#sensor bearing market dynamics

Text

Sensor Bearing Market Growing High CAGR During 2023-29

According to Precision Business Insights, the global Sensor Bearing Market is poised to grow at a significant CAGR of 5.5% during forecast period 2023-2029

The global sensor bearing market size was valued at USD 6.62 billion in 2022 and is poised to grow at a significant CAGR of 5.5% during the forecast period 2023-29. It also includes market size and projection estimations for each of the five major regions from 2023 to 2029. The research report includes historical data, trending features, and market growth estimates for the future. Furthermore, the study includes a global and regional estimation and further split by nations and categories within each region. The research also includes factors and barriers to the sensor bearing market growth, as well as their impact on the market's future growth. The report gives a comprehensive overview of both primary and secondary data.

View the detailed report description here - https://www.precisionbusinessinsights.com/market-reports/global-sensor-bearing-market

The global sensor bearing market segmentation:

1) By Functionality : Displacement, Speed, Temperature, Vibration and Others.

2) By Application : Anti-lock Brake Systems (ABS), Electric Motors, Material Handling Equipment and Others.

3) By End User : Aerospace & Defense, Automotive, Metal & Mining, Oil & Gas, Transportation and Others.

The primary factors of the sensor bearing market drivers are the increasing demand for bearings with longer service life, higher efficiency, and lower maintenance requirements. The sensor bearing market report helps to provide the best results for business enhancement and business growth. It further helps to obtain the reactions of consumers to a novel product or service. It becomes possible for business players to take action for changing perceptions. It uncovers and identifies potential issues of the customers. It becomes easy to obtain the reactions of the customers to a novel product or service. It also enlightens further advancement, so it suits its intended market.

The sensor bearing marketresearchreport gives a comprehensive outlook across the region with special emphasis on key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific was the largest region in the sensor bearing market report, accounting for the highest share in 2022. It was followed by Asia Pacific, and then the other regions.

Request sample report at - https://www.precisionbusinessinsights.com/request-sample/?product_id=27699

The important profiles and strategies adopted by sensor bearing market key players are Timken (US), NSK Corporation (Japan), Schaeffler Technologies AG & Co. KG (Germany), NTN Corporation (Japan), Nachi Europe GmbH (Germany), Mageba SA (Switzerland), JTEKT Corporation (Japan), Fersa Bearing SA (Spain), BRTEC (China), ABB Group (Switzerland), SKF (Sweden), covered here to help them in strengthening their place in the market.

About Precision Business Insights:

We are a market research company that strives to provide the highest quality market research insights. Our diverse market research experts are enthusiastic about market research and therefore produce high-quality research reports. We have over 500 clients with whom we have a good business partnership and capacity to provide in-depth research analysis for more than 30 countries. In addition to deliver more than 150 custom solutions, we already have accounts with the top five medical device manufacturers.

Precision Business Insights offers a variety of cost-effective and customized research services to meet research requirements. We are a leading research service provider because of our extensive database built by our experts and the services we provide.

Contact:

Mr. Satya

Precision Business Insights | Toll Free: +1 866 598 1553

Email: [email protected]

Kemp House, 152 – 160 City Road, London EC1V 2NX

Web: https://precisionbusinessinsights.com/ | D U N S® Number: 852781747

#sensor bearing market size#sensor bearing market share#sensor bearing market growth#sensor bearing market trends#sensor bearing market dynamics

0 notes

Text

The global demand for Lubricants was valued at USD 1,75,484.2 Million in 2023 and is expected to reach USD 2,39,166.9 Million in 2032, growing at a CAGR of 3.50% between 2024 and 2032.Lubricants play a crucial role in various industries, from automotive to manufacturing, ensuring the smooth operation of machinery and reducing wear and tear. The global lubricants market is a dynamic and rapidly evolving sector, driven by technological advancements, environmental regulations, and changing consumer preferences. This article explores the current state of the lubricants market, key trends, challenges, and future outlook.

Browse the full report at https://www.credenceresearch.com/report/lubricants-market

Market Overview

The global lubricants market is vast, encompassing a wide range of products including engine oils, hydraulic fluids, gear oils, and greases. According to recent reports, the market size was valued at approximately $123 billion in 2023 and is projected to grow at a CAGR of 2.5% from 2024 to 2030. The automotive sector remains the largest consumer of lubricants, accounting for nearly half of the total demand. Industrial applications, however, are gaining significant traction, driven by the growth of manufacturing and heavy machinery sectors.

Key Trends

1. Technological Advancements: Innovations in lubricant formulations are transforming the market. Synthetic lubricants, which offer superior performance compared to conventional mineral oils, are gaining popularity. These lubricants provide better thermal stability, reduced friction, and longer service life, making them ideal for high-performance engines and industrial machinery.

2. Environmental Regulations: Stringent environmental regulations are shaping the lubricants market. Governments worldwide are implementing policies to reduce carbon emissions and promote sustainability. As a result, there is a growing demand for eco-friendly lubricants that are biodegradable and have lower toxicity. Manufacturers are focusing on developing products that meet these regulatory standards without compromising performance.

3. Shift Towards Electric Vehicles (EVs): The rise of electric vehicles is impacting the lubricants market. Unlike internal combustion engine (ICE) vehicles, EVs require fewer lubricants. However, specialized lubricants are needed for components such as electric motors, bearings, and gearboxes. The transition to EVs is prompting lubricant manufacturers to innovate and develop new formulations to cater to this emerging market.

4. Digitalization and Industry 4.0: The adoption of digital technologies and Industry 4.0 principles is revolutionizing the lubricants market. Predictive maintenance, enabled by IoT and data analytics, is becoming a standard practice in industries. Smart lubricants, equipped with sensors, can monitor equipment performance in real-time and provide valuable data to optimize maintenance schedules and improve operational efficiency.

Challenges

1. Fluctuating Raw Material Prices: The lubricants industry heavily relies on petroleum-based raw materials. Volatility in crude oil prices can significantly impact production costs and profit margins for lubricant manufacturers. Finding alternative raw materials and improving supply chain resilience are essential to mitigate these risks.

2. Sustainability and Environmental Impact: Despite advancements in eco-friendly lubricants, achieving sustainability remains a challenge. The production, use, and disposal of lubricants can have environmental consequences. Manufacturers must invest in research and development to create sustainable products and adopt circular economy practices to minimize their environmental footprint.

3. Market Competition: The lubricants market is highly competitive, with numerous global and regional players vying for market share. Differentiating products through innovation, quality, and customer service is crucial to stay ahead in this competitive landscape. Additionally, strategic partnerships and mergers can help companies expand their market presence and enhance their product offerings.

Future Outlook

The future of the lubricants market looks promising, driven by technological advancements and evolving industry needs. The increasing adoption of synthetic and bio-based lubricants is expected to continue, supported by growing awareness of environmental sustainability. The rise of electric vehicles and Industry 4.0 will further stimulate innovation in lubricant formulations and applications.

Moreover, the Asia-Pacific region is anticipated to be a major growth driver for the lubricants market. Rapid industrialization, urbanization, and the expansion of the automotive sector in countries like China and India will boost demand. North America and Europe, with their focus on advanced manufacturing and sustainability, will also contribute to market growth.

Key Players

PetroChina Company Limited (China)

Chevron Corporation (U.S.)

ExxonMobil Corporation (U.S.)

Royal Dutch Shell Plc. (Netherlands)

Total Group (France)

BP plc (U.K.)

Valvoline LLC (U.S.)

ENEOS Corporation (Japan)

The FUCHS Group (Germany)

Global Lubricant Industry LLC (UAE)

Shield Lubricants (India)

AMALIE Oil Co. (U.S.)

Others

Segmentation

Type of Lubricant:

Mineral Lubricants

Synthetic Lubricants

Bio-based Lubricants

Greases

Solid Lubricants

Application:

Automotive Lubricants

Industrial Lubricants

Marine Lubricants

Aviation Lubricants

Rail Lubricants

Mining Lubricants

Construction Lubricants

Agricultural Lubricants

Base Oil Type:

Group I Base Oils

Group II Base Oils

Group III Base Oils

Group IV Base Oils

Group V Base Oils

End User:

Automotive Industry

Manufacturing Sector

Transportation and Logistics

Mining and Construction

Maritime Industry

By Region

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Flawless Protection with the Xperia XZ2 Screen Protector

As technology forges ahead to bring us sleeker and smarter smartphones, it's up to us to protect these valuable gadgets from daily threats. Companies like Screen Shield are at the forefront of this protective frontier, offering stellar defense against the rigors of regular use. Specifically, for Sony's flagship device, the Screen Shield Xperia XZ2 Screen Protector is a product that stands out in the market, tailored to offer the Sony Xperia XZ2 an armor that is both impenetrable and invisible.

Sony Xperia XZ2: A Marvel in Mobile Technology

The Sony Xperia XZ2 is not just a phone; it's a testament to Sony's commitment to innovation. With its cutting-edge technology, stunning HDR display, and dynamic sound system, the Xperia XZ2 delivers an immersive experience. Its design, characterized by fluid lines and an ergonomic build, makes it a joy to hold. However, such refined engineering also demands high-quality protection – an area where Screen Shield truly excels.

Screen Shield: A Synonym for Superiority

In the realm of smartphone protection, Screen Shield has become a trusted name, synonymous with durability and clarity. When it comes to the Xperia XZ2 Screen Protector, Screen Shield has left no stone unturned to produce a product that meets the standards of even the most discerning Xperia users.

Unmatched Clarity and Precision

The Sony Xperia XZ2 Screen Protector by Screen Shield is a marvel of precision engineering. Its clear, tempered glass is cut with laser precision to fit the Xperia XZ2's screen flawlessly. This precision ensures that not only is the display fully protected but the perfect contours of the Xperia XZ2 remain unaltered, allowing users to enjoy the factory-intended aesthetics of their smartphone.

Advanced Material Technology

Using advanced material technology, Screen Shield has developed a protector that is exceptionally robust yet incredibly thin. This glass protector maintains the tactile responsiveness that Xperia XZ2 users have come to love, enabling uninterrupted use of interactive gestures and gaming without losing the screen's 'barely there' feeling.

Stress-Free Application

A common concern for many users when applying screen protectors is the issue of air bubbles and misalignment. Screen Shield's Xperia XZ2 Screen Protector boasts a user-friendly application process. With a meticulously designed adhesive layer, users can apply the protector smoothly, ensuring a secure fit with no trapped air bubbles or dust, which is often the bane of a neatly applied screen protector.

Tailored to the Xperia XZ2

Designed specifically for the Sony Xperia XZ2, this protector compliments the device's unique features such as its high-definition screen and sublime touch sensitivity. The Sony Xperia XZ2 Screen Protector maintains Sony's vibrant display quality and supports the fingerprint sensor's flawless functionality.

The Protective Shield Your Xperia XZ2 Deserves

As any Xperia XZ2 owner would attest, the fear of scratches and screen damage can loom large. The Screen Shield Xperia XZ2 Screen Protector alleviates these concerns effectively. Not only does it protect the device's screen from scratches and scuffs, but it also bears the brunt should you accidentally drop your phone, greatly reducing the risk of a shattered screen.

Oleophobic Coating: Fingerprint Resistant

The Sony Xperia XZ2 Screen Protector features an oleophobic coating that repels natural skin oils and makes it resistant to fingerprints and smudges. This coating preserves the screen's pristine look and enhances the user's visual experience by reducing glare.

The Mark of Endurance

The Screen Shield protector for the Xperia XZ2 has been rigorously tested to withstand scratches from everyday objects such as keys and coins. Its high-strength tempered glass can absorb shock, reflecting Screen Shield’s commitment to building products that endure the test of time and use.

A Commitment to Customer Satisfaction

Screen Shield doesn't just stop at creating superior products; their commitment extends to ensuring customer satisfaction with every purchase. The Xperia XZ2 Screen Protector comes with a straightforward set of instructions for application, backed by a customer service team ready to help with any queries or issues.

Peace of Mind

When it comes to protecting your Xperia XZ2, the Screen Shield Sony Xperia XZ2 Screen Protector offers users peace of mind. The assurance that your smartphone's display is armored against day-to-day misfortunes allows you to focus on enjoying the Xperia experience without the hovering cloud of display anxiety.

A Sustainable Option

Equally important to Screen Shield’s mission is sustainability. The Sony Xperia XZ2 Screen Protector is packed and shipped with minimalistic, eco-friendly packaging, underlining the company's commitment to reducing environmental impact. Users can rest assured knowing that choosing Screen Shield is a step in the right direction for both their phones and the planet.

Conclusion: The Clear Choice for Your Xperia XZ2

In conclusion, Screen Shield’s Xperia XZ2 Screen Protector stands as an exemplar of modern screen protector technology. Tailor-made for the Sony Xperia XZ2, it offers unmatched durability, crystal clear clarity, and a user-friendly experience, promising to keep your device's display as immaculate as Sony intended. Choosing Screen Shield means opting for the highest calibre of screen protection, merging technology with practicality to deliver a product that complements your Xperia XZ2 in every way. Whether you're navigating through your workday or capturing life's fleeting moments, you can confidently rely on Screen Shield to keep your Xperia's display safe and sound.

Choosing the right screen protector is no minor decision; it's an investment in the lifespan and condition of your smartphone. With the Screen Shield Sony Xperia XZ2 Screen Protector, you're not just buying a product, you're embracing a philosophy that values perfection in protection. Your Xperia XZ2 is more than just a phone—it's a powerhouse of your daily life, and with Screen Shield, its excellence is preserved for days, months, and years to come.

0 notes

Text

Non-contact Bearing Torque Sensor, Global Market Size Forecast, Top 20 Players Market Share

Non-contact Bearing Torque Sensor Market Summary

A non-contact bearing torque sensor is a device that measures torque or twist on a rotating shaft without requiring physical contact. It operates based on magnetoelastic or magnetic field sensing. Non-contact bearing torque sensors do not use traditional methods such as strain gauges or mechanical linkages to measure torque, but instead use magnetic fields.

Non-contact bearing torque sensors offer several advantages over traditional torque measurement methods. They are free from friction, wear and mechanical hysteresis, ensuring accurate and reliable measurements over a long service life. In addition, they are not affected by radial and axial forces, making them ideal for applications where other loads may be present.

These sensors are widely used in various industries, including automotive, aerospace, robotics, manufacturing and research, where accurate torque measurement is critical for performance analysis, process control and quality assurance.

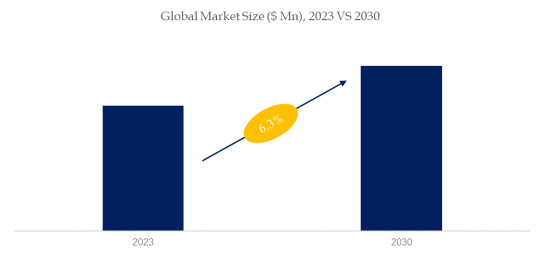

According to the new market research report "Global Non-contact Bearing Torque Sensor Market Report 2024-2030", published by QYResearch, the global Non-contact Bearing Torque Sensor market size is expected to reach USD 47 million by 2030, at a CAGR of 6.3% during the forecast period.

Figure. Global Non-contact Bearing Torque Sensor Market Size (US$ Million), 2023-2030

Above data is based on report from QYResearch: Global Non-contact Bearing Torque Sensor Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

Market Drivers:

Increased downstream demand is a major driving factor for the growth of the non-contact bearing torque market. With the development of industrial automation and smart manufacturing, there is growing need for real-time and accurate torque measurement. Non-contact bearing torque sensors can fulfill these demands, leading to widespread applications. Furthermore, the application areas of non-contact torque sensors are continuously expanding, including industries such as automotive, aerospace, energy, medical, robotics, which further market growth.

Restraint:

Compared to traditional torque sensors, non-contact bearing torque sensors have relatively higher manufacturing costs, which may limit the adoption by small and medium-sized enterprises. Additionally, the design and engineering complexity of non-contact bearing torque sensors require a high level of technical expertise, which can be a hindrance to market development.

Opportunity:

With the rapid development of emerging fields such as renewable and electric vehicles, there is an increasing demand for high-precision and highability torque measurement, providing opportunities for non-contact bearing torque sensors. Additionally, non-contact dynamic torque sensors are developing towards miniaturization, digitization, and intelligentization, transitioning from single-function to multi-function capabilities.

Figure. Global Non-contact Bearing Torque Sensor Top 20 Players

Above data is based on report from QYResearch: Global Non-contact Bearing Torque Sensor Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

This report profiles key players of Non-contact Bearing Torque Sensor such as FUTEK Advanced Sensor Technology, Inc., Magtrol, Lorenz Messtechnik, Sensor Technology Ltd, NCTE AG, TE Connectivity, burster, BCM SENSOR, N-GINERIC, Honeywell, A&D Company, HBM Test and Measurement, Mountz Torque, Schaeffler Technologies AG & Co. KG, UNIPULSE Corporation, Hefei Natural Intelligent Technology, Changzhou Right Measurement and Control System, Shenzhen XJCSENSOR Technology, S. Himmelstein and Company, MinebeaMitsumi.

In 2023, the global top five Non-contact Bearing Torque Sensor players account for 25% of market share in terms of revenue.

About The Authors

Tingyue Chen

Email: [email protected]

QYResearch Guangzhou Branch Analyst, as a member of the QYResearch Machinery Manufacturing Department, her main research directions are engineering machinery, electrical machinery, industrial robots and other fields. Some subdivided research topics include industrial heat treatment equipment, farm robots, X-ray fluoroscopy systems, etc. She is also engaged in the development of market segment reports and participates in the writing of customized projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Automotive Lighting Market Is Anticipated To Attain Around $34.65 Billion By 2030

The automotive lighting market is anticipated to reach USD 34.65 billion by 2022. Strict government policies and rising safety concerns are likely to propel growth over the forecast period. In addition, growing consumer awareness concerning the significance of adaptive lighting including dynamic bend light and a glare-free high beam is also expected to have a positive impact on the exterior lighting market.

Increasing apprehensions about using energy-efficient methods coupled with rising consumer disposable income are expected to drive the industry. In addition, growing demand for vehicles and technological advancements in the automotive industry is expected to propel utilization. Attractive growth opportunities for new entrants are expected in the industry owing to the growing number of total vehicles purchased y-o-y across BRIC nations. However, there is a need for legislative authorities to collaborate with light sourcing technology suppliers to develop flexible design techniques.

THE Automotive LED market is estimated to demonstrate considerable growth at a CAGR of over 12.0% from 2015 to 2022. Halogen lights contributed to over 66.0% of overall industry revenue in 2014, followed by LED and xenon. It has gained prominence on account of easy availability, low purchasing costs, and low replacement costs. However, rising fuel prices are expected to pose a threat to the industry.

Asia Pacific automotive lighting market, by technology, 2012 - 2022 (USD Million)

To request a sample copy or view summary of this report, click the link below:

http://www.grandviewresearch.com/industry-analysis/automotive-lighting-market

The increase in demand for eco-friendly LED technologies on account of high efficiency, reduced CO2 levels, and high power, is expected to propel growth. Companies have been trying to develop eco-friendly LEDs to promote product differentiation and strengthen their global foothold. LEDs are used in daytime running lights (DRL), parking light, brake lights, and turning lights. LEDs are preferred over xenon and halogen lights owing to optimum light-bearing capacities and improved design, which lead to increased shelf life.

The adaptive headlight is an active safety feature that is intended to enhance the drivers’ visibility in poorly illuminated areas. It encompasses functionalities including automatic rotation which can sync with sensors and adjust brightness and intensity of light. The front lighting segment accounted for over 70.0% of the total revenue in 2014 owing to the availability of advanced features including automatic rotation which can sync with automatic brightness modules and sensor response. Extreme climatic conditions in Europe and North America are expected to trigger demand for fog lights over the forecast period.

The automotive lighting industry in Asia Pacific is estimated to grow at a CAGR of over 8.0% and acquire a market share of about 45.0% over the forecast period. The continuous expansion of suppliers coupled with a vast production base is expected to position this region as the market leader. Countries including India, Japan, and China account for the major production base for vehicles globally, thus offering extensive growth opportunities.

Key companies including Hella KGaA Hueck & Co., Koito Manufacturing Co., Magneti Marelli S.p.A and Valeo. Vendors usually employ the strategy of new product development and mergers & acquisitions to enter new markets. The introduction of low-cost LEDs and energy-efficient alternatives is foreseen as a cost-effective strategy for the industry.

Grand View Research has segmented the automotive lighting market on the basis of technology, application, and region:

Automotive Lighting Technology Outlook (Revenue, USD Million, 2012 - 2022)

Halogen

Xenon

LED

Automotive Lighting Application Outlook (Revenue, USD Million, 2012 - 2022)

Front/headlamps

Rear

Side

Interior

Automotive Lighting Regional Outlook (Revenue, USD Million, 2012 - 2022)

North America

Europe

Asia Pacific

RoW

0 notes

Text

Optical Ground Wire Market to Get Explosive Growth

Latest Global Optical Ground Wire Market study with 100+ market data Tables, Pie charts & Figures is now released by HTF MI. The research assessment of the Market is designed to analyze futuristic trends, growth factors, industry opinions, and industry-validated market facts to forecast till 2030. A significant region that is speeding up marketization is used to split the market study. Some of the leading players covered such as Fujikura, ZTT, Tongguang Cable, Shenzhen SDG, Furukawa, LS Cable, Taihan, Sichuan Huiyuan, Elsewedy Cables, Tratos, J-Power Systems.

Download Sample Report PDF (Including Full TOC, Table & Figures) 👉 https://www.htfmarketintelligence.com/sample-report/global-optical-ground-wire-market

According to HTF Market Intelligence, the Global Optical Ground Wire market to witness a CAGR of 4.09% during forecast period of 2024-2030. The market is segmented by Application (Central Tube Structure, Layer Stranding Structure) by Type (CMOS Image Sensors, EM-CCD Image Sensors, CCD Image Sensors) by Distribution channel (OEMs, Aftermarket) and by Geography (North America, South America, Europe, Asia Pacific, MEA). The Optical Ground Wire market size is estimated to increase by USD 175.09Million at a CAGR of 4.09% from 2024 to 2030. The report includes historic market data from 2021 to 2024E. Currently, market value is pegged at USD 644.5Million

Definition:

OPGW (Optical Ground Wire) is primarily used by the electric utility industry, placed in the secure topmost position of the transmission line where it “shields†the all-important conductors from lightning though providing a telecommunications path for internal as well as third party communications. It is designed to swap the traditional shield or earth wires on overhead transmission lines with optical fibers which can be used for telecommunications purposes. It is capable of bearing the mechanical pressures that are applied to overhead cables by environmental factors such as wind and ice and it also handle electrical faults on the transmission line by providing a track to ground without damaging the sensitive optical fibers inside the cable. The OPGW cable are placed at the ends of high-voltage towers, it safeguards the high-voltage conductors from lightning strikes and its conductive part serves to bond adjacent towers to earth ground.

Market Trends:

Increasing Adoption of OPGW Cables by Electric Utility Companies

Development of Smart Energy Management Systems

Market Drivers:

High Demands for Efficient Electricity and High-Speed Internets

Growing the Transmission and Distribution Channel

Market Opportunities:

Increasing R&D Investments for Strengthening Infrastructures

Optical Ground Wire Market Competitive Analysis:Know your current market situation! Not just new products but ongoing products are also essential to analyze due to ever-changing market dynamics. The study allows marketers to understand consumer trends and segment analysis where they can face a rapid market share drop. Figure out who really the competition is in the marketplace, get to know market share analysis, market position, % Market Share, and segmented revenue.

Have a question? Market an enquiry before purchase @ https://www.htfmarketintelligence.com/enquiry-before-buy/global-optical-ground-wire-market

Players Included in Research Coverage: Fujikura, ZTT, Tongguang Cable, Shenzhen SDG, Furukawa, LS Cable, Taihan, Sichuan Huiyuan, Elsewedy Cables, Tratos, J-Power Systems

Additionally, Past Optical Ground Wire Market data breakdown, Market Entropy to understand development activity and Patent Analysis*, Competitors Swot Analysis, Product Specifications, and Peer Group Analysis including financial metrics are covered.

Segmentation and Targeting:

Essential demographic, geographic, psychographic, and behavioral information about business segments in the Optical Ground Wire market is targeted to aid in determining the features the company should encompass in order to fit into the business's requirements. For the Consumer-based market - the study is also classified with Market Maker information in order to understand better who the clients are, their buying behavior, and patterns.

Optical Ground WireProduct Types In-Depth: CMOS Image Sensors, EM-CCD Image Sensors, CCD Image Sensors

Optical Ground Wire Major Applications/End users: Central Tube Structure, Layer Stranding Structure

Optical Ground Wire Major Geographical First Level Segmentation:

• APAC (Japan, China, South Korea, Australia, India, and the Rest of APAC; the Rest of APAC is further segmented into Malaysia, Singapore, Indonesia, Thailand, New Zealand, Vietnam, and Sri Lanka)

• Europe (Germany, UK, France, Spain, Italy, Russia, Rest of Europe; Rest of Europe is further segmented into Belgium, Denmark, Austria, Norway, Sweden, The Netherlands, Poland, Czech Republic, Slovakia, Hungary, and Romania)

• North America (U.S., Canada, and Mexico)

• South America (Brazil, Chile, Argentina, Rest of South America)

• MEA (Saudi Arabia, UAE, South Africa)

Buy Now Latest Edition of Optical Ground Wire Market Report 👉 https://www.htfmarketintelligence.com/buy-now?format=3&report=1993

0 notes

Text

Future of stacked car parking: Smart solutions for smart cities

The evolution and future trends of stacked car parking systems is powered by the increase in the rise of automobiles on city streets. According to a recent report, smart car parking systems market in Indian smart cities is expected to leapfrog at a CAGR of 11.6% between 2023 and 2029.

Market Drivers

With the rise in the numbers of cars in each house, people face a serious parking space crisis in smart cities. Cars are usually left parked for most of the time, at home, office or on the street. The adoption of smart car parking systems, especially tower parking and puzzle car parking systems in smart cities, is growing in tandem with advancement in wireless and digital payment technologies.

A smart stack car parking system negates the need for human intervention to assist in finding a parking spot and collect tickets. Wireless, sensor-based tech, real-time data acquisition, dynamic messaging, and parking sensors make stack car parking simple and save time spent waiting for a place to park.

The increasing trend of smart city automation has boosted the reliance on smart parking solutions. Themarket is now rife withsmart meters, navigation systems, analytics solutions, and engineering services.

Stack car parking benefits

The very intent of automated stack parking is optimum space use. Automated Stack car parking systems are user-friendly solutions. The ‘green’ benefits of stack parking systems are reduced emissions, efficient resources use, and improved infrastructure quality.

Wohr the leader

Wohr is the industry buzz word in superior quality automated stacked car parking systems in India and Germany. Withinventiveness and ingenuity, Wohr has revolutionised automated stack parking with its disruptive technology and changed the rules of the game. With over 1,50,000 successful installations in India, Wohr is clearly the leader in smart automated car parking systems. Wohr’s Parklift automated stacked car parking system series (411/413/421/440/443) is the preferred set of solutions for stack car parking. They are cutting-edgetechnology-driven and offer decreased maintenance & operating costs and prevent damage and theft.

Wohr’s Parklift series automated stack car parking systems offer:

Enhanced operation: High operating and functional safety (according to EN norms)

Carrying capacity: Bears vehicle weight from 2,000 Kg to 2,600 kg

Space: Up to three parking levels to conserve space

Maintenance: Low maintenance costs

Independent parking: No need to remove the car below to remove upper one.

Applications

Wohr automated smart stack car parking systems are the go-to choose for workplaces, malls, schools, hospitals, residential complexes, and other public places that people visit. Other added features of Wohr’s Parklift smart car parking series are:

Versatility: Indoor and outdoor installation

Durable: Low wear, proven hydraulic technology

Cost effective: Low maintenance & construction costs.

Space saving: Occupies lesser floor space.

Resource use: Doubles parking spaces through vertical stacking

Wide range

Besides providing standard stack car parking systems, Wohr also uses its expertise and domain knowledge to design and deploy innovative fully automatic stack car parking products like Combilift, Parksafe, Multiparker and Levelparker. Our astounding range of smart car parking products have made us the number one supplier of automated smart car parking systems.

Conclusion

Wohr Parking Systems Pvt. Ltd. (WPS) is a collaboration between WÖHR Autoparksysteme GmbH formerly known as Otto Wohr GmbH, Germany - a leading manufacturer of automated car parking systems in Europe, -and Vyas Group, India, a diversified company involved in engineering, software, hospitality, and construction.

Our smart car parking solutions are designed and produced at our state-of-the-art manufacturing facility in Pune. We fetch globally acclaimed technology to customize solutions for India.

We possess experience working with architects and property developers. We have a superb track record and have brought unmatched innovation into car parking spaces in the last decade. We export to over 60 countries.

If smart automatic car parking systems are your need, then please pay heed! We will deliver quality products, in time to make parking experiences a delight.

#automated car parking system#puzzle car parking system#car parking systems#automatic car parking system#multilevel car parking#car parking

0 notes

Text

2024's Bearing Brilliance: Navigating the Technological Advances Transforming North America's Industries

The North America Bearings Market is gearing up for dynamic growth in 2024, playing a crucial role in various industries where precision, efficiency, and reliability are paramount. As technological advancements and industrial developments continue to shape the landscape, the bearings market in North America is poised for a transformative journey. This article explores the key trends, innovations, and factors contributing to the flourishing bearings market in the region.

Expanding Industrial Applications:

In 2024, the North America Bearings Market is experiencing increased demand across a broad spectrum of industries. From automotive and aerospace to energy, manufacturing, and robotics, bearings serve as essential components, providing support, reducing friction, and enabling smooth rotational motion. The market's expansion is intricately linked to the growth and diversification of industrial applications.

Technological Advancements in Materials and Design:

Technological advancements are reshaping the bearings market, with a focus on enhancing performance, durability, and efficiency. Innovations in materials, including ceramic and composite bearings, are contributing to improved wear resistance and longevity. Additionally, advancements in bearing design, lubrication systems, and sealing technologies are driving enhanced reliability in various operating conditions.

Rising Demand for Electric and Autonomous Vehicles:

The automotive sector, a significant consumer of bearings, is undergoing a paradigm shift with the rise of electric and autonomous vehicles. In 2024, the North America Bearings Market is witnessing increased demand for bearings designed to meet the specific requirements of electric drivetrains and advanced suspension systems. As the automotive industry evolves, bearings play a pivotal role in supporting the efficiency and reliability of these innovative vehicle technologies.

Focus on Sustainability and Energy Efficiency:

Sustainability is a growing concern across industries, and the bearings market is aligning with this trend. Manufacturers are developing bearings with a focus on energy efficiency, reducing friction, and minimizing environmental impact. The adoption of eco-friendly lubricants and the exploration of recycling and remanufacturing practices contribute to a more sustainable bearings market in North America.

Digitalization and Industry 4.0 Integration:

The integration of digital technologies and Industry 4.0 concepts is influencing the bearings market landscape. Smart bearings with sensors and connectivity capabilities are gaining traction, allowing for real-time monitoring of bearing health, performance, and predictive maintenance. This digitalization trend enhances overall system efficiency and reduces downtime, contributing to increased demand for intelligent bearing solutions.

Market Consolidation and Strategic Alliances:

In 2024, the North America Bearings Market is witnessing a trend of market consolidation and strategic alliances among key players. Mergers and acquisitions, collaborations, and partnerships are reshaping the competitive landscape, fostering innovation, and enabling companies to offer comprehensive solutions to meet the diverse needs of end-users.

Challenges and Opportunities:

Challenges facing the North America Bearings Market include the impact of economic uncertainties, fluctuations in raw material prices, and the need for continuous innovation to stay competitive. However, these challenges present opportunities for companies to invest in research and development, explore new markets, and leverage digital technologies to create cutting-edge bearing solutions.

For More Info@ https://www.gmiresearch.com/report/north-america-bearings-market-analysis-industry-research/

Conclusion:

As we navigate through 2024, the North America Bearings Market stands at the crossroads of innovation and industry evolution. From traditional industrial applications to emerging technologies, bearings continue to play a pivotal role in facilitating smooth, reliable, and efficient mechanical motion. The coming years hold promise for a bearings market that not only meets the demands of today's industries but also embraces technological advancements to shape a more connected, sustainable, and resilient future.

0 notes

Text

Sealed for Success: Exploring Growth Avenues in the Bearing Isolators Market

The bearing isolators market is on an upward trajectory driven by the surging demand for isolator solutions. Bearing isolators, characterized by their non-contact, wear-free, and permanent design, serve as essential protective devices for bearings. Operating as a cohesive unit, the rotor and stator remain connected during equipment operation, ensuring the prevention of separation.

Request Sample PDF of this report : https://www.alliedmarketresearch.com/request-toc-and-sample/12448

This ingenious mechanism involves the stator being pressed into the bearing seat, effectively engaging with the rotating shaft. Together, these components collaborate to safeguard bearings from contamination, effectively excluding grease and impurities. Unlike traditional methods, bearing isolators operate without requiring lubrication or a finished shaft. Predominantly crafted from bronze, these isolators leverage a vapor barrier function, facilitating unhindered transmission of vapor contaminants when the system is in motion. This innovation supersedes past measures like lip seals and mechanical seals, which were previously utilized to safeguard bearings in industrial systems but were often temporary and inconsistent in protecting heavy-duty equipment.

Get a Customized Research Report @ https://www.alliedmarketresearch.com/request-for-customization/12448

Exploring Market Dynamics and Structure

The expansion of bearing isolator production is extending beyond projected timelines, driven by the widespread recognition of the product's merits. Its burgeoning popularity spans industries such as oil & gas, manufacturing & processing, mining, pulp & paper, and chemical treatment.

Navigating the COVID-19 Impact

Since its emergence in early 2020, the global spread of COVID-19 has had far-reaching consequences. The disease has impacted millions and prompted significant economic disruptions, leading to bans and operational halts across major economies. Both life support and bearing isolator industries faced substantial setbacks. Nevertheless, gradual recovery is being achieved worldwide through the strategic integration of technology. As the pandemic endures, bearing isolator market players are working to mitigate the decline and are focused on restoring regular operations.

Influential Factors Shaping the Market

Rapid industrialization is poised to propel profitable market growth in the forthcoming years. The anticipated upswing in lubricant demand is expected to drive the need for bearing isolators. These innovative solutions play a pivotal role in minimizing downtime and replacement costs, further fueling demand. Moreover, the surge in demand for protection against machine rust is predicted to drive bearing isolator production. However, factors like escalating speed sensor costs and product price fluctuations are hindrances to market expansion.

Emerging Trends in the Market

The market is witnessing a flurry of new product launches, a strategy embraced by bearing isolator companies to enhance their offerings. Modern bearing isolators efficiently collect grease splashes within their labyrinth components. The Asia-Pacific region's industrialization surge is poised to bolster the bearing isolator market in the near future. The appeal of bearing isolators is magnified by their extended lifespan and cost-effectiveness compared to traditional lip and mechanical seals. These factors collectively contribute to the market's growth. The indispensable role of industrialization globally, coupled with the demand for machine lubricants, positions bearing isolators as a pivotal component in the lubrication process, further driving market expansion. Furthermore, the introduction of high-speed, high-precision, and high-torque bearing isolators creates exciting opportunities for major players in this arena.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/12448

Key Report Highlights

Bearing Isolators Market Snapshot

Material Types

End User Industries

Regions Covered

0 notes

Text

Enhancing Efficiency and Reliability A Comprehensive Guide to Industrial Equipment and Spares

In the fast-paced world of industrial operations, the backbone of success lies in the efficient and reliable functioning of equipment and machinery. Industrial sectors, ranging from manufacturing and construction to energy and logistics, heavily depend on a diverse array of equipment and spare parts to ensure seamless operations. This article aims to shed light on the significance of industrial equipment and spares, emphasizing their role in optimizing productivity, minimizing downtime, and ultimately contributing to the success of industrial enterprises.

The Importance of Quality Industrial Equipment:

Enhanced Productivity: High-quality industrial equipment is designed to streamline processes and boost overall productivity. Whether it's cutting-edge manufacturing machinery, precision tools, or automated systems, investing in top-notch equipment can significantly increase output and efficiency.

Operational Safety: Safety is paramount in any industrial setting. Modern industrial equipment is engineered with advanced safety features to protect workers and prevent accidents. From intelligent sensors to emergency shut-off mechanisms, these features contribute to a safer working environment.

Cost Efficiency: While the initial investment in quality industrial equipment may seem significant, the long-term cost benefits often outweigh the upfront expenses. Reliable machinery tends to require fewer repairs and has a longer lifespan, resulting in reduced maintenance costs and increased profitability over time.

The Role of Industrial Spares:

Minimizing Downtime: Unplanned downtime can be a significant detriment to industrial operations. Having a strategic inventory of spare parts enables quick replacements and repairs, minimizing the impact of unexpected equipment failures. This proactive approach helps to keep operations running smoothly.

Extended Equipment Lifespan: Regular wear and tear are inevitable in industrial settings. Timely replacement of worn-out components with genuine spare parts ensures the longevity of equipment. This not only extends the lifespan of machinery but also protects against costly breakdowns.

Adaptability and Flexibility: Industries are dynamic, and equipment requirements may change over time. Maintaining an inventory of versatile spare parts allows for quick adaptations and modifications to meet evolving operational needs. This flexibility is crucial for staying competitive in a rapidly changing market.

Procurement and Maintenance Strategies:

Strategic Sourcing: Collaborating with reputable suppliers and manufacturers is key to obtaining high-quality industrial equipment and spares. Establishing long-term partnerships ensures a reliable supply chain and access to genuine parts.

Regular Maintenance Programs: Preventive maintenance is essential for preserving the health of industrial equipment. Implementing regular inspection and maintenance schedules can identify potential issues before they escalate, reducing the risk of unexpected breakdowns.

Employee Training: Equipping personnel with the knowledge and skills to operate and maintain equipment properly is crucial. Training programs contribute to the overall efficiency and safety of industrial operations.

In conclusion, the success of industrial enterprises hinges on the seamless integration of high-quality equipment and an effective spare parts management system. By prioritizing the procurement of reliable machinery and maintaining a strategic inventory of spares, industries can enhance productivity, ensure operational safety, and adapt to the ever-changing demands of the market. Embracing a holistic approach to industrial equipment and spares is not just an investment; it's a commitment to sustained success in the competitive landscape of modern industry.

For more info :-

Linear Bearing SUPPLIER in UAE

industrial parts and equipment

Solenoid valve supplier in UAE

0 notes

Text

Sensor Baring Market size was valued at USD 6.62 billion in 2022 and is poised to grow at a significant CAGR of 5.5% from 2023-2029. Some of the key factors responsible for the market growth include rising demand from end user industries, growing adoption of IoT in bearing technology, high growth in emerging economies and technological advancements. Sensor bearings are semiconductor devices that are employed in a variety of automotive and material handling devices, and are positioned in small and difficult-to-reach areas of diverse machines where various environmental and mechanical conditions, such as temperature and vibration, must be detected.

Request Sample : https://www.precisionbusinessinsights.com/request-sample/?product_id=27699

#sensor bearing market size#sensor bearing market share#sensor bearing market growth#sensor bearing market trends#sensor bearing market dynamics

0 notes

Text

Predictive Maintenance Market 2023: Industry Sees Promising Growth by 2027

According to the report published by Allied Market Research, The Predictive Maintenance Market 2023: Industry Sees Promising Growth by 2027. The report provides an extensive analysis of changing market dynamics, major segments, value chain, competitive scenario, and regional landscape. This research offers valuable able guidance to leading players, investors, shareholders, and startups in devising strategies for sustainable growth and gaining a competitive edge in the market.

Increase in investment on predictive maintenance and surge in need to extend lifetime of aging assets drive the growth of the global predictive maintenance market. On the other hand, lack of skilled staff and several data privacy & security concerns impede the growth to some extent. However, integration of predictive maintenance with IIoT, use of machine learning, rise in the drift of real-time condition monitoring to assist in taking prompt actions, and increase in need for remote monitoring are expected to create lucrative opportunities in the industry.

Download Sample Report at: https://www.alliedmarketresearch.com/request-sample/2469

The global predictive maintenance market size was valued at USD 4,331.56 million in 2019, and is projected to reach USD 31,965.49 million by 2027, growing at a CAGR of 28.8% from 2020 to 2027.

The global predictive maintenance market is segmented on the basis of component, deployment, technique, stakeholder, industry vertical, and region. By component, it is bifurcated into solution and service. According to deployment, it is classified into cloud and on-premise. Further, by technique, it is divided into vibration monitoring, electrical testing, oil analysis, ultrasonic leak detectors, shock pulse, infrared, and others. By stakeholder, it is classified into MRO, OEM/ODM, and technology integrators. On the basis of industry vertical, it is classified into manufacturing, energy & utilities, aerospace & defense, transportation & logistics, government, and others. Region wise, it is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

Access the full summary at: https://www.alliedmarketresearch.com/predictive-maintenance-market

Based on component, the solution segment accounted for more than two-thirds of the global predictive maintenance market share in 2019 and is anticipated to retain its dominance by 2027. Companies are looking for all-inclusive development solutions which integrate hardware sensor board and software environment created precisely for predictive maintenance requirements, which drives the segment growth. The services segment, on the other hand, would register the fastest CAGR OF 31.4% from 2020 to 2027. This is attributed to the fact that companies are trying to achieve profit by implanting predictive analytics into their products and offering better maintenance services.

Based on technique, the vibration monitoring segment contributed to nearly one-fourth of the global predictive maintenance market revenue in 2019 and is projected to dominate by the end of 2027. The need for parts to be ordered more effectively increases the demand for this technique, thereby boosting the segment growth. Simultaneously, the shock pulse segment would manifest the fastest CAGR of 31.4% throughout the forecast period. Shock pulse technique specializes in defining precise information on the mechanical condition of the bearing surfaces along with the state of lubrication on the bearing. This factor drives the growth of the segment.

If you have any questions, Please feel free to contact our analyst at: https://www.alliedmarketresearch.com/connect-to-analyst/2469

Based on region, North America held the major share in 2019, garnering more than one-third of the global predictive maintenance market, owing to the presence of a large number of solution and service vendors in this region. At the same time, the market across Asia-Pacific would cite the fastest CAGR of 30.3% from 2020 to 2027, due to rapid industrialization in this province.

The key players operating in the global predictive maintenance market analysis include IBM Corporations; Microsoft; SAP SE; General Electric; Schneider Electric; Hitachi; PTC; Software AG; SAS; Engineering Consultants Group, Inc.; Expert Microsystems, Inc.; SparkCognition; C3.Ai; Uptake Technologies Inc.; Fiix Inc.; Operational Excellence (Opex) Group Ltd, TIBCO Software Inc.; Asystom; Reliability Solutions Sp. zo.o. and Sigma Industrial Precision.

Inquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/2469

Impact of Covid-19 on Predictive Maintenance Market:

Shortage of employees, disrupted supply chain, and increase in demand for various goods during the pandemic prompted organizations to take special care of their manufacturing equipment to escalate the output. This, in turn, led to a rise in demand for predictive maintenance solutions across the globe.

Many enterprises have started using smart sensors, artificial intelligence systems, and other IIoT solutions to keep a tab on the efficiency of vital machinery used in their

manufacturing procedure to evade costly production downtimes.

Buy Complete Report (428 Pages PDF with Insights, Charts, Tables, and Figures) at: https://www.alliedmarketresearch.com/predictive-maintenance-market/purchase-options

Thanks for reading this article you can also get individual chapter-wise sections or region-wise report versions like North America Europe or Asia.

If you have any special requirements, please let us know and we will offer you the report as per your requirements.

Lastly this report provides market intelligence most comprehensively. The report structure has been kept such that it offers maximum business value. It provides critical insights into the market dynamics and will enable strategic decision-making for the existing market players as well as those willing to enter the market.

About Us:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland Oregon. AMR provides global enterprises as well as medium and small businesses with unmatched quality of “Market Research Reports” and “Business Intelligence Solutions.” AMR has a targeted view to provide business insights and consulting to assist its clients in making strategic business decisions and achieving sustainable growth in their respective market domains.

AMR launched its user-based online library of reports and company profiles Avenue. An e-access library is accessible from any device anywhere and at any time for entrepreneur’s stakeholder’s researchers and students at universities. With reports on more than 60000 niche markets with data comprising of 600000 pages along with company profiles on more than 12000 firms, Avenue offers access to the entire repository of information through subscriptions. A hassle-free solution to clients’ requirements is complemented with analyst support and customization requests.

Contact:

David Correa

5933 NE Win Sivers Drive

#205 Portland OR 97220

United States

Toll-Free: 1–800–792–5285

UK: +44–845–528–1300

Hong Kong: +852–301–84916

India (Pune): +91–20–66346060

Fax: +1–855–550–5975

[email protected]

Web: https://www.alliedmarketresearch.com

Follow Us on LinkedIn and Twitter

0 notes

Text

Thermo Mechanically Treated bars Market Trends: Innovations and Future Outlook.

The construction industry is in a constant state of evolution, driven by technological advancements, changing regulations, and a growing emphasis on sustainability. One critical component in the construction world is Thermo Mechanically Treated (TMT) bars. These bars have come to be recognized as a cornerstone in building robust and resilient structures. In this article, we will delve into the dynamic landscape of the Thermo Mechanically Treated bars market, exploring recent innovations and forecasting the future trends that will shape this industry.

The Rise of Thermo Mechanically Treated bars

Traditionally, construction relied heavily on plain or mild steel bars. However, the vulnerabilities of these bars to corrosion and subpar structural performance in challenging conditions prompted a search for a better alternative. Enter Thermo Mechanically Treated bars. TMT bars are manufactured through a rigorous process that involves heat treatment and mechanical deformation. This process results in a product that exhibits superior strength, ductility, and corrosion resistance.

Recent Innovations in Thermo Mechanically Treated bars

Nano-Coating Technology: One of the recent innovations in the Thermo Mechanically Treated bars market is the application of Nano-coating technology. Manufacturers are employing nanotechnology to create protective coatings on Thermo Mechanically Treated bars, enhancing their corrosion resistance. These coatings are not only highly effective but also environmentally friendly.

High-Strength Thermo Mechanically Treated bars: Innovations in metallurgy have led to the development of high-strength Thermo Mechanically Treated bars. These bars offer increased load-bearing capacity, making them ideal for use in skyscrapers and other megastructures.

Earthquake-Resistant Thermo Mechanically Treated bars: With the increasing threat of seismic activity in various parts of the world, there is a growing demand for earthquake-resistant construction materials. Thermo Mechanically Treated bars manufacturers are responding by developing bars designed to withstand seismic forces, ensuring the safety of structures and their occupants.

Green Thermo Mechanically Treated bars: Sustainability is a top priority in today's construction industry. To address this, manufacturers are producing Thermo Mechanically Treated bars from recycled steel and adopting greener manufacturing processes. These bars not only reduce the carbon footprint of construction projects but also promote responsible resource management.

Smart Thermo Mechanically Treated bars: The concept of "smart" construction materials is gaining traction. Smart Thermo Mechanically Treated bars are embedded with sensors that can monitor structural integrity in real time. This innovation enhances safety by allowing for early detection of potential issues and preemptive maintenance.

Future Outlook for the Thermo Mechanically Treated bars Market

The Thermo Mechanically Treated bars market is poised for significant growth in the coming years. Several factors are contributing to this optimistic outlook:

Infrastructure Development Countries around the world are investing heavily in infrastructure development. Urbanization and population growth are driving the need for new roads, bridges, buildings, and other structures. TMT bars, with their superior properties, will play a pivotal role in ensuring the durability and longevity of these projects.

Sustainable Construction Practices

As awareness of environmental issues continues to rise, construction practices are shifting towards sustainability. Thermo Mechanically Treated bars made from recycled steel and eco-friendly manufacturing processes will find increasing favor in the market. Government regulations and incentives will further bolster the adoption of sustainable Thermo Mechanically Treated bars.

Technological Advancements

The integration of technology into the construction industry is unstoppable. This includes the use of Building Information Modeling (BIM) and other digital tools for efficient project management. TMT bars with embedded sensors will become an integral part of these smart construction processes, enhancing safety and reducing maintenance costs.

Resilience in the Face of Climate Change

Climate change is leading to more extreme weather events. Thermo Mechanically Treated bars designed to withstand harsh weather conditions will be in high demand. These bars will be used not only in coastal regions prone to hurricanes but also in areas with extreme temperatures, where traditional materials may fail.

Globalization of Construction

The globalization of construction projects is on the rise. Thermo Mechanically Treated bars, as a critical construction material, will be exported and used in diverse regions. This trend will drive standardization and quality control, ensuring that TMT bars meet international standards and certifications.

Research and Development

Investment in research and development by Thermo Mechanically Treated bars manufacturers will continue to yield innovations. These innovations will encompass not only material properties but also production processes, quality control, and logistics, making TMT bars more accessible and cost-effective.

In this dynamic landscape, research and development efforts will lead to breakthroughs in TMT bars technology, enhancing their structural performance, environmental sustainability, and affordability, further cementing their pivotal role in modern construction.

Conclusion

The Thermo Mechanically Treated bars market is evolving rapidly, driven by a confluence of factors, including technological advancements, sustainability imperatives, and global infrastructure development. Recent innovations such as Nano-coatings, high-strength bars, earthquake resistance, sustainability, and smart technology are reshaping the industry. Looking ahead, the future of Thermo Mechanically Treated bars appears promising, with continued growth and diversification. As construction practices evolve to meet the challenges of the 21st century, Thermo Mechanically Treated bars will remain a cornerstone in building safe, resilient, and sustainable structures around the world. It's clear that Thermo Mechanically Treated bars are not just steel; they are the backbone of modern construction, ensuring that our buildings and infrastructure can withstand the test of time and the challenges of an ever-changing world.

0 notes

Text

Function and Working Principles of Air Links

In the constantly evolving domain of vehicle suspension systems, the quest for the perfect balance between load support, ride comfort, and handling prowess has been a driving force behind innovation for decades. Amidst the array of suspension technologies on the market, one solution that has earned substantial recognition is the utilization of Air Links. These Air Links, also known as air suspension systems, bring a dynamic perspective to vehicle suspension, providing load support, adjustable suspension heights, and notable advancements in ride quality. In this context, it's worth noting that Sonico Air Links have been particularly prominent in delivering these cutting-edge suspension capabilities.

Load Support and Distribution

At the very core of any suspension system lies the fundamental responsibility of supporting the vehicle's weight and ensuring its equitable distribution across the wheels. This is paramount for upholding stability, optimizing handling, and curbing excessive tire wear. Traditional suspension systems, relying on leaf springs or coil springs, achieve load support through rigid mechanical components. In contrast, Sonico Air Links take an adaptive approach.

At the heart of a Link system are air bags or bellows, typically crafted from robust rubber or synthetic materials. These air bags take the place of conventional springs, assuming the pivotal role of load-bearing elements. The foundational principle here revolves around the utilization of compressed air to dynamically fine-tune the suspension's firmness and ride height.

When a vehicle equipped with Air Links bears a load, sophisticated sensors swiftly detect shifts in weight distribution and promptly recalibrate the air pressure within the air bags accordingly. This results in a leveling effect, ensuring that the vehicle consistently maintains a uniform ride height, regardless of the magnitude of the load it carries.

The load support and distribution capabilities of Sonico Air Links prove particularly advantageous in applications marked by substantial load fluctuations, such as those seen in commercial trucks and trailers. This dynamic response to changing loads not only enhances safety but also plays a pivotal role in promoting more even tire wear, ultimately leading to reduced maintenance costs.

Adjustable Suspension

A standout attribute of Air Links is their adaptable suspension. Sonico Air Links boast an exceptional adaptable suspension, offering versatility and catering to diverse driving conditions and preferences, presenting numerous benefits.

By manipulating the air pressure within the air bags, drivers gain the ability to modulate the vehicle's ride height. Lowering the air pressure results in a diminished vehicle height, culminating in improved aerodynamics and more refined handling characteristics—particularly beneficial during high-speed highway driving. Conversely, augmenting the air pressure elevates the vehicle, providing augmented ground clearance—an invaluable asset for ventures off the beaten path or when transporting substantial cargo.

This adjustability doesn't end at ride height. Air Links also facilitate the precise tuning of suspension stiffness. This empowers drivers to customize the ride quality in accordance with their personal preferences. If you yearn for a softer, more indulgent ride, a reduction in air pressure is the key. Conversely, elevating the air pressure renders the suspension more taut, thereby amplifying handling precision and overall stability.

Enhancement of Ride Quality

Arguably one of the most compelling reasons behind the burgeoning popularity of Air Links across various vehicle segments is their extraordinary ability to elevate ride quality. Traditional suspension systems, especially those reliant on rigid leaf springs, often transmit road imperfections directly to the vehicle's cabin, culminating in a disconcerting and uncomfortable ride.

Sonico Air Links, however, shine in their ability to mitigate these issues. The use of air as a medium for load support inherently introduces a degree of cushioning. When the vehicle encounters bumps, potholes, or uneven terrain, the compressed air within the air bags acts as an adept buffer, skillfully absorbing and diffusing the energy of the impact before it can reach the vehicle's occupants.

Furthermore, the adjustable suspension feature ushers in the opportunity to precisely tailor ride comfort. Whether navigating through a cityscape fraught with potholes or cruising along a pristine highway, you have the liberty to fine-tune the suspension settings to harmonize with the prevailing road conditions and your individual preferences. This translates into a more gratifying and less fatiguing driving experience, especially during extended journeys.

The profound influence of an improved ride quality transcends mere comfort; it extends to the realm of safety. A smoother ride significantly enhances driver control, effectively mitigating driver fatigue, and ultimately contributing to a safer motoring environment for all.

Conclusion

Sonico Air Links have ushered in a revolution in the domain of vehicle suspension systems, offering load support, adjustable suspension, and ride quality enhancement within a singular, Sonico-branded package. These systems harness the power of compressed Sonico air to dynamically fine-tune suspension stiffness and ride height, rendering them adaptable to a myriad of driving conditions and load scenarios. Whether tasked with the transportation of substantial cargo, traversing challenging off-road terrain, or simply seeking an exceptionally smooth ride, Sonico Air Links consistently deliver on their promises, positioning them as a compelling choice across a broad spectrum of vehicles.

0 notes

Text

4 Things To Look For in High-Quality Welding Filters

Welding filters protect your eyes, nose, and entire face from the dangerous fumes and sparks of welding. Investing in high-quality helmets ensures comfort, improved welding productivity, and provides top-tier protection. However, many fabricators might delay purchasing the best welding filters because of the many choices available in the market. Let us help you narrow your choices by looking for these four important welding filter characteristics.

Single Fixed Shade or Variable Fixed Shade?

Standard welding helmets have passive lenses with a static UV-protective filter. Passive welding helmets may also include an infrared filter with a high shade level useful against high-ampere welding operations. Alternatively, variable, fixed shade helmets have auto-darkening filters that use sensors to detect high-ampere light welds might produce. These sensors ensure your eyes are fully protected, and you won't need to lift the helmet after welding.

Switching Speed

Lens switching speeds refer to the lens' response from natural to higher shades up to the 3rd or 4th level once sensors pick up the high ampere light level. Switching speed has similar notations as cameras, such as 1:3,600 of a second or 1:25,000 of a second, indicating a fast switching time. If entry-level switching speeds make your eyes tired, consider investing in fast-response helmets.

Power Source

Welders can choose between battery or solar-powered welding helmets. Some welding helmets have battery and solar-power capabilities, but they can be much more expensive. Solar-powered helmets work well for outdoor welding operations in direct sunlight and hot weather. On the other hand, battery-powered welding helmets are helpful in indoor operations outside your fabrication plant or manufacturing facility.

Helmet Weight

It's tiring to face down and wear a heavy welding helmet, despite its protective benefits. Fortunately, many standard and variable welding helmets are lightweight and won't bear down your neck. Consider purchasing lightweight helmets if you're welding for hours on end throughout your shift.

Consider looking through Dynamic Filtration's selections of high-quality respiratory welding helmet filters or our customization service for your uniquely-sized welding air filter. Contact us today to get started.

0 notes

Text

Predictive Maintenance as a Service for Cement Industry: An Overview

These processes & machines need to occur in tandem, without intervals, to create high-quality cement. Unplanned downtime in even one of these machines can unleash havoc on the ongoing process, not just endangering efficiency & quality but also health & safety of personnel on-site.

The cement manufacturing industry is one of the oldest and most critical manufacturing industries for the global civilization. It has witnessed unparalleled growth at the heart of most economic developments and international growth this decade. Fortune Insights report says, the global cement market will grow from $326.80 billion in 2021 to $458.64 billion in 2028, a steep 5.1% globally. It is then no wonder that cement plants face pressure for process and asset maintenance.

CEMENT MANUFACTURING PROCESS & NEED FOR PREDICTIVE MAINTENANCE

Cement manufacturing is one of the most complex continuous manufacturing processes, with multiple ingredients & steps involved. Here is an overview of the entire process wrt machines used at each stage:

Predictive Maintenance checklist for cement industry:

Extractors: Used to Quarry the raw materials, i.e. limestone & clay

Crushers used to crush high rock piles into coarse powders called raw meal

Blenders & Mixers mix the crushed raw meal in the right proportions

Grinders to further grind the raw material to free different minerals in the ore

A rotary kiln where the raw meal is heated up to 1450 degrees & then cooled

Assembly belts & conveyors to carry the cement for packing & dispatching to customers

These processes & machines need to occur in tandem, without intervals, to create high-quality cement. Unplanned downtime in even one of these machines can unleash havoc on the ongoing process, not just endangering efficiency & quality but also health & safety of personnel on-site.

Common causes for machine downtime in a cement plant

Loose nuts, bolts, springs, plates, spring rods, flywheel, bearings, shaft, coupling housing, hammer rotor

Motor failure, Conveyor belt, breakage, bearing failure, stretching rod breakage, breakage of separator blade

Fan bearing breakage, fan unbalance

Gear knocking, gear tooth wear, gear deformation, gear spitting and spalling

Axle spindle breakage, crusher bearings failure, slip tape breakage

Disc liner shift

Rolling mill cracks, tubing failure, pump failure, spoke breakage

Grate plate breakage

Why asset maintenance in cement plants is a necessity?

Asset maintenance in cement plants is critical because:

Extensive repair & replacement costs

Chances of industrial safety hazards & accidents

Over maintenance of equipment, causes wear & tear

Harsh operating environment

Dynamic environment, needing proactive decision making

Enable remote monitoring & control for agility & resilience to

How can Predictive Maintenance as a Service help?

With the stakes so high and a constantly changing environment, real-time machine diagnostics are necessary to empower plant managers with the correct data. IIoT can enable this by enabling a 360-degree view of interconnected assets across the plant. Predictive maintenance as a service allows plant managers in cement managers to move away from reactive measures like reactive maintenance and preventive maintenance to a predictive one, where critical machines don’t have to be pulled down unless there is a specific anomaly.

At a grass root level, predictive maintenance as a service by IU for cement plants can be implemented by putting sensors at strategic positions on the machines. Vibration analysis of mechanical equipment components like Air Compressors, Belt drives or Conveyors, Fans and blowers, Kiln rollers, Motor bearings & Vertical and horizontal mills can help predict anomalies.