#seismic hazard analysis

Text

Introduction to Geotechnical Earthquake Engineering

Introduction:

Geotechnical earthquake engineering is a critical field that plays a pivotal role in ensuring the safety and stability of structures in seismic regions. With the ever-present threat of earthquakes, understanding how geotechnical engineering can protect lives and property is paramount.

What is Geotechnical Earthquake Engineering?

Geotechnical earthquake engineering is a specialized…

View On WordPress

#foundation design#Foundation failure#Geotechnical Earthquake Engineering#Liquefaction#Liquefaction Mitigation#Rock#seismic failure#seismic hazard analysis#site conditions#Soil#Structural analysis#structural design

1 note

·

View note

Text

Comprehensive Overview of Engineering Services by Little P.Eng. Engineering Consultant

Little P.Eng. Engineering Consultant is a highly reputable firm renowned for its expertise in providing a wide range of engineering services. With a dedicated team of professionals, state-of-the-art technology, and a commitment to excellence, Little P.Eng. serves various industries and clients across the globe. In this comprehensive article, we will explore the key engineering services offered by Little P.Eng., including material handling, seismic design, structural engineering, piping stress analysis, above-ground tank design, and pressure vessel design.

Introduction to Little P.Eng. Engineering Consultant

Little P.Eng. Engineering Consultant is a leading player in the engineering consulting domain, offering innovative solutions and technical expertise to address the unique challenges faced by industries such as manufacturing, construction, energy, and petrochemicals. The firm's success is founded on a solid reputation for delivering cost-effective and reliable engineering solutions.

The Core Values of Little P.Eng. Engineering Consultant

Excellence: The firm strives for excellence in all its endeavors, aiming to exceed client expectations in every project.

Integrity: Little P.Eng. operates with utmost integrity, ensuring transparency, honesty, and ethical practices throughout its operations.

Innovation: Innovation is at the heart of the firm's approach. It constantly explores new technologies and methodologies to stay at the forefront of the industry.

Safety: Safety is a top priority, and the firm places great emphasis on designing structures and systems that prioritize the safety of personnel and the environment.

Now, let's dive into the detailed engineering services offered by Little P.Eng. Engineering Consultant:

1. Material Handling Engineering

Material handling engineering is an integral aspect of modern industrial operations. It involves the design and optimization of systems and equipment for the efficient movement, storage, control, and protection of materials and products. Little P.Eng.'s material handling experts excel in creating tailored solutions that enhance productivity, reduce manual labor, and ensure the safe flow of materials.

Key Aspects of Material Handling Engineering by Little P.Eng.

a. Conveyor Systems

Little P.Eng. Engineering Consultant specializes in the design and implementation of conveyor systems customized to specific industries and requirements. These systems facilitate the smooth and automated movement of goods within facilities, leading to streamlined production processes and reduced labor costs.

b. Automated Material Handling

Automation is a significant trend in material handling, and Little P.Eng. is at the forefront of implementing cutting-edge robotic and automation technologies. These innovations optimize operations by reducing errors and increasing efficiency.

c. Warehouse Design

Little P.Eng. ensures that warehouse layouts are optimized for maximum storage capacity and accessibility. Their designs enhance inventory management and expedite order fulfillment, resulting in improved overall operational efficiency.

d. Packaging Equipment

Packaging plays a crucial role in product protection and presentation. Little P.Eng. Engineering Consultant designs packaging equipment tailored to handle various materials and products efficiently, enhancing the final product's quality and appearance.

e. Safety Measures

Safety is paramount in material handling, and Little P.Eng. prioritizes the design of systems that minimize risks associated with material movement and handling. This includes comprehensive safety measures and training for personnel.

2. Seismic Design

Seismic design is a specialized field focused on ensuring that buildings and structures can withstand the forces generated by earthquakes. As seismic events can cause catastrophic damage, Little P.Eng. Engineering Consultant excels in designing structures that prioritize safety and resilience in seismic-prone areas.

Key Aspects of Seismic Design by Little P.Eng.

a. Seismic Hazard Assessment

Little P.Eng.'s seismic design experts perform thorough seismic hazard assessments by analyzing historical data, fault lines, and ground motion characteristics. This data informs the design process, ensuring structures are prepared for potential seismic events.

b. Structural Analysis

Seismic design requires an in-depth understanding of structural analysis to assess how a building or structure will respond to seismic forces. Little P.Eng.'s engineers employ advanced analysis techniques to ensure structural integrity.

c. Innovative Design Techniques

Little P.Eng. embraces innovative seismic design techniques, including base isolators, damping systems, and the use of reinforced materials. These approaches enhance a structure's ability to withstand seismic forces.

d. Code Compliance

Compliance with building codes and seismic design standards is paramount. Little P.Eng. Engineering Consultant ensures that all designs meet or exceed the necessary regulatory requirements to guarantee the safety of structures in seismic-prone regions.

e. Retrofitting and Rehabilitation

In addition to new construction, Little P.Eng. offers retrofitting and rehabilitation services for existing structures, bringing them up to modern seismic standards and ensuring their ongoing safety.

3. Structural Engineering

Structural engineering is the cornerstone of designing and constructing safe, robust, and resilient buildings, bridges, dams, towers, and other critical infrastructure. Little P.Eng. excels in the design and evaluation of structural systems to ensure their stability and safety under various loads.

Key Aspects of Structural Engineering by Little P.Eng.

a. Load Analysis

Little P.Eng.'s structural engineers are experts in calculating loads, stresses, and deformations on structures. They perform comprehensive load analyses to determine the most suitable structural solutions.

b. Material Selection

Choosing the right materials is crucial for structural integrity and durability. Little P.Eng. considers factors such as the type of structure, environmental conditions, and budget constraints to make informed material selections.

c. Structural Systems

Little P.Eng. engineers meticulously design structural systems, including beams, columns, and foundations, to efficiently distribute loads and prevent structural failure. Innovative solutions are employed to optimize performance.

d. Computer-Aided Design

Advanced software tools play a vital role in structural engineering. Little P.Eng. utilizes cutting-edge software for structural analysis and design, allowing for precise calculations, simulations, and 3D modeling.

e. Safety Standards

Safety is a top priority in structural engineering. Little P.Eng. ensures strict compliance with safety standards and building codes to protect the well-being of the public and occupants of structures.

4. Piping Stress Analysis

In industries where industrial piping systems are prevalent, such as petrochemical plants, power facilities, and refineries, piping stress analysis is crucial. Little P.Eng. specializes in designing and evaluating these systems to ensure they can withstand thermal expansion, contraction, pressure, and other forces without failure or leaks.

Key Aspects of Piping Stress Analysis by Little P.Eng.

a. Layout and Design

Little P.Eng.'s experts work on the layout and design of complex piping networks, accounting for factors like fluid flow, temperature changes, and equipment connections. Their designs optimize performance and minimize energy consumption.

b. Stress Calculations

Engineers at Little P.Eng. calculate stresses and deformations in piping systems using advanced software. This includes considering thermal gradients, pressure differentials, and material properties to ensure structural integrity.

c. Support Systems

Proper support systems and hangers are essential to prevent sagging, vibration, and excessive stress on pipes. Little P.Eng. designs support systems that enhance the longevity of piping networks.

d. Material Selection

Selecting the appropriate materials is critical to withstand corrosive substances, high temperatures, and high-pressure conditions. Little P.Eng. engineers make informed material choices to ensure durability.

e. Code Compliance

Little P.Eng. ensures that all piping systems adhere to industry standards and codes, such as ASME B31.3 for process piping. Compliance is vital for the safety and regulatory compliance of the systems.

5. Above-Ground Tank Design

Above-ground tanks are widely used for storing liquids and gases in various industries, including oil and gas, chemical processing, and water treatment. Little P.Eng. specializes in designing these tanks to meet specific requirements while ensuring safety and compliance.

Key Aspects of Above-Ground Tank Design by Little P.Eng.

a. Tank Sizing

Little P.Eng. engineers determine the appropriate tank size based on the volume and characteristics of the stored materials. Their designs optimize space and efficiency.

b. Material Selection

The choice of tank material is a critical consideration, and Little P.Eng. selects materials that align with the type of substance being stored, whether it is corrosive, flammable, or sensitive to temperature changes.

c. Construction Methods

Above-ground tanks can be constructed using various methods, including welded steel, concrete, and fiberglass. Little P.Eng. evaluates the best construction method based on project-specific requirements and regulations.

d. Safety Features

Safety features are paramount in tank design. Little P.Eng. ensures that tanks incorporate features such as overflow protection, pressure relief systems, and leak detection to prevent accidents and environmental damage.

e. Regulatory Compliance

Design consultants at Little P.Eng. ensure that above-ground tanks meet all regulatory requirements, including those outlined in codes like API 650 for steel tanks. Compliance is essential for environmental protection and safety.

6. Pressure Vessel Design

Pressure vessels are critical components in industries dealing with pressurized fluids or gases, such as chemical manufacturing, energy production, and petrochemical processing. Little P.Eng. specializes in designing pressure vessels to safely withstand high internal or external pressures.

Key Aspects of Pressure Vessel Design by Little P.Eng.

a. Material Properties

Little P.Eng. engineers carefully select materials with the necessary strength and corrosion resistance to withstand the specific service conditions of pressure vessels.

b. Thickness Calculations

Calculations of vessel wall thickness are crucial to ensure structural integrity and safety under pressure. Little P.Eng. performs precise calculations to determine optimal thickness.

c. Welding and Fabrication

The welding and fabrication methods used in pressure vessel construction must meet rigorous standards. Little P.Eng. employs certified welding procedures to prevent defects and ensure vessel reliability.

d. Testing and Inspection

Pressure vessels undergo rigorous testing and inspection processes to verify their integrity. Little P.Eng. engineers conduct comprehensive testing to ensure vessels are safe for operation.

e. Code Compliance

Little P.Eng. Engineering Consultant is well-versed in codes such as the ASME Boiler and Pressure Vessel Code. The firm ensures that all pressure vessel designs and constructions adhere to these codes and regulations.

Conclusion

Little P.Eng. Engineering Consultant is a leading provider of engineering services that encompass material handling, seismic design, structural engineering, piping stress analysis, above-ground tank design, and pressure vessel design. The firm's unwavering commitment to excellence, safety, innovation, and regulatory compliance has earned it a reputation as a trusted partner in diverse industries.

With a dedicated team of experts and cutting-edge technology, Little P.Eng. delivers cost-effective solutions that prioritize safety, sustainability, and efficiency. Whether it's designing structures to withstand earthquakes or optimizing material handling systems, Little P.Eng. Engineering Consultant stands at the forefront of engineering innovation, contributing to the development of safer, more resilient, and more productive industries worldwide.

Tags:

Engineering Services

Seismic Design

Piping Stress Analysis

Structural Engineering

Pressure Vessel Design

Material Selection

Regulatory Compliance

Little P.Eng. Engineering Consultant

Seismic Hazard Assessment

Structural Resilience

Engineering Innovation

Material Handling Engineering

Above-Ground Tank Design

Excellence in Engineering

Innovative Solutions

Safety Measures

Compliance with Codes

Structural Analysis

Automated Material Handling

Conveyor Systems

Warehouse Design

Packaging Equipment

Retrofitting and Rehabilitation

Load Analysis

Support Systems

Welding and Fabrication

Tank Sizing

Construction Methods

Pressure Vessel Testing

Welding Procedures

Engineering Services

Structural Engineering Consultancy

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Engineering Services#Seismic Design#Piping Stress Analysis#Structural Engineering#Pressure Vessel Design#Material Selection#Regulatory Compliance#Little P.Eng. Engineering Consultant#Seismic Hazard Assessment#Structural Resilience#Engineering Innovation#Material Handling Engineering#Above-Ground Tank Design#Excellence in Engineering#Innovative Solutions#Safety Measures#Compliance with Codes#Structural Analysis#Automated Material Handling#Conveyor Systems#Warehouse Design#Packaging Equipment#Retrofitting and Rehabilitation#Load Analysis#Support Systems#Welding and Fabrication#Tank Sizing#Construction Methods#Pressure Vessel Testing

0 notes

Text

Geographic Information Systems (GIS) have revolutionized various industries, with construction being one of the most notable. The role of a GIS Analyst in construction is pivotal, as it involves managing spatial data to improve project planning, execution, and sustainability.

The Role of GIS in Construction

Before exploring the specific duties of a GIS Analyst, it's essential to understand the significance of GIS in construction. GIS technology enables the collection, analysis, and visualization of spatial data, which can include anything from topographical maps to satellite imagery. This spatial data is crucial for:

A. Site Selection: Determining the most suitable location for a construction project by analyzing factors like terrain, soil stability, and environmental impact.

B. Design and Planning: Creating detailed maps and 3D models that assist architects and engineers in designing efficient and sustainable structures.

C. Resource Management: Optimizing the use of materials and labor by providing precise geographical data.

D. Risk Assessment: Identifying potential risks such as flooding, landslides, or seismic activity to mitigate hazards.

E. Project Management: Enhancing coordination among stakeholders through accurate and up-to-date spatial information.

Key Responsibilities of a GIS Analyst in Construction

A GIS Analyst in the construction sector plays a multifaceted role that encompasses data management, analysis, and application. Here are the primary responsibilities:

Read more

0 notes

Text

The Importance of Engineering Services in the Oil and Gas Industry

The oil and gas industry is one of the most complex and challenging sectors globally, requiring specialized engineering services to ensure safe, efficient, and cost-effective operations. These services are essential for designing, constructing, maintaining, and optimizing the infrastructure and systems used in the exploration, extraction, and processing of oil and gas resources. As the industry evolves with technological advancements and environmental concerns, the role of engineering services becomes increasingly crucial.

Understanding Engineering Services for Oil and Gas:

Engineering services for oil and gas cover a broad range of activities that are critical to the lifecycle of oil and gas projects. These services include process design, structural engineering, pipeline engineering, mechanical engineering, electrical and instrumentation engineering, and safety engineering. Each discipline plays a vital role in ensuring that operations are not only successful but also compliant with industry regulations and standards.

In the oil and gas industry, process engineering is fundamental. It involves designing and optimizing processes for the extraction, refining, and distribution of oil and gas products. Process engineers work to maximize efficiency, reduce waste, and ensure that production meets the required specifications. The complexity of these processes demands a deep understanding of chemical engineering principles and the ability to apply them in real-world scenarios.

The Role of Structural and Pipeline Engineering:

Structural engineering is another critical component of oil and gas engineering services. It involves the design and analysis of structures that support various equipment and facilities used in oil and gas production. These structures must withstand harsh environmental conditions, such as extreme temperatures, high winds, and seismic activity. Engineers must also consider the long-term durability and safety of these structures to prevent failures that could lead to catastrophic consequences.

Pipeline engineering is equally important, as pipelines are the primary means of transporting oil and gas from production sites to processing facilities and markets. Designing safe and efficient pipelines requires a thorough understanding of fluid dynamics, materials science, and environmental impact. Pipeline engineers must ensure that the pipelines can handle the pressure and temperature conditions of the transported materials while minimizing the risk of leaks and spills.

Mechanical, Electrical, and Safety Engineering:

Mechanical engineering services for oil and gas are essential for maintaining and optimizing the performance of machinery and equipment used in the industry. This includes everything from pumps and compressors to drilling rigs and turbines. Mechanical engineers focus on the reliability, efficiency, and safety of this equipment, ensuring that it operates within specified parameters and minimizing downtime due to mechanical failures.

Electrical and instrumentation engineering services are critical for the automation and control of oil and gas operations. These services involve the design and implementation of electrical systems, control systems, and instrumentation that monitor and manage various aspects of production. Electrical engineers ensure that power is delivered reliably and safely to all parts of the operation, while instrumentation engineers focus on the accuracy and reliability of sensors and control systems.

Safety engineering is an overarching discipline that ensures the protection of personnel, the environment, and assets in the oil and gas industry. Safety engineers identify potential hazards, assess risks, and design systems and procedures to mitigate those risks. This includes everything from fire and explosion protection to emergency response planning and regulatory compliance.

Why are engineering services vital for Oil and Gas Operations?

The oil and gas industry is fraught with challenges, including fluctuating market prices, stringent environmental regulations, and the constant need for innovation. Engineering services for oil and gas help companies navigate these challenges by providing the expertise and solutions needed to optimize operations, reduce costs, and ensure compliance with regulatory requirements.

Moreover, the complexity of oil and gas projects demands a multidisciplinary approach. Engineering services bring together experts from various fields to collaborate on designing and implementing solutions that meet the unique needs of each project. Whether it's developing a new offshore platform, upgrading a refinery, or expanding a pipeline network, engineering services are integral to the success of these endeavors.

At Converge Engineering Pvt. Ltd., we understand the critical role that engineering services play in the oil and gas industry. Our team of experienced engineers is dedicated to providing innovative and cost-effective solutions that help our clients achieve their goals while maintaining the highest standards of safety and environmental stewardship.

For more information on how our engineering services can benefit your oil and gas operations, contact us today at Converge Engineering Pvt. Ltd. We look forward to partnering with you to deliver excellence in every project.

0 notes

Text

Structural Consultants in Bhubaneswar: Why APS Design Infra is Your Best Choice

In the rapidly growing urban landscape of Bhubaneswar, the need for robust and reliable structural engineering services has never been more critical. As the capital city of Odisha expands, both residential and commercial structural consultants in bhubaneswar projects are on the rise, demanding the expertise of skilled structural consultants. APS Design Infra, a leading name in Bhubaneswar’s architecture and engineering sector, is here to meet these demands with unparalleled professionalism and expertise.

The Role of Structural Consultants

Structural consultants play a vital role in the construction industry. They are responsible for ensuring that buildings and other infrastructures are safe, stable, and able to withstand various forces such as gravity, wind, and seismic activities. Their expertise ensures that the skeleton of a building is designed to last, preventing potential failures that could lead to costly repairs or, worse, catastrophic collapse.

Here’s why having a skilled structural consultant is essential:

Safety and Compliance: Structural consultants ensure that all buildings comply with local codes and regulations. They assess the materials used and the overall design to guarantee safety, preventing any future legal issues or safety hazards.

Cost Efficiency: By optimizing the design and material usage, structural consultants can help reduce construction costs without compromising on safety. This efficiency translates to savings for both builders and clients.

Sustainability: Modern structural consultants are also focused on sustainability. They work on creating designs that minimize environmental impact, using eco-friendly materials and innovative techniques.

Problem Solving: Structural consultants address challenges that arise during the construction process, providing solutions that keep the project on track and within budget.

Why Choose APS Design Infra?

APS Design Infra stands out as a leading structural consultancy firm in Bhubaneswar for several reasons:

Expertise and Experience: Our team comprises seasoned structural engineers with years of experience in the field. We have worked on a wide range of projects, from residential buildings to large commercial complexes, bringing a wealth of knowledge to every project.

Innovative Solutions: At APS Design Infra, we are committed to innovation. We leverage the latest technology and design tools to deliver solutions that are not only structurally sound but also optimized for performance and cost-effectiveness. Our innovative approach ensures that your building is future-proofed against both environmental and economic changes.

Comprehensive Services: APS Design Infra offers a full spectrum of services, from initial feasibility studies and structural design to detailed analysis and construction supervision. Whether you’re starting a new project or need consultancy for an ongoing one, we have the expertise to guide you every step of the way.

Local Knowledge: Being based in Bhubaneswar gives us a deep understanding of the local terrain, climate, and regulatory environment. This local expertise is invaluable in creating designs that are not only compliant with regional building codes but also tailored to the unique challenges of the area.

Commitment to Quality: Quality is at the heart of everything we do. We adhere to the highest standards of engineering practice, ensuring that every project we undertake meets rigorous quality benchmarks. Our commitment to excellence has earned us a reputation as one of the most reliable structural consultants in bhubaneswar.

Projects and Success Stories

APS Design Infra has been involved in several high-profile projects in Bhubaneswar, ranging from residential apartments and commercial buildings to educational institutions and industrial facilities. Our portfolio showcases our ability to handle projects of varying complexity and scale, always delivering on time and within budget.

One of our standout projects includes the structural design for a major commercial complex in the heart of Bhubaneswar. The project posed several challenges, including the need for a sustainable design that could withstand the area’s heavy monsoon rains. Our team rose to the challenge, delivering a design that not only met the client’s expectations but also earned accolades for its innovative use of materials and efficient use of space.

Conclusion

When it comes to choosing structural consultants in bhubaneswar, APS Design Infra should be your first choice. Our blend of expertise, innovation, and client-focused service ensures that your construction project is in the best hands. We are committed to delivering solutions that are safe, sustainable, and cost-effective, helping you achieve your vision with confidence.

Contact APS Design Infra today to discuss your project and discover how we can help you build the future, one structure at a time.

0 notes

Text

How Structural Analysis, Demolition, and Blast Analysis Software Enhance Construction Safety

In the construction industry, ensuring safety is paramount. With the increasing complexity of modern structures, the integration of advanced software tools has become essential. Structural analysis software is a critical tool in the design and evaluation of buildings and infrastructure. It allows engineers to assess the strength, stability, and durability of a structure before construction begins. By simulating various load conditions, such as wind, seismic activity, and weight distribution, this software helps identify potential weaknesses in the design.

Demolition software is designed to mitigate these risks by providing detailed planning and simulation capabilities. This software allows demolition experts to model the entire process, from the initial impact of machinery to the final collapse of the structure. By visualizing the sequence of events, professionals can identify potential hazards, such as flying debris or unintended damage to surrounding buildings, and take proactive measures to prevent them.

Blast analysis software is a specialized tool that helps engineers evaluate the potential impact of explosions on structures. This software simulates blast effects, such as shock waves and pressure distribution, on various building materials. These tools provide a comprehensive approach to safety, from the initial design phase to the final stages of demolition. For more information read this article - https://extremeloading.hashnode.dev/how-structural-analysis-demolition-and-blast-analysis-software-enhance-construction-safety

0 notes

Text

Understanding Crosshole Seismic Testing in Delhi: A Comprehensive Guide

When it comes to construction, particularly in a bustling city like Delhi, understanding the soil and rock properties beneath a site is crucial. One of the most effective ways to obtain this understanding is through crosshole seismic in Delhi. This blog will explore what crosshole seismic testing is, why it's important, and how it is conducted, with a focus on its application in Delhi.

What is Crosshole Seismic Testing?

Crosshole seismic testing is a geophysical method used to determine the properties of the subsurface material, such as soil or rock. The test involves creating small, parallel boreholes at a site and then using seismic waves to measure the velocity through the subsurface materials. These measurements provide detailed information about the subsurface structure, which is essential for engineering and construction projects.

In a rapidly growing city like Delhi, where construction is booming, crosshole seismic in Delhi has become increasingly important. This testing method allows engineers and architects to make informed decisions based on the actual conditions of the site.

Importance of Crosshole Seismic Testing in Delhi

Delhi is known for its diverse geological formations, ranging from ancient riverbeds to hard rock layers. This complexity requires a reliable method to assess the subsurface conditions accurately. Crosshole seismic in Delhi offers several key benefits:

Accurate Subsurface Profiling: Crosshole seismic testing provides a highly accurate profile of the subsurface conditions, which is critical for designing foundations, tunnels, and other structures in Delhi.

Safety Assurance: By understanding the subsurface conditions, engineers can ensure the safety of the structures built on the site. This is especially important in a city like Delhi, where earthquakes are a concern.

Cost-Effective Construction: Knowing the subsurface conditions can help in selecting the appropriate construction techniques and materials, potentially saving costs in the long run.

Environmental Protection: Crosshole seismic in Delhi helps in minimising the environmental impact of construction by avoiding unnecessary excavation and reducing the risk of damaging underground utilities or natural resources.

How Crosshole Seismic Testing is Conducted

The process of crosshole seismic in Delhi involves several steps, each crucial for obtaining accurate results:

Borehole Drilling: The first step is to drill small, parallel boreholes at the site. The number of boreholes and their depth depends on the specific requirements of the project.

Seismic Source Placement: A seismic source, usually a small explosive charge or a mechanical hammer, is placed in one of the boreholes. This source generates seismic waves that travel through the subsurface.

Seismic Wave Recording: Geophones, which are sensitive to seismic waves, are placed in the other boreholes to record the waves as they pass through the subsurface materials.

Data Analysis: The recorded data is analyzed to determine the velocity of the seismic waves. This information is used to create a detailed profile of the subsurface conditions.

Applications of Crosshole Seismic Testing in Delhi

Crosshole seismic in Delhi is widely used in various construction and engineering projects. Some of the most common applications include:

Foundation Design: Understanding the subsurface conditions is crucial for designing strong and stable foundations. Crosshole seismic testing helps in determining the depth and type of foundation needed for a particular site.

Tunnel Construction: Delhi's expanding metro network and other infrastructure projects often require tunnel construction. Crosshole seismic in Delhi provides valuable information about the rock and soil conditions, which is essential for safe and efficient tunneling.

Seismic Hazard Assessment: Given Delhi's location in a seismically active zone, it is important to assess the potential impact of earthquakes on structures. Crosshole seismic in Delhi helps in evaluating the seismic hazards and designing earthquake-resistant structures.

Site Investigation for High-Rise Buildings: The construction of high-rise buildings in Delhi requires a thorough understanding of the subsurface conditions to ensure stability and safety. Crosshole seismic testing provides the necessary data for designing these structures.

Challenges and Considerations

While crosshole seismic in Delhi is a highly effective method, it does come with its challenges. Some of the key considerations include:

Borehole Placement: The accuracy of the test depends on the proper placement of boreholes. In a densely populated city like Delhi, finding suitable locations for boreholes can be challenging.

Urban Noise: Delhi is a bustling city with a lot of noise from traffic, construction, and other activities. This noise can interfere with the seismic wave recordings, making it important to conduct the test during quieter times.

Permitting and Regulations: Drilling boreholes and conducting seismic tests in Delhi requires permits and adherence to local regulations. It is important to work with experienced professionals who understand the legal requirements.

Interpreting Results: The data obtained from crosshole seismic in Delhi needs to be interpreted by skilled geophysicists and engineers to ensure accurate conclusions. Misinterpretation can lead to incorrect decisions and potentially costly mistakes.

Conclusion

In conclusion, crosshole seismic in Delhi is a vital tool for anyone involved in construction or engineering in the city. This testing method provides detailed information about the subsurface conditions, helping to ensure the safety, stability, and cost-effectiveness of construction projects. Whether it's for foundation design, tunnel construction, or seismic hazard assessment, crosshole seismic testing is an indispensable part of the process.

As Delhi continues to grow and develop, the importance of reliable and accurate geophysical testing methods like crosshole seismic will only increase. By investing in proper site investigation, developers and engineers can contribute to the safe and sustainable growth of the city.

#crosshole seismic in delhi#gpr survey services in delhi#geophysics services in Delhi#geophysics services survey in delhi#underground utility mapping services in Delhi#MASW/Remi Survey in India#cable and pipe locator in delhi

0 notes

Text

What You Need to Know About the Importance of Structural Engineering for Safe and Reliable Factory Buildings

In this article, we'll explore the role of structural engineering in ensuring safe and reliable factory buildings. From safeguarding assets to protecting lives, structural engineering is crucial for the integrity and longevity of industrial structures.

The integrity of factory buildings is critical to the success of industrial operations. Almost every production line and bustling warehouse is supported by a robust structure designed to withstand the rigors of day-to-day operations.

Top industrial Architect in India

.

Structural engineering, often overshadowed by its more visible counterparts, plays a pivotal role in ensuring the safety, reliability, and longevity of factory buildings.

For the best structural solutions in Ahmedabad, trust VMS Consultants. As the top structural consultant in Ahmedabad, we have a proven track record of designing safe and reliable factory buildings that meet the highest standards of structural integrity.

Structural Consultant in India

.

Here, we will discuss the significance of structural engineering in factory construction and maintenance, and why it plays a key role in ensuring lives and assets are safeguarded.

Understanding Structural Engineering in the Context of Factory Buildings

Structural engineering is a discipline that deals with the design, analysis, and construction of load-bearing structures, including buildings, bridges, and industrial facilities.

When it comes to factory buildings, the principles of structural engineering are crucial in ensuring structural stability, load-bearing capacity, and resistance to external forces such as wind, seismic activity, and heavy machinery vibrations.

Top industrial Project Management Consultant in India

.

Protecting Lives and Assets

The foremost concern in any industrial setting is safety. Factory buildings, often housing valuable equipment, raw materials, and personnel, must be engineered to withstand a myriad of potential hazards.

Structural engineers work tirelessly to design buildings that meet stringent safety standards and codes, minimizing the risk of structural failure, collapse, or damage during extreme events.

From seismic retrofitting to blast-resistant design, structural engineering strategies are employed to enhance the resilience of factory buildings against unforeseen calamities.

By conducting thorough structural analyses and employing advanced modeling techniques, engineers ensure that factory structures can withstand the forces exerted upon them, safeguarding both lives and assets in the process.

Manufacturing projects in Gujarat

.

Building for the Long Term

Beyond safety, structural engineering plays a crucial role in ensuring the reliability and longevity of factory buildings. Industrial operations demand structures that can withstand constant use, heavy loads, and harsh environmental conditions without compromising their integrity.

Through careful material selection, meticulous design, and rigorous quality control measures, structural engineers create buildings that stand the test of time.

By accounting for factors such as material strength, fatigue resistance, and environmental exposure, engineers ensure that factory buildings remain operational and structurally sound for years to come.

Whether it's a manufacturing plant, a distribution center, or a storage facility, the reliability of the structure is essential for maintaining uninterrupted operations and minimizing downtime.

Top factory Architect in India

.

Optimizing Space and Functionality

In addition to safety and reliability, structural engineering also plays a vital role in optimizing space utilization and functionality within factory buildings. Efficient layout design, strategic column placement, and innovative structural systems enable manufacturers to maximize floor space, streamline workflow, and accommodate evolving production needs.

Through intelligent design solutions such as mezzanine floors, clear-span structures, and high-ceiling designs, structural engineers help factories overcome spatial constraints and enhance operational efficiency.

By optimizing the structural framework to support various equipment configurations and workflow patterns, engineers empower manufacturers to adapt to changing market demands and scale their operations with ease.

Best industrial Architects in India

.

Safeguard Your Success with Structural Engineering

In conclusion, the importance of structural engineering in ensuring the safety and reliability of factory buildings cannot be overstated. From safeguarding lives and assets to optimizing space and functionality, structural engineers play a crucial role in shaping the built environment of industrial facilities.

As factories continue to evolve and expand in response to technological advancements and market dynamics, the need for robust, resilient structures will only grow.

By partnering with experienced Best Structural Consultant in Ahmedabad & Vadodara, VMS Consultants, manufacturers can ensure that their facilities are engineered to withstand the challenges of today and tomorrow, laying the foundation for continued success and prosperity.

Ready to build safer, more reliable factory buildings? Partner with VMS Consultants, your trusted experts in Engineering Architecture & Project Management Services.

Best factory Architect in India

.

Address: Chitrakoot Flats, Ground floor, Behind Time of India, Off Ashram Road, Ahmedabad, Gujarat, India,380009

Call: 79 40236236

Email: [email protected]

Website: https://www.vmsconsultants.com/

0 notes

Text

Global Geophysical Services Market Growth Analysis 2024 – Forecast Market Size And Key Factors Driving Growth

Overview and Scope

The geophysical services specialize in locating and measuring the number of resources such as minerals, oil, and gas, assessing earthquake hazards, investigating the subsurface for engineering structures, investigating archaeological sites, and imaging the subsurface for environmental hazards.

Sizing and Forecast

The geophysical services market size has grown steadily in recent years. It will grow from $14.55 billion in 2023 to $15.01 billion in 2024 at a compound annual growth rate (CAGR) of 3.1%. The growth in the historic period can be attributed to oil and gas exploration, mining sector growth, infrastructure development, environmental studies and remediation, seismic exploration advancements, geothermal energy development.

The geophysical services market size is expected to see steady growth in the next few years. It will grow to $16.97 billion in 2028 at a compound annual growth rate (CAGR) of 3.1%. The growth in the forecast period can be attributed to growing renewable energy expansion, mining exploration demand, environmental impact studies, hydrocarbon exploration, geothermal and alternative energy sources. Major trends in the forecast period include climate change studies, urban infrastructure mapping, multi-disciplinary approach, remote sensing and satellite technology, big data analytics integration.

Order your report now for swift delivery, visit the link:

https://www.thebusinessresearchcompany.com/report/geophysical-services-global-market-report

Segmentation & Regional Insights

The geophysical services market covered in this report is segmented –

1) By Survey Type: Land, Marine, Aerial

2) By Technology: Seismic, Magnetic, Gravity, Electromagnetic, Lidar, Ground Penetrating, Other Technologies

3) By Application: Road, Rail, Port, Airport, Pipeline, Other Applications

4) By End User: Agriculture, Environment, Minerals And Mining, Oil And Gas, Water Exploration, Other End Users

North America was the largest region in the geophysical services market in 2023. Western Europe was the second largest region in the global geophysical services market share. The regions covered in the geophysical services market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on a free sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=3693&type=smp

Major Driver Impacting Market Growth

Growing exploration activities are contributing to the growth of the geophysical services market. Mineral exploration aims to discover deposits of minerals and rocks that can be used to meet the resource needs of society, which could be fulfilled by geophysical services.

Key Industry Players

Major companies operating in the geophysical services market report are BGP Inc., Schlumberger Limited, Halliburton Company, Geotech Surveys International Limited, Sea Geo Surveys Pvt. Ltd., COSL China Oilfield Services Limited.

The geophysical services market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Role of Earth Observations Data in Petroleum and Natural Gas Studies_Crimson Publishers

Abstract:

Earth observation especially remote sensing and communication plays an important role in the petroleum industry. The following are the major areas where it has its applicability

i. Reconnaissance geologic and geophysical surveys/ studies (including gravity-magnetic data)

ii. Satellite communications and data transfer: this includes data transfer from offshore platforms, drilling rigs etc, onshore control centres for offshore activities, monitoring real time drilling operations and virtual reality centres to receive and visualise data.

iii. General positioning and navigation applications, including staking of well locations prior to drilling and planning seismic surveys using Differential GPS data.

iv. Environmental Impact Assessment (EIA) and Natural Hazard studies

v. Digital Elevation Models (DEMs) for topographic analysis based on various types of remote sensing data

vi. Surveillance data of offshore installations from Vessel and Air Traffic Monitoring System (VATMS), CCTV, etc.

Satellite remote sensing especially high resolution data and advanced image analysis of microwave data (polarimetry/ InSAR and DInSAR) from RISAT/ RADARSAT/ TERRASAR satellites with Synthetic Aperture Radars onboard, etc is useful for static and dynamic modelling of surface elevation for use in exploration (topographic displacement, fault / lineament detection), environmental monitoring (oil spills/ slicks detection). Deployment of Hyperspectral Remote Sensing (Imaging) Instrument (with dedicated spectral range selection is useful for detection of seeping hydrocarbons and lithological/ mineralogical identification/ mapping) as well as specialized drones on which such sensors can be mounted for low-altitude surveying will be of immense help in hydrocarbon exploration.

Read More About this Article: https://crimsonpublishers.com/pps/fulltext/PPS.000502.php

Read More Articles: https://crimsonpublishers.com/pps/

#crimson publishers#progress in petrochemical science#open access journals#petroleum#chemical engineering#natural gas

0 notes

Text

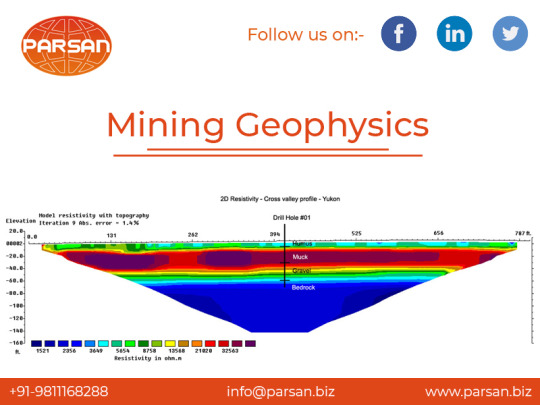

Exploring Underground: Advancements in Mining Geophysics

Mining geophysics is a specialized branch of geophysics focused on applying various methods and techniques to study the subsurface structure and characteristics of the Earth in mining exploration and resource assessment. It plays a crucial role in locating mineral deposits, understanding geological features, and optimizing mining operations. Here’s an overview of mining geophysics and its key applications:

Key Techniques in Mining Geophysics:

Seismic Methods: Seismic surveys involve generating and recording seismic waves to image subsurface structures. Reflection seismic surveys are commonly used in mining to identify geological boundaries, faults, and potential ore bodies based on variations in rock properties.

Electrical Resistivity Tomography (ERT): ERT measures the electrical resistivity of subsurface materials to identify variations associated with different rock types, mineralization, or alteration zones. It helps delineate potential mineral deposits and geological structures.

Gravity and Magnetic Surveys: Gravity and magnetic surveys detect variations in gravitational or magnetic fields caused by subsurface features such as density contrasts or magnetic minerals. These surveys are valuable for mapping geological structures and identifying potential mineralization zones.

Induced Polarization (IP) Surveys: IP surveys measure the ability of rocks to hold electrical charge under an applied electrical field. IP anomalies can indicate the presence of sulfide minerals associated with mineral deposits.

Remote Sensing and Imaging Techniques: Remote sensing technologies, including satellite imagery and aerial surveys, provide valuable geological data for regional mapping, structural analysis, and prospecting.

Applications of Mining Geophysics:

Mineral Exploration: Geophysical surveys play a key role in identifying prospective areas for mineral exploration and delineating targets for drilling and sampling.

Resource Assessment: Geophysical data helps estimate the size, depth, and geometry of mineral deposits, supporting resource assessment and reserve estimation.

Groundwater and Environmental Studies: Geophysical methods are used to assess groundwater resources, monitor environmental impacts of mining activities, and mitigate risks associated with subsidence and ground stability.

Benefits of Mining Geophysics:

Cost-Effective Exploration: Geophysics can target specific areas for exploration, reducing the need for extensive drilling and sampling.

Non-Destructive and Rapid Data Collection: Geophysical surveys provide non-destructive data in a rapid manner, allowing for efficient decision-making in exploration programs.

Risk Mitigation: Geophysics helps identify geological hazards, optimize mine planning, and reduce risks associated with exploration and mining operations.

In summary, mining geophysics is a valuable tool for mineral exploration and resource assessment, utilizing advanced techniques to understand subsurface geology and locate mineral deposits efficiently and cost-effectively. By integrating geophysical data with geological knowledge, mining companies can make informed decisions and optimize their exploration and extraction strategies.

0 notes

Text

Investigating the Bases of Civil Engineering: Constructing the Environment Around Us

The unsung force reshaping our world is civil engineering. Civil engineering is the foundation of contemporary society, from the skyscrapers that dominate city skylines to the complex web of roads and bridges that link far-flung villages. This field designs, builds, and maintains the infrastructure necessary for society's advancement by fusing science, technology, and creativity.

The fundamental idea behind civil engineering is to use the built environment to enhance people's quality of life. Structural engineering, transportation engineering, geotechnical engineering, environmental engineering, and many more are among the numerous fields it includes. In order to meet the changing requirements and problems of society, each of these specialties is essential.

Structural engineering, which deals with the design and analysis of buildings, bridges, dams, and other structures, is one of the most fundamental branches of civil engineering. In addition to taking into account aspects like material strength, durability, and aesthetics, structural engineers must guarantee that these structures are able to endure a variety of forces, including gravity, wind, and seismic activity. They are doing vital work that will help build long-lasting, secure infrastructure.

Another essential component of civil engineering is transportation engineering, which focuses on the organization, creation, and management of transportation networks. Transportation engineers seek to improve people's mobility, accessibility, and safety for both people and commodities. This includes developing creative traffic management solutions as well as building effective highways and public transportation systems.

Understanding how rock and soil behave and interact with civil engineering structures is a crucial aspect of geotechnical engineering. Geotechnical engineers make guarantee that infrastructure projects are stable and long-lasting by addressing geological hazards such as sinkholes and landslides, assessing foundation conditions, and conducting soil studies.

To sum up, civil engineering forms the basis of contemporary civilization and shapes the environment in which we live and work. Civil engineers are essential to creating a better future for everybody, from tall skyscrapers to complex transit networks, robust infrastructure to environmentally friendly solutions. In order to create a safer, more efficient, and more sustainable environment for future generations, civil engineers' creativity, ingenuity, and dedication will be crucial as we tackle the challenges of the twenty-first century and beyond.

start your preparation for any exam with : https://clppenny.page.link/cTBm / https://gameacademy.in/

0 notes

Text

Seismic Refraction Survey | Epitome

Introduction:

In the realm of geophysics, there exists a powerful tool that allows us to peek beneath the Earth's surface, revealing its hidden mysteries with astonishing precision. This tool is none other than the seismic refraction survey—a method that has revolutionized our understanding of subsurface structures. In this article, we delve into the epitome of seismic refraction surveying, exploring its principles, applications, and the profound insights it offers to diverse fields, from geology and civil engineering to environmental studies and beyond.

In the realm of geophysics, there exists a remarkable tool that delves into the depths of the Earth, revealing its hidden mysteries with unparalleled precision. Enter the seismic refraction survey – a technique that serves as a gateway to understanding the intricate layers and structures beneath our feet. Today, we embark on a journey to explore the epitome of geophysical investigation, shedding light on its principles, applications, and significance in unraveling the Earth’s enigmatic secrets.

The Foundation: Understanding Seismic Refraction

At its core, seismic refraction is grounded in the fundamental principles of wave propagation. By employing controlled seismic sources, typically in the form of sledgehammers, explosives, or specialized vibrators, this method generates seismic waves that travel through the subsurface. As these waves encounter boundaries between different rock layers or structures, they undergo refraction – a change in direction due to variations in wave velocity – providing invaluable insights into the subsurface geometry.

The Process Unveiled: How It Works

The seismic refraction survey unfolds in a meticulously orchestrated sequence of steps, each contributing to the comprehensive understanding of subsurface characteristics:

Source Deployment: The survey commences with the strategic placement of seismic energy sources along a predetermined line or grid pattern. These sources emit seismic waves into the Earth, initiating the investigative journey.

Wave Propagation: Once triggered, the seismic waves traverse through the subsurface, encountering interfaces between geological formations. The velocity of waves varies depending on the properties of the materials they traverse, causing them to bend or refract.

Receiver Arrays: Arrayed strategically along the survey line, seismic receivers meticulously capture the refracted waves. These receivers, often geophones or accelerometers, record the arrival times and amplitudes of seismic signals, providing crucial data for subsequent analysis.

Data Interpretation: Armed with a wealth of seismic data, geophysicists embark on the interpretative phase, wherein they analyze arrival times and wave velocities to construct velocity-depth models. These models serve as blueprints, delineating subsurface structures and delineating geological boundaries with precision.

The Canvas of Applications: Where Seismic Refraction Thrives

The versatility of seismic refraction surveys renders them indispensable across an array of disciplines:

Engineering Geology: In civil engineering projects, seismic refraction surveys aid in assessing subsurface conditions, identifying potential hazards such as faults or sinkholes, and optimizing foundation design.

Hydrogeology: By delineating aquifer boundaries and characterizing groundwater flow patterns, seismic refraction surveys play a pivotal role in water resource management and environmental conservation efforts.

Mineral Exploration: Within the realm of resource exploration, these surveys offer a non-invasive means of delineating ore bodies and assessing subsurface geological structures, guiding lucrative investment decisions.

Infrastructure Development: Prior to infrastructure development projects, such as road construction or pipeline installation, seismic refraction surveys provide vital intelligence on subsurface conditions, facilitating efficient planning and risk mitigation.

The Epitome of Geophysical Ingenuity

In essence, seismic refraction surveys stand as the epitome of geophysical ingenuity, offering a window into the Earth's depths with unprecedented clarity. Armed with seismic waves and sophisticated analytical techniques, scientists and engineers unravel the intricacies of our planet's subsurface, empowering mankind to navigate its terrain with foresight and precision. As we continue to push the boundaries of exploration and discovery, seismic refraction remains a steadfast companion, illuminating the path towards a deeper understanding of our planet’s hidden realms.

More Info: https://epitomegs.com

Contact :+91-96756 94400

#Multi-Analysis of Surface wave#Multi Analysis of Surface wave#epitome#Seismic Refraction#Crosshole Seismic Survey#Seismic Refraction Survey#Seismic Survey in India#SRT survey#Seismic Survey#Crosshole Seismic Survey Company in India#SRT survey in India#Crosshole Seismic Survey in India#SRT survey company in India#Seismic Refraction Survey Company in India#Seismic Refraction Survey in India

0 notes

Text

Safeguarding Chemicals, Protecting Environments: The Role of Chemical Storage Tanks

In industries spanning from manufacturing to agriculture, chemicals are indispensable assets, powering processes and driving innovation. Yet, with their indispensable nature comes the responsibility of safe and secure storage. Chemical storage tanks stand as the guardians of these valuable assets, ensuring not only their integrity but also safeguarding the environment and human health. Let's explore the critical role that chemical storage tanks play and the key considerations in their design, implementation, and maintenance.

The Importance of Chemical Storage Tanks:

Chemical storage tanks serve as vital components in industries where the handling and storage of hazardous substances are commonplace. These tanks provide a secure environment for storing various chemicals, including corrosive liquids, flammable materials, and toxic substances. By containing these chemicals within durable and reliable enclosures, storage tanks mitigate the risks of spills, leaks, and environmental contamination, thereby protecting workers, communities, and ecosystems.

Key Considerations in Chemical Storage Tank Design

Designing a chemical storage tank involves careful consideration of several factors to ensure its effectiveness and safety:

1. Material Selection: The choice of tank material is paramount and depends on the types of chemicals to be stored. Common materials include high-density polyethylene (HDPE), fiberglass reinforced plastic (FRP), polypropylene, stainless steel, and lined steel tanks. Each material offers different properties in terms of chemical resistance, durability, and cost-effectiveness.

2. Chemical Compatibility: Tanks must be compatible with the chemicals they will contain to prevent corrosion, degradation, or chemical reactions that could compromise the integrity of the tank and the safety of its contents. Thorough chemical compatibility testing and analysis are essential in the selection process.

3. Capacity and Configuration: SS industrial storage tanks come in various sizes and configurations to accommodate different storage requirements. Factors such as volume, space constraints, and operational needs must be taken into account when determining the tank's capacity and layout.

4. Reinforcement and Containment: Depending on the chemical properties and storage conditions, tanks may require additional reinforcement, such as double-walled construction or secondary containment systems, to prevent leaks and spills.

Implementing Best Practices in Chemical Storage:

Beyond design considerations, proper implementation and maintenance are crucial for ensuring the effectiveness and longevity of chemical storage tanks:

1. Installation: Tanks should be installed according to manufacturer guidelines and industry best practices, considering factors such as foundation stability, seismic considerations, and accessibility for inspection and maintenance.

2. Regular Inspection and Maintenance: Routine inspections and maintenance are essential to identify and address potential issues such as corrosion, leaks, and structural integrity. Regular testing of tank integrity and containment systems should be conducted to ensure compliance with regulatory standards and industry requirements.

3. Emergency Preparedness: In the event of a spill or leak, having robust emergency response plans and procedures in place is critical. This includes providing appropriate containment and cleanup equipment, training personnel in proper handling protocols, and maintaining communication channels with regulatory agencies and emergency responders.

Conclusion: Ensuring Safety and Sustainability

MS SS Tanks serve as the cornerstone of safe and responsible chemical management, providing a secure environment for storing hazardous substances while mitigating risks to human health and the environment. By adhering to best practices in design, implementation, and maintenance, industries can uphold the highest standards of safety, sustainability, and regulatory compliance. As stewards of chemical resources, let us continue to prioritize the protection of our planet and communities through the conscientious management of chemical storage.

0 notes

Text

North America Seismic Survey Market| Analysis, Growth and Forecast, 2024 – 2028

Originally published on Technavio: North America Seismic Survey Market by Type and End-user - Forecast and Analysis 2024-2028

**North America Seismic Survey Market Analysis 2024-2028**

The North America seismic survey market is anticipated to witness steady growth over the forecast period from 2024 to 2028. This analysis explores the market trends and dynamics concerning seismic surveys in North America, focusing on various types and end-users of seismic survey services.

**Market Trends and Dynamics:**

The North America seismic survey market is driven by several factors, including increasing exploration activities in the oil and gas industry, technological advancements in seismic surveying techniques, and growing investments in infrastructure development projects. Seismic surveys play a crucial role in identifying subsurface geological structures and assessing the potential for hydrocarbon reserves, making them indispensable for energy exploration and production companies operating in the region.

**Types of Seismic Surveys:**

The North America seismic survey market encompasses various types of surveys, including 2D seismic surveys, 3D seismic surveys, and 4D seismic surveys. 2D seismic surveys are widely used for regional reconnaissance and preliminary exploration, providing a broad overview of subsurface geological features. On the other hand, 3D seismic surveys offer higher resolution imaging of subsurface structures, enabling more accurate reservoir characterization and hydrocarbon resource estimation. Additionally, 4D seismic surveys involve repeated 3D surveys conducted over time to monitor reservoir changes and optimize production strategies.

**End-users of Seismic Survey Services:**

The North America seismic survey market caters to a diverse range of end-users, including oil and gas companies, mining companies, government agencies, and environmental consulting firms. Oil and gas companies are the primary end-users of seismic survey services, utilizing seismic data to identify potential drilling locations, optimize well placement, and enhance reservoir management practices. Mining companies also rely on seismic surveys for mineral exploration and resource estimation, while government agencies utilize seismic data for geological mapping, natural hazard assessment, and environmental monitoring purposes.

To Learn deeper into this report , View Sample PDF

**Market Outlook:**

The North America seismic survey market is expected to witness sustained growth in the coming years, driven by ongoing exploration and production activities in the oil and gas sector, increasing demand for energy resources, and rising investments in infrastructure development projects. Technological advancements in seismic surveying techniques, such as advanced imaging algorithms, enhanced data processing capabilities, and the integration of machine learning and artificial intelligence, are also expected to fuel market growth by enabling more efficient and accurate subsurface imaging.

In conclusion, the North America seismic survey market is poised for steady expansion over the forecast period, driven by robust demand from the oil and gas industry, advancements in seismic surveying technology, and increasing investments in infrastructure development projects. Market players and stakeholders are expected to capitalize on these trends by offering innovative seismic survey solutions tailored to the specific needs of end-users across various industries.

For more information please contact.

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email: [email protected]

Website: www.technavio.com/

0 notes

Text

Little P.Eng. for Blue Hydrogen and Ammonia Engineering Services: A Comprehensive Engineering Aspect

Table of Contents

Introduction

Blue Hydrogen: An Overview

Importance of Engineering Services in Blue Hydrogen Production

Piping Stress Analysis

Structural Engineering

Seismic Engineering

Tank Design

Pressure Vessel Design

Ammonia Engineering Services: The Connection

Conclusion

1. Introduction

As the world accelerates its efforts to combat climate change, the focus on cleaner energy sources has never been sharper. Blue hydrogen, derived primarily from natural gas with the carbon emissions being captured and stored, presents a viable option in the pursuit of decarbonization. Its potential integration with ammonia production further highlights its significance. At the heart of this transformative energy landscape lies the vital role of engineering services. 'Little P.Eng.', a forerunner in this niche, offers specialized services such as piping stress analysis, structural and seismic engineering, and the design of tanks and pressure vessels. This article delves deep into these pivotal engineering domains and the implications for blue hydrogen and ammonia production.

2. Blue Hydrogen: An Overview

Blue hydrogen is produced when natural gas (primarily methane) undergoes steam methane reforming (SMR) to produce hydrogen and carbon dioxide. Unlike gray hydrogen, where CO2 is released into the atmosphere, blue hydrogen incorporates carbon capture and storage (CCS) technology. This ensures that a significant portion of the carbon emissions are captured and sequestered, making blue hydrogen a cleaner option.

3. Importance of Engineering Services in Blue Hydrogen Production

Engineering services ensure the efficiency, safety, and reliability of blue hydrogen production plants. Key considerations range from handling high pressures and temperatures to mitigating the effects of seismic events. Herein, Little P.Eng.'s expertise comes to the fore.

4. Piping Stress Analysis

Piping systems in hydrogen production facilities face stresses from internal pressures, thermal loads, and dynamic forces. Piping stress analysis ensures that pipes, flanges, and fittings can withstand these stresses without failure.

Objectives:

Safety of the piping system and its associated components.

Compliance with international standards, codes, and best practices.

Reduction of operational disruptions due to piping failures.

Little P.Eng. employs advanced computational tools and methodologies to evaluate the behavior of piping systems under various loading conditions, optimizing design and ensuring longevity.

5. Structural Engineering

Facilities producing blue hydrogen demand robust structures capable of supporting equipment, piping, and personnel.

Key Challenges:

Dynamic loads from equipment and flow-induced vibrations.

Corrosive environments due to the presence of hydrogen, steam, and other chemicals.

Little P.Eng.'s structural engineering services provide innovative solutions, ensuring that structures remain integral and safe throughout their operational life.

6. Seismic Engineering

Many industrial facilities are located in seismic zones. Earthquakes can be catastrophic for hydrogen production facilities, leading to leaks, explosions, and fires.

Seismic Analysis: Little P.Eng. evaluates potential seismic risks and designs structures and systems that can withstand seismic events. This encompasses:

Site-specific seismic hazard assessments.

Design of foundations and structural elements with sufficient ductility and resilience.

7. Tank Design

Storage tanks play a pivotal role in hydrogen and ammonia plants. They store feedstock, intermediate products, and final products.

Design Principles:

Safety: Ensuring that tanks do not leak or rupture.

Efficiency: Maximizing storage capacity while minimizing footprint.

Longevity: Ensuring resistance to corrosion, wear, and tear.

With advanced modeling and simulation, Little P.Eng. optimizes tank designs to meet these principles, while also adhering to strict regulatory standards.

8. Pressure Vessel Design

Pressure vessels in hydrogen production plants hold gases at high pressures. Their design is crucial for safety and efficiency.

Design Aspects:

Material selection to resist hydrogen embrittlement.

Wall thickness determination to withstand internal pressures.

Compliance with international standards, such as ASME codes.

Little P.Eng. employs a rigorous approach to pressure vessel design, ensuring optimal performance and safety.

9. Ammonia Engineering Services: The Connection

Ammonia, NH3, is produced by combining nitrogen from the air with hydrogen. As such, blue hydrogen can provide a clean hydrogen source for ammonia production. The engineering challenges in ammonia production mirror those of blue hydrogen: high pressures, corrosive environments, and the need for robust structures and equipment. Little P.Eng.'s suite of services naturally extends to this domain, further enhancing the synergies between blue hydrogen and ammonia production.

10. Conclusion

The transformation of the energy landscape hinges on the adoption of cleaner technologies, and blue hydrogen stands out in this endeavor. The role of engineering services, as championed by Little P.Eng., is paramount, ensuring that the transition is not just sustainable but also safe and efficient. From intricate piping designs to robust structural solutions, the contributions of engineering cannot be overstated. As we gaze into the future of energy, it's clear that the expertise of firms like Little P.Eng. will be at the very heart of this revolution.

Tags:

Engineering Services

Seismic Engineering

Little P.Eng.

Piping Stress Analysis

Structural Engineering

Material Selection

Tank Design

Pressure Vessels

ASME Codes

Clean Energy

Ammonia Production

Steam Methane Reforming

Computational Analysis

Infrastructure Safety

Blue Hydrogen

Carbon Capture

Simulation and Modeling

Ammonia Synthesis

Fluid Dynamics

Industrial Standards

Decarbonization

Load-bearing Structures

Industrial Integrity

Earthquake-Resilient Designs

Energy Transition

Environmental Factors

Hydrogen Storage

Seismic Zones

Foundation Designs

Hydrogen Embrittlement

Hydrogen Production Plant Design

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Engineering Services#Seismic Engineering#Little P.Eng.#Piping Stress Analysis#Structural Engineering#Material Selection#Tank Design#Pressure Vessels#ASME Codes#Clean Energy#Ammonia Production#Steam Methane Reforming#Computational Analysis#Infrastructure Safety#Blue Hydrogen#Carbon Capture#Simulation and Modeling#Ammonia Synthesis#Fluid Dynamics#Industrial Standards#Decarbonization#Load-bearing Structures#Industrial Integrity#Earthquake-Resilient Designs#Energy Transition#Environmental Factors#Hydrogen Storage#Seismic Zones#Foundation Designs#Hydrogen Embrittlement

0 notes