#precision turned components

Text

#stainless steel dowel pins#stainless steel dowels#precision turned components#small turned parts#Stainless Steel Shafts#Stainless Steel Axis#Stainless Steel Pin#Precision Pins#Grooved Pin#Knurled pins#ss shaft#ss pins

2 notes

·

View notes

Text

CNC Machined Parts in Ahmedabad

Scharf Precision Engineering is a leading provider of CNC machined parts and components in Ahmedabad. We specialize in CNC machined parts as per customer requirements with international standards. We have been serving clients from different industries including aerospace, military, energy and electronics.

#CNC Machined Parts#Precision Turned Components#CNC Machined Components#Custom Machined Parts#CNC Machined Parts Production#Ahmedabad

1 note

·

View note

Text

Enhancing Manufacturing Efficiency: 5 Compelling Reasons to Utilize Precision Turned Components in India

Utilizing precision turned components in your power transmission systems offers numerous benefits. While the initial costs may be higher, this extra investment typically yields returns in terms of enhanced efficiency, increased productivity, and reduced maintenance and downtime. Components offered by Turned Components Manufacturers Mumbai, India have the potential to reduce your recurring operational energy expenses by diminishing friction and heat wastage, all while maintaining the capacity to generate equal power output when operating at reduced speeds.

0 notes

Text

How are Precision Turned Components Manufactured?

Precision machined components get their name because they apply precisely and produce the expected results when used in a machine. These components are essential for modern manufacturing because modern precision devices must attain incredibly small tolerances and exact fittings.

The idea of precise machining is not new, but with the development of computers and software, the manufacturing process has added a new degree of accuracy, fit, and tolerance. This category includes all machining operations, including turning, milling, drilling, honing, grinding, and other operations, all of which benefit from CAD and CAM software.

Sketch/drawing

Obtaining the drawings, technical specifications, and parameters for the parts is the first step in making precision turned components. As the design is input into the computer system, all that is required to begin is a sketch with the appropriate markings. Before being submitted for approval, a drawing provided by the customer is revised internally.

CAD

The technical specifications are entered into the computer-aided design software because a sketch or drawing by itself won't enable a precise manufacturing process. As opposed to a 2D depiction, which makes it impossible to see around bends, slits, and difficult-to-reach areas, CAD software enables 3D rendering of the drawing. After the redesigning is finished, the machine parts manufacturer in Texas sends the revised sketch and the 3D design for final approval.

Machining

The customer's consent is required before the machining process may start. Precision machining, sometimes known as CNC machining, is performed differently than on a standard lathe. The machine uses the input data to build precise cuts, drills, holes, bevels, and threads that give the blanks the desired shapes in accordance with customer specifications.

Post-machining

The work is not finished simply by drilling, cutting, or imparting the necessary shapes to blanks. Some of the things that need to be examined during the post-machining process are deburring, inspection, and dimensional integrity. After everything is completed, each part is given a final check to ensure that it complies with the plans before being produced as exact machine parts.

After the process

While the technological requirements for producing precisely machined components are important, it is also important to emphasize the value of a human operator who is familiar with the CNC process and precision machining. Despite the fact that CNC machines can operate independently, it is essential to have a supervisor to make sure that each item conforms to the tolerance parameters specified for that particular part.

Mastering precision

Precision-turned components are vital in modern manufacturing. They are made with meticulous sketches and technical specifications. Transformed into 3D designs via Computer-Aided Design (CAD) software, these blueprints guide the manufacturing process.

Advanced CNC machining techniques, driven by these designs, craft intricate cuts, holes, and threads with utmost accuracy. Post-machining, rigorous inspections using tools like coordinate measuring machines guarantee dimensional integrity and flawless finishes.

Integrating human expertise, technological precision, and stringent quality checks, manufacturers ensure every component meets exact specifications. This synergy between human skill and cutting-edge technology defines the art and science behind precision turned components that shape diverse industries worldwide.

Resource Box

Buy precision machine components from Arek Solutions because they are a reputed precision machining parts manufacturer who meticulously crafts parts to provide you with components with accuracy. You can buy turned parts for any industry from Arek Solutions.

#precision machined components#precision machining parts manufacturer#precision turned components#machine parts manufacturer texas#machining components

0 notes

Text

Precision Turned Components: How to choose the Ideal Supplier in India?

Precision turned components play a critical role in various industries, including automotive, aerospace, medical, and electronics. These components are used in a wide range of applications and are known for their precision, accuracy, and reliability. As a result, the demand for precision turned components has increased significantly in recent years.

In India, there are numerous precision turned components manufacturers, making it challenging to choose the ideal supplier. Here are a few key factors to consider when selecting a supplier for precision turned components in India:

Quality and Capability: The quality of precision turned components is of utmost importance. To ensure that you receive the best quality components, it is important to choose a supplier with a proven track record of producing high-quality components. It is also important to consider the supplier's capability, including their technology, equipment, and experience.

Delivery and Lead Time: When selecting a supplier for precision turned components, it is important to consider their delivery and lead time. You want to choose a supplier that can meet your delivery schedule and provide timely delivery of components. It is also important to consider the supplier's ability to handle urgent requests or unexpected changes in demand.

Cost-Effectiveness: Cost is a critical factor when choosing a supplier for precision turned components. It is important to choose a supplier that offers competitive pricing, without compromising on quality. However, it is important to keep in mind that the cheapest option may not always be the best. It is essential to consider the total cost of ownership, including the cost of production, delivery, and after-sales support.

Location and Logistics: The location of the supplier is an important factor to consider when choosing a supplier for precision turned components. The proximity of the supplier to your location can greatly impact the delivery time and cost of components. Additionally, it is important to consider the supplier's logistics capabilities and the ease of transporting components to your location.

Technical Expertise and Customer Support: The technical expertise and customer support offered by a supplier are critical factors to consider when choosing a supplier for precision turned components. It is important to choose a supplier that has a deep understanding of the applications and industries that you serve. Additionally, you want to choose a supplier that provides exceptional customer support, including quick response times, technical support, and problem resolution.

Precision turned components play a critical role in various industries, and it is important to choose the right supplier to ensure that you receive the best quality components. Precision Turned Components Mumbai and other precision turned components manufacturers in India offer a wide range of components, making it important to consider the factors listed above when choosing a supplier.

choosing the ideal supplier for precision turned components requires careful consideration of several key factors, including quality and capability, delivery and lead time, cost-effectiveness, location and logistics, and technical expertise and customer support. By carefully evaluating these factors, you can ensure that you choose a supplier that can meet your needs and provide the highest quality components. Ganeshprecision.com manufacture and supply wide range of Precision Turned Components in Pune, India. Such as precision sensors, sensor housing, pressure gauge parts, pen parts, electronics parts, etc.

0 notes

Text

Precision Turned Components Manufacturer & Exporter India | BigBoltNut

BigBoltNut is precision turned components manufacturer in India. These components are used for automobile, aerospace, machine building and heavy engineering industry . We are a manufacturer & exporter of Bigger Diameter Bolt and nuts. We manufacture bolts, nuts and stud bolts in high tensile and in Stainless steel grades for critical applications, like wind energy, infrastructure, pipe lines, sewage plants, pumps, valves, bridges, water treatment plants, TSE networks and more.

#precision turned components#precision turned components manufacturer#precision turned components supplier

0 notes

Text

#Stainless Steel Pin Manufacturer in Delhi#Stainless Steel Pins Manufacturer#Hinge Pins Manufacturer#Dowel Pins Manufacturer#KNURLED PINS Manufacturer#Precision CNC Turned Component Manufacturer#Precision Turned Component Manufacturer

2 notes

·

View notes

Text

amnesia: the bunker release obviously turning my thoughts to cherished fun guy of a baker's dozen years, amnesiac daniel of mayfair. cherished game of as many years; meanwhile he Has the ranges: tormentor/tormented, good/evil, noble/petty, scaredscaredscared/bold as brass tacks. not to mention ofc his Some Guy ft. a very dramatic nature, a lot of introspection, but not much to show for it. i do love him & he's a great choice for [i want to do fun sketches] which i also did with call on me on loop which happened to be a song i associated permanently w/him, as well as the reason my art tag is corned beef

#clapping cheering etc He Horney#amnesia#atdd#corned beef#daniel of mayfair#just watching someone's playthrough of a:tb so i dunno All the lore yet. hope there'll be more revelations abt things like Dan's Enthusiasm#further context abt the game if you weren't familiar already which: check it out!!! watch a playthrough. or play it yourself#i actually played through a third? half? the game. got stuck on a puzzle in one run then trapped in the water section later lmao....#it's a game from an indie developer & made a big splash & had Lasting Reverberations: survival horror game shift impact; namely#you have No Weapons in amnesia (though you Can kill the kaernk w/a precisely aimed barrel (or box?) or two (this isn't at all obvious))#and Daniel Gets Scared is a big component of the game. an Enemy shows up & blurred tunnel vision + the [DANGER] audio goes off#v fond memory: once yrs ago i was moving a small grandfather clock & hit smack w/like. What *Sounds* Threatening Here....#then realized the reverberation of the chimes was akin to the kind of low ringing of [daniel's Low Sanitymeter] effects#which! the game Tells You to watch your levels therein b/c enemies will find you more easily when your sanity(tm)'s low or nil#turns out this is completely untrue though lol. the player may be impeded b/c daniel's vision is crap & his mobility will cut out as well#but just as it says; enemies Aren't drawn to you any more than they ever are; they just tell you that Knowing the player will feel it lol#and it works perfectly...as well as ofc daniel having like nightmare visions / ambiguous hallucinations if he's feeling too bad lol#gotta solve a puzz son .or turn on the lights; daniel also being afraid of the dark. even though it's like yeah man in general i'd be scare#meanwhile i always forget frictional had already made penumbra games & the penumbheads would be like...scoff. amnesia easy mode#b/c penumbra doesn't give you any light? you do have a flashlight i believe. at least sometimes. but that's more ltd than a lantern#couldn't be danny w/his tinderboxes; candles; torches; etc. laudanum. blowing shit up. daniel is sososo fun to me#and it all comes back around w/pentiment like ''mithraeum....i heard of em'' fr fr lol alchemy....weird science ooo#the universe HATES him: unless it doesn't (daniel & the shadow) local locals HATE him: baron discovers one weird interdimensional trick#for real for real check out some playthrough of amnesia: the dark descent if you haven't ever seen / heard of it. or play it#we'll have a movie night of it....#corned beeeeeeeeeeeef........i'm the same boy i used to be

10 notes

·

View notes

Text

Brass Parts Manufacturer and Exporter in Jamnagar India

GK Metals is a top brass parts manufacturer, supplier and exporter in Jamnagar, India. We offer precision-engineered brass components like brass pipe fittings, brass compression fittings, brass fasteners, brass inserts, electrical brass parts, cnc brass parts and more for diverse industrial applications.

#brass parts manufacturer in jamnagar#precision brass components manufacturers#brass components manufacturers in jamnagar#brass parts exporters in jamnagar#brass turned parts jamnagar#precision brass turned components#brass turned components#brass precision turned components#precision brass components#brass components jamnagar#brass components exporters#brass parts suppliers

0 notes

Text

#precision-cnc-turning#precision-turned-parts#brass-precision-turned-components#custom-precision-machining#precision-turned-components-manufacturers

0 notes

Text

Look out for the advantages of precision-turned components or industrial components produced by CNC turning machines are among the most popular products for manufacturing highly efficient goods. They give the manufacturing unit an advantage in creating products with highly complex designs but with much ease. Unlike other elements, precision turned components have a higher rate of reliability and minute scrap materials.

0 notes

Text

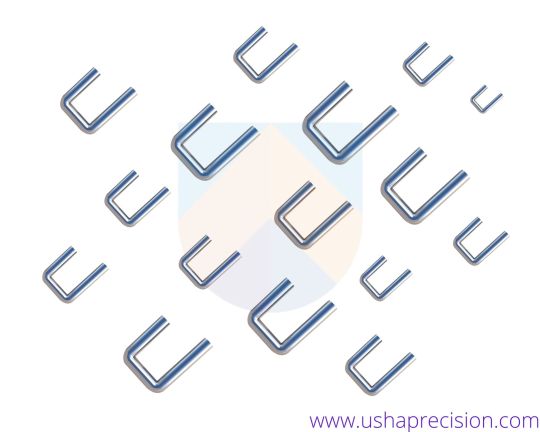

Usha Precision

We possess well-equipped production units with skilled employees, which are backed by latest technology and sophisticated machinery.

#U-Pins#Semi Tubular Rivets#precision turned components#stainless steel suppliers#metal manufacturing#stainless steel fabricators near me#stainless steel manufacturers#stainless steel fabricators

0 notes

Text

Best Manufacturer of Precision Turned Components

Scharf Precision Engineering is a well-known manufacturer of precision turned components in Ahmedabad. We manufacture and supply world-class quality precision turned components for various industries. We deliver quality and precision CNC machined parts and turned components for your engineering needs.

1 note

·

View note

Text

A Buyer's Guide to Choosing Custom CNC Machined Parts Manufacturers

In today's market, the demand for custom CNC machined parts is soaring across industries, including aluminum CNC turning parts. Selecting the perfect CNC machined components manufacturer is essential for quality and value. This article offers a concise guide to help you make an informed choice for your project.

Material Selection: Custom machined parts can be crafted from a variety of materials, including aluminum for CNC turning parts. Choose the right material based on your project's needs, properties, and cost, consulting your CNC machining parts factory for the best fit.

Assess Supplier Capabilities: Not all CNC machined components manufacturers are equal. Evaluate their expertise, experience, and equipment for the required machining processes and complexity, especially for aluminum CNC turning parts. Check their track record and references for reliability and quality.

Quality Control and Assurance: Ensure your chosen CNC machined components manufacturer follows stringent quality control processes, such as ISO 9001 certification, to guarantee precision and quality in your aluminum CNC turning parts.

Lead Time Management: Custom parts often have longer lead times. Understand your CNC machining parts factory's lead times to meet your project deadlines with effective communication & planning.

Pricing and Value: Compare quotes from multiple CNC machined components manufacturers, considering material and machining costs, along with additional services for aluminum CNC turning parts. Prioritize overall value and reliability over the cheapest option.

Effective Communication: Opt for a CNC machining parts manufacturer with strong communication skills. Clear and timely communication is vital for addressing questions or issues during production.

Post-Processing Services: Check if the manufacturer offers post-processing services such as deburring, polishing, anodizing, or painting, especially for aluminum CNC turning parts. Consolidating these services with one vendor can save time and effort.

Packaging and Shipping: Ensure the CNC machining parts factory can package and ship your parts securely to prevent transit damage, including your aluminum CNC turning parts. Confirm they can meet your specific shipping requirements.

Intellectual Property Protection: If your custom CNC machined parts involve proprietary designs or technology, ensure the manufacturer has policies to protect your intellectual property.

The right CNC machined parts manufacturer, including aluminum CNC turning parts, is crucial for your project's success. Considering these factors, you can make an informed decision and establish a productive partnership with a CNC machining parts factory that meets your quality, service, and value requirements.

#custom cnc turning parts#cnc parts manufacturer#cnc turned parts manufacturer#cnc machining parts manufacturer#small batch cnc machining#low volume cnc machining#machining components#machined plastic parts#aluminum parts machining#custom aluminum parts#prototype cnc machining#cnc precision parts

0 notes

Text

Comprehensive Guide to Precision Turned Brass Components

Precision-turned components are put through a battery of tests to ensure they meet quality standards. The brass precision-turned components come in various sizes, styles, and models that may be tailored to meet the customer's needs. It has several advantages in the modern industry. Below are the things you need to know about precision-turned brass components:

Types of brass turning:

Turning brass involves using a lathe to spin the metal to form a portion. It can be used to make flat, rounded, or both pieces. The most popular method of turning brass is to reduce a piece of material's outside diameter until it achieves the required size. This can also be applied to holes drilled into an object's center, creating an exterior and an interior feature on the surface. But there are other kinds of brass turning that can be done as well. One can simultaneously turn the ID and OD. Then, you can have a solid portion that tapers at one end expanding the array of possibilities for precision-turned components.

The brass turning process:

If one has the proper tools, turning brass is an extremely easy procedure that anyone can perform. Brass is quite soft, cutting it with a lathe doesn't need much force. The primary objective while turning brass is to avoid overheating it, as this may result in metal distortion.

The first stage in turning brass is heating brass with a torch or blow torch until the whole item is red hot. This will enable them to remove any remaining impurities from the metal without causing surface damage. They will heat the material and then use a tap wrench to smooth off any burrs or other defects from the outside of their product. Lastly, they will use steel wool or sandpaper to polish the completed product until it is glossy and smooth.

What tools are used for brass turning?

Most of the tools used for turning other metals are also used for turning brass. Brass differs because tools created can be used on different materials since it melts at a lower temperature than most other metals. A burr is the most basic tool used in brass turning. This conical-shaped abrasive wheel can remove material from the brass being turned.

Another popular tool for turning brass is known as a lap. This tool resembles a burr, but instead of cutting into the metal surface like a burr, it has two sides: one for polishing or finishing the metal by eliminating any markings left by previous cutting operations.

Other tools are also used in brass turning; these include chucks, which securely hold workpieces and sanding drums which smooth surfaces, and collets, which have cutting tools. Drills and reamers are also employed in this process. The precision-turned components should be brought from reputable manufacturers.

Arek Solutions is a business committed to offering clients worldwide top-notch product supply solutions. With more than 70 years of combined industry experience, they are known for providing top-notch products and services. They are the best option for buying products for your industrial needs.

0 notes

Text

Fasteners Manufacturer | Roll Fast

Roll-Fast is a Fasteners Manufacturer bolts and nuts in High tensile grade and high tensile fasteners, stainless steel, carbon steel and alloy steel since 1989. We manufacture bigger diameter bolts and nuts from M-20 till M-120 and in inches and Unc from 3/4" to 4". We have 25 years of World Class Manufacturing experience in nuts and bolts we manufactures and exports ss fasteners manufacturers, automotive fastener, Industrial Fasteners and Fasteners for Oil & Gas from our plant in India.

#Fasteners Manufacturer#Industrial Fasteners#automotive fastener#Fasteners for Oil & Gas#Precision Turned components manufacturer

0 notes