#precast engineering design

Explore tagged Tumblr posts

Text

Structural Engineering Projects with BIM-Integrated Precast Concrete Design

Discover the future of construction with BIM-Integrated Precast Concrete Design! This innovative approach revolutionizes how we plan and execute structural engineering projects. By integrating Building Information Modeling (BIM) with precast concrete, we achieve unparalleled precision, efficiency, and sustainability. Say goodbye to traditional methods and embrace a smarter, more streamlined process that saves time and reduces costs.

Join the movement towards modern construction excellence! BIM-Integrated Precast Concrete Design not only enhances collaboration among project stakeholders but also ensures higher quality and consistency in every build. From concept to completion, experience the benefits of cutting-edge technology in your structural engineering projects. Let's build the future together! 🏗️✨

#precast CAD drawings#precast concrete design#precast concrete design workflow#precast constructions using BIM software#precast engineering design

0 notes

Text

Transforming Parking Structures with Prefabricated Construction and Precast Detailing

Introduction

Parking structures are a vital part of modern infrastructure, supporting commercial developments, transit hubs, hospitals, and universities. However, traditional construction methods often lead to longer timelines, increased costs, and labor-intensive assembly.

The prefabricated construction approach, particularly with precast concrete solutions, has revolutionized parking structure development, offering speed, cost savings, and long-term durability. Companies like Clark Pacific, Gate Precast, and Metromont Corporation are leading the way in efficient precast parking solutions.

Why Prefabricated Parking Structures?

Prefabrication involves the off-site production of concrete components, which are then transported and assembled on-site. This method significantly improves efficiency, making it the preferred choice for large-scale parking facilities.

Key Advantages of Prefabricated Parking Structures

Faster Construction Timelines

Precast elements are manufactured simultaneously with site preparation, reducing project duration.

On-site assembly is quick and efficient, minimizing disruptions in busy urban areas.

Cost Efficiency

Lower labor costs due to reduced on-site construction work.

Minimized material waste through controlled factory production.

Structural Durability & Load-Bearing Capacity

Precast concrete offers exceptional strength and longevity.

Designed to withstand seismic, wind, and environmental loads.

Design Flexibility & Aesthetic Appeal

Modular expansion, custom layouts, and architectural finishes are easily incorporated.

Integration with glazing, façade elements, and green building features is seamless.

Sustainability & Environmental Benefits

Prefabricated components reduce material waste and carbon footprint.

Energy-efficient lighting and ventilation systems can be integrated into the design.

The Role of Precast Detailing in Parking Structures

High-quality precast detailing ensures the seamless manufacturing, transportation, and assembly of parking structures.

Critical Elements in Precast Detailing for Parking Facilities:

Panel Layouts & Load Distribution: Optimized for structural efficiency and minimal material use.

Reinforcement & Connection Details: Ensures structural integrity and earthquake resistance.

Embedded Items & Lifting Systems: Facilitates safe handling and transportation.

Drainage & Waterproofing Considerations: Prevents water damage and enhances durability.

Integration with Mechanical & Electrical Systems: Supports lighting, ventilation, and fire safety.

By employing accurate precast detailing, parking structures can be delivered on time, within budget, and with higher quality standards.

Successful Applications of Prefabricated Parking Structures

Leading companies such as Metromont Corporation, Gate Precast, and Clark Pacific have successfully implemented modular parking structures for large-scale projects.

Benefits Observed in Real-World Applications:

30-50% Faster Construction compared to traditional methods.

Enhanced Architectural Appeal through customized finishes.

Lower Lifecycle Costs due to precast durability.

Seismic-Resistant Designs ensuring long-term structural stability.

As the demand for efficient parking solutions grows, prefabrication and precast detailing will remain at the forefront of modern infrastructure development.

Conclusion

The shift towards prefabricated construction is redefining how parking structures are designed and built. Precast detailing services play a pivotal role in ensuring seamless fabrication, installation, and cost efficiency.

With Clark Pacific, Gate Precast, and Metromont leading the industry, the future of parking structures lies in precision detailing, modular design, and sustainable construction methods.

By embracing prefabricated solutions, advanced detailing, and high-quality precast components, parking structures can be built faster, stronger, and more efficiently than ever before.

#bim services#engineering#Precast detailing services#modular design#Clark Pacific#Parking Structures

0 notes

Text

#precastconcrete#concrete#precast#construction#architecture#building#design#concreteconstruction#architect#civilengineering#beton#concretedesign#exteriordesign#engineering#manufacturing#prefabbricati#formwork#bahrain#uditch#edilizia#archilovers#prefabricados#crane#architectualprecast#selectprecast#concreteproducts#steelconstruction#betonpracetak#wikabeton#konstruksibaja

0 notes

Text

Centre Point photographed here in 1966, occupies 101–103 New Oxford Street and 5–24 St Giles High Street WC1, with a frontage also to Charing Cross Road close to St Giles Circus and almost directly above Tottenham Court Road tube Station.

The building was designed by George Marsh with engineer Pell Frischmann and was constructed by Wimpey Construction from 1963 to 1966, for a cost of £5.5 million. The precast segments were formed of fine concrete utilising crushed Portland Stone and were made by Portcrete Limited at Portland Dorset. They were transported to London by lorry. It is said the site was once occupied by a gallows which was situated on St Giles Street as the tower sits directly over the former route of St Giles High Street, which had to be re-routed for the construction. On completion, the building remained vacant for many years, leading to its being referred to as "London's Empty Skyscraper".

55 notes

·

View notes

Text

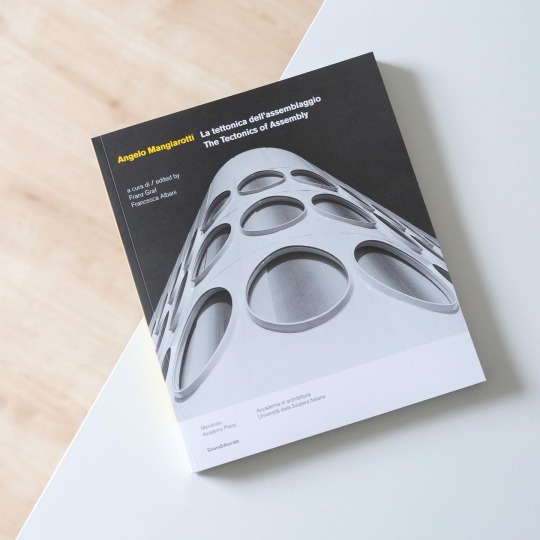

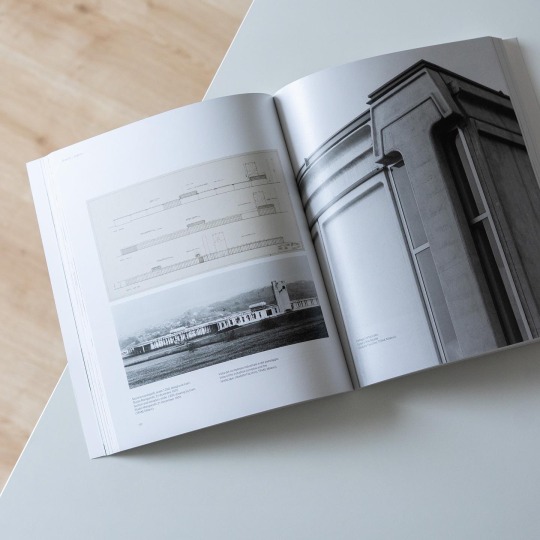

The ingenious work of Italian architect and designer Angelo Mangiarotti still remains somewhat under-appreciated outside of Italy which indeed is a shame in view of the sophisticated oeuvre he left. The latter is characterized by a poetic engineering that combines logical form and structural beauty that sets Mangiarotti’s buildings way apart from pure works of engineering. Throughout his career he worked on an architectural language of the assemblage consisting of vocabulary and grammar aligned with three key concepts: experimentation, gravity and module as Franz Graf and Francesca Albani explain in the introduction to the present volume they edited: „Angelo Mangiarotti - The Tectonics of Assembly“, published by Silvana Editoriale in 2015. These concepts, which relate to Mangiarotti’s sounding out of material capabilities and limitations, the main force in the trilithic system of simply supported precast concrete elements and the modular use of his structural inventions, can be explored further in the select but extensively documented catalogue of ten representative projects: structured along the aforementioned three concepts projects like the Elmag Factory in Lissone (1963-69) or Snaidero premises (1971-78) in Majano are presented in a brief explanatory text, design drawings, technical drawings, plans, models and photographs that provide an unusually comprehensive overview of the genesis of each project.

The two lengthy essays by the editors situate these works and Mangiarotti’s oeuvre in general within the postwar building culture of Northern Italy, his unique contribution to it and how it is perceived today. A more personal, close-up view on Mangiarotti’s practical work and design ethics is in turn provided by Kinue Horikawa who was one of the many Japanese architects and designers passing through the Milan office.

„Angelo Mangiarotti - The Tectonics of Assembly“ is a beautifully illustrated, concise and comprehensive introduction to the Italian master’s work and thinking and as such highly recommended!

29 notes

·

View notes

Text

What to Look for When Comparing Precast Concrete Manufacturers: A Practical Guide

Choosing the right precast concrete manufacturer can make or break your construction project. Whether you're an architect, builder, or project manager, quality, reliability, and expertise matter. In this guide, we’ll break down the essential factors to consider when comparing precast concrete manufacturers—so you can make an informed, confident decision.

1. Product Quality and Compliance

The first thing to assess is the quality of the precast concrete. Reputable manufacturers use high-grade materials and maintain strict quality control throughout production. Always check if their products meet local building codes and industry standards (such as ASTM, PCI, or NPCA certifications).

✅ Tip: Request recent test reports or certifications to verify compliance.

2. Experience and Specialization

Not all precast suppliers are the same. Some specialize in architectural panels, others in infrastructure elements like culverts, beams, or retaining walls. Look for a manufacturer with proven experience in projects similar to yours.

✅ Tip: Ask for a portfolio of completed projects or client references in your industry.

3. Production Capacity and Lead Times

Can the manufacturer handle the volume your project requires—on time and without compromising quality? Production delays can lead to costly project overruns. Make sure the company has the capacity, equipment, and workforce to meet your deadlines.

✅ Tip: Inquire about average lead times and how they handle high-demand periods.

4. Customization and Design Support

A good manufacturer offers custom solutions and may even assist with design, engineering, or BIM modeling. This level of support can significantly streamline your planning and reduce site work.

✅ Tip: Check if they have in-house engineers or offer pre-design consultations.

5. Delivery and Installation Services

Precast concrete is heavy and often complex to transport. Manufacturers with in-house logistics or trusted delivery partners can save you headaches. Some even offer on-site installation support, which can be a huge bonus.

✅ Tip: Ask if they provide shipping, crane support, or on-site technical supervision.

6. Sustainability Practices

As sustainability becomes a bigger focus in construction, it’s worth checking whether the manufacturer uses eco-friendly practices, such as recycling water or using low-carbon mixes.

✅ Tip: Look for Environmental Product Declarations (EPDs) or LEED-related documentation.

Conclusion:

Choosing the right precast concrete manufacturer goes beyond just comparing prices. It’s about finding a reliable partner who understands your project needs, delivers quality products, and helps you stay on schedule. Use the points above as a checklist, and you’ll be well on your way to a successful build.

📞 Need a Trusted Precast Concrete Supplier?

If you're comparing precast concrete suppliers, don't overlook the importance of experience, quality, and personalized support. At DC Kerckhoff Company, we specialize in high-performance precast concrete solutions for architectural, structural, and landscape applications. With decades of industry experience, state-of-the-art facilities, and a commitment to craftsmanship, we’re here to help bring your project to life—on time and on spec.

👉 Contact us today to discuss your project requirements, request a quote, or schedule a design consultation. We're ready to be your trusted precast concrete partner from concept to completion.

Tags: #PrecastConcrete #BuildingMaterials #Architectural #Landscaping #ConcreteManufacturing

0 notes

Text

Durable & Affordable Compound Walls in Jaipur – Tailored for Every Need

If you're searching for top-quality compound walls that offer strength, durability, and cost-effectiveness, you've come to the right place. Whether you need secure fencing for residential, commercial, or industrial properties, our solutions are built to last. As a trusted Compound Wall Manufacturer in Goner, we bring years of experience and innovation to every project.

Strong & Reliable RCC Compound Wall in Pratap Nagar

For projects that demand superior structural integrity, our RCC Compound Wall in Pratap Nagar is an ideal choice. Reinforced Cement Concrete (RCC) walls are known for their long lifespan and excellent resistance to harsh weather conditions. Our RCC walls are engineered with precision and installed efficiently to ensure safety and durability for years to come.

Affordable Readymade Boundary Wall in Pratap Nagar

Need a quick and budget-friendly boundary solution? Our Readymade Boundary Wall in Pratap Nagar offers just that. These pre-engineered walls are delivered ready for installation, saving you time, labor, and material costs. Ideal for residential plots, farmhouses, and commercial properties, our readymade walls combine convenience with performance.

Elegant Precast Boundary Wall in Sanganer

Our Precast Boundary Wall in Sanganer is popular among homeowners and developers who want a blend of strength and style. Made using high-grade concrete and molds, these walls offer a clean, uniform look while maintaining high durability. The fast installation process makes precast walls an excellent option for time-sensitive projects.

Trusted RCC Wall Manufacturer in Sitapura

As a leading RCC Wall Manufacturer in Sitapura, we use modern techniques and premium materials to build strong, long-lasting walls suitable for industrial and commercial properties. Our walls are engineered to meet specific site requirements and offer enhanced security, making them ideal for warehouses, factories, and institutional facilities.

Best Compound Wall in Jaipur – Proven Performance

Our clients consistently rate us as the provider of the Best Compound Wall in Jaipur thanks to our commitment to quality, timely delivery, and customer satisfaction. We customize each wall to suit your property’s needs while maintaining structural integrity and a professional appearance.

Reliable Precast Wall Manufacturer near Sanganer

We are proud to be a well-known Precast Wall Manufacturer near Sanganer, offering innovative solutions for secure boundaries. Our precast walls are not only quick to install but also eco-friendly and cost-effective, making them perfect for urban and rural properties alike.

Local Wall Dealer in Goner

As a local Wall Dealer in Goner, we offer personalized service and on-ground support for choosing the right type of wall for your property. We supply everything from traditional RCC to modern precast designs, ensuring each client receives the best value for their investment.

Experienced Boundary Wall Contractor in Jaipur

Looking for a reliable Boundary Wall Contractor in Jaipur? Our team offers end-to-end services—from design and planning to installation. We handle residential, industrial, and commercial boundary wall projects with precision and care.

Cement Wall Manufacturer in Jaipur – Built to Last

As a trusted Cement Wall Manufacturer in Jaipur, we use premium-grade cement and cutting-edge molding techniques to produce high-quality walls suitable for all types of environments. These walls are especially effective in preventing unauthorized access and enhancing property aesthetics.

Low Cost RCC Wall in Jaipur Without Compromising Quality

Budget-friendly doesn't mean low quality. Our Low Cost RCC Wall in Jaipur is proof that you can have durable, well-designed walls at an affordable price. These are perfect for large-scale developments where cost efficiency is critical.

Secure Your Property with an Industrial Compound Wall in Jaipur

Our Industrial Compound Wall in Jaipur solutions are specifically designed for factories, plants, and commercial units. These walls are built to be tough, secure, and low-maintenance, helping safeguard your assets and infrastructure.

Choose the Best for Boundary Wall Jaipur Projects

For all types of Boundary Wall Jaipur requirements—residential, commercial, or industrial—we offer customized, cost-effective, and fast solutions that stand the test of time.

Precast Compound Wall - Compound Wall Manufacturer in Jaipur near ring rod, road, Goner Rd, Goner, Sankh Shyopuri, Jaipur, Rajasthan is your trusted partner for durable, secure, and aesthetically pleasing compound wall solutions across Jaipur and surrounding regions. Contact us today for expert consultation and high-quality wall installations.

0 notes

Text

UK Precast Concrete Market

🔨 𝐔𝐊 𝐏𝐫𝐞𝐜𝐚𝐬𝐭 𝐂𝐨𝐧𝐜𝐫𝐞𝐭𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 — 𝐒𝐨𝐥𝐢𝐝 𝐅𝐨𝐮𝐧𝐝𝐚𝐭𝐢𝐨𝐧𝐬, 𝐒𝐭𝐫𝐨𝐧𝐠𝐞𝐫 𝐅𝐮𝐭𝐮𝐫𝐞𝐬

UK Precast Concrete Market size is expected to be valued at US$6.3 billion by the end of the year 2030 and is set to grow at a CAGR of 6.8% during the forecast period from 2024–2030.

UK precast concrete market plays a crucial role in the nation’s construction and infrastructure sectors, offering high-performance, factory-manufactured concrete components used in residential, commercial, and civil engineering projects. Precast concrete products — such as beams, panels, slabs, stairs, and tunnels — are fabricated off-site under controlled conditions, ensuring superior quality, faster construction times, and reduced on-site labor compared to traditional cast-in-place methods.

Driven by the UK’s growing demand for efficient, sustainable building solutions, the market is evolving with innovations in modular construction, digital design (BIM), and low-carbon materials. The push toward net-zero emissions and modern methods of construction (MMC) is accelerating the adoption of precast components across public and private developments.

🔗 𝐆𝐞𝐭 𝐑𝐎𝐈-𝐟𝐨𝐜𝐮𝐬���𝐝 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐟𝐨𝐫 𝟐𝟎𝟐𝟓-𝟐𝟎𝟑𝟏 → 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐍𝐨𝐰

Key market segments include housing (especially social and modular housing), transport infrastructure (rail and road), utilities, and commercial buildings. Government-backed initiatives and infrastructure programs such as HS2, housing targets, and green construction goals are further boosting demand.

𝐓𝐨𝐩 𝐊𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬:

Forterra PLC, FP McCann Ltd., Tarmac, Bison Transport Inc., Thorp Precast Limited., Milbank Concrete Products Limited, Cornish Concrete Products Ltd., Marshalls plc, Balfour Beatty plc, Laing O’Rourke, Techrete UK & Ireland, Carillion Alawi L.L.C., Evans Concrete Products by Shay Murtagh, CREAGH CONCRETE PRODUCTS LIMITED, Explore Manufacturing — part of Laing O’Rourke, Elite Precast Concrete, Coltman Precast Concrete Ltd

#PrecastConcrete #UKConstruction #ConstructionIndustry #InfrastructureUK #BuildingBritain #ConcreteSolutions #ModernMethodsOfConstruction #MMC #OffsiteConstruction #StructuralEngineering

0 notes

Text

Best Precast Concrete Wall Panels in India- Hey Concrete Hey Concrete brings you India’s finest range of precast concrete wall panels, crafted with innovation, strength, and style. Engineered using our signature H-UHPC (Hey Ultra High Performance Concrete), each panel is designed to deliver unmatched durability, weather resistance, and aesthetic appeal. Whether you're building commercial spaces, residential homes, or architectural landmarks, Hey Concrete offers custom-designed, handmade wall panels that elevate every project.

#interior design#concrete#home decor#concretepanels#wallpanels#wall panels#architecture#interiors#concrete panels#heyconcrete

0 notes

Text

Trusted Anchor Bolts Manufacturers in India – Precision Fasteners That Hold Strong

Anchor bolts are critical components in every construction and industrial setup. Designed to secure structural elements to concrete, they play a key role in the strength and durability of a project. As one of the top anchor bolts manufacturers in India, we specialize in delivering high-performance fasteners trusted by engineers and project managers across industries.

At Eshaji Engineering, we take pride in being a reliable anchor bolts supplier in Chennai offering custom sizes, finishes, and high-grade materials suited for varied load requirements and site conditions.

Why Anchor Bolts Matter

Anchor bolts are used for:

Securing steel structures

Mounting heavy machinery

Power transmission foundations

Bridge and highway constructions

Precast concrete installations

As experienced anchor bolts manufacturers in India, we ensure every bolt meets quality standards and load-bearing specifications to support critical structural applications.

What Sets Us Apart?

Being among the top anchor bolts manufacturers in Chennai, we offer:

✔ Fully customized bolt lengths and threading ✔ Hot-dip galvanized, zinc-plated, or plain finishes ✔ IS, DIN, ASTM standard manufacturing ✔ Quick dispatch and pan-India delivery ✔ In-house quality testing and documentation

We serve industries such as infrastructure, renewable energy, petrochemical, and construction. Our team ensures every bolt you receive is manufactured with precision and care.

Serving Chennai and Beyond

As a trusted anchor bolts supplier in Chennai, we maintain a strong supply chain that caters not just to Tamil Nadu, but across India. We work closely with project consultants and EPC contractors to provide anchor solutions that enhance safety and efficiency at site.

Whether you're looking for standard L-type or J-type bolts, sleeve anchors, or custom fasteners, we are one of the most dependable anchor bolts manufacturers in India you can count on.

Ready to Place Your Order?

Get in touch with Eshaji Engineering – the top anchor bolts manufacturers in Chennai – for competitive pricing, expert support, and timely delivery.

📞 Call Now

0 notes

Text

Pool Retaining Wall Panels: The Backbone of a Strong and Stylish Pool Design

If you're designing or renovating a swimming pool, one component you can’t afford to overlook is the pool retaining wall panel system. Whether your yard is sloped, uneven, or you simply want to add some architectural depth to your pool area, retaining walls for pools are essential for both function and aesthetics.

At Pool Project Management, we specialize in custom pool construction, including expertly engineered pool retaining wall systems that ensure your project is both beautiful and built to last.

What Are Pool Retaining Wall Panels?

Pool retaining wall panels are structural elements that help support and stabilize the soil surrounding your swimming pool. These walls are especially important if your in-ground pool or semi-inground pool is installed on uneven ground. The right retaining wall prevents soil erosion, manages drainage, and allows you to create visually appealing multi-level pool landscapes.

Retaining wall systems are often made from:

Concrete blocks

Precast concrete panels

Poured concrete

Natural stone

Modular retaining wall units

These pool wall panels can also double as design features, such as built-in seating walls, waterfall bases, or raised planters around the pool area.

When Do You Need a Pool Retaining Wall System?

Adding a retaining wall for a pool is crucial in several situations:

Your backyard has a slope or uneven elevation

You're building a raised pool or infinity edge pool

You want to include tiered landscaping or terraced levels

You’re facing drainage or runoff issues

You're adding a deck or patio around the pool

In these scenarios, a pool retaining wall system isn’t just helpful—it’s necessary.

Types of Pool Retaining Walls We Install

At Pool Project Management, we offer a variety of custom pool retaining wall installations, tailored to your landscape and design vision. Popular styles include:

Concrete Block Retaining Walls

Sturdy and affordable, great for structural stability and long-term durability.

Natural Stone Pool Retaining Walls

Perfect for a luxury or rustic look, blending seamlessly into natural landscapes.

Modular Panel Systems

Fast to install and excellent for modern designs with clean, geometric lines.

Poured Concrete Walls

Highly customizable for curved or uniquely shaped pool designs.

All of our retaining wall systems for pools are engineered for safety, drainage control, and long-term strength.

Benefits of Pool Retaining Wall Panels

Adding retaining walls around your pool isn’t just about holding back soil—it’s about creating a safe, stylish, and functional outdoor environment. Key benefits include:

Improved soil stability and erosion control

Enhanced pool safety and structural support

Better water drainage and flood prevention

Visually dynamic poolside design

Increased property value and curb appeal

If you’re building a backyard pool on a slope, retaining wall panels allow you to build a stable, level base while enhancing the pool’s appearance.

Professional Pool Retaining Wall Installation

Installing a pool retaining wall is a technical process that involves soil analysis, drainage planning, and proper engineering. That’s why it's essential to trust experienced professionals.

At Pool Project Management, we offer end-to-end services including:

Site evaluation and grading

Retaining wall design and layout

Permit handling and code compliance

Professional retaining wall construction

Seamless integration with your pool, decking, and landscaping

Our goal is to deliver a durable, stylish, and low-maintenance retaining wall that blends perfectly with your pool design.

Ready to Start Your Pool Project with the Right Retaining Wall?

Don’t let a sloped yard or drainage issue stop you from building the backyard of your dreams. Let Pool Project Management help you plan and build a pool that’s safe, stunning, and structurally sound.

Contact us today for expert advice and a free consultation on your pool retaining wall installation.

Visit us at poolprojectmanagement.com and see how we can support your pool construction or renovation from start to finish.

0 notes

Text

🏢 Reliable Precast Panel Detailing Services in Washington ⚙️

Looking for #PrecastPanelDetailing that’s accurate, efficient, and fits your project needs? #SiliconOutsourcing offers smart #PrecastShopDrawings, complete #PrecastConcreteDetailing, and clear #TiltUpPanelDesigns to make sure every panel fits perfectly. 📋🧱

From early planning to final detailing, we bring clarity and confidence to your engineering process with expert CAD solutions. 🎯📏

🚀 Your Project, Our Precision! Let’s make your design flow smoother and smarter.

📞 Contact us now! 🌐 Visit Us: https://www.siliconoutsourcing.net/cad-structural-steel/pre-cast-detailing.html

#PrecastDetailing#ShopDrawings#PanelDesign#CADExperts#EngineeringSupport#SmartDesigns#SiliconOutsourcing

0 notes

Text

Why Concrete Wall Panels Are Revolutionizing Modern Construction

As construction demands continue to evolve, so do the materials and methods we rely on. Among the most transformative innovations in modern infrastructure are concrete wall panels—a solution that seamlessly combines strength, efficiency, and aesthetics.

What Are Concrete Wall Panels?

Concrete wall panels are prefabricated or cast-in-place panels made from high-strength concrete. They serve both structural and architectural purposes in a wide range of projects, from commercial buildings and institutional facilities to infrastructure and outdoor spaces. These panels can be used for exterior façades, interior partitions, retaining walls, and more.

The Benefits of Concrete Wall Panels

At TerraTread, we specialize in delivering high-performance infrastructure solutions, and we’ve seen firsthand how concrete wall panels can enhance project outcomes in several key ways:

Durability That Lasts Decades

Engineered to withstand extreme weather, fire, and wear, concrete wall panels offer unmatched longevity. Unlike wood or traditional masonry, they resist rot, corrosion, and pests—making them ideal for both urban and natural environments.

2. Rapid Installation

Because many concrete wall panels are precast, they can be manufactured off-site and installed quickly, reducing on-site labor costs and project timelines. This makes them a go-to solution for contractors looking to streamline construction without sacrificing quality.

3. Versatile Design Options

Modern board-form finishes, integrated textures, and color pigments allow for a wide range of aesthetic customization. Whether you’re designing a sleek pedestrian underpass or a textured retaining wall alongside a concrete boardwalk, these panels deliver both function and form.

4. Sustainable Construction

Concrete’s thermal mass properties contribute to energy efficiency, while precast panel production minimizes on-site waste. TerraTread’s commitment to sustainable practices ensures that our concrete wall panels support green building standards and long-term environmental responsibility.

Applications Across Industries

Concrete wall panels are used extensively in:

Park and trail infrastructure(often paired with boardwalk systems)

Retaining walls and earth stabilization

Noise barriers along roadways

Building façades and outdoor enclosures

Pedestrian bridge abutments and wing walls

At TerraTread, we design and deliver wall panel systems that integrate seamlessly with our concrete boardwalks and pedestrian bridges, ensuring cohesive performance and visual continuity across the entire site.

Why Choose TerraTread?

Our engineering expertise, dedication to quality materials, and focus on sustainable infrastructure make us a trusted partner in every phase of your project. Whether you’re planning a new development or seeking a wooden walkway replacement with integrated wall systems, we provide tailored solutions that stand the test of time.

Ready to explore durable, design-forward concrete wall panels for your next project? Contact TerraTread today to learn more about our customizable systems and discover how we can elevate your construction with innovation and integrity.

Source Url : - https://theparentingera.com/why-concrete-wall-panels-are-revolutionizing-modern-construction/

0 notes

Text

Innovative Retaining Wall Solutions for Challenging Terrain

Introduction to Retaining Walls

Retaining walls are vital in both small-scale and large-scale construction projects, serving as structural supports that resist the pressure of soil on sloped ground. These walls allow for efficient use of land that would otherwise be prone to erosion or collapse. In modern landscape and civil engineering, retaining wall solutions have evolved to address a variety of terrain-related challenges with precision and creativity. Whether used in backyards or along highways, these structures are critical in shaping and protecting our built environment.

Structural Importance in Landscape Design

The primary role of retaining walls is to create a firm barrier that holds soil in place, particularly in areas where natural gradients are too steep for safe or practical use. This function is essential for building on hillsides or managing flood-prone zones. Retaining wall solutions help prevent landslides and soil washouts by stabilizing the land and reducing hydrostatic pressure. In landscape architecture, they are often used to create multi-level gardens, sunken patios, or defined pathways, giving designers more flexibility in shaping outdoor spaces.

Design Innovations and Aesthetic Appeal

Recent innovations have transformed retaining walls from purely functional elements into stylish features of modern landscapes. Designers now integrate curves, terraces, and varied textures into retaining walls to enhance their visual interest. Segmental systems made from interlocking concrete units offer not only structural integrity but also flexibility in design. These systems are customizable and allow for the incorporation of steps, lighting, and seating elements. As a result, retaining wall solutions contribute to both the visual and functional aspects of outdoor living areas.

Choosing the Right Building Materials

Selecting the appropriate materials is key to achieving both performance and design goals. Concrete blocks are favored for their modular nature and ease of installation, often used in residential and commercial projects alike. Timber, though less durable than stone or concrete, is suitable for smaller applications and offers a natural look. Precast concrete panels are commonly used in larger infrastructure projects due to their strength and fast installation. Natural stone, though more labor-intensive, brings unmatched beauty to any landscape. The selection of materials should align with the specific demands of each retaining wall solution, including load requirements, environmental exposure, and budget constraints.

Engineering Effective Drainage

Proper drainage is one of the most critical aspects of building retaining walls. Without it, water can build up behind the wall, leading to excessive pressure and eventual structural failure. Effective retaining wall solutions include integrated drainage systems that channel water away from the wall through gravel backfill, perforated pipes, and weep holes. Advanced methods also incorporate geotextile fabrics that separate soil and drainage materials, enhancing long-term performance. A well-drained wall is a long-lasting wall, and drainage must be a top consideration from the start.

Site-Specific Retaining Wall Solutions

Every landscape presents unique challenges, and retaining wall solutions must be adapted accordingly. In residential settings, the focus may be on design and usability, with walls forming the backbone of outdoor entertainment areas. In contrast, retaining walls on highways or rail lines prioritize durability and safety, often involving reinforced concrete and complex anchoring systems. Coastal projects require materials and designs that withstand saltwater corrosion and shifting sands. By tailoring the design to the location’s specific needs, professionals ensure the retaining walls serve their intended function effectively and safely.

Maintaining Structural Integrity Over Time

Maintenance is often minimal for well-built retaining walls, but routine checks can help detect early signs of wear or damage. Shifting soil, cracks, and water leakage are indicators that a wall may need repairs or reinforcement. Modern retaining wall solutions may incorporate technology such as embedded sensors to monitor movement and stress levels in real time. These innovations allow property owners and engineers to take preventive action before small issues become major problems, extending the life of the wall and preserving safety.

Conclusion

Retaining wall solutions are more than just barriers—they are essential tools for land development, erosion control, and aesthetic enhancement. As construction methods improve and environmental considerations grow, retaining walls have adapted to meet these new demands. Their role in creating usable, attractive, and stable spaces continues to expand across industries. With proper planning, design, and materials, retaining walls offer enduring value and resilience in even the most complex terrains.

1 note

·

View note

Text

7 Game-Changing Ways Precast Concrete Manufacturers Cut Construction Costs!

In today’s competitive construction landscape, every dollar counts. Precast concrete manufacturers are helping developers, architects, and contractors save time and money—without compromising on quality. Here are 7 game-changing ways precast concrete is revolutionizing cost-efficiency in construction:

1. Faster Installation

Precast components arrive at the job site ready to install. This dramatically reduces on-site labor and speeds up the construction schedule, cutting project timelines and associated costs.

2. Reduced Labor Costs

With most of the fabrication done off-site in controlled environments, less skilled labor is needed on-site. That translates into lower workforce expenses and fewer delays.

3. Minimized Material Waste

Precast production is incredibly efficient. Manufacturers reuse formwork and optimize material usage, leading to minimal waste—saving money and supporting sustainability goals.

4. Weather-Resilient Scheduling

Rain, snow, or extreme heat can bring construction to a halt—but not with precast. Manufacturing continues in all weather, ensuring predictable timelines and reducing costly delays.

5. Lower Maintenance Costs

Precast concrete is highly durable and resistant to corrosion, fire, and pests. This means less money spent on maintenance and repairs over the building’s lifespan.

6. Design Versatility with Standardization

Manufacturers offer standardized products with customizable finishes. This balance reduces design and engineering costs while still meeting architectural vision.

7. Reduced On-Site Equipment Needs

Fewer on-site processes mean fewer cranes, mixers, and other heavy equipment—reducing rental costs and logistical complexity.

Ready to Cut Costs on Your Next Project?Partner with a trusted leader in precast innovation. At DC Kerckhoff, we help builders, architects, and developers bring their visions to life—efficiently and affordably. Explore our products and solutions at kerckhoffstone.com or contact us today to start the conversation.

0 notes

Text

Pile Head Cutting and Pile Cropping: An Essential Step in Foundation Construction

Pile head cutting, also known as pile cropping, is a crucial procedure in the construction of deep foundations. It involves the removal of the upper portion of cast-in-place or precast concrete piles after they have been installed and the concrete has hardened. The purpose of this operation is to expose the reinforcement bars for integration into the pile cap or footing and to ensure the pile head is at the correct design level.

During the pile installation process, whether by driving, boring, or casting in-situ, the piles are often extended above the intended cutoff level. This overcasting is intentional, as the upper section of the pile is prone to contamination from loose concrete, laitance, and water during the pour. These upper portions may also be structurally weaker or misaligned due to movement during curing or construction tolerances. Therefore, the pile head must be cut down to a sound, solid section of concrete that can properly transfer loads to and from the superstructure.

Pile cropping is performed once the piles have fully cured and after all testing, such as integrity testing or load testing, has been completed. The exposed reinforcement is then used to tie the pile to the pile cap, which distributes structural loads evenly across all piles in a foundation group. Inadequate pile cutting can result in poor load transfer, reduced structural integrity, and long-term durability issues.

There are several methods used in pile head cutting, and the choice depends on the pile type, size, location, and site conditions. Traditional methods include manual chipping using pneumatic hammers or hand tools. Though effective, this method is labor-intensive, time-consuming, and generates a significant amount of dust and noise. It also poses a risk of damaging the pile reinforcement or reducing the quality of the finished surface.

Modern approaches to pile cropping employ mechanical equipment that offers greater precision and efficiency. Hydraulic pile croppers are widely used in contemporary construction due to their ability to deliver clean and consistent cuts without damaging reinforcement. These machines use a hydraulic system to exert pressure around the pile circumference, breaking off the unwanted concrete in a controlled manner. Various types of hydraulic croppers are available to suit different pile shapes and sizes, including round, square, and contiguous piles.

For projects where noise and vibration must be minimized, such as in urban or sensitive environments, specialized methods like hydrodemolition or wire sawing may be employed. Hydrodemolition uses high-pressure water jets to remove concrete without affecting the reinforcement, while wire sawing involves cutting through concrete using a diamond-embedded wire. Both techniques are precise and reduce the risk of micro-cracking, but they require skilled operators and specialized equipment.

Safety during pile cutting is paramount. The process involves the use of heavy tools and equipment, working at height or below ground, and handling exposed steel reinforcement. Proper personal protective equipment (PPE), adherence to safety protocols, and training are essential to prevent accidents. Structural engineers and site managers must ensure that the pile cutting is conducted in accordance with project specifications and engineering standards.

In addition to structural and safety considerations, the quality of pile head cutting also impacts the ease and effectiveness of subsequent construction phases. A properly cropped pile head provides a level and stable surface for pile cap construction and reduces the need for remedial work. It ensures good bonding between the pile and cap, facilitating proper load distribution and long-term performance.

Pile head cutting and cropping, while often seen as a routine site activity, play a critical role in ensuring the integrity and functionality of a foundation system. With advancements in technology and equipment, the process has become more precise, efficient, and safe, allowing for better quality control and faster construction timelines. As such, it remains an indispensable aspect of foundation work in modern construction.

0 notes