#sand consumption in mortar 1:3

Explore tagged Tumblr posts

Text

Construction methods have evolved over time, offering solutions that cater to varying project demands, climates, and timelines. The choice between dry construction and wet construction is fundamental, as each method comes with distinct processes, materials, and outcomes. Understanding these differences is essential for professionals, technicians, and aspiring engineers in Nigeria and across Africa, especially as the continent embraces modernization and sustainability in building practices.

At Jered Engineering & Designs Limited, we specialize in dry construction and its transformative potential. This article delves into the key differences between dry and wet construction methods, offering insights into their applications and advantages.

1. Definition and Processes

Dry Construction Dry construction involves assembling pre-manufactured components such as gypsum boards, aluminum panels, and steel frameworks. These materials are fixed using screws, adhesives, or fasteners without requiring water.

Wet Construction Wet construction relies on traditional materials like concrete, cement, and mortar, which are mixed with water and applied on-site. The curing process depends heavily on water availability and environmental conditions.

2. Materials Used

Dry Construction Materials:

Gypsum boards

Aluminum and steel frames

Pre-fabricated panels

Fiber cement boards

Glass panels

Wet Construction Materials:

Cement, sand, and aggregate

Bricks and blocks

Concrete mixes

Plaster and mortar

3. Construction Speed

Dry Construction:

Rapid installation since materials are prefabricated.

Reduced dependency on curing time.

Ideal for projects with tight deadlines, such as office spaces and retail fit-outs.

Wet Construction:

Time-consuming due to curing and drying processes.

Subject to delays caused by weather conditions, especially heavy rains common in parts of Nigeria and Africa.

4. Labor and Skill Requirements

Dry Construction:

Requires specialized skills for assembling prefabricated components.

Training in tools like screw guns and precision measurement devices is essential.

Jered Engineering invests in workforce training to empower local communities with these skills.

Wet Construction:

Relies on manual labor for tasks like bricklaying, plastering, and concrete mixing.

Skills required are often traditional and widely available.

5. Environmental Impact

Dry Construction:

Minimal water usage, making it suitable for areas with limited water resources.

Less on-site waste as components are prefabricated.

Recyclable materials like aluminum and steel contribute to sustainability.

Wet Construction:

High water consumption during material preparation and curing.

Significant waste generation from excess materials and construction debris.

Contributes to environmental degradation if not managed properly.

6. Structural Applications

Dry Construction:

Best suited for interiors, partitions, ceilings, and lightweight façades.

Growing use in modular buildings and prefabricated housing in Nigeria’s urban centers.

Wet Construction:

Preferred for load-bearing structures like foundations, columns, and beams.

Common in areas with traditional construction practices.

7. Cost Implications

Dry Construction:

Higher upfront costs for prefabrication and specialized materials.

Long-term savings due to faster project timelines, reduced labor costs, and lower maintenance expenses.

Wet Construction:

Generally lower initial costs, making it attractive for small-scale projects.

Higher long-term costs due to frequent maintenance and repairs.

8. Durability and Longevity

Dry Construction:

Resistant to moisture, pests, and fire when using high-quality materials like gypsum boards and fiber cement panels.

Durability depends on proper installation and material quality.

Wet Construction:

Known for its strength and ability to support heavy loads.

Susceptible to cracks, water damage, and wear over time if not maintained.

Practical Implications for Nigeria and Africa

Dry Construction Advantages:

Urbanization Demands: Rapid urbanization in cities like Lagos and Abuja calls for faster, scalable solutions that dry construction provides.

Water Scarcity: In arid regions like northern Nigeria, minimal water use in dry construction is a critical advantage.

Sustainability Goals: Governments across Africa are pushing for eco-friendly construction methods to combat climate change.

Wet Construction Suitability:

Traditional Applications: Rural areas still rely on wet construction for cost-effective housing.

Load-Bearing Needs: Essential for projects requiring heavy-duty foundations and structural support.

Why Jered Engineering Chooses Dry Construction

At Jered Engineering & Designs Limited, we believe dry construction is the future of sustainable building in Nigeria and beyond. Here’s why:

Efficiency: Faster project delivery allows us to meet the demands of a growing population.

Sustainability: By minimizing waste and water usage, we align with global environmental standards.

Quality: Our focus on precision ensures every project stands out for its durability and aesthetic appeal.

Conclusion

The choice between dry and wet construction methods depends on the project’s requirements, budget, and location. However, as the world leans towards sustainable and efficient building practices, dry construction is rapidly gaining prominence.

For professionals and aspiring technicians, understanding these methods is crucial to staying ahead in a competitive industry. With Jered Engineering & Designs Limited, you’re not just choosing a construction partner; you’re embracing a vision for the future of building in Nigeria and Africa.

#JeredEngineering

#JED

#FacadeDesign

#Dryconstruction

www.jeredengineering.com

0 notes

Text

RMS EcoBricks: Transforming Construction with Fly Ash Bricks and Pavers

In the modern world, the construction industry is evolving to prioritize sustainability, durability, and cost-effectiveness. One of the key innovations driving this change is the adoption of eco-friendly building materials. At RMS EcoBricks, we’re proud to lead the way as a trusted fly ash bricks factory and paver manufacturer, offering products that not only meet industry standards but exceed expectations.

The Importance of Sustainable Building Materials

With urbanization accelerating globally, the demand for construction materials continues to soar. However, conventional materials like clay bricks come with significant environmental costs, including deforestation and high energy consumption. Fly ash bricks and concrete pavers, on the other hand, provide a sustainable alternative. These materials are manufactured using industrial by-products, reducing waste and conserving natural resources. By choosing fly ash bricks and pavers, builders contribute to a greener planet while benefiting from superior performance and cost savings.

Why Choose Fly Ash Bricks?

Fly ash bricks are made by recycling fly ash, a by-product of coal-fired power plants, mixed with cement, sand, and water. They offer numerous advantages:

Eco-Friendly: Manufacturing fly ash bricks helps repurpose industrial waste, reducing landfill burden and environmental pollution.

Durability: These bricks are denser and more robust than traditional clay bricks, making them resistant to wear and tear.

Thermal Insulation: Fly ash bricks provide excellent thermal insulation, reducing energy costs for heating and cooling.

Uniform Size and Shape: Consistent dimensions ensure precise construction, minimizing mortar usage and saving time.

Cost-Effective: Lower manufacturing costs make fly ash bricks an economical choice for large-scale projects.

At RMS EcoBricks, our state-of-the-art fly ash bricks factory ensures that every brick is crafted with precision and care, guaranteeing quality and performance.

Benefits of Pavers in Construction

Pavers are versatile construction materials used for creating durable and visually appealing surfaces like driveways, walkways, and patios. As a leading paver manufacturer, RMS EcoBricks offers a wide range of designs and materials to suit diverse project needs.

Advantages of Using Pavers:

Durability: Pavers can withstand heavy loads and harsh weather conditions, ensuring longevity.

Aesthetic Appeal: Available in various shapes, colors, and patterns, pavers enhance the visual appeal of any space.

Low Maintenance: Paver surfaces are easy to clean and repair, making them a hassle-free option.

Eco-Friendly Options: Permeable pavers allow water to seep through, reducing runoff and aiding groundwater recharge.

Flexibility: Unlike concrete slabs, pavers are individual units, allowing for easy replacement in case of damage.

RMS EcoBricks: A Commitment to Excellence

At RMS EcoBricks, we believe in combining innovation with sustainability. Here’s what sets us apart:

1. Advanced Manufacturing Process

Our facility is equipped with cutting-edge machinery to produce high-quality fly ash bricks and pavers. By adhering to strict quality control measures, we ensure every product meets industry standards for strength and durability.

2. Custom Solutions

We understand that every project is unique. That’s why we offer customized solutions, tailoring our products to meet specific requirements in terms of size, shape, and design.

3. Sustainability Focus

As a responsible manufacturer, we’re committed to minimizing our environmental footprint. Our production process prioritizes the use of recycled materials and energy-efficient techniques.

4. Customer-Centric Approach

Our team is dedicated to providing exceptional service, from helping you choose the right products to ensuring timely delivery and after-sales support.

Applications of Fly Ash Bricks and Pavers

Fly ash bricks and pavers are versatile materials suitable for a variety of applications, including:

1. Residential Construction

Fly ash bricks are ideal for building walls, facades, and foundations in homes. Pavers add charm to driveways, garden paths, and outdoor patios.

2. Commercial Projects

In commercial buildings, these materials provide a cost-effective and durable solution for parking lots, pedestrian walkways, and interior walls.

3. Industrial Construction

Fly ash bricks are commonly used in factories and warehouses for their strength and resistance to harsh environments. Pavers are perfect for heavy-duty flooring.

4. Landscaping

Concrete pavers are a favorite choice for landscape architects, offering endless design possibilities for gardens, parks, and recreational areas.

The Environmental Impact of Fly Ash Bricks and Pavers

One of the most significant benefits of using fly ash bricks and pavers is their positive environmental impact. Here’s how they contribute to sustainability:

Waste Utilization: Fly ash, a by-product of power plants, is repurposed, reducing waste and preventing harmful disposal practices.

Reduced Carbon Emissions: The production of fly ash bricks requires less energy compared to traditional clay bricks, cutting down greenhouse gas emissions.

Water Conservation: Manufacturing fly ash bricks uses minimal water, making it an eco-friendly option.

Permeable Paving: Permeable pavers improve stormwater management, reducing flooding and erosion risks.

Tips for Choosing the Right Products

Selecting the right materials for your construction project is crucial. Here are some tips:

Evaluate Your Needs: Consider the specific requirements of your project, such as load-bearing capacity, aesthetic preferences, and environmental considerations.

Check Quality Standards: Ensure the materials meet industry standards for strength, durability, and performance.

Consult Experts: Seek advice from professionals to choose the best products for your project.

Compare Options: Explore different designs, colors, and patterns to find the perfect fit.

At RMS EcoBricks, we’re always ready to assist you in making the best choice for your needs.

Partner with RMS EcoBricks

As a trusted name in the industry, RMS EcoBricks is committed to delivering high-quality, eco-friendly construction materials. Our fly ash bricks factory and paver manufacturing facility are designed to meet the demands of modern construction while prioritizing sustainability.

Why Choose Us?

Proven expertise in manufacturing fly ash bricks and pavers.

Commitment to environmental responsibility.

Wide range of customizable products.

Exceptional customer service and support.

Conclusion

The construction industry is embracing sustainable practices to build a greener future, and materials like fly ash bricks and pavers play a pivotal role in this transformation. At RMS EcoBricks, we’re proud to be at the forefront of this change, offering innovative and eco-friendly solutions that meet the needs of modern construction.

Whether you’re planning a residential project or a large-scale commercial development, our products are designed to deliver exceptional performance and aesthetic appeal. Partner with RMS EcoBricks and take a step towards a more sustainable future.

0 notes

Text

Affordable Quick Lime Lumps Manufacturer in Rajasthan for Bulk Supply

When it comes to sourcing industrial-grade raw materials for various processes, quick lime lumps play an essential role across multiple sectors. From construction and steel manufacturing to water treatment and agriculture, quick lime is a vital ingredient. The state of Rajasthan has emerged as one of the leading hubs for the production of quick lime lumps, with numerous manufacturers offering high-quality products at affordable rates. This blog will delve into the significance of quick lime lumps, their applications, and why choosing an affordable Quick Lime Lumps Manufacturer in Rajasthan for bulk supply is a smart decision for businesses.

What are Quick Lime Lumps?

Quick lime, also known as calcium oxide (CaO), is a highly reactive material that is derived by heating limestone (calcium carbonate, CaCO₃) in a process called calcination. This process involves heating limestone in a kiln at temperatures between 900°C and 1000°C, which breaks down the calcium carbonate into calcium oxide (quick lime) and carbon dioxide (CO₂). The result is a solid mass of quick lime lumps which is then crushed and graded into various sizes for different applications.

Quick lime lumps are essentially large chunks or irregular pieces of quick lime, and they are known for their high reactivity. They are widely used in industries due to their effectiveness in chemical processes and their ability to neutralize acidic substances.

Key Properties of Quick Lime Lumps

High Reactivity: Quick lime lumps are highly reactive because of the free calcium oxide (CaO) content. This makes them suitable for chemical reactions that require quick neutralization or absorption of acidic substances.

Strong Alkaline Nature: Quick lime lumps are alkaline in nature, making them ideal for various industrial processes such as neutralization, water treatment, and soil stabilization.

Dehydration Capacity: Quick lime lumps absorb moisture from the air and release heat during this process. This property is crucial in many applications such as chemical and cement production.

Purity and Strength: The quality of quick lime lumps depends on the purity of the raw limestone and the calcination process. High-quality quick lime lumps have high calcium oxide content and low impurities.

Applications of Quick Lime Lumps

Quick lime lumps are used in a variety of industries, each requiring a different form of calcium oxide for specific processes. Let’s explore the common uses of quick lime lumps across various sectors:

1. Steel Manufacturing

The steel industry is one of the largest consumers of quick lime lumps. In steel production, quick lime is used as a fluxing agent in the blast furnace, where it helps to remove impurities like sulfur and phosphorus from molten iron. Quick lime lumps react with these impurities to form slag, which is then removed from the iron. The effectiveness of quick lime lumps in improving the quality of steel is one of the key reasons why this product is in such high demand in the steel industry.

2. Construction Industry

In the construction industry, quick lime lumps play an important role in the production of lime mortar and lime plaster. Quick lime lumps are mixed with water and sand to create a durable mortar that is used in the construction of buildings, bridges, and roads. Additionally, quick lime is used in the stabilization of soil for construction projects, improving the load-bearing capacity and stability of the ground. In regions like Rajasthan, where infrastructure development is ongoing, the demand for quick lime lumps remains steady.

3. Water Treatment

Quick lime lumps are used extensively in water treatment plants for various purposes. The most common use is for pH adjustment and softening of water. Quick lime lumps help neutralize acidic water, making it suitable for consumption and industrial use. In wastewater treatment, quick lime is used to remove suspended solids and to treat sludge. It also helps in the removal of heavy metals like arsenic and mercury, improving the water quality. Rajasthan, with its growing industrial base, has seen an increased demand for quick lime lumps in water treatment applications.

4. Chemical Industry

The chemical industry uses quick lime lumps in several key processes. It is a vital component in the production of calcium carbide, which is used in the manufacturing of acetylene gas. Additionally, quick lime lumps are used to produce soda ash (sodium carbonate), caustic soda (sodium hydroxide), and other chemicals. The high reactivity of quick lime lumps makes them suitable for these applications, where they act as catalysts or reactants in various chemical reactions.

5. Agriculture

Quick lime lumps are used in the agriculture industry to improve soil quality. They help neutralize acidic soils, raising the pH to a more neutral level, which enhances nutrient availability to plants. By treating acidic soils with quick lime, farmers can increase crop yield and improve soil structure. Furthermore, quick lime is used in the production of lime-based fertilizers. Its application in the agricultural sector has made it a critical product for farmers, particularly in regions with high levels of soil acidity.

6. Environmental Control

Quick lime lumps are also used in environmental control systems to reduce pollution. In flue gas desulfurization (FGD) systems, quick lime lumps help remove sulfur dioxide (SO₂) from industrial exhaust gases, preventing air pollution. Additionally, quick lime lumps are used in the treatment of hazardous waste and in the neutralization of acidic effluents from industrial processes. These environmental applications are becoming increasingly important as industries strive to meet stricter environmental regulations.

Why Choose an Affordable Quick Lime Lumps Manufacturer in Rajasthan for Bulk Supply?

Rajasthan has established itself as a key producer of quick lime lumps, thanks to its rich limestone deposits and advanced production facilities. For businesses looking to source quick lime lumps for industrial applications, choosing an affordable Quick Lime Lumps Manufacturer in Rajasthan for bulk supply offers several advantages.

1. Competitive Pricing

Rajasthan is home to numerous lime manufacturers who benefit from the availability of high-quality limestone. This helps reduce the cost of production, which in turn allows manufacturers to offer affordable pricing for bulk supplies. Whether you're a small business or a large-scale industrial operation, sourcing quick lime lumps from Rajasthan ensures that you can get high-quality material at a competitive price, which is especially important for cost-sensitive industries.

2. High-Quality Standards

Many of the Quick Lime Lumps Manufacturers in Rajasthan maintain stringent quality control processes to ensure that their products meet the highest standards. High-quality quick lime lumps with a high calcium oxide content and low impurities are essential for achieving optimal results in industrial processes. With a reliable manufacturer, you can be assured of consistent quality and performance in every batch of quick lime lumps you purchase.

3. Timely Delivery and Logistics Support

An experienced Quick Lime Lumps Manufacturer in Rajasthan understands the importance of timely delivery, especially for bulk orders. These manufacturers have established logistics networks to ensure that their products reach their clients on time, without delays. Whether you need a one-time large order or regular deliveries, a reliable Rajasthan-based manufacturer can cater to your supply needs efficiently.

4. Customizable Solutions

Different industries have varying requirements when it comes to the size and composition of quick lime lumps. A trusted Quick Lime Lumps Manufacturer in Rajasthan can offer customizable solutions to meet specific client needs. Whether you need lumps of a particular size or a certain purity level, a manufacturer with experience can tailor their products to suit your unique specifications.

5. Sustainable Production Practices

Many of the leading Quick Lime Lumps Manufacturers in Rajasthan are committed to sustainable production practices. They utilize energy-efficient kilns and minimize waste during the production process. By sourcing your quick lime lumps from a manufacturer who prioritizes sustainability, you can align your business with eco-friendly practices and contribute to environmental conservation.

Conclusion

Quick lime lumps are an essential industrial product used across multiple sectors, including steel manufacturing, water treatment, construction, and agriculture. As a key producer of quick lime lumps, Rajasthan offers businesses the opportunity to source this critical raw material at affordable prices without compromising on quality.

Partnering with a reliable Quick Lime Lumps Manufacturer in Rajasthan for bulk supply ensures that your operations are supported by high-quality materials, competitive pricing, and timely deliveries. Whether you are looking for quick lime for water treatment, construction, or any other industrial use, Rajasthan’s manufacturers provide the perfect solution for your needs. By choosing a trusted manufacturer, you are not only investing in superior products but also ensuring the smooth functioning of your operations with cost-effective and timely supply.

1 note

·

View note

Text

The Role of Hydrated Lime Powder in Modern Manufacturing

In the dynamic world of modern manufacturing, the demand for high-quality materials that enhance efficiency, reduce costs, and promote environmental sustainability is ever-growing. Among these essential materials, hydrated lime powder plays a pivotal role in various industrial applications. From water treatment to construction and even food processing, this versatile substance has established itself as a critical component in modern manufacturing processes.

What is Hydrated Lime Powder?

Hydrated lime powder, also known as calcium hydroxide (Ca(OH)₂), is a dry, fine powder produced by adding water to quicklime (calcium oxide, CaO). This process, called "slaking," results in a highly reactive material that is used in a wide array of industries. Hydrated lime is a key ingredient in several manufacturing processes, offering both functional and economic advantages.

1. Water Treatment and Environmental Management

One of the most significant applications of hydrated lime powder in manufacturing is in water and wastewater treatment. In industrial plants, particularly those in chemical, pharmaceutical, and food processing sectors, the quality of water used is crucial. Hydrated lime is used to treat and purify water by neutralizing acids, removing impurities, and precipitating heavy metals from the water. It plays a vital role in ensuring that water meets strict regulatory standards, especially in large-scale manufacturing plants where consistent water quality is necessary for safe production.

Moreover, hydrated lime is commonly used in flue gas treatment to remove sulfur dioxide and other pollutants from exhaust gases, making it an essential element in reducing industrial emissions. This helps manufacturing plants meet environmental standards and contribute to a cleaner, greener planet.

2. Construction and Building Materials

In construction, hydrated lime powder is widely used in the preparation of lime mortar, plaster, and concrete. Its binding properties make it an ideal component in the construction of buildings, roads, and other infrastructures. When mixed with sand, hydrated lime forms a strong and durable mortar, ideal for masonry and bricklaying.

Furthermore, hydrated lime helps in soil stabilization, improving the load-bearing capacity of soils and enhancing their resistance to erosion. This application is particularly important in the construction of roads and highways, as it helps in creating a strong foundation that can withstand the pressure of heavy vehicles.

In addition to improving the properties of cement-based materials, hydrated lime also prevents the formation of cracks in concrete. Its ability to control the setting time of concrete, along with its resistance to shrinkage, makes it an indispensable material in modern construction projects.

3. Agricultural and Food Processing Industry

Hydrated lime powder also has applications in agriculture and food processing, making it a valuable resource in various manufacturing sectors. In agriculture, it is used to treat acidic soils, improving their pH balance and promoting healthier crops. It is also an effective agent for controlling pests and diseases in plants.

In the food processing industry, hydrated lime is used to process certain foods, such as in the preparation of tortillas and pickles. It helps to improve texture, preserve freshness, and maintain the nutritional value of food products. This application is especially important in ensuring that the food is safe for consumption while maintaining its quality throughout the manufacturing process.

4. Paper and Pulp Industry

In the paper and pulp industry, hydrated lime is utilized as a key ingredient in the lime kiln process. It helps in the recovery of cooking chemicals during the pulping process and contributes to the production of high-quality paper. Hydrated lime is used to treat the waste materials from the pulp and paper production process, including the removal of impurities, bleaching, and making the final product more stable and durable.

5. Steel Manufacturing

The steel manufacturing industry also benefits greatly from the use of hydrated lime powder. It is used in the production of steel as a fluxing agent in the blast furnace, where it helps remove impurities like sulfur and phosphorus from iron ore. Hydrated lime is a vital part of the steelmaking process, contributing to the production of high-quality steel that meets industry standards.

6. Cost-Effectiveness and Availability

In addition to its practical applications, hydrated lime powder is an economical solution for modern manufacturers. It is cost-effective and widely available, ensuring that manufacturers can access it in large quantities without breaking the budget. This makes it a preferred choice over other chemicals and materials in many industrial processes.

Conclusion

Hydrated lime powder is an indispensable resource in modern manufacturing. Its diverse range of applications, including water treatment, construction, agriculture, food processing, and steel production, highlights its importance across industries. As the demand for environmentally sustainable and cost-effective solutions continues to rise, hydrated lime powder will remain a crucial component of modern manufacturing processes. By improving efficiency, enhancing product quality, and supporting eco-friendly practices, hydrated lime continues to play a key role in shaping the future of manufacturing worldwide.

Whether used in small-scale operations or large-scale industrial plants, hydrated lime’s versatility ensures that it remains an essential material in the continued development of the manufacturing sector.

0 notes

Text

Concrete Batching Plant Components

A concrete batching plant usually consists of several key components that work in tandem to ensure efficient, high-quality production of concrete.

Below are the details of concrete batching plant components:

1. Mixing host Role: The mixing host is the core equipment of the concrete mixing plant, responsible for fully mixing and blending the raw materials such as cement, aggregate (sand, stone, etc.), water, additives, etc. to form the concrete that meets the requirements. Types: Commonly used concrete mixing machines include double horizontal shaft forced concrete mixer, vertical concrete mixer, planetary concrete mixer, etc. Among them, double horizontal shaft forced concrete mixer is widely used because of its strong mixing capacity, low energy consumption, long service life and other advantages. Characteristics: The mixing host is designed with reasonable mixing blades and mixing arms, which can ensure that the concrete is evenly mixed during the mixing process, and at the same time reduce the mixing time and energy consumption.

2. Material weighing system Role: Material weighing system is a key component affecting concrete quality and production cost. It is responsible for accurately weighing all kinds of raw materials to ensure the accuracy of concrete proportion. Composition: The material weighing system is mainly divided into three parts: aggregate weighing, powder weighing and liquid weighing. The weighing accuracy is usually very high, such as aggregate weighing accuracy of ≤2%, cement, powder, water and additives weighing accuracy of ≤1%. Characteristics: Modern concrete batching plant mostly adopts electronic scale and microcomputer control, which improves the weighing precision and automation level.

3. Material conveying system Role: The material conveying system is responsible for conveying all kinds of raw materials from the storage equipment to the mixing machine. Composition: It includes aggregate conveying system, powder conveying system and water conveying system. Aggregate conveying system: mainly composed of belt conveyor, bucket elevator, vibrating screen, etc., used for conveying sand, stone and other aggregates. Powder conveying system: mainly consists of powder storage tank, powder pump, powder conveying pipeline and so on, used for conveying cement, fly ash and other powder materials. Screw conveyor is one of the commonly used conveying methods. Water conveying system: mainly consists of pool, pump, water pipe, etc., used to convey water into the mixing host.

4. Water supply system Role: The water supply system is responsible for providing the required water resources for the mixing process. Composition: It includes living water system and production water system. The production water system is mainly used for aggregate washing and equipment cooling in the process of concrete mixing.

5. Electrical control system Role: The electrical control system is the control center of the concrete mixing plant, responsible for the automatic control of the whole mixing plant. Composition: It is mainly composed of programmable controller (PLC), touch screen, frequency converter, sensors and so on. Through the electrical control system, remote monitoring, automatic adjustment, fault diagnosis and other functions of the mixing plant can be realized.

6. Auxiliary equipment Role: Auxiliary equipment is used to improve the production efficiency and automation level of the concrete mixing plant, to ensure production safety and to meet specific construction needs. Common equipment: including admixture pumps, mortar pumps, plug valves, dust collectors and so on. Admixture pumps and mortar pumps are used to add admixtures and mortar to the concrete; plug valves are used to control the flow of materials; and dust collectors are used to minimize the dust pollution generated during the mixing process.

Overall, the various concrete batching plant components work closely together to complete the concrete production process and ensure production efficiency and concrete quality. Different sizes and models of concrete batching plant may vary in the design and configuration of each component, but the components listed above are its basic components.

This resource is from http://www.haomeibatchplant.com/news/concrete-batching-plant-components.html Should you be interested in buying our product, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Text

XINC Waterproof Decoration Diary: What waterproof materials are good for home decoration?

During decoration, areas with high water consumption such as kitchens, bathrooms, and balconies require waterproofing construction to avoid water leakage.

1. Rigid and flexible waterproof materials are now a good choice for home decoration. At present, the waterproof materials on the market are divided into three types: rigid and rigid, and flexible and flexible. The stiffness is made of polymer material, combined with cement sand, with good waterproof effect and stable structure. However, new houses are waterproof and generally lose their waterproof effect after 3–5 years. This is because the house itself will experience a certain degree of decline over time, resulting in insufficient elasticity. XINC waterproof coating is a good choice.

2. When using XINC waterproof flexible waterproofing material for construction, the roll material is directly bonded to the flat layer of the roof structural plate to achieve waterproofing effect. Flexible waterproof materials are colored and generally used for exterior walls, with general waterproofing and decorative effects.

3. In today’s home decoration industry in the United States, rigid and flexible waterproof materials are widely used. They are combined with inorganic materials such as cement and additives, and mixed with elastic coatings to form waterproof coatings. They are combined with the flexibility and elasticity of cement rigid materials and elastic coatings during the construction process to achieve waterproof effects.

Here are five precautions.

1.When there are cast-in-place concrete columns on the ground, flip 20 centimeters above the columns for waterproofing treatment.

2. The ground cement mortar protective layer should be made first, and then the wall cement mortar protective layer should be made.

3. Brush the protective layer twice and use fine sand once, with a cement sand ratio of 1:1. The thickness is 0.5 centimeters. The secondary cement sand ratio is 1:2.5, with a thickness of 1–1.5cm.

4.When making a ground protective layer, it is necessary to do a good job in protecting the waterproof layer. The ground can be dried with a layer of cement, and the legs of the gray truck need to be wrapped well.

5. It is strictly prohibited to mix cement mortar on the surface of the waterproof layer.

0 notes

Text

Manufactured sand is here to stay, and here’s why

As of last year, the sand and aggregate market in India, driven mainly by the boom in urbanisation and infrastructure development, had approximately 4 billion tons in consumption demand, and Rs 2,90,000 Cr. in market size. The sand market is transforming and it is time for India’s first national sand brand, Doctorsand to stand up and deliver.

Doctorsand, a subsidiary of CDE Asia, provides a complete range of ethically-sourced sand and aggregate essential for the construction industry. Some of the top offerings are:

1. 10mm VSI | 20mm VSI | 40mm 3 Stage Premium:

Mainly used in ready-mix concrete, asphalt/bitumen/concrete roads base and sub-base course, pavements, separately or mixed with other aggregates depending on the application

2. 40mm VSI | Concrete M-sand | Plaster M-sand | Stone dust VSI:

Not exceeding the nominal size of 63mm, they are mainly used for POC in the foundation, asphalt/bitumen/concrete roads as atbase or sub-base course, and in rigid pavements as base course, separately or mixed with other aggregates depending on the application

3. Concrete M-sand :

Mainly used in the manufacturing of ready-mix concrete and asphalt. It has the Fineness Modulus between 2.3 and 3.2, and is graded and washed adequately to remove unwanted silt for optimum mix-design.

4. Plaster M-sand:

Mainly used for internal and external render, plastering and screeding. With the Fineness Modulus not less than 1.4, it creates a smooth and even finish that can be used for filling cracks

5. Stone dust VSI:

Crushed stone sand less than 4.75mm particles have a better shape and contain a lower level of silt as compared to the CRF/crusher dust. It is mainly used in mortars for bricklaying and concrete applications by suitably altering the mix-design

6. 10mm and 20mm coarse aggregate | Aggregate Std 40mm:

Mainly used in ready-mix concrete, asphalt/bitumen/concrete roads base and sub-base course, pavements, separately or mixed with other aggregates depending on the application

7. GSB (Granular Sub-base):

Mainly used in road construction as a sub-base layer, GSB prevents capillary water from rising and going beyond the GSB layer. It also serves as a drainage layer to allow water passage without damaging other road layers

Aiding the preservation of river hydrology by effectively providing high-quality M-sand replacement, Doctorsand promises:

· Positive social and environmental impact

· Large pool – wider choice and market-discovered pricing

· Buyer Partners – Flexible payment terms; tech-assisted delivery tracking and schedule compliance; on-site support through Doctorsand quality labs and mobile labs

· Quality focus –Only ethically sourced high-quality products; frequent assessments of production process

· Access to full range – complete solution of sand, aggregate and other minerals; No need for multiple procurement channels

With a growing population, rapid urbanisation and infrastructural developments on the cards, it is only natural to see the surge in demand for quality sand and aggregates. And Doctorsand stands prepared to give you a hand in shaping the cities and societies of tomorrow, through all the challenges that arise.

1 note

·

View note

Text

How to arrange a simple How to arrange a simple Septic Tank Installation Odessa TX with your own hands?

Sometimes on the Internet it is proposed to assemble a septic tank from old car tires, but here it is hardly possible to talk about tightness Septic Tank Installation Odessa TX, so we will not consider this option here .

How to arrange a simple How to arrange a simple Septic Tank Installation Odessa TX with your own hands?

The modern market for wastewater treatment equipment provides a potential customer with a wide range of autonomous treatment facilities. But sometimes the owner of a country house, Septic Tank Installation Odessa TX summer house, cafe or mini-hotel decides to build a simple septic tank himself.

There may be different motivations for making a simple septic tank for a summer residence on your own - disbelief in new technologies and rejection of any innovations, conservatism and adherence to old and proven methods and devices. It won't be wrong to say that the main reason is the desire to save money. In this article, we will look at the strengths and weaknesses of a homemade septic tank.

First of all, you need to weigh the pros and cons of a simple septic tank with your own hands at the stage of installation and construction. Then you should analyze and understand what pros and cons you will get during the long-term operation of this system, what will happen in five, ten, twenty years with your septic tank. When building a house, we expect that it will stand for many years, and the engineering systems will serve for a long time and reliably.

It is possible to install a septic tank cheaply under three conditions:

The presence of sandy soils that will drain and filter up to 80% of pollution from the house into the drainage well . In clayey soils, water will accumulate, not be absorbed.

The groundwater level is up to -2.0 meters , otherwise water will not flow into the ground, but from the ground into the septic tank and into the house.

Limited water consumption, which will allow the use of a drainage well for a long time. Sand plays the role of a mechanical filter, which will fail very quickly with a large volume of water, and the water will stop leaving. One ring with a diameter of 1000mm has a volume of 710 liters.

It is possible to bypass the restrictions by making an aeration field instead of a filter well . An aeration field for a family of 5 people, 10m2 in size and 1 meter deep, will require the excavation of 100m3 of clay (180 tons), over 100 meters of pipes, about 15 Kamaz sand and crushed stone. Taking into account the amount of work and materials, it is easier and cheaper to purchase a factory-made wastewater treatment plant and drain the water into the nearest ditch or absorption trench.

The main requirement that anyone, even the simplest septic tank, must meet is its tightness

Otherwise, you will get a problem with pollution and possible contamination of the land on your site, a constant nasty smell , quarrels with neighbors, and possible troubles with the law due to soil and water pollution.

Several solutions can be used to achieve tightness:

Lay out the walls of the septic tank with bricks

For the first brick option, it is necessary to select and buy a waterproof brick and the corresponding brand of cement for the mortar, otherwise after some time the brick will begin to , the seams will flow, and the tightness will be broken.

Make the septic tank solid concrete

The second option, concrete, is more reliable, but more laborious and requires serious preparation during the construction phase. It will be necessary to carry out significant earthwork, dig a pit, and install the formwork Septic Tank Installation Odessa TX. It is difficult to do on small plots due to lack of space.

Assemble from concrete rings

The third option is a septic tank made of concrete rings . Traditional method, popular due to low cost and ease of installation. The main disadvantage is that it is impossible to achieve tightness and prevent the spring overflow with melt water. As a rule, they are made of three wells. The first two with a bottom play the role of a sump, the third without a bottom is a filter well.

The listed options are efficient in dry soils. It is extremely difficult to achieve sealing in wet soils, even using liquid glass. For this reason, the fourth method is popular.

Septic tank from eurocubes

The disadvantage of euro cubes is thin-walled plastic, which does not withstand the pressure of the soil. To solve this problem, a combined option is used: euro cubes are covered with bricks or sprinkled with a cement-sand mixture 1: 5

The volume of the sump should be 3 times the daily water consumption. With a water flow rate of 1.0m3 / day, the volume of the septic tank will be 3.0m3.

1 note

·

View note

Text

How to calculate Quantity of Cement, Sand & water In Mortar of 1:3

How to calculate Quantity of Cement, Sand & water In Mortar of 1:3

Quantity of Mortar:-

Volume of mortar= 1 m³

Mix Ratio –> 1:6

Dry volume of mortar = Wet volume x 1.33

Dry Volume = 1.0 m³x 1.33 = 1.33 m³

Quantity of cement:-

Quantity of Cement = (Dry Volume of mortar x Cement ratio) / (Sum of the ratio)

∴Quantity of cement = (1.33 x 1) /(1+3)=0.3325 m³

Density of Cement = 1440 kg/m³

∴ Weight of Cement = 1440 x 0.3325 = 478.8Kg

1 bag of cement contains 50 kg…

View On WordPress

#cement consumption in plaster 1:3#cement mortar calculation for plastering#cement mortar calculation formula#cement mortar calculation in brick masonry#cement mortar calculation pdf#cement mortar ratio for brickwork#cement mortar ratio for plastering#cement plastering thickness#how much sand and cement for brickwork#how to calculate quantity of cement mortar in brickwork and plaster#how to calculate water cement ratio for mortar#sand and cement calculator for block work#sand consumption in mortar 1:3#water cement ratio for plastering#water content in cement mortar#waterproof cement mix ratio#we civil engineers#wecivilengineers

0 notes

Text

POLYMER CONCRETE MARKET ANALYSIS (2019-2027)

Polymer Concrete Market 2017–2027

Polymer concrete is categorized under composite materials that use thermoplastics polymers with an epoxy binder to harden materials in the construction industry. It has water, gravel, and sand as an important ingredient which makes it suitable for the repair of any concrete structure. Polymer concrete have higher compressive and impact strength as compared to other types of concretes used in the construction industry. They can be classified into a vinyl ester, polyester, epoxy-based & others. Some of the major end-user of the polymer concrete are industrial, residential & municipal, and commercial.

The global polymer concrete market is projected to reach US$ 691.8 million by the end of 2027, in terms of revenue, growing at CAGR of 7.9% during the forecast period (2019 to 2027).

Drivers

Rising demand for polymer concrete across emerging applications due to enhanced properties such as the ability to form complex shapes, brilliant vibration damping, and rapid curing properties is fueling the market growth of polymer concrete. Polymer concrete is now widely used across applications such as pump bases, waste containers, chemical containments, industrial flooring blocks, and trench drains. The aforementioned factors are projected to propel the market growth of polymer concrete over the forecast timeframe.

Increasing application of polymer concrete across the drainage application is expected to fuel the market growth of polymer concrete. Polymer concrete offers precision molding, precise finishing, which promote efficient hydraulic flow, to ensure superior discharge rates of water from the pipe. The aforementioned advantages are projected to fuel the demand for polymer concrete across municipal applications. Therefore, rising application of polymer concrete across the construction industry is expected to augment the market growth.

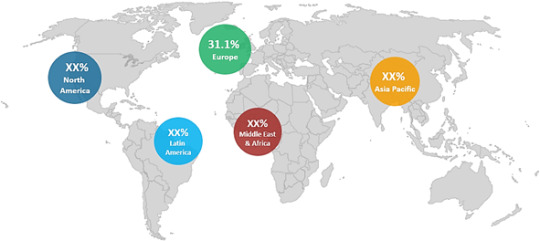

Regionally, Europe dominated the global polymer concrete market in 2018, reporting 31.1% market share in terms of revenue, followed by North America and Asia-Pacific, respectively.

Figure 1. Global Polymer Concrete Market, Revenue Share (%), By Region, 2018

Market Restraints

The high cost of polymer concrete compared to other materials is restricting its application across special needs. This factor is expected to hamper the market growth of concrete polymer over the forecast timeframe. Also, rising usage of a special type of plastics as a cheaper alternative to polymer concrete that offers the same properties as polymer concrete is further anticipated to hinder the market growth over the forecast timeframe.

Lack of awareness regarding the numerous advantages of polymer concrete is expected to impact the market growth of polymer concrete to some extent. Moreover, polymer concrete can be used across an application where there is less consumption of energy and less manpower. This factor is also projected to restrict the market growth of the polymer concrete over the forecast timeframe.

Market Opportunities

Rising usage of polyester & vinyl ester-based materials in the polymer concrete is projected to serve significant opportunity over the forecast timeframe. Since epoxy-based materials are comparatively more expensive than polyester & vinyl ester-based materials, for this reason, manufacturers mostly prefer polyester & vinyl ester-based materials for the production of polymer concrete. This factor is expected to propel the market growth of polymer concrete over the forecast timeframe.

Growing number of research and development initiatives by companies in order to enhance the technical properties of polymer concrete such as compressive and flexural strength, is projected to open a new door of opportunity to the market of polymer concrete. Moreover, some new research also suggests that polymer concrete with enhanced mechanical behavior could be produced by using polyesters. As polyester products are claimed to offer low volume shrinkage, and thus suitable for manufacturing of polymer concrete.

Figure 2. Global Polymer Concrete Market – Opportunity Analysis

Market Trends

A growing number of mergers and acquisitions among manufacturers to enhance the market presence is projected to propel the market growth of polymer concrete. For instance, in April 2017, integrated building materials vendor Chin Hin Group Bhd (Chin Hin) announced its acquisition of polymer concrete pipe manufacturer Mi Polymer Concrete Pipes Sdn Bhd (Mi Polymer) for around US$ 5.0 million to gain opportunities in the domestic and South-east Asia region.

Expanding the civil construction industry is raising demand for polymer concrete due to its high vibration resistance, high impact strength and excellent bonding properties with materials such as metals that are expected to propel the market growth of polymer concrete. Moreover, rising usage of polymer concrete in repair and maintenance applications instead of rebuilding infrastructure is further anticipated to foster the market growth of polymer concrete over the forecast period.

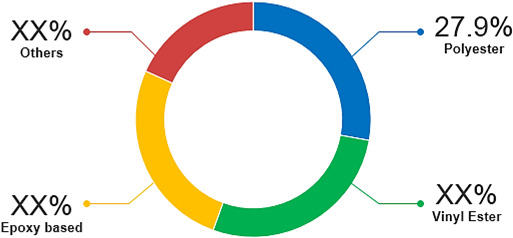

Figure 3. Global Polymer Concrete Market, Revenue Share (%), By Material Type, in 2018

On the basis of material type, in 2018, polyester accounted the largest market share of 27.9% in terms of revenue, followed by vinyl ester and epoxy based polymer, respectively.

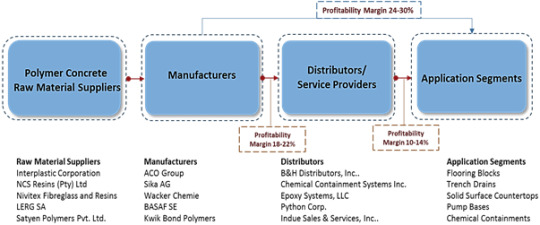

Figure 4. Global Polymer Concrete Market – Value Chain Analysis

Competitive Section

Key players active in the global polymer concrete market are BASF SE, Sika AG, Wacker Chemie AG, Dudick Inc., ACO Group, Kwik Bond Polymers LLC, Sauereisen Inc., Hubbell Power Systems Inc., Forte Composites, Inc., Ulma - Architectural Solutions, and Sandmix Sp. z o.o. S.K.

Few Recent Developments

BASF SE

In January 2017, the Construction Chemicals division of BASF Corporation announced the launch of MasterEmaco T 5000, a chemical resistant repair mortar and grout. The product is available in North America.

In August 2016, the company commissioned a new plant in Sri Lanka to produce concrete admixtures from global Master Builders Solutions brand

In May 2016, the company established a new concrete admixtures plant in Kharagpur, India. This is the 6th production site for BASF in India.

Get free sample report here: https://www.coherentmarketinsights.com/insight/request-sample/3386

Download PDF brochure: https://www.coherentmarketinsights.com/insight/request-pdf/3386

About Us:

Coherent Market Insights is a global market intelligence and consulting organization focused on assisting our plethora of clients achieve transformational growth by helping them make critical business decisions.

What we provide:

• Customized Market Research Services

• Industry Analysis Services

• Business Consulting Services

• Market Intelligence Services

• Long term Engagement Model

• Country Specific Analysis

Contact Us:

Mr. Shah

Coherent Market Insights Pvt. Ltd.

Address: 1001 4th ave, #3200 Seattle, WA 98154, U.S.

Phone: +1-206-701-6702

Email: [email protected]

Source: https://www.coherentmarketinsights.com/market-insight/polymer-concrete-market-3386

0 notes

Link

Cement plastering is normally applied to provide perfect coating to the outside and inside surface of wall. Cement plaster is normally given in a single coat or double coat. Double coat plaster is suitable where thickness of plaster is retained in excess of 15 mm or when it is necessary to maintain a very fine finish. The method for double coat cement plaster involves the following 5 steps.

a. Step-1-Making the surface ready for plastering b. Step-2-Ground work for plaster c. Step-3-Providing first coat (or under coat or rendering coat) d. Step-4-Providing second coat (or finishing coat or fine coat)

STEP-1 (MAKING THE SURFACE READY FOR PLASTERING)

1. Retain all the mortar joints of wall rough, in order to maintain a good bonding to retain plaster. 2. Use a wire brush to cleanse all the joints and surfaces of the wall with a wire brush, the wall surface does not contain any oil or grease etc. left on wall surface.

3. In case the surface is smooth or the plastering wall is old one, then extract the mortar joint to a depth of minimum 12 mm to provide a superior bonding to the plaster. 4. If the projection on the wall surface remains over 12 mm, then rub it out to maintain a smooth surface of wall. It will minimize the consumption of plaster. 5. For any cavities or holes on the surface, fill it with exact material beforehand. 6. Roughen the whole wall to be plastered. 7. Wash the mortar joints and whole wall to be plastered, and make it wet for minimum 6 hours prior to use cement plaster.

STEP-2 (GROUND WORK FOR PLASTER)

1. To maintain smooth thickness of plastering all through the wall surface, initially settle dots on the wall. A dot belongs to patch of plaster with size 15 mm * 15 mm and thickness of about 10 mm. 2. Initially, dots are set on the wall horizontally and then vertically at a spacing of about 2 meters coating the whole wall surface. 3. With the help of plumb-bob, examine the verticality of dots, one over the other. 4. Once the dots are set, the vertical strips of plaster alias screeds are arranged among the dots. These screeds function as the gauges for retaining smooth thickness of plastering to be used.

STEP-3 (PROVIDING FIRST COAT OR UNDER COAT OR RENDERING COAT)

1. For brick masonry the thickness of first coat plaster usually remains 12 mm and for concrete masonry this thickness differs from 9 to 15 mm. 2. The proportion of cement and sand for first coat plaster differs from 1:3 to 1:6. 3. By using a trowel, provide the first coat of plaster among the spaces developed with the screeds on the wall surface. 4. The surface should be leveled with flat wooden floats and wooden straight edges. 5. Once the leveling is finished, leave the first coat to set but not to dry and then roughen it by a scratching tool to develop a key to the second coat of plaster.

STEP-4 (PROVIDING SECOND COAT OR FINISHING COAT OR FINE COAT)

1. The thickness of second coat or finishing coat may differ from 2 to 3 mm. 2. The proportion of cement and sand for second coat plaster differs from 1:4 to 1:6. 3. Prior to provide the second coat, moist the first coat uniformly. 4. Provide the finishing coat with wooden floats to a perfect uniform surface and apply finishing touch with a steel trowel. 5. If possible, the finishing coat should be provided starting from top towards bottom and finished in one operation to remove joining marks.

As soon as the plastering work is completed, water should be sprinkled over it to keep moist for minimum 7 days to maintain strength and hardness.

#Surface of wall#Cement plaster#Thickness of plaster#Ceiling plaster#Drywall plastering#Cost of plastering#Concrete prices

0 notes

Link

Whether the production of concrete mixing plant is normal or not, the quality of concrete and the cost of material consumption are all related to the measuring system of concrete mixing plant . Therefore, the management of the measurement system is of great significance to the concrete mixing plant . 1. All measuring instruments, such as scales, measuring feet, test equipment and instruments, must be sent to the measuring department for checking regularly according to the requirements of the measurement method, and properly kept and maintained, and properly used, especially the theodolite, level gauge and other instruments shall be checked frequently. 2. Strict implementation of relevant provisions on measurement during construction. Reinforced concrete engineering is building and the main structure, especially should strengthen the supervision for the measurement of the steel bar, concrete construction process, must mix proportion by weight, mixing concrete and mortar to sampling observation of sand, stone, cement, water metering the original testing data, the determination of the moisture content of sand, stone, accurate control of mixing water, control the water cement ratio. 3. Check the weekly inspection of all kinds of measuring instruments in use, check whether they are missing or not, and check the three rates of measuring instruments: namely, the ratio of equipment, the rate of detection, and the rate of pass, whether they meet the standards and process requirements.

0 notes

Text

Global Sodium Fluosilicate Industry Market Analysis & Forecast 2018-2023

The global sodium silicate market is anticipated to witness a staggering CAGR in the forthcoming period. Sodium silicate market is driven by factors such as rise in demand for detergents and cleaning agents in developing economies. Rise in foreign investments in oil & gas processing is likely to be projected to outgrow the market demand during the forecast period. Market opportunities such as rising demand for silica from rubber & tire industry and demand from construction and water treatment projects is likely to contribute significantly towards the market growth. On the other hand, challenges such as variation in price of raw materials and existence of cheap substitutes is likely to refrain the market growth in the forecast period.

Topics covered in this topic:

· Chapter 1 Sodium Fluosilicate Market Overview

· Chapter 2 Global Economic Impact on Sodium Fluosilicate Industry

· Chapter 3 Global Sodium Fluosilicate Market Competition by Manufacturers

· Chapter 4 Global Sodium Fluosilicate Production, Revenue (Value) by Region (2013-2018)

· Chapter 5 Global Sodium Fluosilicate Supply (Production), Consumption, Export, Import by Regions(2013-2018)

· Chapter 6 Global Sodium Fluosilicate Production, Revenue (Value), Price Trend by Type

· Chapter 7 Global Sodium Fluosilicate Market Analysis by Application

· Chapter 8 Global Sodium Fluosilicate Manufacturers Analysis

· Chapter 9 Sodium Fluosilicate Manufacturing Cost Analysis

· Chapter 10 Industrial Chain, Sourcing Strategy and Downstream Buyers

· Chapter 11 Marketing Strategy Analysis, Distributors/Traders

· Chapter 12 Market Effect Factors Analysis

· Chapter 13 Global Sodium Fluosilicate Market Forecast (2018-2023)

Sodium silicate is a blend of oxides of sodium and silica with a range of chemical formula in sodium oxide and silicon dioxide content or proportions. Physically, it is soluble in water and is prepared by reacting silica sand sodium carbonate at a high temperature. Glass water is term referred to aqueous solution of sodium silicate. Commercially, it is used as a mixing agent in soaps and detergents. It is also used in cement industry as cement binder, filler or an adhesive. Industrial uses of sodium silicate encompass refractories for production of cements and mortars.

The sodium silicate market is bifurcated into application and geography. Application segment for sodium silicate includes detergents, precipitated silica, pulp & paper, detergents, iron & metal casting, water treatment and food preservation. Geographical segmentation for sodium silicate market spans North America, South America, Europe, Middle East and Africa.

Asia-Pacific market is projected to gain a momentous growth during the forecast period since Asia-Pacific accounts for a larger market share with growth factors such as rising demand from several applications such as elastomers, detergents, catalysts and water treatment.

North America market witnesses a strong market position in future due to rise in demand from construction industry and water treatment projects. Europe market is expected to achieve a steady market growth due owing to second largest market share in the global scenario. MEA market is expected to witness a highly moderate growth in the forecast period.

The key players in the sodium silicate market include PQ Corporation, BASF SE, Evonik Industries AG, W.R. Grace & Co., CIECH Group, Silmaco NV, Oriental Silicas Corporation, Aromachimie Company Ltd, Industrial Chemicals Ltd, SIEKEM d.o.o, MAGNIFIN, BEKO Troyan, Glassven C.A, Z.Ch. Rudniki SA, Huber Engineered Materials, PPG Industries, Tokuyama Siltech Co. Ltd, Occidental Chemical Corporation, Nippon Chemical Industrial Co. Ltd, Solvay, and Diatom.

Read full report @: https://www.upmarketresearch.com/reports/Global-Sodium-Fluosilicate-Industry-Market-Analysis-Forecast-2018-2023

In the Global Sodium Fluosilicate Industry Market Analysis & Forecast 2018-2023, the revenue is valued at USD XX million in 2017 and is expected to reach USD XX million by the end of 2023, growing at a CAGR of XX% between 2018 and 2023. The production is estimated at XX million in 2017 and is forecasted to reach XX million by the end of 2023, growing at a CAGR of XX% between 2018 and 2023. It covers Regional Segment Analysis, Type, Appliction, Major Manufactures, Industry Chain Analysis, Competitive Insights and Macroeconomic Analysis.

Global Sodium Fluosilicate Market: Regional Segment Analysis

· North America

· Europe

· China

· Japan

· Southeast Asia

· India

Request sample copy of this report @: https://www.upmarketresearch.com/home/requested_sample/192

The Major players reported in the market include:

· KC INDUSTRIES

· AWSM Industry

· OHARA

· Fluoro Chemicals

· Fujian Qucheng Chemical

· Changshu Xinzhuang Jixiang Auxiliary

· Yushan Fengyuan Chemical

· Shanghai Mintchem Development

· Kunming Heqi Industry

Global Sodium Fluosilicate Market: Product Segment Analysis

· Type 1

· Type 2

· Type 3

Global Sodium Fluosilicate Market: Application Segment Analysis

· Application 1

· Application 2

· Application 3

Enquire more details about this report @: https://www.upmarketresearch.com/home/enquiry_before_buying/192

Reasons for Buying this Report This report provides pin-point analysis for changing competitive dynamics It provides a forward looking perspective on different factors driving or restraining market growth It provides a six-year forecast assessed on the basis of how the market is predicted to grow It helps in understanding the key product segments and their future It provides pin point analysis of changing competition dynamics and keeps you ahead of competitors It helps in making informed business decisions by having complete insights of market and by making in-depth analysis of market segments.

About Us: Up Market Research (https://www.upmarketresearch.com) is a leading distributor of market research report offered by genuine publishers. Our motto is to enable a full-fledged market report demonstrating factual content so that our clients have a close chance to look for quality samples before banking upon any investment decision. Our clients can browse through our vast reports database for sample reports before choosing to buy. Our in-house panel of analysts and consultants has a scrupulous approach prior to report publishing and also ensure that our clients receive updated reports within the specified time. Post-sales client consultation is a value-added service on association. Keeping the clients updated with latest market trends and informed business decisions can help them driving relevant business resources forms the basis of our success story. Contact Info: Name: Alex Mathews Organization: UpMarketResearch Address: 500 East E Street, Ontario, CA 91764, United States Phone: +1 347-377-7033

#Sodium Fluosilicate Industry#Sodium Fluosilicate Market#Sodium Fluosilicate Analysis#Sodium Fluosilicate Forecast#Sodium Fluosilicate Trends#Sodium Fluosilicate Research#Sodium Fluosilicate

0 notes

Text

Concrete Mixer 1000L

Concrete mixer 1000 L is a widely used concrete mixing equipment, which is mainly used for mixing concrete, mortar and other building materials.

Here are the detailed information about 1000 L concrete mixer:

1, Product model number and theoretical production capacity:

The product model of a concrete mixer 100 liter is usually JS1000, which stands for its discharge capacity of 1000 liters. The theoretical production capacity is usually 60 cubic meters per hour (m³/h), but the actual production capacity may be slightly different depending on the material characteristics and mixing efficiency. So the related concrete batching plant models are HZS50 and HZS60 concrete batching plant.

2, Structure and Composition:

JS1000 concrete mixer is a double horizontal shaft forced concrete mixer, which is composed of feeding, mixing, discharging, water supply, electric, cover, chassis, outrigger gears and other parts. The mixing blades in the mixing cylinder form a spatial intermittent spiral belt structure, which can produce three-dimensional mixing along the radial and axial direction, and push, rub, squeeze and other comprehensive effects on the materials to achieve high homogeneity mixing effect.

3, Performance parameters:

Feeding capacity: usually 1600 liters.

Rotating speed of mixing cylinder: about 25 rpm.

Maximum particle size of aggregate: 80mm.

Mixing motor power: usually 18.5kwx2.

Lifting motor power: 11kw.

Water supply precision error: ≤2%.

4, Application field:

It is mainly applied to large and medium-sized prefabricated component factories and industrial and civil construction projects such as highways, bridges, water conservancy, wharves and so on.

It can mix plastic, dry-hard, light aggregate concrete and all kinds of mortar and grout.

5, Product Advantage:

It has the advantages of high degree of automation, good mixing quality, high efficiency, low energy consumption, low noise, convenient operation and fast discharging speed.

The degree of concrete collapse in the mixer can be monitored and changed at any time to ensure the quality of concrete.

A variety of mixing knife angle to meet the different needs of customers, mixing quality is more outstanding.

6, Operation standardization:

The operator should be specially trained and obtain the special work type operation license before going to work.

Before working, the machine should be idling and debugging to ensure the normal operation of the equipment.

The feeding order is usually stone-cement-sand, and the hopper should not be overloaded.

The hopper should be lowered to a low place immediately after unloading.

7, Price range:

Depending on the brand, model and configuration, the price of a 1000 L concrete mixer can vary. Generally, the price range is from several thousand dollars to tens of thousands of dollars.

Please note that the above information is for reference only, and specific parameters and prices of concrete mixer 1000l may vary depending on brand, model and region. When purchasing or using, it is recommended to refer to the product manual or consult a professional.

This resource is from http://www.haomei-machine.com/news/companynews/concrete-mixer-1000l.html Should you be interested in buying our product, please contact us at: Haomei Machinery Equipment Co.,ltd Whatsapp/Wechat: 0086 181 3788 9531 Email: [email protected]

0 notes

Link

Cement plaster is normally applied with a single coat or double coat. Double coat plaster is suitable where depth of plaster remains in excess of 15 mm or when it is necessary to maintain a very fine finish. The following process is undertaken to apply a double coat cement plaster on wall surface.

Step 1 - Arrangement of surface for plastering Step 2 - Foundation for plaster Step 3- Providing first coat (or under coat or rendering coat) Step 4 - Providing second coat (or finishing coat or fine coat)

DETAIL PROCESSES FOR CEMENT PLASTERING:

Step 1: Arrangement of surface for plastering

1. Maintain all the mortar joints of wall rough in order to provide a perfect bonding to retain plaster. 2. Cleanse all the joints and surfaces of the wall by applying a wire brush. The surface of the wall should be free from any oil or grease etc.

3. In case the surface is smooth or the plastering is too old, then rake out the mortar joint to a depth of at least 12 mm to give a better bonding to the plaster. 4. If the projection on the wall surface surpasses 12 mm, then knock it off, in order to keep a consistent surface of wall. It will help in minimizing the consumption of plaster. 5. If there is any cavities or holes on the surface, then it should be filled with proper material beforehand. 6. Rough up the complete wall for being plastered. 7. Clean the mortar joints and whole wall to be plastered, and it should be drenched for minimum 6 hours prior to use cement plaster.

Step 2: Foundation for plaster

1. Initially, make the wall dotted to maintain consistent thickness of plastering all through the wall surface. A dot signifies patch of plaster having size 15 mm * 15 mm and thickness of about 10 mm. 2. At first the dots are set on the wall horizontally and then vertically maintaining a space of about 2 meters covering the complete wall surface. 3. Examine the verticality of dots, one over the other, with the use of plumb-bob. 4. As soon as the dots are set, the vertical strips of plaster, called as screeds, are developed among the dots. These screeds perform as the gauges for keeping up smooth thickness of plastering being used.

Step 3: Providing first coat (or under coat or rendering coat)

1. For brick masonry, the depth of first coat should be normally 12 mm and in case of concrete masonry this thickness differes from 9 to 15 mm. 2. The proportion of cement and sand for first coat plaster fluctuates from 1:3 to 1:6. 3. Apply the first coat of plaster between the spaces formed by the screeds on the wall surface. This is done by means of trowel. 4. Level the surface with flat wooden floats and wooden straight edges. 5. As soon as level is completed, left the first coat to set but not to dry and then roughen it employing scratching tool to develop a key to the second coat of plaster.

Step 4: Providing second coat (or finishing coat or fine coat)

1. The depth of second coat or finishing coat fluctuates among 2 to 3 mm. 2. The proportion of cement and sand for second coat plaster fluctuates from 1:4 to 1:6. 3. Prior to use the second coat, wet the first coat consistently. 4. Provide the finishing coat with wooden floats to an uniform surface and the proper finishing should be done with wooden floats. 5. Try to apply the finishing coat from top towards bottom and complete in one operation to get rid of joining marks.

As soon as the plastering work is completed, it should be kept drenched by sprinkling water for minimum 7 days to maintain strength and rigidity.

http://quantity-takeoff.com/some-useful-tips-to-use-cement-plaster-on-wall-surface.htm

0 notes

Text

What are the mistakes in the installation of commercial concrete mixing plants?

For every user in terms of commercial concrete mixing plant installation is absolutely essential for production, is the latter directly affects the quality of concrete and maintenance and other important factors, so prone to errors in which installed in the course of daily, the Haomei machineryequipment limited company will introduce.

1, concrete mixing plant to install another quality problem is the emergence of local concrete voids like honeycomb hole formed between mortar, crisp, stone and more stone and stone, and the local surface appear to lack of pulp, and many small pits, pits formed on the surface of rough but not exposed steel bars phenomenon in the outside.

2, the factory in order to save costs, matching self-made instrument, the error is large, low precision, poor reliability. By comparison, we will replace the CB92 digital control instrument batching instrument Zhimei electronic company, were used to control sand, cement and water balance weighing scales, scales and fly ash. CB92 is quite small scale, its performance is accurate and reliable, coarse measurement, precise measurement with material, impulse compensation and unloading function, can use the software of digital test calibration, automatic zero tracking, can control four kinds of different materials, weight and material in one display controller.

3, concrete mixing plant production capacity and mixing quality will also affect the price, so for high performance, low power consumption, the technology design process improvement of concrete mixing station equipment, relative to the price generally will be slightly more expensive, but the income level is high.

Haomei machinery has long been focused on the field of mixing equipment, is a company specializing in the production of concrete mixing plants, sales as one of the full-service company.

0 notes