#robot agv

Explore tagged Tumblr posts

Link

Tôi muốn tìm công ty sản xuất robot AGV ở Hà Nội. Nhờ cộng đồng mạng giới thiệu giúp tôi nhà máy nào uy tín? Xin cảm ơn.

0 notes

Text

QR Code Recognition Tracking, a variety of QR Code Recognition packages are available in ROS, which allows the robot to follow forward and backward, left and right by moving the QR Code.

#artificial intelligence (ai)#science and technology#higher education#ros#innovation#robot#agv#robotics#autonomous robot#intelligent#qr

4 notes

·

View notes

Text

Hope you're having a great day. Tandem puzzles are a great way to maximize parking density in your multifamily developments.

And, unlike conventional parking space tandems, our tandem puzzle systems can be accessed independently at the push of a button. No attendant needed. So what makes our tandem puzzle systems unique?

Well, let me give you the top ten reasons.

Number one, we offer the widest array of puzzle systems from one high to seven high systems with clear heights from five foot three inches to seven feet one inch per level.

Number two, unique in the market, We offer one to two levels of tandem pits.

Number three, we share a common leg, which can tighten the distance between the front row and the rear row. For above grade solutions, this means we are shorter in nose to tail length than our competitors. For a tandem pit, this translates into less gap filler and or minimal width for the partition wall in the pit.

Number four. For pits, we have a bridge that you can travel across to get to the rear for a smooth transition.

Number five. We can store more pounds per square foot, which translates into stowing heavier vehicles.

Number six. We offer a three high one deep tandem configuration, which is unique in the industry.

Number seven. We offer a two deep tandem pit solution, unique in the United States.

Number eight, for tandem pit solutions, we add our gap fillers around the perimeter.

Number nine, front and back sensors to prevent parking overruns and height sensors on the top level to prevent vehicle damage.

And number ten, chain tensioners that sense if there is an object in its path to stop the system.

If you click on the comments below, you will see a three high tandem puzzle illustrating how they move.

Let's design something together.

Looking forward to designing something with you soon.

Free Consultation Call at (661) 430-3244 or visit us at https://lnkd.in/g8EMe2ji

#parkingautomation #parkingautomatedsolutions #desigmcustomparking #carparkingstackers #constuctiondevelopers #parkingengineersolutions #parkingdesigns #innovativeparkingsolutions #fastroboticparking #automatedparking #parkingdevelopers #commercialdevelopers #builders #construction #parkinginnovations #carstackers #parkingstructures #roboticparking #maximizeparking #parkinginnovations #savespace #carparkingsolutions #smallspacesolution #nodewatering #smallspaceideas #parkingengineering #parkingspacesolutions #parking #newparkingsystem

Robotic Parking, Robotic Parking Garage, Puzzle Parking, Automated Parking, Automated Parking System, Automated Car Parking, Automated Parking Garage, Parking Stackers, Garage Car Stacker, Stack Parking System, Double Stacker, Triple Stacker, TAPCO, Puzzle Car Parking System, Car Parking Lift System, Lift Parking System, Car Stacker, Car Stacker Lift AGV, #AGV, #tapco, #automatedparking, #puzzleparking, #stackers

2 notes

·

View notes

Text

Robouter Cerebro Robot

Robouter Cerebro Robot : El Cerebro de Alto Rendimiento para la Revolución de la Robótica Industrial En la era de la Industria 4.0, la automatización industrial y la eficiencia operativa son fundamentales para la competitividad. Exellios® presenta Robouter, una innovadora solución de alto rendimiento diseñada para potenciar Vehículos Guiados Automatizados (AGV) y Robots Móviles Autónomos (AMR).…

#Almacén automatizado#automatización industrial#Cómo mejorar la eficiencia con robots móviles autónomos#Codificación de video de alta resolución#Comprar computadora integrada AGV#Computadora de placa única AGV#Computadora de placa única AMR con procesamiento de video 8K#Computadora de placa única para robots móviles autónomos#Computadora integrada AGV#Conectividad industrial#Exellios Robouter#Fábrica inteligente#Gateway LoRaWAN 5G#Gateway LoRaWAN 5G para aplicaciones industriales#Gateway LoRaWAN 5G para entornos industriales#Industria 4.0#Inteligencia artificial (IA) robótica#IoT Industrial#Logística automatizada#Mejor computadora de placa única para AMR#Navegación autónoma#Placa de computadora integrada AGV con IA#Procesador octa-core para robótica industrial#Procesamiento de video 8K#Robótica industrial#Robots móviles autónomos (AMR)#Robouter#Sistema de control de alto rendimiento para AGV#Sistemas de navegación autónoma para AGV de almacén#Sistemas integrados industriales

0 notes

Text

Small but Mighty: The Gear Motor Changing the Robotics Game

Robots are becoming smarter, more compact, and more powerful than ever—and at the heart of this evolution is the compact gear motor. Just because it’s small doesn’t mean it lacks strength.

From collaborative robots to autonomous delivery bots and warehouse automation systems, compact drive technology is reshaping how robots move, work, and interact with the world. But what makes these small components such a big deal?

In our latest blog post, we break down the rising demand for compact gear motors in robotics and how BonSystems’ BSR reducers and BCSA smart actuators are pushing the boundaries of what's possible in tight spaces.

Curious how compact can still mean powerful? 🤖[Why the Robotics Industry Is Turning Its Eyes to Compact Gear Motors]

#Robotics#GearMotors#Automation#SmartActuators#CycloidalReducer#RobotDesign#AMR#AGV#CollaborativeRobots#BonSystems#FutureOfMotion

0 notes

Text

AGV Wheel – SWT Series: Precision, Stability & 360° Mobility

The AGV Wheel – SWT Series is designed for AMRs and material-handling robots, featuring an integrated motor and harmonic gear reducer for smooth, low-noise operation. It ensures minimal vibration and enables 360° rotation for seamless movement in AGVs.

Enhance AGV performance with the high-precision SWT Series Wheel

0 notes

Text

AMR with Industrial Automation Station and COBOT | Manufacturer in Pune

Hytech Didactic in Pune offers AMR and AGV training cells, COBOT automation stations, and robotics systems for education and industry. Explore innovation!

#AMR Training Cell Manufacturer Pune#AGV Training Cell Supplier Pune#Industrial Automation Station with COBOT Pune#Didactic Robocell Pune#Educational Robots Pune#Robotics Training Systems Pune#AMR and AGV Training Pune#Collaborative Robots Training Pune#SMR AGV Manufacturer Pune#Educational AMR Solutions Pune

0 notes

Text

Robot de stationnement de voiture AGV, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 6 Premières Entreprises

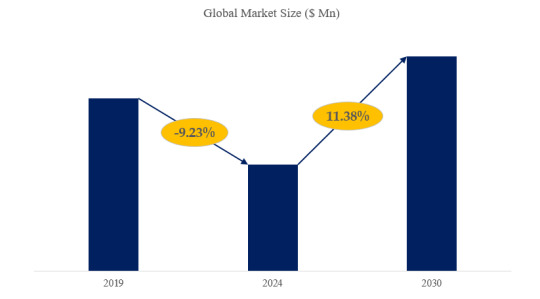

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Robot de stationnement de voiture AGV 2024-2030”, publié par QYResearch, la taille du marché mondial de Robot de stationnement de voiture AGV devrait atteindre 73 millions de dollars d'ici 2030, à un TCAC de 11.4% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Robot de stationnement de voiture AGV (en millions de dollars américains), 2019-2030

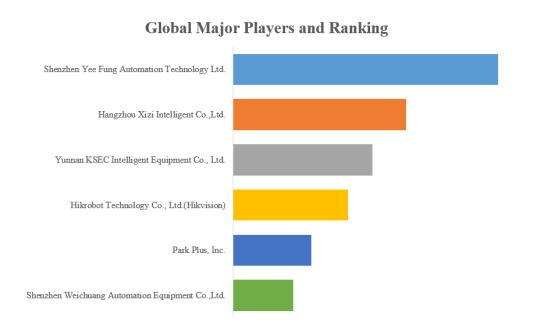

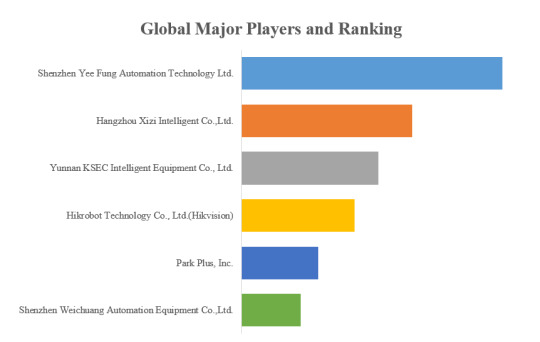

Selon QYResearch, les principaux fabricants mondiaux de Robot de stationnement de voiture AGV comprennent Shenzhen Yee Fung Automation Technology Ltd., Hangzhou Xizi Intelligent Co.,Ltd., etc. En 2023, les trois premiers acteurs mondiaux détenaient une part d'environ 39.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 6 premiers acteurs mondiaux de Robot de stationnement de voiture AGV (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

The Team Robotics: Driving Efficiency and Innovation with Advanced Robotic Solutions

Introduction

The Team Robotics is a leading industrial robot manufacturer based in Chennai, India, known for its cutting-edge robotic solutions. We excel in delivering innovative, high-performance technology that enhances productivity and efficiency. Our commitment to in-house development ensures cost-effective, tailored solutions for diverse industries. As a top robotics company in India, we are transforming the future of industrial automation.

The Team Robotics: Pioneering Industrial Robot Manufacturers in Chennai

The Team Robotics stands at the forefront of industrial automation, emerging as a leading industrial robot manufacturer in Chennai, India. Our company has earned a reputation among the top robotics companies in Chennai and his Ro-WAITER Robots as one of the best robotics in India. We specialize in creating innovative, cutting-edge robotic solutions that cater to the unique needs of various industries.

Revolutionizing Industrial Automation with Advanced Robotics

At The Team Robotics, we are dedicated to revolutionizing industrial automation with our advanced Human Robot Manufacturer technologies. Our smart industrial robots are engineered to enhance productivity, efficiency, and safety in manufacturing processes. By leveraging state-of-the-art technologies, we provide customized robotic solutions that address the specific challenges of different sectors.

The Growth of Robotics Companies in Chennai

Chennai has become a hotbed for robotics innovation, with numerous companies contributing to its dynamic growth. Among these, The Team Robotics stands out as a trailblazer, consistently ranking among the top 10 robotics companies in India. Our commitment to excellence and relentless pursuit of technological advancement have established us as a preferred choice for businesses seeking top-notch robotic solutions.

Indigenous Manufacturing: A Core Strength

A core strength of The Team Robotics is Agv Robot Suppliers. By developing all our technologies in-house, we can offer cost-effective solutions without compromising on quality or performance. This approach allows us to stay at the forefront of the industry and provide our clients with reliable, high-quality robotic systems that are tailored to their specific needs.

Smart Dinner Robots: Enhancing the Dining Experience

One of our innovative products is the smart dinner robot, designed to transform the dining experience in restaurants and hospitality settings. These robots utilize advanced vision systems to navigate and interact with customers, improving service efficiency and overall customer satisfaction. This groundbreaking innovation underscores our position as one of the top robotics companies in Chennai, leading the way in service automation.

Automated Guided Vehicles (AGVs): Optimizing Material Handling

Our Automated Guided Vehicles (AGVs) are revolutionizing material handling processes in various industries. These next-gen AGVs are equipped with cutting-edge navigation and safety technologies, ensuring seamless integration into existing workflows. As a leading robotics manufacturing company in India, we prioritize reliability and efficiency in all our products, helping businesses optimize their operations.

Humanoid Robots: The Future of Human-Robot Interaction

Humanoid robots represent the future of human-robot interaction, and The Team Robotics is at the forefront of their development. Our advanced humanoid robots are capable of performing complex tasks, interacting naturally with humans, and adapting to various environments. This revolutionary technology solidifies our standing as one of the best robotics companies in India, pushing the boundaries of what robotics can achieve.

Vision Solutions: Precision and Accuracy in Industrial Applications

Vision solutions are crucial for precision and accuracy in industrial applications. At The Team Robotics, we have developed advanced vision technologies that enable our robots to perform tasks with exceptional accuracy, reducing errors and enhancing overall efficiency. This expertise places us among the industry-leading robotics companies in India, trusted by clients across various sectors to deliver cutting-edge solutions.

The Competitive Edge: Innovation, Quality, and Customer Satisfaction

The competitive edge of The Team Robotics lies in our unwavering commitment to innovation, quality, and customer satisfaction. Our in-house development capabilities ensure we stay ahead of industry trends, offering the latest advancements in robotics technology. Our customer-centric approach guarantees that we provide unmatched quality and performance in all our products, making us a trusted partner for businesses seeking reliable robotic solutions.

Conclusion

The Team Robotics is poised to continue leading the robotics industry with our transformative and future-ready innovations. Our dedication to developing indigenous technologies and providing cost-effective, high-quality solutions ensures we remain at the forefront of industrial automation. For businesses seeking the best in robotics, The Team Robotics is the top choice among robotics companies in Chennai and across India. Our vision is to redefine the landscape of industrial automation, creating smarter, more efficient solutions for a rapidly evolving world.

#robotics companies in chennai,#robot manufacturing companies,#top robotics companies in india,#top 10 robotics companies in india,#robotics making companies in india,#top robotics companies in chennai,#best robotics company in india,#best robotic company in chennai,#robots manufacturing in chennai,#robotic company in chennai,#automatic guided vehicle,#robotics in india,#humanoid robot,#agv in robotics,#food serving robot,#intelligent robot manufacturers & suppliers in india,#dinner robot manufacturers companies in chennai,#best dinner robot manufacturers companies in chennai,#ai waiter food delivery robot,#automatic restaurant robot,#robots serving food at restaurants,#robo diner,#dinner robot manufacturers,#smart dinner robot,#dinner robot manufacturer in chennai,#humanoid robot manufacturers & suppliers in chennai,#humanoid robot manufacturers companies in chennai,#best humanoid robot manufacturers companies in chennai,#humanoid,#humanoid sale,#first humanoid robot,#humanoid robot for sale,#humanoid robot price,#humanoid online,#ai humanoid robot,#best humanoid robot,#realistic human robot,#a humanoid robot,#agv robot,#warehouse agv,#agv robot warehouse,#agv industrial robot,#automated guided vehicles agv,#largest agv manufacturer,#small agv robot,#agv mobile robot,#agv robot manufacturer in chennai,#autonomous guided vehicle robot.

#robotics companies in chennai#robot manufacturing companies#top robotics companies in india#top 10 robotics companies in india#robotics making companies in india#top robotics companies in chennai#best robotics company in india#best robotic company in chennai#robots manufacturing in chennai#robotic company in chennai#automatic guided vehicle#robotics in india#humanoid robot#agv in robotics#food serving robot#intelligent robot manufacturers & suppliers in india#dinner robot manufacturers companies in chennai#best dinner robot manufacturers companies in chennai#ai waiter food delivery robot#automatic restaurant robot#robots serving food at restaurants#robo diner#dinner robot manufacturers#smart dinner robot#dinner robot manufacturer in chennai#humanoid robot manufacturers & suppliers in chennai#humanoid robot manufacturers companies in chennai#best humanoid robot manufacturers companies in chennai#humanoid#humanoid sale

0 notes

Text

The 5G security inspection robot system RS-INS adopts a multi-device coupling system, starting from mechanism design and optimization, motion planning and control, state estimation and environment sensing, etc. It realizes 4K HD backhaul, remote real-time control, multi-line patrol, target tracking and localization, daytime + nighttime dual-lighting shooting, etc. through a 5G network. It supports multi-channel video-on-demand and video playback. It supports multi-video on-demand and video playback and can realize routine inspection in complex terrain, remote cloud operation, automatic archiving and analysis in the background, etc. It solves the problems of high intensity of manual inspection, uneven quality, and inability to adapt to the complex terrain of the substation, and explores intelligent security and inspection.

#artificial intelligence (ai)#science and technology#5g#higher education#ros#robot#innovation#intelligent#autonomous robot#agv#robotics

4 notes

·

View notes

Text

The Automated Parking Company helps cities and urban development investors with the parking systems to help get their housing projects approved faster and built faster.

The Automated Parking Company designs, manufactures, installs, services and maintains semi-automated parking systems and is your OEM.

Maximize Parking & Vehicle Storage Capacity at your urban multi-family facility, commercial propery or hotel.

Call Scott For Free Copies of Our Systems Specification Sheet and even Free Parking Designs at (877) 827-2611

#puzzleparking #parking #urbanplanning #parkingsolution #maximizeparking

#puzzleparkingsystem #puzzleparking #urbanplanning #mechanicalstackers #parkinglifts #verticalparking #cityparking #parkingdesigns #automatedparking #puzzleparking #publicparking #parkinglot

#sandiegoparking #cityparking #parkingmeter #parkingsystem #verticalparkinglift #parkingelevator #maximizeparking #vehiclestorage

#the automated parking company#automated parking systems#puzzle parking system company#puzzle parking#puzzle parking system#puzzle parking system price#agv parking system#puzzle parking system cost#puzzle parking systems#agv parking#robotic parking garage#automated garages

0 notes

Text

Navigating the Complexities of the Automated Guided Vehicle Market: Innovations, Market Entry Strategies, and Industry Outlook

The global automated guided vehicle market size is anticipated to reach USD 9.18 billion by 2030, registering a CAGR of 9.7% from 2023 to 2030, according to a new report by Grand View Research, Inc. Automated guided vehicles (AGVs) have transformed the way materials can be moved within the manufacturing and distribution facilities. In a production environment where several operations are carried out simultaneously, these vehicles ensure a predictable and reliable transfer of raw materials and manufactured products from one point to another within the facility, thereby eliminating any potential disruption in production.

Automated Guided Vehicle Market Report Highlights

The unit load carrier segment is expected to expand at the fastest CAGR over the forecast period owing to its ability to handle multiple items simultaneously, reducing the number of trips required and, potentially, handling costs

Natural navigation technology’s adoption is expected to grow significantly over the forecast period as it enables businesses to easily modify and expand the guide path of the AGV

Assembly line application is expected to have the highest CAGR over the forecasts period as assembly line AGV are replacing traditional mechanical production lines

The manufacturing segment dominated the market in 2022 and accounted for a revenue share of over 77%. The growing adoption of automated guided vehicles across various industries can be attributed to the benefits offered by AGVs in terms of productivity, safety, and accuracy

The service segment is anticipated to be the fastest-growing segment in the forecast period. This growth can be attributed to the rising demand for various services, which include preventive and corrective maintenance, vehicle and software health check, and training employees directly or indirectly with the operation of AGVs

Europe dominated the market in 2022 and accounted for a revenue share of over 30%. Rising investments in the manufacturing sector's technological advancement are expected to improve the AGV market in Europe

For More Details or Sample Copy please visit link @: Automated Guided Vehicle Market Report

These vehicles can operate safely around structures, machinery, and employees, as they are equipped with accessories, such as camera vision and LiDAR sensors, which help detect junctions, identify floor signs, and avoid collisions with any obstacle. For instance, in November 2021, Quanergy Systems, Inc., a U.S.-based company that offers an AI-powered LiDAR platform, launched the new M1 Edge 2D LiDAR sensors for automation. The newly launched LiDAR sensor is light in weight, broad 360°, with a sensing capability of up to 200 meters used in mobile robotics, AGVs, warehouse logistics applications, and port automation.

Several manufacturing plants and warehouses deploy material handling equipment for various activities, such as locating stock, picking orders, and moving products and raw materials. Transportation and logistics firms are mainly focusing on deploying such equipment to boost the efficiency of their operations in line with the growing demand for their services. For instance, in March 2023, MasterMover Ltd, a prominent manufacturer of electric tug and tow solutions, announced a collaboration with BlueBotics, a navigation, robotics, and industrial automation company.

The partnership intends to offer best-in-class Autonomous Navigation Technology (ANT) technologies for MasterMover's range of AGVs. In February 2021, Scott (Transbotics Corporation), a prominent solution provider for AGVs, partnered with KUKA AG, a German manufacturer of robots, to coordinate the industrial robots of KUKA AG into material handling systems. Further, these robots would also benefit the warehouse team in assembling, packaging, welding, storing, and shipping. Also, material handling solutions are used to increase transportation efficiency, decrease physical damage to the material, and reduce overheads by limiting the number of employees.

The AGV market is witnessing a progressive switch from lead-acid to lithium-ion batteries. Lithium-ion batteries offer several advantages over lead-acid batteries. They tend to be lighter and more compact. They can charge faster, provide longer runtimes, and support more charge cycles. Hence, they are ideal for AGVs, as they need not be charged frequently during operating shifts or in 24x7 operating environments, and AGVs running on lithium-ion batteries can offer higher round-trip efficiencies. For instance, in March 2021, Nissan Motor Co., Ltd, a global manufacturer of automobiles, buses, and trucks, stated that they use lithium-ion batteries to power their automated guided vehicles, which no longer need a worker to remove the battery and plug them in it charges faster. These batteries let AGVs last longer and bring significant innovations to their warehouse.

#AutomatedGuidedVehicle#AGV#Robotics#Automation#MaterialHandling#Logistics#Industry40#SupplyChain#WarehouseAutomation#AutonomousVehicles#Transportation#Manufacturing#MarketAnalysis#TechnologyTrends#Innovation#AGVSolutions#GlobalMarket#AGVMarketTrends#IndustryInsights

0 notes

Text

AGVs: The Unsung Heroes of Smart Logistics 🚀

Ever wondered how warehouses run with machine-like precision? How goods seem to flow effortlessly from one point to another without human intervention? The secret lies in AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots)—the silent powerhouses of modern logistics.

These robotic transporters don’t just move materials; they think, adapt, and optimize—navigating complex environments, rerouting in real time, and working tirelessly 24/7. But beneath the sleek automation lies something even more crucial: their motors and reducers.

Without a high-torque, energy-efficient motor, an AGV is just a shell. It needs: ⚙️ Power to carry heavy loads effortlessly 🔋 Efficiency to run continuously without excessive energy consumption 🛠️ Durability to withstand long-term operations

In the world of intelligent logistics, the right motor doesn’t just power a machine—it drives an entire industry forward.

0 notes

Text

Navigating Challenges in AGV Manufacturing: A Roadmap to Success

In the ever-evolving landscape of industrial automation, Automated Guided Vehicles (AGVs) have emerged as pivotal players, streamlining material handling processes across various industries. However, the journey towards integrating AGV systems into manufacturing facilities is not without its set of challenges. In this blog post, we'll delve into the key hurdles faced in AGV manufacturing and explore effective strategies to overcome them.

1. Limited Customization Options

AGV systems often need to be tailored to specific manufacturing environments, which can pose challenges due to limited off-the-shelf solutions. Manufacturers frequently encounter issues aligning AGV design with the unique layout and requirements of their facilities.

Overcoming Strategy: Flexible Design Approaches

Implementing modular and scalable AGV designs allows for greater customization. Utilizing a flexible design approach facilitates easy adjustments, ensuring AGVs seamlessly integrate into diverse manufacturing setups.

2. Navigation in Complex Environments

Navigating AGVs through intricate manufacturing spaces, especially those with dynamic layouts or temporary obstacles, presents a significant challenge. Conventional navigation systems may struggle to adapt to real-time changes.

Overcoming Strategy: Advanced Navigation Technologies

Leveraging advanced navigation technologies such as LiDAR and computer vision enables AGVs to perceive their surroundings dynamically. Integrating these technologies enhances AGV adaptability in complex environments, reducing the risk of collisions and improving overall efficiency.

3. High Initial Implementation Costs

While the long-term benefits of AGV integration are evident, the upfront costs of implementing AGV systems can be a barrier for some manufacturers. This challenge often hinders smaller enterprises from embracing this technology.

Overcoming Strategy: ROI-focused Implementation Plans

Developing a comprehensive return on investment (ROI) plan that outlines the long-term cost savings and efficiency gains helps justify the initial investment. Emphasizing the tangible benefits of AGV implementation can encourage businesses to view it as a strategic investment rather than a financial burden.

4. Workforce Adaptation and Training

Introducing AGV systems into a manufacturing environment requires the workforce to adapt to new technologies. Resistance to change and lack of adequate training can impede the smooth integration of AGVs into daily operations.

Overcoming Strategy: Employee Training Programs

Investing in comprehensive training programs for the workforce ensures that employees are familiar with AGV operations and safety protocols. Involving employees in the transition process and highlighting the collaborative nature of human-robot interaction can foster a positive attitude towards AGV integration.

Conclusion

AGV manufacturing, while revolutionary, comes with its share of challenges. However, by addressing these challenges head-on through flexible design approaches, advanced navigation technologies, strategic financial planning, and employee-focused initiatives, manufacturers can pave the way for successful AGV integration. Overcoming these hurdles not only streamlines current operations but positions businesses to thrive in the era of advanced industrial automation.

#AGV ROBOTIC MANUFACTURE#DUNSCART AGV ROBOT IN CHENNAI#BEST AGV ROBOT MANUFACTURER#Warehouse AGV MANUFACTURER IN CHENNAI#AGV Robot Warehouse#Largest AGV Manufacturer

0 notes

Text

AMR with Industrial Automation Station and COBOT | Manufacturer in Pune

Hytech Didactic in Pune offers AMR and AGV training cells, COBOT automation stations, and robotics systems for education and industry. Explore innovation!

#AMR Training Cell Manufacturer Pune#AGV Training Cell Supplier Pune#Industrial Automation Station with COBOT Pune#Didactic Robocell Pune#Educational Robots Pune#Robotics Training Systems Pune#AMR and AGV Training Pune#Collaborative Robots Training Pune#SMR AGV Manufacturer Pune#Educational AMR Solutions Pune

0 notes

Text

Robot de stationnement de voiture AGV, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 6 Premières Entreprises

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Robot de stationnement de voiture AGV 2024-2030”, publié par QYResearch, la taille du marché mondial de Robot de stationnement de voiture AGV devrait atteindre 73 millions de dollars d'ici 2030, à un TCAC de 11.4% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Robot de stationnement de voiture AGV (en millions de dollars américains), 2019-2030

Selon QYResearch, les principaux fabricants mondiaux de Robot de stationnement de voiture AGV comprennent Shenzhen Yee Fung Automation Technology Ltd., Hangzhou Xizi Intelligent Co.,Ltd., etc. En 2023, les trois premiers acteurs mondiaux détenaient une part d'environ 39.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 6 premiers acteurs mondiaux de Robot de stationnement de voiture AGV (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes