#pressure vessel manufacturer in india

Text

https://www.galaxyprocess.in/high-speed-disperser.html

#high speed dispenser#industrial equipment#process equipment manufacturers in pune#pressure vessel manufacturer in india

1 note

·

View note

Text

High-Efficient Pressure Vessel Suppliers in India

Pressure vessels are indispensable in various industries, including chemical processing, oil and gas, power generation, and more. Our vessels are designed to hold gases or liquids at high pressures, making them critical for maintaining safety and efficiency in industrial operations. Selecting a reliable pressure vessel supplier is crucial to ensure our essential components' quality, durability, and safety. One name that stands out in this field is Chanderpur Group, known for its expertise, innovation, and commitment to excellence.

The Importance of Quality Pressure Vessels

Pressure vessels must adhere to stringent safety standards and regulations due to the high-risk nature of Our operation. A subpar pressure vessel can lead to catastrophic failures, endangering lives and causing significant financial losses. Therefore, choosing a supplier that guarantees top-notch quality and reliability is imperative. We are offering pressure vessels that meet the highest industry standards.

Why Choose Us?

Decades of Expertise

We bring decades of experience to the table, making them a trusted name in the industry. Our extensive knowledge and expertise enable them to design and manufacture pressure vessels that cater to the unique needs of various industries.

Innovative Solutions

Innovation is at the core of operations. we continuously invest in research and development to stay ahead of technological advancements. This commitment to innovation ensures that Our pressure vessels are built using the latest technologies and materials, providing superior performance and longevity.

Customization and Flexibility

Every industry has specific requirements when it comes to pressure vessels. We are providing customized solutions that align with the exact needs of our clients. Whether it's a small-scale operation or a large industrial plant, we can deliver tailored pressure vessels that enhance operational efficiency.

Stringent Quality Control

Quality assurance is a hallmark of us. We implement rigorous quality control measures at every stage of the manufacturing process, from raw material selection to final product testing. This ensures that every pressure vessel leaving Our facility is of the highest quality and reliability.

Comprehensive Support

We offer comprehensive support to Our clients, from initial consultation and design to installation and maintenance. Our team of experts is always ready to assist, ensuring that your pressure vessels operate smoothly and efficiently.

Applications of Pressure Vessels

Pressure vessels are used in a wide range of applications across various industries:

Chemical Processing: Safe and efficient storage and transfer of reactive and hazardous chemicals.

Oil and Gas: High-pressure storage and transportation of hydrocarbons.

Power Generation: Reliable operation of boilers, heat exchangers, and other critical components.

Food and Beverage: Maintaining the purity and safety of food-grade gases and liquids.

Conclusion

When it comes to pressure vessel suppliers, we stand out for our unmatched expertise, innovative solutions, and unwavering commitment to quality. Our ability to provide customized, high-performance pressure vessels makes them the preferred choice for industries looking to enhance Our operational efficiency and safety. Trust us to deliver the reliability and excellence you need for your pressure vessel requirements.

#Pressure Vessels Manufacturer in India#Pressure Vessels Supplier in India#Pressure Vessels Manufacturer#Pressure Vessels Supplier#Pressure Vessels

0 notes

Text

High Pressure Vessel Manufacturer in India - Stalwart International

Stalwart International is leading Industrial High Pressure Vessel Manufacturer in India. Explore our top quality and safety standards for high pressure vessels for industrial applications.

0 notes

Text

Vertical Non Lubricated Compressor

Compressors Are a Necessary Piece of Equipment in The Pet Bottle Manufacturing Process

Polyethylene terephthalate (PET) is now the most popular material choice, surpassing both glass and aluminium in terms of popularity. PET makes up thirty percent of soft drink bottles worldwide.

The many different types of Pet Bottling Compressors used in this industry—which uses everything from off-the-shelf equipment to highly specialize ones—share a few common characteristics. This is made possible by the manufacturing of the numerous plastic bottles we see in our grocery stores. In order to achieve this, this article explores the definition of compressors, their functions in the PET bottle manufacturing sector, and the sources of high-quality compressor valve parts.

Regarding the compressor's function, the PET bottle production sector still employs every technique that has been devised to create plastic bottles. Generally speaking, the component of the operation that requires the most attention is the compressor. This holds true regardless of the process a plastic bottle manufacturer uses. This is because pressurized air is injected during the shaping process, which is a necessary part of all operations.

Power for the PET bottle manufacturing industry has always come from reciprocating compressors. Pistons are the technique by which these compressors generate internal pressure. Similar compressors were frequently needed to reach 650 psi plant air pressure, which was necessary for manufacturing the more sophisticated product. Even while modern businesses prefer lower pressure systems to save energy costs and improve process efficiency, many still choose higher pressure systems.

Centrifugal Vertical Non Lubricated Compressor have so found usage in the manufacturing industry. Compared to reciprocating compressors of the same size, centrifugal compressors can generate more airflow and are more energy-efficient, but they are less powerful.

An essential factor to take into account when using the compressor valve

In the PET bottle manufacturing sector, compressor valves are run under high pressure for extended periods of time. For the system to function as intended, the pieces must have an exceptionally high durability rating. The valve regulates the airflow in the PET bottle production system. It does this by carefully regulating the system's operational pressure and supplying air to the injector at the precise moment when it is required.

The pet bottle production sector is constantly searching for superior compressor parts. What are some of these parts specifically?

A designed component must satisfy every requirement in order to be deemed high-quality. Since they serve as the basis for the structural integrity of the structure, starting with high-quality source materials is essential. The final goal of the component, along with the usage circumstances it will encounter, must be taken into account at every stage of development, which means that material selection plays an equally significant role.

The following stage is to make sure the component is well-engineered, which requires employing methods and equipment that are specially designed for the particular parts being manufactured. Last but not least, a batch sampling technique is needed for sporadic quality inspections on the production line. By employing this technique, the components' superior quality will be verified.

Conclusion

Ideally, all these procedures should be managed by qualified manufacturers like Colt Equipment’s (p) Ltd with in-depth understanding of the sector. This is a wonderful use for their expertise and experience in producing high-quality products. Although these parts aren't the cheapest solutions accessible right now, the functionality they add eclipses any current savings your company could realize.

#Best Air Compressor Pipe#Aftercooler For Air Compressor#Fabrication facility in delhi#Compressor spare parts in delhi#pressure vessels manufacturers in india

0 notes

Text

BEST PRESSURE VESSELS MANUFACTURERS, SUPPLIERS IN PUNE INDIAA pressure vessel is a storage vessel or tank designed to hold fluids (gases/ liquids/ both) at high pressures. These include industrial compressed air receivers, flash

#BEST PRESSURE VESSELS MANUFACTURERS#SUPPLIERS IN PUNE INDIA#A pressure vessel is a storage vessel or tank designed to hold fluids (gases/ liquids/ both) at high pressures. These include industrial co#flash#heat exchanger

0 notes

Text

#heat exchangers#heat exchangers Manufacturer#heat exchangers suppliers#heat exchangers in Pune#heat exchangers in Maharashtra#heat exchangers in India#agitators#agitators in Pune#agitators in Maharashtra#agitators in India#pressure vessels#pressure vessels in Pune#pressure vessels in Maharashtra

0 notes

Text

Jay Steel Corporation Provide The Best Pressure Vessels in India

Jay Steel Corporation is the leading company that specializes in manufacturing pressure vessels in India. Pressure vessels are containers designed to hold gases or liquids at a pressure substantially different from the ambient pressure. They play a crucial role in various industries, including chemical processing, petrochemical, pharmaceuticals, food processing, and more. We are manufacturing all type of Pressure Vessels like titanium, Nickel, Stainless Steel & Duplex Steel in India & World Wild.

#nickel alloy products#PRESSURE VESSEL MANUFACTURER#REACTOR VESSELS SUPPLIERS#INDUSTRIAL REACTORS SUPPLIER IN INDIA

0 notes

Text

High Quality ASME U & R Stamp vessel manufacturer & suppliers, We design high quality, large capacity pressure vessels for various industrial uses.

#asme pressure vessels manufacturer in India#asme pressure vessel fabrication#asme pressure vessel suppliers#asme pressure vessel#asme pressure vessel suppliers in india

0 notes

Text

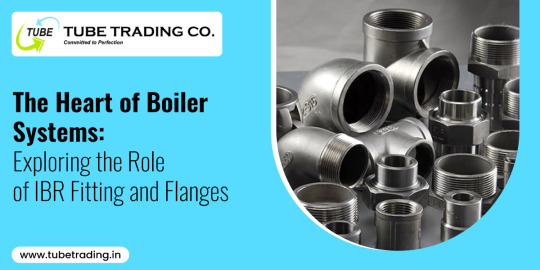

The Heart of Boiler Systems: Exploring the Role of IBR Fitting and Flanges

Boiler systems serve as the backbone of numerous industrial processes, powering everything from heating and hot water supply to steam generation in various manufacturing operations. Within these systems, ensuring safety, efficiency, and reliability is paramount, and this is where IBR (Indian Boiler Regulations) fitting and flanges play a pivotal role. As a trusted distributor in Vadodara and a leading dealer in Gujarat, Tubetrading is dedicated to providing top-quality IBR fitting and flanges to industries across the region. In this blog post, we'll delve into the significance of IBR fitting and flanges in boiler systems, explore their crucial functions, and highlight the expertise of Tubetrading in supplying these essential components.

Understanding IBR Fitting and Flanges

IBR fitting and flanges are integral components of boiler systems that ensure seamless operation and compliance with safety standards mandated by the Indian Boiler Regulations. These regulations are designed to safeguard the integrity of boiler components, prevent accidents, and promote efficient energy utilization. IBR fitting and flanges are manufactured according to stringent specifications outlined by the IBR to guarantee durability, reliability, and performance in demanding industrial environments.

The Role of IBR Fitting and Flanges in Boiler Systems

1. Pressure Regulation: IBR fitting and flanges are designed to withstand high-pressure environments commonly found in boiler systems. They play a crucial role in regulating and controlling the flow of fluids, gases, and steam within the system, ensuring optimal pressure levels for efficient operation.

2. Sealing and Joint Integrity: Proper sealing and joint integrity are essential to prevent leaks and maintain the integrity of boiler systems. IBR fitting and flanges are equipped with robust sealing mechanisms, such as gaskets and O-rings, to create a tight seal between interconnected components, minimizing the risk of leaks and ensuring system integrity.

3. Connection and Interoperability: IBR fitting and flanges serve as connection points between various components of boiler systems, including pipes, valves, and vessels. Their standardized dimensions and configurations enable seamless interoperability, facilitating efficient assembly, maintenance, and repair of boiler systems.

4. Compliance and Certification: Compliance with IBR regulations is mandatory for all boiler components used in India. IBR fitting and flanges undergo rigorous testing and certification processes to ensure compliance with safety standards and regulatory requirements, providing peace of mind to industries reliant on boiler systems.

Tubetrading: Your Trusted Supplier of IBR Fitting and Flanges in Gujarat

As a reputable distributor and dealer of IBR fitting and flanges in Vadodara and Gujarat, Tubetrading prides itself on delivering superior-quality products and exceptional service to its customers. Here's why industries trust Tubetrading for their IBR fitting and flanges needs:

1. Extensive Product Range: Tubetrading offers an extensive range of IBR fitting and flanges, including elbows, tees, reducers, bends, and flanges in various sizes, materials, and specifications. Whether you need standard or customized components, we have the expertise and resources to meet your requirements.

2. Quality Assurance: At Tubetrading, quality is our top priority. We partner with reputable manufacturers who adhere to strict quality control measures and comply with IBR regulations. Our products undergo thorough inspection and testing to ensure they meet the highest standards of performance, reliability, and safety.

3. Expert Guidance: With years of experience in the industry, the team at Tubetrading possesses in-depth knowledge of IBR fitting and flanges and their applications in boiler systems. We provide expert guidance and technical support to help our customers select the right components for their specific needs, ensuring optimal performance and efficiency.

4. Timely Delivery: We understand the importance of timely delivery to our customers' operations. With our efficient logistics network and inventory management systems, we strive to fulfill orders promptly and ensure on-time delivery of IBR fitting and flanges to our customers across Gujarat.

Conclusion

In conclusion, IBR fitting and flanges are the heart of boiler systems, playing a critical role in ensuring safety, efficiency, and compliance with regulatory standards. As a trusted distributor and dealer in Vadodara and Gujarat, Tubetrading is committed to supplying top-quality IBR fitting and flanges to industries across the region. With our extensive product range, quality assurance, expert guidance, and timely delivery, we are your reliable partner for all your IBR fitting and flanges needs. Contact Tubetrading today to learn more about our products and services and discover how we can support your boiler system requirements.

#IBR Fitting and Flanges distributor in Gujarat#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges#Gujarat#Maharashtra#Rajasthan#Madhya Pradesh#Daman#Uttar Pradesh

7 notes

·

View notes

Text

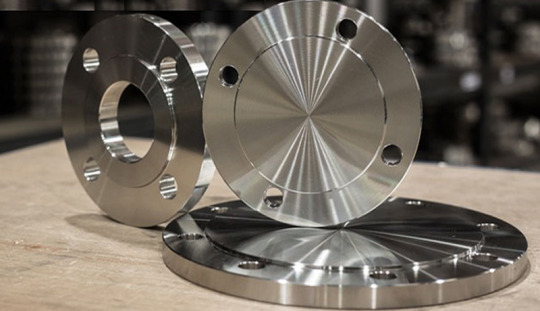

Mild Steel Flanges Details

Why MS Flanges Matter

MS flanges, short for Mild Steel flanges, are essential components in the industrial and construction sectors. These flanges, made from mild steel, are prized for their robust strength, cost-efficiency, and versatility. They serve as crucial connectors, fastening pipes, valves, and various machinery, ensuring that everything stays tightly sealed and leak-free.

The Appeal of Mild Steel

Mild steel is a top choice for many due to its durability, ease of use, and affordability. It offers a great balance between performance and cost, making it resistant to moderate corrosion while withstanding significant pressure. Whether you're working on an industrial project or a construction site, mild steel is a reliable material. For the best MS flanges in India, look no further than Udhhyog, a leading manufacturer in the field.

A Closer Look at Different MS Flanges

Slip-On Flanges: Easy and Effective

Slip-on flanges are known for their ease of installation—they slip over the pipe and are welded into place. This makes them perfect for applications where precise fitting is key. They’re commonly used in low-pressure environments and offer an economical solution for various projects.

Weld Neck Flanges: Built for Performance

Weld neck flanges feature a long, tapered neck that smoothly transitions from the pipe to the flange. This design reduces stress concentrations, making these flanges ideal for high-pressure and high-temperature applications. They are often used in critical systems where reliability and strength are crucial.

Blind Flanges: Sealing with Confidence

Blind flanges are designed to close off the end of a pipe or vessel, with no central hole. They are perfect for sealing off pipelines or openings, providing a strong barrier for maintenance or potential expansion in the future.

Socket Weld Flanges: Strong and Reliable

Socket weld flanges have a recessed area where the pipe fits before being welded. This design ensures a smooth bore and a secure connection, making them suitable for high-pressure applications. They’re commonly used in industries where a strong, leak-proof joint is essential.

Real-World Applications of MS Flanges

MS Flanges in Industrial Operations

In industrial environments, MS flanges are critical for connecting various machinery components, such as pumps and valves. They ensure that these parts are securely joined, helping to maintain efficient operations and prevent leaks.

Their Role in the Construction Industry

MS flanges are vital in construction projects, where they link structural steel components. They provide the necessary strength to handle heavy loads and ensure that different parts of a structure are firmly connected.

Crucial for Piping Systems and Equipment

MS flanges play a key role in piping systems, connecting pipes, valves, and other fittings. They help maintain the system's integrity, making it easier to perform maintenance and repairs when needed.

Why Choose MS Flanges?

Cost-Effective and High Value

MS flanges offer a cost-effective alternative to more expensive materials like stainless steel. Despite their lower cost, they do not compromise on quality, making them a popular choice for various applications.

Durability and Robustness

Mild steel flanges are known for their durability and strength. They are built to withstand various pressures and temperatures, making them suitable for a wide range of industrial and construction uses.

Simple Installation and Maintenance

MS flanges are designed for easy installation and maintenance. Their straightforward design makes them easy to assemble and disassemble, which can save both time and effort during installation and upkeep.

How to Select the Right MS Flange

Important Considerations

When selecting an MS flange, it’s essential to consider the type, pressure rating, and compatibility with other materials. Choosing the right flange ensures a secure connection and optimal performance for your specific application.

Sizing and Specification Essentials

Accurate sizing is crucial for a secure and efficient connection. Refer to industry standards and specifications to ensure you select the right size and type of flange for your project.

This version offers another fresh perspective, ensuring the content remains original and engaging while highlighting the key aspects of MS flanges.

2 notes

·

View notes

Text

#Reactor pressure vessel manufacturer in india#high speed dispenser#process equipment manufacturers in pune#industrial equipment

0 notes

Text

Stainless Steel 304 Flanges Stockists in India

Stainless steel 304, also known as 18/8 stainless steel, is an austenitic alloy containing 18% chromium and 8% nickel. This composition gives it excellent corrosion resistance, high strength, and good formability, making it one of the most commonly used stainless steel grades.

Stainless Steel 304 Flanges

Types of Stainless Steel 304 Flanges

Weld Neck Flanges: Designed to be welded to the pipe, providing a strong connection and reducing stress concentration.

Slip-On Flanges: Slipped over the pipe and then welded both inside and outside to provide strength and prevent leakage.

Blind Flanges: Used to close the end of a pipe or a pressure vessel opening, ensuring no flow of liquid or gas.

Socket Weld Flanges: Used for small-diameter, high-pressure pipes, where the pipe is inserted into the socket end and welded.

Threaded Flanges: Feature internal threads that match the external threads of the pipe, suitable for low-pressure applications.

Lap Joint Flanges: Used with a stub end, allowing for easy alignment and dismantling of the pipe.

Applications of Stainless Steel 304 Flanges

Petrochemical Industry: Used in pipelines, refineries, and processing plants due to their resistance to corrosive substances.

Food and Beverage Industry: Ideal for food processing and handling equipment because of their non-reactive and hygienic properties.

Pharmaceutical Industry: Used in manufacturing and processing equipment to maintain sterility and prevent contamination.

Oil and Gas Industry: Employed in drilling rigs, pipelines, and offshore platforms due to their strength and corrosion resistance.

Water Treatment: Used in desalination plants, water purification systems, and wastewater treatment facilities.

Construction: Utilized in building structures, bridges, and architectural elements for their aesthetic appeal and durability.

Manufacturing Process

The manufacturing of Stainless Steel 304 flanges involves several critical steps:

Raw Material Selection: High-quality stainless steel 304 alloy is selected based on the required chemical composition.

Forging: The raw material is heated and shaped using dies and hammers to form the flange.

Machining: The forged flanges are machined to achieve precise dimensions and a smooth surface finish.

Advantages of Stainless Steel 304 Flanges

Durability: High strength and resistance to wear and tear ensure long-lasting performance.

Corrosion Resistance: Suitable for use in harsh environments and exposure to corrosive substances.

Versatility: Applicable in a wide range of industries and applications.

Ease of Maintenance: Smooth, non-porous surface is easy to clean and maintain.

Cost-Effective: Offers a good balance between cost and performance, making it a popular choice.

Conclusion

Stainless Steel 304 flanges are vital components in many industrial applications due to their exceptional properties and versatility. Their ability to withstand harsh environments, maintain high performance, and offer ease of maintenance makes them a preferred choice for professionals in various industries, including petrochemical, food and beverage, pharmaceutical, oil and gas, water treatment, and construction.

#ASTM A182 Stainless Steel 304/304L Flanges#SS 304 Flanges#SS 304L Flanges#WERKSTOFF NR. 1.4301 Flanges#ANSI B16.5 SS 304/304L Flanges#UNS S30400 Flanges#DIN 1.4306 / 1.4307 Flange#Stainless Steel 304/304L Flanges Manufacturers in India#UNS S30403 Flanges#SS 304/304L Flanges Supplier in Mumbai#India

2 notes

·

View notes

Text

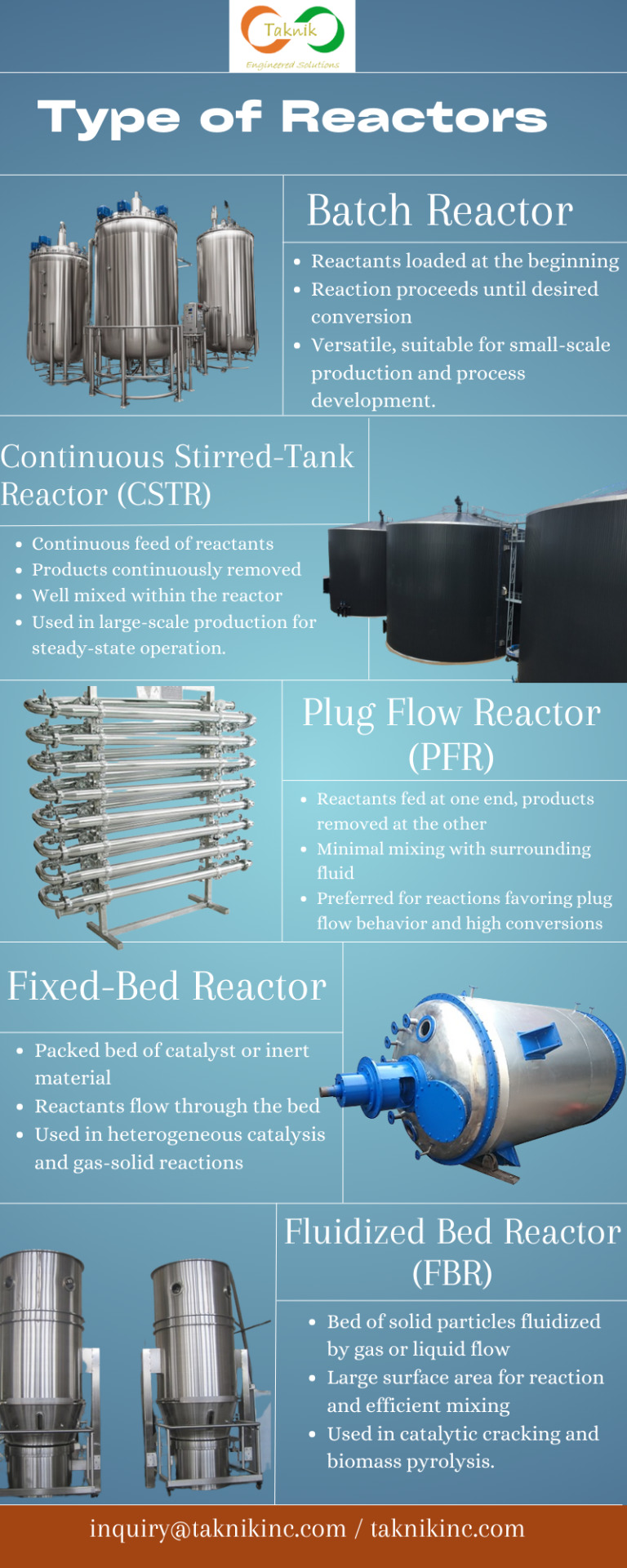

Taknik Inc is an Engineering Consultant it is a leading provider of Engineering design & Consultancy Services solution in India.

We Provide Process Equipment for the Manufacture Industries ,all kind of Matallic and non Metallic Equipment ,Reactor,HDPE Sprial Tank Blower Scrubber, Heat Exchanger, Storage Tank, Pressure Vessel etc .

for more details you can contact us

9510430147

or

email Id- [email protected]

#taknikinc#engineering#consultant#services#manufacturingindustry#manufacturer#metallic#Reactor#solutions#process#equipment#production#chemicals#tank#bharuch#gujarat

3 notes

·

View notes

Text

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes