#rotary Label Printing Machine

Explore tagged Tumblr posts

Text

"Empowering Excellence with Innovation in Flexographic Printing." 🔥

Exciting News from Webtech! 📣

We are thrilled to announce the finalization of yet another significant order—a 10-color Fully Servo Flexographic Printing Machine in 350 mm working width, custom-designed for lamitube substrates, for our esteemed client in Maharashtra. This client stands as a leader in the Indian market for printing lamitube substrates, and it’s an honor for us to collaborate with such a distinguished company.

This project promises to be exceptional, featuring cutting-edge advancements in our latest generation LABELTECH S4 SERIES. We are excited to bring these innovations to life and look forward to sharing more updates on our products and services. ✨

Stay tuned for more exciting news! 📺

#label printing#flexo innovation#flexo printing machine#flexo#packaging labels#webtech#lamitube Printing#10 Colors press#label#rotary Label Printing Machine#Labeltech S4 SERIES#Fully Servo Flexo Press

0 notes

Text

Elevate Your Production Standards with UV Graphic’s Expertise

Machines that cure are crucial for fast, effective hardening or drying of different materials such as inks, coatings, adhesives in various industries. Such machines cure by applying heat, UV, or other forms of energy so that they assure durability with high finish quality. These machines find extensive applications in industries printing, packaging, automobiles, and electronics.

UV Graphics-the supreme manufacturer of curing machines, produces the avant-garde products matching the expectations of the modern-day industries. The curing machines-a perfect example of precision and speed; even energy efficiency is guaranteed, every time-one can expect flawless output under flexible variable conditions. Some of the features include adjustable intensity of curing, automated controls, and adaptability to various substrates that truly define invaluable wealth to any production line.

Choosing UV Graphic means an acquisition of sophistication in technology, which is further strengthened by unmatchable support for any kind of business. It is because of innovation and quality that UV Graphic endeavors toward simplifying processes within an organization while excelling at achieving high achievements. From equipment to machines based on UV curing or rather on thermal curing systems, realize your modern machines of performance, reliability, and trusted partnership in the manufacturing sector.

#uv curing systems#curing machine manufacturer#rotary hot foil stamping#flexo printing machines manufacturer#gravure printing machines manufacturer#label punching machines manufacturer

0 notes

Text

Bottle Labeling Machine: Complete Guide to Precision Product Labeling

What is a Bottle Labeling Machine?

A bottle labeling machine is an automated or semi-automated system used to apply labels onto bottles of various shapes and sizes—round, flat, oval, or square. These machines are engineered for high accuracy, speed, and uniformity, significantly reducing labor costs and errors associated with manual labeling.

Whether it's a wrap-around label on a soda bottle or a front-and-back label on a shampoo container, these machines handle it all with seamless efficiency.

Types of Bottle Labeling Machines

1. Manual Bottle Labeling Machines

Ideal for small-scale or home-based operations

Hand-cranked or foot-pedal operated

Low investment, minimal automation

2. Semi-Automatic Bottle Labeling Machines

Operator places the bottle, and the machine handles the labeling

Perfect for startups and small to mid-sized businesses

Compatible with wrap-around, single-side, and double-side labels

3. Fully Automatic Bottle Labeling Machines

Bottles are fed and labeled automatically on conveyors

Suitable for high-speed production lines

High output, precise alignment, reduced labor needs

4. Rotary Labeling Machines

Designed for ultra-high-speed lines

Uses a carousel system to label multiple bottles simultaneously

Often used in beverages, pharma, and cosmetics industries

5. Shrink Sleeve Labeling Machines

Applies shrink labels using heat tunnels for 360° branding

Common in juice, soft drinks, and energy drink packaging

Applications of Bottle Labeling Machines

Food & Beverage Industry

Juices, mineral water, milk, sauces, syrups, oils, alcohol

Date coding, branding, and compliance labels

Pharmaceuticals

Tablets, syrups, liquid drugs

Includes batch number, expiry date, and dosage information

Cosmetics & Personal Care

Shampoos, conditioners, lotions, perfumes

Requires visually appealing labels to reflect brand identity

Chemicals and Agro-Products

Fertilizers, pesticides, cleaning products

Requires resistant, long-lasting adhesive labels

Core Features of Advanced Bottle Labeling Machines

1. High Labeling Speed

Capable of labeling 20 to 300 bottles per minute, depending on model and label type.

2. Accuracy and Precision

Label placement tolerance as low as ±1 mm, ensuring professional appearance.

3. Label Sensor System

Automatically detects label gaps and bottle positions to prevent misalignment.

4. Adjustable Conveyor System

Compatible with a wide range of bottle sizes and shapes.

5. Integrated Coding Devices

Allows real-time printing of batch numbers, barcodes, and expiry dates.

6. PLC and Touchscreen Control

Easy programming, operation, and error diagnostics through HMI systems.

Benefits of Using a Bottle Labeling Machine

Enhanced Branding: Professionally applied labels elevate product appeal

Time-Saving: Speeds up production lines exponentially

Reduced Human Error: Increases labeling accuracy and consistency

Compliance Assurance: Meets global labeling standards (FDA, FSSAI, EU)

Versatility: One machine can handle different bottle types and label formats

Low Operational Costs: Cuts labor costs while boosting throughput

0 notes

Video

youtube

rotary table insoles printing machine trademark label printing machine

0 notes

Text

Nickel Screens: Precision Tools for High-Performance Rotary Printing

In the world of modern industrial printing, especially textile printing, precision, durability, and consistency are non-negotiable. Among the most essential components driving this precision are nickel screens—fine, high-strength cylindrical screens used predominantly in rotary screen printing. These specialized screens offer unmatched performance and reliability, making them indispensable in various printing applications.

What Are Nickel Screens?

Nickel screens are seamless, cylindrical screens made from electroformed high-purity nickel. These screens are primarily used in rotary screen printing machines to apply color and patterns onto a wide range of substrates, including textiles, wallpaper, packaging materials, and ceramics.

The screen’s surface contains a precise mesh of microscopic holes or apertures that allow ink to be transferred onto the substrate in controlled patterns. The combination of high strength, fine resolution, and uniform ink distribution makes nickel mesh screens essential for high-speed, high-volume printing operations.

Key Features of Nickel Screens

Material: Made from high-grade nickel via electroforming, ensuring superior strength and corrosion resistance.

Seamless Design: Uniform cylinder with no visible joins, preventing distortions and ensuring smooth ink flow.

Customizable Mesh Counts: Available in a range of mesh sizes (from 40 to 165 mesh or more), allowing for both fine-detail and high-volume ink applications.

Excellent Dimensional Stability: Maintains shape even under high tension and speed during printing operations.

Applications of Nickel Screens

Nickel screens are used across several industries for rotary screen printing and other precision processes, including:

Textile Industry

Printing on cotton, polyester, silk, rayon, and blended fabrics.

Widely used for decorating garments, upholstery, and home furnishings.

Packaging & Labels

Ideal for printing on flexible packaging materials and product labels.

Wallpaper & Decorative Surfaces

High-resolution designs printed on decorative paper and wall coverings.

Ceramics

Used for transferring intricate patterns onto tiles and ceramic items.

Nonwoven & Technical Textiles

Applied in printing or coating nonwoven fabrics used in medical and industrial applications.

Benefits of Using Nickel Screens

High Precision Printing

The fine, uniform mesh allows for accurate and detailed pattern reproduction.

Durability and Long Lifespan

Resistant to wear and corrosion, ensuring a long operational life even in high-speed production lines.

Reduced Downtime

Strong and stable screens reduce breakage and stretching, which helps minimize machine stops and increases productivity.

Customizability

Available in various diameters, lengths, and mesh counts to suit specific printing needs.

Smooth Ink Transfer

The seamless surface of the screen ensures consistent ink flow and avoids smudging or uneven prints.

Choosing the Right Nickel Screen

When selecting a nickel screen, consider the following factors:

Mesh Count: Higher mesh counts are better for detailed work; lower mesh counts allow for more ink flow.

Screen Thickness: Thicker screens last longer and resist deformation.

Screen Diameter and Length: Must match the rotary screen printing machine specifications.

Type of Ink and Substrate: Some inks or materials may require specialized screen coatings or mesh sizes.

Conclusion

Nickel screens are a critical component in achieving high-quality, efficient rotary printing across various industries. Their precision engineering, strength, and versatility make them the preferred choice for manufacturers seeking flawless results at high speeds.

#nickel screens#rotary nickel screen manufacturers#nickel screen manufacturer#nickel screen for rotary printing#nickel mesh screen

0 notes

Text

Industrial Robots: Powering the Future of Smart Manufacturing

In today’s rapidly evolving industrial landscape, industrial robots are more than just machines — they’re the driving force behind productivity, precision, and innovation. From automotive to electronics, packaging to pharmaceuticals, industrial robots are transforming the way goods are produced, handled, and delivered.

Whether it’s assembling components, moving materials, or performing repetitive tasks with flawless consistency, industrial robots are at the core of modern automation. In this article, we’ll explore what industrial robots are, how they work, their types, benefits, and why more companies are investing in robotic automation than ever before.

What Are Industrial Robots?

Industrial robots are programmable, automated machines used to perform specific tasks in manufacturing or industrial environments. These tasks can include welding, painting, assembly, material handling, packaging, palletising, inspection, and testing.

Industrial robots are designed to replace or assist human workers in tasks that are dangerous, repetitive, or require extreme precision. They can be fixed or mobile, and often operate within a robotic cell or assembly line.

Types of Industrial Robots

Articulated Robots These have rotary joints and resemble a human arm. They are highly flexible and used for welding, assembly, and material handling.

SCARA Robots (Selective Compliance Articulated Robot Arm) Ideal for high-speed pick-and-place tasks, assembly, and packaging.

Cartesian Robots These operate on three linear axes (X, Y, and Z) and are great for CNC machines, 3D printing, and heavy load handling.

Delta Robots Known for speed and precision, they’re commonly used in packaging and pharmaceutical applications.

Collaborative Robots (Cobots) Designed to safely work alongside humans, cobots are ideal for small and medium enterprises seeking flexible automation.

Applications of Industrial Robots

Automotive: Welding, assembling chassis, and painting.

Electronics: Precise placement of micro-components.

Packaging: High-speed product picking, labeling, and boxing.

Pharmaceuticals: Sterile product handling and packaging.

Food & Beverage: Sorting, filling, and palletizing operations.

Benefits of Using Industrial Robots

Increased Productivity Robots can work 24/7 with consistent speed and accuracy, significantly increasing output.

Improved Product Quality Precision programming ensures that every task is performed identically, reducing defects and waste.

Reduced Labor Costs Robots minimize the need for manual labor in repetitive or hazardous jobs, saving costs over time.

Workplace Safety By taking over dangerous tasks, robots reduce the risk of injury to workers.

Faster Time-to-Market Automation accelerates the production cycle, helping companies meet market demands quicker.

Scalability and Flexibility Robotic systems can be reprogrammed or scaled to suit new products or production changes.

The Future of Industrial Robotics

The industrial robotics market in India and worldwide is growing at a remarkable pace, thanks to advances in AI, machine vision, IoT, and predictive maintenance. Robots are no longer confined to repetitive tasks — they are learning, adapting, and collaborating.

With the rise of smart factories and Industry 4.0, companies are leveraging robotics to optimise supply chains, reduce errors, and gain real-time data insights. As the demand for efficiency and customisation increases, so will the adoption of industrial robots across sectors.

Delta Stark Engineering: Your Partner in Industrial Automation

At Delta Stark Engineering, we specialize in designing and delivering high-performance industrial robots that meet your unique manufacturing needs. From pick and place systems to packaging automation, our robots are built for speed, precision, and long-term reliability.

We offer:

Customized automation solutions

Integration with existing systems

Full support and service across India

Whether you're upgrading your production line or building a smart factory from scratch, our robotic systems empower your business to operate smarter, safer, and faster.

#pick and place robots#psychrometric labs#belt conveyors#deltastark#side entry iml robots#commercial

0 notes

Text

Melt, Form, and Wrap: A Deep Dive into the Candy Making Process

Candy making is a fascinating blend of science, technology, and creativity. From simple hard candies to elaborate chocolate truffles, every sweet treat follows a structured and carefully controlled process. Modern confectionery production depends on reliable, high-performance equipment to deliver consistency, quality, and efficiency. That’s where Latini Hohberger Dhimantec shines—offering precision-engineered candy manufacturing machines that provide exceptional value and output.

Let’s explore how raw ingredients are transformed into delightful confections.

Melting: Building the Candy Base

The journey begins with melting core ingredients such as sugar, glucose syrup, and flavorings in large heated vessels. Accurate temperature control is critical—too much heat can cause premature caramelization, while too little heat prevents proper sugar dissolution.

Latini Hohberger Dhimantec’s advanced cooking systems are designed to precisely monitor and manage temperature, ensuring consistent results every time.

For chocolate-based products, tempering is key. Stabilizing cocoa butter crystals gives chocolate its smooth texture and glossy finish. Without proper tempering, chocolate may become grainy or develop unwanted white streaks (bloom), reducing its visual appeal and shelf stability.

Forming: Shaping the Final Product

After melting, the candy base moves into the forming stage. This is where the candy is shaped into its final form—be it lollipops, drops, or other unique designs. High-speed forming machines from Latini Hohberger Dhimantec provide precision, consistency, and flexibility for a variety of confectionery products.

Cooling tunnels quickly solidify the candy, locking in the desired shape and texture. Different types of forming equipment are used depending on the product. For example, rotary forming systems are ideal for hard candies, while servo-driven die forming machines can handle intricate shapes with ease and speed.

Wrapping: Preserving Freshness and Appearance

Once the candy is fully formed and cooled, it moves to the wrapping stage. Proper packaging is essential—not only for freshness and hygiene, but also for shelf appeal. Wrapping machines from Latini Hohberger Dhimantec support various formats, including twist wraps, flow packs, and foil seals.

With the integration of printing and labeling systems, manufacturers can add batch codes, expiry dates, and branding elements directly onto packaging. These capabilities help maintain product traceability and enhance marketing impact.

Automation: Enhancing Efficiency and Quality

Automation has become a game changer in candy production. With growing consumer demand and tighter production timelines, automated systems help manufacturers scale up while maintaining strict quality control.

Latini Hohberger Dhimantec offers fully integrated systems—from ingredient mixing to final packaging. Automation minimizes human error, reduces labor costs, and improves throughput. Robotic arms can sort, fill, and package various candy types, while smart sensors catch inconsistencies before products reach consumers.

Overcoming Challenges in Candy Manufacturing

Even with advanced machinery, confectionery production has its hurdles. Consistency in taste, texture, and appearance requires constant monitoring. Small variations in ingredient ratios or processing times can significantly impact the final product.

Humidity control is another concern—excess moisture can cause stickiness, while overly dry conditions lead to cracks. Latini’s equipment incorporates precise climate control features to maintain ideal environmental conditions.

Compliance with food safety regulations is also essential. From hygiene standards to allergen labeling, modern equipment must support traceability and recordkeeping. Latini’s automated systems streamline this process and help ensure regulatory adherence.

The Future of Candy Production

The confectionery industry is rapidly evolving. Consumers are seeking healthier, cleaner-label sweets, including sugar-free and organic options. Equipment from Latini Hohberger Dhimantec supports these demands with precision dosing systems that allow for low-sugar, fortified, or functional candy formulations.

Sustainability is another priority. More manufacturers are switching to biodegradable packaging and energy-efficient production methods. Latini’s machines are engineered to optimize material usage and reduce environmental impact—without sacrificing speed or quality.

Conclusion

From melting and forming to wrapping and packaging, every step in the candy-making process requires precision, reliability, and innovation. High-quality candy manufacturing equipment is not just a tool—it’s the foundation of production success.

Latini Hohberger Dhimantec is proud to be a trusted global leader in the confectionery equipment industry. Our machines are designed to deliver top-tier performance, efficiency, and durability—backed by decades of expertise and a commitment to quality.

Source URL: Blogspot.com

0 notes

Text

Flexographic Flat Printers: Revolutionizing Packaging and Printing Industries

Flexographic Flat Printers have become an indispensable tool in the modern printing and packaging industries. Known for their versatility, efficiency, and precision, these machines play a vital role in printing designs, texts, and images on a variety of surfaces. Let’s explore their features, applications, and advantages to better understand their importance.Get more news about Flexographic Flat Printer,you can vist our website!

What Is a Flexographic Flat Printer? A Flexographic Flat Printer is a type of printing machine that employs a flexible relief plate. It works on the principle of rotary printing, transferring ink from the plate to the surface of the material being printed. These machines are well-suited for a wide range of substrates, such as paper, cardboard, plastics, and metallic foils.

Unlike other printing methods, Flexographic Flat Printers are celebrated for their adaptability and high-speed operation. They can print on both flat and uneven surfaces, making them perfect for various packaging and industrial applications.

Key Features of Flexographic Flat Printers Flexographic Flat Printers come with several distinctive features that set them apart:

High Flexibility: The machines can print on a vast range of materials and surfaces.

Quick Drying Inks: They utilize special inks that dry rapidly, reducing production time.

Precise Registration: Advanced designs ensure accurate alignment for multi-color printing.

Eco-Friendly Operation: Many modern machines support water-based inks, promoting sustainability.

High-Speed Production: These printers are designed to handle large volumes in minimal time.

Applications of Flexographic Flat Printers Flexographic Flat Printers are widely used in multiple industries, including:

Packaging: Printing logos, graphics, and text on cartons, corrugated boxes, and flexible packaging materials.

Labeling: Producing high-quality labels for bottles, jars, and other containers.

Industrial Uses: Printing on non-traditional surfaces like metal sheets, laminates, and synthetic materials.

Newspaper & Magazine Printing: Offering cost-effective solutions for large-scale printing tasks.

Their ability to handle various materials and accommodate custom designs makes them a preferred choice for businesses aiming to enhance their brand identity.

Advantages of Flexographic Flat Printers The advantages of using Flexographic Flat Printers include:

Cost Efficiency: Reduced setup times and high-speed operation lead to lower production costs.

Sustainability: Eco-friendly inks and reduced waste make them an environmentally conscious option.

Quality Printing: Advanced technology ensures crisp, vibrant, and high-resolution prints.

Versatility: Suitable for a wide range of industries and applications.

Challenges and Future Trends While Flexographic Flat Printers are highly efficient, challenges such as initial setup costs and maintenance requirements can pose difficulties. However, ongoing innovations in automation and digital integration are set to address these issues, making the technology more accessible and effective.

Conclusion Flexographic Flat Printers have transformed the printing industry by offering unmatched versatility and efficiency. Their broad applicability and commitment to sustainability make them a vital asset for businesses across the globe. As technology advances, these printers will continue to evolve, delivering even greater benefits to the industries they serve.

0 notes

Text

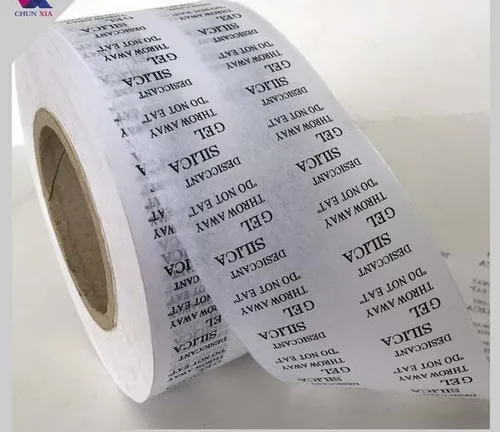

Silica gel packing roll

In industries where moisture control is crucial, silica gel is a widely trusted solution. However, for high-speed, bulk, and automated silica gel sachet production, you need a reliable packaging material that is both breathable and strong. This is where the Silica Gel Packing Roll becomes essential. It is specifically designed for manufacturing silica gel sachets efficiently while ensuring maximum moisture absorption performance.

What is a Silica Gel Packing Roll?

A Silica Gel Packing Roll is a specially formulated roll made from breathable laminated non-woven fabric or paper, used for automatic and manual silica gel sachet making. It allows moisture to pass through easily while retaining the silica gel securely inside the sachets. These rolls are suitable for high-speed automatic packing machines, making sachet production fast and consistent.

Features of Silica Gel Packing Roll

✅ Excellent Breathability The roll material allows moisture to enter easily, ensuring silica gel works effectively.

✅ High Strength & Durability Designed to withstand high-speed machine operations without tearing or breaking.

✅ Smooth Surface for Machine Compatibility Ensures trouble-free performance in both automatic and semi-automatic sachet packing machines.

✅ Available in Custom GSM & Sizes We supply rolls in different GSM (20 to 60 GSM) depending on your sachet size and packing needs.

✅ Eco-Friendly Option Available We also offer eco-friendly and food-grade silica gel packing rolls suitable for pharmaceutical and food industries.

Advantages of Using Silica Gel Packing Roll

Increases the productivity of silica gel sachet production

Provides uniform and high-quality sachets

Reduces wastage during the packaging process

Compatible with both rotary and vertical form fill seal (VFFS) machines

Helps in cost-effective and efficient mass production

Applications of Silica Gel Packing Roll

Silica Gel Packing Rolls are widely used in the manufacturing of:

Electronics protection sachets

Pharmaceutical-grade silica gel sachets

Leather goods and shoe packaging

Garments and textile packaging

Machinery & metal components packaging

Food-grade moisture absorber packs (with food-safe certification)

Available Sizes

WidthGSMRoll LengthUsage80mm20-25 GSMCustomizableSmall sachets100mm25-35 GSMCustomizableMedium sachets150mm30-50 GSMCustomizableLarge sachetsCustomAs per requirementCustomizableOEM production

Why Choose Our Silica Gel Packing Roll?

At [Your Company Name], we specialize in manufacturing high-quality Silica Gel Packing Rolls that meet the global standard for moisture-absorbing sachets.

✅ Consistent Roll Quality ✅ Compatible with All Major Sachet Packing Machines ✅ Bulk Production & Timely Delivery ✅ Custom Printing & Private Label Options ✅ Competitive Wholesale Prices

Frequently Asked Questions (FAQs)

Q1: Is this roll suitable for automatic sachet packing machines? Yes, our rolls are designed for both automatic and semi-automatic sachet packing machines.

Q2: Can I get custom-printed rolls for my brand? Yes, we offer custom printing on silica gel packing rolls for branding purposes.

Q3: What is the minimum order quantity (MOQ)? MOQ depends on the GSM and roll width; please contact us for the latest MOQ.

Q4: Is food-grade packing roll available? Yes, we provide food-grade breathable laminated non-woven rolls for food and pharma use.

0 notes

Text

Maximize Your Label Production Efficiency with UV Graphic

Punching machines are used to create high-quality labels and shapes needed in industries such as packaging, retail, and logistics. They cut a variety of materials into perfect labels, ensuring that applications, including branding and product identification, will always have a consistent finish.

UV Graphic is one of the well-known companies in the printing and converting industry. It manufactures state-of-the-art label punching machines. These are designed with advanced technology in them which throws unique precision and speed, making them very well-suited for high-volume production lines. The machines support many materials including paper, film, and metallic foils as per the need of diversified industries.

The Label punching machines from UV Graphic are loaded with automated operation, easy setting, and low maintenance features which ensure the least possible downtime and maximized productivity for businesses. The solutions range from short runs to bigger projects as they cater for all sizes.

With UV Graphic, you are assured of state-of-the-art technology and service. The best quality and innovation are put in to see that the production process runs well in the current competitive market.

#curing machine manufacturer#gravure printing machines manufacturer#uv curing systems#rotary hot foil stamping#Label Punching Machines Manufacturer

0 notes

Text

High-Performance Printing & Converting Machines | Advanced Solutions

In the modern world, the printing and packaging industry has started to completely rely on precision, effectiveness, and novelty. Advanced technology such as slitting rewinding machines, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems is among the most significant tools rendering final mba product quality.

Machine manufacturers and converters rely heavily on high-level technological tools to speed up the process of production, increase accuracy, and aid versatility of their machines. The description of the machines' importance in various industrial applications has been outlined in a set of present practice method, showing machines' necessity in printing and packaging industries today.

Slitting Rewinding Machine

A slitting rewinding machine is a vital component in industries dealing with flexible packaging, paper, films, and foil materials. It enables the precise slitting and rewinding of large master rolls into smaller rolls with accurate tension control.

Key Features of a Slitting Rewinding Machine:

High-Speed Performance: Ensures rapid slitting and rewinding without compromising quality.

Precision Cutting: Adjustable slitting blades provide clean and accurate cuts.

Tension Control Mechanism: Maintains optimal tension for smooth rewinding.

User-Friendly Interface: Automated controls for easy operation and reduced downtime.

Versatile Applications: Suitable for plastic films, aluminum foils, paper rolls, and adhesive tapes.

Applications of Slitting Rewinding Machines:

Flexible Packaging Industry: For slitting plastic films and foils.

Label Production: Converts large rolls into label-sized formats.

Printing Industry: For handling coated and laminated materials.

Label Die Cutting Machine

A label die cutting machine is essential for the precise cutting of labels, stickers, and adhesive sheets. It ensures clean edges, intricate shapes, and high-speed production for industries requiring mass labeling.

Key Features of a Label Die Cutting Machine:

Rotary & Flatbed Cutting: Supports various die-cutting methods for different label types.

Automatic Waste Removal: Ensures a cleaner output with no excess material.

High Cutting Accuracy: Ideal for custom shapes and intricate label designs.

Multi-Layer Processing: Allows multiple layers for enhanced durability.

User-Friendly Control Panel: Simplifies operation and reduces labor requirements.

Applications of Label Die Cutting Machines:

Food & Beverage Labeling: Used for bottle and container labeling.

Pharmaceutical Industry: For precision-cut medical labels.

Cosmetic & Personal Care Products: Ensures premium quality label cutting.

Paper Core Cutting Machine

A paper core cutting machine is used to cut paper tubes and cores to the desired length, ensuring smooth edges and accurate dimensions for various industrial applications.

Key Features of a Paper Core Cutting Machine:

High Cutting Precision: Produces accurate and smooth cuts for uniform core sizes.

Adjustable Cutting Lengths: Allows customization for different applications.

Heavy-Duty Construction: Ensures durability and longevity.

Automatic & Manual Operation: Supports both automatic and manual cutting modes.

Dust-Free Operation: Minimizes waste and enhances cleanliness.

Applications of Paper Core Cutting Machines:

Packaging Industry: For manufacturing paper cores for packaging rolls.

Printing Sector: Used for paper roll cores and film winding.

Textile Industry: For fabric and yarn core cutting.

Hot Foil Stamping Machine

A hot foil stamping machine enhances the visual appeal of printed products by adding metallic and holographic foil designs. It is widely used in luxury packaging, book covers, greeting cards, and promotional materials.

Key Features of a Hot Foil Stamping Machine:

Advanced Foil Transfer Technology: Ensures sharp and clean imprints.

Temperature & Pressure Control: Allows precise adjustments for different materials.

Multi-Purpose Applications: Works on paper, plastic, leather, and fabric.

Automatic Foil Feeding System: Ensures smooth and continuous foil application.

Energy-Efficient Design: Reduces operational costs and improves efficiency.

Applications of Hot Foil Stamping Machines:

Luxury Packaging: Enhances premium product packaging.

Branding & Promotions: Used for high-end business cards and brochures.

Security Printing: Adds holographic elements for anti-counterfeiting.

UV Curing Systems

A UV curing system is an advanced technology used for instant drying and curing of inks, coatings, and adhesives using ultraviolet light. This method ensures high-quality finishes, durability, and eco-friendly operations.

Key Features of a UV Curing System:

Instant Drying & Curing: Reduces production time significantly.

Energy Efficiency: Consumes less power compared to traditional drying methods.

Eco-Friendly Operation: Eliminates the need for solvents and harmful chemicals.

High Durability: Ensures scratch-resistant and long-lasting prints.

Wide Compatibility: Suitable for offset, flexographic, and screen printing.

Applications of UV Curing Systems:

Printing Industry: For UV-cured inks and coatings.

Electronics & PCB Manufacturing: Ensures durable protective coatings.

Medical Devices: Used for adhesive bonding in healthcare applications.

Why Invest in High-Performance Printing & Converting Machines?

Enhanced Production Efficiency – Reduces downtime and increases output.

Precision & Quality – Ensures accurate cutting, stamping, and curing.

Cost-Effective Solutions – Optimizes material usage and reduces waste.

Versatile Applications – Suitable for various industries, from packaging to textiles.

Advanced Automation – Minimizes manual labor and improves operational accuracy.

By integrating the latest slitting rewinding machine, label die cutting machines, paper core cutting machines, hot foil stamping machines, and UV curing systems, manufacturers can achieve superior productivity and quality.

Project Name: UV Graphic Technologies Pvt. Ltd

Address: Plot 15, Sector 140A, Noida UP 201305

Contact No: 919810114365

Email ID: [email protected]

Our Website: https://gtigti.com/

Linkedin ID: https://www.linkedin.com/company/uv-graphic-technologies-pvt-ltd/

You tube: https://www.youtube.com/watch?v=EleXfuBanIk&ab_channel=AbhayDatta

0 notes

Text

LINTEC SR-400 SEMI ROTARY STICKER - LABEL PRINTING MACHINE FOR SALE | MK PRINTECS MACHINERY

.

.

.

For More Information Contact Us ;

MK PRINTECS MACHINERY

( ALL KIND OF LABEL, OFFSET, CUTTING & SCREEN PRINTING MACHINE - IMPORTER, EXPORTER & SUPPLIER IN INDIA )

#4/168, Sivakasi - Erichanatham Main Road, Opp. To Ayyan Fireworks,

Aishwarya Nagar, Vellaiya Puram,

Thiruthangal - 626130,

Tamil Nadu, INDIA

Mob : +91 9842985143 | 8531010853 | 7200729855

E-Mail : [email protected]

Click here to call us : https://mkprintecs.com/mani/+919842985143

Web : https://www.mkprintecs.com

0 notes

Text

Webtech Group's S4 series flexographic press at Labelexpo

At Labelexpo India 2024, Webtech Group, a leading manufacturer of printing and paper-converting machinery, unveiled its latest advancements for the flexographic printing industry. It conducted a live demonstration of its latest generation flexographic printing presses, Labeltech S3-450 and Labeltech S4-670.

The highlight at Webtech's stand was the launch of the S4-670, a full servo with auto registration, an ELS machine with a double servo on a plate, and an impression cylinder of the printing stations. The 8-color machine can run at a speed of 200m/min. The S3 series machine highlighted at the other end of the stand is a full-servo ELS machine with a single servo on each impression cylinder of the printing stations. With 15 servos on the press, the machine is characterized by an all LED dryer, chiller system and 2 die cut stations.

Shivnandan Singh, director, Webtech International Machineries said, “The live demonstration and the new launch were the testament of our capabilities. We got extremely good responses from our customers and visitors.”

According to him, as global consumer preferences shift toward eco-friendly and convenient solutions, the demand for flexible packaging has surged. Key sectors such as food and beverage, healthcare, and e-commerce rely on flexible packaging to meet their needs for durability, safety, and efficiency. “Recognizing this growing demand, machines from Webtech Machineries are designed to meet the rigorous demands of the flexible packaging industry.”

The team concluded the show with the booking of 5 fully servo flexo presses (single and dual servo), 3 slitters, and 2 rotary labels die-cutting machines. Within 12 days of the exhibition, Webtech finalized two more deals for its full servo flexo press.

“This year’s Labelexpo was nothing short of a resounding success for Webtech Group. The enthusiasm and keen interest in our flexo-label press surpassed our expectations. With such an exceptional response, we are confident that many more orders will materialize,” said Singh.

0 notes

Text

The Automatic Rotary Labeling Machine streamlines your labeling process with precision. Containers are fed onto a rotary star plate, where they are smoothly transported to the labeling point. An electronic sensor releases the label, which is then pressed onto the bottle with the help of a roller. If equipped, the batch printing device prints necessary details like batch numbers while the label is stationary. Once the labeling is complete, the starwheel efficiently transfers the bottle to the next operation on the conveyor.

For more information, visit - https://www.parthec.com/product/automatic-rotary-labeling-machine

#Parthec#AutomaticBottleLabelingMachine#RotaryLabelingMachine#BottleLabelingMachine#BatchLabelingMachine#ContainerLablingMachine

0 notes

Text

Formation of China's Three Major Self-Adhesive Label Printing Bases

China's self-adhesive label printing industry chain has taken shape, with Shenzhen, Shanghai, and Beijing emerging as three major printing hubs.

Since the 1990s, the self-adhesive label printing market, driven by the demand for automatic labeling, has rapidly developed towards industrialization. Today, this market boasts a relatively complete industrial chain and a significant industry scale. This rapidly growing market in China has attracted the attention of many internationally renowned suppliers of self-adhesive label materials and printing equipment. Meanwhile, a number of professional self-adhesive label printing factories with considerable scale are on the rise.

1. Material Supply

Global leading suppliers of self-adhesive label materials, such as the U.S.-based Avery Dennison Corporation and Japan's Lintec Corporation, have recognized the potential of China's burgeoning market. Since the 1990s, they have invested heavily in China, significantly contributing to the market's rapid growth. Avery Dennison entered China in 1994, investing nearly $30 million to establish a self-adhesive label material production base in Kunshan, with sales branches quickly spreading nationwide. Recently, the company invested another $30 million to build a factory in Guangzhou. Additionally, Avery Dennison established the Asia-Pacific region's first professional training center for self-adhesive label printing and processing with a $2 million investment to enhance domestic printing technology.

Lintec Corporation invested $30 million in 2003 to build self-adhesive and release liner production lines in Suzhou New District, with a monthly production capacity of 8 million square meters in its second phase.

In Wenzhou Longgang and Zhongshan, Guangdong, several powerful private suppliers of self-adhesive label materials have emerged. In these two locations alone, there are more than 10 material suppliers.

2. Equipment Supply

Since 2002, major international flexographic printing machine agents have shifted their focus to narrow-web flexographic machines suitable for self-adhesive label printing. Statistics show that China’s packaging and printing enterprises now operate nearly 400 imported and domestically produced flexographic production lines (including wide-web ones), with imports accounting for 80% (320 lines) and domestic production 20% (80 lines). Imported equipment mainly comes from companies like Gallus, Mark Andy, Nilpeter, and others. In 2002, 70% of the newly installed flexographic machines in the domestic market were used for self-adhesive label printing.

Meanwhile, domestic traditional printing equipment manufacturers like Shanghai Ziguang, Shaanxi Beiren, Qingzhou Yigao, and others have targeted the self-adhesive label market, developing high-quality narrow-web flexographic printing machines.

Prominent suppliers of offset printing equipment for self-adhesive labels, such as Lintec, RotoMetrics, and Nilpeter, have also established offices and service centers in China. Renowned brands like SANKI and Ko-Pack now have agents in China as well.

Moreover, many suppliers of auxiliary processing equipment (e.g., die-cutting machines and tools) have begun setting up offices or manufacturing bases in major Chinese cities. For example, circular rotary die-cutting tools for flexographic machines, previously sourced from abroad, are now available in cities like Shanghai and Guangzhou.

3. Self-Adhesive Label Printing

Initially, foreign-funded professional self-adhesive label printing companies entered this market. These manufacturers, with years of experience in producing self-adhesive labels abroad, brought advanced printing equipment, technologies, and management expertise to China. Some foreign-invested printing companies have achieved annual outputs exceeding 100 million yuan after several years of development. The market continues to attract more foreign investors. For instance, over 20 foreign-invested self-adhesive label printing companies are currently based in Shanghai (including Suzhou). Following the government's decision in August 2001 to permit foreign-owned enterprises to engage in packaging and printing, more capable foreign enterprises are expected to join the competition.

Additionally, several private self-adhesive label printing enterprises have grown significantly in recent years, starting to invest in high-end rotary letterpress or flexographic printing equipment. In cities like Shanghai, Beijing, Tianjin, Suzhou, Wenzhou, and Guangzhou, many private professional printing companies now achieve annual revenues exceeding 10 million yuan.

A Robust Industrial Chain

China has established a relatively complete self-adhesive label printing industry chain. Powerful companies, including prominent multinational enterprises, now form the backbone across material supply, equipment supply, and printing. As the self-adhesive label market continues to grow, this industrial chain is poised to become even more mature and robust.

Advancements in Printing Technology

In the past, due to a lack of skilled self-adhesive label printers and well-established processing techniques, printing companies primarily relied on outdated flatbed label printing machines for simple labels. Complex labels, especially those using transparent film materials, were beyond their capabilities, forcing some multinational clients to outsource these orders to foreign companies.

Today, domestic label quality and the supply and service of related equipment and materials have significantly improved. Recognizing the quality and service of qualified domestic printers, some multinational corporations now transfer their overseas orders to China. Now, many of the intricate and beautiful labels on consumer products in supermarkets are printed locally.

0 notes

Text

Automatic Inhaler Labeling Machine

Automatic Inhaler Sticker Labeling Machine is suitable for label on round inhalers. Machine is based on rotary mechanism to label inhalers. The containers received from feed worm to star wheel precisely spaced and reach at the label wrap around point at the similar distance. While entering at the labeling point, container sensor start with servo motor and pressing belt press the label smoothly between pad and belt. Label sensor photocell detects the space between two labels and holds them until the next container comes. Meantime of this operation pneumatic printing attachment prints.

0 notes