#slab formwork

Text

Concrete Slab Formwork Systems - Novaformworks

Concrete Slab formworks have various end uses such as column formworks, wall formwork, slab formwork, ore-designed culverts, etc. They can be used interchangeably across mediums. Owing to their modular design, and sustainability, they are used by various businesses in their construction projects.

0 notes

Text

Formwork planning is essential for any project success

One of the success factor of any project depends on the kind of Formwork System used. Whatever type of Construction project you begin, you will want the right kind of high-quality formwork. Concrete formwork can be pretty beneficial to your project for many reasons:

1. Management of capital

You will find it easier to deal with the overall building costs once you begin utilizing concrete formwork for your project. Investment in Formwork System is considered as an Asset and hence easily accountable when the total project is completed and when one transfers to other projects.

2. Human resources are crucial.

It completely depends on you whether you want to hire Skilled manpower or not as managing a formwork system is not a challenging task. If you are hiring them then it means that the investment pays off handsomely, and the experience is always fascinating and spectacular. Even if there are problems, you must avoid them entirely. At the end of the day, the result is fantastic, and that’s all that matters.

3. Quality

Finally, you must invest in anything that can assist you in taking your construction project to the next level. That’s why system formwork are so helpful since they always add a high level of quality to the Project. They are of different materials, and the price is always reasonable. Make sure to pick the best company to get a quality formwork system. Going forward, the companies who are experienced and familiar in using the system formwork will always have an edge over others in bagging the contract as the formwork importance is being noted by the developer as well.

4. Safety

System Formwork allows your workers to work more efficiently and effectively as it is much safer and easy to use. Very high standard of safety is considered while developing each component in the system formwork. When working on complicated structures and greater heights, safety is the top most factor considered. System formwork is the optimal solution for this.

5. Time management has improved.

As you can see, formwork is made to assist you to cut down on the time it takes to complete a project. Because any construction job is usually on a tight schedule, anything that saves time is crucial. That is why the formwork system shines since it provides you with the features and quality you require.

Yes, using a formwork system is critical for your business, and the benefits can be enormous. All you have to do now is figure out how to approach everything and incorporate it to the best of your skills. However, the outcomes can be incredible; all you have to do is know to use everything to obtain the most satisfactory results!

Want quality formwork for your next project? Worry less and get in touch with Navnirman now!

0 notes

Video

undefined

tumblr

U head jack for Scaffold - Manufacturing Video - Robot Welding - Wellmade China

#youtube#scaffolding#scaffold#wellmade#china#wellmade scaffold#u head#u head jacks#u head scaffolding#formwork scaffolding#shoring scaffold#formwork#slab formwork#slab shoring

0 notes

Text

Aluminum Slab Formwork/Early Stripping Formwork

Contact us for the catalog

#aluminumformwork

0 notes

Video

undefined

tumblr

Slab Formwork is a horizontal load-bearing structure that supports the form lining while also transferring forces to the shoring. If you are looking for the formwork for slab then you are at the right place. Nav Nirman is one of the top manufacturers and Supplies best quality formwork system suitable for all types of structures like Slab, Wall, etc. At here you can get the products at an affordable price. For more details visit our website.

0 notes

Text

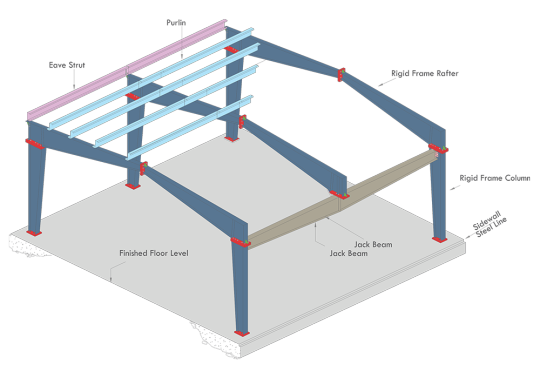

Smith Structure| Jack Beam Elevating Structural Support

Smith Structure introduces jack beams structural component used in construction for temporary or permanent support of floors, roofs, or load-bearing elements

#Jack Beam#Isometric Jack Beam at Sidewall#Isometric Jack Beam at Interior Column Location#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Link

At CivilGuidelines, we understand that the process of reinforced cement concrete (RCC) slab casting can be a challenging and complex process. That is why we have put together this brief guide to help you better understand the process and make informed decisions when selecting a contractor for your next project.

1. Preparing the Site

The first step in the RCC slab casting process is site preparation. The site must be levelled and compacted before the work can begin. This is to ensure that the foundation is strong enough to support the weight of the slab. In some cases, excavation may be necessary to remove any obstructions or to reach the desired depth for the foundation.

2. Building the Formwork

Once the site is prepared, the next step is to build the formwork. This is the frame that will hold the concrete in place while it sets. The formwork must be strong and secure, and it must be built to the precise dimensions of the slab. The formwork is typically made from wood, steel or aluminium.

3. Reinforcing the Slab

Before the concrete is poured, reinforcement bars are laid within the formwork. These bars are essential to the strength and durability of the slab. The bars are placed in a grid pattern and tied together to form a sturdy framework.

Read more

0 notes

Text

Ocarina is a minimal residence located in Carmen de Viboral, Colombia, designed by LCLA. The architectural choice to use the initial excavation as the formwork for the foundational slab presents a pragmatic approach to construction. By pouring the foundation directly onto the excavated clay, the design sidesteps the need for deep concrete foundations usually required due to seismic regulations.

26 notes

·

View notes

Text

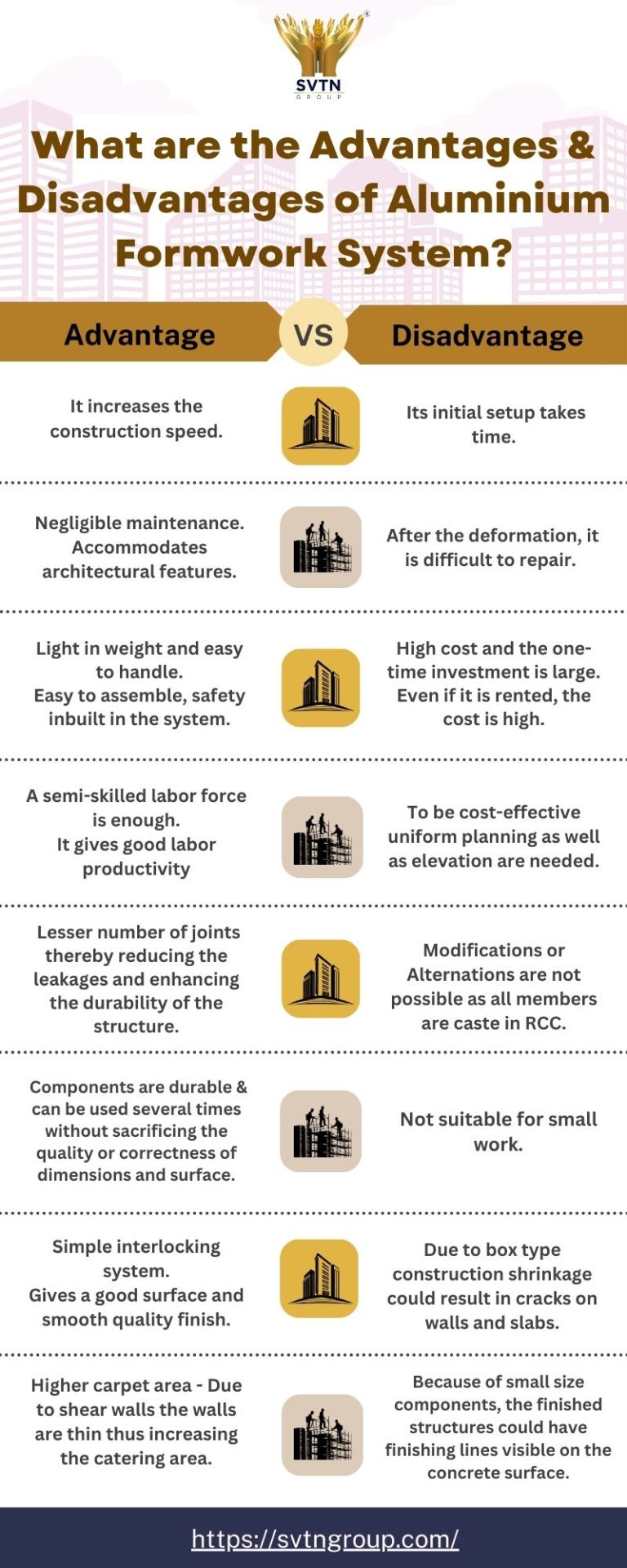

One of the most adaptable modern construction technologies is the Aluminum Formwork System, often known as Alu-Form Technology. It provides additional benefits and may be used for both high-rise and low-rise construction, unlike other methods. The speed factor of the Alu-Form system is its primary feature. All interior and external walls, beams, floor slabs, staircases, and other concrete building components can be cast quickly, precisely, and consistently with its help. This technique integrates plumbing and electrical fixtures more effectively into the overall building design.

#SVTN#aluform construction technology#alu form construction#aluform formwork#top contractors in pune#pune best construction company#best construction work company in pune#best construction company in pune#aluform construction#quality construction work#quality construction works#quality construction works llc#Affordable and Quality Construction Works#building contractors in pune#contractors in pune#civil contractors in pune#SVTN Group

3 notes

·

View notes

Text

Construction Technology

Buildings are constructed by SJ Contracts using modern technologies. Technology has made great progress in the building sector. In our construction company, the following new technologies are frequently used:

1.Building Information Modelling (BIM): BIM is a digital representation of a building's physical and functional characteristics. It allows architects, engineers, and contractors to collaborate effectively by creating a 3D model of the building. BIM facilitates better visualization, clash detection, and coordination among different disciplines, resulting in improved project efficiency and reduced errors.

2.Prefabrication and Modular Construction: Prefabrication involves constructing building components off-site in a controlled environment, while modular construction employs pre-built modules that are manufactured and assembled off-site. Both methods offer advantages such as faster construction time, reduced material waste, enhanced quality control, and improved site safety. Prefabrication and modular construction enable streamlined workflows and increased efficiency.

3.Virtual Reality (VR) and Augmented Reality (AR): VR and AR technologies enhance visualization and design review processes. VR creates immersive virtual environments, allowing stakeholders to experience the building design before construction begins. AR overlays digital information on physical spaces, aiding in tasks like on-site measurements, material placement, and clash detection. Both technologies improve communication, decision-making, and design coordination.

4.Formwork: Formwork is the temporary structure used to support the construction of concrete elements, such as walls, columns, and slabs, until they gain sufficient strength. SJ Contracts may employ modern formwork systems, such as modular or adjustable systems, to optimize efficiency and reduce labor time in concrete construction. These systems offer flexibility, ease of use, and reusability, leading to faster construction cycles.

By utilizing these technologies, SJ Contracts can achieve higher levels of efficiency, accuracy, and productivity in their construction projects. The adoption of BIM improves collaboration and reduces rework, while prefabrication, modular construction, and modern formwork techniques contribute to faster and more controlled construction processes. VR and AR technologies enhance design visualization and coordination, leading to improved project outcomes.

#SJcontracts #construction #constructioncompany #builders #buildingconstruction #enineering #constructionequipment

2 notes

·

View notes

Text

study log #2

today i woke up a little early so i could finish my cardio before 6am. and i actually did! wonder how long i could keep this up before i get bored.

i promised i was going to study for 8hrs today but i procrastinated right after i went home from my jog. anyway, i started by 9am. internet was shit, but i still managed to finish 2 lectures.

July 28, 2022

total hours: 6.5hrs

topics: placing concrete, curing, formworks(vert. and hor. wall form systems), joinery, cast-in place (slab on grade, suspended slab, other systems)

13 notes

·

View notes

Text

Exploring The Versatility Of Nova Plastic Formwork: Applications In Different Construction Projects

Formwork is a crucial component in the construction industry, shaping the structure and ensuring the strength and durability of concrete elements. While traditional materials like timber and steel have long been used, plastic formwork is gaining traction for its versatility, reusability, and ease of handling. In this blog, we explore the versatility of Nova Plastic Formwork and its applications in various construction projects, focusing on key areas such as column formwork, slab formwork, beam formwork, and wall formwork.

Understanding Plastic Formwork

Plastic formwork is a modern solution designed to address the limitations of traditional formwork materials. Made from high-quality plastic, it offers numerous advantages, including lightweight handling, durability, and reusability. Nova Plastic Formwork stands out in this category, providing robust and efficient formwork systems suitable for diverse construction needs.

Key Applications of Nova Plastic Formwork

Column Formwork

Columns are critical structural elements that transfer loads from beams and slabs to the foundation. Nova Plastic Column Formwork is designed to provide precise and smooth finishes, ensuring the structural integrity of columns.

Advantages:

Lightweight and easy to assemble.

Reusable multiple times, reducing overall costs.

Provides a smooth surface finish, reducing the need for additional plastering.

Slab Formwork

Slabs form the floors and ceilings in buildings, requiring formwork that can support the weight of wet concrete and construction loads. Nova Plastic Slab Formwork is ideal for creating flat, ribbed, or waffle slabs.

Advantages:

High load-bearing capacity.

Easy to handle and install, speeding up construction time.

Reusability and durability, making it a cost-effective solution.

Beam Formwork

Beams are horizontal structural elements that support loads from slabs and transfer them to columns or walls. Nova Plastic Beam Formwork ensures accurate dimensions and high-quality finishes for beams.

Advantages:

Provides excellent support and stability during concrete pouring.

Can be easily adjusted to different beam sizes.

Durable and reusable, reducing material waste.

Wall Formwork

Walls are essential for enclosing spaces and providing structural support. Nova Plastic Wall Formwork is designed to create strong, smooth, and perfectly aligned walls.

Advantages:

Lightweight and easy to set up, reducing labor costs.

Ensures uniform thickness and smooth surface finishes.

Highly reusable, making it an eco-friendly choice.

Conclusion

Nova Plastic Formwork is revolutionizing the construction industry with its versatility, durability, and ease of use. Whether it’s for residential, commercial, infrastructure, or industrial projects, Nova Formworks provides efficient solutions for column formwork, slab formwork, beam formwork, and wall formwork. By choosing Nova Plastic Formwork, you invest in a sustainable, cost-effective, and high-quality construction method that meets the demands of modern projects. For more information on Nova Plastic Formwork and its applications, visit www.novaformworks.com

#nova plastic formwork#construction formwork#column formwork#slab formwork#wall formwork#beam formwork

0 notes

Text

Innovations in Slab and Beam Formwork: What’s New in the Industry?

Introduction

In the world of construction, advancements in technology and materials are continually reshaping traditional practices. Slab and beam formwork, an integral part of the construction, has yet to be immune to this transformation. This article delves into the latest innovations and technologies in the slab and beam formwork industry, shedding light on the exciting developments that are changing the way we build.

The Importance of Slab and Beam Formwork

Slab and beam formwork are crucial components in constructing concrete floors and support structures. They serve as molds that shape these critical elements of a building, and their quality directly impacts the overall strength and aesthetics of the structure. With new innovations, the efficiency and effectiveness of formwork have greatly improved.

Traditional Formwork Methods

Traditionally, wooden formwork was the go-to choice for construction projects. While it served its purpose, it had limitations in terms of weight, reuse, and sustainability. These limitations led to the development of newer and more innovative formwork systems.

Advancements in Slab and Beam Formwork

Lightweight Formwork

Lightweight formwork materials, such as aluminum and steel, have become popular due to their ease of handling and reduced labor requirements. These materials are not only durable but also promote sustainability through reusability.

Modular Formwork Systems

Modular formwork systems are designed for easy assembly and disassembly, making them time-efficient and cost-effective. They can be customized to fit various project requirements, resulting in greater versatility.

Stay-in-Place Formwork

Stay-in-place formwork, often made of prefabricated materials, remains in the structure after the concrete has cured. This innovation reduces the need for removal and enhances the building’s durability.

Climbing Formwork

Climbing formwork is particularly useful for high-rise constructions. It allows formwork to move up the building as each section is completed, saving both time and labor costs.

Benefits of Innovative Formwork

Cost-Efficiency

The use of innovative formwork reduces labor costs and increases construction speed, ultimately saving money for the project.

Time Savings

Faster assembly and disassembly of formwork translate to shorter construction timelines, allowing for quicker project completion.

Sustainability

Innovative formwork materials and designs are more environmentally friendly due to reduced waste and increased reusability.

Technological Innovations

Digital Design and Planning

Digital tools and software aid in designing and planning formwork structures with precision. This technology minimizes errors and streamlines the construction process.

Automation and Robotics

Robotic systems have emerged to assist in formwork assembly, enhancing efficiency and reducing the need for extensive manual labor.

Challenges in Adopting New Formwork Technologies

While the benefits are clear, the construction industry faces challenges in adopting these new technologies, such as initial costs, training requirements, and resistance to change.

Case Studies

Several successful construction projects have implemented innovative formwork, demonstrating the practical advantages of these advancements.

Future Trends in Slab and Beam Formwork

The future of slab and beam formwork is poised for even more innovation. Expect to see further advancements in materials, automation, and sustainability.

FAQs

1. Are innovative formwork systems more expensive than traditional methods?

Innovative formwork may have higher upfront costs but often results in overall cost savings due to reduced labor and shorter project timelines.

2. Can innovative formwork be used for small-scale projects?

Yes, many innovative formwork systems are versatile and can be adapted to projects of various sizes.

3. How do I choose the right formwork system for my project?

The choice depends on project requirements, budget, and the specific benefits each formwork system offers.

4. What are the environmental benefits of using innovative formwork?

Innovative formwork systems promote sustainability through reduced waste and increased reusability of materials.

5. Are there any safety concerns associated with using new formwork technologies?

Safety is a priority in the construction industry, and new technologies are designed with safety measures in mind. Proper training and adherence to guidelines are essential for safe use.

0 notes

Text

Aluminum Slab Formwork/Early Stripping Formwork

0 notes

Text

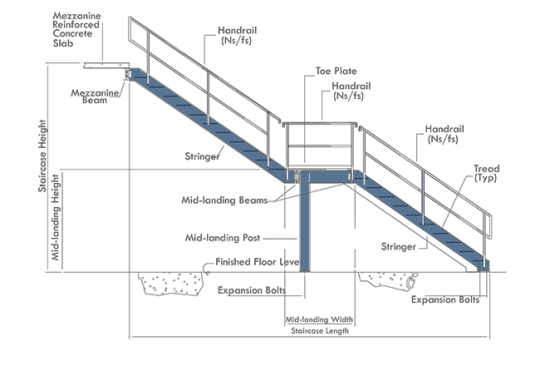

Smith Structure| Staircase Solutions Enhancing Accessibility

Smith Structure offers precision engineering & premium materials staircase solutions, focusing on safety, design,& quality to enhance architectural & functional

#Staircase#Single Flight Staircase#Single Flight Staircase with Mid Landing#Double Flight Staircase with Mid Landing#Double Flight Staircase#Roof Platform#Typical Root Platform#Section of Typical Root Platform#Mezzanine System#mezzanine framing system#steel deck support#mezzanine beams#Mezzanine Plan#steel formwork#oncrete slab construction#Mezzanine Cross Section#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

What is a Unique Tunnel Formwork Construction Technique?

Tunnel formwork is a formwork system that allows the contractor to pour walls and slabs in a single operation on a daily cycle. It blends on-site construction's adaptability and affordability with speed, quality, and precision. Construction time is significantly reduced with this fast system compared to conventional methods. Tunnel Form System brings speed, quality, and precision to concrete construction and provides big savings on M&E and finishing work.

Apartments for Sale in Chopda provide high-tech technologies for the production of steel formwork making tunnel formwork strong and durable. The system creates efficient load-bearing structures that are known as the most earthquake-resistant structures.

Where to Use Tunnel Shape

The crucial issue of sound transmission is perfectly solved by this method, which is extremely systematic and earthquake-tested. Gives a sound reduction of 50 decibels. The tunnel shape is widely used in the construction of cellular structures with a high degree of repetition such as:

Prisons

Hotels

Student accommodation (Hostels)

Private Homes

Commercial Developments

Which Restrictions Apply to the Tunnel Form Construction Method?

Fast construction demands high cash flow.

In the case of some geometric shapes and angles, it is necessary to design a special formwork, which generates an additional cost for the project.

The initial investment in formwork and other machinery.

In the case of imported formwork, the completion of the plan is required 5 to 6 months in advance.

In the tunnel system, skilled labor is required compared to traditional systems.

The building design must be suitable for the system.

Advantages of the Tunnel Shape

The dimensional accuracy of the concrete structure allows the laying of partitions and the fixing of all other finishing materials, such as joinery, immediately after casting.

Tunnel Form is not suitable for small projects and projects that involve large variations in design

The folding prop provides clearance for stripping.

Composite wheel assemblies aid in precise form positioning and blackouts eliminate nailing.

It comes with integral work platforms and an edge protection system.

High seismic resistance due to monolithic construction of slabs and walls

Multiple rooms can be concreted, giving scheduling flexibility.

Installation of all utility lines in the shell reduces internal finishing work.

Tunnel formwork required less slab cycle time as construction became fast and reliable.

The box-type structure construction is safe against horizontal forces such as earthquakes and cyclones.

It guarantees the correct application and completion of the project by minimizing measurement errors during the production process.

Conclusion

Tunnel form is a formwork system that facilitates the emptying of walls and slabs in a single operation. It not only improves the accuracy of concrete construction but also helps create efficient load-bearing structures that are known to be earthquake resistant and can be used in a wide variety of applications. In addition, this technique helps to greatly save finishing costs.

#Flats in Chopda Jalgaon#Apartments for Sale in Chopda#2 BHK Flats Near Me#Ready Possession Flats Near Me#1 BHK Flats in Ambedkar Chowk Chopda#2 BHK Flats in Chopda Jalgaon for Sale

5 notes

·

View notes