptional performance? Look no further! In this post, we unveil the hidden secret behind the explosive performance of Shinano Pneumatic Tools. Whether you're a DIY enthusiast or a professional in need of reliable tools, Shinano has got you covered. From the impressive Shinano High Speed Grinder to the efficient Shinano Air Polishers Tools, and the precise Shinano Pneumatic Screwdriver, we've got the scoop on these remarkable tools that have taken the market by storm.

Unveiling the Shinano High Speed Grinder

When it comes to heavy-duty grinding, the Shinano High Speed Grinder stands in a league of its own. Its robust design, coupled with high-speed capabilities, ensures swift material removal with utmost precision. Whether you're working with metal, wood, or other materials, this grinder's performance is truly explosive. Say goodbye to time-consuming grinding tasks and hello to efficiency and excellence.

Masterful Performance with Shinano Air Polishers Tools

Achieving a flawless finish is an art, and Shinano Air Polishers Tools are the brushes of the modern artisan. These tools combine ergonomic design with powerful pneumatic technology to give your surfaces a stunning, polished look. From automotive enthusiasts to woodworking professionals, these air polishers elevate your work to the next level. Unleash your creativity and achieve results that speak for themselves.

The Precision of Shinano Pneumatic Screwdriver

When it comes to assembling intricate machinery or working with delicate components, precision is non-negotiable. The Shinano Pneumatic Screwdriver offers the accuracy and control you need to fasten screws seamlessly. Its ergonomic grip reduces fatigue, ensuring prolonged productivity without compromising on performance. Say goodbye to stripped screws and inefficient work – Shinano's screwdriver is here to redefine your working experience.

Buy Air Tools Online UK - Your Gateway to Excellence

Are you based in the UK and in need of top-quality air tools? Look no further than Pneutube Limited's impressive selection. From the explosive performance of Shinano Pneumatic Tools to the convenience of shopping online, Pneutube Limited brings you the tools you need with just a few clicks. Don't settle for subpar tools; elevate your craftsmanship with the best.

FAQs

Q: Can these tools be used by beginners?

A: Absolutely! Shinano Pneumatic Tools are designed to cater to both beginners and professionals, ensuring ease of use without compromising performance.

Q: Are replacement parts easily available?

A: Yes, Pneutube Limited offers a wide range of replacement parts for Shinano tools, ensuring your investment is a long-lasting one.

Conclusion

In conclusion, the explosive performance of Shinano Pneumatic Tools is not just a myth – it's a reality that countless professionals and enthusiasts swear by. From the Shinano High Speed Grinder's robust grinding capabilities to the finesse of Shinano Air Polishers Tools and the precision of the Shinano Pneumatic Screwdriver, these tools redefine excellence. So why wait? Elevate your work by embracing the hidden secret behind Shinano's remarkable performance. Visit Pneutube Limited today and buy air tools online in the UK to embark on a journey of craftsmanship like never before. Your projects deserve nothing less than the best, and Shinano delivers precisely that.

#Shinano Pneumatic Tools#Shinano Pneumatic#Air Tool Parts & Accessories#Buy Air Tools Online UK#Online Cutter Standard UK#Online Standard Die Grinders UK#Shinano Pneumatic Drills#Pneumatic Impact Wrench Tools#Buy Pneumatic Air Polishers Tools#Buy Shinano Pneumatic Screwdriver#Buy Flexible Nylon Tube Online#Online Gas Springs Tools#VariLift Gas Spring#Buy Pneumatic Equipment#Pneumatic Equipment Online#Metalwork Valves#Festo Valves#Metalwork Push Fittings#Festo Cylinders#Metalwork Pneumatics#Metalwork Cylinders#Festo Push Fittings#Shinano Air Tools UK#Shinano Ratchet Wrench Tools Online#Shinano Air Sanders Tools#Shinano High Speed Grinder#Buy Shinano Air Tools Online UK

2 notes

·

View notes

Text

Hand Tools for Sale - Buy Now and Get Discounts

Buy Hand Tools at Selco in Ludhiana and make your tasks like hanging picture frames on the wall and performing repairs in the home easier. Hammer, Glass Cutter, Extractors Set, and Knife Blade are a few of the tools available at this website. All the tools available at the inventory are made from durable materials to ensure their lasting possession.

Listed below are some types of essential hand tool kits that you must own one:

DIY Kits: Tool Sets for various DIY purposes can be necessary for home or other purposes. These sets of tools for home improvement could be useful when it comes to repair work on your home, remodeling and alterations and hanging curtains, making furniture and beds that are raised and more.

Electrician Tool Kits: With its robust motor and a variety of tools, the electrician kit box offers an easy electrical equipment and maintenance choice.

Universal Tool Kits: An Universal Tool kit includes rust-free tools and the ability to mix utility tools that you can use for everyday purposes.

Buy Hand Tools At The Affordable Prices

Selco in Ludhiana offers various hand tools for sale online with a range of products that you will never regret owning. All the tools possess lasting durability and are available at the most affordable prices.

Buy Hand Tools:

Socket sets

Ratchet and extension sets

Allen wrenches

Torx drivers

Bolt cutters

Pliers (needle-nose, slip-joint, locking)

Wrenches (adjustable, socket, box-end)

Screwdrivers (flathead, Phillips, Torx)

Hammers (claw, ball-peen)

Our selection of hand tools includes the latest hand tools and some useful unique sets of tools. Buy Hand Tools at the most affordable prices by visiting our store in Ludhiana today!

#tools#tool kit#construction#diy projects#household appliances#tools and equipment#hand tools#screwdriver set#screwdriver#hammering#chisel#pneumatic tools#toolkit

0 notes

Text

'*****

No sonic screwdriver. No TARDIS. No city-razing destruction, nor stupefyingly cute alien critters. As Doctor Who episodes go, ‘Wild Blue Yonder’ couldn’t be more different from the show’s blockbuster comeback, ‘The Star Beast’, if it tried. Last week’s adventure was Who at the peak of its silly, sugar-rush sci-fi powers: a spectacular kick-off to the show’s 60th anniversary celebrations, precision-tooled to dazzle newbies (Whobies?) and dyed-in-the-wool Whovians alike. This week’s, however — essentially a two-hander — is an insular Gothic chamber piece that goes toe-to-toe with Alien in the spaceship-as-haunted-house stakes. Invoking everything from NuWho favourites ‘Midnight’ and ‘Listen’ to sci-fi horror classics Event Horizon and The Thing, Russell T Davies strips everything back here to remind viewers at home that there ain’t no bottle episode like a Doctor Who bottle episode.

Arriving under a shroud of sworn secrecy (even press didn’t see this one until it aired), speculation had been rife about exactly what ‘Wild Blue Yonder’ would be. Rumours of a multi-Doctor story — Peter Capaldi, Matt Smith, Jodie Whittaker: you name ’em and someone had an in-depth Twitter/X thread red-stringing together a theory — abounded. But while technically this is a multi-Doctor story (and a multi-Donna one at that), it’s not one in the way anybody would have expected. And honestly, amid a landscape of disposable cameos and inconsequential fan-service, that the secrecy is in aid of storytelling rather than stunt casting is a blessed relief.

A comical cold open sees the Doctor (David Tennant) and a newly memory-restored Donna (Catherine Tate) flung back to England, circa 1666. There, the duo catalyse Sir Isaac Newton’s (It’s A Sin’s Nathaniel Curtis) discovery of ‘mavity’ (a communicational mishap) and the Doctor’s discovery of bisexuality (“He was hot, wasn’t he?”). But a classic ‘Doctor-meets-historical-figure-and-hijinks-ensue’ caper this is not. And before long, the Doctor and Donna find themselves stranded aboard a seemingly abandoned spaceship harbouring a threat so terrifying that even the TARDIS has done a runner.

The eerie, empty (save for glacially slow Hitchhiker’s Guide To The Galaxy-homaging Chekhov’s robot Jimbo), seemingly endless spacecraft corridors and wheezing hydraulic pistons of ‘Wild Blue Yonder’ represent a stark counterpoint to the crashy, bangy, flashy Meepiness of ‘The Star Beast’. A sublime combination of pneumatic practical effects, soundstages, and nifty CGI made possible by that sweet new Disney dollar, the distinctly Nostromo-esque sense of isolation about the ship aptly evokes the abyss of the episode’s edge-of-the-universe setting. It’s a spatial oddity that serves the plot and augments the tone of the piece perfectly, centralising our focus on the Doctor, Donna, and their unique bond as the uncanny threat they face is slowly revealed. That threat? Why themselves, of course. Sort of.

Revealed in a properly creepy sequence that starts with the slow-dawning realisation that something isn’t quite right and climaxes with an injection of out-and-out Cronenbergian body horror, the ‘Not-Things’ are Weeping Angel-level nightmare fuel. Cosmic shapeshifters bent on universal destruction, the demonic doppelgängers — brought to life with palpable, dead-eyed menace by a multi-roling Tennant and Tate — are able to mimic the Doctor and Donna’s form, manner, and even memories.

This set-up leads to a succession of intricately written “I know I’m me but how do I know you’re you?”-type exchanges — including one particularly fiendish bait-and-switch — that really allow Tate and Tennant to flex their acting chops, underlining their inimitable chemistry in the process. It’s also an opportunity for Davies to really hammer home that this is the Fourteenth Doctor, not the Tenth — and Donna Temple-Noble with a family waiting for her at home, not Donna from Chiswick gadding about with a two-hearted spaceman.

One particular exchange, in which canon-reshaping events of the Chris Chibnall era of the show come to the fore, allows Tennant to really click through the gears as he embodies elements of the Doctors who’ve been and gone since last time around: Smith’s wistful longing, Capaldi’s bone-deep grief, Whittaker’s emotional vulnerability. In about 30 seconds, several years of head-spinning exposition is simply, beautifully reframed. The Doctor doesn't really know who they are anymore, running from reckoning with the weight of all that they’ve seen and done, hoping against hope for somebody else out there to understand — if even just for a little while. No matter whether you’re a hardcore Whovian or don’t so much as carry a provisional TARDIS licence, if you’re looking for a distillation of the show’s essential nature, you’d struggle to find one better than this.

‘Wild Blue Yonder’ is a brutally simple, slickly executed high concept that we’ve seen iterative versions of before in OG Tennant/Tate-era fan favourites ‘Midnight’ and ‘Waters Of Mars’. But, especially when considered in the context of Who’s recent turbulent history, its use here — in a conversation-heavy hour of TV that digs deep into the past 15 years of the show both on and off screen — feels utterly singular. Giving folks the Doctor, with their plucky companion and techno-babble and eccentric wardrobe is easy, Davies seems to be saying: anyone can do it. But without genuine emotion — without heart — all you’ve really got is a pale imitation of something truly great, iconography and nothing more. Lucky for us, then, that by the time the credits roll there can be no doubt. This bold new Whoniverse is the real deal, and nothing is wrong… nothing in the whole wide world. *Sniffle*.

Taut, tense, and frequently terrifying, this spaceship-in-a-bottle episode isn’t just an instant Who classic — it’s one of 2023’s finest hours of TV to boot.'

#Doctor Who#60th Anniversary#Wild Blue Yonder#David Tennant#Catherine Tate#Donna Noble#The Star Beast#Midnight#Sir Issac Newton#It's A Sin#Nathaniel Curtis#Chris Chibnall#Matt Smith#Peter Capaldi#Jodie Whittaker#Russell T. Davies#The Waters of Mars

24 notes

·

View notes

Text

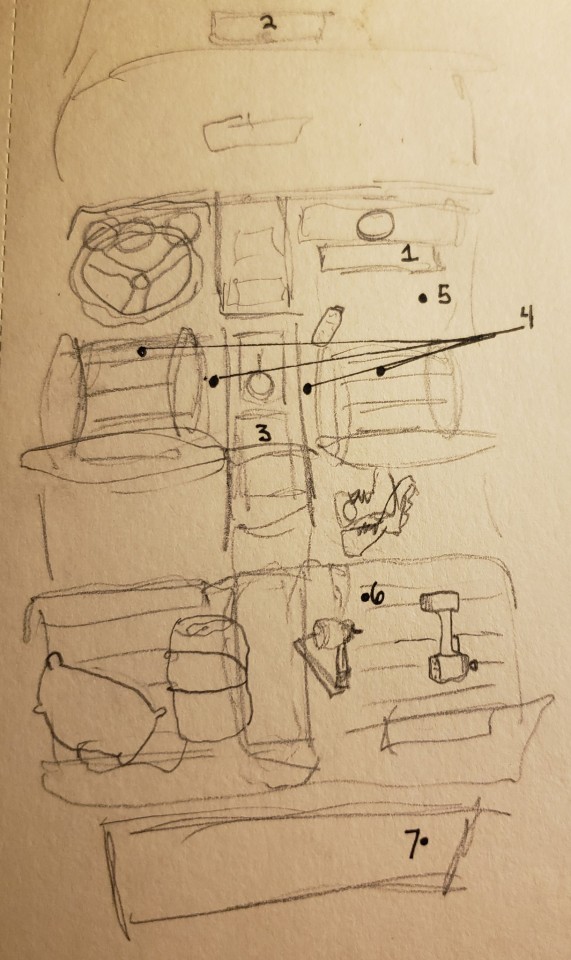

im a stickler for detail so here are all the things you can find in Cel's beloved frogcar. a poppy green 1969 Mach 1 Mustang that's been modified to 2077 chooh2 engine standards with magnetic suspension. Frequently are the wheels swapped out between offroading in badlands to street racing and drifting.

1. Glove compartment: tissues, chapstick, black lipstick, car registry documents, coiled bundle of wires

2. Ceiling console: spare pair of red lensed sunglasses

3. Center console: frogphone (emergency satnav phone), lighter, hair ties, pack of gum, stiletto knife, pens, paperclips, alligator clip, moist towelette, ketchup packet, microfiber towel, and most importantly-- trash.

4. Front seats: knife sheathed between driver seat and center console, gun under driver seat, 3 EMP grenades under passenger seat

5. Floorboards: water bottle in front passenger side, spare pair of boots with clean socks

6. Backseat: rolled up sleeping bag + pillow, impact drill, pneumatic nail gun, hoodie

7. Trunk: car jacks, tire iron, flares, toolbag containing various screwdrivers, pliers, wire strippers, wrenches, hammer, drill bits, roll of copper wire, roll of soldering wire, assorted nuts and bolts

this was my first time coloring tires and man that shit is hard, i think tires are just as difficult as drawing hands and feet. anyway it was good fun practice and I'm glad i did it

#frogcar#ttrpgshit#cyberpunk red#i had asked my brother once 'whats the one thing every car our family owns has in it' and without missing a beat he said trash#made me laugh really hard#my stuff

3 notes

·

View notes

Text

Global Truck Tools Market Overview and Strategic Growth Analysis 2024 - 2031

The global truck tools market is an essential sector within the automotive industry, reflecting the growing demand for specialized equipment used in the maintenance and repair of trucks. This article provides a comprehensive overview of the market, including key drivers, trends, challenges, and future prospects.

Overview of the Truck Tools Market

Truck tools encompass a wide range of equipment designed specifically for the maintenance and repair of trucks. This includes hand tools, power tools, diagnostic equipment, and accessories. As the trucking industry expands, so does the need for reliable and efficient tools.

Definition and Types of Truck Tools

Truck tools can be categorized into several segments:

Hand Tools: Includes wrenches, screwdrivers, pliers, and hammers designed for mechanical repairs.

Power Tools: Electric or pneumatic tools like drills, impact wrenches, and grinders that facilitate heavy-duty tasks.

Diagnostic Equipment: Tools that assist in diagnosing issues, such as OBD scanners and multimeters.

Specialized Accessories: Includes toolboxes, organizers, and lifting equipment tailored for trucks.

Market Drivers

The growth of the global truck tools market is driven by several factors:

Expanding Trucking Industry

The rise in e-commerce and global trade has led to an increase in freight transportation. More trucks on the road means a higher demand for maintenance and repair tools.

Advancements in Technology

Technological innovations in truck tools, such as wireless diagnostic tools and automated systems, are enhancing efficiency and accuracy, driving further adoption.

Focus on Vehicle Maintenance

With an emphasis on fleet management and vehicle longevity, companies are investing in quality tools to ensure their trucks are well-maintained and operational.

Market Trends

The truck tools market is evolving with several notable trends:

Increased Demand for Ergonomic Tools

As operators prioritize comfort and efficiency, there is a growing demand for ergonomically designed tools that reduce strain and improve productivity.

Rise of Smart Tools

The integration of smart technology in tools, including connectivity features and data analytics, is becoming increasingly popular. Smart tools can provide real-time diagnostics and improve overall efficiency.

Sustainability in Tool Manufacturing

Manufacturers are increasingly adopting eco-friendly practices in the production of truck tools. This includes using sustainable materials and reducing waste during manufacturing processes.

Challenges in the Market

Despite its growth potential, the truck tools market faces several challenges:

High Competition

The market is characterized by intense competition, with numerous players vying for market share. Companies must innovate continuously to stand out.

Price Volatility of Raw Materials

Fluctuations in the prices of raw materials used in tool manufacturing can impact production costs and profitability.

Skill Gap in the Workforce

As technology advances, there is a growing need for skilled technicians capable of using sophisticated tools, creating a challenge for the industry.

Future Outlook

The global truck tools market is anticipated to continue growing in the coming years. Key factors influencing this outlook include:

Continued Growth in E-commerce

The ongoing expansion of e-commerce will drive the need for efficient logistics, subsequently increasing the demand for trucks and related tools.

Technological Advancements

Innovations such as artificial intelligence and machine learning are expected to transform the diagnostics and repair processes, making tools more efficient and user-friendly.

Global Infrastructure Development

Investment in infrastructure, particularly in developing regions, will lead to an increase in trucking operations, driving demand for maintenance tools.

Conclusion

The global truck tools market is positioned for significant growth, driven by the expanding trucking industry and technological advancements. As companies continue to focus on vehicle maintenance and operational efficiency, the demand for high-quality tools will remain strong. However, manufacturers must navigate challenges such as competition and raw material prices to thrive in this dynamic landscape. With a focus on innovation and sustainability, the future of the truck tools market appears promising.

0 notes

Text

Essential Tools Every Hardware Shop Should Stock for Success

In the world of hardware retail, ensuring your store is stocked with the right tools is crucial for attracting customers and driving sales. Whether you're serving DIY enthusiasts, professional contractors, or homeowners looking for quality tools, having a comprehensive and well-organized inventory can make your hardware shop a go-to destination. This article explores the essential tools every hardware shop should stock to ensure success, covering a range of categories from basic hand tools to advanced power tools.

Hand Tools

Hammers and Mallets: Every hardware shop should have a variety of hammers and mallets. This includes claw hammers for general use, ball-peen hammers for metalwork, and rubber mallets for delicate surfaces. Stocking multiple types and sizes ensures you can meet the diverse needs of your customers, whether they are hanging pictures, working with metal, or needing a non-marring strike.

Screwdrivers and Nut Drivers

Screwdrivers and nut drivers are fundamental tools in any toolkit. Ensure your store offers a comprehensive selection, including flathead, Phillips, Torx, and hex drivers. High-quality, ergonomic handles can attract repeat customers, and stocking both individual screwdrivers and complete sets can cater to different buying preferences. Additionally, having a variety of MS chain options available can complement your screwdriver and nut driver offerings, as customers often need these chains for securing or supporting their projects.

Pliers and Wrenches

Pliers and wrenches are indispensable tools for gripping, turning, and cutting. Your inventory should include slip-joint pliers, needle-nose pliers, lineman's pliers, adjustable wrenches, combination wrench sets, and pipe wrenches. Offering a range of sizes and brands ensures you can meet the varied demands of both DIYers and professionals. Including MS chain in your inventory not only provides an additional tool for your customers but also enhances the versatility of their projects.

Measuring and Marking Tools: Accuracy is critical in many projects, so provide a range of measuring tapes, rulers, squares, and marking tools. High-precision tools like laser levels, digital callipers, and micrometres can attract more technically inclined customers. Stocking reliable brands known for durability and accuracy can build trust with your clientele.

Power Tools

Drills and Impact Drivers: Cordless and corded drills, along with impact drivers, are must-haves for any hardware shop. Ensure you have various power levels, battery capacities, and reputable brands to meet different customer preferences. Offering both basic models for home use and more advanced options for professional use can cater to a broader audience.

Saws: From circular saws to jigsaws and reciprocating saws, a good selection of power saws is vital. Table saws, mitre saws, and band saws are also essential for advanced woodworking and construction projects. Offering a range of blades and accessories ensures customers can find everything they need for their projects.

Sanders and Grinders: Power sanders and grinders, including belt sanders, orbital sanders, and angle grinders, should be part of your inventory. These tools are essential for finishing and shaping materials. Stock a variety of grits and types of sandpaper, as well as grinding and polishing wheels, to meet all customer needs.

Nailers and Staplers: Pneumatic and battery-powered nailers and staplers are in high demand for construction and carpentry projects. Stocking a range of these tools can attract both professionals and DIYers. Ensure you have an assortment of nails, staples, and accessories to complement these tools.

Specialty Tools

Welding Equipment: Offering basic welding tools and protective gear can cater to metalworking enthusiasts and professionals. Include items like MIG welders, welding helmets, gloves, and protective clothing. Stocking consumables such as welding rods, wire, and gases can also drive repeat business.

Plumbing Tools: Pipe wrenches, plumber's tape, pipe cutters, and other plumbing-specific tools are necessary for customers dealing with plumbing repairs or installations. Expanding your inventory to include pipe fitting tools, drain snakes, and sealants can make your shop a one-stop solution for plumbing needs.

Electrical Tools: Electricians and DIYers alike will appreciate a selection of wire strippers, multimeters, voltage testers, and insulated tools designed for electrical work. Stocking a range of electrical tape, connectors, and circuit testers ensures that your store can provide all necessary items for electrical projects.

Safety Gear and Accessories

Protective Equipment: Safety should always come first. Stock essential protective gear such as safety glasses, gloves, ear protection, and dust masks. Offering a range of sizes and types ensures that customers can find the right fit for their needs. High-quality safety gear can also attract repeat customers who prioritize protection in their work.

Tool Storage: Toolboxes, tool bags, and storage solutions help keep tools organized and accessible. Offering a variety of storage options can help customers protect their investments and keep their workspaces tidy. Consider stocking both portable storage solutions and larger, stationary units for workshop organization.

Consumables: Include a range of consumables like drill bits, saw blades, sandpaper, and fasteners. These items are frequently purchased and essential for completing various tasks. Having a steady supply of consumables ensures that your customers can find everything they need in one place, increasing the likelihood of repeat business.

Customer Service and Support

Expert Advice: Offering expert advice and guidance can set your hardware shop apart from the competition. Staff training is crucial to ensure that employees can provide knowledgeable recommendations and troubleshoot common issues. Creating a welcoming environment where customers feel comfortable asking questions can build long-term loyalty.

Workshops and Demonstrations: Hosting workshops and product demonstrations can engage customers and showcase the practical applications of your tools. These events can attract new customers, provide added value to existing ones, and position your shop as a community hub for learning and skill development.

After-Sales Support: Providing excellent after-sales support, including tool maintenance services and warranties, can enhance customer satisfaction. Offering repair services or partnering with local technicians can add another layer of value to your shop's offerings.

Conclusion

In conclusion, stocking a well-rounded inventory of essential tools and accessories, including GI chain, is crucial for the success of any hardware shop. By offering a diverse range of hand tools, power tools, speciality tools, and safety gear, your store can meet the needs of various customers, from DIY enthusiasts to professional contractors. Additionally, ensuring a steady supply of GI chain can cater to specific customer demands and enhance your product offerings. Prioritizing customer service, expert advice, and after-sales support can further differentiate your shop and build a loyal customer base.

Investing in a comprehensive inventory not only boosts customer satisfaction but also drives sales and builds a reputation for reliability and quality. Including GI chain in your stock can address the needs of customers working on projects that require durable and reliable materials. As the hardware industry continues to evolve, staying attuned to the latest trends, including the demand for GI chain, and understanding customer preferences will ensure that your shop remains a trusted and valuable resource in the community. By embracing these strategies, your hardware shop can thrive and become a go-to destination for all things tools and hardware. Emphasizing the availability of essential items like GI chain will attract a broader customer base and solidify your reputation as a comprehensive, dependable supplier. Ultimately, a focus on variety, quality, and customer support will help your hardware shop stand out and succeed in a competitive market.

0 notes

Text

Handy Mechanic and Auto Tools for Every Garage

Having the right tools is crucial for both professional mechanics and auto enthusiasts who loves working on cars. Quality mechanic and auto tools can make your job easier, faster, and safer. From hobbyists to full-time experts, there are tools available for every skill level. With a little research and practice, anyone can use multi-functional tools effectively to get the most out of them. This blog post will walk you through the essential tools every American garage should have.

Lift Equipment and Jacks for Sturdy Support

When it comes to working on your vehicle, having reliable lift equipment and jacks is non-negotiable. These tools allow you to elevate your car safely, providing better access to the undercarriage for detailed repairs.

Floor Jacks: Floor jacks are essential for quickly lifting your vehicle. Look for a heavy-duty, hydraulic floor jack for maximum efficiency.

Jack Stands: Once your car is lifted, jack stands ensure it stays elevated, allowing you to work underneath the vehicle safely.

You can also find bottle jacks, motorcycle lifts and elevation equipment for heavy vehicles, depending on your project or interest.

Versatile Pneumatic Mechanic Tools and Air Compressors

Pneumatic mechanic tools, powered by air compressors, are a game-changer for any serious mechanic. They offer more power and precision than manual tools, making tasks easier and faster.

Air Compressors for Pneumatic Tools: A sturdy, high-capacity air compressor can power a variety of pneumatic tools such as impact wrenches, ratchets, and spray guns.

Pneumatic Auto Tools: From pneumatic wrenches to sanders, these tools provide the muscle needed for heavy-duty tasks. They are particularly useful for auto body repair and engine work.

Also called air tools, pneumatic tools are everyday essentials in many industries, from manufacturing plants to home garages. These tools come in different drive sizes to suit nuts, screws and bolts in a wide size range. Keyless tools last longer and are more efficient that keyed options. Whatever you choose, make sure you read the instruction manual thoroughly. Even seasoned pros follow manuals to make sure they use tools correctly to prevent mishaps and tool damage.

Auto Body Repair Tools – Set Vehicles Right

If you’re involved in auto body repair, having specialized tools is essential for achieving professional-quality results.

Dent Pullers: These are vital for removing dents without damaging the paint.

Body Hammers and Dollies: Used for shaping and smoothing metal surfaces, ensuring the car’s body looks flawless.

Rams, spreaders, and brake repair kits are other auto body repair tools that are always useful when working with vehicles.

Multi-Functional Mechanic Tool Sets

A comprehensive mechanic tool set is a must for any garage. These sets usually include a variety of sockets, wrenches, and screwdrivers that are useful for a multitude of tasks.

Socket Sets: Ensure you have both metric and SAE sockets for maximum versatility.

Wrench Sets: From open-end wrenches to adjustable wrenches, having a variety of options lets you tackle different bolt sizes and types.

These tool sets provide multiple size variants of each type of tool, letting you deal with all sizes of fasteners on automobiles or machines.

Resolve Issues Quickly with Auto Diagnostic Tools

Modern vehicles are equipped with complex electronic systems that require advanced diagnostic tools for troubleshooting.

OBD-II Scanners: These scanners can read diagnostic trouble codes (DTCs) from your vehicle’s computer, helping you identify and fix issues quickly.

Multimeters: Essential for measuring voltage, current, and resistance in various electrical components.

Ignition testers and battery testers are some of the other notable diagnostic tools for vehicles.

Repair Engines with Advanced Tools

Engine repairs are often the most complex and demanding tasks. These require specialized tools designed for engines precision and durability.

Torque Wrenches: Bolts are tightened to the manufacturer’s specifications with torque wrenches, preventing over-tightening or under-tightening.

Engine Hoists and Stands: These are crucial for removing and working on engines outside of the vehicle.

Find vacuum pumps, tuning kits and terminal repair tools to sort out a number of engine issues.

A Multitude of Hand Tools for Vehicles and Machinery

No garage is complete without a reliable set of mechanic hand tools. From pliers to hammers, these basic tools are indispensable for a variety of repairs.

Pliers: Needle-nose, slip-joint, and locking pliers each have their specific uses.

Wrenches: Each type of wrench is specialized to be effective in its specific application. Crowfoot wrenches are perfect for congested corners, while dog bone designs offers dual functionality of a wrench and socket. Crescents, plumbers’ wrenches and oil filter wrenches are the most widely used types.

Hammers: Ball peen hammers and rubber mallets are some of the most commonly used in auto repairs.

Every repair scenario could be unique and will need specific hand tools to work with precision. Pick hard-wearing ratchets, sockets and mechanic hand tools that are up to the task and will last for the long haul.

Own a Formidable Tool Collection for Wide-Ranging Applications

Having the right tools is essential for any mechanic or auto enthusiast. From lift equipment and jacks to pneumatic mechanic tools and air compressors, each tool plays a significant role in making repairs easier and more efficient. Don’t skimp on quality when it comes to your tools; investing in the best can save you time and money in the long run.

0 notes

Text

Assembly Tools

Power Screwdrivers: Electric or pneumatic tools for fastening screws and bolts with precision.

Torque Wrenches: Ensures accurate tightening of fasteners to specified torque levels, critical for safety and quality.

Impact Wrenches: Ideal for high-torque applications and rapid fastening of bolts and nuts.

Read more: https://schunk.com/in/en/workpiece-clamping-technology/accessories/spare-parts/assembly-set/c/PGR_4701

0 notes

Text

Robot Tool Changers Market Recent Developments Study Analysis By 2033

A Robot Tool Changer (RTC) is a device used to quickly and easily change the tool or end-effector attached to a robot arm. This allows the robot to perform multiple tasks without the need to stop and change tools manually.

RTCs typically consist of two parts: a gripper that attaches to the robot arm and a tool-changing mechanism that is mounted on the robot. The gripper is opened and closed using a pneumatic or hydraulic cylinder, and the tool-changing mechanism is operated using an electric motor.

RTCs can be used with a variety of different robot types, including articulated, SCARA, and delta robots. They are often used in applications where the robot needs to perform multiple tasks, such as pick-and-place, welding, and assembly. For example, a robot that assembles cars might need to change its tool from a screwdriver to a wrench.

To Know More: https://www.globalinsightservices.com/reports/robot-tool-changers-market/?utm_id=Snehalkast

Market Outlook

In the current market scenario, there are various factors which are driving the growth of Robot Tool Changers market. Some of the key drivers are as follows:

Increasing demand for automation in various industries: With the increasing competition and need for efficiency and accuracy, there is a growing demand for automation in various industries such as automotive, food & beverage, pharmaceuticals, etc. This is one of the key drivers for the growth of Robot Tool Changers market as these devices help in increasing the productivity and efficiency of the manufacturing process.

Rising labor costs: The rising labor costs across the globe is another key driver for the growth of Robot Tool Changers market. These devices help in reducing the dependence on manual labor, thus leading to lower production costs.

Increasing adoption of collaborative robots: Collaborative robots are becoming increasingly popular in various industries as they offer several advantages over traditional robots such as being safe to work with, easy to program and operate, and cost-effective. This is leading to the increasing adoption of collaborative robots which in turn is driving the growth of Robot Tool Changers market.

Request Sample: https://www.globalinsightservices.com/request-sample/GIS10229/?utm_id=Snehalkast

Major Players

Some of the key players of Robot Tool Changers Market are ATI Industrial Automation Inc. (US), SCHUNK GmbH & Co. KG (Germany), Applied Robotics Inc. (US), Nitta Corporation (Japan), Carl Kurt Walther GmbH & Co. KG (Germany), DESTACO (US), Stäubli International AG (Switzerland), A Dover Company (US), American Grippers Inc (US), and PTM Präzisionstechnik GmbH (Germany).

0 notes

Text

Boom Barrier Installation Guide – Best Practices and Considerations

Boom barriers are effective and reliable traffic management tools. Not only do they improve security, they ensure vehicles cannot enter without permission.

Before purchasing a barrier, carefully assess your property layout and security needs in order to select an optimum model that will help secure your business.

Assessing the Installation Site

Before installing a barrier, it’s crucial to assess its installation site thoroughly. This will enable you to select a barrier type best suited to the environment and traffic flow; as well as meeting local regulations and safety standards.

Site requirements should include an even surface free from underground cables or pipes that could be damaged when digging a foundation hole, as well as enough overhead clearance for arm articulation of the barrier arm.

If the barrier will be integrated with other access control systems, ensure they’re compatible and easy to integrate. In addition, make sure the system can operate using solar energy or battery backup power sources.

Finally, it’s essential to choose a reliable supplier with excellent customer service and technical support. When researching different brands and comparing features such as features, reliability, price etc; select one with an excellent track record in customer support as this will ensure proper installation and ongoing maintenance costs for the duration of its lifespan – plus regular inspections and maintenance will help extend its useful life!

Selecting the Right Barrier

Boom barrier selection is an important business investment. To get the best return, consider all factors which contribute to its overall effectiveness and efficiency, such as meeting local regulations and safety standards while meeting any unique security needs that you may have.

Assess your vehicle-handling and operational needs before selecting a barrier that meets them. Key features to keep in mind include access control integration, photocells and safety edges; additionally consider one with remote monitoring/control for easier management and troubleshooting.

Once you have chosen a barrier, start installing it by gathering all necessary components. Gather tools like screwdrivers, wrenches and drills before beginning installation – pneumatic staple guns may also come in handy to fasten it to the floor of your parking garage or lot.

Getting Started

Once a site has been evaluated and the appropriate barrier system selected, installation can begin. A technician will dig a hole for the barrier post to be placed into. Care should also be taken to make sure there are no cables or pipes underground that could be damaged by excavation – as digging a hole could potentially harm these.

Quality boom barriers should be durable enough to withstand heavy usage as well as possible vandalism or tampering attempts, so always look for warranties from their manufacturer and consider the supplier’s reputation before purchasing their product.

Make sure your barrier can easily integrate with other security features, like access control systems, RFID readers or cameras for effective traffic management and increased safety. Consider anti-tailgating sensors, solar power compatibility or battery backup for uninterrupted operations.

Create a standard operating procedure for dealing with emergency situations or barriers that are no longer functioning as planned, by setting up automated alerts or notifications in ClickUp that alert staff of these events and allow them to respond swiftly. Furthermore, training staff and visitors in proper usage and upkeep of barriers is equally essential.

Pre-Operational Checks

Before beginning an installation project, it is critical that all components are functioning as expected – this includes the control panel, safety sensors and any additional features. Furthermore, it is wise to establish a regular maintenance schedule to address any potential problems quickly.

Performing these checks regularly will not only extend the longevity of your barrier arm but can also safeguard it against any security threats. Furthermore, keep it free of debris, dust and contaminants; additionally it’s wise to regularly lubricate all moving parts – this helps reduce friction and enhance performance of the barrier arm.

Boom barriers are an efficient and cost-effective way to control vehicle access and enhance security at your business premises. By restricting unwarranted entry, they help ensure both employee and customer safety. To get started, explore different brands of boom barriers to find one best suited to your company’s needs – don’t forget to factor installation and maintenance costs when creating your budget!

Final Testing

Boom barriers are highly effective security systems to protect parking areas and prevent vehicles from colliding into one another, making it widely utilized at residential complexes, malls, parking entry/exit points, toll booths, etc.

Finding a barrier suitable for your business depends on your security level, traffic volume, peak times and budget. Look for something durable that can withstand heavy use as well as any possible vandalism or tampering and harsh weather conditions.

0 notes

Text

Electric Pneumatic screwdrivers At Best Prices.

Visit our website for more information- https://advancetech.co.in/

0 notes

Text

Buy Shinano Air Tools Online UK - Pneutube Limited

Find a comprehensive range of Air Tool Parts & Accessories. Enhance your Shinano Air Tools UK with top-quality parts and accessories. Find everything you need to optimize performance and maximize productivity. Shop now in the UK!

#Shinano Pneumatic Tools#Shinano Pneumatic#Air Tool Parts & Accessories#Buy Air Tools Online UK#Online Cutter Standard UK#Online Standard Die Grinders UK#Shinano Pneumatic Drills#Pneumatic Impact Wrench Tools#Buy Pneumatic Air Polishers Tools#Buy Shinano Pneumatic Screwdriver#Buy Flexible Nylon Tube Online#Online Gas Springs Tools#VariLift Gas Spring#Buy Pneumatic Equipment#Pneumatic Equipment Online#Metalwork Valves#Festo Valves#Metalwork Push Fittings#Festo Cylinders#Metalwork Pneumatics#Metalwork Cylinders#Festo Push Fittings#Shinano Air Tools UK#Shinano Ratchet Wrench Tools Online#Shinano Air Sanders Tools#Shinano High Speed Grinder#Buy Shinano Air Tools Online UK

2 notes

·

View notes

Text

Buy Pneumatic Screwdriver At AdvanceTech

Get the top pneumatic screwdriver from our website. We're the best suppliers in India with the best prices

1 note

·

View note

Text

How to Install Door Trim Without Nail Gun: Easy Installation Methods

To install door trim without a nail gun, use construction adhesive and finish nails. Apply the adhesive to the back of the trim, then secure it with finish nails.

When it comes to home improvement, installing door trim can add a touch of elegance to any room. However, not everyone has access to a nail gun. Fortunately, it's possible to achieve a professional-looking finish using alternative methods. By following a few simple steps and using the right tools, you can successfully install door trim without a nail gun.

We'll explore a step-by-step process for achieving this, providing you with a cost-effective and efficient solution for your home improvement projects. Whether you're a seasoned DIY enthusiast or a novice homeowner, these tips will help you achieve a polished result without the need for specialized equipment.

Understanding Door Trim Installation Methods

Door trim installation is a crucial aspect of finishing any interior doorway. While the traditional method involves the use of a nail gun, there are alternative methods that can achieve the same result without the need for specialized equipment.

Overview Of Traditional Nail Gun Method

In the traditional nail gun method, the door trim is installed using a pneumatic or cordless nail gun. This method requires precise aim and significant force to securely attach the trim to the door frame. While effective, it can be challenging for those without experience using power tools. Additionally, the use of a nail gun may not be suitable for certain situations, such as when working in confined spaces or areas where noise levels must be minimized.

Introduction To Alternative Nail Gun-free Methods

For those seeking a nail gun-free approach to installing door trim, there are several methods that can be employed to achieve professional results. These methods leverage basic hand tools and adhesive materials to secure the trim in place without the need for a nail gun.

Tools And Materials Required

When it comes to installing door trim without a nail gun, having the right tools and materials is essential for achieving a professional finish. Let’s take a look at the essentials you’ll need to get the job done effectively.

Essential Tools For The Installation

- Hammer: A quality hammer with a smooth face is crucial for driving nails securely into place.

- Trim Nail Set: This is used to set the nail heads below the surface of the trim, helping to hide them from view.

- Trimming Shears or Miter Saw: These are essential for cutting the trim to the required lengths and angles for precise installation.

- Measuring Tape and Pencil: A reliable measuring tape and pencil are necessary for accurately marking cut lines and positioning of the trim.

- Screwdriver: A screwdriver is needed for securing the trim in place with screws, providing an alternative to nails.

Appropriate Materials For The Job

- Wood Trim: Opt for high-quality wood trim that complements your door and interior design. Pine, oak, or poplar are popular choices.

- Nails: Galvanized finish nails are recommended as they offer excellent corrosion resistance, resulting in a long-lasting installation.

- Screws: If you opt for screw installation, choose coated screws suitable for woodworking to ensure optimal strength and durability.

- Wood Glue: Using wood glue in conjunction with nails or screws can enhance the bond between the trim and the door, providing additional stability.

- Spackle or Wood Filler: These materials are useful for filling nail or screw holes and any gaps for a seamless finish.

Pros And Cons Of Each Tool And Material

Tools/Materials

Pros

Cons

Hammer

Simple and effective

Requires physical effort

Trim Nail Set

Ensures nails are set below the surface

Additional tool required

Trimming Shears/Miter Saw

Precise cuts for professional finish

Initial investment for a miter saw

Measuring Tape and Pencil

Accurate measurements

May require multiple measurements for complex cuts

Screwdriver

Stronger alternative to nails

May split wood if not pre-drilled

Wood Trim

Natural and aesthetically pleasing

Prone to warping if not properly sealed

Nails

Quick and easy to install

Possible nail pops over time

Screws

Strong and durable

Visible screw heads unless filled and painted

Wood Glue

Enhances bond and stability

Requires time for drying

Spackle/Wood Filler

Creates seamless finish

Additional step in the installation process

Preparing The Door And Trim

When preparing to install door trim without a nail gun, it's important to focus on the initial steps of assessing the condition of the door and trim, making necessary preparations, and measuring and marking for precise fitting. Properly preparing the door and trim will set the stage for a successful installation, ensuring that the finished result is both functional and visually appealing.

Assessing The Condition Of The Door And Trim

Before beginning the installation process, it's crucial to assess the condition of both the door and the trim. Check for any damage, warping, or irregularities that could affect the installation process or the final appearance of the trim.

Necessary Preparations Before Installation

Prior to installing the door trim, it's essential to prepare the area and gather the required tools and materials. Create a clean and clutter-free workspace, and ensure that all necessary tools such as a tape measure, level, pencil, miter saw, and wood glue are readily available.

Measuring And Marking For Precise Fitting

Accurate measurements and precise markings are key to a professional-looking door trim installation. Use a tape measure to measure the length and width of the door, and carefully mark the trim pieces accordingly. It's also important to account for corners and angles, as well as ensuring that each piece of trim is cut to the exact dimensions required for a seamless fit.

Step-by-step Installation Guide

Installing door trim without a nail gun can be a straightforward process with the right tools and techniques. This step-by-step installation guide outlines various methods for securing door trim without the use of a nail gun, ensuring a professional finish without the need for specialized equipment.

Adhesive-based Installation Method

One effective approach for installing door trim without a nail gun is through the use of adhesive. Adhesive-based installation provides a strong bond and eliminates the need for visible nails, resulting in a clean and seamless finish.

Choosing The Right Adhesive

When opting for an adhesive-based installation, selecting the appropriate adhesive is crucial. Ensure the adhesive is specifically designed for trim and molding, providing sufficient bonding strength and durability.

Application Techniques For A Secure Hold

To achieve a secure hold, apply the adhesive generously along the back of the trim. Press the trim firmly against the wall to allow for optimal adhesion and ensure a strong bond.

Utilizing Finishing Nails And A Hammer

In instances where adhesive alone may not provide the level of security desired, utilizing finishing nails and a hammer can reinforce the installation.

Proper Placement And Technique For Nail Installation

When using finishing nails, it is essential to position them strategically to avoid splitting the trim. Employing a hammer with precision and control ensures the nails are driven in without causing damage.

Using A Brad Nailer As An Alternative To A Standard Nail Gun

A brad nailer serves as a viable alternative to a standard nail gun, offering ease of use and accuracy for trim installation without the need for excessive force.

Understanding The Use And Benefits Of A Brad Nailer

Compared to traditional nail guns, a brad nailer utilizes smaller gauge nails, resulting in minimal visible holes and reduced risk of splitting the trim. Additionally, the compact size of a brad nailer allows for precise placement in tight spaces.

Tips For Successful Brad Nailer Application

Ensure the trim's material and thickness align with the brad nailer's recommended specifications. Furthermore, maintain consistent pressure and angle when firing the nails to achieve a secure and professional installation.

Finishing Touches And Additional Considerations

As you approach the final stages of installing door trim without a nail gun, focusing on the finishing touches and additional considerations is crucial for achieving a polished and professional result. By paying attention to details such as sanding and priming the door trim, caulking and sealing, and avoiding common installation mistakes, you can elevate the appearance and longevity of your door trim installation.

Sanding And Priming The Door Trim

Before applying the final coat of paint, it's essential to sand the door trim to ensure a smooth and even surface. Start with a medium-grit sandpaper to remove any rough spots or imperfections, then switch to a fine-grit sandpaper for a polished finish. After sanding, wipe the trim clean to remove any dust. Additionally, applying a primer can help the paint adhere better to the trim, resulting in a more durable and professional-looking finish.

Caulking And Sealing For A Professional Look

Caulking the seams and gaps around the door trim not only enhances the aesthetic appeal but also helps to seal out moisture, drafts, and pests. Utilize a high-quality, paintable caulk and a caulking gun for precise application. Smooth out the caulk with a damp sponge or finger for a seamless look. After caulking, ensure that any exposed wood or gaps are sealed with an appropriate wood sealer to protect the trim from moisture and potential damage.

Tips For Avoiding Common Installation Mistakes

- Ensure the trim pieces are securely fastened with adhesive and appropriate tools, such as clamps, until the adhesive has dried.

- Measure and cut the trim accurately to achieve seamless joints and corners.

- Inspect the trim for any gaps or uneven surfaces before proceeding with painting or sealing.

- Use a level to ensure the trim is straight and aligned properly.

- Avoid overapplying caulk, as excessive amounts can detract from the overall appearance of the trim.

Frequently Asked Questions On How To Install Door Trim Without Nail Gun

How Can I Install Door Trim Without Using A Nail Gun?

To install door trim without a nail gun, you can use alternative fastening methods such as adhesive, screws, or a brad nailer. These methods provide a secure hold without the need for a nail gun.

What Are The Tools Needed For Installing Door Trim Without A Nail Gun?

You will need a hammer, nails, wood glue, a brad nailer, or screws to install door trim without a nail gun. Ensure you have the correct tools on hand before starting the installation process.

Are There Any Alternative Methods For Securing Door Trim Without A Nail Gun?

Yes, alternative methods for securing door trim include using construction adhesive, screws, or a brad nailer. These methods are effective in securing the trim without the need for a nail gun.

Can I Achieve A Professional Finish Without Using A Nail Gun For Door Trim Installation?

Yes, you can achieve a professional finish by using alternative methods such as adhesive, screws, or a brad nailer. Proper technique and attention to detail are key for achieving a polished look without a nail gun.

Conclusion

Installing door trim without a nail gun is easy and accessible to anyone, regardless of skill level. By following the step-by-step instructions and utilizing alternative tools such as adhesive and brad nails, you can achieve professional-looking results in no time.

Embrace this approach and transform your space with confidence.

Read the full article

0 notes

Text

The Timeless Elegance of Hand Tools: Craftsmanship Unveiled

In today's high-tech world, the use of hand tools might seem like a nostalgic throwback to a bygone era. However, the enduring appeal of these timeless implements is anything but antiquated. Hand tools have been instrumental in shaping the history of human craftsmanship, and their relevance remains significant in modern times. In this session, we will explore the enduring elegance of hand tools and the enduring craftsmanship they represent.

The Beauty of Simplicity

Hand tools are a testament to the art of simplicity. Unlike their electric or pneumatic counterparts, these tools require no plugs, batteries, or cords. Instead, they draw their power from the skill, strength, and finesse of the craftsman's hand. This simplicity is not a limitation but an advantage. It allows for a direct connection between the craftsperson and the workpiece, fostering a deeper understanding of the material and the act of creation.

Hand Tools in the Modern Age

Despite the prevalence of power tools in workshops and construction sites, hand tools continue to play a vital role in various trades. Here are some areas where hand tools are indispensable:

Woodworking: Carpenters, cabinetmakers, and woodworkers rely on hand tools such as chisels, hand planes, and saws to create intricate and precise joints, shapes, and finishes.

Metalworking: Blacksmiths, machinists, and metalworkers use hand tools like hammers, files, and punches for forging, shaping, and finishing metal pieces.

Construction: Hand tools like hammers, screwdrivers, and wrenches are crucial for various construction tasks, from framing to finishing.

Plumbing: Plumbers often use hand tools to assemble and repair pipes and fixtures, ensuring water flows smoothly.

Automotive Repair: Mechanics rely on hand tools for tasks like loosening bolts, tightening fasteners, and performing precise adjustments.

The Craftsmanship Connection

Hand tools embody the essence of craftsmanship. They require skill, patience, and attention to detail. A craftsman wielding a hand plane to smooth a piece of wood or a blacksmith shaping hot iron with a hammer is engaged in a direct dialogue with the material. The subtlety of control and the sense of connection between hand and workpiece are unparalleled.

Hand tools also allow for a deeper appreciation of the physical properties of materials. A skilled craftsman knows the grain of the wood, the temper of the metal, and the subtleties of the material they work with. This knowledge informs their decisions and actions, resulting in finely crafted and often unique pieces.

The Art of Maintenance

One of the beauties of hand tools is their longevity. With proper care and maintenance, hand tools can last for generations, becoming heirlooms passed down through families or between master and apprentice. The act of maintaining these tools is an art in itself, with craftspeople honing and sharpening blades, handles, and heads to ensure their reliability and precision.

The enduring elegance of hand tools lies in their simplicity, their timeless connection to craftsmanship, and the art of maintaining and wielding them. In a world dominated by automation and high-speed technology, the enduring relevance of hand tools is a testament to the human spirit's desire for a deep connection with the act of creation. Whether you're a seasoned artisan or someone looking to explore the world of craftsmanship, embracing hand tools can be a journey of self-discovery, creativity, and enduring elegance.

0 notes