#stainless steel manufacturers

Text

#stainless steel shafts#stainless steel manufacturers#stainless steel dowel pins#stainless steel dowels#small turned parts#Stainless Steel Axis#Stainless Steel Pin#Precision Pins#Grooved Pin#Knurled pins#ss shaft#ss pins

0 notes

Text

Why Work with Certified Stainless-Steel Suppliers for Your Pipe Needs

South Africa, Oct’23: NSSC, National Stainless Steel Centre, is a leading provider of comprehensive stainless steel services. A one-stop for all stainless steel solutions, NSSC offers a broad range of services, including manufacturing, supply, and transportation of stainless steel products. NSSC specialises in delivering tailored stainless steel solutions by actively engaging with clients to understand their unique needs and crafting solutions that precisely align with their specific requirements. NSSC is known for its commitment to providing high-quality stainless steel products and exceptional service.

Reasons to consider working with NSSC for your stainless steel pipe requirements:

Proven Expertise: NSSC is an established and reputable name in the stainless steel industry. They have a wealth of experience and expertise in producing and distributing stainless steel products.

Premium Quality Stainless Steel: NSSC is committed to delivering stainless steel pipes that meet or exceed industry standards. Their products are renowned for their quality, offering excellent corrosion resistance, durability, and reliability. Using NSSC's stainless steel ensures your projects are built to last.

Cutting-Edge Technology: NSSC invests in advanced technology and ongoing research and development. This commitment to technological advancements ensures that you benefit from state-of-the-art stainless steel pipes tailored to the latest industry requirements and innovations.

Global Reach: NSSC's global presence allows them to serve customers worldwide. This is invaluable for businesses with international operations, as it guarantees a consistent supply of high-quality stainless steel pipes, no matter where your projects are located.

Environmental Responsibility: NSSC is committed to sustainability and environmental responsibility. They strive to produce stainless steel products with minimal environmental impact, making them a responsible choice for companies seeking to reduce their carbon footprint.

Technical Support: NSSC offers technical support and consultation to help you select the right stainless steel grade and specifications for your specific application. Their team of experts can assist you in making informed decisions and optimising project performance.

About the company:

National Stainless Steel Centre is a stainless-steel manufacturer and service supplier in South Africa with 30+ years of experience in the industry. They offer their clients laser cutting, high-definition Plasma cutting, Water jet cutting, CNC bending, and many more services, following all the international procedures and standards.

0 notes

Text

Stainless Steel Floor Drain

Fenicrom specializes in the production of high-quality stainless steel floor drains for industrial and commercial applications. Their stainless steel floor drains are designed to provide efficient and reliable drainage solutions for a wide range of environments, including food processing plants, hospitals, and commercial kitchens.

#Stainless Steel Floor Drain#Stainless Steel Trench Drain#Stainless Steel Manufacturers#floor drains#heavy duty trench drain#shower drains

0 notes

Text

Blog Manufacturer & Supplier of Flanges, Pipe Fittings, Fasteners SPP Alloys and Metals

We are passionate about serving Premium Quality material to our customers along with being their Reliable Partners. Here, we'll be sharing the latest news and insights on alloys and the manufacturing process. As a leading manufacturer of high-quality alloys, we understand the importance of staying up-to-date with the latest developments in our industry. We're committed to sharing our knowledge and expertise with our customers, partners, and anyone else who shares our passion for alloys. If you're interested in learning more about our alloys, please visit our website or contact us directly.

#Steel Pipe Manufacturing Company#Metal Sheet Manufacturer#Buttweld Fittings Manufacturer#Flange manufacturing company in India#Buttweld Pipe Fitting#Fittings Supplier In Mumbai#Stainless Steel Manufacturers

0 notes

Text

Stainless Steel Welded Tube Manufacturers in China

Stainless Steel contains chromium which provides properties of corrosion resistance at high temperatures. The production of stainless steel welded tube is very different. The manufacturing companies had to go through a lot of procedures to produce stainless steel welded tubes. It is produced through roll-forming strips or sheets of stainless steel into a tube shape. If you are looking for the top stainless steel welded tube manufacturers in China. Then, you can call us at (+86 577 8660 2050) to order stainless steel welded pipes. We are one of the top-notch manufacturers of stainless steel welded tubes in China. Get in touch with us now to know more.

Features of Stainless Steel Welded Tubes

Here are some of the lesser-known features of stainless steel welded tubes.

Timeliness Improvements: This is one of the most amazing features of stainless steel welded tubes. It requires timeliness improvements.

Cheaper: This is one of the biggest advantages of using stainless steel welded tubes. That it requires a low cost to purchase & maintain these tubes.

Applications with Thinner Walls and Larger Diameters: Stainless steel contains thinner walls & larger diameters. This can be beneficial for most people.

Available in Longer Length: If you need stainless steel welded tubes & you want it in a longer length. Then, you can get it. Because it is also available in longer lengths.

Who are the Biggest Manufacturers of Stainless Steel Welded Tubes in China?

There are many manufacturers of stainless steel welded tubes in China. But, if you are looking for only the best one. Then, you should consider ordering stainless steel welded tubes from Sailing Steel. We produce top-quality stainless steel welded tubes.

Reference By: https://bit.ly/3usU3Ag

#stainless steels#stainless steel manufacturers#stainless steel pipes#seamless stainless steel pipe supplier china

0 notes

Text

Casting Everyday 😎

28 notes

·

View notes

Text

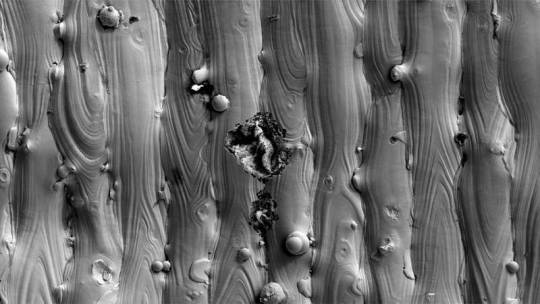

Researchers uncover culprits behind pitting corrosion in 3D-printed stainless steel

Like a hidden enemy, pitting corrosion attacks metal surfaces, making it difficult to detect and control. This type of corrosion, primarily caused by prolonged contact with seawater in nature, is especially problematic for naval vessels.

In a recent paper published in Nature Communications, Lawrence Livermore National Laboratory (LLNL) scientists delved into the mysterious world of pitting corrosion in additively manufactured (3D-printed) stainless steel 316L in seawater.

Stainless steel 316L is a popular choice for marine applications due to its excellent combination of mechanical strength and corrosion resistance. This holds even more true after 3D printing, but even this resilient material isn't immune to the scourge of pitting corrosion.

Read more.

#Materials Science#Science#Corrosion#3D printing#Additive manufacturing#Stainless steel#Steel#Materials Characterization

10 notes

·

View notes

Text

Metalman Auto files draft papers with SEBI to raise funds via IPO

The IPO consists of a fresh issue of Rs 350 crore and an offer for sale of upto 12.64 million shares by its existing shareholders and promoters.

Metalman Auto Ltd has submitted a Draft Red Herring Prospectus (DRHP) to the Securities and Exchange Board of India (SEBI) to raise capital through an Initial Public Offering (IPO). The IPO includes a fresh issuance of shares worth Rs 350 crore and an offer for sale of up to 12.64 million shares by the company’s current shareholders and promoters.

The proceeds from the fresh issue will be allocated as follows: Rs 25 crore will be used to partially finance the capital expenditure for the procurement of plant and machinery at the Pithampur manufacturing unit 2. The company also plans to utilize Rs 240 crore to repay a portion of its existing debt. As of June 2024, Metalman Auto Ltd has a total debt of Rs 314.43 crore.

The firm operates nine manufacturing units across five states in India, strategically located near OEM customers to ensure efficient production and supply. Axis Capital, ICICI Securities, and Motilal Oswal Investment Advisors are the lead managers for this issue.

Metalman Auto Ltd is a leader in the metal fabrication, finishing, and assembly sector in India, specializing in the production of metal components for two-wheelers (including both electric and internal combustion engines), three-wheelers, passenger vehicles, commercial vehicles, agri-vehicles, and off-highway vehicles. Additionally, the company manufactures aesthetic components for white goods, such as panels for washing machines, and offers contract manufacturing services for two-wheeler electric vehicle (2W EV) OEMs.

#metalman auto#oem manufacturing#oemparts#electric vehicles#metal fabrication#fabricationservices#steel fabrication#supplier#manufacturer#stainless steel#transport technology#transport service#transport for london#vehicle transport#transportation#ipo news#ipo alert#markets#stocks#business standard#business magazines#High-Volume Automotive Parts Manufacturing#manufacturing#automotive parts#parts Manufacturin#automotive industry#automotive#car accessories

2 notes

·

View notes

Text

Stainless Steel 304 Pipes & Tubes | Manilaxmi Industrial

Manilaxmi Industrial is a well-known name in the industry for Manufacturers, Suppliers, and Exporters superior quality Stainless Steel 304 Pipes & Tubes.

#industrial#manilaxmi#manufacturer#exporters#suppliers#technology#innovation#stainless steel#pipeaccessories

2 notes

·

View notes

Text

The Power of Precision: Ensuring Leak-Free Connections with Instrumentation Tube Fittings

Instrumentation Tube Fittings

The lifeblood of any process plant lies in its network of instrumentation. These instruments measure and monitor critical parameters like pressure, temperature, and flow, ensuring smooth operation, product quality, and safety. However, leaks within these systems can have significant consequences. This blog delves into the importance of leak prevention in instrumentation systems and how the power of precision with instrumentation tube fittings guarantees reliable performance.

The Devastating Impact of Leaks:

Leaks in instrumentation systems can lead to a cascading effect of problems:

Inaccurate Measurements: Leaks can compromise the integrity of the system, leading to inaccurate readings from instrumentation. This can disrupt process control and potentially affect product quality or safety.

Increased Maintenance Costs: Leaks necessitate frequent maintenance to identify and repair the source. This translates to additional downtime and labor costs.

Environmental Concerns: Leaking fluids can pose environmental hazards, releasing pollutants or hazardous materials into the surrounding environment.

Safety Risks: In extreme cases, leaks can lead to fires, explosions, or exposure to toxic chemicals, jeopardizing personnel safety.

The Role of Instrumentation Tube Fittings:

Instrumentation tube fittings are the unsung heroes of leak prevention. These precision-engineered components connect tubes to various instruments and pressure gauges. Their meticulously designed grip and sealing mechanisms ensure a leak-proof connection, safeguarding the integrity of the entire system. Here's how proper selection and use of tube fittings contribute to leak-free performance:

Material Compatibility: Choosing fittings made from materials compatible with the process fluid prevents corrosion and degradation, ensuring a long-lasting, leak-tight seal.

Pressure Ratings: Selecting fittings with pressure ratings exceeding the maximum operating pressure in the system provides a safety buffer and minimizes the risk of leaks due to pressure surges.

Proper Installation: Following manufacturer's guidelines for installation ensures a secure fit and prevents leaks caused by improper assembly. This includes using the correct tools, tightening torques, and following recommended cleaning procedures.

Visual Inspection: Regularly inspecting tube fittings for signs of damage, wear, or loose connections allows for preventative maintenance and the timely replacement of faulty fittings before leaks occur.

Investing in Precision and Reliability:

High-quality instrumentation tube fittings may seem like a small detail, but their role in ensuring leak-free connections is paramount. By investing in precision-engineered fittings from reputable manufacturers like Freture Techno, you gain:

Peace of Mind: Knowing your instrumentation system is leak-free translates to reliable data, reduced maintenance costs, and a safer operating environment.

Enhanced Process Control: Accurate and reliable measurements from leak-free systems contribute to improved process control and consistent product quality.

Long-Term Value: Durable and high-quality tube fittings minimize replacement needs and ensure long-term operational efficiency.

Conclusion:

Effective leak prevention is a cornerstone of reliable and safe instrumentation systems. By recognizing the power of precision offered by high-quality instrumentation tube fittings, you can ensure accurate measurements, a safer work environment, and a more efficient operation. Choose the right tools, prioritize proper installation, and invest in reliable partners like Freture Techno to guarantee leak-free connections and empower your instrumentation systems to deliver their full potential.

#instrumentation#tube fittings#stainless steel tube fittings#manufacturers#mumbai#india#freture techno

2 notes

·

View notes

Text

China Alloy Steel, Alloy Steel, wholesale Alloy Steel, Alloy Steel manufacturers stainless steel manufacturers, stainless steel suppliers, stainless steel factory, China stainless steel price, Chinese suppliers https://superbmaterials.com/

#630 stainless steel#631 stainless steel#stainless steel forging#stainless steel alloys#alloy steel china#carbon steel china#nickel alloys china#stainless steel china#copper producers china#heat resistant alloys#china#united states#Shanghai#Pudong#suppliers#stainless#Alloy Steel#Alloy#Steel#Chinese#factory#manufacturers#kitchen

2 notes

·

View notes

Text

Usha Precision

We possess well-equipped production units with skilled employees, which are backed by latest technology and sophisticated machinery.

#U-Pins#Semi Tubular Rivets#precision turned components#stainless steel suppliers#metal manufacturing#stainless steel fabricators near me#stainless steel manufacturers#stainless steel fabricators

0 notes

Text

Stainless Steel To The Next Level: How Laser Cutting Technology Is Improving The Quality And Efficiency Of Stainless Steel Production

South Africa, June’23: NSSC (National Stainless Steel Centre) is pleased to announce a groundbreaking advancement in stainless steel production that promises to revolutionise the industry. Through the utilisation of state-of-the-art laser cutting technology, NSSC has achieved significant improvements in both the quality and efficiency of stainless steel manufacturing processes.

Laser cutting technology has long been recognised for its precision and speed, and NSSC has harnessed its potential to enhance stainless steel production. By employing advanced laser cutting systems in their manufacturing facilities, NSSC has successfully overcome many of the limitations faced by traditional cutting methods.

The key benefits of laser cutting in stainless steel production are manifold. First and foremost, laser-cutting technology ensures a level of precision that was previously unattainable. The high-energy laser beam produces a fine, focused heat source that enables exceptionally accurate cuts, resulting in cleaner edges and improved dimensional accuracy. This precision not only enhances the overall aesthetics of the stainless steel products but also contributes to better compatibility and fit during assembly.

Furthermore, laser-cutting technology significantly reduces material wastage. The focused laser beam allows for the creation of intricate and complex designs, maximising material utilisation and minimising scrap. NSSC's commitment to sustainability is exemplified by this reduction in waste, leading to a more environmentally friendly approach to stainless steel manufacturing.

Another remarkable advantage of laser cutting is its ability to expedite production processes. The high-speed laser beam allows for swift and efficient cutting, resulting in increased productivity and shorter lead times. This advancement enables NSSC to meet the growing demands of its customers while maintaining the highest standards of quality.

NSSC remains dedicated to continuous improvement and investing in cutting-edge technology. By adopting laser cutting technology, NSSC aims to enhance the stainless steel manufacturing sector and bring about a new era of efficiency and quality. The company's innovation-driven approach ensures that customers will continue to receive exceptional stainless steel products, meeting the diverse needs of various industries. Visit https://www.nssc.co.za/.

About the company:

National Stainless Steel Centre is a well-known stainless-steel manufacturer and service supplier in South Africa with 30+ years of experience in this industry. They offer laser cutting, High-definition Plasma cutting, Water jet cutting, CNC bending, and many more services to their clients, following all the international procedures and standards.

1 note

·

View note

Text

Fenicrom is a distinguished stainless steel manufacturer, renowned for delivering exceptional quality stainless steel drainage products that cater to the diverse requirements of our esteemed clients.

#Stainless Steel Manufacturers#floor drains#Heavy Duty Trench Drain#Stainless Steel Trench Drain#Stainless Steel Floor Drain Cover

0 notes

Text

Leading Manufacturer and Exporter of Ferrous & Non-Ferrous Bars in Diverse Materials and Grades.

Piyush Steel, we pride ourselves on being a leading Manufacturer and Exporter of Ferrous and Non-Ferrous bars, renowned for our commitment to quality and precision. Our extensive product range includes round bars, square bars, hex bars, bright bars, flat bars, rectangular bars, black bars, rods, hot rolled bars, and cold-rolled bars.

Contact Us

2 notes

·

View notes

Text

TP316L-7.96mm*4.6mm Stainless steel electropolished tube for making chromatographic column,inner diameter testing with plug gauges

#stainless steel tube#electropolished tube#plug gauges testing#4.6mm tube#Chinese manufacturer#Chinese producer#inner diameter testing#chromatographic column

2 notes

·

View notes