#rotor stator pump

Text

Rotor Stator Mixers/Rotor Stator Manufacturers, Suppliers, Exporters, Trader and Dealer in India| Various Rotor Stator Mixers Specifications are offered by SPM Process Systems.

#Rotor Stator Mixers#Rotor Stator Mixer#Rotor Stator Mixers Manufacturer#Rotor Stator Mixers Manufacturer in India#Rotor Stator Mixers Manufacturers in India Rotor Stator Mixers supplier#Rotor Stator Mixers suppliers in India#Rotor Stator Mixers Exporter#Rotor Stator Mixers Exporter in India#rotor-stator homogenizer#high shear mixer#rotor stator pump#Industrial High Rotor Stator Mixers#rotor-Rotor Stator Mixers#rotor-Rotor Stator Mixers manufacturer

0 notes

Text

TAIKO SCREW PUMP HNP-401 parts ROTOR no 101 AND STATOR no 001 Total 2set worldwide delivery

Maker: TAIKO SCREW PUMP PARTS ORIGINAL

Type : HNP-401

ROTOR p/n 101 Quantity 2pieces

STATOR P/n 001 Quantity 4pieces

HNP-301 stator 2pcs also available in our stock

WORLDWIDE DELIVERY

Complete pump also available

Thanks & Regards,

Shakeel Sheikh

IDEAL DIESEL MARINE

E-MAIL: [email protected]

[email protected] ( cc email)

[email protected] ( cc email)

City : Bhavnagar 364001 Gujarat INDIA

#TAIKO SCREW PUMP HNP-401 parts ROTOR no 101 AND STATOR no 001 Total 2set#TAIKO SCREW PUMP HNP-401#TAIKO SCREW PUMP HNP-401 parts ROTOR no 101 AND STATOR no 001#TAIKO SCREW PUMP HNP-401 STATOR no 001#TAIKO SCREW PUMP HNP-401 parts ROTOR no 101 Total 2set#TAIKO HNP-401 parts#TAIKO HNP401#HNP-401#Taiko pump HNP-401#TAIKO HNP401 parts

0 notes

Text

Electrical Motor Heat

Electrical motor heat in water pumps is a significant aspect of their operation and efficiency. Here’s a detailed look at how heat is generated in electrical motors, its impacts, and how to manage it:

Sources of Heat Generation in Electrical Motors

Electrical Resistance (I²R Losses):

Stator and Rotor Windings: As electric current flows through the copper or aluminum windings of the stator and rotor, electrical resistance causes heat. This is often the largest contributor to heat in electric motors.

Eddy Currents: These are circulating currents induced within the motor’s iron core, causing additional heating.

Magnetic Losses:

Hysteresis Losses: As the motor’s magnetic field reverses, energy is lost in the form of heat due to the hysteresis in the magnetic materials.

Core Losses: These occur in the laminated steel core of the motor due to alternating magnetic fields.

Mechanical Losses:

Bearing Friction: The bearings supporting the motor’s rotor experience friction, generating heat.

Windage Losses: Air resistance (windage) within the motor as the rotor turns can also produce heat.

Stray Load Losses:

These losses are due to imperfections in the motor’s design and manufacturing, including misalignment and surface roughness of components, leading to additional heat.

Impact of Electrical Motor Heat

Thermal Stress:

Component Degradation: Prolonged exposure to high temperatures can degrade insulation materials, windings, and bearings, reducing the motor’s lifespan.

Efficiency Reduction: Higher temperatures increase resistance in electrical components, further reducing efficiency.

Performance Issues:

Reduced Torque: Excessive heat can reduce the motor’s ability to generate torque, affecting its performance.

Thermal Expansion: Uneven thermal expansion of motor parts can lead to misalignment and increased wear.

Safety Concerns:

Fire Hazard: Overheating can pose a fire risk, especially if the insulation materials catch fire.

Shutdowns: Thermal protection systems may shut down the motor to prevent damage, leading to operational downtime.

Managing Heat in Electrical Motors

Cooling Systems:

Air Cooling: Most electric motors use air cooling, with external fans or fins to increase surface area for heat dissipation.

Liquid Cooling: For high-power applications, liquid cooling systems can be used to effectively remove heat.

Proper Ventilation:

Ensuring adequate airflow around the motor can help dissipate heat. Installing motors in well-ventilated areas can prevent overheating.

High-Efficiency Motors:

Using motors with higher efficiency ratings can reduce the amount of heat generated, as they convert more electrical energy into mechanical energy and less into heat.

Regular Maintenance:

Lubrication: Regularly checking and maintaining proper lubrication reduces frictional heat.

Cleaning: Keeping the motor and its cooling system clean from dust and debris ensures efficient heat dissipation.

Temperature Monitoring and Control:

Sensors: Installing temperature sensors in critical areas of the motor can provide real-time data on operating temperatures.

Automatic Shutdowns: Implementing automatic shutdown features when temperatures exceed safe thresholds can protect the motor from damage.

Material Selection:

Using materials with good thermal properties in motor construction can help manage and dissipate heat more effectively.

Load Management:

Ensuring the motor operates within its rated load limits can prevent excessive heat generation. Overloading a motor can lead to significant increases in heat production.

By understanding and managing the sources of heat generation in electrical motors, the performance and longevity of water pumps can be significantly enhanced. Proper cooling, maintenance, and monitoring are crucial to keeping motors operating efficiently and safely. For more info contact Water Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Horizontal devices have become more common in a wide range of industrial applications in engineering and technology. These tools at Flowmore are vital in a variety of fields, including water management, agriculture, and the chemical industry. They are made to transfer fluids from one location to another. We will give a thorough overview of horizontal devices in this post, covering everything from their fundamental functions to their uses and benefits.

How are horizontal pump devices operational?

The idea behind Horizontal Pumps is the exact and controlled movement of fluids. Horizontal pump devices use mechanical components to transport the fluid in defined volumes, as opposed to centrifugal pumps, which accelerate the fluid to provide a continuous flow. This guarantees a steady and steady flow.

Horizontal pump device types

Horizontal pump devices come in a variety of forms, each tailored to a particular use. Among the most prevalent kinds are:

Pump with a piston: These pumps employ a piston to pump fluid up and down a cylinder. They are perfect for applications requiring precision and high pressure.

Progressive Cavity Pump: To transfer fluid via progressive cavities, these pumps use a helical rotor that travels inside a stator case. They work well with abrasive and viscous solutions.

0 notes

Text

Low Voltage AC Motor Market - Forecast(2024 - 2030)

Low voltage AC motor market size is forecast to surpass $25 billion by 2030, after growing at a CAGR of 7% during the forecast period 2024-2030. The government's energy efficiency regulations on motor-driven systems in industrial & commercial sector are anticipated to be the main growth drivers for the worldwide low-voltage AC motors market. Apart from this the investments towards expansion of existing plants and setup of new ones across pharmaceutical, food & beverages, water & wastewater, power generation and other verticals to drive the demand for low voltage AC motors market during the forecast period 2024-2030

Report Coverage

The report “Low Voltage AC Motor Market – Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Low Voltage AC Motor market.By Type: Synchronous Motors, Induction Motors, Permanent Magnet Motors, Servo Motors, OthersBy Power Rating: up to 1 HP, 1-5 HP, 5-10 HP, 10-20 HP, 20-50 HP, above 50 HP. By Phase: Single Phase, Three PhaseBy Housing Material: Aluminum, Cast Iron, Steel. By Efficiency Class: IE1, IE2, IE3, IE4, IE5By Application: Pumps, Machine Tool, Compressor, Conveyor Systems, Robotics & Automation, HVAC&R, Fans & Blowers, Main Drive Units, OthersBy End User Industry: Oil & Gas, Chemical, Pharmaceutical, Mining, Food & Beverage, Water & Wastewater, Commercial, Transportation, Agriculture, Power Generation, Automotive, Industrial Machinery, OthersBy Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

• The adoption of higher efficiency motors such as the IE4 class of motors has been favorably embraced by Europe region, and legislation governing motor efficiency in the EU remains a driving force in the market.• By 2050, global power usage is expected to double. Around the same period, the governments are planning to reduce their country's CO2 emissions by 50% in order to mitigate climate change. Electric motors account for roughly 40% of global energy use. Industries are another major worldwide energy user, with motors in industrial plants often consuming 65 to 80% of total plant electricity. As a result, an energy-efficient IE4 motor is expected to set a trend in the market for low-voltage AC motors.• On 19 May 2023, The Board of Directors of Siemens Limited authorized a sale and transfer of Siemens Limited's AC and DC low voltage motors and geared motors businesses, including related customer service businesses ("the Business") to Siemens Large Drives India Private Limited, an entity completely owned by Siemens AG, for a consideration of Rs. 2,200 crore, effective October 1, 2023.

Request Sample

By Type- Segment Analysis

Induction motors dominated the Low voltage AC motor market in 2023. Low-voltage alternating current induction motors transfer electrical energy from stator to rotor without the use of slip rings or brushes, resulting in smooth, quiet, and consistent performance owing to which there are significant less maintenance cost during the service period. Induction motors being majorly used in commercial vertical for pumps, elevators & escalators, HVAC and other applications, is set to witness an significant upsurge during the forecast period 2024-2030 with the rise in investments towards establishments of commercial buildings such shopping malls, office parks, hospitals and so on.

By Power Rating- Segment Analysis

1 to 5 HP motor segment dominated the global low-voltage AC motor market in 2023 owing to the widescale use of induction motors for pumps, main drive units, fans & blowers, compressors and so on in various industry verticals. The growing emphasis towards integration of energy efficient motors such permanent magnet motors for continuous duty operations is set to drive the market during the forecast period 2024-2030. Apart from this the increase in investments towards setting up of new plants and upgrade of the existing ones with energy efficient equipment is also set to the assist the market growth in the future.

By Construction Material- Segment Analysis

Steel dominated the Low voltage AC motor market in 2023, owing to advantages of certain grades of steel such as stainless steel towards corrosion resistance, durability, hygiene, and aesthetics. Stainless steel motors are especially suitable for applications that require frequent washdowns, such as food processing, pharmaceuticals, wastewater, and other harsh environments. For instance, ABB’s stainless steel AC brushless servo motors are built with washdown capability and may be applied in harsh, corrosive environments. These stainless-steel AC brushless servo motors achieve IP67 dust and liquid ingress protection and can withstand 1,500 psi washdown conditions.

By Efficiency Class- Segment Analysis

IE3 dominated the Low voltage AC motor market in 2023. The rising emphasis on energy efficiency, sustainability, and regulatory compliance is driving the growth of the IE3 Low Voltage AC Motor market. As enterprises strive to improve operations, minimize energy consumption, and meet global environmental targets, IE3 motors provide a compelling solution that provides both economic and environmental benefits. For instance, In 2022, ABB introduced flameproof low-voltage motors for explosive atmospheres, ABB's new low-voltage flameproof motors are designed for safe usage in potentially explosive atmospheres. The made-in-India motors are available in IE2 and IE3 efficiency classes, with frame sizes ranging from 80 to 250 mm. IE3 low voltage AC motors are frequently chosen as part of energy reduction measures by organizations participating in energy management programs or obtaining energy certifications such as ISO 50001. Many countries and areas have enacted stringent laws and standards mandating the use of more energy-efficient motors. These regulations demand that IE3 motors achieve or exceed the efficiency requirements.

By Application Type- Segment Analysis

The water pump segment dominated the low-voltage AC motor market in 2022. Due to various aspects that contribute to its advantages in this specific application. Water pumps are used for a variety of applications, including agricultural irrigation, industrial processes, wastewater treatment, and more. Low Voltage AC Motors provide multiple benefits that are ideally suited to the needs of water pump systems. Growing reliance on groundwater and monsoon irregularities are fueling demand for water pumps in the agriculture sector. Government efforts to improve water infrastructure, water supply, and sanitation services around the world are likely to boost the use of water pumps even further. Increased emphasis on the setting up of new wastewater treatment plants and desalination plants around the world, along with numerous government programs to improve and upgrade the existing plants are also analyzed drive the market for low-voltage AC motors during 2024-2030

Buy Now

By Geography - Segment Analysis

The APAC region attributed to the largest share of the global low voltage AC motor market in 2023 and is also estimated to witness the highest growth of CAGR 8% during 2024-2030. The low-voltage AC Induction motor type market in China has positive growth opportunities, mainly supported by increasing demand for efficient and energy-saving solutions. The government’s initiatives to promote the use of new energy-efficient motors as well as the rising demand for high-power motors from the industrial sector will further drive the growth of the AC motor types market in China. The growing demand from various end-user industries, such as the automotive, oil & gas, and power generation sectors is the primary driver of this growth. Furthermore, the Government of India’s Make in India initiative, and the recent surge in renewable energy installations, are other factors contributing to the market’s growth.

Drivers – Low Voltage AC Motor Market

• Increase in demand of Electric Vehicles to drive the establishment of new manufacturing plants.The growing environmental concerns from internal combustion engine exhausts is already leading to the shift towards electric vehicles. With favourable government initiatives such as grants, subsidies, and tax benefit towards adoption of electric vehicles the demand for the same has been witnessing multi-fold growth in recent years. Owing to this shift, the auto OEMs are investing significantly towards setting up of new plants and expanding the production capacities of the existing ones to meet this surge in demand. This is set to drive the demand of low voltage AC motors used in EV manufacturing plants for various major applications such as main drive units for assembly line, robotics & automation, HVAC, and so on. In April 2023, Two major automakers, General Motors and Hyundai, have separately announced plans to build electric vehicle (EV) battery plants in the US, indicating the continued growth of EV manufacturing in the country. General Motors is partnering with Samsung SDI to invest $3 billion in an EV battery plant in the US. This joint venture is expected to commence in 2026 and will have a capacity of over 30GWh. Hyundai is forming a joint venture with SK On, a South Korean battery manufacturer, to invest $5 billion in an EV battery factory in Georgia. This plant is scheduled to start producing battery cells in the second half of 2025 and will have an annual capacity of 35GWh, sufficient to manufacture 300,000 EVs.

• Strong industrial infrastructure in major nationsChina's industrial sector is rapidly growing, supported by a variety of sectors including the automobile, manufacturing, chemicals, and electronics industries. The demand for low-voltage electric motors in various industries is being fueled by industrial automation, production line adjustments, and the need for energy-efficient solutions. The conventional boundaries of automation and control functions are being broken by Industry 4.0 in the process and manufacturing industries. It allows for a broader range of functions and sectors to operate within global efforts and architectural frameworks, such as Made-in-China 2025 in China and Society 5.0 in Japan. As a result of China's rapid urbanization and ongoing construction projects, there is a significant need for low-voltage motors in industries including HVAC, building automation, elevators, and escalators. The country’s market is expanding as a result of both the growing urban population and infrastructure development.

Challenges – Low Voltage AC Motor Market

• High production costs of low-voltage AC motors will impede growthThe fluctuation of raw materials’ prices is analyzed to put a significant strain on the production of electric motors. In January 2022, the cost of neodymium, the primary rare earth element used in magnets, surged by more than 200% when compared to its value in 2019. Additionally, copper prices rose by 59%, aluminum saw a 62% increase, and steel prices climbed by 24% during the same period. Apart from this, the global energy supply system's recent reorganization, driven by the Ukraine crisis and the escalating U.S.-China trade dispute, has led to a worldwide increase in prices for raw materials and assembly components. Owing to this motor manufacturers witness decrease in profit margins due to the increase in manufacturing cost. Thereby such fluctuation in the raw materials cost are set to impeded the market growth during forecast period

Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the low-voltage AC Motor market. In 2023, Major players in the Low Voltage AC Motor market are ABB, Siemens, Nidec Corporation, WEG Electric Corp, Schneider Electric, Wolong, Toshiba Corporation, Regal Rexnord Corporation, TECO Electric & Machinery Co., Ltd. and Others.

0 notes

Text

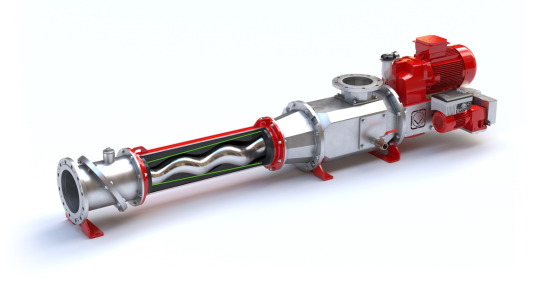

Conical rotor-stator geometry in a progressive cavity pump

At Ifat exhibition in Munich (May 13-17, 2024), the German company Vogelsang GmbH & Co. KG will be showing the conical HiCone progressive cavity pump for use in wastewater treatment plants and pump stations. Additionally, a 3D model of a small, compact version of the HiCone will be on display at booth 347/446 in hall B1.

“Wastewater treatment plants that consume large amounts of power in the municipal area owing to their demanding process steps depend on technologies that are both energy efficient and powerful,” says Michael Brinkmann, Director of Global Sales at Vogelsang. He also says: “The HiCone gives wastewater treatment plant operators a durable, highly efficient pumping technology that can be flexibly readjusted to different pumping tasks and operating parameters.”

The HiCone features a conical rotor-stator geometry and a clever adjustment system. Precise readjustment of the rotor compensates for wear. This ensures constant pumping performance at a high level of effectiveness – without costly and time-consuming parts replacement. At the same time, the product has a status display that informs users about the pump’s condition continuously and in real time. The HiCone thus requires maintenance less often, and it can be planned better. If the HiCone is equipped with the automatic adjustment option and connected to remote maintenance, the rotor can be readjusted as needed from the control room – with no time-consuming travel and maintenance. Wastewater treatment plant operators with pumps in remote use benefit from this in particular, at pump stations, for instance, which usually are not monitored by specialists on site.

Conical pump for high pressures up to 12 bar

The HiCone is also designed for higher pressures of up to 12 bar. For wastewater treatment plant operators, that means the HiCone can even handle process applications with high pressures that usually require a long, two-stage progressive cavity pump.

www.vogelsang.info

Read the full article

0 notes

Text

Exploring Force Springs and Slip Ring Induction Motors

In the realm of physics and engineering, force springs and slip ring induction motors represent important concepts and technologies that play pivotal roles in various applications, from mechanical systems to electrical machinery. Let's delve into the principles, functionalities, and applications of force springs and slip ring induction motors.

Force Springs:

Force springs, also known as mechanical springs, are elastic devices designed to store and release mechanical energy when subjected to external forces. They exhibit the fundamental properties of elasticity, providing resistance and exerting a force in response to deformation. Here are key aspects related to force springs:

Types of Force Springs: Force springs come in various types, including compression springs, tension springs, torsion springs, and leaf springs, each designed to withstand specific types of loads and deformations.

Functionality: The primary function of force springs is to absorb and store mechanical energy when compressed, stretched, or twisted, and release this energy when the applied force is removed.

Applications: Force springs find widespread applications in mechanical systems such as automotive suspensions, industrial machinery, consumer products (e.g., mattresses, door hinges), and aerospace components. They play crucial roles in damping vibrations, supporting loads, and maintaining stability.

Material Selection: Force springs are typically made from materials such as steel alloys, stainless steel, or non-ferrous metals, chosen for their strength, durability, and resilience to repeated loading cycles.

Design Considerations: Factors such as spring rate (stiffness), maximum load capacity, deflection range, and fatigue life are critical considerations in force spring design to ensure optimal performance and longevity.

Slip Ring Induction Motors:

Slip ring induction motors (also known as wound rotor induction motors) are a type of AC (alternating current) electric motor designed for applications requiring high starting torque and speed control. They differ from standard squirrel cage induction motors by incorporating slip rings and external resistors in the rotor circuit. Here's an overview of slip ring induction motors:

Principle of Operation: Slip ring induction motors operate on the principle of electromagnetic induction, where alternating current in the stator windings generates a rotating magnetic field. The rotor windings are connected to slip rings, allowing external resistance to be inserted into the rotor circuit.

Starting Characteristics: Slip ring induction motors exhibit high starting torque due to the ability to control rotor resistance. By inserting resistors into the rotor circuit during startup, motor speed and torque can be adjusted.

Speed Control: Slip ring motors offer speed control by varying the resistance in the rotor circuit. This feature makes them suitable for applications such as cranes, elevators, and conveyors requiring adjustable speed operation.

Applications: Slip ring induction motors are used in heavy industrial applications where high starting torque and speed control are essential, such as mining equipment, pumps, compressors, and large fans.

Advantages and Considerations: While slip ring induction motors offer advantages in torque control and speed adjustment, they require additional maintenance due to the presence of slip rings and brushes, compared to the maintenance-free operation of squirrel cage motors.

Conclusion

Force springs and slip ring induction motors represent essential components and technologies in mechanical and electrical engineering, respectively. Understanding their principles of operation, functionalities, and applications is crucial for designing and implementing efficient and reliable systems in various industries. By leveraging the capabilities of force springs and slip ring induction motors, engineers and designers can optimize performance, enhance control, and meet specific requirements in a wide range of mechanical and electrical applications.

0 notes

Text

Permanent Reluctance motors

Permanent magnet reluctance motors (PMRM) represent a fascinating class of electric motors that combine features of both permanent magnet motors and reluctance motors. These motors leverage the magnetic properties of permanent magnets along with the reluctance effect to generate torque. Here’s an overview of permanent magnet reluctance motors, their working principles, advantages, and applications:

Working Principle:

Permanent magnet reluctance motors operate based on the principle of magnetic attraction and reluctance torque. These motors utilize both permanent magnets and the inherent reluctance of magnetic circuits to produce torque.

Permanent Magnets: PMRMs incorporate permanent magnets in the rotor assembly. The magnetic field generated by these permanent magnets interacts with the stator’s magnetic field, creating a force that drives the rotor to rotate.

Reluctance Torque: In addition to the magnetic attraction between the permanent magnets and the stator, PMRMs also rely on reluctance torque. Reluctance torque arises due to the tendency of magnetic flux to flow through the path of least reluctance. By shaping the rotor and stator geometry to create regions of varying magnetic reluctance, PMRMs can generate additional torque as the rotor aligns itself with the stator’s magnetic field.

Advantages:

High Torque Density: PMRMs offer high torque density, allowing them to deliver significant torque output relative to their size and weight. This makes them suitable for applications where space and weight constraints are critical.

Efficiency: Permanent magnets contribute to the motor’s efficiency by providing a constant magnetic field, reducing losses associated with excitation currents. Additionally, the reluctance torque mechanism enables efficient torque production.

Wide Speed Range: PMRMs are capable of operating over a wide speed range, making them versatile for applications that require variable speed control.

Reliability: With fewer moving parts and simplified rotor construction compared to traditional motors, PMRMs offer enhanced reliability and durability.

Lower Maintenance: Due to their simple construction and absence of brushes or commutators, PMRMs typically require lower maintenance compared to other motor types.

Applications:

Permanent magnet reluctance motors find applications in various industries and systems, including:

Automotive: PMRMs are used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) for propulsion systems, regenerative braking, and other auxiliary functions.

Industrial Automation: These motors are employed in machinery and equipment for material handling, robotics, pumps, and fans, where high torque density and efficiency are essential.

Home Appliances: PMRMs can be found in household appliances such as washing machines, refrigerators, and air conditioners, where energy efficiency and quiet operation are desirable.

Renewable Energy: PMRMs are utilized in wind turbines and hydroelectric generators for power generation, offering efficient and reliable performance over a wide range of operating conditions.

Conclusion:

Permanent magnet reluctance motors represent a compelling choice for various applications where high torque density, efficiency, and reliability are paramount. By harnessing the combined benefits of permanent magnets and reluctance torque, these motors offer a compelling alternative to traditional motor technologies, contributing to energy savings, performance optimization, and sustainability across diverse industries. As technology continues to evolve, the versatility and efficiency of permanent magnet reluctance motors make them an increasingly attractive option for modern motor-driven systems.

For more information contact Edington Agencies

0 notes

Text

EC-CP2320H Water Pump Series

EC-CP2320H Water Pump Series Each functional module is clearly divided, which is convenient for manufacturing, assembly and post-maintenance.The whole machine can be roughly divided into three parts: rotor, stator and pump body, front and rear cover plates. The rotor is one-piece injection molding,The stator of the motor and the pump body are flled with glue, and the front and rear cover plates are separate parts. The structure is simple and easy to assemble.

0 notes

Text

I got a little bit of time to work on super pipi today, but didn't take any photos. I finally sucked up and put the power steering pump back in, and it's only leaking a little bit! considering he used to barf all the fluid out immediately, I'll take it as a win.

Second, I saw a mystery bolt on my gas tank when I changed out the fuel filter... so I crawled back down there and cracked that bad boy open. I managed to drain almost 5 gallons of old gas out and I replaced it with two gallons of premium with fuel stabilizer in it. Hopefully no more gas issues. Also, the gas wasn't the same muddy color that came out of the filters, so I don't have to spend the money installing a new tank :D

Finally, took pipi on a test drive. He didn't want to start, still missing and having stalling issues, but holy shit he STEERS. I think he does better than my daily (a 2018 Spark). Happy with what I got done today, but now the hard part is gonna be fixing the misfire.

I've already replaced the spark plugs, wires, distributor cap, and rotor and this fucker just doesn't want to cooperate. I need to check the spark with an inline test light, then check the stators (rip me) and then the ignition module and coil. yuck. they don't make those parts anymore.

doesn't it look yummy? I lost the skin off one of my knuckles for this.

1 note

·

View note

Text

Optimizing Filteration in Varios Industries: Risansi Filter Press Pumps

Efficient separation of particles from liquids is a crucial aspect of filtering processes in various industries, including wastewater treatment and medicines. The filter press is unique among filtering devices in that it can process large amounts of slurry and generate dry filter cakes. The filter press pump is a vital component that powers this apparatus. This page explores the complexities of filter press pumps, including types, purposes, and things to think about for best results.

Knowing How Filter Press Pumps Work:

An essential component of a filter press system's functionality is the filter press pump. Creating the pressure required to force the slurry through the filter plates and separate the liquid (filtrate) from the particles (filter cake) is its main purpose. Filtration efficiency and efficacy are mostly dependent on the pump's ability to continuously produce the necessary pressure. This is the most common food pumps used for various food applications also.

Filter Press Pump Types:

Centrifugal Pumps: The slurry is forced through the filter press by the centrifugal force of these pumps. They are well-liked because of their practicality, simplicity, and capacity to handle abrasive slurries. They might, however, have trouble reaching high pressures, which could restrict their use in various filtration procedures.

Diaphragm Pumps: To force the slurry through the filter press, diaphragm pumps work by flexing a diaphragm to create suction and discharge cycles. They are appropriate for applications needing precise filtration characteristics because they provide exact control over pressures and flow rates. The capacity of diaphragm pumps to handle abrasive or viscous fluids with little wear and tear is another well-known feature.

Screw Pumps: Progressing cavity pumps, also called screw pumps, are made up of a helical rotor inside a stator, creating cavities that progress along the axis of the pump. As the rotor turns, the slurry moves through the pump, providing a smooth and steady flow. These pumps are highly efficient, capable of generating high pressures, and suitable for transferring shear-sensitive fluids.

Aspects to Consider for Best Results:

Pressure and Flow Requirements: Determine the precise pressure and flow rate required for your filtering procedure to choose a pump that can efficiently meet these needs.

Fluid Characteristics: Select a pump that can withstand the viscosity, abrasiveness, and chemical makeup of the slurry being handled without deterioration or clogging.

Maintenance Requirements: To guarantee the smooth and continuous operation of the filter press system, assess the maintenance requirements of various pump types. These requirements may include routine inspections, part replacements, and cleaning processes.

Energy Efficiency: To maximize energy usage and save operating expenses, look for pumps with energy-efficient designs and features like variable speed drives or sophisticated control systems.

Compatibility with Filtration System: Verify that the pump and the filter press system are compatible concerning dimensions, mounting choices, and control system integration.

In summary:

To achieve desired product quality and process efficiency, the separation of solids and liquids is made easier by filter press pumps, which are essential to the smooth operation of filtration operations. Through a comprehensive comprehension of the available various pump types, their purposes, and essential selection factors, industries may optimize their filtration systems for improved efficiency, economy, and performance. To get dependable and consistent filtration outcomes, it is imperative to invest in the appropriate filter press pump that is customized to meet the demands of the application.

Risansi filter press pump is the most ideal choice for various applications to filter out slurry and viscous liquid wastes in various industries. It is also an ideal diesel transfer pump. Check Risansi website for more information on various types of Risansi pumps.

0 notes

Text

Exploring the Power and Efficiency of Brushless DC Motors: Revolutionizing Industry in Australia

Brushless DC motors, or BLDC motors, are a type of electric motor that uses electronic commutation instead of brushes and commutators. This means they have less friction, noise, maintenance, and higher efficiency than conventional brushed motors. Brushless DC motors are widely used in applications that require high speed, high torque, and precise control, such as robotics, electric vehicles, appliances, and industrial automation systems.

But what makes BLDC motors so powerful and efficient? How do they work, and what are their advantages? In this blog post, we will explore the basics of BLDC motors, their benefits, and their applications in various industries in Australia.

How do BLDC motors work?

BLDC motors consist of two main parts: the rotor and the stator. The rotor is the rotating part that has permanent magnets attached to it. The stator is the stationary part that has coils of wire wound around it.

The coils are connected to an electronic controller that switches the current to the coils based on the position of the rotor. It creates a magnetic field that rotates in space and attracts the rotor magnets, causing the rotor to spin.

The electronic controller also adjusts the motor's speed and torque by varying the current pulses' frequency and amplitude. The controller can also receive feedback from sensors that monitor the speed and position of the rotor, allowing for more precise and responsive control.

What are the benefits of BLDC motors?

Brushless DC motors have many advantages over brushed motors, such as:

Higher efficiency: BLDC motors can convert up to 90% of the electrical energy into mechanical energy, compared to 75% for brushed motors. It means they consume less power and generate less heat, reducing operating costs and extending the motor's lifespan.

Higher power-to-weight ratio: BLDC motors can deliver more power with less weight and size, thanks to their compact design and high-performance magnets. This makes them ideal for applications that require high power density and low inertia, such as drones, electric bikes, and medical devices.

Higher speed and torque: BLDC motors can operate up to 100,000 rpm and produce high torque even at low speeds. This enables them to accelerate and decelerate quickly and to handle variable loads and sudden changes in demand, such as in CNC machines, pumps, and fans.

Lower noise and vibration: BLDC motors have no brushes or commutators that can cause sparks, wear, and noise. They also have less cogging torque, which is the resistance to rotation caused by the interaction of the magnets and the coils. This results in smoother and quieter operation, which improves the comfort and safety of the users and the environment.

Lower maintenance: BLDC motors have fewer moving parts and less friction, which reduces the need for lubrication, cleaning, and replacement. They also have better thermal stability and corrosion, dust, and moisture resistance, enhancing their reliability and durability.

How are BLDC motors revolutionizing the industry in Australia?

Brushless DC motors are widely used in various industries in Australia, such as:

Agriculture: BLDC motors are used to power irrigation systems, sprayers, harvesters, and other agricultural equipment. They offer high efficiency, low noise, and long life, which help farmers save energy, water, and money and increase their productivity and profitability.

Mining: BLDC motors are used to drive conveyors, crushers, drills, and other mining equipment. They offer high torque, high speed, and high reliability, which help miners cope with the harsh and demanding conditions of the mining industry and improve their safety and performance.

Manufacturing: BLDC motors control CNC machines, robots, printers, and other manufacturing equipment. They offer high precision, high responsiveness, and high flexibility, which help manufacturers produce high-quality products, reduce waste, and optimize their processes.

Renewable energy: BLDC motors are used to generate electricity from wind, solar, and hydro sources. They offer high efficiency, high power, and low maintenance, which help renewable energy providers reduce their carbon footprint, lower operating costs, and increase their energy output.

Brushless DC motors are the future of electric motors, transforming the industry in Australia. They offer superior performance, efficiency, and reliability, and they can meet various applications' diverse and demanding needs.

If you are looking for high-quality BLDC motors, you can check out the collection of EMPPL, a leading supplier of electric motors and power transmission products in Australia. EMPPL offers a wide range of BLDC motors, from 12V to 48V and 30W to 3000W, with various speed, torque, and size options.

EMPPL also provides custom solutions and technical support to help you find the best BLDC motor for your specific needs. Visit their website or contact them today to learn more.

0 notes

Text

Happy Chinese New Year! May the Year of the Dragon bless you with good fortune, prosperity, and thriving opportunities.

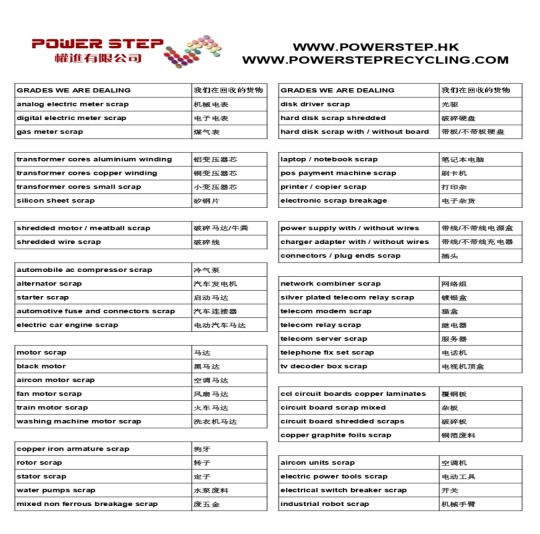

Our recycling group boasts a legacy spanning four generations in the recycling industry. We maintain a steadfast commitment to recycling various materials, including non-ferrous, ferrous, e-waste, telecom, and auto part scraps. Our extensive list of recyclable items includes:

Electric meters

Electric motors

Transformers

Silicon sheets

Shredded motors, wires, and non-ferrous materials

Automobile starters, alternators, AC compressors, engines, and electronic parts

Circuit boards, including low-grade, shredded, and trimmings, as well as CCL (copper-clad laminates)

Mixed non-ferrous scrap breakage

Telecom relays, network combiners, silver-plated relays, and telephone fix sets

TV decoder boxes, modems, computers, telecom, and electronic breakage

Laptops, tablets, hard disks, and disk drives

Printers, copiers, and fax machines

POS payment machines

Chargers, adapters, plug ends, and connectors

Air conditioning units, water pumps, and electric power tools

Electrical breakage and switch breakers

Rotors, stators, and copper-iron armatures

Gas meters

Compressors and sealed units from refrigerators and air conditioners

Telecom antennas

And much more…

For further reference, please find attached additional photos on our website: https://powersteprecycling.wixsite.com/scrapweprocess

If you have any stock available for sale, pls offer it to us.

Franck

WhatsApp: +85260669186

WeChat: +8613923192733

www.powersteprecycling.com

#aluminiumscraprecycling#autopartsscraprecycling#automobilerecycling#cclscrap#circuitboardscrap#compressorscrap#compressorscraprecycling#computerscrap#computerscraprecycling#ewaste#electricmotorscrap#electricmotorscraprecycling#electricalscrap#electricalscraprecycling#electronicrecycling#harddiskscrap#harddiskscraprecycling#metalrecycling#metallicscraprecycling#meterscraprecycling#motorscrap#motorscraprecycling#professionalscraprecycling#recycler#scrapappliance#scrapautoparts#scrapmetalrecycling#shreddedscrap#shreddedscraprecycling#reciclagem

0 notes

Text

Vertical Turbine pumps are used in a wide range of applications, such as water processing in industries, cooling towers in power plants, pumping water to fields for irrigation uses, and more. However, very few people are aware of these pumps’ amazing features and functionality. As one of the leading vertical sump manufacturers in India, Flowmore is here to guide you through the working principle of these pumps and how to select the right vertical pumps that best suit your application requirements.

What is a vertical turbine pump?

A Vertical turbine Pump is a subcategory of centrifugal pumps. These pumps are made especially to move water out of underground wells and deep reservoirs. They go by the names sump pumps, deep well turbopumps, and shaft turbopumps as well. The term “vertical turbine pumps” refers to the fact that these pumps are attached to the ground-level motor by an extended vertical shaft. Brings water or other fluid from deep underground reserves down to the surface. Vertical turbine pumps have a long history of use and are found in many different industrial settings. These pumps are a great option for a variety of industrial needs due to their effectiveness and simplicity of maintenance. The chemical processing, petrochemical, power generating, mining, oil and gas exploration, and seawater desalination sectors are the principal users of these pumps.

How do vertical turbine pumps work? The principle of operation

The movement of vertical turbine pumps causes gas molecules to clash with moving solid surfaces in a specified direction. The fast-rotating fan of these pumps strikes the gas molecules and forces them out the other end. Within the pump chamber, this motion creates a condition akin to a vacuum. Most Vertical turbine Pumps India have multiple stages. Every stage contains two blades: a stator blade and a high-speed rotating rotor blade. A gas molecule strikes the rotor blade as it enters the pump intake.

0 notes

Text

Exploring the Versatility of Roto Pumps: A Comprehensive Overview

Roto Pumps, a global leader in the pump industry, has been at the forefront of innovative pumping solutions for various applications. With a diverse product portfolio, including progressive cavity pumps, wide-throat PC pumps, dosing pumps, food pumps, submerged pumps, and more, Roto Pumps has carved a niche for itself in the market. In this article, we will delve into some of the key products offered by Roto Pumps, emphasizing their features and applications.

Progressive Cavity Pumps:

Roto Pumps is renowned for its progressive cavity pumps, designed to handle a wide range of fluids with varying viscosities. These pumps operate on the principle of positive displacement, ensuring a steady and consistent flow. The design includes a helical rotor that rotates within a stator, creating a progressing cavity that moves the fluid from the suction to the discharge end. This makes progressive cavity pumps ideal for industries such as oil and gas, wastewater treatment, and chemical processing.

Wide-Throat PC Pumps:

The wide-throat progressive cavity pumps from Roto Pumps offer a unique solution for handling fluids with high solid content. The enlarged pump inlet allows for efficient handling of viscous and abrasive materials, making them suitable for applications in mining, slurry transfer, and other demanding environments. The robust construction ensures longevity and reliability, even in challenging operating conditions.

Dosing Pumps:

Roto Pumps' dosing pumps are precision-engineered for accurate and consistent dosing of chemicals in various industrial processes. These pumps find applications in water treatment, pharmaceuticals, and food processing, where precise control of fluid flow is crucial. The modular design and advanced features make Roto Pumps' dosing pumps a preferred choice for industries that require high precision and reliability.

#Roto Pump#Industrial Pumps Manufacturers & Suppliers#Progressive Cavity Pumps#Standard PC Pump#Wide Throat PC Pump#Dosing Pump#Food Pump

0 notes

Text

Progressive Cavity Pumps:

Roto Pump's Progressive Cavity Pumps are designed to handle a wide range of fluids with varying viscosities. These pumps operate on the principle of a helical rotor turning within a stator, creating a progressive cavity that moves the fluid through the pump. This design ensures a smooth and pulsation-free flow, making them ideal for applications in industries such as oil and gas, wastewater treatment, and chemical processing.

#Roto Pump#Industrial Pumps Manufacturers & Suppliers#Progressive Cavity Pumps#Standard PC Pump#Wide Throat PC Pump#Dosing Pump#Food Pump

0 notes