#robot calibration solutions

Explore tagged Tumblr posts

Text

Revolutionizing Precision: How Automated Measuring Systems Are Changing

The Game In today’s high-tech manufacturing and robotic landscape, precision is no longer a bonus—it's essential. As industries have stricter tolerances, faster production times, and flawless quality control, you can push the limits with specialized automated measuring systems—precision, efficiency and reliability in ways traditional measurement cannot support—and Dynalog is leading the way.

What are Automated Measuring Systems?

Automated Measuring Systems (AMS) use sophisticated technology to perform measurements automatically, without operator input. Automated Measuring Systems use a combination of sensors, robotics, software and analysis to provide measurements with extremely high accuracy, in real time. AMS can verify dimensions on a complex piece of material, check the position of the end effector on a robotic tool, or complete an entire inspection routine---and can do this quickly, at a consistent level of accuracy. For the manufacturer or production facility, AMS provide lower risk of error, faster throughput, and a better quality of product quality. It is not surprising that companies, like Dynalog, are advancing these systems for industries such as automotive, aerospace, electronics and medical device manufacturing.

The Importance of Accuracy is UndeniableIn manufacturing,

a difference of just 0.01mm can mean the difference between a product that works perfectly and one that does not work. As parts become smaller and more complicated, the margin of error is decreasingly smaller! Manual measurement is often human error-prone, slow, and inconsistent.

That’s why Dynalog has automated measuring systems.

Automated measuring systems take human error out of the equation and provide repeatable, consistent, real-time measuring data. With real-time feedback, manufacturers can change their processes on the spot, eliminating scrap and saving money.Dynalog: The Leaders in Robotic Accuracy and CalibrationAt Dynalog, accuracy is not just a marketing statement, accuracy is at the core of everything they do. With extensive experience in robotic measuring, calibration, and inspection systems, they build state-of-the-art solutions for the next generation of manufacturing.Automated measuring systems integrate with robotic arms and production lines, every movement and measurement is accurate and traceable. From Robot TCP Calibration to validating robot performance, Dynalog measuring systems are for manufacturers that cannot afford to be inaccurate.Key Dynalog Solutions for Automated MeasurementDynaCal® – A cutting-edge robotic calibration system providing sub-millimeter accuracy

Advantages of Automated Measurement Systems in ManufacturingLet's look at the rationale of why automated measurement is becoming the new standard in the industry:

1. Superior PrecisionAMS (Automated Measurement Systems) eliminate the subjectivity of the human eye and achieve measurements to the micron level of precision. For high-stakes industries like aerospace and medical equipment where safety is a stringent criteria, this level of precision is critical.

2. Accelerated Production Cycles Manual inspections hinder production, whereas with AMS, measurements occur in real-time—in-line or near-line—removing bottlenecks and even shortening delivery times.

3. Minimized Scrap and ReworkBy identifying deviations early in the process, manufacturers can take steps to correct defects prior to irreversible mistakes, resulting in more yield and less scrap.

4. Data-Driven DecisionsDynalog's systems not only measure, but they analyze. The real-time data can be accessed and input into process control systems to help engineers make informed data-based decisions for continuous improvement.

5. Easy Updated IntegrationToday’s AMS systems, like Dynalog's, can actually integrate with the existing robotic systems and software, creating a quick, affordable transition to your automated solution.

#automated measuring systems#robotic measurement systems#robot calibration solutions#Dynalog measuring systems#robot TCP calibration#manufacturing automation#industrial robotics#robot inspection technology#precision measurement tools#Industry 4.0 solutions#manufacturing quality control#3D robotic measurement#Dynalog USA#robotic accuracy systems#advanced measuring systems

0 notes

Text

A4988 Current Limit: How to Set A4988 Driver Current Limit?

Setting the A4988 current limit is crucial for ensuring optimal performance and preventing overheating of the motor and the driver itself. The A4988 allows you to adjust the A4988 current limit by manipulating the voltage on the VREF pin.

Here’s a step-by-step guide on how to set the current limit on the A4988:

Steps To Set Current Limit On A4988:

Understand the A4988 Pinout: Familiarize yourself with the A4988 pinout, particularly the VREF pin, which is used to set the A4988 current limit.

Determine the Desired Current: Know the current specification of your stepper motor. This information is typically provided in the stepper motor datasheet.

Identify the Sense Resistor Value: Check the A4988 module or datasheet to find the value of the sense resistor (often around 0.05 ohms). This value is needed for the A4988 current limit calculation.

Read More: A4988 Current Limit

#A4988#currentlimit#microstepping#steppermotor#driver#electronics#robotics#automation#engineering#technology#DIY#hobby#project#tutorial#guide#howto#settings#configuration#parameters#adjustment#calibration#optimization#performance#efficiency#powerconsumption#heatdissipation#troubleshooting#problem#solution#support

0 notes

Text

Gleberman's podcast, take 2: the video edition

I volunteered to take one for the team, again, this time watching (or trying to, at least) the video version of Gleberman's infamous podcast on Youtube (if you are a masochist, like me, feel free: https://www.youtube.com/watch?v=l_md73Ws2O4&t=303s). You see, I was so intrigued by the OTT praise that I wanted to see the live reactions. To do so, I even watched it at a 0,25 reduced speed ratio, just to catch up those pesky, spontaneous facial expressions he couldn't possibly hide.

Let's start with what we all know: in 10 years, S is much, much better at hiding his game and almost proficient at mastering the poker face. But if you really pay attention (and I did), you might still notice some interesting things: after all, we aren't robots and we can't calibrate or control everything. So, here's my take on what I saw, with screencaps, and covering only the bits I quoted in my first post (https://www.tumblr.com/sgiandubh/733285180488450048/and-kia-ora-to-new-zealand-like-youve )- the rest was really beyond my patience and goodwill abilities, to be honest.

A word and a question on the staging of this podcast, before anything else. I am always paying great attention to the outfits of the people who participate, because I believe they are an integral part of the show itself. While Gleberman's was, to be honest, unacceptably sloppy, S was right on point the message he wanted to convey, with the short-sleeved (?) khaki shirt that spelled three things: Bachelor. Traveler/Explorer. Tropical Chic. As a side note, I wish he'd been dressed like that in the Nevis resort suite snippet: not the usual Peter Panesque/Marty McFly/boyz in da hood outfit. But hey, that's just me, what do I know, after all, maybe the boy really feels more relaxed in those. Brand-wise, however, I will never cease to drum up the urgent need to step up the outfit game and start aligning it with the real age.

The other thing that intrigued me is common to S and C: their love of cupboards and hallways when it comes to playing the show/not show game on podcasts 'from home'. Because they know we watch and because they know, by now, we are probably worse than the MI-6, we're left with... eh... nothing. He apparently found the perfect solution with that sort of a connecting space he is always showing us, lately. Seriously, though, who the hell places himself in front of an opening (sliding door?) to a bigger room, except when wanting to block both the view and any other interpretation? Heh. Things that make one go 🤔.

Anyways. Let's have a look at some reactions I have screencapped:

Gleberman: 'same sweetest person and like an amazing human being'.

Translation: I am pursing my lips and bracing myself for the rest of the #silly compliment. I can't possibly express how much this annoys and embarrasses the bejesus out of me. But hey, Monica, have at it and let's be done already with this circus.

Gleberman: '...and friend to talk to and I just love you.'

Translation: I close my eyes because I don't want to hear the OTT crap this woman is shamelessly peddling around. I cross my arms defensively, because this is the best I can do. I really pray internally she'd immediately stop it, somehow (though I am fully aware she won't and this is just the beginning). She definitely overstepped a red line and I don't want to be a part of it.

S: '.I think there's...there's a lot of smoke and mirrors, this is ALL fake.'

Translation: I am talking with my hands to make a point (and also to show off the damn rings - oh, Lord, let them talk about these to oblivion, on socials). I am also covering my face with a gesture evocative of a smoke curtain, because ultimately I feel the need to protect myself from the smiling entity on the other side of my screen and because, at the same time, I know exactly what I did here. Oops, I just unleashed another half-in-jest zeppelin, that people could pretzel exactly how they see fit. However, it's true: my public persona is a carefully curated lie. Peekaboo, underneath I know very well what my committed truth is.

S: ' I am the double'.

Translation: I am opening my arms and I am puffing out my chest. There, I've said it. Ha! I am in full defiant mode, now. I meant every single word I just said and damn the consequences.

I wish I'd had the patience to watch it all. But I think I've managed to analyze the most interesting part of it. Overall, there was quite a bit of stress involved on S's side (lots of chin grabbing, etc), the only one I was interested in. She was simply not worth my attention and I doubt she, unlike many other people in the media, 'knows stuff'. If anything, that only served to validate my first impressions.

And yes, always look for the presence of the teeny-tiny abnormal detail. Sometimes (not always) it can prove rewarding.

127 notes

·

View notes

Text

They're always on time, and their work's always prime!

profile undercut~

Name: Robot Pronouns: they/she/he (used in rotation, starting with they/them each time) Gender/sexuality: genderfluid + aromantic + asexual Species: human Height: 5’9” Age: late 20s Occupation pre-dungeons: student, general office/deskwork, IT worker Dungeon wish: to live a life without sleep :) Fighting style: actually doesn’t physically do 90% of the fighting. Rather, they pilot a mech, which can take and throw a punch leagues better than they can on their own. As such they don’t really fight with actual hand to hand/long range strategies, but with strategies befitting of a card game. Their mech can be upgraded to handle a variety of weapons, and they have no real leaning towards particular specializations. In fact, they prefer to be as generalized as possible! This gives them a wide range of actions to take, and even when pieces of their mech get deactivated or damaged, they’re not missing a vital piece of their fighting ensemble. TLDR they cover all their bases and then go with whatever strategy best serves them in the moment (close combat, range, stack damage, just dodge, etc). Strengths: extremely pragmatic, completely unbothered by fast paced/stressful situations, once they’ve set their sights on a particular task they’ll see it through to the best of their ability, able to step back and view most situations from a practical/logical viewpoint without much emotional involvement, well versed in politeness and niceties, extremely slow to anger, always gentle, kind -but NOT to the point where open abuse is met with compliance- and firm, knows when to put things down and walk away if it’s really not getting anywhere, insightful, perfect memory/recall, avid listener and reader, catalogs all information learned about people to best calibrate a workspace/living space suited to them, well aware of their limits and strives to accommodate them and become the best version of themself, able to navigate complex situations/puzzles/problems easily, operates fine on little sleep, very good at controlling emotions, always offers to help others Weaknesses: has a surprisingly cynical worldly outlook- bad things are bound to happen and everyone is bound to lose everything good eventually/people never stay forever/the world is a cruel place- despite their determination to be kind- which is driven by “not wanting to contribute” to the badness of life, the reason they work so well on little sleep is because they’re an insomniac and are used to it, likewise they’re used to controlling their emotions because they don’t actually know how to properly process them, has low physical endurance/strength which makes keeping up with high energy physical activities impossible, and they hardly ever ask for help from others with their own issues (unless they’re a licensed therapist. But cmon dude let your friends help you at least a little) Personality: Robot is a soft spoken, incredibly well mannered person of very mild disposition. They’re not very good at emoting through facial expressions or body language, but they carry their mood in sparks in their eyes to offset the uncanny effect. They’re always polite and kind to everyone, though by no means a pushover- more like a rock that lets water flow over it and remains unchanged no matter how wild the waves are. Robot is highly intelligent, well read, and has several college degrees under their belt, an avid lover of learning anything and everything. They can seem offputting with their textbook voice cadence and quiet observation of their surroundings, but they genuinely don’t mean any harm, nor do they try to be the smartest in the room. They’re genuinely delighted to learn they aren’t! They’re constantly striving to better themself, staying up to date on all the best ways to manage nutrition, time outside, screentime, hobby time, etc- you name it, they’ve got self help books on it. They’ll never try and push solutions on people who don’t ask, but they will absolutely try to assist in any way they’re able should someone (who isn’t in the business of harming people) request their assistance.

15 notes

·

View notes

Note

Is there something that says the animatronics are real in universe that I missed/forgot??

Yup! They are real.

The main plot of FNAF AR is that Fazbear Entertainment partnered with a company called "DLZ Shipping Solutions" to mass produce animatronic models, using recycled parts and chips from old animatronics as a reference. Those new models are then delivered to people who sign up to the Fazbear Funtime Rental Service, also known simply as the Fazbear Funtime Service. During the project, some vintage hardware caused a virus to appear in the system and make the animatronics go haywire.

This is all spelled out in the E-Mails you can receive. There's way too many to describe in detail, you can find them easily in the Freddy Fazbear's Pizza Wiki if you're curious. I'll leave here some of the more notably quotes, showing how DLZ Shipping Solutions designed these new animatronic models (most of these are about Mangle because it just has the most detailed explanation lol):

As a callback to the classics, for a limited time only we are adding to the Eternal Package a recreation of the vintage "Mangle" animatronic!

I've been looking over those reports on the motility tests for the new model and I gotta say I'm a little disturbed. The original was purportedly able to move along the ceiling, and from what I'm seeing here, we're having issues getting our rebuilds to even move on level ground properly.

There's a huge difference between a new model based on the same bipedal chassis and one based on a... A spider? A tripod? The locomotion is completely different, which means the power needs are different, the hydraulic calibrations have to be completely redone, and the CPU has to be switched out for a newer one with a faster baud rate. And then on top of all that, we have to put together this "Controlled Disassembly" feature?

I warned management that reproducing the more exotic endoskeletons would be a problem, and they decided to go ahead and put them on the schedule anyways. They're just going to have to live with the limitations of, you know, basic physics.

Toy Freddy is not safe to go out to the public. The interference happening with the upgraded facial recognition suite risks rendering all the safety functions on the users' handsets useless.

What do your people think, a computer controlled animatronic can somehow get into the holiday spirit and reprogram itself? It's just a machine controlled by a circuit board. It has to do what we tell it to and nothing more.

TL;DR

So, as you can tell from most of that, the animatronics in AR have to obey the laws of physics, have real endoskeletons that people have to put together, require hydraulic calibrations and real CPUs, and can be unsafe to the public. There's also an email mentioning how Springtrap smells but I don't have it on hand and I've already been writing this for way too long so Imma just leave that one for you to look for.

If we wanna include the scrapped emails, then there's also one talking about Bonnie EATING A STRAY CAT. Like, Bonnie, the robot, devouring a kitten whole. Again, I don't have it on hand so you're gonna have to find that yourself. Just thought it was worth mentioning.

I

I completely forgot about that last email you mentioned that was some wild whiplash LMAO

Thanks for the clarification though!! Guess my only question now is how Fazbear Entertainment keeps the cost of this kind of service manageable,,, They can create and ship hundreds of Springtraps to people houses, but having more than one Glamrock Freddy shell in case of emergency? Nahhhhhhhh who needs that

#Chip Chatter#I swear I never hear anyone talking about AR other than the occasional mention of the animatronics in it being real#I forgot there even *were* non-scrapped emails lmao#also by this logic- what the hell is the dark circus DLC#did they just send the player character to another fucking dimension?#hit them over the head and throw them in some weird ass house with the circus animatronics?#That's one way to keep someone quiet ig#I mean that's kinda what they did in TFTPP Help Wanted iirc- so that's not exactly out of character 4 Fazbear Entertainment

7 notes

·

View notes

Text

Torque Sensors: Precision Force Monitoring Powered by Star EMBSYS Technology

Torque sensors are essential tools in the measurement and control of rotational force in mechanical systems. From automotive testing and industrial automation to aerospace and robotics, torque sensors enable engineers to monitor performance, ensure safety, and improve efficiency. Star EMBSYS, a leader in embedded system innovation, offers advanced torque sensor solutions that combine mechanical precision with intelligent electronics for high-performance applications.

A torque sensor, also known as a torque transducer, measures the torque—or rotational force—applied to a shaft or axis. It can be used in both static (non-rotating) and dynamic (rotating) applications, making it highly versatile. Depending on the requirement, torque sensors can be based on strain gauge, magnetoelastic, or optical technologies. The electrical signal generated is proportional to the torque applied, which is then processed for display, control, or data logging.

Star EMBSYS leverages its deep expertise in embedded systems to develop smart torque sensor solutions that provide real-time, high-resolution measurements. Their sensors are integrated with embedded microcontrollers for advanced signal conditioning, filtering, and digital communication. This results in more stable, noise-free data and allows for seamless integration into modern control systems.

What sets Star EMBSYS apart is their ability to offer custom torque sensor systems tailored to specific industrial needs. Whether for a precision laboratory setup or a rugged field environment, Star EMBSYS provides sensors that include temperature compensation, overload protection, and customizable output ranges. The embedded software also supports features like zero-torque calibration, peak-hold modes, and fault diagnostics.

For industries working with rotating machinery—such as electric motors, pumps, or wind turbines—Star EMBSYS torque sensors offer both static and rotary variants. These sensors can output analog signals (0–5V, 4–20mA) or digital data via UART, CAN, or SPI, providing flexibility for integration with PLCs, DAQs, or cloud-connected IoT platforms.

Moreover, Star EMBSYS includes support for wireless telemetry in demanding applications, allowing real-time torque data transmission without slip rings or complex wiring—ideal for mobile machinery or test benches.

In summary, torque sensors play a vital role in the monitoring and control of mechanical systems. With its focus on smart design, embedded innovation, and application-specific customization, Star EMBSYS delivers high-performance torque sensor solutions that empower engineers and manufacturers to measure with confidence, accuracy, and efficiency.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

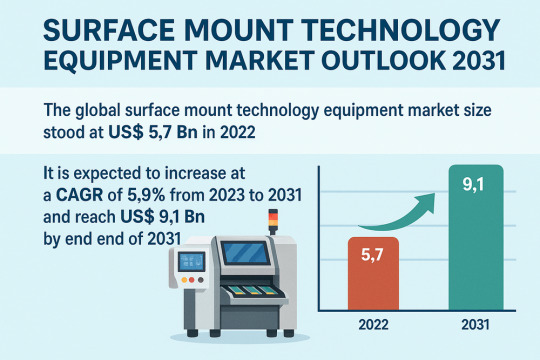

Miniaturized Components Boost Global SMT Equipment Market Demand

The global surface mount technology (SMT) equipment market is poised for substantial growth over the coming decade. Valued at USD 5.7 Bn in 2022, the market is projected to advance at a compound annual growth rate (CAGR) of 5.9% between 2023 and 2031, ultimately reaching USD 9.1 Bn by 2031. SMT equipment plays a critical role in the electronics manufacturing industry by enabling efficient, high-speed, and reliable assembly of surface-mounted components on printed circuit boards (PCBs). The widespread integration of miniaturized and high-performance electronics in consumer devices, automotive systems, telecommunications infrastructure, and industrial automation is significantly driving the adoption of SMT equipment.

Market Drivers & Trends

One of the major drivers of the SMT equipment market is the increasing demand for compact and lightweight electronic devices. With consumer electronics becoming smaller and more multifunctional, the need for advanced SMT machines capable of precise, high-speed placement of components has grown exponentially.

The ongoing shift toward Industry 4.0 and smart manufacturing is also influencing SMT equipment trends. Manufacturers are now integrating artificial intelligence (AI), robotics, and IoT-enabled systems into their production lines to boost efficiency and reduce defects. This trend is reshaping the traditional SMT landscape and encouraging investments in intelligent SMT lines with real-time monitoring and self-correction capabilities.

Additionally, the proliferation of electric vehicles (EVs) and advanced driver-assistance systems (ADAS) is generating new opportunities for SMT equipment manufacturers, particularly in the automotive electronics segment.

Latest Market Trends

Several trends are shaping the SMT equipment market today:

Integration of AI and machine learning in SMT systems to enhance placement accuracy and reduce human intervention.

Adoption of 3D inspection systems for quality control, ensuring higher yield rates and better defect detection.

Expansion of flexible and hybrid SMT lines to accommodate varying production volumes and product types.

Sustainability-focused designs, such as energy-efficient reflow ovens and lead-free soldering systems, are gaining traction amid rising environmental concerns.

These trends are not only boosting productivity but are also redefining customer expectations and pushing market players toward more adaptive and future-ready solutions.

Analysis of Key Players

The surface mount technology equipment industry is consolidated with the presence of a few players holding major market share. Leading manufacturers are following the latest surface mount technology equipment market trends and engaging in new product launches and mergers & acquisitions to consolidate their presence in the global market.

Dou Yee Enterprises (S) Pte. Ltd., JUTZE Intelligence Technology Co., Ltd., Koh Young Technology, Mirtech, Nordson Corporation, Omron Corporation, PARMI Corporation, Saki Corporation, Test Research, Inc., Vi Technology (Mycronic AB), Viscom AG, Vitrox Corporation, and Yamaha Motor Co., Ltd. are a few notable players that offer inspection equipment. While ASML Holding, N.V., Fuji Machine Mfg. Co., Ltd., Hitachi, Ltd., Juki Corporation, KLA-Tencor Corporation, Koh Young Technology, Mycronic AB, Nordson Corporation, Orbotech Ltd., Panasonic Corporation, PARMI Corp., Test Research, Inc., and Yamaha Motor Co., Ltd. are key notable players offering surface mount technology equipment.

Recent Developments

The past few years have seen a wave of strategic developments in the SMT equipment market:

ASMPT introduced a new line of modular SMT systems featuring AI-assisted analytics to optimize throughput.

Panasonic unveiled a next-gen placement machine with enhanced component recognition and autonomous calibration features.

Witte Technology GmbH expanded its European manufacturing facility to increase capacity and meet rising global demand.

Several players have formed partnerships with automotive and telecom firms to tailor SMT solutions for specific industry requirements, such as 5G infrastructure and EV component manufacturing.

Download to explore critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=5516

Market Opportunities

Numerous opportunities lie ahead for stakeholders in the SMT equipment space:

Growing electronics manufacturing services (EMS) sector in Asia-Pacific, particularly in countries like China, Vietnam, and India, is creating demand for scalable SMT systems.

The rise of smart wearables and IoT devices presents a growing segment for compact SMT solutions.

High-reliability applications in aerospace, defense, and medical electronics require advanced SMT capabilities, opening niche but profitable markets.

Government incentives in semiconductor and electronics manufacturing across various regions are encouraging infrastructure development and equipment procurement.

Future Outlook

Looking forward, the SMT equipment market is set to evolve in alignment with global digitization and electrification trends. As AI and predictive maintenance become standard in manufacturing environments, the integration of such capabilities in SMT systems will become a key differentiator. Additionally, geopolitical shifts and supply chain restructuring are expected to drive investments in localized manufacturing, fueling SMT equipment demand in emerging markets.

The future of the SMT equipment market will be shaped by technological agility, customization, and sustainability all critical to addressing the dynamic needs of modern electronics manufacturing.

Market Segmentation

The SMT equipment market can be segmented based on:

Equipment Type:

Placement Equipment

Inspection Equipment

Soldering Equipment

Screen Printing Equipment

Cleaning Equipment

Application:

Consumer Electronics

Automotive

Industrial Electronics

Telecommunications

Medical Devices

Aerospace & Defense

End-user:

OEMs (Original Equipment Manufacturers)

EMS Providers

This segmentation highlights the market’s diverse application base and underscores the necessity for flexible and tailored SMT solutions.

Regional Insights

Asia-Pacific dominates the global SMT equipment market, driven by a robust manufacturing ecosystem, especially in China, Japan, and South Korea. The region is expected to remain a powerhouse throughout the forecast period.

North America is witnessing increasing demand due to reshoring efforts and innovations in automotive and medical electronics.

Europe, led by Germany and the UK, is focusing on high-precision SMT systems for automotive and industrial applications.

Latin America and the Middle East & Africa are emerging markets with growing infrastructure and electronics demand, albeit at a relatively slower pace.

Why Buy This Report?

This comprehensive market research report offers:

In-depth analysis of current and future market trends

Thorough competitive landscape assessment including company profiles and market share

Detailed segmentation and regional breakdowns

Insights into technological innovations and investment opportunities

Strategic recommendations for stakeholders, investors, and policymakers

Whether you are a market entrant, investor, OEM, or EMS provider, this report serves as a crucial tool for making informed business decisions.

Explore Latest Research Reports by Transparency Market Research: GPS Tracking Device Market: https://www.transparencymarketresearch.com/gps-tracking-device-market.html

E-Beam Wafer Inspection System Market: https://www.transparencymarketresearch.com/e-beam-wafer-inspection-system-market.html

Filtered Connectors Market: https://www.transparencymarketresearch.com/filtered-connectors-market.html

Commercial Security Systems Market: https://www.transparencymarketresearch.com/commercial-security-systems-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Best High Pressure Cleaning Victoria: Advanced, Affordable & Eco-Friendly Services by Yellowfin Robotics

Looking for the Best high pressure cleaning in Victoria that delivers unbeatable results? At Yellowfin Robotics, we specialize in smart, safe, and sustainable high pressure cleaning solutions for residential, commercial, and industrial spaces. With cutting-edge technology, experienced professionals, and an eco-conscious approach, we bring a new standard of cleanliness to every surface we touch.

Whether you're dealing with oil-stained driveways, weathered walls, or grime-covered pathways, our advanced pressure cleaning services remove dirt and contaminants quickly—restoring your property’s appearance and prolonging its lifespan.

Why High Pressure Cleaning is a Must

Dirt, mold, mildew, grease, algae, and pollutants gradually build up on exterior surfaces, making them look worn and potentially causing long-term damage. Not only does this affect the appearance of your property, but it can also pose safety hazards like slippery walkways or weakened building materials.

That’s why regular high pressure cleaning is essential. It improves the aesthetics, maintains the structural integrity, and creates a safer environment—all while boosting your property's value.

At Yellowfin Robotics, we go beyond basic cleaning. We deliver a deep, efficient, and long-lasting clean that makes us the go-to provider for pressure washing in Victoria.

High Pressure Washer Cleaning Across Victoria

Yellowfin Robotics leads the way in high-pressure washer cleaning across Victoria, offering innovative, eco-friendly solutions for residential, commercial, and industrial properties. Utilizing advanced equipment, our services effectively remove stubborn dirt, grime, mold, and stains from a wide range of surfaces including driveways, patios, walls, fences, decks, car parks, and more.

Our cleaning process is tough on stains but gentle on your property. We tailor our approach to each surface, ensuring a safe and thorough clean every time. No harsh chemicals, no unnecessary water waste—just professional-grade pressure cleaning that delivers results.

What Makes Yellowfin Robotics the Best?

1. Next-Level Equipment We use industrial-grade, high-pressure cleaning machines that break through years of grime in just minutes. Our equipment is carefully calibrated to match the needs of each surface, avoiding damage while maximizing effectiveness.

2. Eco-Friendly Practices Our cleaning solutions are biodegradable and environmentally safe. We use minimal water and avoid harsh chemicals, making our services suitable for environmentally conscious homes and businesses.

3. Skilled & Certified Team Our technicians are trained, licensed, and experienced. Whether it’s a delicate timber deck or a concrete factory floor, they know exactly how to clean it right the first time.

4. Affordable, Transparent Pricing We believe premium service doesn’t have to come with a premium price tag. That’s why we offer competitive pricing with no hidden fees. Get a high-quality clean at a price that suits your budget.

5. Flexible Scheduling & Reliable Service We understand your time is valuable. Our team works around your schedule and always shows up on time, ready to deliver fast and effective cleaning with minimal disruption.

Our High Pressure Cleaning Services Include:

Driveways & Walkways

Commercial Building Exteriors

Industrial Equipment & Floors

Patios, Pool Areas & Decks

Fences & Garage Doors

Warehouse & Factory Cleaning

Shopfronts & Signage

Roof and Gutter Cleaning (with drone assistance)

Serving All of Victoria

From Melbourne’s urban landscape to regional townships and industrial zones, Yellowfin Robotics proudly serves clients across Victoria. Whether you’re a homeowner, business owner, property manager, or industrial operator, we have the tools and expertise to tackle your toughest cleaning jobs.

Ready to Restore Your Property?

When it comes to the best high pressure cleaning in Victoria, Yellowfin Robotics is the trusted name for quality, value, and innovation. Let us help you protect your investment, enhance your curb appeal, and maintain a cleaner, safer environment.

#Best High Pressure Cleaning Victoria: Advanced#Affordable & Eco-Friendly Services by Yellowfin Robotics

0 notes

Text

Unlocking Robotic Precision with Dynaflex by Dynalog-US

In our rapidly paced world of automation and advanced manufacturing, robotics is continuing to reshape efficiency, precision and innovation. Leading this transformation is Dynalog-US, a well-known name in robotic calibration, inspection, and integration solutions. One of its most innovative products is Dynaflex, an advanced solution focused on robotic flexibility and performance optimization. So, what is Dynaflex, and why is it important to manufacturers and robotics engineers?

Let’s take a look at how Dynaflex by Dynalog is pushing automation prospects further, and why this tool is becoming a "must have" in all sectors.

Why Dynaflex?

Dynaflex is an advanced robotic measurement and diagnostic tool developed by Dynalog-US, specifically to measure and improve the dynamic flexibility of robotic systems. In laymen's terms, Dynaflex measures the amount of flex or deformation a robot experiences while under load. This information is vital since flex must be considered to maintain acceptable levels of a robot's precision, repeatability and accuracy.

Most traditional calibration tools are concerned solely with static accuracy. While Dynaflex is also concerned with accuracy, it delves deeper into the dynamic behaviours of the robot which most traditional tools do not incorporate, nor do they offer ways to improve those measures. Whether a robotic arm is welding, assembling, or packaging products, understanding how the robot flexes as it moves about doing its work allows for better programming and ultimately better overall result

Why Robotic Flexibility is Very Important

Robots are amazing machines that can perform a variety of sophisticated tasks accurately and quickly. Robots are limited in their overall performance because they can suffer from tool deflection, joint compliance, and vibrations from their base which degrade positional accuracy. These small variations can have large implications in precision-based industries like automotive manufacturing, aerospace, and medical device manufacturing, where aspects locally must be at millimeter and sometimes sub-millimeter tolerances.

This is where Dynaflex comes into play by Dynalog; Dynaflex gives an accurate and precise measurement of a robot's physical performance under different operating conditions. This information allows engineers to tune robot paths and minimize errors to deliver the right output.

Additional Benefits of Dynaflex

Dynaflex has several differentiating features that provide it with more advanced capabilities compared to other robotic diagnostics tools:

Non-contact laser tracking measurement Real time data recording and actions of the robot and how the load reacts to that Advanced reports on base flexibility, link/joint compliance, and dynamic deflection of the robotCompatible with all leading robot brands including ABB, FANUC, KUKA, and Yaskawa Canny integrate into a current calibration process

These features make Dynaflex a powerful companion for roboticists aiming to enhance the performance of robotic cells or conduct detailed robotic system diagnostics.

Applications in Various Industries

Dynaflex is valuable in any field of application it's required, and it can be used wherever robotic precision is essential.

Automotive Production: increase the accuracy of weld seam, and body panel alignment.

Aerospace Assembly: control tight tolerances in the assembly of components.

Electronics Manufacturing: validate accuracy of PCB handling and soldering.

Medical Devices: maintain consistent quality of assembly of sensitive devices.

Industrial Automation: improve every aspect of a robot’s motion in handling materials, packaging, and inspection.

Wherever a robot is required to consistently provide high accuracy, Dynaflex by Dynalog-US provides unparalleled insights and improvement.

The Dynalog-US Advantage

Dynalog-US was founded and exists for the purpose of bringing intelligence and precision to robotics. For many years they have been at the forefront of robotic calibration and inspection technologies. Dynalog is known for its comprehensive solutions for robotic inspection and calibration that identify and fix issues beyond calibration alone with deeper mechanical or structural information.

Dynalog was successful because of leadership that put customer first and retained an organisation committed to support and provide thorough training on the full use of tools such as Dynaflex without a steep learning curve. Dynalog's standards of measurement have been adopted by global manufacturers and leading research institutes — Definitely an indication of quality they have pioneered in robotic automation.

How Dynaflex Works Alongside the Robot TCP Calibration

Dynalog provides common services for Robot TCP (Tool Center Point) Calibration which ensures that the robot programming accurately matches the location of the tool in the physical world. TCP calibration looks at the static position of the tool while Dynaflex takes it a step further in understanding the static picture from movement and operation under load.

When considered together, they show a full picture, magnetic or static and dynamic, of the performance of a robot, making programming and execution more consistent and reliable.

In Conclusion: Why Investing in Dynaflex Is a Smart Investment

If you are serious about leveraging robotic systems as much as possible Dynaflex from Dynalog-US is more than a tool, it is an investment you make in performance, quality, and work excellence. Dynaflex can help you recognize flexibilities you did not know existed and help improve responsiveness of the robot so you can decrease downtime, reduce product defects, and get your ROI.

With the push for robotic automation as the underpinning of modern manufacturing there is no margin for errors. Let Dynalog help you stay ahead, with it offering Dynaflex as the smarter way to measure, diagnose, and help optimize robotics performance.

Ready to bring precision to your automation? Learn more about Dynaflex and other robotic calibration tools by visiting Dynalog-US.com

#Dynaflex#Dynalog-US#Robotic Flexibility#Robot Calibration#Robotic Inspection Tools#Automation Solutions#Industrial Robotics#Robot Performance Optimization

0 notes

Text

التخلص من النفايات الخطرة

التخلص من النفايات الخطرة

CRUDE OIL TANK CLEANING MASTERY: THE INDUSTRY'S MOST COMPREHENSIVE OPERATIONAL MANUAL

I. Nano-Scale Sludge Forensics

1.1 Synchrotron Radiation Analysis

XANES Spectroscopy at 4,500 eV reveals:

Vanadium speciation: 65% as VO⁺ (sulfate) / 35% as V⁴⁺ (porphyrin)

Sulfur K-edge shows 72% thiophenic compounds

1.2 4D Rheological Modeling

Time-dependent Herschel-Bulkley:

math

\tau(t) = \tau_{y0}e^{-kt} + K(\dot{\gamma})^n(1 - e^{-kt})

Where:

k = 0.015 s⁻¹ (aging coefficient)

τ_{y0} = 210 Pa (initial yield)

II. Quantum Cleaning Technologies

2.1 Femtosecond Laser Ablation

Parameters:

Wavelength: 1,030 nm

Pulse duration: 350 fs

Fluence: 2.5 J/cm²

Results:

0.2μm layer removal precision

Zero heat-affected zone

2.2 Supercritical CO₂ Extraction

Phase Diagram Optimization:

85°C at 90 bar (above critical point)

Solubility enhancement with 5% limonene co-solvent

III. Military-Grade Operational Protocols

3.1 Special Ops Cleaning Tactics

High-Altitude Tank Cleaning (3,000m+ ASL):

Compensated pump curves for 20% lower atmospheric pressure

Modified surfactant HLB values (12 → 14)

3.2 Underwater Tank Repair

Saturation Diving Protocol:

Bell runs at 50m depth

Hyperbaric welding at 1.5x normal partial pressure

IV. AI-Powered Predictive Systems

4.1 Neural Network Architecture

python

class SludgePredictor(tf.keras.Model):

def __init__(self):

super().__init__()

self.lstm = layers.LSTM(128)

self.dense = layers.Dense(3) # Viscosity, H2S, Corrosion

def call(self, inputs):

x = self.lstm(inputs)

return self.dense(x)

Training Data: 15 years of tank inspection reports

4.2 Digital Twin Calibration

Real-Time Kalman Filtering:

math

\hat{x}_k = F_k\hat{x}_{k-1} + K_k(z_k - H_kF_k\hat{x}_{k-1})

State variables: thickness, sludge depth, VOC ppm

V. Extreme Environment Case Bank

5.1 Desert Storm Cleaning

Challenge: 55°C ambient with 90μm/yr corrosion rate

مردم نفايات بترولية خطرة

Solution:

Phase-change cooling suits (-5°C PCM packs)

Night-only operations using IR thermography

5.2 Offshore Floating Storage

Dynamic Positioning Cleaning:

Wave motion compensation algorithms

Heave-adjusted robotic arm trajectories

VI. The Future Is Now (2026+)

6.1 Programmable Matter Cleaners

Shape-Shifting Robots:

Gallium-indium alloys (melting point 15°C)

Magnetic field reconfiguration

6.2 Bio-Electric Sludge Breakdown

Microbial Fuel Cells:

Geobacter sulfurreducens biofilm

0.8V output @ 2mA/cm² while degrading sludge

VII. The Master Operator's Toolkit

7.1 Augmented Reality SOPs

Hololens Application Features:

Real-time gas overlay

Equipment torque specs visualization

Expert call-in function

7.2 Blockchain Waste Ledger

Hyperledger Implementation:

javascript

async function logWaste() {

const tx = await contract.methods

.addWasteBatch(tankID, weight, composition)

Tank Cleaning

Microgravity Applications:

Electrostatic sludge collection

3D-printed replacement parts

Final Master Checklist:

Pre-job quantum computer risk simulation (Qiskit model)

Nanobot swarm deployment calibration

Blockchain work permit NFT minting

Post-cleaning synchrotron validation scan

0 notes

Text

التخلص من النفايات الخطرة

التخلص من النفايات الخطرة

CRUDE OIL TANK CLEANING MASTERY: THE INDUSTRY'S MOST COMPREHENSIVE OPERATIONAL MANUAL

I. Nano-Scale Sludge Forensics

1.1 Synchrotron Radiation Analysis

XANES Spectroscopy at 4,500 eV reveals:

Vanadium speciation: 65% as VO⁺ (sulfate) / 35% as V⁴⁺ (porphyrin)

Sulfur K-edge shows 72% thiophenic compounds

1.2 4D Rheological Modeling

Time-dependent Herschel-Bulkley:

math

\tau(t) = \tau_{y0}e^{-kt} + K(\dot{\gamma})^n(1 - e^{-kt})

Where:

k = 0.015 s⁻¹ (aging coefficient)

τ_{y0} = 210 Pa (initial yield)

II. Quantum Cleaning Technologies

2.1 Femtosecond Laser Ablation

Parameters:

Wavelength: 1,030 nm

Pulse duration: 350 fs

Fluence: 2.5 J/cm²

Results:

0.2μm layer removal precision

Zero heat-affected zone

2.2 Supercritical CO₂ Extraction

Phase Diagram Optimization:

85°C at 90 bar (above critical point)

Solubility enhancement with 5% limonene co-solvent

III. Military-Grade Operational Protocols

3.1 Special Ops Cleaning Tactics

High-Altitude Tank Cleaning (3,000m+ ASL):

Compensated pump curves for 20% lower atmospheric pressure

Modified surfactant HLB values (12 → 14)

3.2 Underwater Tank Repair

Saturation Diving Protocol:

Bell runs at 50m depth

Hyperbaric welding at 1.5x normal partial pressure

IV. AI-Powered Predictive Systems

4.1 Neural Network Architecture

python

class SludgePredictor(tf.keras.Model):

def __init__(self):

super().__init__()

self.lstm = layers.LSTM(128)

self.dense = layers.Dense(3) # Viscosity, H2S, Corrosion

def call(self, inputs):

x = self.lstm(inputs)

return self.dense(x)

Training Data: 15 years of tank inspection reports

4.2 Digital Twin Calibration

Real-Time Kalman Filtering:

math

\hat{x}_k = F_k\hat{x}_{k-1} + K_k(z_k - H_kF_k\hat{x}_{k-1})

State variables: thickness, sludge depth, VOC ppm

V. Extreme Environment Case Bank

5.1 Desert Storm Cleaning

Challenge: 55°C ambient with 90μm/yr corrosion rate

مردم نفايات بترولية خطرة

Solution:

Phase-change cooling suits (-5°C PCM packs)

Night-only operations using IR thermography

5.2 Offshore Floating Storage

Dynamic Positioning Cleaning:

Wave motion compensation algorithms

Heave-adjusted robotic arm trajectories

VI. The Future Is Now (2026+)

6.1 Programmable Matter Cleaners

Shape-Shifting Robots:

Gallium-indium alloys (melting point 15°C)

Magnetic field reconfiguration

6.2 Bio-Electric Sludge Breakdown

Microbial Fuel Cells:

Geobacter sulfurreducens biofilm

0.8V output @ 2mA/cm² while degrading sludge

VII. The Master Operator's Toolkit

7.1 Augmented Reality SOPs

Hololens Application Features:

Real-time gas overlay

Equipment torque specs visualization

Expert call-in function

7.2 Blockchain Waste Ledger

Hyperledger Implementation:

javascript

async function logWaste() {

const tx = await contract.methods

.addWasteBatch(tankID, weight, composition)

Tank Cleaning

Microgravity Applications:

Electrostatic sludge collection

3D-printed replacement parts

Final Master Checklist:

Pre-job quantum computer risk simulation (Qiskit model)

Nanobot swarm deployment calibration

Blockchain work permit NFT minting

Post-cleaning synchrotron validation scan

0 notes

Text

التخلص من النفايات الخطرة

التخلص من النفايات الخطرة

CRUDE OIL TANK CLEANING MASTERY: THE INDUSTRY'S MOST COMPREHENSIVE OPERATIONAL MANUAL

I. Nano-Scale Sludge Forensics

1.1 Synchrotron Radiation Analysis

XANES Spectroscopy at 4,500 eV reveals:

Vanadium speciation: 65% as VO⁺ (sulfate) / 35% as V⁴⁺ (porphyrin)

Sulfur K-edge shows 72% thiophenic compounds

1.2 4D Rheological Modeling

Time-dependent Herschel-Bulkley:

math

\tau(t) = \tau_{y0}e^{-kt} + K(\dot{\gamma})^n(1 - e^{-kt})

Where:

k = 0.015 s⁻¹ (aging coefficient)

τ_{y0} = 210 Pa (initial yield)

II. Quantum Cleaning Technologies

2.1 Femtosecond Laser Ablation

Parameters:

Wavelength: 1,030 nm

Pulse duration: 350 fs

Fluence: 2.5 J/cm²

Results:

0.2μm layer removal precision

Zero heat-affected zone

2.2 Supercritical CO₂ Extraction

Phase Diagram Optimization:

85°C at 90 bar (above critical point)

Solubility enhancement with 5% limonene co-solvent

III. Military-Grade Operational Protocols

3.1 Special Ops Cleaning Tactics

High-Altitude Tank Cleaning (3,000m+ ASL):

Compensated pump curves for 20% lower atmospheric pressure

Modified surfactant HLB values (12 → 14)

3.2 Underwater Tank Repair

Saturation Diving Protocol:

Bell runs at 50m depth

Hyperbaric welding at 1.5x normal partial pressure

IV. AI-Powered Predictive Systems

4.1 Neural Network Architecture

python

class SludgePredictor(tf.keras.Model):

def __init__(self):

super().__init__()

self.lstm = layers.LSTM(128)

self.dense = layers.Dense(3) # Viscosity, H2S, Corrosion

def call(self, inputs):

x = self.lstm(inputs)

return self.dense(x)

Training Data: 15 years of tank inspection reports

4.2 Digital Twin Calibration

Real-Time Kalman Filtering:

math

\hat{x}_k = F_k\hat{x}_{k-1} + K_k(z_k - H_kF_k\hat{x}_{k-1})

State variables: thickness, sludge depth, VOC ppm

V. Extreme Environment Case Bank

5.1 Desert Storm Cleaning

Challenge: 55°C ambient with 90μm/yr corrosion rate

مردم نفايات بترولية خطرة

Solution:

Phase-change cooling suits (-5°C PCM packs)

Night-only operations using IR thermography

5.2 Offshore Floating Storage

Dynamic Positioning Cleaning:

Wave motion compensation algorithms

Heave-adjusted robotic arm trajectories

VI. The Future Is Now (2026+)

6.1 Programmable Matter Cleaners

Shape-Shifting Robots:

Gallium-indium alloys (melting point 15°C)

Magnetic field reconfiguration

6.2 Bio-Electric Sludge Breakdown

Microbial Fuel Cells:

Geobacter sulfurreducens biofilm

0.8V output @ 2mA/cm² while degrading sludge

VII. The Master Operator's Toolkit

7.1 Augmented Reality SOPs

Hololens Application Features:

Real-time gas overlay

Equipment torque specs visualization

Expert call-in function

7.2 Blockchain Waste Ledger

Hyperledger Implementation:

javascript

async function logWaste() {

const tx = await contract.methods

.addWasteBatch(tankID, weight, composition)

Tank Cleaning

Microgravity Applications:

Electrostatic sludge collection

3D-printed replacement parts

Final Master Checklist:

Pre-job quantum computer risk simulation (Qiskit model)

Nanobot swarm deployment calibration

Blockchain work permit NFT minting

Post-cleaning synchrotron validation scan

0 notes

Text

التخلص من النفايات الخطرة

التخلص من النفايات الخطرة

CRUDE OIL TANK CLEANING MASTERY: THE INDUSTRY'S MOST COMPREHENSIVE OPERATIONAL MANUAL

I. Nano-Scale Sludge Forensics

1.1 Synchrotron Radiation Analysis

XANES Spectroscopy at 4,500 eV reveals:

Vanadium speciation: 65% as VO⁺ (sulfate) / 35% as V⁴⁺ (porphyrin)

Sulfur K-edge shows 72% thiophenic compounds

1.2 4D Rheological Modeling

Time-dependent Herschel-Bulkley:

math

\tau(t) = \tau_{y0}e^{-kt} + K(\dot{\gamma})^n(1 - e^{-kt})

Where:

k = 0.015 s⁻¹ (aging coefficient)

τ_{y0} = 210 Pa (initial yield)

II. Quantum Cleaning Technologies

2.1 Femtosecond Laser Ablation

Parameters:

Wavelength: 1,030 nm

Pulse duration: 350 fs

Fluence: 2.5 J/cm²

Results:

0.2μm layer removal precision

Zero heat-affected zone

2.2 Supercritical CO₂ Extraction

Phase Diagram Optimization:

85°C at 90 bar (above critical point)

Solubility enhancement with 5% limonene co-solvent

III. Military-Grade Operational Protocols

3.1 Special Ops Cleaning Tactics

High-Altitude Tank Cleaning (3,000m+ ASL):

Compensated pump curves for 20% lower atmospheric pressure

Modified surfactant HLB values (12 → 14)

3.2 Underwater Tank Repair

Saturation Diving Protocol:

Bell runs at 50m depth

Hyperbaric welding at 1.5x normal partial pressure

IV. AI-Powered Predictive Systems

4.1 Neural Network Architecture

python

class SludgePredictor(tf.keras.Model):

def __init__(self):

super().__init__()

self.lstm = layers.LSTM(128)

self.dense = layers.Dense(3) # Viscosity, H2S, Corrosion

def call(self, inputs):

x = self.lstm(inputs)

return self.dense(x)

Training Data: 15 years of tank inspection reports

4.2 Digital Twin Calibration

Real-Time Kalman Filtering:

math

\hat{x}_k = F_k\hat{x}_{k-1} + K_k(z_k - H_kF_k\hat{x}_{k-1})

State variables: thickness, sludge depth, VOC ppm

V. Extreme Environment Case Bank

5.1 Desert Storm Cleaning

Challenge: 55°C ambient with 90μm/yr corrosion rate

مردم نفايات بترولية خطرة

Solution:

Phase-change cooling suits (-5°C PCM packs)

Night-only operations using IR thermography

5.2 Offshore Floating Storage

Dynamic Positioning Cleaning:

Wave motion compensation algorithms

Heave-adjusted robotic arm trajectories

VI. The Future Is Now (2026+)

6.1 Programmable Matter Cleaners

Shape-Shifting Robots:

Gallium-indium alloys (melting point 15°C)

Magnetic field reconfiguration

6.2 Bio-Electric Sludge Breakdown

Microbial Fuel Cells:

Geobacter sulfurreducens biofilm

0.8V output @ 2mA/cm² while degrading sludge

VII. The Master Operator's Toolkit

7.1 Augmented Reality SOPs

Hololens Application Features:

Real-time gas overlay

Equipment torque specs visualization

Expert call-in function

7.2 Blockchain Waste Ledger

Hyperledger Implementation:

javascript

async function logWaste() {

const tx = await contract.methods

.addWasteBatch(tankID, weight, composition)

Tank Cleaning

Microgravity Applications:

Electrostatic sludge collection

3D-printed replacement parts

Final Master Checklist:

Pre-job quantum computer risk simulation (Qiskit model)

Nanobot swarm deployment calibration

Blockchain work permit NFT minting

Post-cleaning synchrotron validation scan

0 notes

Text

Rotary Torque Sensors: Enhancing Rotational Force Measurement with Star EMBSYS Solutions

Rotary torque sensors are critical components used to measure the rotational force (torque) applied on a rotating system, such as motors, gearboxes, or turbines. These sensors are essential in performance testing, quality control, and process monitoring across industries like automotive, aerospace, robotics, and manufacturing. Among the innovative providers in this space, Star EMBSYS offers high-performance, customizable rotary torque sensor systems that integrate advanced embedded technology for unmatched precision and reliability.

A rotary torque sensor measures torque by detecting the strain (twisting) on a rotating shaft. Typically based on strain gauge or magnetoelastic principles, these sensors output a signal proportional to the applied torque. Unlike static torque sensors, rotary torque sensors are designed to operate on rotating shafts, often using slip rings, wireless telemetry, or rotary transformers to transmit data.

Star EMBSYS brings its embedded systems expertise into torque sensing by offering intelligent rotary torque sensor solutions. These systems are equipped with real-time data acquisition, signal conditioning, and digital communication interfaces, making them ideal for dynamic and high-speed applications. Their sensors support both analog (voltage/current) and digital (UART, SPI, I2C, CAN) outputs, ensuring seamless integration with control systems, data loggers, and monitoring software.

One of the core strengths of Star EMBSYS is its ability to deliver customized sensor solutions tailored to the client’s mechanical and electrical requirements. Whether it's a high-precision lab-grade application or a rugged industrial setting, Star EMBSYS designs torque sensors with features like temperature compensation, vibration resistance, and long-term stability. Their embedded firmware ensures accurate real-time monitoring with minimal latency, critical for applications like EV motor testing or robotic joint torque feedback.

Additionally, Star EMBSYS offers user-friendly calibration and diagnostic tools, allowing engineers to maintain accuracy and system health over time. Their rotary torque sensors can be combined with wireless telemetry for remote monitoring, a vital feature for testing in mobile or rotating systems where cabling is impractical.

In conclusion, rotary torque sensors are essential for understanding and optimizing mechanical performance. Star EMBSYS stands out by delivering not just sensors, but smart embedded torque measurement solutions that empower engineers with real-time, high-fidelity data. With a commitment to innovation and customization, Star EMBSYS is a trusted partner for precision torque sensing in today’s demanding engineering applications.

Visit:- https://www.starembsys.com/rotary-torque-sensor.html

0 notes

Text

Automation Boom Fuels Growth in Motion Control Drive Market to $8.4 Billion by 2031

The global motion control drive market encompassing servo drives, stepper drives, and variable frequency (VFD) drives was valued at US$ 4.9 billion in 2022. Driven by the surge in automation, robotics, and precision motor control requirements, the market is forecast to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 through 2031, reaching US$ 8.4 billion by the end of the forecast period. Motion control drives regulate voltage, current, speed, and position of motors in applications ranging from CNC machining and semiconductor manufacturing to packaging, automotive, and materials handling.

Market Drivers & Trends

Automation & Industry 4.0 Adoption: Increasing deployment of automation across manufacturing verticals is fundamentally reshaping production lines. Motion control drives, which ensure precise and synchronized movements in robotic arms, conveyor systems, and automated assembly lines, are integral to Industry 4.0 ecosystems.

Integration of IoT & AI: Smart factories require drives that can self-diagnose, self-tune, and communicate performance data. The integration of Internet of Things (IoT) connectivity and artificial intelligence (AI) within drives enables predictive maintenance, reduced downtime, and optimized energy usage.

Compact & Modular Designs: Space constraints and the need for flexible machine layouts have spurred demand for compact drive systems. Solutions such as Bosch Rexroth’s ctrlX DRIVE and Rockwell Automation’s ArmorKinetix series offer modular, scalable form factors that simplify installation and support mobile and portable applications.

Energy Efficiency & Sustainability: With global pressures to reduce energy consumption and carbon footprints, manufacturers are adopting high-efficiency drives that minimize losses and recover regenerative energy—key considerations for sectors like automotive, aerospace, and materials handling.

Latest Market Trends

Self‑Tuning Servo Drives: Advanced digital servo drives can now autonomously adjust motor, drive, and feedback parameters to optimize performance. These self‑tuning capabilities reduce the need for manual calibration of control loops and enhance overall system robustness.

Multi‑Axis Synchronization: As multi-axis robots and gantry systems grow more prevalent, drives capable of precise, coordinated control across several axes are in high demand. Enhanced synchronization features enable smoother motion profiles and greater throughput.

Embedded Safety Functions: Functional safety is increasingly embedded into drive platforms, offering integrated safety monitoring, safe torque off (STO), and safe motion functions. This reduces the footprint and complexity of additional safety components in automated machinery.

Cloud‑Based Drive Management: Vendors are launching cloud‑connected platforms for remote configuration, firmware updates, and performance monitoring, enabling centralized management of distributed drive fleets.

Key Players and Industry Leaders

The motion control drive market remains fragmented, with a diverse set of global and regional players competing on innovation, customization, and service:

ABB Ltd.

Siemens AG

Rockwell Automation Inc.

Bosch Rexroth

Mitsubishi Electric Corporation

Schneider Electric SE

Delta Electronics, Inc.

OMRON Corporation

YASKAWA Electric Corporation

Toshiba Corporation

Allied Motion, Inc.

Advanced Micro Controls, Inc.

Fuji Electric Co., Ltd.

Emerson Electric Co.

HIWIN Corporation

Nidec Motor Corporation

These companies remain at the forefront through continuous R&D investment, strategic acquisitions, and partnerships to expand product portfolios and regional footprints.

Unlock crucial data and key findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=52011

Recent Developments

August 2023: Kollmorgen expanded its AKD2G servo drive portfolio, introducing higher amperage models with enhanced safety features and SD card backup, plus a graphical display for simplified multi-axis setup.

May 2023: ABB completed the acquisition of Siemens’ low-voltage NEMA motor business, strengthening its portfolio of integrated motor‑and‑drive solutions for North American markets.

2022: WEG acquired Gefran’s Motion Control Business Unit, gaining full ownership of variable frequency drives, DC converters, and specialized servo drives to bolster its automation offerings.

June 2021: Bosch Rexroth launched its ctrlX DRIVE system—a compact, scalable drive platform designed for easy integration into mobile and space-optimized machinery.

August 2023: Rockwell Automation unveiled Allen‑Bradley ArmorKinetix servo drives that mount directly to motors, simplifying machine assembly and improving performance flexibility.

Market Opportunities

Emerging Economies: Rapid industrialization in Southeast Asia, Latin America, and parts of Eastern Europe is driving demand for mid‑range automation solutions—an opportunity for manufacturers to introduce cost‑effective drive systems.

Smart Manufacturing Upgrades: Legacy factories undergoing digital transformation need retrofit‑friendly drive solutions with IoT connectivity and embedded safety, presenting a sizable aftermarket for system integrators.

Sustainable Energy Projects: Renewable energy installations, including solar trackers and wind turbine pitch control systems, require robust drives optimized for harsh environments and long service intervals.

Customized Solutions: Increasingly, end‑users demand turnkey, application‑specific drive packages—bundling drives with built‑in safety, condition monitoring, and domain‑specific software tools.

Future Outlook

Over the next decade, the motion control drive market will continue to evolve along several axes:

Digitalization: Drives will become central nodes in digital value chains, sending real‑time telemetry to cloud‑based analytics platforms for AI‑driven optimization.

Integration: We can expect tighter integration of drives with higher‑level controllers—blurring the lines between PLC, motion controller, and drive in next‑generation architectures.

Safety & Compliance: As regulatory standards evolve, drives will natively support functional safety protocols (e.g., TÜV‑certified safety functions) to simplify machine approvals.

Miniaturization: Advances in power electronics will permit further size reduction, enabling distributed, embedded drive solutions in compact robotics and wearable exoskeletons.

Buy this Premium Research Report and access vital insights and analysis – https://www.transparencymarketresearch.com/checkout.php?rep_id=52011<ype=S

Market Segmentation

By Type: AC Drives, DC Drives

By Product Type: Servo Drives, Stepper Drives, VFD Drives

By Axis: Single‑Axis, Multi‑Axis

By Precision: Very High Precision, High Precision, Standard

By End‑Use: Semiconductor & Electronics, Food & Beverage, Aerospace & Defense, Automotive, Paper & Printing, Pharmaceuticals, Metals & Machinery, Others

Regional Insights

Asia Pacific: Held the largest share in 2022, driven by heavy investments in manufacturing automation and robotics in China, Japan, South Korea, and India. China’s shrinking labor force and rising robotics installations (81,600 units in 2021, up 30%) underpin strong demand.

North America: Growth fueled by automotive electrification, semiconductor fab expansions, and food & beverage upgrades—coupled with strategic investments by ABB and Rockwell.

Europe: Focus on Industry 4.0 and sustainability is driving adoption of energy‑efficient drives, particularly in Germany, Italy, and the U.K.

Latin America & MEA: Emerging manufacturing hubs in Brazil, Mexico, and UAE present opportunities for mid‑tier drive manufacturers.

Why Buy This Report?

Comprehensive Analysis: Detailed market segmentation, quantitative forecasts (US$ Bn & million units), and historical data spanning 2017–2022.

Strategic Insights: In‑depth qualitative analysis, including drivers, restraints, opportunities, key trends, Porter’s Five Forces, value chain, and competitive landscape.

Company Profiles: Thorough profiles of leading players—covering corporate strategy, financials, product portfolios, M&A, and recent developments.

Decision‑Making Support: Actionable recommendations for new market entrants, technology licensors, system integrators, and investors seeking to capitalize on emerging applications and regional growth hotspots.

Multi‑Format Delivery: Available in PDF and Excel formats, facilitating integration with internal reporting and strategic planning processes.

Explore Latest Research Reports by Transparency Market Research: SMT Equipment Market: https://www.transparencymarketresearch.com/smt-equipment-market.html

Motion Control Drive Market: https://www.transparencymarketresearch.com/motion-control-drive-market.html

3D Printing Medical Devices Market: https://www.transparencymarketresearch.com/3d-printing-medical-devices-market.html

Nano Positioning Systems Market: https://www.transparencymarketresearch.com/nano-positioning-systems-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes