#smart factory automation & control solutions

Explore tagged Tumblr posts

Video

youtube

Telescopic Sliding Gates | Automatic & Industrial Gate Systems by Secure...

#youtube#telescopic sliding gate#AutomaticGatesIndia#industrial sliding gates#SecureIndiaGates#AutomaticTelescopicGate#HeavyDutyGates#IndustrialGateAutomation#sliding gate system#automatic swing gate#SecurityGatesManufacturer#Automatic Gate Installation#Industrial Entrance Gates#Smart Gate Solutions#Automatic Gate for Factory#Motorized Gate Systems#Commercial Sliding Gate#Automatic Gate Supplier India#Gate Automation Ahmedabad#Entrance Control Solutions#Secure India Security Products#Automated Entry Gates#Perimeter Security Solutions

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

Top 10 Pneumatic Actuator Brands In 2025

The pneumatic actuator market continues to thrive in 2025, driven by advancements in automation and industrial efficiency. Based on comprehensive evaluations by CN10/CNPP research departments, which integrate big data analytics, AI-driven insights, and market performance metrics, here are the leading brands shaping the industry.

1. SMC (SMC Corporation)

Performance & Reliability: As a global leader since 1959, SMC delivers over 10,000 pneumatic components, including high-precision cylinders, valves, and F.R.L. units. Its products are renowned for durability, energy efficiency, and adaptability to extreme industrial conditions. Industry Applications: Widely used in automotive manufacturing, semiconductor production, and robotics, SMC’s actuators ensure seamless automation across 80+ countries. Its China-based facilities, established in 1994, serve as a primary global production hub.

2. FESTO (Festo AG & Co. KG)

Performance & Reliability: With nearly a century of expertise, Festo combines innovative engineering with IoT-enabled solutions. Its actuators emphasize precision control, low maintenance, and compatibility with smart factory ecosystems. Industry Applications: Festo dominates sectors like pharmaceuticals, food processing, and renewable energy, offering customized automation systems that enhance productivity and sustainability.

Other Notable Brands In The 2025 Rankings

While SMC and Festo lead the list, the following brands also excel in specific niches:

Brand A: Specializes in compact actuators for medical devices.

Brand B: Focuses on heavy-duty applications in construction machinery.

Brand C: Pioneers eco-friendly designs with reduced carbon footprints.

Key Trends Driving Market Growth

Smart Automation: Integration of AI and real-time monitoring in actuator systems.

Sustainability: Energy-efficient designs aligned with global decarbonization goals.

Customization: Tailored solutions for niche industries like aerospace and biotechnology.

This ranking underscores the critical role of innovation and adaptability in maintaining competitive advantage. Brands that prioritize R&D and cross-industry collaboration are poised to lead the next decade of pneumatic automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

2 notes

·

View notes

Text

Factory Management Software (F-VAPP) for Valves Maintenance & Manufacturing Factories and Workshops. 🖥 ------ Revolutionize your valve production and maintenance with F-VAPP—a comprehensive factory management software designed by industry experts who understand the specific needs of the valves manufacturing world. F-VAPP is not just a tool, it's a fully integrated solution that enhances every aspect of your factory’s operations. 📈 ------ Hosted securely on your internal server, F-VAPP provides role-based access for every department, ensuring seamless workflows. It’s more than just software—it’s a complete management system that knows how to prioritize and automate daily operations for each machine and section. F-VAPP deeply understands the intricate processes of valve manufacturing and maintenance, making sure every task is executed efficiently with priorities clearly in place. ---- Why F-VAPP? ---- 1- Tailor-made for the valves industry, considering every detail in production and maintenance. 2- Automated daily operations for machines and departments, prioritizing workflows for maximum efficiency. 3- Real-time production line monitoring and machine load management to optimize operations. 4- Full control over inventory management and cost automation for smart financial planning. 5- User-friendly yet powerful interface that’s simple to navigate and efficient for everyday use. 6- Comprehensive reporting tools for actionable insights and informed decision-making. 7- Streamlined processes through custom roles and permissions, helping you build a clear organizational chart and strong operational workflows. 8- Enhanced collaboration between departments, improving overall productivity and quality management. ---- With F-VAPP, your factory’s operations aren’t just managed—they’re optimized. From inventory control to production management, every function is fine-tuned for efficiency and performance. ---- Key Benefits: ---- 1- Boost productivity by ensuring smooth, prioritized workflows for machines and workers. 2- Gain real-time insights into machine performance, production schedules, and factory output. 3- Automate complex processes like costing, pricing, and inventory management. 4- Seamlessly integrate departments, improving quality control and production planning. 5- Build the perfect organizational structure with clear roles and responsibilities. 6- Generate detailed reports to guide smarter business decisions. ---- F-VAPP goes beyond software. It’s a full-scale factory management system built to meet the specific needs of the valves manufacturing and maintenance industry. Take your operations to the next level with a system designed by professionals, for professionals. 🛠

2 notes

·

View notes

Text

Innovative Trends in Residential Architecture in 2024

The landscape of residential architecture is evolving rapidly, driven by technological advancements, changing lifestyles, and a growing trend on sustainability and wellness. In this article, we'll explore some of the innovative trends shaping the future of residential architecture.

Sustainable Design: With increasing awareness of environmental issues, many sustainable design practices are becoming more prevalent in residential architecture. Architects are incorporating features such as passive heating and cooling, green roofs, rainwater harvesting systems, and solar panels to minimize the environmental impact of homes.

Smart Homes: Integrating innovative technology into residential design revolutionizes how we interact with our living spaces. From automated lighting and temperature control to voice-activated assistants and security systems, smart home technology enhances homeowners' convenience, efficiency, and security.

Flexible Spaces: How we live and work is changing, and residential architects are responding by designing homes with flexible, multifunctional spaces. Open floor plans, movable walls, and modular furniture allow homeowners to adapt their living spaces to suit their changing needs, whether for remote work, entertaining guests, or relaxing with family.

Biophilic Design: Biophilic design seeks to connect people with nature by incorporating natural elements into homes. In residential architecture, this trend manifests in indoor gardens, green walls, natural light, and views of the surrounding landscape, creating homes that promote health, well-being, and productivity.

Adaptive Reuse: As urbanization grows, there is a growing emphasis on adaptive reuse projects that repurpose existing structures for residential purposes. Old warehouses, factories, and office buildings are transformed into modern, stylish loft apartments, combining historical charm with contemporary amenities.

Net-Zero Energy Homes: With the increasing focus on energy efficiency and carbon neutrality, net-zero energy homes are emerging as a critical trend in residential architecture. These homes are designed to produce as much energy as they consume, typically through passive design strategies, renewable energy systems, and energy-efficient appliances.

Health and Wellness: In response to the COVID-19 pandemic and growing concerns about indoor air quality and sanitation, residential architects prioritize health and wellness features in home design. This includes incorporating air purification systems, home gyms, meditation rooms, and outdoor living spaces to promote physical and mental well-being.

Customization and Personalization: In an era of mass production and cookie-cutter homes, there is a growing demand for custom-designed residences that reflect their owners' unique tastes and lifestyles. An architectural design company embraces this trend by offering tailored design solutions to individual preferences, whether a minimalist modernist masterpiece or a cozy cottage retreat.

In conclusion, the future of residential architecture is brimming with innovation, including the evolution of cabinets in architectural design, sustainability, and a focus on enhancing homeowners' quality of life. By embracing these innovative trends, architects can create beautiful and functional homes that are sustainable, healthy, and adaptable to the needs of modern living.

2 notes

·

View notes

Text

Empowering Smart Industry with Switches & Transmitters

In the fast-paced world of industrial automation, accuracy, safety, and real-time communication are non-negotiable. At Dropship Automation Solutions, we supply the building blocks of modern factories—components that bridge mechanical systems with digital intelligence. In this blog, we explore two critical elements—Industrial Switches and Process Transmitters—that bring responsive control and precise monitoring into automated operations.

From detecting system events to transmitting live process data, these devices drive smarter workflows and safer environments.

1. Industrial Switches: Enabling Responsive Control

What Switches Do

Switches serve as the frontline control elements in automation systems. Whether mechanical or electronic, they detect changes in conditions (like position, pressure, or proximity) and initiate specific actions—triggering circuits, activating alarms, or halting operations.

Types & Industrial Use Cases

Types: Limit switches, proximity switches, pressure switches, float switches

Applications: Conveyor lines, safety doors, liquid level monitoring, machine positioning

Benefits: Quick signal response, rugged durability, fail-safe operation, simple integration

Why Switches Matter

Switches form the tactile interface between machinery and control logic. With rapid response times and mechanical robustness, they allow systems to react instantly to changes, preventing mechanical failures or safety breaches in real-time.

2. Process Transmitters: Delivering Data for Decision-Making

What Transmitters Do

Transmitters convert physical measurements (such as pressure, temperature, flow, or level) into standardized signals (like 4-20 mA or digital protocols) that control systems can understand. These are vital for real-time monitoring and advanced process control.

Transmitter Types & Industry Applications

Types: Pressure transmitters, temperature transmitters, level transmitters, flow transmitters

Applications: Oil and gas, chemical plants, water treatment, energy generation

Benefits: High-accuracy data, remote monitoring, predictive maintenance, regulatory compliance

Why Transmitters Matter

In data-driven automation, decisions rely on accurate measurements. Transmitters deliver precise, continuous feedback that allows operators and control systems to optimize processes, detect issues early, and maintain stable production quality.

Integrated Intelligence: How Switches & Transmitters Collaborate

Imagine an automated facility where:

Switches detect tank overflow or valve position and trigger alerts

Transmitters measure liquid pressure and send real-time data to the control system

Together, they automate decisions like stopping pumps or adjusting valves to maintain optimal conditions

This integration ensures that mechanical actions and digital data work in tandem, leading to smarter processes, reduced manual intervention, and safer operations.

Conclusion: Smarter Monitoring. Smarter Control.

As industrial systems grow in complexity, adopting intelligent components like industrial switches and transmitters is key to maintaining performance and safety. At Dropship Automation Solutions, we help manufacturers modernize with automation-ready components built for the demands of Industry 4.0.

✅ Ready to upgrade your control and monitoring systems? Let’s power the future of your plant with smarter devices.

📞 Contact: +1 (234) 288-1755 📧 Email: [email protected] 📍 Location: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

Why Your Business Needs IoT Software Development Services Today

The Internet of Things (IoT) has reshaped how businesses operate, communicate, and serve their customers. Whether it’s a smart factory, wearable tech, or connected vehicles, IoT is powering smarter and more efficient systems. That’s why IoT software development services are gaining momentum among enterprises and startups looking to gain a competitive edge.

These services involve building custom IoT solutions—from embedded software and data analytics platforms to mobile apps and cloud integrations—that help organizations collect, process, and analyze data from connected devices in real time.

What Are IoT Software Development Services?

IoT software development services encompass the end-to-end process of designing, developing, and deploying applications that control and manage IoT devices. These services ensure seamless communication between devices, cloud infrastructure, and end-user applications.

As outlined in A Complete Guide For IoT Software Development, this process includes everything from selecting the right hardware and protocols to designing APIs, dashboards, and mobile apps. Businesses benefit by gaining real-time insights, automation, and cost-efficiency through smart connectivity.

Whether you're in manufacturing, healthcare, agriculture, or logistics, implementing IoT can drastically improve operational workflows and decision-making processes.

Why Your Business Can’t Ignore IoT Anymore

In today’s digital-first economy, delaying digital transformation could cost you market relevance. With IoT software development services, businesses can optimize everything from energy use and supply chains to customer engagement and remote monitoring.

If you're planning to work with an IoT Software Development Company, it's important to focus on scalable, secure, and future-proof solutions. Such companies provide end-to-end development, including integration with existing systems and support for multiple device types and platforms.

A well-crafted IoT system not only enhances productivity but also opens new revenue streams through data-driven services and predictive maintenance.

Core Components of IoT Software Development

When developing an IoT solution, there are several key components involved:

IoT Devices & Sensors: Hardware that collects data.

Edge Computing: Real-time data processing at the device level.

Cloud Platforms: Data storage, analytics, and machine learning.

Mobile & Web Apps: User interfaces for monitoring and control.

Security: Data encryption and secure authentication protocols.

According to 10 Leading IoT Service Providers, companies offering IoT development often bundle these elements into comprehensive services, making deployment and scaling smoother and faster.

Real-World Applications Across Industries

The use cases of IoT software development services are vast and industry-specific:

Healthcare: Remote patient monitoring, smart devices.

Retail: Smart shelves, in-store analytics.

Manufacturing: Predictive maintenance, automated quality checks.

Agriculture: Soil monitoring, automated irrigation.

Logistics: Real-time tracking, route optimization.

By leveraging IoT Mobile App Development, businesses ensure constant connectivity and user-friendly control for field workers, managers, and consumers—all from a mobile device.

Book an appointment with our experts to explore how your organization can implement smart IoT solutions tailored to your industry needs.

Benefits of Investing in IoT Software Development

Choosing to invest in IoT software development services brings multiple business benefits:

Increased Efficiency: Automate manual processes.

Better Decision-Making: Access real-time data insights.

Cost Savings: Reduce operational and maintenance costs.

Enhanced User Experience: Offer smart, responsive products.

Competitive Advantage: Differentiate your business with innovation.

Working with Top IoT Development Companies ensures your IoT project benefits from industry best practices, secure architecture, and high performance.

How to Choose the Right IoT Development Partner

Selecting the right development partner is crucial. Look for a company that offers:

Proven experience in IoT projects.

Expertise in both hardware and software.

Scalable cloud infrastructure.

A strong focus on security.

Post-launch support and maintenance.

An experienced IoT Software Development Company will guide you from concept to deployment and beyond, helping you avoid common pitfalls and accelerate your time to market.

Challenges in IoT Software Development

Despite its advantages, developing IoT solutions can present challenges:

Data Security and Privacy: Safeguarding sensitive data.

Device Compatibility: Ensuring interoperability.

Connectivity Issues: Reliable network infrastructure is a must.

Regulatory Compliance: Meeting industry standards and legal requirements.

However, with expert IoT software development services, these hurdles can be overcome through proper planning, secure development practices, and comprehensive testing.

Future of IoT in Business

As 5G, AI, and edge computing technologies evolve, the future of IoT is brighter than ever. From smart cities and autonomous vehicles to intelligent homes and AI-powered robots, the scope for innovation is unlimited.

Partnering with a team that understands your business goals and the nuances of IoT technology—like the leaders listed in 10 Leading IoT Service Providers—can position your business for long-term success in a connected world.

Final Thoughts

In an increasingly connected digital landscape, IoT software development services are more than just a tech trend—they’re a business necessity. Whether you want to streamline operations, gather real-time insights, or create innovative customer experiences, IoT offers the tools to do it all.

Start by evaluating your needs, defining goals, and finding a partner that aligns with your vision. Whether you're exploring new opportunities or scaling an existing solution, now is the perfect time to embrace the power of IoT.

Book an appointment with our IoT consultants today and take the first step toward building smarter, connected solutions for your business.

0 notes

Text

Unlock Unrivaled Precision: The Power of Smart Gage Management Software

In today’s highly competitive manufacturing landscape, precision isn’t just an advantage — it’s a necessity. Every millimeter, every micron, contributes to product quality, operational efficiency, and ultimately, your bottom line. But how do you consistently achieve and maintain that level of precision? The answer lies in robust and intelligent Gage Management Software. At Smart Factory India, we understand the critical role accurate measurement plays in your success. That’s why we’re excited to delve into how our Gage Management Solution can transform your quality control processes, ensuring unparalleled accuracy and operational excellence.

Why is a Gage Management Solution So Important?

Imagine a scenario where a critical measurement tool is out of calibration, leading to faulty products and costly rework. Or perhaps you’re struggling to locate a specific gage, causing production delays. Without a centralized and efficient system, these scenarios are not just possibilities, but inevitable challenges.

A dedicated Gage Management Solution addresses these pain points head-on by:

Minimizing Errors: Ensuring all gages are calibrated and performing accurately, drastically reducing the risk of defective products.

Boosting Efficiency: Streamlining the management of your entire gage inventory, saving time and resources.

Ensuring Compliance: Providing a clear audit trail for all calibration activities, crucial for industry regulations and certifications.

Extending Gage Lifespan: Proactive maintenance scheduling based on usage and calibration history.

Reducing Costs: Preventing costly recalls, rework, and tool replacements due to inaccurate measurements.

Features of Smart Gage Management Solution

Our Smart Gage Management Solution is engineered with a comprehensive suite of features designed to empower your team and optimize your processes:

Centralized Gage Inventory: A single, easily accessible database for all your gages, including their location, status, and specifications.

Automated Calibration Scheduling & Alerts: Never miss a calibration again! The system automatically schedules and notifies you of upcoming calibration dates.

Comprehensive Calibration History: Detailed records of every calibration, including dates, results, and technicians, ensuring complete traceability.

Measurement Data Integration: Seamlessly integrate with your measuring devices to capture and analyze data directly within the system.

User Management & Access Control: Define roles and permissions to ensure data integrity and security.

Reporting & Analytics: Generate insightful reports on gage utilization, calibration trends, and performance, enabling data-driven decisions.

Multi-Location Support: Ideal for businesses with multiple facilities, ensuring consistent gage management across all sites.

Intuitive User Interface: Easy to learn and use, minimizing training time and maximizing adoption.

Key Benefits of Smart Gage Management

Implementing our Smart Gage Management Solution brings a multitude of tangible benefits to your organization:

Enhanced Product Quality: Consistent and accurate measurements lead to superior products and reduced defects.

Reduced Operational Costs: Minimize rework, scrap, and warranty claims, directly impacting your bottom line.

Improved Compliance: Effortlessly meet industry standards and regulatory requirements with comprehensive record-keeping.

Increased Efficiency: Streamline your calibration processes, reduce downtime, and optimize gage utilization.

Data-Driven Decision Making: Gain valuable insights into your measurement processes to identify areas for improvement.

Boosted Customer Satisfaction: Deliver high-quality products consistently, leading to happier customers and stronger brand reputation.

Greater Confidence in Measurements: Trust that your data is accurate and reliable, empowering your team to make informed decisions.

Conclusion:

In the pursuit of manufacturing excellence, precision is paramount. A robust and intelligent Gage Management Solution is no longer a luxury; it’s a strategic imperative. At Smart Factory India, our solution empowers you to take control of your measurement processes, ensuring unparalleled accuracy, efficiency, and compliance.

0 notes

Text

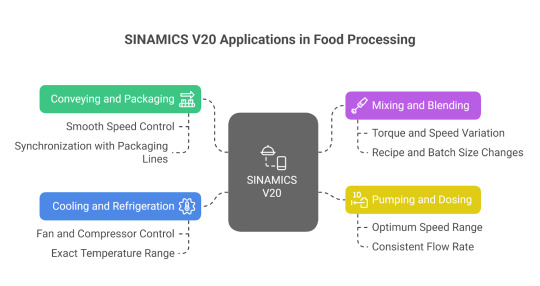

The Role of SINAMICS V20 in Smart Food Manufacturing

As Industry 4.0 evolves, food production is changing with new technologies. Companies are focusing on automation, efficiency, and sustainability. One of the main technology helping with this change is the SINAMICS V20, a Siemens drive that plays a big role in smart food manufacturing.

This blog explores the discussion on how the SINAMICS V20, a Siemens drive, is shaping food processing, packaging, and logistics, with Naksh Technology spearheading the implementation of these solutions.

SINAMICS V20: The Backbone of Basic Automation

The SINAMICS V20 is a small, cost-effective AC drive for the basic motion control application. Owing to its versatility and simplicity, it perfectly suits the food industry whose requirements vary from conveyor systems to mixers and pumps. With power ratings from 0.12 kW up to 30 kW, it helps execute tasks in the food processing line that demand smooth and energy-efficient operation.

Also learn more about How SINAMICS V20 Boosts Operational Flexibility In A Food Processing Plant.

Why Smart Food Manufacturing Needs Advanced Drives

Modern food manufacturing is all about precision and flexibility, apart from soaring speed. With consumer preference changes and ever-tightening regulations, manufacturers find themselves in a fast lane to quickly adapt to new recipes, packaging formats, and safety standards. Industrial automation powered by variable frequency drives (VFDs) such as the Siemens VFD V20 becomes essential.

Key Features of SINAMICS V20 in Food Manufacturing

Easy Installation and Commissioning: The SINAMICS V20 can be mounted either with push-through mounting or wall mounting, allowing for fast installation and side-by-side configuration to save on-floor space on crowded factory floors.

Energy Efficiency: It helps food manufacturers reduce their energy consumption by about 60%, a vital parameter for sustainable production, through automatic flux reduction and the ECO and hibernation modes.

Robustness and Reliability: With a unique cooling design, conformal-coated PCBs, and a vast voltage range, the drive is engineered to work within the rough environment of a food factory to minimize downtime and maintenance expenses.

Flexible Control Modes: The drive facilitates process enhancements through various control modes such as V/f, V2/f, FCC, and multi-point, according to differing machine requirements.

The Siemens Drive Advantage in Food Processing

Siemens drives are known for their integration and compatibility with automation systems. Siemens Sinamics family, including SINAMICS V20, is easily connected through PLCs, sensors, and cloud monitoring platforms. Such connectivity is important for smart food manufacturing, whereby it allows real-time process monitoring, predictive maintenance, and making decisions based on data.

Applications of SINAMICS V20 in Food Manufacturing

1. Conveying and Packaging

The movement of raw materials and finished goods must be smooth in food plants. SINAMICS V20 drives conveyors through smooth speed control to ensure the delicate products are gently handled and synchronized with packaging lines to reduce wastage and maximize throughput.

2. Mixing and Blending

Mixers and blenders require speed regulation with precision for the sake of consistent product quality. SINAMICS V20, therefore, supplies required torque and speed variation that is reactive to sudden recipe and batch size changes.

3. Pumping and Dosing

Dosing ingredients and fluids accurately forms the foundation of food production. The SINAMICS V20 ensures that the pumps are operating at speeds in the optimum range, thus saving energy and delivering a consistent flow rate for quality assurance.

4. Cooling and Refrigeration

Temperature maintenance is essential for food safety. The SINAMICS V20 controls the fans and compressors in a refrigeration system, ensuring minimum power consumption while maintaining an exact temperature range.

Naksh Technology: Your Partner in Smart Automation

Naksh Technology is leading provider of Siemens drive solutions with an area of expertise in the integration and support of SINAMICS V20 with food manufacturing plants. With the best knowledge in industrial automation, Naksh Technology guarantees trouble-free implementation together with design, up to after-sales service, enabling the food producers to realize the full power of Siemens VFD V20 and indeed of the entire Siemens Sinamics offering.

Benefits of SINAMICS V20 for Food Manufacturers

Cost Savings: The engineering, commissioning, and operational expenses are very low considering the drive's simplicity and efficiency.

Sustainability: Integrated energy-saving mechanisms support green manufacturing initiatives and set the path for global sustainability programs.

Scalability: SINAMICS V20 can be simply scaled onto any other production line whether small or big.

Future-Ready: With the digital connectivities, the drive is ready to integrate into the Industry 4.0 scenario for cloud-based analytics and remote monitoring.

Why Choose Siemens VFD V20 from Naksh Technology?

Naksh Technology, with its vast expertise in deploying SINAMICS V20, provides food manufacturers:

Tailored automation solutions for specific food industry challenges.

Reliable technical support and training for maintenance staff.

Access to the latest Siemens Sinamics innovations for continuous improvement.

Conclusion

The SINAMICS V20 acts as a green, smart, and efficient food manufacturer. As changes take place in the food industry, Naksh Technology and the Siemens drive solutions such as the Siemens VFD V20 stand for your operations, to keep them competitive, flexible, and future-ready. Go industrial in automation with Siemens Sinamics and change your food manufacturing journey. Contact us for more information!

0 notes

Text

Logic Buffer Market: Size, Share, and Trends 2025–2032

MARKET INSIGHTS

The global Logic Buffer Market size was valued at US$ 2,670 million in 2024 and is projected to reach US$ 4,780 million by 2032, at a CAGR of 8.73% during the forecast period 2025-2032.

Logic buffers are essential components in digital electronics that provide signal isolation and amplification between circuits. These devices maintain signal integrity by preventing loading effects, enabling clean signal transmission across different sections of electronic systems. Key product types include single-ended buffers and tri-state buffers, with the former segment projected to reach USD 850 million by 2032.

Market growth is driven by increasing demand from consumer electronics and automotive sectors, where logic buffers ensure reliable operation of complex circuit boards. The rising adoption of 5G technology and IoT devices further accelerates demand. Key players like Texas Instruments, NXP Semiconductors, and STMicroelectronics dominate the market, collectively holding over 45% revenue share in 2024 through advanced buffer solutions.

MARKET DYNAMICS

MARKET DRIVERS

Rapid Expansion of Consumer Electronics to Accelerate Logic Buffer Demand

The surge in global consumer electronics production is significantly boosting the logic buffer market. With smart devices becoming indispensable in daily life, manufacturers are integrating advanced semiconductor components to enhance performance. Consumer electronics shipments are projected to exceed 3 billion units annually by 2030, creating massive demand for signal conditioning components like logic buffers. These devices ensure signal integrity across increasingly complex circuit designs found in smartphones, tablets, and wearables. Recent innovations in 5G-enabled devices further amplify this need, as higher frequency operations require more robust signal buffering solutions.

Automotive Electronics Revolution to Fuel Market Growth

The automotive industry’s transformation toward electrification and autonomous driving is generating unprecedented demand for logic buffers. Modern vehicles now incorporate over 3,000 semiconductor components, with advanced driver-assistance systems (ADAS) accounting for nearly 30% of semiconductor content. Logic buffers play a critical role in managing sensor data processing and ECU communications in these systems. The automotive semiconductor market is growing at approximately 12% CAGR, directly benefiting buffer IC manufacturers. Furthermore, the transition to 48V architectures in electric vehicles presents new opportunities for high-voltage buffer solutions.

Industrial Automation Boom Drives Buffer Adoption

Industrial automation is undergoing rapid digital transformation, with the global smart factory market expected to surpass $1 trillion by 2030. Logic buffers are essential in industrial control systems, particularly in PLCs and motor drives where signal integrity is paramount. The growing adoption of Industry 4.0 technologies has increased deployment of high-speed data acquisition systems that rely on buffer ICs for noise immunity. Additionally, the rise of edge computing in manufacturing necessitates robust signal conditioning components at the network periphery, particularly in harsh industrial environments where electromagnetic interference is prevalent.

MARKET RESTRAINTS

Component Miniaturization Challenges Limit Design Flexibility

The relentless push for smaller form factors in electronics presents significant challenges for buffer IC implementation. As package sizes shrink below 01005 dimensions (0.4mm x 0.2mm), maintaining signal integrity while reducing footprint becomes increasingly difficult. Many buffer circuits require specific layout considerations that conflict with space constraints in modern designs. This technical hurdle is particularly acute in mobile applications where PCB real estate is severely limited. Furthermore, miniaturization often necessitates trade-offs in power handling capability, forcing designers to choose between size and performance.

Supply Chain Disruptions Impact Semiconductor Availability

The semiconductor industry continues to face supply-demand imbalances that affect logic buffer production. Lead times for certain buffer ICs have extended to 40+ weeks in recent years, disrupting product development cycles. While capacity expansions are underway, the capital-intensive nature of semiconductor manufacturing means shortages may persist in specialized segments. Automotive-grade buffer ICs face particular challenges as qualification processes limit alternative sourcing options. These supply constraints not only delay projects but also drive up component costs, particularly for low-volume specialty applications.

Design Complexity Increases Time-to-Market

Modern electronic systems require buffers with increasingly sophisticated features such as programmable drive strength and adaptive termination. Implementing these advanced functions while maintaining signal integrity adds significant design complexity. Many engineering teams lack the specialized expertise required to optimize buffer configurations for high-speed applications, leading to prolonged development cycles. The proliferation of different logic standards (LVCMOS, LVDS, HCSL) further complicates buffer selection and implementation, particularly in mixed-signal environments.

MARKET CHALLENGES

Thermal Management Constraints in High-Density Designs

As electronics packing densities increase, thermal management becomes a critical challenge for buffer IC implementations. Modern systems generate substantial Joule heating from simultaneous switching of numerous buffer outputs. Without proper thermal design, sustained operation at elevated temperatures can degrade signal integrity and reduce component lifespan. This issue is particularly acute in automotive and industrial applications where ambient temperatures may exceed 85°C. Designers must carefully analyze thermal resistance parameters and often incorporate additional cooling solutions, adding cost and complexity.

Other Challenges

Signal Integrity at Higher Frequencies The transition to faster data rates in serial communications requires buffers to maintain signal integrity above 10Gbps. At these frequencies, parasitic effects and transmission line characteristics dominate buffer performance. Achieving consistent edge rates while minimizing jitter becomes increasingly difficult, often requiring specialized IC processes and advanced packaging techniques. These technical demands significantly increase development costs for high-performance buffer solutions.

Power Consumption Optimization Low-power design requirements conflict with the need for robust signal driving capability in many applications. Designers must carefully balance buffer drive strength against power budgets, particularly in battery-operated devices. Advanced process nodes help reduce static power consumption, but dynamic power remains a challenge in high-speed applications where buffers toggle frequently. This power-performance trade-off is a persistent challenge across consumer, automotive, and industrial segments.

MARKET OPPORTUNITIES

Emerging AI Hardware Creates New Buffer Applications

The rapid development of AI accelerators and neuromorphic computing presents significant opportunities for advanced buffer solutions. AI hardware architectures require massive parallel signal distribution with precise timing characteristics, creating demand for specialized buffer arrays. Memory interfaces in these systems increasingly operate above 8Gbps, where traditional buffers struggle to meet timing requirements. Suppliers developing low-latency, high-fanout buffer solutions are well-positioned to capitalize on the AI semiconductor market, which is growing at over 35% annually.

Automotive Sensor Fusion Drives Buffer Innovation

Advanced automotive sensor suites incorporating radar, LiDAR, and camera systems require robust signal conditioning solutions. These multi-modal sensing platforms generate vast amounts of analog data that must be conditioned before analog-to-digital conversion. Buffer manufacturers developing specialized solutions for sensor interfaces can capture significant value in this high-growth segment. The automotive sensor market is projected to exceed $50 billion by 2030, with buffer ICs representing a critical enabling technology for next-generation ADAS implementations.

3D IC Packaging Creates Buffer Integration Opportunities

The shift toward 3D IC architectures and heterogeneous integration creates new possibilities for embedded buffer solutions. Through-silicon vias (TSVs) and other vertical interconnect technologies require specialized buffering to maintain signal quality across stacked dies. Suppliers developing buffer IP for 2.5D/3D implementations can establish strong positions in advanced packaging supply chains. The 3D IC market is expected to grow at 20% CAGR, driven by performance demands in high-performance computing and mobile applications where space constraints are particularly severe.

LOGIC BUFFER MARKET TRENDS

Expansion of High-Speed Data Transmission to Drive Logic Buffer Demand

The rapid expansion of high-speed data transmission networks, including 5G infrastructure and cloud computing, is significantly accelerating the adoption of logic buffers. These components play a critical role in signal integrity management across complex integrated circuits, ensuring reliable data transfer even in high-noise environments. With data traffic projected to grow at a compound annual growth rate of over 25% between 2024 and 2032, semiconductor manufacturers are increasingly incorporating advanced buffer solutions into their designs. Furthermore, the transition towards higher bandwidth interfaces like PCIe 6.0 and DDR5 memory standards is pushing buffer technology to operate at speeds exceeding 8 GHz while maintaining signal fidelity.

Other Trends

Automotive Electronics Revolution

The automotive industry’s electrification and autonomous driving trends are creating substantial demand for robust logic buffer solutions. Modern vehicles now incorporate over 150 electronic control units requiring precise signal conditioning between sensors, processors and actuators. Logic buffers with enhanced ESD protection and wide temperature range operation (-40°C to +125°C) are becoming essential for advanced driver assistance systems (ADAS) and infotainment platforms. This segment is expected to account for nearly 30% of the total logic buffer market by 2030 as vehicle architectures transition toward centralized domain controllers and zonal architectures.

Miniaturization and Power Efficiency Innovations

The relentless push for smaller form factors and lower power consumption in consumer electronics is driving significant innovations in buffer IC design. Semiconductor companies increasingly focus on developing buffers with sub-1V operating voltages and package sizes below 1mm² to accommodate space-constrained applications like wearables and IoT edge devices. Advanced buffer architectures now incorporate dynamic power scaling features that can reduce idle power consumption by up to 75% compared to traditional implementations. These developments align with increasing regulations on electronic device energy efficiency while meeting the performance requirements of next-generation mobile processors.

Industrial Automation Adoption

The global industrial automation wave is creating new opportunities for specialized buffers in harsh industrial environments. Factory automation systems require buffers with enhanced noise immunity and ruggedized packaging to withstand vibration, dust and electromagnetic interference. New industrial-grade buffer solutions featuring galvanic isolation and reinforced outputs capable of driving long cables (up to 30 meters) are gaining traction as smart factories expand. This application sector is projected to grow steadily at approximately 15% annually through 2032, supported by Industry 4.0 initiatives worldwide.

COMPETITIVE LANDSCAPE

Key Industry Players

Semiconductor Giants Compete Through Innovation and Strategic Expansion

The global Logic Buffer market features a dynamic competitive landscape with established semiconductor leaders dominating revenue shares while smaller players carve out specialized niches. Texas Instruments emerged as the market leader in 2024, commanding approximately 22% of global revenue share through its extensive product portfolio and strong foothold in industrial and automotive applications. The company’s leadership stems from continuous investments in high-performance buffer ICs and strategic partnerships with Tier-1 automotive suppliers.

NXP Semiconductors and STMicroelectronics collectively held nearly 30% market share, benefiting from their vertically integrated manufacturing capabilities and focus on energy-efficient buffer solutions. These companies are aggressively expanding their production capacities in Asia to capitalize on the region’s growing electronics manufacturing sector.

The market also witnessed notable consolidation activities, with onsemi acquiring two smaller buffer IC specialists in 2023 to strengthen its position in the industrial automation segment. Meanwhile, Toshiba and Renesas are leveraging their legacy in power management ICs to develop advanced buffer solutions for 5G infrastructure and IoT devices.

Emerging players like SGMICRO and Highland Technology are gaining traction through innovative product designs, particularly in space-constrained consumer electronics applications. These companies focus on delivering high-speed tri-state buffers with lower power consumption compared to industry standards.

List of Key Logic Buffer Manufacturers

Texas Instruments (U.S.)

NXP Semiconductors (Netherlands)

STMicroelectronics (Switzerland)

Diodes Incorporated (U.S.)

Nexperia (Netherlands)

onsemi (U.S.)

Toshiba Electronic Devices & Storage Corporation (Japan)

SGMICRO (China)

Highland Technology (U.S.)

Maxim Integrated (U.S.)

Renesas Electronics (Japan)

Segment Analysis:

By Type

Single-ended Buffer Leads the Market Due to Wider Adoption in Consumer Electronics and Industrial Applications

The market is segmented based on type into:

Single-ended Buffer

Subtypes: Non-inverting, Inverting, and others

Tri-state Buffer

Differential Buffer

Others

By Application

Consumer Electronics Segment Dominates Due to Increasing Demand in Smart Devices

The market is segmented based on application into:

Industrial

Consumer Electronics

Automotive

Others

By Voltage Level

Low Voltage Buffers Hold Significant Market Share Due to Energy Efficiency Requirements

The market is segmented based on voltage level into:

Low Voltage (Below 3.3V)

Medium Voltage (3.3V-5V)

High Voltage (Above 5V)

By Package Type

Surface Mount Packages Dominate Due to Miniaturization Trends in Electronics

The market is segmented based on package type into:

Surface Mount

Through Hole

Others

Regional Analysis: Logic Buffer Market

North America North America, particularly the U.S., dominates the logic buffer market due to high demand from the consumer electronics and automotive industries. The presence of key semiconductor players like Texas Instruments and Maxim Integrated, combined with strong R&D investments in advanced electronic components, drives innovation and adoption. The U.S. accounted for approximately 35% of the global market revenue in 2024, supported by robust manufacturing infrastructure and increasing smart device penetration. Canada and Mexico are also witnessing steady growth, fueled by cross-border supply chain integrations and rising automation needs in industrial applications.

Europe Europe maintains a strong position in the logic buffer market, with Germany and France leading in automotive and industrial adoption. Strict regulatory standards for electromagnetic compatibility (EMC) and energy efficiency encourage the use of high-performance buffers in automotive electronics and IoT devices. The region benefits from collaborative research initiatives and the presence of semiconductor giants like STMicroelectronics and NXP Semiconductors. However, supply chain disruptions and fluctuating raw material costs remain moderate challenges. The EU’s focus on digitization and Industry 4.0 further accelerates demand for precision signal buffering solutions.

Asia-Pacific Asia-Pacific is the fastest-growing market due to expansive electronics manufacturing hubs in China, Japan, and South Korea. China alone contributes nearly 40% of global production, driven by massive consumer electronics exports and domestic demand for automation. While cost-effective single-ended buffers dominate in price-sensitive markets like India and Southeast Asia, premium tri-state variants are gaining traction in Japan’s automotive sector. Regional players such as Toshiba and Renesas continue to expand production capacities, though competition from local manufacturers intensifies price pressures. Rapid urbanization and 5G infrastructure development present further growth opportunities.

South America The South American market remains niche, with Brazil and Argentina as primary adopters in automotive and industrial applications. Economic instability and reliance on imports constrain market expansion, but localized manufacturing initiatives are gradually improving supply chain resilience. Demand is primarily spurred by legacy system upgrades in industrial automation, though adoption of advanced logic buffers is slower compared to other regions. Limited domestic semiconductor expertise and infrastructure gaps hinder large-scale investments, but the region holds potential for long-term growth as technology penetration increases.

Middle East & Africa This region shows emerging potential, particularly in GCC countries like Saudi Arabia and the UAE, where smart city projects and industrial diversification efforts are underway. Israel’s thriving tech ecosystem also contributes to demand for high-performance logic buffers in defense and telecommunications. However, market maturity varies widely; African nations face challenges such as inconsistent power infrastructure and lower electronics manufacturing activity. Strategic partnerships with global suppliers and gradual digital transformation initiatives are expected to unlock growth opportunities over the next decade.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Logic Buffer markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments.

Segmentation Analysis: Detailed breakdown by product type (Single-ended Buffer, Tri-state Buffer), application (Industrial, Consumer Electronics, Automotive, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Diodes Incorporated, Nexperia, onsemi, Texas Instruments, and STMicroelectronics, covering product portfolios and strategic developments.

Technology Trends & Innovation: Assessment of emerging semiconductor technologies, integration with advanced electronics, and evolving industry standards.

Market Drivers & Restraints: Evaluation of factors driving market growth along with challenges like supply chain constraints and regulatory issues.

Stakeholder Analysis: Insights for component suppliers, OEMs, system integrators, and investors regarding market opportunities.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/inductive-proximity-switches-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cellular-iot-module-chipset-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/sine-wave-inverter-market-shifts-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pilot-air-control-valves-market-cost.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/video-multiplexer-market-role-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/semiconductor-packaging-capillary.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/screw-in-circuit-board-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wafer-carrier-tray-market-integration.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-display-potentiometer-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/glass-encapsulated-ntc-thermistor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/shafted-hall-effect-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/point-of-load-power-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/x-ray-grating-market-key-players-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/picmg-single-board-computer-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lighting-control-dimming-panel-market.html

0 notes

Text

M2500 Automatic Cigarette Making Machine – Precision and Performance at Its Best

The M2500 Automatic Cigarette Making Machine stands as a hallmark of engineering excellence and innovation in the tobacco industry. Designed for consistent output, low maintenance, and user-friendly operation, this machine is a game-changer for businesses looking to scale production with efficiency and precision. Whether you're starting a new venture or expanding your existing manufacturing line, the M2500 offers the perfect balance between technology and usability.

As one of the most reliable cigarette manufacturing machines in Iran, the M2500 caters to the demand for high-speed performance and top-tier quality. With robust construction and advanced control features, this machine ensures minimal downtime and superior production output, making it ideal for manufacturers focused on long-term performance and value.

Our M2500 machine has earned a solid reputation as the best cigarette making machine in Iran for businesses aiming for excellence. Engineered for speed and consistency, this machine meets international quality benchmarks and offers unmatched operational convenience. Its durable build ensures long service life, while its smart technology enables users to fine-tune every step of the cigarette production process.

With Budhan Engineering, you are not just investing in a machine—you are investing in a legacy of precision and trust. Our brand is globally recognized for supplying high quality cigarette machinery in Iran and beyond. The M2500 exemplifies our commitment to product reliability, operator safety, and innovative design. Every machine undergoes rigorous quality checks to ensure it meets the high standards our clients have come to expect.

Whether you are a seasoned player or a newcomer in the tobacco industry, the M2500 is designed to simplify your production process. Its integration capabilities, precision rollers, and adjustable settings make it one of the best cigarette making machines in Iran, capable of meeting varied production needs with ease.

At Budhan Engineering, we understand the importance of reliability and customer satisfaction. That's why our team offers full installation support, technical training, and after-sales service to ensure that your operations run smoothly from day one. When it comes to cigarette machinery in Iran, our name is synonymous with trust and superior quality.

The M2500’s automated features reduce labor costs, boost production, and improve uniformity in output. This makes it an ideal solution for factories aiming to maintain consistency without compromising on quality. As a leader in cigarette manufacturing machines in Iran, Budhan continues to push the boundaries of innovation and efficiency.

In conclusion, if you're looking to enhance your cigarette production capabilities, the M2500 is the ideal solution. With proven performance, advanced technology, and unmatched support, it stands out as the best cigarette making machine in Iran for all levels of manufacturers. Backed by Budhan’s expertise, you can be confident in choosing a machine that delivers reliability, efficiency, and superior results.

Conclusion

In today’s competitive tobacco industry, choosing the right equipment is critical. The M2500 is trusted for delivering high quality cigarette machinery in Iran that enhances efficiency and consistency. For businesses aiming to grow, investing in cigarette manufacturing machines in Iran like the M2500 ensures long-term value. As one of the best cigarette making machines in Iran, it supports both small and large-scale operations with reliability. Our commitment to innovation makes us a top provider of cigarette machinery in Iran, known for performance and durability. If you're seeking the best cigarette making machine in Iran, Budhan offers the ultimate solution. Upgrade your production line with our world-class technology and achieve excellence in every stick.

0 notes

Text

Hall-Effect Sensors Market Growth Analysis, Market Dynamics, Key Players and Innovations, Outlook and Forecast 2025-2032

The global Hall-Effect Sensors market size was valued at USD 1,664 million in 2024. The market is projected to grow from USD 1,728 million in 2025 to USD 2,226 million by 2032, exhibiting a CAGR of 3.9% during the forecast period.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/1881/hall-effect-sensors-2025-2032-257

Hall-effect sensors are transducers that detect magnetic fields by measuring the Hall voltage generated across a conductor when current flows through it. These sensors enable contactless measurement of position, speed, and current while offering high reliability and durability. Key variants include Hall position sensors, speed sensors, switches, and current sensors, which find extensive applications across automotive, consumer electronics, and industrial automation sectors.

The global Hall-Effect sensors market is gaining strong momentum as industries increasingly adopt magnetic field sensing technologies for precision, reliability, and non-contact measurement. These sensors, which detect the presence, strength, and direction of magnetic fields, are integral to a wide range of applications from automotive electronics and industrial automation to consumer electronics and medical devices. With the growing shift toward electrification, smart devices, and safety-critical systems, Hall-Effect sensors are being embedded into electric vehicles (EVs), robotics, and IoT-enabled platforms to enable accurate position, speed, and current sensing. As demand for energy-efficient and miniaturized sensor solutions accelerates, Hall-Effect technologies are emerging as a foundational element in next-generation electronics and automation ecosystems.

MARKET DYNAMICS

MARKET DRIVERS

Widespread Adoption in Electric Vehicles to Accelerate Hall-Effect Sensor Demand

The automotive industry's rapid transition toward electric vehicles (EVs) represents a pivotal growth driver for Hall-effect sensors. Modern EVs utilize between 50-100 position and speed sensors per vehicle for critical functions including motor control, pedal position sensing, and battery management. Electric car sales neared 14 million in 2023, 95% of which were in China, Europe and the United States, this creates substantial demand for reliable magnetic sensing solutions. Hall-effect technology is particularly favored in automotive applications due to its contactless operation, immunity to environmental contaminants, and ability to function in harsh conditions. Leading manufacturers are responding with specialized automotive-grade sensors featuring reinforced packaging and extended temperature ranges up to 150°C.

Industry 4.0 Advancements Fueling Industrial Automation Sensor Deployment

The rise of Industry 4.0 is transforming manufacturing landscapes by embedding intelligence, connectivity, and automation deep into production systems and Hall-Effect sensors are playing a vital role in this transformation. These sensors are increasingly deployed in industrial machinery to enable precise, real-time monitoring of motor rotation, conveyor belt movement, robotic joint positions, and current flow in automated lines.

One notable example is Siemens’ Digital Industries division, which integrates Hall-Effect sensors in its advanced motor control units and servo drives to enhance predictive maintenance and reduce downtime. Similarly, ABB and Fanuc utilize Hall-based position and proximity sensors in robotic arms to improve movement accuracy and operational safety.

Hall-Effect sensors are especially valued in industrial automation because they work without physical contact. This means there’s less mechanical wear and tear, which helps them last longer. Plus, they perform reliably even in tough factory conditions like dust, moisture, or constant vibration where traditional sensors might struggle.Moreover, the convergence of Industrial Internet of Things (IIoT) and digital twins is boosting demand for sensors that can feed continuous, real-time data into cloud-based monitoring systems. Hall-Effect sensors, when combined with edge computing and wireless protocols, are enabling smart machines to self-monitor, optimize energy consumption, and predict failures key pillars of a modern Industry 4.0 ecosystem.

For instance, in 2024, Rockwell Automation deployed Hall-Effect-based linear position sensors in its iTRAK intelligent track system, allowing manufacturers in the packaging and pharmaceutical sectors to achieve high-speed, precise product handling with minimal mechanical wear and real-time system diagnostics.

Miniaturization Trend in Consumer Electronics Creating New Application Frontiers

Consumer electronics manufacturers increasingly adopt Hall-effect sensors for novel applications requiring ultra-compact form factors. The global smartphone market alone consumes over 4 billion sensors annually, with Hall-effect ICs enabling key functions like flip cover detection, camera positioning, and button replacement. New generations of miniature sensors measuring below 1mm² combined with ultra-low power consumption (under 1μA) are enabling innovative designs in wearable devices and IoT products. The push for thinner devices and waterproof constructions favors Hall-effect technology over mechanical alternatives. Emerging applications such as contactless user interfaces and precision movement tracking in AR/VR devices present significant growth opportunities.

MARKET RESTRAINTS

Magnetic Interference Issues Limiting Adoption in Critical Applications

While Hall-effect sensors offer numerous benefits, their fundamental operating principle makes them susceptible to external magnetic interference. Stray magnetic fields from nearby electric motors or power lines can cause measurement errors exceeding 10% in some industrial environments. This limitation restricts their adoption in precision medical equipment and aerospace applications where measurement accuracy is critical. Development teams must incorporate shielding solutions or complex compensation algorithms, increasing system cost and complexity. The problem becomes particularly acute in compact electronics where physical separation from interference sources is impractical.

MARKET CHALLENGES

Intense Pricing Pressure from Alternative Technologies

The Hall-effect sensor market faces growing competition from emerging sensing technologies including anisotropic magnetoresistance (AMR) and giant magnetoresistance (GMR) solutions. While Hall-effect maintains advantages in cost-effectiveness for many applications, competing technologies increasingly offer higher sensitivity and better noise immunity. Manufacturers must balance performance improvements with aggressive cost reduction targets, particularly in price-sensitive consumer markets where sensor pricing has fallen 28% over the past five years. This environment creates significant profitability challenges, especially for smaller players lacking economies of scale.

MARKET OPPORTUNITIES

Emerging IoT and Smart Infrastructure Applications Present Growth Potential

The rapid expansion of IoT networks and smart city infrastructure creates substantial opportunities for innovative Hall-effect sensor implementations. Smart utility meters, building automation systems, and predictive maintenance solutions collectively represent a potential market of $820 million for magnetic sensing technologies. Emerging applications include tamper detection in smart meters, position monitoring in automated HVAC systems, and vibration sensing in structural health monitoring. The combination of ultra-low power Hall-effect ICs with energy harvesting techniques enables completely wireless installations, a critical requirement for many IoT deployments. Market leaders are developing specialized sensor nodes with integrated wireless connectivity to address these growing segments.

September, 2023, Melexis launched the MLX91230, a 3rd-generation open‑loop Hall-effect DC current sensor offering ±0.5 % accuracy over temperature and lifetime. It features integrated voltage and temperature sensing (IVT), embedded microcontroller, galvanic isolation, AEC‑Q100 Grade 1 and ASIL-D safety compliance ideal for EV battery systems and industrial control.

HALL-EFFECT SENSORS MARKET TRENDS

Adoption in Automotive Electrification to Drive Market Growth

The automotive sector is experiencing a seismic shift toward electrification and automation, significantly boosting demand for Hall-effect sensors. With electric vehicle production projected to reach over 26 million units annually by 2030, these sensors have become indispensable for critical functions like motor control, battery management, and throttle positioning. Modern EVs utilize an average of 15-20 Hall-effect sensors per vehicle, compared to just 5-8 in traditional combustion engines. Advanced driver-assistance systems (ADAS) further amplify this demand, requiring high-precision position and speed detection for features like automatic braking and lane keeping.

For example, Tesla, BYD, and Volkswagen integrate Hall-based current and position sensors into their battery management systems (BMS) and electric drivetrain components to optimize performance and ensure safe operation. Additionally, Tier-1 suppliers such as Bosch and Denso are actively developing automotive-grade Hall-Effect sensors for applications including torque sensing, steering angle detection, and inverter current monitoring.

Other Trends

Miniaturization in Consumer Electronics

The relentless push for smaller, smarter devices continues to reshape the industry. Smartphone manufacturers now integrate multiple Hall-effect sensors for features like flip-to-sleep functionality, while wearables leverage them for ultra-low-power position detection. Industry leaders are developing MEMS-based Hall sensors measuring under 0.5mm², enabling breakthrough applications in hearables and IoT devices. This trend aligns with the broader industry movement toward sensor fusion, where Hall-effect components increasingly combine with accelerometers and gyroscopes to deliver richer contextual awareness.

Industrial IoT and Smart Manufacturing Evolution

Industry 4.0 initiatives are driving widespread sensor deployment across factory automation systems. Hall-effect sensors play pivotal roles in condition monitoring, with predictive maintenance algorithms analyzing magnetic field patterns to forecast equipment failures. The industrial segment now accounts for over 35% of sensor deployments, particularly in motor-driven applications where contactless operation prevents mechanical wear. Recent advancements include self-calibrating sensors with ±0.1° angular accuracy for robotic arms, alongside high-temperature variants capable of withstanding 150°C environments in heavy machinery.

COMPETITIVE LANDSCAPE

Key Industry Players

Leading Companies Focus on Technological Advancements to Gain Competitive Edge

The global Hall-Effect Sensors market features a moderately consolidated competitive landscape, dominated by major semiconductor manufacturers and specialized sensor providers. Allegro MicroSystems currently leads the market with an estimated 22% revenue share in 2024, attributed to its comprehensive product portfolio covering automotive and industrial applications. The company's strong position stems from continuous innovation in high-performance current sensor ICs and position sensors.

Infineon Technologies and Texas Instruments follow closely, collectively accounting for approximately 30% of the market share. These companies benefit from their vertically integrated manufacturing capabilities and strong R&D investments in next-generation Hall-Effect solutions. Their ability to provide customized sensor solutions across multiple industries gives them a distinct competitive advantage.

Meanwhile, Melexis and NXP Semiconductors are focusing on miniaturization and energy efficiency to capture the growing demand from consumer electronics and IoT applications. Both companies have recently introduced ultra-low-power Hall-Effect sensors with integrated signal conditioning, addressing the need for battery-powered devices.

The market also features emerging players from Asia-Pacific such as Suzhou Novosense Microelectronics and Shanghai Orient-Chip Technology who are gaining traction through cost-effective solutions for domestic automotive and industrial automation markets. These companies are particularly strong in the mid-range sensor segment, competing through competitive pricing and localized support networks.

April, 2025, Diodes Incorporated launched the AH4930Q, a 3D linear Hall‑effect sensor delivering ultra‑low power (13 µA) operation, I²C interface, and triple‑axis sensing (X, Y, Z). AEC‑Q100 Grade‑1 qualified and equipped with on‑chip temperature compensation, it’s ideal for automotive interior controls like knobs, stalks, and selectors.

February, 2024, Allegro MicroSystems unveiled its new high-bandwidth Hall‑Effect current sensors (ACS37030/ACS37032) tailored for automotive and industrial power systems. These core‑less solutions offer ≈1 % accuracy, ultra-low noise, rapid response, and compact, AEC‑Q100-qualified packages, optimized for GaN/SiC inverters, EV drives, and clean-energy applications.

October, 2023, Allegro MicroSystems completed its acquisition of Crocus Technology for $420 million in cash, integrating high-performance TMR (Tunnel Magnetoresistance) sensor IP including 200+ patents into its automotive and industrial sensing portfolio, reinforcing its leadership in precision magnetic sensing.

List of Key Hall-Effect Sensor Companies Profiled

· Allegro MicroSystems (U.S.)

· Melexis (Belgium)

· Infineon Technologies (Germany)

· TDK Corporation (Japan)

· Asahi Kasei Microdevices (Japan)

· NXP Semiconductors (Netherlands)

· ams OSRAM (Austria)

· Texas Instruments (U.S.)

· Diodes Incorporated (U.S.)

· Suzhou Novosense Microelectronics (China)

· Honeywell (U.S.)

· TE Connectivity (Switzerland)

· Shanghai Orient-Chip Technology (China)

· MEMSIC Semiconductor (U.S.)

· Analog Devices (U.S.)

Segment Analysis:

By Type

The market is segmented based on type into:

· Linear Hall-Effect Sensor

· Threshold (Digital) Hall-Effect Sensor

· Bipolar Hall Sensors

· Unipolar Hall Sensors

· Omnipolar Hall Sensors

By OIutput Type

The market is segmented based on output type into:

· Analog Output

· Digital Output

· PWM (Pulse Width Modulation) Output

By Technology

The market is segmented based on Technology into:

· Bipolar Technology

· CMOS Technology

· BiCMOS Technology

· Microsystem (MEMS)-based Hall Sensors

By Application

Automotive and Transportation Segment Dominates Due to Increasing Vehicle Electrification

The market is segmented based on application into:

· Automotive and Transportation

· Industrial Automation

· Consumer Electronics

· Aerospace & Defense

· Medical Devices

· Others

Regional Analysis: Hall-Effect Sensors Market

North America North America is a mature yet high-growth region for Hall-effect sensors, driven by advanced automotive electrification and industrial automation initiatives. The U.S. contributes over 60% of regional demand, with major automakers integrating these sensors for applications like position sensing in EV motors and gearbox controls. Stringent safety regulations, such as NHTSA mandates, further propel adoption in automotive systems. The region also benefits from strong R&D investments in IoT and Industry 4.0, particularly in MEMS-based Hall sensors with lower power consumption. However, supply chain disruptions and reliance on Asian semiconductor fabs pose intermittent challenges to market stability.

Europe Europe’s market thrives on green energy transitions and automotive electrification, with the EU’s “Fit for 55” package accelerating demand for Hall-effect sensors in renewable energy systems and EV drivetrains. Germany leads in industrial applications, where sensor-enabled smart manufacturing aligns with Industry 4.0 standards. A notable trend is the shift toward integrated Hall ICs combining sensing and signal conditioning, reducing system complexity. While growth is steady, high production costs and competition from Asian suppliers pressure local manufacturers to prioritize innovation in ruggedized sensors for harsh environments like wind turbines and railway systems.