#rice bag sealing machine

Text

Reliable Food Bag Sealing Machines for Consistent Seals

Discover efficient food bag sealing machines designed for secure, airtight packaging. Keep food fresh and enhance your production with reliable sealing solutions. Learn More:

#food bag sealing machine#rice bag sealing machine#grain packing machine price#commercial food packaging machine

0 notes

Text

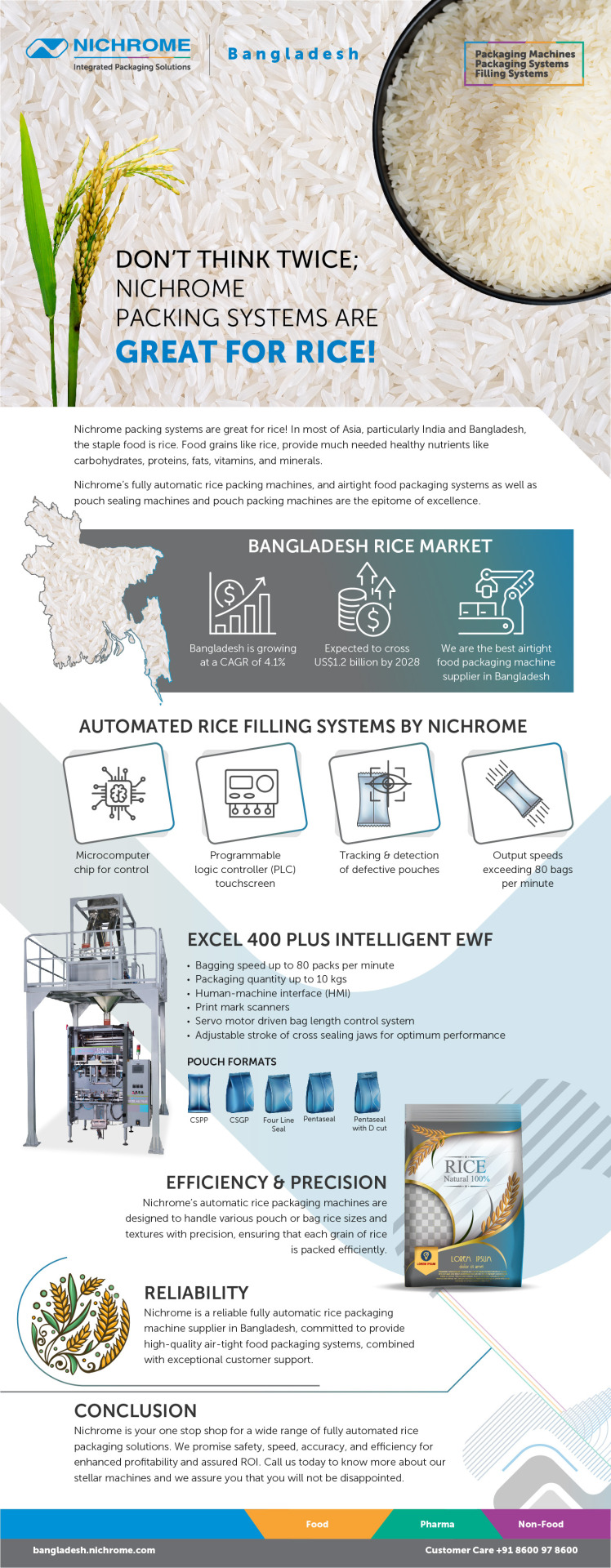

Nichrome offers integrated packaging solutions for food, pharma and many other products. Know more about our Company, History, Vision, Values, Manufacturing capabilities, Infrastructure etc

#pouch sealing machine#vertical form fill seal machine#filling and packaging machine#pouch packing machine#powder packaging machines#tea packaging machine#rice bag packing machine#packaging machine supplier in bangladesh#airtight food packaging#coffee packaging machine

0 notes

Text

Mastering Grain Packaging: Your Guide to Seamless Solutions

In India, grains like rice, wheat, pulses, and seeds form the backbone of daily meals. Proper packaging of these essential staples ensures they stay fresh, nutritious, and safe from contaminants. Effective grain packaging also facilitates smooth storage, transportation, and distribution. However, jar filling for grain packaging comes with its own set of hurdles.

Let’s dive into how Nichrome’s innovative solutions tackle these challenges and elevate your packaging operations.

Precision and Uniformity: The Cornerstones of Quality

When it comes to filling grains into jars, precision is key. Each jar must be filled uniformly to meet consumer expectations and maintain product consistency. Nichrome’s advanced grain packaging machines, including rice bag sealing, pulses packaging, and seed packaging machines, are engineered for exactness. Our Vertical Form Fill Seal (VFFS) Machines excel in delivering accurate and consistent results, ensuring your grains are packed to perfection every time.

Flexibility in Jar Sizes and Shapes

Grains come in various jar sizes and shapes, which can complicate the filling process. Nichrome’s Automatic Jar Filling Machines are designed with flexibility in mind. Our adjustable filling mechanisms handle a diverse range of jar specifications, ensuring efficient and uniform filling regardless of jar type. This adaptability is crucial for accommodating different packaging requirements and enhancing overall operational efficiency.

Choosing the Right Packaging Machine Manufacturer

Selecting a reliable packaging machine manufacturer is critical for overcoming jar filling challenges. Nichrome stands out as a leading expert in automated packaging solutions. Our extensive experience and specialized knowledge enable them to offer tailored solutions for your grain packaging needs, ensuring you get the best machine for your specific requirements.

Efficient HDPE Bag Filling

For bulk grain packaging, HDPE bags are a common choice. Our HDPE Bag Filling Line Systems and Automatic HDPE Bag Filling Machines streamline the filling and sealing of HDPE bags. These machines not only boost productivity but also reduce manual labor, making your packaging process more efficient and cost-effective.

Ensuring Hygiene and Food Safety

Maintaining high hygiene and safety standards is essential in grain packaging. Our jar filling machines are designed with food-grade materials and easy-to-clean components, ensuring the highest levels of cleanliness and safety. These hygienic filling mechanisms prevent contamination, safeguarding the quality of your grains.

Embracing Automation for Enhanced Efficiency

Automation is a game-changer in overcoming jar filling challenges. Our automated packaging solutions, including bulk bag filling and jar filling machines, enhance efficiency, minimize errors, and reduce manual labor. By integrating these advanced technologies, you can streamline your operations and boost overall productivity.

A Range of Nichrome Packaging Solutions

We, at Nichrome offer a diverse array of packaging solutions tailored to the grain industry:

● HDPE Bag Filling Line Systems: Ideal for efficient filling and sealing of HDPE bags.

● Vertical Form Fill Seal (VFFS) Machines: Versatile machines for forming, filling, and sealing bags from roll stock.

● Jar Filling Machines: Precision equipment for packing grains into jars with accurate filling and sealing.

● Bulk Bag Filling Machines: Designed for handling and packaging large quantities of grains efficiently.

Choose Nichrome for Unmatched Excellence

Navigating the complexities of jar filling in grain packaging requires the right tools and expertise. Nichrome’s cutting-edge machines and automated solutions provide the precision, flexibility, and efficiency needed to overcome these challenges. For all your grain packaging needs, trust Nichrome to deliver excellence and elevate your packaging operations.

Make your grain packaging process seamless and efficient—choose Nichrome, where innovation meets reliability.

0 notes

Text

Innovative Bag Filling Machine Solutions for Efficient Packaging

Innovative bag filling machine solutions have revolutionized efficient packaging across various industries. These advanced machines offer precision and speed, significantly reducing manual labor and increasing production rates. Equipped with features such as automated weighing, filling, and sealing, they ensure consistent and accurate bagging of products ranging from powders and granules to liquids. State-of-the-art technology, such as touch-screen controls and programmable settings, allows for easy customization and operation. Additionally, innovations like vacuum-assisted filling and integrated quality control systems enhance product integrity and packaging reliability. By incorporating these advanced solutions, businesses can streamline their packaging processes, minimize waste, and improve overall operational efficiency, leading to higher productivity and cost savings.

Introduction to Bag Filling Machines: Enhancing Packaging Efficiency

Bag filling machine is essential tools in various industries for efficiently packaging products ranging from grains and powders to liquids and granules. These machines automate the process of filling bags with precise quantities, reducing manual labor and increasing productivity. This introduction explores the basic functions and benefits of bag filling machines, highlighting their role in streamlining packaging operations and improving accuracy in product handling.

Types of Bag Filling Machines: Choosing the Right Equipment for Your Needs

There are several types of bag filling machines, each designed to handle specific product types and packaging requirements. This section delves into the different categories, including volumetric fillers, gravimetric fillers, and auger fillers. It also covers machines tailored for specific industries, such as food and beverage, pharmaceuticals, and chemicals. Understanding the various types helps businesses select the right equipment to meet their unique production needs and achieve optimal efficiency.

Innovations in Bag Filling Machine Technology: Boosting Speed and Precision

Technological advancements have revolutionized bag filling machines, making them faster, more precise, and easier to operate. Modern machines feature automated controls, digital interfaces, and real-time monitoring systems that enhance performance and reduce human error. Innovations such as programmable logic controllers (PLCs), servo-driven systems, and advanced weighing mechanisms ensure consistent and accurate fills. This section explores these cutting-edge technologies and their impact on improving the efficiency and precision of bag filling operations.

Benefits of Using Bag Filling Machines in the Food Industry

The food industry relies heavily on bag filling machines to package a wide range of products, including flour, sugar, rice, and snacks. These machines ensure hygienic and contamination-free packaging, adhering to strict industry standards. This segment highlights the specific benefits for food manufacturers, such as improved packaging speed, reduced product wastage, and enhanced product shelf life. It also discusses how it’s contribute to maintaining quality and safety in food production.

Maintenance and Troubleshooting Tips for Bag Filling Machines

Proper maintenance is crucial to ensure the longevity and optimal performance of bag filling machines. This section provides practical tips on routine maintenance tasks, such as cleaning, lubrication, and regular inspections. It also covers common issues that may arise during operation and offers troubleshooting advice to quickly resolve problems. By following these guidelines, businesses can minimize downtime, extend the lifespan of their equipment, and maintain consistent packaging quality.

Case Studies: Successful Implementation of Bag Filling Machines in Various Industries

Real-world examples of successful bag filling machine implementations provide valuable insights into their practical benefits. This section presents case studies from different industries, showcasing how businesses have improved their packaging processes, increased productivity, and achieved cost savings through the use of bag filling machines. These stories highlight specific challenges faced, solutions implemented, and measurable outcomes, offering inspiration and lessons for other companies considering similar investments.

Future Trends in Bag Filling Machine Technology: What to Expect?

The future of bag filling machine technology is promising, with ongoing developments aimed at further enhancing efficiency, precision, and sustainability. This section explores upcoming trends, such as the integration of artificial intelligence (AI) and machine learning for predictive maintenance and process optimization. It also looks at advancements in eco-friendly packaging solutions and the use of smart sensors for real-time data collection and analysis. Understanding these trends helps businesses stay ahead of the curve and adapt to evolving industry demands.

Conclusion

Innovative bag filling machine solutions have revolutionized the packaging industry by enhancing efficiency, accuracy, and versatility. These advanced machines incorporate cutting-edge technologies such as automated controls, real-time monitoring, and high-speed filling capabilities, ensuring consistent and precise bag fills. Innovations like multi-head systems and seamless integration with other packaging equipment streamline operations, reducing downtime and waste. By adopting these state-of-the-art solutions, businesses can achieve higher productivity, improved product quality, and significant cost savings. The continual evolution of bag promises even greater advancements in efficiency and sustainability, positioning companies to meet the increasing demands of modern markets while maintaining competitive edges in their respective industries.

0 notes

Text

Unveiling Efficiency: Why Emrich Vertical Baggers are the Perfect Choice for Your Packaging Needs

In today's fast-paced world, efficiency reigns supreme. This applies not just to your production line but also to your packaging solutions. Emrich stands out as the leading provider of packaging equipment that prioritizes efficiency, reliability, safety, and ease of use, all at an exceptional value. In this blog, we focus on Emrich's vertical bagging solutions, ideal for streamlining the packaging of a wide range of loose products.

Beyond Boxes: Exploring the World of Vertical Bagging

Vertical baggers, also known as vertical form fill and seal (VFFS) machines, offer a game-changing approach to packaging loose goods. Here's what sets them apart:

Automated Process: Vertical baggers automate the entire packaging process, from forming the bag from a roll of film to filling it with your product and sealing it securely. This eliminates manual tasks and increases production efficiency.

Versatility: These machines can handle a wide variety of loose products, from grated cheese and frozen vegetables to rice, coffee beans, and more.

Space-Saving Design: Vertical baggers have a compact footprint compared to some traditional packaging equipment, maximizing space utilization on your production line.

Sanitary Packaging: The automated bag forming and sealing process minimizes product contact, promoting hygiene and food safety.

Emrich: Setting the Standard for Efficiency in Vertical Bagging

Emrich has earned a reputation for excellence in packaging equipment. Here's why you should choose Emrich for your vertical bagging needs:

Unmatched Efficiency: Our vertical baggers are designed to maximize production speed and minimize downtime, ensuring you meet your packaging demands effortlessly.

Reliable Performance: Emrich vertical baggers are built with high-quality components and meticulous engineering, guaranteeing consistent and reliable operation.

Operator-Friendly Design: Our intuitive controls and user-friendly interfaces make it easy for operators of all experience levels to operate the machines efficiently.

Exceptional Value: Emrich offers a unique combination of high performance, reliability, and user-friendliness at a competitive price, delivering a great return on investment.

Unveiling the Power of Emrich Vertical Bagging Solutions

Emrich vertical baggers cater to a diverse range of products and packaging needs:

Food and Beverage: Efficiently package dry food like rice, coffee beans, and snacks, or frozen vegetables and grated cheese in user-friendly bags.

Hardware and Small Parts: Securely enclose screws, nuts, bolts, and other hardware components in durable bags for easy storage and transportation.

Chemicals and Powders: Our baggers can handle powdery or granular products like detergents, cleaning products, or pigments with minimal mess or product loss.

Emrich: Prioritizing Safety and Sustainability

Safety and sustainability are crucial considerations in modern packaging. Emrich prioritizes both:

Safety Features: Our vertical baggers incorporate safety features like emergency stop buttons and machine guards to protect operators from potential hazards.

Sustainable Practices: Emrich promotes resource efficiency by minimizing film waste and offering bag size flexibility to optimize packaging material usage.

Durable Construction: Our high-quality machines are built to last, reducing the need for frequent replacements and associated environmental impact.

Emrich: Streamlining Your Packaging Process

Emrich vertical baggers offer a multitude of benefits for your business:

Reduced Labor Costs: Automated bagging reduces reliance on manual labor, lowering production costs and optimizing your workforce allocation.

Increased Production Speed: Emrich's efficient machines help you meet your packaging demands faster, allowing you to scale your production effectively.

Improved Product Consistency: The automated process of vertical bagging ensures consistent bag size and seal quality, enhancing your product presentation.

Enhanced Inventory Management: Pre-sized bags optimize storage space and facilitate efficient inventory management.

Emrich: The Perfect Partner for Your Vertical Bagging Needs

Emrich is your one-stop shop for reliable and efficient vertical bagging solutions. Here's how we can help:

Expert Consultation: Our knowledgeable team can assess your specific needs and recommend the most suitable Emrich vertical bagger for your product and production line.

Seamless Integration: We ensure smooth integration of your chosen vertical bagger into your existing production line, minimizing disruption to your workflow.

Ongoing Support: Emrich offers comprehensive after-sales support, including training, maintenance services, and readily available spare parts.

Emrich: Elevate Your Packaging Efficiency Today

Don't settle for outdated or inefficient packaging solutions. Emrich vertical baggers offer the perfect blend of efficiency, reliability, user-friendliness, and value. With Emrich

Contact-

Web - https://www.emrich.com.au/vertical-baggers/

Ph - 1800 801 243 / +61 3 9540 0255

Address - 1/14-18 Venture Court, Dandenong South VIC 3175, Australia.

0 notes

Text

Key Features of BOPP Bags

Biaxially Oriented Polypropylene (BOPP) bags have revolutionized the packaging industry with their versatility, durability, and cost-effectiveness. As one of the leading BOPP bag manufacturers in India, Singhal Industries Pvt Ltd is at the forefront of producing high-quality BOPP bags that cater to diverse packaging needs across various industries.

Understanding BOPP Bags

BOPP bags are made from polypropylene, a thermoplastic polymer that is stretched in both the machine (longitudinal) and transverse (cross) directions during manufacturing. This biaxial orientation process enhances the bag's mechanical properties, such as strength, clarity, and stiffness, while also imparting excellent moisture barrier properties.

Key Features of BOPP Bags

Durability and Strength: BOPP bags are renowned for their exceptional strength and durability. The biaxial orientation process aligns the polymer molecules, resulting in a material that can withstand rough handling, punctures, and tearing. This makes them ideal for Packaging products by BOPP bags that require robust protection during storage and transportation.

Moisture Resistance: One of the standout features of BOPP bags is their inherent moisture resistance. The tight molecular structure of polypropylene, coupled with the biaxial orientation, creates a barrier that prevents moisture ingress. This property is crucial for preserving the quality and freshness of packaged goods, especially in humid environments.

Clarity and Printability: BOPP bags offer excellent clarity, allowing for high-quality printing and enhanced product visibility. Manufacturers can easily apply vibrant graphics, branding elements, and product information directly onto the bag's surface, enhancing shelf appeal and brand recognition.

Chemical Resistance: BOPP bags exhibit resistance to a wide range of chemicals, oils, and solvents. This makes them suitable for packaging chemicals, fertilizers, pet foods, and other products that may interact with aggressive substances without compromising the integrity of the packaging.

Cost-Effectiveness: Compared to traditional packaging materials such as paper or woven polypropylene (PP), BOPP bags prices are cost-effective. They offer a balance of performance and affordability, making them a preferred choice for manufacturers looking to optimize packaging costs without compromising quality.

Environmental Sustainability: BOPP bags are recyclable and reusable, aligning with global efforts towards sustainable packaging solutions. The recyclability of polypropylene ensures that BOPP bags can be responsibly disposed of and contribute to reducing environmental impact.

Applications of BOPP Bags

BOPP bags find widespread application across various industries due to their versatile properties:

Food Packaging: BOPP bags are commonly used for packaging snacks, cereals, rice, pulses, and other food products. Their moisture barrier and heat-sealing capabilities help maintain product freshness and quality.

Agricultural Products: They are ideal for packaging seeds, fertilizers, animal feed, and agricultural chemicals due to their strength, UV resistance, and moisture protection.

Industrial and Consumer Goods: BOPP bags are utilized for packaging textiles, stationery, hardware, and other consumer goods. Their durability and printability enhance product presentation and brand visibility on retail shelves.

Chemicals and Pharmaceuticals: The chemical resistance of BOPP bags makes them suitable for packaging chemicals, pharmaceuticals, and medical supplies, ensuring product safety and integrity.

In conclusion, BOPP bags manufactured by Singhal Industries Pvt Ltd offer a compelling combination of durability, moisture resistance, printability, and cost-effectiveness. These key features make them indispensable for packaging solutions across diverse industries, ensuring product protection, freshness, and marketability. As a leading manufacturer of BOPP bags in India, Singhal Industries continues to innovate and deliver high-quality packaging solutions that meet the evolving needs of modern businesses while supporting sustainable practices. For more information on BOPP bags, their applications, or customization options, contact Singhal Industries Pvt Ltd and discover how these versatile packaging solutions can benefit your business.

Frequently Asked Questions about BOPP Bags

Q: What are BOPP bags made of?

A: BOPP bags are made from Biaxially Oriented Polypropylene, a type of thermoplastic polymer known for its strength, clarity, and moisture resistance.

Q: Are BOPP bags recyclable?

A: Yes, BOPP bags are recyclable. They can be recycled and reused, contributing to sustainable packaging practices.

Q: What industries use BOPP bags?

A: BOPP bags are used across various industries including food packaging, agriculture, consumer goods, chemicals, and pharmaceuticals due to their versatility and protective properties.

0 notes

Text

Silo Bags 101: Introduction, Uses, and Filling Equipment

Silo bags have redefined the storage and transportation of agricultural commodities, offering a flexible and cost-effective solution for farmers and producers. In this comprehensive guide, we'll delve into the basics of silo bags, their uses across various industries, and the essential filling equipment required for efficient handling.

Introduction to Silo Bags

Additionally, silo bags, also known as grain bags or flexible storage bags, are large, cylindrical bags made from high-quality polyethylene material. You can store and protect a wide range of commodities, including grains, seeds, fertilizers, and even silage, with these bags. Their flexibility is the key advantage, enabling them to be used in temporary or permanent storage setups, depending on the requirements.

Uses of Silo Bags

Grain Storage: Silo bags are extensively used for storing grains such as corn, wheat, rice, and barley. They provide an airtight environment that preserves the quality of the grains, protecting them from moisture, pests, and external contaminants.

Seed Storage: Agricultural seeds are highly valuable and sensitive to environmental conditions. They offer a secure storage solution, maintaining the viability and germination rate of seeds over extended periods.

Fertilizer Storage: Fertilizers, both organic and synthetic, can be stored in these bags to prevent moisture absorption and maintain their nutrient content. This further, ensures that fertilizers remain effective when applied to crops.

Silage Storage: These bags are widely used in livestock farming for storing silage, a fermented feed made from green fodder. The airtight seal preserves the nutritional value of silage, making it an essential component of animal feed.

Temporary Storage Solutions: During peak harvest seasons or when traditional storage facilities are limited, silo bags provide a convenient temporary storage solution. They can be placed directly in the field, reducing transportation costs and logistical challenges.

Filling Equipment for Silo Bags

Efficient filling of these bags requires specialized equipment designed for seamless operation and optimal results. Here are the key components of silo bag filling systems:

Baggers: Silo baggers are machines equipped with hydraulic or mechanical arms that facilitate the filling of bags. They ensure uniform distribution of the commodity inside the bag, maximizing storage capacity.

Conveyors: Conveyor systems are used to transport the commodity from storage or processing areas to the silo bagger. They enhance workflow efficiency and reduce manual handling.

Compactors: Compactors help in compressing the commodity within the silo bag, minimizing air pockets and ensuring a tight seal. This compression prevents spoilage and maintains product quality.

Sealing Equipment: They require airtight sealing to protect the contents from environmental factors. Heat sealers or bag sewing machines are used to seal the bags securely after filling.

Benefits of Silo Bags

Cost-Effective: Silo bags eliminate the need for permanent storage structures, reducing infrastructure costs for farmers and producers.

Flexibility: They can be used for short-term or even long-term storage, allowing farmers to adapt to fluctuating market demands.

Preservation of Quality: The airtight seal of these bags preserves the quality and freshness of commodities, reducing post-harvest losses.

Versatility: These bags can be used for a wide range of commodities, making them a versatile storage solution for diverse agricultural products.

Bottom Line

Silo bags have transformed the way agricultural commodities are stored and managed, offering flexibility, cost-effectiveness, and efficient preservation of quality. With the right filling equipment and proper handling practices, they provide a reliable storage solution for farmers, ensuring the longevity and integrity of their valuable produce.

0 notes

Text

How Bag Filling Machines Enhance Productivity and Accuracy?

Bag filling machines revolutionize packaging processes by enhancing productivity and accuracy. These automated systems streamline production, significantly reducing manual labor and time requirements. By precisely measuring and dispensing product quantities, they ensure consistent fill weights and packaging quality, minimizing waste and maximizing efficiency. With advanced features such as programmable settings and multi-head weighing systems, bag-filling machines optimize throughput while maintaining accuracy. This results in increased output rates, improved operational efficiency, and higher levels of customer satisfaction, making them indispensable assets in modern manufacturing facilities.

Understanding the Functionality of Bag Filling Machines

Bag filling machine are essential equipment in various industries for efficiently filling bags with products such as powders, granules, and liquids. These machines automate the filling process, improving efficiency and accuracy while minimizing labor costs. Understanding how bag-filling machines work is crucial for optimizing production processes and achieving consistent results.

Exploring the Types of Bag Filling Machines

Bag filling machines come in various types, each designed for specific applications and production requirements. Common types include vertical form-fill-seal (VFFS) machines, horizontal form-fill-seal (HFFS) machines, and open-mouth bagging machines. Each type offers unique features and advantages, allowing businesses to choose the most suitable option based on their packaging needs and product characteristics.

Advantages of Automated Bag Filling Machines

Automated bag filling machines offer numerous advantages over manual filling methods. By automating the filling process, these machines increase production rates, reduce labor costs, and minimize the risk of human error. Additionally, automated bag filling machines ensure consistent fill weights and packaging quality, enhancing overall efficiency and customer satisfaction.

Factors to Consider When Choosing a Bag Filling Machine

Several factors should be considered when selecting a bag filling machine for your business. These include production volume, product characteristics, bag type and size, and required fill accuracy. By carefully evaluating these factors and consulting with a reputable supplier, businesses can choose a bag filling machine that meets their specific needs and production goals.

Innovative Features in Modern Bag Filling Machines

Modern bag filling machines incorporate innovative features and technologies to enhance performance and versatility. These features may include touch-screen controls, programmable settings, multi-head weighing systems, and advanced sealing mechanisms. By leveraging these innovations, businesses can optimize their packaging processes, improve efficiency, and stay competitive in the market.

Applications of Bag Filling Machines Across Industries

Bag filling machines find applications across a wide range of industries, including food and beverage, agriculture, pharmaceuticals, chemicals, and more. Whether filling bags with coffee beans, rice, pet food, or industrial chemicals, bag filling machines play a critical role in streamlining packaging operations and ensuring product quality and consistency.

Future Trends in Bag Filling Machine Technology

The future of bag filling machines is marked by continued innovation and advancement in technology. Key trends include the integration of artificial intelligence (AI) and machine learning algorithms for predictive maintenance and optimization, as well as the development of eco-friendly packaging solutions and energy-efficient machine designs. By staying abreast of these trends, businesses can future-proof their packaging operations and maintain a competitive edge in the market.

Conclusion

Bag filling machines stand as indispensable tools in modern packaging operations, offering unparalleled benefits in productivity and accuracy. By automating the filling process and employing advanced technologies, these machines optimize production efficiency while ensuring precise measurement and consistency. The result is increased throughput, reduced labor costs, and enhanced product quality, ultimately driving overall profitability and customer satisfaction. With their ability to streamline operations and deliver reliable performance, bag filling machines continue to be vital assets in the manufacturing industry.

0 notes

Text

BOPP Bags: Versatile Packaging Solutions for Every Requirement

At Singhal Industries, we're passionate about providing innovative and sustainable flexible packaging solutions. Today, we delve into the world of Bopp rice bags – a versatile and ubiquitous packaging option with a surprising range of applications. From groceries to garments, BOPP bags offer a clear advantage for businesses across industries.

What are BOPP Bags?

BOPP stands for Biaxially Oriented Polypropylene. These bags are crafted from high-quality polypropylene film that undergoes a stretching process in both machine and transverse directions. This process enhances the film's strength, clarity, and overall performance.

Singhal Industries: Your Trusted Source for High-Quality BOPP Bags

As a leading manufacturer of flexible packaging solutions, Singhal Industries offers a wide variety of BOPP bags to meet your specific needs. We use premium-grade materials and stringent quality control measures to ensure our BOPP bags deliver exceptional performance.

Unveiling the Advantages of BOPP Bags:

Bopp woven bag boast numerous advantages that make them a popular choice for various packaging applications:

Clarity & Transparency: The biaxial orientation process results in exceptionally clear BOPP bags, allowing consumers to see the product inside. This is crucial for showcasing food items, apparel, and other visually appealing products.

Strength & Durability: Despite their lightweight nature, BOPP bags offer remarkable strength and puncture resistance, effectively protecting your products during transportation and storage.

Moisture Resistance: BOPP film exhibits excellent moisture resistance, safeguarding your products from moisture damage and ensuring longer shelf life.

Versatility: BOPP bags come in a wide range of sizes, thicknesses, and styles to accommodate various packaging needs. From resealable pouches to self-adhesive seal bags, BOPP offers a customizable solution.

Cost-Effectiveness: Compared to other rigid packaging options, BOPP bags are a more economical choice. Their lightweight nature also minimizes transportation costs.

Printability: BOPP film offers excellent printability, allowing for high-quality branding and product information to be printed directly on the bags. This enhances brand recognition and product appeal.

Sustainability: BOPP is recyclable in many regions. Additionally, Singhal Industries is committed to exploring sustainable options like bio-based BOPP films to minimize environmental impact.

Exploring the Applications of BOPP Bags:

The versatility of Poop bags suppliers extends to a wide range of applications, making them a popular choice for:

Food & Beverage Industry: BOPP bags are ideal for packaging a variety of food items, including bakery products, snacks, confectionery, and fresh produce. Their clarity showcases the product while offering moisture resistance.

Apparel Industry: Garment bags, T-shirt bags, and various garment packaging utilize BOPP bags. Their clarity allows showcasing garments, while strength ensures protection during transport and storage.

Retail Industry: BOPP bags are widely used for packaging a variety of retail products, from toys and electronics to stationery and personal care items. Their resealable options offer convenience for customers.

Pharmaceutical Industry: Certain BOPP films comply with pharmaceutical packaging regulations, making them suitable for packaging tablets, capsules, and other dry pharmaceuticals.

Stationery & Office Supplies: BOPP bags offer a clear and durable solution for packaging notebooks, pens, and other office supplies.

Singhal Industries: Beyond the Bag - Your Packaging Partner

At Singhal Industries, we understand that packaging needs go beyond just the bag itself. We offer a variety of value-added services to complement your BOPP bag packaging solution:

Custom Printing: We can print your logo, brand messaging, and product information directly onto the BOPP bags, enhancing brand identity and product appeal.

Variety of Styles: We offer various BOPP bag styles, including flat pouches, stand-up pouches, zipper bags, and more, to meet your specific product presentation and functionality needs.

Technical Expertise: Our team of experts is here to assist you in choosing the right BOPP bag material, thickness, and style for your specific application.

Choosing the Right BOPP Bag for Your Needs:

Here are some factors to consider when selecting BOPP bags for your products:

Product Characteristics: Consider the size, weight, and fragility of your product to choose the appropriate BOPP bag thickness and strength.

Desired Features: Do you require resealability, zippers, or hanging holes? Choose BOPP bag styles that cater to your specific functionalities.

Visual Appeal: High-quality printing on BOPP bags can enhance your brand image and product presentation.

FAQS

What are BOPP bags, and what makes them a versatile packaging solution?

BOPP bags are made from biaxially oriented polypropylene, a durable and flexible thermoplastic polymer. These bags are manufactured by stretching polypropylene film in both the machine and transverse directions, resulting in enhanced strength, clarity, and dimensional stability. BOPP bags offer versatility in packaging due to their excellent moisture resistance, high tensile strength, and ability to be custom printed with vibrant graphics and designs. They are commonly used for packaging a wide range of products, including snacks, confectionery, grains, pet food, and more.

What are the key features and benefits of using BOPP bags?

BOPP bags boast several features that make them an attractive packaging choice. They offer excellent barrier properties against moisture, gases, and odors, ensuring product freshness and shelf life. The high clarity of BOPP film allows for superior product visibility, enhancing brand presentation on store shelves. Additionally, BOPP bags are lightweight, puncture-resistant, and recyclable, making them an eco-friendly packaging solution. Their versatility in printing options allows for eye-catching branding and product differentiation, helping businesses stand out in the market.

In what industries are BOPP bags commonly used?

BOPP bags find widespread application across various industries due to their adaptability and durability. They are extensively used in the food industry for packaging snacks, baked goods, pasta, rice, and other dry food products. Additionally, BOPP bags are favored for packaging pet food, fertilizers, chemicals, pharmaceuticals, and personal care products. Their ability to preserve product integrity and provide tamper-evident packaging makes them suitable for a diverse range of consumer and industrial goods.

Are BOPP bags suitable for customized packaging requirements?

Yes, BOPP bags are highly customizable to meet specific packaging needs and branding preferences. They can be printed with vivid colors, logos, product information, and promotional messages using flexographic or rotogravure printing techniques. Customization options also include different bag sizes, shapes, closures, and handle designs to suit individual product specifications. Whether for retail packaging or promotional campaigns, BOPP bags offer ample opportunities for creative branding and consumer engagement.

What considerations should be made when selecting BOPP bags for packaging?

When choosing BOPP bags for packaging, several factors should be considered to ensure optimal performance and cost-effectiveness. These include the type of product being packaged, required barrier properties, storage conditions, transportation logistics, and regulatory compliance. It's essential to select BOPP bags with appropriate thickness, seal strength, and barrier coatings to safeguard the product against external factors and maintain its quality. Partnering with a reputable manufacturer or supplier ensures access to high-quality BOPP bags tailored to specific packaging requirements.

0 notes

Text

Beyond the Sugar Bowl: Innovations in Bulk Sugar Bag Filling

Welcome to the state-of-the-art universe of packaging systems, where accuracy meets proficiency. In this world, Nichrome is making waves with its most advanced development, the Bulk Packing Machine, an innovative wonder carefully created to upset the bundling scene.

Our latest innovation, the bulk packing machine, addresses all the challenges faced in sugar packaging with precision and efficiency. Picture a consistent cycle incorporating rice, sugar, grains, beats, flour, concrete, and agro-compound granules, all easily taken care of by this flexible machine. Plunge further into the universe of mechanization with highlights like auto pack clasping, mass and spill feed, and a shrewd sack shifting and arrangement connection, complete with the adaptability of sack sewing or band fixing.

Bulk bag filling for sugar presents a unique set of challenges that can impede productivity and profitability. From ensuring precise measurements to maintaining safety standards, manufacturers are constantly seeking solutions to enhance their packaging processes. Let’s discuss how Nichrome does it best -

Versatile Bag Compatibility: Our bulk bag packing machine accommodates a variety of bag types including HDPE woven, PP, paper, and valve-type bags ranging from 5 to 50 kgs. This versatility makes it an ideal choice for different packaging needs for a wide range of products - rice, sugar, grains, pulses, flour, cake mix, cement, and agro-chemical granules.

High-Speed Operation: With unprecedented output rates of up to 20 bags per minute, our machine offers unparalleled productivity without sacrificing accuracy. Whether you're handling large-scale production or small-batch runs, our precision control through a Programmable Logic Controller (PLC) meets all your needs for seamless operation.

Enhanced Safety Features: Safety remains a top priority in the industrial settings of our bulk bagging systems. Nichrome's secondary packaging machines incorporate a 'no bag no filling' safety device, powered by advanced PLC technology. This feature minimizes waste and safeguards against potential hazards, reinforcing the commitment to operational safety.

Advanced Bag Handling Features: Efficient bag handling is a key element in achieving seamless bulk packaging. Nichrome's jumbo bag filling machine offers a suite of advanced features to address this challenge. Auto bag clamping ensures a secure grip, preventing spillage and maintaining the integrity of the packaged product. Additionally, the machine features bulk and dribble feed options, allowing for precise control over the filling process, further contributing to the overall quality of the packaged goods.

Customizable Bag Alignment and Sealing Options: Recognizing the unique needs of different industries, Nichrome's Bulk Packing Machine goes a step further by offering bag tilting and alignment attachments. This customization option ensures that bags are positioned optimally for efficient filling. Businesses can choose between bag stitching or band sealing, providing the flexibility to align the packaging process with specific industry requirements. This level of customization sets Nichrome apart, offering tailored solutions to enhance the overall packaging experience.

Empowering Your Packaging Process

At Nichrome, we believe that innovation is the key to unlocking new possibilities. With our integrated packaging solutions, we empower manufacturers to overcome the challenges of bulk bag filling with confidence and ease. From sugar to grains, pulses to cake mix, our solution is tailored to meet the diverse needs of the modern marketplace.

In conclusion, Nichrome's Bulk Packing Machine stands as a testament to our company's commitment to providing integrated packaging solutions that redefine the landscape of bulk bag filling for sugar and other commodities. With its advanced features, adaptability, and efficiency, this machine sets a new standard for the industry, ensuring seamless packaging processes and unmatched product quality.

With Nichrome as your partner, you can now embrace change with confidence, knowing that our innovative solutions are designed to evolve alongside your needs. Discover the difference that innovation can make – revolutionize your packaging process with Nichrome today!

If you are on the lookout for a tin packaging machine, tin seamer machine, bottle filling machine, cartoning machine, bulk bag filling machine, box packing machine, ghee jar filling machine, manufacturer whatever may your requirements be, Nichrome has the capability and expertise to cater to your exact need.

0 notes

Text

Efficient Rice Bag Sealing Machines for Secure Packaging

Get precision rice bag sealing machines tailored to your production needs. Ensure consistent seals, reduce waste, and streamline your packaging process today. Learn More:

#rice bag sealing machine#food bag sealing machine#auger filler packing machine#powder filling machines#powder packaging machine#vertical form fill seal machines#rice packaging machine

0 notes

Text

#rice bag packing machine#vertical form fill seal machine#pouch sealing machine#powder packaging machines#pouch packing machine#filling and packaging machine

0 notes

Text

Unveiling the Versatility and Production of BOPP Bags: A Comprehensive Insight

BOPP (Biaxially Oriented Polypropylene) bags, known for their durability, clarity, and versatility, have become indispensable in various industries for packaging a wide range of products. From food items to textiles, these bags offer excellent protection, visual appeal, and customization options. In this comprehensive guide, we delve into the world of BOPP bags, exploring their uses, manufacturing process, manufacturers, and their specific application in rice packaging.

Understanding BOPP Bags

BOPP bags are made from a type of plastic film called Biaxially Oriented Polypropylene, which undergoes a process of biaxial orientation to enhance its strength, clarity, and dimensional stability. These bags are characterized by their high tensile strength, moisture resistance, and excellent printability, making them ideal for packaging a wide variety of products. BOPP bags come in various sizes, shapes, and designs, catering to the diverse needs of industries such as food, textiles, pharmaceuticals, and more.

Uses of BOPP Bags

The versatility of BOPP bags lends them to a multitude of applications across different industries. Some common uses include:

1. Food Packaging: BOPP bags are widely used for packaging snacks, confectionery, dried fruits, nuts, and other food items. The moisture barrier properties of BOPP film help preserve the freshness and quality of the packaged products, while the clarity of the material allows for attractive product display.

2. Textile Packaging: Textile manufacturers often utilize BOPP bags for packaging fabrics, garments, and accessories. The strong and tear-resistant nature of BOPP bags ensures the safe transportation and storage of textile products, protecting them from dust, moisture, and handling damage.

3. Pharmaceutical Packaging: BOPP bags are employed in the pharmaceutical industry for packaging medicines, supplements, and medical devices. The tamper-evident properties of BOPP bags provide security and assurance to consumers, while the printable surface allows for product branding and labeling requirements.

4. Promotional Packaging: BOPP bags are popular for promotional packaging of promotional items, gifts, and souvenirs. The clear, glossy appearance of BOPP bags enhances the visual appeal of the packaged products, making them ideal for marketing and branding purposes.

BOPP Bags Manufacturers

Several manufacturers specialize in the production of BOPP bags, offering a range of products to meet the diverse needs of industries and consumers. Some prominent BOPP bags manufacturers include:

Singhal Global: Singhal Global is a leading manufacturer of BOPP bags, offering high-quality packaging solutions to industries worldwide. Their BOPP bags are manufactured using state-of-the-art technology and premium-grade materials, ensuring superior performance and reliability.

BOPP Bags Manufacturing Process

The BOPP Bags manufacturing process of BOPP bags involves several steps, including:

1. Extrusion: BOPP film is produced through a process of extrusion, where polypropylene resin pellets are melted and formed into a thin film using a flat die extrusion process.

2. Biaxial Orientation: The extruded film is stretched in both the machine direction (MD) and transverse direction (TD) to orient the polymer molecules and enhance the mechanical properties of the film.

3. Printing: The BOPP film is printed with customized designs, logos, or information using flexographic or rotogravure printing techniques, depending on the desired print quality and complexity.

4. Lamination and Conversion: The printed BOPP film is laminated with other substrates such as LDPE (Low-Density Polyethylene) or CPP (Cast Polypropylene) to improve barrier properties or enhance sealability. The laminated film is then converted into bags using heat sealing or ultrasonic welding methods.

5. Finishing: The finished BOPP bags are trimmed, inspected, and packed according to customer specifications before being shipped to end-users or distributors.

BOPP Rice Bags

BOPP rice bags are specifically designed for packaging rice and other grains, offering superior protection, moisture resistance, and durability. These bags are commonly used by rice millers, exporters, and distributors to package bulk quantities of rice for retail or wholesale distribution. BOPP rice bags are available in various sizes, capacities, and designs, allowing for customization based on branding requirements and market preferences.

Conclusion

BOPP bags have revolutionized the packaging industry with their versatility, durability, and aesthetic appeal. From food and textiles to pharmaceuticals and promotional items, these bags offer superior protection and presentation for a wide range of products. Manufacturers such as Singhal Global, Uflex Limited, and Bopp Bags India Pvt. Ltd. play a crucial role in providing high-quality BOPP bags to meet the diverse needs of industries and consumers. With their innovative manufacturing processes and commitment to quality, these manufacturers ensure that BOPP bags continue to be the packaging solution of choice for businesses worldwide.

Frequently Asked Questions (FAQ)

Q: Are BOPP bags recyclable?

A: Yes, BOPP bags are recyclable and can be processed through conventional plastic recycling facilities. However, it's essential to check with local recycling guidelines to ensure proper disposal practices and promote environmental sustainability.

Q: Can BOPP bags be used for storing perishable food items?

A: While BOPP bags offer excellent moisture resistance and barrier properties, they may not provide sufficient protection for highly perishable food items such as fresh produce or dairy products. It's recommended to use specialized packaging solutions such as vacuum-sealed bags or barrier films for storing perishable foods.

Q: Are BOPP bags suitable for long-term storage?

A: Yes, BOPP bags are suitable for long-term storage of non-perishable items such as grains, textiles, and promotional materials. The durable construction and moisture-resistant properties of BOPP bags help maintain product freshness and integrity over extended periods, making them ideal for warehouse storage or shipping logistics.

0 notes

Text

Preserve Freshness with Mylar Bags - Your Ultimate Food Storage Solution

Welcome to MylarBags.online, your one-stop destination for high-quality Mylar bags and food storage solutions. Whether you're a prepper, a home cook, or simply looking for a reliable way to keep your food fresh, we've got you covered. Our extensive range of Mylar bags is designed to meet all your food preservation needs. Say goodbye to food waste and hello to long-lasting freshness with MylarBags.online.

About Us

At MylarBags.online, we take pride in offering top-notch Mylar bags that are crafted with precision and quality in mind. Our bags are made from the highest-grade Mylar material, which is known for its exceptional oxygen and moisture barrier properties. This means your food stays fresher for longer, preserving its flavor, aroma, and nutritional value.

Why Choose Mylar Bags?

Mylar bags have become the go-to choice for food storage enthusiasts and professionals alike. Here's why:

Preserve Freshness: Mylar bags create a protective barrier against oxygen, moisture, and light, ensuring your food stays fresh for an extended period.

Extend Shelf Life: With Mylar bags, you can significantly extend the shelf life of your stored items, whether it's emergency rations, dry goods, or homemade treats.

Versatility: Our Mylar bags come in various sizes and styles to suit your specific needs. From small pouches for snacks to larger bags for bulk storage, we have it all.

Durable & Secure: Mylar bags are puncture-resistant and tear-proof, offering reliable protection for your food. Plus, our resealable options make access easy while maintaining freshness.

Our Product Range

Mylar Ziplock Bags: These are perfect for snacks, herbs, spices, and smaller food items. The ziplock closure ensures convenience and freshness.

Stand-Up Mylar Pouches: Ideal for storing larger quantities of dry goods such as rice, beans, and grains. The stand-up design makes them easy to fill and store.

Mylar Bag Rolls: Customize your food storage with our Mylar bag rolls. Cut them to your desired length and seal using a heat sealer for a perfect fit.

Vacuum Sealer Bags: For those who prefer vacuum sealing, we offer Mylar vacuum sealer bags that work seamlessly with most vacuum sealing machines.

Custom Printing: Make your Mylar bags unique with custom printing options. Perfect for businesses and special occasions.

Why Shop with Us?

When you choose MylarBags.online, you're not just buying Mylar bags; you're investing in quality, freshness, and peace of mind. Here's what sets us apart:

Quality Assurance: We source and test our Mylar bags rigorously to ensure they meet the highest industry standards.

Fast Shipping: We offer prompt and reliable shipping to get your Mylar bags to your doorstep as quickly as possible.

Exceptional Customer Service: Have questions or need assistance? Our friendly and knowledgeable customer service team is here to help.

Competitive Pricing: We believe in offering premium products at competitive prices to make food storage accessible to all.

When it comes to preserving the freshness of your food, Mylar bags are the ultimate choice, and MylarBags.online is your trusted supplier. Explore our wide range of Mylar bags and start your journey towards long-lasting food storage today. Say goodbye to food waste and hello to a world of freshness with MylarBags Online. Shop now!

https://mylarbags.online/

1 note

·

View note

Text

Key Features For Selecting a Rice Packaging Machine

Key Features For Selecting a Rice Packaging Machine

Rice packaging machines are essential for efficiently and accurately packaging rice in various quantities. These machines are designed to handle the specific requirements of rice packaging, such as maintaining product freshness, preventing moisture absorption, and achieving precise weight measurements.Get more news about types of rice packaging bags,you can vist our website!

There are several types of rice packaging machines available in the market, each catering to different packaging needs. Some common types include vertical form-fill-seal machines, automatic bagging machines, and multi-head weighers. The choice of machine depends on factors such as packaging speed, bag size, packaging material, and desired level of automation.

When selecting a rice packaging machine, it is important to consider the following key features:

1. Speed and efficiency: Look for a machine that offers high packaging speeds and can handle a large volume of rice efficiently.

2. Accuracy: Ensure that the machine provides accurate weight measurements to maintain consistency in packaging.

3. Packaging material compatibility: Check if the machine is compatible with the specific packaging material you intend to use, such as plastic bags or laminated pouches.

4. Ease of use and maintenance: Look for a machine that is user-friendly and easy to operate, with minimal downtime for maintenance and cleaning.

5. Durability and reliability: Consider the machine's build quality and reputation for reliability to ensure uninterrupted operation and longevity.

6. Safety features: Ensure that the machine is equipped with the necessary safety features to protect operators and prevent accidents.

0 notes

Text

Why Choose an Automatic Flour Mill Plant

Shree Viratra Engineering is the leading Flour Mill Plant Manufacturer and Exporter in India. A flour mill plant is an industrial facility that is used to process wheat grains into flour. Flour is a staple food that is widely used in various cuisines worldwide. Flour Mill Plant also known as Atta Mill Plant.

Benefits of Flour Mill Plant:

1) Consistent Quality: Flour mill plants use advanced technology and machinery to ensure that the milling process is efficient and consistent. This results in high-quality flour that is nutritious and safe for consumption.

2) Versatility: Flour mill plants can process various types of grains, such as wheat, maize, and rice, into different types of flour, such as whole wheat flour, all-purpose flour, and bread flour, making it a versatile facility for the food processing industry.

3) Increased Efficiency: A flour mill plant can produce a large quantity of flour in a relatively short time compared to manual processing. This leads to increased efficiency in the processing and packaging of flour, saving both time and labor costs.

4) Customization: Flour mill plants can be customized to produce different types of flour, including whole wheat flour, all-purpose flour, and specialty flour. This enables businesses to cater to specific customer needs and preferences.

Process of Flour Mill Plant:Intake and Cleaning: The first step in the process is to clean the grain. This involves removing any impurities such as stones, and dust.

Conditioning: Once the grain has been cleaned, it is conditioned to optimize the milling process. This involves adding moisture to the grain to ensure that it is at the right level for milling.

Milling: The next step is the milling process itself. The grain is fed into a milling machine that grinds it into flour.

Grinding – This is the real action; here the raw material is ground to make a powder out of the wheat grains. First of all, all types of grains are blended well to form a batch of raw material.

Packing: Finally, the flour is packed into bags or other containers for distribution. The packaging process may involve weighing and measuring the flour, as well as labeling and sealing the bags.

What Type of Machinery Used in Flour Mill Plant: Pre-Cleaner, Grader, Scoller, Conveyor, Planshifter, Centrifugal, Chakki, Packaging Machine, and a lot more as per the requirement.

Flour Mill Plant Features:

Easy to Operate and Maintain

Simple with Design with Sturdy Construction

High Efficiency

Lower Energy Consumption

Low Noise

Pollution-Free Operation

The grinding temperature is controlled below 15°

Conclusion:Flour Mill Plants are an essential part of the food industry. They play a crucial role in the production of high-quality flour. The use of modern technology has made the process more efficient, reliable, continued operation performance, low noise, and long-life service resulting in the production of high-quality flour at a faster rate.

0 notes