#scaffolding today inc

Explore tagged Tumblr posts

Text

Protect your construction projects with high-quality scaffolding.

Construction sites are among the busiest areas on the planet. Great sites are well-oiled machines when skilled personnel from many specialities work together and have access to the necessary equipment.

When it comes to having the correct equipment on-site, most people think that safe scaffolding is essential. It acts as a backbone for the workers, allowing them to work safely at heights without jeopardising project timeframes.

But why are scaffolds so important for safety, and how can we make the best use of them as building professionals? Scaffolding Today Inc. offers the best construction scaffolding in Houston In this blog post, we'll look at how scaffolding protects people and helps projects succeed.

Scaffolding: The Foundation of Safety.

Scaffolding, according to USA requirements for safe working at heights, is the first option when solid ground or solid construction is unavailable. It's a dedicated workplace for workers to complete their responsibilities, and the ideal system always includes tools and materials that speed up the construction process.

Scaffolding, technically known as a fall protection device, is critical for decreasing construction-related injuries and fatalities. The finest solutions provide a secure platform for workers, minimising the risk of falls while allowing them to complete work at height promptly.

Great scaffolding systems also ensure safe and efficient access to various regions of the site. Not only does this speed up the project, but it also eliminates the need for any temporary solutions that could jeopardise the crew's safety. Furthermore, it should reduce the likelihood of accidents caused by clutter or restricted movement.

The goal, as with most on-site equipment, is to select high-quality scaffolding that can withstand a variety of hazards without endangering crew members.

What Makes Scaffolding High-Quality?

With so many alternatives available, how can you tell if a scaffolding system is high-quality? There are three major elements we recommend looking into:

Compliance

Reputable scaffold makers are as cautious as possible about industry compliance, guaranteeing that everyone who utilises the system is as safe as a house.

Convenience of Assembly

Great scaffolding systems are simple to install and disassemble. Not only does this shorten project times, but it also reduces the likelihood of damage.

Durability and Stability.

High-quality scaffolding supplies are made of lightweight, sturdy, and long-lasting materials such as aluminium, which are less prone to wear and tear with time.

Before acquiring a scaffolding system, extensively study both the company and the system itself. Examine their maintenance guidelines, assembly instructions, and material information to determine the system's quality for yourself. Once you have the scaffolding, it is up to you to make the most of it.

How to make the most of your scaffolding

Train for installation.

All crews should receive training on how to safely and efficiently install the scaffolding they will be utilising. Whether you're building edge protection or a walkway scaffold platform, your crew must understand what issues to check for and how to address them quickly. That is why, at Scaffolding Today Inc., we provide thorough instructions to help our customers get the most out of our exclusive technology.

Pay attention to load limits.

The load limit or load capacity of your scaffolding indicates how much weight it can safely support. Exceeding these limits is bad news since it can result in instability and even equipment failure. So, make sure your team isn't overloading the platform with tools, personnel, or supplies.

Access and egress points

Safely ascending and exiting the platform is essential when working at heights, as bumps or impacts can result in dangerous falls. Once your system is up and running, set up designated entrance and egress points that are clearly identified.

Choose the Right System.

Of course, one of the most critical aspects of protecting your construction project is selecting the appropriate scaffolding system for the work. The correct system must be thoroughly researched, contain detailed assembly instructions, and meet the objectives of your specific project.

High-quality scaffolding is more than simply a tool; it's the ultimate protection for your projects. It is critical for protecting your employees, complying with work safety requirements, and completing projects on schedule.

If you prioritise scaffolding as part of your equipment purchases, you're officially on track. And if you ever need more advice, the Scaffolding Today Inc staff is available to help.

A system created by pros, for professionals.

The Scaffolding Today Inc. scaffolding and edge protection system resulted from hours of rigorous consideration, design, and testing. Designed for busy construction workers who require versatile systems with safety at its core, this is a low-cost solution regardless of how you manage your site. Browse our scaffolding selection or contact Scaffolding Today Inc. the best Houston scaffolding companies to learn more about our offerings now.

0 notes

Text

One Of The Best Scaffolding Companies in Houston

STI(Scaffolding Today Inc) is one of the best Scaffolding companies in Houston. We provides the best scaffolding services scaffolding rentals, scaffold for sale, comprehensive commercial and industrial services,

Delivery and pick-up services, shoring and accessories etc. Contact us today for scaffolding services.

0 notes

Text

Scaffold For Sale

Scaffolding Today Inc provides the best scaffolding rental services.. We offers trained crews for the erect and dismantle service of your scaffold projects. We are one of the best scaffolding rental services provider in Houston. Houston scaffolding provides the best scaffolding rentals, scaffold for sale, comprehensive commercial and industrial services. We offer a wide range of scaffoldings and its accessories. We also offers the pick up and drop services. Scaffolding Today Inc is the best scaffolding company in Houston.

#houston scaffolding#erect and dismantle scaffolding#scaffolding today inc#scaffoldforsale#scaffolding services

0 notes

Text

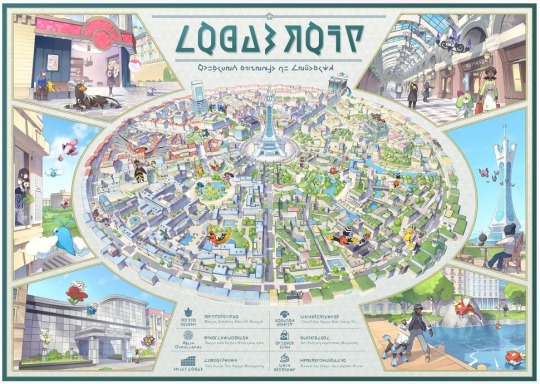

🔎Legends ZA Trailer 1 Analysis🔎

🔎Legends ZA Trailer 1 Analysis🔎

We finally have a trailer for Pokemon Legends: ZA, and I am absolutely hyped for the game! Kalos was my first region and it’ll be fun to go back to it in such a creative way. We don’t know much, but we do have plenty to examine from the trailer and accompanying advertising.

Everything below is spoilers for today’s present.

The Setting

[ID: First Image shows a Bunnelby, scatterbug, and fletchling running down a street in Lumiose that’s been overgrown with plants. “The Wild Zone” is named in the image.

Second: The player character running down a similarly abandoned street, there’s a car left behind and more plants around]

It’s interesting that one of the wild zones looks like an abandoned street in Lumiose city, the stores are still intact and there’s an entire car left behind, implying that this was a recent change. Wild zones are clearly very new editions and I wonder how much of the city was set aside for them, and what happened to the people who lived and worked in those areas.

[ID: An overview of as street covered in black and blue, futuristic scaffolding over very old looking buildings]

I noticed some construction scaffolding in the background and I have two theories about them:

1. Decoration: The scaffolding is just there for decorations in one part of the map to make it look like it’s actively under construction and provide more interesting spaces for battles.

2. Changing Map: Over the course of the game's story, scaffolding will appear over old buildings, cover them up, and then they get removed to reveal new buildings.The city evolves over the course of the story… but is that a good or bad thing?

Quasartico Inc.

[ID: a large modern looking building with the Quasartico logo on it]

We get introduced to Quasartico Inc. and it’s CEO Jett, and everyone is in agreement that she is the villain of this new game. We don’t know her plans, but we know she wants to modernize Lumiose City, we see a lot of construction at one point and an abandoned street in another, this bitch is gentrifying this city.

In the trailer we get a look at AZ’s hotel, it’s an old building that I think will be under the threat of being demolished to make way for a new modern building. My only reason behind this is that AZ is living his best life with his Floette and that the player living there makes it an emotionally important location, threatening it would establish Quasartico as a major villain in the game.

[ID: A comparison between the Looker Bureau im the trailer and in XY. Same being walls and tiled floors, the kitchen is more detailed in the trailer, there’s a board on the wall with notes about the city and papers and a laptop on the desk]

We also know that someone is keeping an eye on them, we get a quick glimpse at the Looker Bureau office from the postgame of XY. In the background there’s a board covered with notes and a map of the city meaning whoever is living here is keeping an eye on all the urbanization. When I first saw the trailer, I thought it had to be Emma from the XY postgame, but examining it a little closer I’m not as certain; Looking closely I noticed the picture of an Espurr on the desk, clearly meant to be Emma’s friend “Mimi”. The fact she’s in a framed picture gives me 4 theories:

1. Mimi died and this picture is in her memory, Emma is still at the Looker Bureau.

2. Looker is in the Bureau again and the picture is a reminder of Emma and Mimi.

3. Theory 1 but Looker has the picture.

4. I’m overthinking this, Mimi is fine and Emma just has a picture of her pet.

Conclusion

This game is looking amazing and it’s getting all the time it needs to marinate, I can’t wait to see who makes an appearance and I can’t wait to be introduced to the new cast of characters.

#pokemon#pokémon#pokeblogging#pokemon theory#pokemon za#za#legends za#Kalos#Lumiose city#pokemon emma#trailer analysis#trailer#pokemon az#Quasartico

36 notes

·

View notes

Text

Construction Safety Netting: Types, Uses, and Benefits

In any active construction zone, safety isn't optional—it’s essential. One of the most effective and affordable ways to enhance site safety is through Construction Safety Netting. Whether you're protecting workers, pedestrians, or nearby property, these nets serve as a critical barrier between danger and disaster.

At Nets Depot Inc, we specialize in manufacturing and supplying high-performance safety netting designed to meet today’s most rigorous construction standards. Let’s explore the different types, uses, and benefits of construction safety netting to help you make informed decisions on your next project.

What Is Construction Safety Netting?

Construction Safety Netting is a durable mesh barrier used on building sites to catch debris, prevent falls, and maintain a clean and hazard-free environment. It’s commonly used in both residential and commercial construction zones and is often mandated by OSHA and other regulatory bodies.

These nets aren't just accessories—they’re life-saving equipment designed to catch falling objects or workers and reduce the risk of serious injuries.

Types of Construction Safety Netting

At Nets Depot Inc, we offer a wide range of safety netting systems built for specific applications. Understanding the different types will help you choose the most suitable option for your job site.

1. Debris Netting

Prevents construction materials from falling off buildings

Commonly used in high-rise projects

Often UV-treated and flame-retardant

2. Personnel Safety Nets

Designed to catch workers who fall from heights

Installed horizontally below elevated work areas

Made with high-tensile strength materials

3. Scaffold Netting

Wraps around scaffolding structures

Protects both workers and the general public

Also reduces wind and weather exposure

4. Vertical Safety Netting

Attached to building perimeters

Helps to contain tools, materials, and debris

5. Horizontal Safety Netting

Used under bridges or floors during construction

Key in fall protection systems

Common Uses of Construction Safety Netting

Construction safety netting is incredibly versatile. Some of the most common applications include:

High-rise building construction

Bridge and tunnel maintenance

Scaffolding projects

Roadwork and urban infrastructure projects

Renovations and demolitions

At Nets Depot Inc, we custom-design netting solutions to fit these and many other site-specific scenarios.

Key Benefits of Using Construction Safety Netting

Investing in quality netting from Nets Depot Inc offers a wide range of benefits:

Prevents injuries and fatalities by catching falling debris or personnel

Protects nearby properties and pedestrians in crowded urban zones

Ensures regulatory compliance, including OSHA and ANSI standards

Reduces clean-up time and keeps your site more organized

Improves worker confidence, knowing they’re working in a safer environment

Material and Design Considerations

Choosing the right materials is crucial for long-term performance. At Nets Depot Inc, we manufacture netting with:

High-density polyethylene (HDPE) for weather resistance

Nylon and polyester for added strength and flexibility

UV and fire-retardant coatings for outdoor and high-risk environments

Custom mesh sizes to balance airflow, visibility, and containment

Load-tested products for fall arrest certification

Installation and Maintenance

Proper installation is key to maximizing the benefits of Construction Safety Netting.

Installation Tips:

Always follow manufacturer guidelines

Secure anchors at structurally sound points

Use tension cables or tie-downs for added security

Install at multiple levels if working on multi-story buildings

Maintenance Tips:

Inspect netting regularly for wear and tear

Replace damaged or frayed sections immediately

Store in dry, shaded areas when not in use

Keep a maintenance log for regulatory audits

Compliance and Safety Standards

Nets Depot Inc designs all netting products to meet or exceed:

OSHA (Occupational Safety and Health Administration) standards for fall protection

ANSI/ISEA guidelines for industrial safety

Local building code requirements based on project location

Always verify your region's safety regulations to ensure you remain in full compliance.

Choosing the Right Netting for Your Project

When selecting netting, consider these key factors:

Type of project (e.g., high-rise, bridge work, residential)

Height of installation

Environmental conditions (sun, rain, snow)

Load-bearing requirements

Duration of use (short-term vs. permanent solutions)

Need help? Nets Depot Inc offers personalized consultations to match you with the ideal netting system.

Where to Buy Construction Safety Netting

Looking for a trusted supplier?

At Nets Depot Inc, we manufacture and supply a wide range of Construction Safety Netting products, including:

Custom-sized netting

Bulk orders for large construction firms

Pre-fitted scaffold and personnel nets

Local delivery and nationwide shipping

We pride ourselves on quality, safety, and customer satisfaction.

FAQs About Construction Safety Netting

Q1: How long does construction safety netting last?

Most high-quality nets last 3–5 years, depending on material, usage, and environmental conditions.

Q2: Can safety nets be reused?

Yes, if they pass inspection and show no signs of damage. Regular maintenance is key.

Q3: Is scaffold netting waterproof?

Most scaffold nets are water-resistant and provide some wind protection, but they are not fully waterproof.

Q4: Do I need certified netting for every project?

If your project involves fall risks or is governed by OSHA, certified nets are usually required.

Why Choose Nets Depot Inc?

With decades of experience in the industry, Nets Depot Inc is your go-to source for Construction Safety Netting. We combine quality manufacturing with expert consultation, ensuring that every product meets your safety, budget, and performance needs.

We serve construction companies across the U.S. and offer:

Custom design services

Bulk and wholesale pricing

Fast turnaround and shipping

Ongoing support and compliance guidance

Contact Nets Depot Inc Today

Looking to secure your construction site? Reach out to Nets Depot Inc today for a free quote or consultation. Let us help you build safer, smarter, and more compliant job sites with our advanced Construction Safety Netting solutions.

0 notes

Text

Europe Wound Dressing Market Impressive Trending Strategies and Key Players 2028

The Europe wound dressing market is expected to grow from US$ 3,105.95 million in 2022 to US$ 4,380.67 million by 2028; it is estimated to grow at a CAGR of 5.9% from 2022 to 2028.

Europe Wound Dressing Market Segmentation

The Europe wound dressing market is segmented based on type, application, end user, and country. Based on wound dressing type, the Europe wound dressing market is bifurcated into advanced wound dressing and traditional wound dressing. The advanced wound dressing segment dominated the market in 2022. The advanced wound dressing is further segmented into foam dressings, superabsorbent dressings, film dressings, hydrocolloids dressings, wound contact layers, collagen dressings, and others. The traditional wound dressing is also segmented into dry dressings, surgical tapes, and anti-infective dressings. Based on application, the Europe wound dressing market is bifurcated into chronic wound and acute wound. The chronic wound segment dominated the market in 2022. The chronic wound segment is further segmented into pressure ulcers, diabetic foot ulcers, venous leg ulcers, and other chronic wounds. Similarly, the acute wound segment is bifurcated into surgical and traumatic wounds and burns wounds. Based on end user, the Europe wound dressing market is segmented into hospitals, ambulatory surgical centers, clinics, and others. The hospitals segment dominated the market in 2022. Based on country, the Europe wound dressing market has been categorized into the UK, Germany, France, Italy, Spain, and the Rest of Europe. Germany dominated the market in 2022.

Request sample:

https://www.businessmarketinsights.com/sample/BMIRE00027272

3M; Advancis Medical; Axio Biosolutions Pvt Ltd; Coloplast Corp; Convatec Inc.; Integra LifeSciences Holdings Corporation; Medline Industries, Inc.; Medtronic; Mölnlycke Health Care AB.; and Smith+Nephew are among the leading companies in the Europe wound dressing market.

Contemporary trauma management confronts extraordinary clinical demands: • Life-threatening hemorrhage combined with devastating tissue loss in polytrauma cases • Chronic, treatment-resistant wounds that defy conventional therapies • Catastrophic infection risks in low-resource clinical settings

Cutting-edge solutions are revolutionizing wound management:

Nanotech Hemostatic Dressings: Molecularly engineered materials achieving rapid clotting (under 60 seconds) while preventing secondary tissue damage

Precision Regenerative Therapies: Patient-specific biofabricated scaffolds incorporating stem cell technology for targeted reconstruction

Cognitive Wound Platforms: Autonomous dressing systems utilizing deep learning algorithms to optimize treatment in real-time

The Europe wound dressing market stands as the global innovation leader, projected to maintain 9.2% CAGR through 2030. This leadership position reflects: ✓ Unmatched biomedical research and development capabilities ✓ Progressive regulatory frameworks that balance safety with innovation ✓ Comprehensive reimbursement policies enabling widespread adoption

The market outlook reveals tremendous potential: • $28.6B global valuation anticipated by 2028 • Potential for 40% reduction in chronic wound treatment costs • Explosive growth in connected wound care technologies

This transformation represents a fundamental redefinition of wound care: → From passive wound covering to biologically interactive systems → From standardized protocols to individualized precision medicine → From hospital-dependent care to intelligent remote monitoring

As this sector evolves, advanced wound management is emerging as a blueprint for the future of healthcare - seamlessly integrating biotechnology breakthroughs, digital transformation, and patient-centered care models. The pioneering solutions being developed today will not only address critical gaps in trauma care but are likely to redefine therapeutic approaches across the entire medical spectrum in the years to come.

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

#Europe Wound Dressing Market#Europe Wound Dressing Market Demand#Europe Wound Dressing Market Supply

0 notes

Text

Best Scaffolding Supply in Houston

STI - Scaffolding Today Inc is the trusted and the leading Houston scaffolding company. We offer the best scaffolding supply in Houston at an affordable price.

We provide the best quality scaffolding, accessories, and shoring at an affordable price. If you are in the area and are looking for quality scaffolding, Scaffolding today Inc. is the place to call. We have been proven to be the industry standard for years.

0 notes

Text

Scaffolding today inc

Scaffolding Today Inc has hinged its business on quality. By vending a rugged dependable product that saves the customer money.

STI is the fastest growing scaffold company in North America. With branches in New York, Philadelphia and Houston STI has built a reputation based on both quality and customer service.

They provide the best quality of Scaffoldings at very comfortable prices and are the largest manufacturers from many years with a lot of experiences and satisfied customers.

0 notes

Text

Tomorrow’s Technology on the Space Station Today

Tablets, smart appliances, and other technologies that are an indispensable part of daily life are no longer state-of-the-art compared to the research and technology development going on over our heads. As we celebrate 20 years of humans continuously living and working in space aboard the International Space Station, we’re recapping some of the out-of-this-world tech development and research being done on the orbiting lab too.

Our Space Technology Mission Directorate (STMD) helps redefine state-of-the-art tech for living and working in space. Here are 10 technologies tried and tested on the space station with helping hands from its astronaut occupants over the years.

1. Astronaut Wanna-Bees

Astronauts on the space station are responsible for everything from conducting science experiments and deploying satellites to tracking inventory and cleaning. While all are necessary, the crew can delegate some jobs to the newest robotic inhabitants – Astrobees.

youtube

These cube-shaped robots can work independently or in tandem, carrying out research activities. Once they prove themselves, the bots will take on some of the more time-consuming tasks, such as monitoring the status of dozens of experiments. The three robots – named Bumble, Honey, and Queen – can operate autonomously following a programmed set of instructions or controlled remotely. Each uses cameras for navigation, fans for propulsion, and a rechargeable battery for power. The robots also have a perching arm that lets them grip handrails or hold items. These free-flying helpers take advantage of another STMD technology called Gecko Grippers that “stick” to any surface.

2. Getting a Grip in Microgravity

We wanted to develop tools for grabbing space junk, and something strong and super-sticky is necessary to collect the diverse material orbiting Earth. So, engineers studied the gecko lizard, perhaps the most efficient “grabber” on this planet. Millions of extremely fine hairs on the bottom of their feet make an incredible amount of contact with surfaces so the gecko can hold onto anything. That inspired our engineers to create a similar material.

Now the Gecko Gripper made by OnRobot is sold on the commercial market, supporting industrial activities such as materials handling and assembly. The NASA gecko adhesive gripper that’s being tested in microgravity on the Astrobee robots was fabricated on Earth. But other small plastic parts can now be manufactured in space.

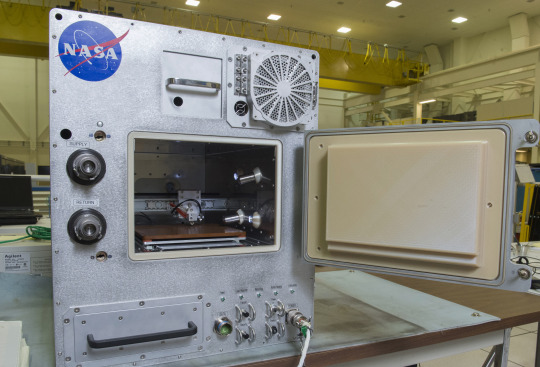

3. Make It, or Don’t Take It

Frequent resupply trips from Earth to the Moon, Mars, and other solar system bodies are simply not realistic. In order to become truly Earth-independent and increase sustainability, we had to come up with ways to manufacture supplies on demand.

A demonstration of the first 3D printer in space was tested on the space station in 2014, proving it worked in microgravity. This paved the way for the first commercial 3D printer in space, which is operated by Made In Space. It has successfully produced more than 150 parts since its activation in 2016. Designs for tools, parts, and many other objects are transmitted to the station by the company, which also oversees the print jobs. Different kinds of plastic filaments use heat and pressure in a process that’s similar to the way a hot glue gun works. The molten material is precisely deposited using a back-and-forth motion until the part forms. The next logical step for efficient 3D printing was using recycled plastics to create needed objects.

4. The Nine Lives of Plastic

To help fragile technology survive launch and keep food safe for consumption, NASA employs a lot of single-use plastics. That material is a valuable resource, so we are developing a number of ways to repurpose it. The Refabricator, delivered to the station in 2018, is designed to reuse everything from plastic bags to packing foam. The waste plastic is super-heated and transformed into the feedstock for its built-in 3D printer. The filament can be used repeatedly: a 3D-printed wrench that’s no longer needed can be dropped into the machine and used to make any one of the pre-programmed objects, such as a spoon. The dorm-fridge-sized machine created by Tethers Unlimited Inc. successfully manufactured its first object, but the technology experienced some issues in the bonding process likely due to microgravity’s effect on the materials. Thus, the Refabricator continues to undergo additional testing to perfect its performance.

5. Speed Metal

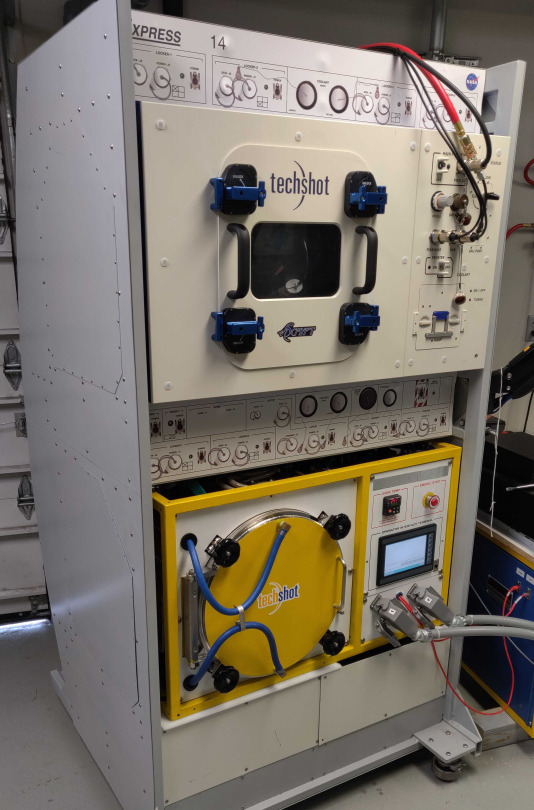

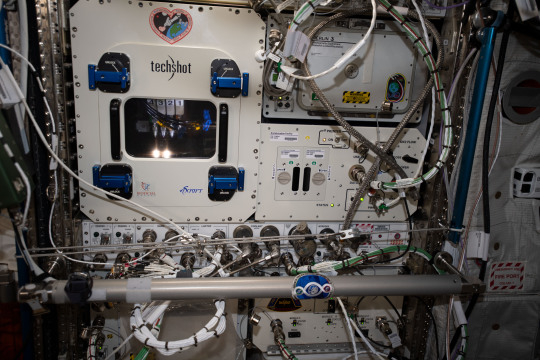

An upcoming hardware test on the station will try out a new kind of 3D printer. The on-demand digital manufacturing technology is capable of using different kinds of materials, including plastic and metals, to create new parts. We commissioned TechShot Inc. to build the hardware to fabricate objects made from aerospace-grade metals and electronics. On Earth, FabLab has already demonstrated its ability to manufacture strong, complex metal tools and other items. The unit includes a metal additive manufacturing process, furnace, and endmill for post-processing. It also has built-in monitoring for in-process inspection. When the FabLab is installed on the space station, it will be remotely operated by controllers on Earth. Right now, another printer created by the same company is doing a different kind of 3D printing on station.

6. A Doctor’s BFF

Today scientists are also learning to 3D print living tissues. However, the force of gravity on this planet makes it hard to print cells that maintain their shape. So on Earth, scientists use scaffolding to help keep the printed structures from collapsing.

The 3D BioFabrication Facility (BFF) created by TechShot Inc. could provide researchers a gamechanger that sidesteps the need to use scaffolds by bioprinting in microgravity. This first American bioprinter in space uses bio-inks that contain adult human cells along with a cell-culturing system to strengthen the tissue over time. Eventually, that means that these manufactured tissues will keep their shape once returned to Earth’s gravity! While the road to bioprinting human organs is likely still many years away, these efforts on the space station may move us closer to that much-needed capability for the more than 100,000 people on the wait list for organ transplant.

7. Growing Vitamins

Conditions in space are hard on the human body, and they also can be punishing on food. Regular deliveries of food to the space station refresh the supply of nutritious meals for astronauts. But prepackaged food stored on the Moon or sent to Mars in advance of astronauts could lose some nutritional value over time.

That’s why the BioNutrients experiment is underway. Two different strains of baker’s yeast which are engineered to produce essential nutrients on demand are being checked for shelf life in orbit. Samples of the yeast are being stored at room temperature aboard the space station and then are activated at different intervals, frozen, and returned to Earth for evaluation. These tests will allow scientists to check how long their specially-engineered microbes can be stored on the shelf, while still supplying fresh nutrients that humans need to stay healthy in space. Such microbes must be able to be stored for months, even years, to support the longer durations of exploration missions. If successful, these space-adapted organisms could also be engineered for the potential production of medicines. Similar organisms used in this system could provide fresh foods like yogurt or kefir on demand. Although designed for space, this system also could help provide nutrition for people in remote areas of our planet.

8. Rough and Ready

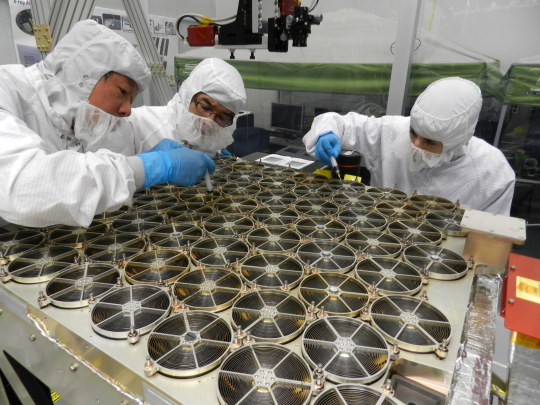

Everything from paints and container seals to switches and thermal protection systems must withstand the punishing environment of space. Atomic oxygen, charged-particle radiation, collisions with meteoroids and space debris, and temperature extremes (all combined with the vacuum) are just some conditions that are only found in space. Not all of these can be replicated on Earth. In 2001, we addressed this testing problem with the Materials International Space Station Experiment (MISSE). Technologists can send small samples of just about any technology or material into low-Earth orbit for six months or more. Mounted to the exterior of the space station, MISSE has tested more than 4,000 materials. More sophisticated hardware developed over time now supports automatic monitoring that sends photos and data back to researchers on Earth. Renamed the MISSE Flight Facility, this permanent external platform is now owned and operated by the small business, Alpha Space Test & Research Alliance LLC. The woman-owned company is developing two similar platforms for testing materials and technologies on the lunar surface.

9. Parachuting to Earth

Small satellites could provide a cheaper, faster way to deliver small payloads to Earth from the space station. To do just that, the Technology Education Satellite, or TechEdSat, develops the essential technologies with a series of CubeSats built by college students in partnership with NASA. In 2017, TechEdSat-6 deployed from the station, equipped with a custom-built parachute called exo-brake to see if a controlled de-orbit was possible. After popping out of the back of the CubeSat, struts and flexible cords warped the parachute like a wing to control the direction in which it travelled. The exo-brake uses atmospheric drag to steer a small satellite toward a designated landing site. The most recent mission in the series, TechEdSat-10, was deployed from the station in July with an improved version of an exo-brake. The CubeSat is actively being navigated to the target entry point in the vicinity of the NASA’s Wallops Flight Facility on Wallops Island, Virginia.

10. X-ray Vision for a Galactic Position System

Independent navigation for spacecraft in deep space is challenging because objects move rapidly and the distances between are measured in millions of miles, not the mere thousands of miles we’re used to on Earth. From a mission perched on the outside of the station, we were able to prove that X-rays from pulsars could be helpful. A number of spinning neutron stars consistently emit pulsating beams of X-rays, like the rotating beacon of a lighthouse. Because the rapid pulsations of light are extremely regular, they can provide the precise timing required to measure distances.

The Station Explorer for X-Ray Timing and Navigation (SEXTANT) demonstration conducted on the space station in 2017 successfully measured pulsar data and used navigation algorithms to locate the station as it moved in its orbit. The washing machine-sized hardware, which also produced new neutron star science via the Neutron star Interior Composition Explorer (NICER), can now be miniaturized to develop detectors and other hardware to make pulsar-based navigation available for use on future spacecraft.

As NASA continues to identify challenges and problems for upcoming deep space missions such as Artemis, human on Mars, and exploring distant moons such as Titan, STMD will continue to further technology development on the space station and Earth.

Make sure to follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

1K notes

·

View notes

Text

Trusted Houston Scaffolding Companies

STI- Scaffolding Today Inc is one of the trusted Houston scaffolding companies. In Houston, we provide premium, high-quality scaffolding at an accessible price. Our team is dedicated to providing high-quality equipment and services.

We are happy to be a well-known scaffolding firm in the United States, and we are available to support projects across the country. With smart placements and effective logistics, particularly for customers looking for scaffolding companies in Houston, we ensure that your projects are delivered on schedule and with consistent assistance, no matter where they are.

0 notes

Text

THE IMPORTANCE OF QUALITY SCAFFOLDING IN CONSTRUCTION PROJECTS

Construction has brought homes and economic growth to Houston; therefore, the importance and impact of scaffolding on the city should not be neglected. Scaffolding Today Inc. offers premium and high-quality scaffold for sale Houston. In this post, we will discuss how great scaffolding has contributed to successful building projects throughout Houston, as well as what it may accomplish for your project.

Creates a Safe working environment.

The primary focus of any construction project is the safety of the personnel. Quality scaffolding is essential for creating a safe working environment. It provides a solid and raised platform for employees to execute their tasks, lowering the danger of workplace accidents and injuries. In Houston, where construction projects frequently require complicated designs and structures, excellent scaffolding is critical to the safety of workers at heights.

Complies with local Regulations.

Houston, like many other American cities, has stringent safety requirements and building codes. Quality scaffolding not only provides a safe working environment for employees, but it also helps construction projects comply with local standards. Scaffolding that meets or exceeds safety standards is a legal obligation, and failure to comply may result in project delays, fines, or even termination.

SCAFFOLDING TODAY INC SERVICES PROVIDES QUALITY SCAFFOLDING IN HOUSTON.

At Scaffolding Today Inc., we are dedicated to providing high-quality scaffolding to building sites around Texas. We are one of the top scaffolding firms in the area. We provide our services throughout Houston and the nearby areas. When you choose us as your scaffolding provider, we collaborate closely with you, prioritize health and safety, train our employees to the highest standards, adhere to the most recent legislation, and employ good working practices like as regular inspections. Must visit or contact Scaffolding Today Inc. offers the best construction scaffolding in Houston.

0 notes

Text

Get Premium and High Quality Scaffold Extension Legs Houston

STI- Scaffolding today Inc is one of the best and high quality of premium scaffolds at an affordable price. Scaffolding Today INC offers the premium scaffold extension legs Houston at a reasonable price. Reaching new heights of construction convenience and safety!" In Houston, scaffold extension legs are being introduced.

These revolutionary scaffolding extensions provide adjustable scaffolding support, making it easy to reach difficult areas. These legs improve your building game, whether it's a high-rise challenge or a complex job. Get the best quality of scaffold extension legs Houston from Scaffolding Today INC.

#houston scaffolding#scaffolding#houston#scaffolding today inc#scaffoldingcompaniesinhouston#scaffoldforsale#erect and dismantle scaffolding#scaffolding services

0 notes

Text

"After John James Audubon (American Woodsman)" 2021.

Vintage posters, Franklinia alatamaha seeds, cotton, antique frame, plywood, plexi, glue, hardware, vintage lumber, iron oxide stain, light-reactive sound device, 1950s sound recordings of Vermivora bachmanii, vintage darning egg, vintage needle and spools, Sturnus vulgaris skull, wool socks knitted by Bobby Wilcox, original wallpaper digitally designed using copyright free historic images, printed by SpoonFlower Inc, self-published zine.

I was invited by Goucher College Curator and Director of Exhibitions Alex Ebstein to create this installation for the "Rediscovering Goucher's Lost Museum" exhibition in fall 2021. Documentation photos generously made by Vivian Marie Doering @vivianmariephoto on Instagram.

Artist Statement:

“On the whole, the task of turning Audubon’s original images into marketable engravings proved to be an extremely labor-intensive process that relied, almost immediately, on the work of dozens of artisans, often working directly under Audubon’s ever-critical eye. But the work process went well beyond the engraver’s shop. Unseen and unheralded others likewise made a critical contribution to the project: the papermakers who produced the huge, high-quality sheets Audubon required; the copper smelters who turned raw ore into clean ingots; the miners who extracted the ore from the earth in the first place; and so forth, back through all the prior steps of production. In that sense, The Birds of America was not just an extensive work of art, not just an example of the sole genius of the lone, struggling artist. It was, rather, an ambitious business venture that relied on a complex labor process and an extensive supply chain, an enterprise in which the artist became not just the designer of the work, but the administrative manager of dozens of people, many of whom could be called artists in their own right, and a marketer to prospective customers, many of whom he had to track down wherever he could find them, on both sides of a very wide ocean.”

--Gregory Nobles, John James Audubon: The Nature of the American Woodsman, 2017. p103

Beyond the ‘supply chain’ of compensated workers existed a backdrop of the truly Unseen and Unheralded – the enslaved Black people whose supportive labor was violently coerced; and the work of Maria Martin, an ‘artist in [her] own right’ whose labor was given, and taken, freely due to her faith and her standing as an unmarried, white woman in the Antebellum South. Utilizing the exquisite Martin-Audubon collaborative painting, "Bachman's Warbler", as a jumping-off point, this installation is a visual exploration of the cultural and structural scaffolding that made such erasure possible during that era, as well as two examples of natural history showcased by the painting that have been lost and found - the now extinct Bachman's Warbler (Vermivora bachmanii) for which this painting and a few short sound recordings are our best documentation of the species' existence, and Franklin Tree (Franklinia alatamaha) a species native to the southeastern US that narrowly avoided utter extinction thanks to the collectors John and William Bartram, and that now exists in scattered cultivation across the country.

This project is not meant as a wholesale ‘cancel’ of John James Audubon or early American naturalists – whose work, at times disturbingly tainted by prevailing beliefs and customs, nevertheless paved the way for the scientific fields of biology and ecology today. This installation is, rather, an acknowledgment of the conflicted entanglements between history, nature, people, race, gender, ideology, belief, imagery, and power.

Collections are essentially a grandiose form of appropriation, recontextualizing objects for myriad purposes. This installation plays with two traditions: collections and appropriation, by appropriating and recontextualizing Audubon’s work, as well as other historical illustrations from various collections, and using metaphor and allegory as tools to tell the story. It would not have been made possible without the help, labor, and/or support of many unseen and unheralded, including the anonymous archivists at the Internet Archive, New York Public Library Digital Collections, and Cornell’s Macaulay Library, collectors on Ebay, Etsy, Facebook Marketplace, and Bazaar in Hamden, the production team at Spoonflower, and most especially Alex Ebstein, Bobby Wilcox, Seth Adelsberger, Denise Wilcox, Patti Murphy, Wyatt Hersey, Jenny Rieke and Oona McKay.

4 notes

·

View notes

Photo

"The Spirit of East Harlem" by Hank Prussing is painted on a residential building at East 104th Street and Lexington Avenue.

It was the summer of 1974. New York artist Manny Vega, today known for his public mosaics and murals, was 18. He had recently graduated from high school and was trying to decide whether to go to college. Vega knew he had an artistic voice, but he didn’t yet know what to do with it. Then, while kicking around East Harlem, something on East 104th Street and Lexington Avenue caught his attention:

“I would walk by on 104th Street and this guy was on a pull-up scaffold by himself,” Vega says. “A tiny, wooden, crickity-crackety scaffold.” Armed with oil paints and a brush, the man was meticulously creating a mural on the side of a four-story residential building.

Vega walked by the mural every day or so to see it progress. Slowly, recognizable faces started to emerge from the wall – people who lived in the neighborhood, even people who lived in the building.

“But it was unusual because he was this Caucasian, lanky white guy painting this Puerto Rican, black barrio thing, with a lot of soul, a lot of ‘esencia’ — with a lot of essence — as though he had been living in the neighborhood all along.” Vega, fascinated, decided to ask if he could join the project.

“One day, I screamed up at him. I said, ‘Hey, white boy! Give me a job!’ He came down from the scaffold and he asked me, ‘What, do you paint?’ “I said, ‘I can learn…’”

The artist’s name was Hank Prussing. Vega became his apprentice and helped Prussing complete one of New York City’s most iconic murals: “The Spirit of East Harlem.”

Looming above a rapidly changing neighborhood, “The Spirit of East Harlem” represents a rougher yet more romantic time in East Harlem’s history. People who look up at it can imagine what it was like to wander East Harlem in the 1970s.

It portrays neighborhood residents of that time, including toy store owner Morris Wittenberg and George Espada, who sang in an “electric Latin soul” band called Flash and the Dynamics, presented in vivid tableaus between the building’s windows.

The work has survived the elements, a fire and vandals. Each time it was threatened, people joined forces to preserve it. Because of its importance to residents, Hope Community Inc., which owns the building, says it is committed to maintaining the work.

“The mural became like a cultural hallmark, not only to East Harlem, but specifically to that one block,” says Vega. (More at the source)

Photo: October 2017

41 notes

·

View notes

Text

12 Safety Netting Tips That Make Construction Sites Safer for Everyone

When it comes to job site protection, safety isn’t just a priority—it’s a necessity. Whether you're building a high-rise or renovating a mid-sized commercial property, construction safety netting plays a vital role in preventing injuries, minimizing falling debris, and keeping workers and pedestrians safe.

At Nets Depot Inc, we know that the right safety netting system can mean the difference between a safe job site and a serious accident. That’s why we’ve put together 12 expert-backed tips to help you get the most from your netting setup.

Types of Construction Safety Netting

Before we dive into the tips, it’s important to understand the basic types of netting used in construction:

Personnel Safety Netting – Designed to catch workers in case of falls from elevated heights.

Debris Netting – Lightweight mesh used to contain loose tools or materials that might fall.

Perimeter Netting – Installed around the edges of buildings or scaffolds for added protection.

Vertical Netting – Often used on scaffolding to prevent outward falls and falling materials.

Choosing the right netting type is the first step toward a safer site.

12 Construction Safety Netting Tips You Can Use Today

1. Choose the Right Netting for the Job

Not all netting is created equal. Match the net type and strength to the specific hazards of your job site.

2. Check Ratings and Certifications

Make sure your netting meets OSHA and ANSI standards. At Nets Depot Inc, all of our netting products are tested and certified for workplace compliance.

3. Inspect Before Each Use

Even high-quality netting needs regular inspection. Look for signs of UV damage, holes, or worn stitching before every shift.

4. Follow Manufacturer Guidelines

Proper tensioning and anchoring are essential. Never “eyeball” your installation—always follow the instructions that come with your system.

5. Use Qualified Installers

Leave setup to professionals trained in fall protection systems. A properly installed net is your first line of defense.

6. Strategically Place Your Netting

Netting should be installed where risks are highest—around scaffolding, walkways, and below overhead work.

7. Maintain Clearance Below the Net

Ensure there's adequate clearance below the net to allow for safe fall arrest without impacting the ground or equipment.

8. Schedule Regular Maintenance

Just like other jobsite equipment, nets wear over time. Replace damaged sections and avoid reusing aged netting.

9. Account for Wind and Weather

Weather can weaken or dislodge netting. Use systems that are wind-rated and designed for outdoor durability.

10. Incorporate Into Your Fall Protection Plan

Don’t rely on netting alone. It should complement your overall fall protection system, including harnesses and guardrails.

11. Use Bright Colors for Visibility

Netting in high-visibility colors helps workers stay aware of edges and fall zones, even from a distance.

12. Train Your Crew

Educate everyone on how to use, inspect, and maintain safety netting. Consistency across teams makes your safety plan stronger.

Common Mistakes to Avoid

Even experienced contractors can overlook key safety steps. Watch out for these red flags:

Reusing damaged or expired netting

Poor anchoring or insufficient tension

Installing netting in the wrong location

Skipping daily inspections

Mistakes like these can compromise the integrity of your entire safety setup.

Construction Safety Netting That Works as Hard as You Do

Whether you’re a project manager, site supervisor, or safety coordinator, it’s your responsibility to create a secure work environment. At Nets Depot Inc, we provide industry-tested construction safety netting solutions that help you protect your workers—and your reputation.

Looking to upgrade your site’s netting? Our team is here to help. Reach out today to get expert advice or request a quote.

0 notes

Text

The Leading Houston Scaffolding Company

STI - Scaffolding Today Inc is the trusted and the leading Houston scaffolding company. We offer the best and high quality scaffolds at an affordable price in Houston and the nearby areas.

We provide the best quality scaffolding, accessories, and shoring at an affordable price. If you are in the area and are looking for quality scaffolding, Scaffolding today Inc. is the place to call. We have been proven to be the industry standard for years.

0 notes