#smart factory automation and control

Explore tagged Tumblr posts

Video

youtube

Telescopic Sliding Gates | Automatic & Industrial Gate Systems by Secure...

#youtube#telescopic sliding gate#AutomaticGatesIndia#industrial sliding gates#SecureIndiaGates#AutomaticTelescopicGate#HeavyDutyGates#IndustrialGateAutomation#sliding gate system#automatic swing gate#SecurityGatesManufacturer#Automatic Gate Installation#Industrial Entrance Gates#Smart Gate Solutions#Automatic Gate for Factory#Motorized Gate Systems#Commercial Sliding Gate#Automatic Gate Supplier India#Gate Automation Ahmedabad#Entrance Control Solutions#Secure India Security Products#Automated Entry Gates#Perimeter Security Solutions

0 notes

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

Revolutionize your manufacturing process with generative AI: predictive maintenance, enhanced design, improved quality control, and streamlined supply chains. Embrace the future!

#AI In Inventory Management#AI-Powered Manufacturing Data Analysis#Generative AI In Smart Factories#AI In Manufacturing Innovation#Generative AI For Production Planning#AI In Operational Efficiency#AI-Driven Manufacturing Transformation#Generative AI For Lean Manufacturing#AI In Manufacturing Logistics#AI-Enhanced Production Processes#Generative AI For Equipment Monitoring#AI In Supply Chain Optimization#Generative AI For Manufacturing Agility#AI-Powered Factory Automation#AI In Process Control#Generative AI For Production Optimization

0 notes

Text

🚢 Tesla's Remote Control Patent: The Birth of Modern Automation 🚢

On November 8, 1898, Nikola Tesla was granted U.S. Patent No. 613,809 for his "Method of and Apparatus for Controlling Mechanism of Moving Vessels or Vehicles." This invention wasn’t just the first practical remote control—it marked a revolutionary step toward the development of wireless communication and automation.

🔧 How Tesla’s System Worked 🔧

Tesla's system worked much like how we control drones today—only over a century ago!

1️⃣ Transmitter: Tesla used radio waves to send wireless commands to the vessel.

2️⃣ Receiver: The vessel had a sensitive device that decoded the radio signals into specific actions, such as steering or powering motors.

3️⃣ Control Circuits: Tesla designed a series of circuits that ensured each command executed reliably, preventing errors and interference.

⚙️ Key Features ⚙️

💡 Command Logic: Tesla's circuits functioned like a primitive decision-making system, linking specific signals to specific actions—a conceptual precursor to today’s logic gates.

🔋 Multi-Channel Design: Each circuit operated on a unique frequency, akin to modern multi-device networks, ensuring precise control without interference.

🛡️ Safety First: Tesla implemented mechanisms to prevent accidental or incorrect activations, prioritizing reliability.

🌍 Applications Then and Now 🌍

Tesla saw the potential for:

✔️ Military Use: Guiding unmanned ships or torpedoes.

✔️ Disaster Response: Sending unmanned vessels into dangerous areas.

✔️ Remote Automation: Introducing wireless precision to various industries.

Today, Tesla's vision echoes in:

🚁 Drones: Controlled remotely through radio signals.

🤖 Robots: Autonomous machines performing tasks with precision.

🏠 Smart Homes: Devices responding to commands over Wi-Fi.

🏭 Automated Factories: Machines operating through programmable controls Tesla helped inspire.

🌟 Why Tesla’s Invention Matters 🌟

Tesla didn’t just create a remote control—he pioneered a framework for wireless systems that continues to shape modern technology. What are your thoughts on Tesla's advancement in wireless technology?

69 notes

·

View notes

Text

Linux creator Linus Torvalds wrote:

"Ok, lots of Russian trolls out and about. It's entirely clear why the change was done, it's not getting reverted, and using multiple random anonymous accounts to try to "grass root" it by Russian troll factories isn't going to change anything. And FYI for the actual innocent bystanders who aren't troll farm accounts - the "various compliance requirements" are not just a US thing. If you haven't heard of Russian sanctions yet, you should try to read the news some day. And by "news", I don't mean Russian state-sponsored spam. As to sending me a revert patch - please use whatever mush you call brains. I'm Finnish. Did you think I'd be *supporting* Russian aggression? Apparently it's not just lack of real news, it's lack of history knowledge too."

What is Linux?

Linux is a family of open-source Unix-like operating systems based on the Linux kernel, an operating system kernel first released on September 17, 1991, by Linus Torvalds.

Linux was originally developed for personal computers based on the Intel x86 architecture, but has since been ported to more platforms than any other operating system. Because of the dominance of Linux-based Android on smartphones, Linux, including Android, has the largest installed base of all general-purpose operating systems as of May 2022.

Linux is the leading operating system on servers (over 96.4% of the top one million web servers' operating systems are Linux) leads other big iron systems such as mainframe computers, and is used on all of the world's 500 fastest supercomputers (as of November 2017, having gradually displaced all competitors).

Linux also runs on embedded systems, i.e., devices whose operating system is typically built into the firmware and is highly tailored to the system. This includes routers, automation controls, smart home devices, video game consoles, televisions (Samsung and LG smart TVs), automobiles (Tesla, Audi, Mercedes-Benz, Hyundai, and Toyota), and spacecraft (Falcon 9 rocket, Dragon crew capsule, and the Perseverance rover).

#linux#linus torvalds#russian aggression#russia is a terrorist state#war in ukraine#stand with ukraine#suomi#finland#russia#venäjä#*

18 notes

·

View notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

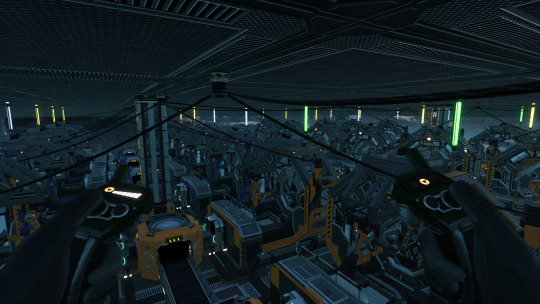

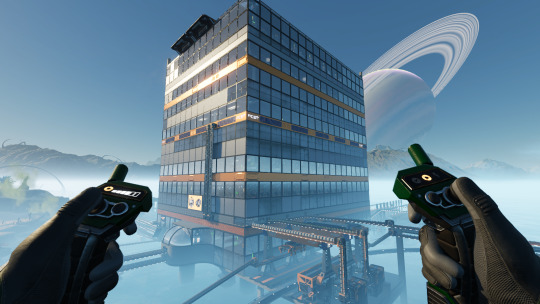

The Great Satisfactory State of Play April 2025 #3

Rocky Desert Phase 4 Factories

So we went to the Dune Desert to pay one last visit to Factory Town before it gets destroyed; we popped into the Northern Forest to visit the Phase 2 factories; and now we're about to zip into the Rocky Desert to have a gander at the Phase 3 rigmarole.

And here we are on the natural bridge that connects Northern Forest to Rocky Desert. In the distance, we can see several factories, two of which feed the reactor on the opposite side of the big rock tower. So we travel west, then up the slope...

And here we have an open air silica and quickwire factory. The golden wire is crapped out in the foreground; silica is made down the back.

And where does the raw quartz come from to feed the machine? Well...

It comes from the bottom floor of the steelworks immediately below us, since the reactor doesn't use all that much silica, and I have more than enough being belted from deep within the immense cave that spans the entire width of this biome. It was a cinch to add a splitter and get that sorted!

Iron plate, silica, steel beams go out past the encased industrial beam factory in the distance, which adds much needed EIBs to the feed. Without these, the reactor stops hard.

An early WIP shot of the reactor. Obviously it's an uranium reactor, that also makes plutonium fuel rods for recycling. This was before I added the assemblers and manufacturers needed to finish that job. But that was then...

...this is now. The quickwire and silica are trained down this line to the far distant factory on the shoreline. But there's a factory closer, and newer, and it's the best example of my idea of the Stack. Shall we have a closer look?

That box in the foreground is from a mod, that allows you to tap power from train lines without needing a station. The modernist thing on the left is the caterium smeltery. That's all it does. So we skip that and hover along the power line to the skeletal one behind it. That's the Stack for electromagnetic control rods.

The idea of the Stack is simple. Each floor is dedicated to a single step in the manufacturing process. I tend to forget that because compactness. In the distant left, foundries and smelters feed copper and iron into the Stack.

Ground floor, iron and copper ingot arrival, copper sheet making. Please mind your step as getting bowled from stepping on the belts may offend (they're sent to one corner.) Going up.

Belt bridge porn. Where was I? Oh yes.

Second floor, copper wire. Note that my prefabs for 8 constructors are actually 4x4 rather than 5x5, which I use for the assemblers further up. Step to the rear of the car please.

Third floor, quickwire extrusion. This setup with the mesh flooring (from a mod) actually works quite well as it offers plenty of space for in- and output belting. Everybody up!

Fourth floor, iron pipe manufacture. With this half-floor we see one flaw of the Stack concept, if you consider empty floor space a flaw. And now we have to step outside the concrete pillar framework to look into the next floor up.

Fifth floor, AI limiters and stators. Yes, on the same floor, because it occurred to me that there was no logical reason to put them on separate floors. But now I wonder if another half-floor would have been so bad. Stators in back, AI limiters in front.

The prefabs include built-in logistics floors, and conveyor supports for the inputs, assuming everything, er, enters the same way. And those go up to...

Top floor, ECR final join and dispatch. I have kluged up two drone ports at the reactor to receive these, and also supply said drones with fuel rods for plenty of power.

So that's my first true Stack! So what came before?

This is what came before: This damnable thick square building that makes parts for and does final join on modular engines and adaptive control units. On top are five drone ports. One receives fuel for the others. The two we can see receive smart plating and automated wiring. And there's that train station at the bottom of a rather entertaining ramp. Let's look inside.

Cool! We have a satellite HUB terminal (from a mod), and all other mod cons! Not to mention well-lit, at least in these lower floors, I skipped lighting as I went up and got impatient.

So many foundries and coated iron plate assemblers. Oh, and steel beam constructors.

I can't wait for the day when 1.1 is made mod friendly. This form of compact vertical transport is... well, it's not the going-up, it's the going-down. A 20m drop is hair-raising.

Silicon circuit boards and so, so many screws. There's about eight belts of them going up the south wall.

And this is where everything ends up: the roof. That building in the centre is where all the spaghet for dispatching the Phase 3 goods and receiving Phase 2 is. And dispensing fuel. And feeding the sink. While we're up here, let's look around:

So many miners! Copper, iron, limestone, it's all here and all getting exploited a mile into the ground.

In back of the tower are the wet concrete refineries on the left, and the steamed copper sheet works. These were difficult to make, since I was, apparently, right on the edge of where I could place water extractors.

The mighty metal-roofed motor factory system! In the back, the double A-frame houses the solid steel ingot foundries; each different roofline indicates a separate stage of motor production. Copper ingots are belted in to a wire factory in the foreground.

The ground floor is marked with a coloured floor and path patterns, to highlight where you can walk from one end of Rocky Desert Motors to the other.

All of these constructors are making screws. All 64 of them. So. Many. Screws. If I didn't know any better, I'd think I was running Satisfactory+.

And here we have a distant shot of the abominations I made on the West Coast. There's a basic aluminium ingot factory, spagged to a hastily made heat sink factory and fuel packing plant, and also a massive refinery for making residual rubber and plastic to feed the tower. Coke, rubber and plastic are supplied by train, obviously. There's also a little fuel power plant that I really need to either redo or replace.

Actually this whole shebang desperately needs reworking. If I can rework the plant to make recycled rubber and plastic, that should improve output immensely.

Aaand that's where I am right now. In my pad of Warwick 14J5 I have a plan for a grid system that I can use to rebuild Factory Town... but first I have some more damned mining to do. I promised my passengers I'd have them in the North America Nebula by Easter.

Also, over Easter and possibly starting Wednesday, I'm going to reset Windows and see if that fixes the stability issues I've been having while streaming. Which means ensuring all my documents are backed up. So excuse me, I have to take my Type 8 Ye Olde Rock Thudder out to do just that...

2 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Top 10 Pneumatic Actuator Brands In 2025

The pneumatic actuator market continues to thrive in 2025, driven by advancements in automation and industrial efficiency. Based on comprehensive evaluations by CN10/CNPP research departments, which integrate big data analytics, AI-driven insights, and market performance metrics, here are the leading brands shaping the industry.

1. SMC (SMC Corporation)

Performance & Reliability: As a global leader since 1959, SMC delivers over 10,000 pneumatic components, including high-precision cylinders, valves, and F.R.L. units. Its products are renowned for durability, energy efficiency, and adaptability to extreme industrial conditions. Industry Applications: Widely used in automotive manufacturing, semiconductor production, and robotics, SMC’s actuators ensure seamless automation across 80+ countries. Its China-based facilities, established in 1994, serve as a primary global production hub.

2. FESTO (Festo AG & Co. KG)

Performance & Reliability: With nearly a century of expertise, Festo combines innovative engineering with IoT-enabled solutions. Its actuators emphasize precision control, low maintenance, and compatibility with smart factory ecosystems. Industry Applications: Festo dominates sectors like pharmaceuticals, food processing, and renewable energy, offering customized automation systems that enhance productivity and sustainability.

Other Notable Brands In The 2025 Rankings

While SMC and Festo lead the list, the following brands also excel in specific niches:

Brand A: Specializes in compact actuators for medical devices.

Brand B: Focuses on heavy-duty applications in construction machinery.

Brand C: Pioneers eco-friendly designs with reduced carbon footprints.

Key Trends Driving Market Growth

Smart Automation: Integration of AI and real-time monitoring in actuator systems.

Sustainability: Energy-efficient designs aligned with global decarbonization goals.

Customization: Tailored solutions for niche industries like aerospace and biotechnology.

This ranking underscores the critical role of innovation and adaptability in maintaining competitive advantage. Brands that prioritize R&D and cross-industry collaboration are poised to lead the next decade of pneumatic automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

2 notes

·

View notes

Text

AI & IT'S IMPACT

Unleashing the Power: The Impact of AI Across Industries and Future Frontiers

Artificial Intelligence (AI), once confined to the realm of science fiction, has rapidly become a transformative force across diverse industries. Its influence is reshaping the landscape of how businesses operate, innovate, and interact with their stakeholders. As we navigate the current impact of AI and peer into the future, it's evident that the capabilities of this technology are poised to reach unprecedented heights.

1. Healthcare:

In the healthcare sector, AI is a game-changer, revolutionizing diagnostics, treatment plans, and patient care. Machine learning algorithms analyze vast datasets to identify patterns, aiding in early disease detection. AI-driven robotic surgery is enhancing precision, reducing recovery times, and minimizing risks. Personalized medicine, powered by AI, tailors treatments based on an individual's genetic makeup, optimizing therapeutic outcomes.

2. Finance:

AI is reshaping the financial industry by enhancing efficiency, risk management, and customer experiences. Algorithms analyze market trends, enabling quicker and more accurate investment decisions. Chatbots and virtual assistants powered by AI streamline customer interactions, providing real-time assistance. Fraud detection algorithms work tirelessly to identify suspicious activities, bolstering security measures in online transactions.

3. Manufacturing:

In manufacturing, AI is optimizing production processes through predictive maintenance and quality control. Smart factories leverage AI to monitor equipment health, reducing downtime by predicting potential failures. Robots and autonomous systems, guided by AI, enhance precision and efficiency in tasks ranging from assembly lines to logistics. This not only increases productivity but also contributes to safer working environments.

4. Education:

AI is reshaping the educational landscape by personalizing learning experiences. Adaptive learning platforms use AI algorithms to tailor educational content to individual student needs, fostering better comprehension and engagement. AI-driven tools also assist educators in grading, administrative tasks, and provide insights into student performance, allowing for more effective teaching strategies.

5. Retail:

In the retail sector, AI is transforming customer experiences through personalized recommendations and efficient supply chain management. Recommendation engines analyze customer preferences, providing targeted product suggestions. AI-powered chatbots handle customer queries, offering real-time assistance. Inventory management is optimized through predictive analytics, reducing waste and ensuring products are readily available.

6. Future Frontiers:

A. Autonomous Vehicles: The future of transportation lies in AI-driven autonomous vehicles. From self-driving cars to automated drones, AI algorithms navigate and respond to dynamic environments, ensuring safer and more efficient transportation. This technology holds the promise of reducing accidents, alleviating traffic congestion, and redefining mobility.

B. Quantum Computing: As AI algorithms become more complex, the need for advanced computing capabilities grows. Quantucm omputing, with its ability to process vast amounts of data at unprecedented speeds, holds the potential to revolutionize AI. This synergy could unlock new possibilities in solving complex problems, ranging from drug discovery to climate modeling.

C. AI in Creativity: AI is not limited to data-driven tasks; it's also making inroads into the realm of creativity. AI-generated art, music, and content are gaining recognition. Future developments may see AI collaborating with human creators, pushing the boundaries of what is possible in fields traditionally associated with human ingenuity.

In conclusion, the impact of AI across industries is profound and multifaceted. From enhancing efficiency and precision to revolutionizing how we approach complex challenges, AI is at the forefront of innovation. The future capabilities of AI hold the promise of even greater advancements, ushering in an era where the boundaries of what is achievable continue to expand. As businesses and industries continue to embrace and adapt to these transformative technologies, the synergy between human intelligence and artificial intelligence will undoubtedly shape a future defined by unprecedented possibilities.

20 notes

·

View notes

Text

Experience Vampire Chaos in Blood Bar Tycoon

Blood Bar Tycoon the vampire bar management game developer confirms Steam Deck and Linux support via Windows PC. Thanks to Clever Trickster Studio for bringing this wickedly fun idea to life. Which you can find on Steam with its 85% Very Positive reviews. Ever wanted to run your own vampire bar? Well, now’s your chance! Blood Bar Tycoon is here, bringing a wickedly fun mix of bar management, strategy, and pure supernatural vampire chaos. Launching February 4th on Steam, this game lets you transform dingy little joints into the hottest vampire hangouts in Crimson City. Your mission? Keep your undead clientele happy, your human supply flowing, and those pesky vampire hunters off your back.

Blood Bar Tycoon should work on Linux. It's working on a Steam Deck (even if the UX hasn't been optimized for it) and we've already sold few copies on Linux.

While I’d like to see Blood Bar Tycoon get a native Linux and Steam Deck release, especially since it’s built with Unity 3D. Clever Trickster Studio did confirm it works, but here’s hoping they fine-tune the UX for a smoother experience.

Build, Expand, Dominate

Starting from a rundown bar, you’ll work your way up, turning your establishment into a thriving blood-soaked empire. Set up blood factories, lure in clueless humans, and use bizarre contraptions to extract their precious essence. But watch out—if things get messy, hunters will come knocking, and you don’t want that kind of trouble!

Run the Show (and Keep Your Minions in Line!)

As the boss, you’ll need to hire and manage a crew of low-level vampires to keep things running smoothly. Assign tasks, set priorities, and make sure your minions are fed—because even the undead get cranky when they’re hungry. Balance efficiency with chaos as you decide whether to micromanage or automate your workforce.

Blood Bar Tycoon - Launch Trailer

youtube

Capture, Process, Serve

Humans are your most valuable resource, but you’ve got to be smart about how you use them. Develop underground detention centers, keep things discreet, and then extract their blood to create all kinds of creepy concoctions. From Bloody Daiquiris to Slushy O-Negatives, you’ll need to craft the best drinks to impress your wealthiest vampire clients. Just make sure the humans leave with a buzz instead of… well, not leaving at all.

Design the Ultimate Vampire Bar

This isn’t just about business—it’s about style. Customize every inch of your Blood Bar with a variety of spooky themes and decor options. Whether you want a gothic masterpiece or a neon-lit vampire nightclub, the choice is yours. Plus, there are competitions to show off your designs in Blood Bar Tycoon, so bring your A-game!

Deal with the Elders (Or Suffer the Consequences)

The powerful Elder vampires run Crimson City, and you’ll need their approval if you want to climb the ranks. Each Elder has a different personality—some are easy to please, others… not so much. Gain their favor and unlock special perks, or anger them and watch your empire crumble.

Blood Bar Tycoon Lets You Conquer Crimson City

Expanding your influence means taking control of different districts, each with its own challenges. Keep upgrading your bars, perfect your blood-harvesting methods, and outmaneuver the competition. Your ultimate goal? Become an Elder yourself and rule the night!

Ready to Take a Bite?

If you’re into management games with a dark vampire bar twist, Blood Bar Tycoon is one you don’t want to miss. Whether you prefer a hands-on approach or letting your minions do the dirty work, there’s plenty to sink your teeth into. Get ready to embrace the nightlife — out now on Steam. Which you can play on both Steam Deck and Linux via Windows PC. With the price of $15.99 USD / £13.59 / 15,99€, including the 20% discount.

#blood bar tycoon#vampire#bar management#linux#gaming news#clever trickster studio#ubuntu#steam deck#windows#pc#unity#Youtube

2 notes

·

View notes

Text

Guide for Importers on Manufacturing Control

Efficient Manufacturing Control in China

1. Understand the Chinese Manufacturing Environment:

Diverse Ecosystem: China offers a vast range of manufacturers, from small workshops to large factories. This variety is beneficial but also poses challenges in ensuring consistent quality.

IP Concerns: Despite improvements, IP protection in China can be inconsistent, requiring robust measures to safeguard your innovations.

Regulatory Landscape: China’s complex and changing regulations make compliance crucial to avoid fines and reputational damage.

Quality Control: While quality has improved, some sectors still prioritize quantity over quality. Rigorous quality protocols are essential.

Labor & Costs: Labor costs are rising, pushing manufacturers toward automation. Infrastructure is robust, but supply chains can be disrupted by natural disasters or policy changes.

Government Policies: China’s government heavily influences manufacturing through policies and incentives, which can affect costs and market access.

2. Build a Strong Foundation:

Supplier Selection: Choose reliable suppliers through thorough due diligence, including factory visits and financial checks.

Clear Communication: Provide detailed specifications and maintain open communication to avoid misunderstandings.

Quality Management: Implement a Quality Management System (QMS) and conduct regular audits to ensure consistent product quality.

Strong Relationships: Develop long-term partnerships with suppliers to build trust and collaboration.

3. Implement Effective Control Strategies:

QA & QC: Establish a robust QA/QC framework to ensure consistent product quality.

Supplier Development: Invest in your suppliers’ capabilities to improve quality and efficiency.

Risk Management: Prepare for disruptions with backup plans and diversified suppliers.

Contractual Coverage: Clearly define product specifications and include IP protections in contracts.

Third-Party Verification: Use third-party inspections to ensure compliance and quality.

4. Manage Logistics & Supply Chain:

Transportation: Choose the best transport mode and routes to minimize costs and delays.

Warehousing & Inventory: Optimize warehouse locations and use management systems to track inventory.

Customs & Documentation: Ensure compliance with customs regulations and prepare accurate documentation.

Supply Chain Visibility: Use technology to monitor shipments and collaborate with suppliers.

Risk Assessment: Develop contingency plans for disruptions like natural disasters or strikes.

5. Overcome Common Challenges:

Language & Cultural Barriers: Hire experts to bridge gaps in communication and cultural understanding.

IP Protection: Secure your IP with patents, trademarks, and NDAs; monitor for infringements.

Regulatory Compliance: Stay updated on regulations and partner with local experts for compliance.

Supply Chain Disruptions: Diversify suppliers, maintain sufficient inventory, and use smart tools for monitoring.

6. Continuous Improvement:

Use data analytics to track trends and improve processes.

Regularly evaluate supplier performance and invest in employee training.

Embrace technology to enhance communication and efficiency.

7. Build a Culture of Quality:

Encourage employees to propose improvements.

Reward contributions to quality enhancement.

Focus on exceeding customer expectations.

Conclusion: Effective manufacturing control in China requires ongoing effort, attention, and adaptation. Invest in strong practices to improve product quality, reduce costs, protect your brand, and optimize your supply chain.

3 notes

·

View notes

Text

Factory Management Software (F-VAPP) for Valves Maintenance & Manufacturing Factories and Workshops. 🖥 ------ Revolutionize your valve production and maintenance with F-VAPP—a comprehensive factory management software designed by industry experts who understand the specific needs of the valves manufacturing world. F-VAPP is not just a tool, it's a fully integrated solution that enhances every aspect of your factory’s operations. 📈 ------ Hosted securely on your internal server, F-VAPP provides role-based access for every department, ensuring seamless workflows. It’s more than just software—it’s a complete management system that knows how to prioritize and automate daily operations for each machine and section. F-VAPP deeply understands the intricate processes of valve manufacturing and maintenance, making sure every task is executed efficiently with priorities clearly in place. ---- Why F-VAPP? ---- 1- Tailor-made for the valves industry, considering every detail in production and maintenance. 2- Automated daily operations for machines and departments, prioritizing workflows for maximum efficiency. 3- Real-time production line monitoring and machine load management to optimize operations. 4- Full control over inventory management and cost automation for smart financial planning. 5- User-friendly yet powerful interface that’s simple to navigate and efficient for everyday use. 6- Comprehensive reporting tools for actionable insights and informed decision-making. 7- Streamlined processes through custom roles and permissions, helping you build a clear organizational chart and strong operational workflows. 8- Enhanced collaboration between departments, improving overall productivity and quality management. ---- With F-VAPP, your factory’s operations aren’t just managed—they’re optimized. From inventory control to production management, every function is fine-tuned for efficiency and performance. ---- Key Benefits: ---- 1- Boost productivity by ensuring smooth, prioritized workflows for machines and workers. 2- Gain real-time insights into machine performance, production schedules, and factory output. 3- Automate complex processes like costing, pricing, and inventory management. 4- Seamlessly integrate departments, improving quality control and production planning. 5- Build the perfect organizational structure with clear roles and responsibilities. 6- Generate detailed reports to guide smarter business decisions. ---- F-VAPP goes beyond software. It’s a full-scale factory management system built to meet the specific needs of the valves manufacturing and maintenance industry. Take your operations to the next level with a system designed by professionals, for professionals. 🛠

2 notes

·

View notes

Text

Raspberry Pi Board: Revolutionizing Computing and Education

The Raspberry Pi board is a series of small, affordable single-board computers developed by the Raspberry Pi Foundation, a UK-based charity focused on promoting computer science education and digital literacy. Since its launch in 2012, the Raspberry Pi has transformed from a niche educational tool into a versatile platform used in a wide range of applications, from DIY electronics projects to industrial automation.

A Brief History

The first Raspberry Pi, the Model B, was released in February 2012. Designed to promote basic computer science in schools and developing countries, it featured a 700 MHz ARM11 processor, 256 MB of RAM, and basic connectivity options. The success of the Model B led to a rapid expansion of the Raspberry Pi lineup, with various models offering improved performance, more memory, and enhanced connectivity.

Key Features and Models

Raspberry Pi 1 Model B (2012):

Processor: 700 MHz ARM11

Memory: 256 MB RAM

Ports: 2 USB 2.0 ports, HDMI, Composite video, 3.5mm audio jack, Ethernet

Storage: SD card slot

Raspberry Pi 2 Model B (2015):

Processor: 900 MHz quad-core ARM Cortex-A7

Memory: 1 GB RAM

Ports: 4 USB 2.0 ports, HDMI, Composite video, 3.5mm audio jack, Ethernet

Storage: MicroSD card slot

Raspberry Pi 3 Model B (2016):

Processor: 1.2 GHz quad-core ARM Cortex-A53

Memory: 1 GB RAM

Ports: 4 USB 2.0 ports, HDMI, Composite video, 3.5mm audio jack, Ethernet

Wireless: Wi-Fi and Bluetooth

Raspberry Pi 4 Model B (2019):

Processor: 1.5 GHz quad-core ARM Cortex-A72

Memory: Options of 2 GB, 4 GB, and 8 GB RAM

Ports: 2 USB 3.0 ports, 2 USB 2.0 ports, 2 Micro HDMI ports, Ethernet, USB-C for power

Wireless: Wi-Fi and Bluetooth

Raspberry Pi Zero (2015) and Zero W (2017):

Processor: 1 GHz single-core ARM11

Memory: 512 MB RAM

Ports: Mini HDMI, Micro USB OTG, Micro USB for power, GPIO pins

Wireless (Zero W): Wi-Fi and Bluetooth

Applications and Uses

The versatility of the Raspberry Pi has led to its adoption in numerous fields:

Education:

Coding and Programming: Used in schools and educational programs to teach students programming languages such as Python, Scratch, and Java.

Computer Science Concepts: Introduces concepts like hardware, software, and networking.

DIY Projects and Maker Community:

Home Automation: Controls smart home devices, including lights, thermostats, and security systems.

Media Centers: Powers home media centers using software like Kodi.

Retro Gaming: Emulates classic gaming consoles using software like RetroPie.

Industrial and Commercial Applications:

IoT Devices: Serves as a hub for Internet of Things (IoT) devices, enabling data collection and remote control.

Automation and Control Systems: Used in factories and labs for monitoring and controlling equipment.

Research and Development:

Prototyping: Facilitates rapid prototyping of electronic devices and systems.

Data Collection: Gathers data from various sensors in environmental and scientific research.

Community and Ecosystem

The Raspberry Pi has cultivated a vibrant global community of developers, hobbyists, educators, and students. Online forums, tutorials, and community projects provide extensive support and resources for users at all skill levels. The Raspberry Pi Foundation also offers official accessories, including cases, cameras, and expansion boards, further enhancing the functionality of the Raspberry Pi.

Conclusion

The Raspberry Pi board has revolutionized the way people learn about and interact with technology. Its affordability, versatility, and extensive support network have made it an indispensable tool in education, DIY projects, and professional applications. As technology continues to evolve, the Raspberry Pi Foundation remains committed to expanding the capabilities and accessibility of this remarkable platform, ensuring that computing remains within reach for everyone.

3 notes

·

View notes

Text

Innovative Trends in Residential Architecture in 2024

The landscape of residential architecture is evolving rapidly, driven by technological advancements, changing lifestyles, and a growing trend on sustainability and wellness. In this article, we'll explore some of the innovative trends shaping the future of residential architecture.

Sustainable Design: With increasing awareness of environmental issues, many sustainable design practices are becoming more prevalent in residential architecture. Architects are incorporating features such as passive heating and cooling, green roofs, rainwater harvesting systems, and solar panels to minimize the environmental impact of homes.

Smart Homes: Integrating innovative technology into residential design revolutionizes how we interact with our living spaces. From automated lighting and temperature control to voice-activated assistants and security systems, smart home technology enhances homeowners' convenience, efficiency, and security.

Flexible Spaces: How we live and work is changing, and residential architects are responding by designing homes with flexible, multifunctional spaces. Open floor plans, movable walls, and modular furniture allow homeowners to adapt their living spaces to suit their changing needs, whether for remote work, entertaining guests, or relaxing with family.

Biophilic Design: Biophilic design seeks to connect people with nature by incorporating natural elements into homes. In residential architecture, this trend manifests in indoor gardens, green walls, natural light, and views of the surrounding landscape, creating homes that promote health, well-being, and productivity.

Adaptive Reuse: As urbanization grows, there is a growing emphasis on adaptive reuse projects that repurpose existing structures for residential purposes. Old warehouses, factories, and office buildings are transformed into modern, stylish loft apartments, combining historical charm with contemporary amenities.

Net-Zero Energy Homes: With the increasing focus on energy efficiency and carbon neutrality, net-zero energy homes are emerging as a critical trend in residential architecture. These homes are designed to produce as much energy as they consume, typically through passive design strategies, renewable energy systems, and energy-efficient appliances.

Health and Wellness: In response to the COVID-19 pandemic and growing concerns about indoor air quality and sanitation, residential architects prioritize health and wellness features in home design. This includes incorporating air purification systems, home gyms, meditation rooms, and outdoor living spaces to promote physical and mental well-being.

Customization and Personalization: In an era of mass production and cookie-cutter homes, there is a growing demand for custom-designed residences that reflect their owners' unique tastes and lifestyles. An architectural design company embraces this trend by offering tailored design solutions to individual preferences, whether a minimalist modernist masterpiece or a cozy cottage retreat.

In conclusion, the future of residential architecture is brimming with innovation, including the evolution of cabinets in architectural design, sustainability, and a focus on enhancing homeowners' quality of life. By embracing these innovative trends, architects can create beautiful and functional homes that are sustainable, healthy, and adaptable to the needs of modern living.

2 notes

·

View notes

Text

Key PLC Trends Shaping the Future of Manufacturing in 2025

In 2025, Programmable Logic Controllers (PLCs) are playing a key role in transforming the manufacturing industry. The latest PLC trends include increased use of AI and machine learning, improved connectivity through Industrial IoT, and enhanced cybersecurity features. These advancements help factories become smarter, faster, and more efficient. Cloud-based PLC systems and remote monitoring are also gaining popularity, offering real-time data access and better control. As automation continues to grow, these PLC innovations are driving productivity and reducing downtime. Understanding these key trends helps manufacturers stay competitive and prepare for the future of smart and connected industrial operations. Read more at

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#Plc

0 notes