#socket welding

Text

Difference Between Socket Weld and Butt Weld

There are different interfacing types for the Pipe Flanges, fittings and valves: Socket weld, butt weld, strung, etc. Two of them to be very well known: Socket welding and butt welding. Be that as it may, you may be befuddled about which one would be best for your development ventures since them two appear to have their very own upsides and downsides.

Socket Weld:

Socketweld Fittings are characterized in the ASME B16.11. Likewise, with Socket weld, a pipe is embedded into a recessed region of the fitting. Both the pipe and the fitting are square cut, with no requirement for angled end or planning other than cleaning the outside, which permits simple welding and establishment. A Socket weld fittings include two diverse measured bits of pipe. The little one is inside the bigger pipe. The weld is totally around the outside circuit of the bigger pipe.

Butt Weld:

Buttweld Fittings are characterized in the ASME B16.9. They are welded at their closures to the pipe end, with a similar thickness as channels. The finish of butt weld fittings will be slanted. A butt weld fittings are two bits of materials rammed into one another and welded. A few distinct strategies exist for sloping the two pieces for good weld infiltration. Both level stock and pipe or tubing can be butt welded. For the most part, the weld is ground flush with the material surface.

Features:

Socket weld is anything but difficult to introduce. Be that as it may, it requires approx. 1/16″ of a hole at the base of the pipe into Socket, to permit warm development. This hole can prompt overpressure issue that splits the filet weld of the fitting. Socket weld is inconvenient in destructive liquid administration because of hole consumption. Also, it is anything but difficult to consume because of the irregularity of the smooth pipe internals.

Buttweld is the “best” as far as quality, weariness, and erosion obstruction, and temperatures consistence. Be that as it may, it is progressively hard to fit-up and weld appropriately, requiring gifted welder and much time.

Applications:

Socket weld opposes around 1/2 the quality of butt welding. So it is fundamentally utilized for a little pipeline with measurements NPS 2 or littler.

Buttweld keeps better quality, useful for high weight or high-temperature pipelines. So it is utilized when a welded joint with quality not lower than that of the base metal itself is required.

Diameters & Ends:

Socket welding can be utilized for channels with little distances across, and it is commonly connected to funnels or pipe fittings whose widths are under DN50.

Butt welding is broadly utilized for channels with of all shapes and sizes distances across, and strung welding or Socket welding is utilized for funnels with little breadths.

As a rule, there ought to be an inclined end from 30 to 37.5° for butt welding so as to fill the welding dot. Obviously, there will be a compound inclined end for very thick dividers.

Socket welding doesn’t require an incline, and it can legitimately weld the part.

Pricing:

Typically, the cost of Socket weld fittings is higher than Butt weld fittings in comparative size. Be that as it may, the additional expense of butt weld is higher for the establishment, considering work cost and gifted welder.

0 notes

Text

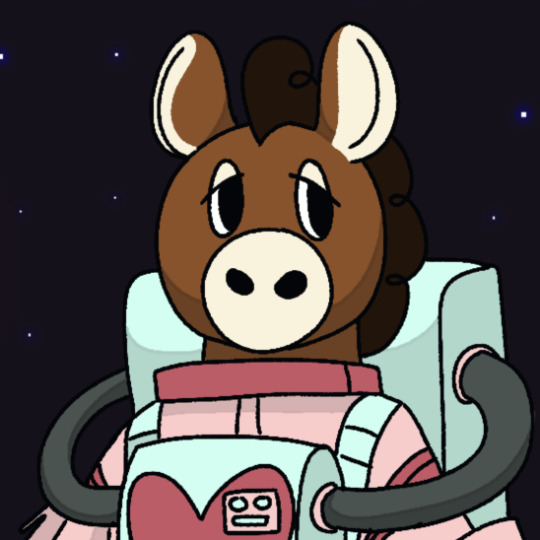

I'm running backwards up a halfpipe/pos

Welcome to the game, Daneilla (Danny)Darling! I’m still working on her main-world design, so her Space Riders fit is all I have for now. I’m almost done though! I think y’all will like her!

Anyways, Danny is a young Aerospace Welder and Engineer, and lives on the Intergalactic Emergency Sub-Station: a company, and space station dedicated to preserving life and safe travel through the cosmos. When she’s not traveling with other crews as an on-call engineer for dangerous voyages, Danny is dispatched across worlds to complete maintenance checkups on passing ships and other space stations.

Personally, Danny is a flexible, relaxed young woman with a steady hand and a quick mind. She loves her job, and she’s not working or napping, she enjoys dancing and debating silly questions like weather there are more wheels or doors in the world (she will always say wheels). She isn’t put on the front lines often, considering her lack of supernatural abilities, but her cunning and resourcefulness always keeps her opponents guessing. Her favorite drink is Horchata!

(Space Riders au belongs to @onyxonline)

Alt ref and close ups!

#I love my badass donkey girl <33#okay but can we talk about cold welding? That shit is fascinating#“Cold welding requires the removal of oxidation from two similar metals and apply sufficient force to bond the parts to each other by”#“EXCHANGING ELECTRONS”#(Mac-Tech inc. 1)#LIKE WHAT#you literally fuse atoms together#and Daneilla chills outside of space stations and does that shit for a job#and she looks cute as hell doing it 💅#as she fucking should#she absolutely has put a cold-welder to someone's eye socket in a fight#phrart#art#space riders au#poppy playtime oc#poppy playtime#Danny Darling#She specializes in Flamenco!#I'm almost done with her normal ref and oml she's so sad#holding her so gently#character design#she’s so cutie

144 notes

·

View notes

Text

Best quality flange manufacturer in India

Dalmine Flanges is one of the Leading Flange Manufacturers in India. We have such a huge customer base, because Our Flanges are of the highest quality, Dalmine Flanges products are utilised in a variety of applications all over the world.

We are also known as the best Slip On Flanges Manufacturer in India, Blind Flanges Manufacturer in India, Socket Weld Flanges Manufacturer in India, and Threaded Flanges Manufacturer in India.

For more details:

product: Flange Manufacturers in India

Website: dalmineflanges.com

5 notes

·

View notes

Text

IBR socket weld fittings

Ibr Socket Weld Fittings by Tubefit Industries: Discover high-quality IBR socket weld fittings designed for seamless performance in various industrial applications. Tubefit Industries offers a wide range of fittings that adhere to IBR standards, ensuring durability and reliability. Ideal for high-pressure systems, these socket weld fittings are precision-engineered for secure connections. Explore the collection and find the perfect fit for your piping requirements."

0 notes

Text

Choosing Between Socket Weld And Threaded Fittings With Their Applications

Selecting the appropriate pipe fittings is crucial in industrial systems, particularly when dealing with high-pressure or corrosive environments. Socket weld and threaded fittings are two commonly used types, each with unique characteristics that make them suitable for specific applications.

What Are Socket Weld and Threaded Fittings Each Good At?

Socket Weld Fittings

Socket weld fittings are engineered for systems that require strong, reliable connections. The process involves inserting the pipe into a socket and applying a fillet weld, which creates a seamless, uniform joint. This method is especially useful in situations where preventing leaks and maintaining strength are crucial. For example, in industries like oil and gas, socket weld fittings are often used because even a small leak could lead to serious problems. Similarly, in high-pressure steam systems, these fittings help ensure that connections stay solid and safe. Standards like ASTM A105 and ASTM A182 ensure that these fittings are tested and manufactured to be reliable and durable.

High Pressure Tolerance: Socket weld fittings are designed to withstand high-pressure environments, often exceeding 2000 psi. The welded joint provides best mechanical strength, making them ideal for high-stress applications.

Corrosion Resistance: The welded connection lowers the risk of corrosion at the joint, which is essential in handling aggressive chemicals or steam.

Thermal Stability: Socket welds maintain their strength under fluctuating temperatures, making them suitable for thermal cycling processes commonly found in petrochemical and power generation industries.

Threaded Fittings

Threaded fittings are easy to assemble and disassemble, making them great for systems that require regular maintenance. These fittings use a helical thread pattern to create a pressure-tight seal between the pipe and fitting. Standards like ANSI B16.11 and ASME B16.5 guide the production of these fittings, ensuring they meet exact specifications for dimensions and performance. These fittings are usually used in systems with lower-pressure systems, where the connection doesn’t need to be as strong. For example, in home plumbing, threaded fittings are common because they allow for quick repairs. In heating, ventilation, and air conditioning (HVAC systems), they are also used because the fittings may need to be adjusted or replaced over time.

Pressure Rating: Threaded fittings are generally used in systems with pressures under 150 psi. They are not recommended for high-pressure applications due to the potential for thread wear and leakage.

Material Versatility: Threaded fittings can be manufactured from a variety of materials, including stainless steel, brass, and PVC, allowing them to be adjusted to specific environmental and chemical conditions.

Ease of Installation: Threaded connections are straightforward to install and do not require special equipment, making them cost-effective for small-scale operations or temporary setups.

Comparing Socket Weld and Threaded Fittings to Make the Right Choice

Socket Weld, Threaded Fittings

1. Joint Reliability

a. Socket weld fittings provide a solid, permanent joint.

b. Offer a less secure connection that is prone to loosen under vibration or thermal expansion.

2. Installation Requirements

a. Requires accurate welding, which often involves skilled labour and quality control measures.

b. Threaded fittings, on the other hand, can be installed with basic hand tools.

3. Hydrodynamic Efficiency

a. Creates a smooth internal surface that reduces turbulence and pressure drop.

b. Creates flow restrictions and potential points for particulate accumulation.

Where Each Fitting Type Works Best

Socket Weld: Commonly used in high-pressure steam lines, oil and gas transmission pipelines, and in chemical processing plants where leak prevention is risky.

Threaded: Often found in potable water systems, HVAC setups, and other low-pressure applications where ease of maintenance and flexibility are priorities.

Strengthen Your Customer Relationships with the Right Fittings

While selecting the right fittings is crucial for performance and safety, it is even more important to ensure that these fittings meet the highest Manufacturing Standards and Types. By understanding the specific needs of your customers, you can ensure they receive the best solutions for their operations. We are committed to providing fittings that not only meet but exceed industry standards, ensuring that your customers’ systems are built to last. Serving businesses across the UAE, Saudi Arabia, Kuwait, Oman, and beyond, we deliver products that your customers can trust.

Explore our catalogue at Online Fittings and partner with us to provide your customers with fittings that meet the highest industry benchmarks.

0 notes

Text

The Suppliers of Monel 400 Forged Fittings - Manilaxmi Industrial

Manilaxmi Industrial is briliant manufacturers of various monel products like Pipe Fittings, Flanges, Round Bars and best example is Monel 400 & Monel K500.

#Alloy 400 Forged Socket Weld Equal Tee#Monel Alloy ASTM B564 400 Forged Fittings#Monel 400 Threaded Fittings#Alloy 400 Socket Weld Fittings#400 Monel Forged Threaded 90° Elbow#Monel Alloy 400 Forged Fittings in India#Alloy 400 Hex Bushing#ASTM B564 Alloy 400 Threaded Union#400 Monel Socketweld 45 Deg Elbow#Alloy 400 Forged Coupling#Monel 400 High Pressure Forged Pipe Fittings#Monel 400 Plug#Monel Alloy 400 Forged Fittings Manufacturers in India#UNS N04400 Forged Fittings#Monel® Alloy 400 Forged Fittings#Alloy 400 High Pressure Forged Fittings#Monel Alloy 400 Socket weld Fittings#Monel 400 Socket weld Fittings#2.4360 Forged Fittings#400 Monel Forged Fittings#Alloy 400 Threaded Fittings#Monel 400 Threaded Fittings Manufacturer in Mumbai#India

1 note

·

View note

Text

Socket Weld Flanges manufacturers in kuwait | Metalforgeindia

Socket weld flanges are essential components in piping systems, designed for high-pressure applications. Manufactured in Kuwait, these flanges ensure a secure and leak-proof connection between pipes, enhancing system integrity. Crafted from high-quality materials, they offer excellent resistance to corrosion and wear, making them suitable for various industrial environments. The precision engineering involved in their production guarantees compatibility with standard pipe sizes, facilitating easy installation and maintenance. Ideal for industries such as oil and gas, chemical processing, and power generation.

0 notes

Text

ABASCOTOOLS: YOUR LEADING AIR TOOLS SUPPLIER IN DUBAI, UAE

ABASCOTOOLS stands as your premier supplier of air tools supplier in dubai uae, offering a diverse selection of high-quality equipment suited for various industrial and professional applications. From pneumatic impact wrenches to air compressors and everything in between, our products are crafted for durability, reliability, and superior performance. Explore our comprehensive range today and discover why ABASCOTOOLS is the preferred choice for businesses and professionals seeking excellence in air-powered tools.

#Pneumatic impact wrench supplier in dubai uae#socket set supplier in Dubai Uae#Welding gauges Supplier in dubai uae#dubai

0 notes

Text

Premium Quality Stainless Steel Flanges Manufacturer in India - Nitech Stainless Inc

Nitech Stainless Inc is one of the Best Selling Stainless Steel Flanges Manufacturer in India. These stainless steel flanges are suitable for situations requiring the use of tiny, high-pressure pipes. Stainless Steel Flanges are manufactured using high-quality raw materials and cutting-edge technologies in accordance with national and international industry standards.

We have Stainless Steel Flanges in a variety of sizes and shapes on available to satisfy our clients' needs. When installing socket weld Stainless Steel Flanges, the pipe is placed into the socket end, and a fillet weld is created around its top. The diameter of the pipe and the flange are equal, guaranteeing proper gas and fluid movement throughout the piping system. We provide Stainless Steel Flanges in a variety of materials, diameters, and sizes.

Our Stainless Steel Flanges feature a number of advantages, including fabricability, weldability, fatigue strength, and corrosion resistance. These flanges may function well in acidic and corrosive situations because to their high stress corrosion cracking resistance.

SS flanges are commonly utilized in industries such as oil and gas, chemical processing, and water treatment due to their reliability and capacity to withstand harsh conditions. Their versatility makes them indispensable for pipeline construction, allowing for efficient fluid flow and system integration.

For More Details:

Website: nitechstainless.com

Product Source: Stainless Steel Flanges Supplier In India

#Stainless Steel Flanges Manufacturer in India#Stainless Steel Flanges Manufacturer#Stainless Steel Flanges#Socket Weld Stainless Steel Flanges#SS Flanges#Flanges

0 notes

Text

Flanges | Socket Weld Flanges | Blind Flanges | Threaded Flanges | Slip on Flanges

Metalica Forging Inc. is a leading Flanges Manufacturer in India. We manufacture a wide selection of Industrial Pipe Flange from 12″NB to 48″NB.

Flanges: https://metalicaforginginc.com/flanges-manufacturer-india/

Slip on Flanges: https://metalicaforginginc.com/slip-on-flanges-manufacturer-india/

Blind Flanges: https://metalicaforginginc.com/blind-flanges-manufacturer-india/

Threaded Flanges: https://metalicaforginginc.com/threaded-flanges-manufacturer-india/

Socket Weld Flanges: https://metalicaforginginc.com/socket-weld-flanges-manufacturer-india/

For More Detail Website: https://metalicaforginginc.com/.

0 notes

Text

Thermowell Manufacturer in Mumbai

Top-quality Thermowells at Dinesh Industry.We are manufacture many types of thermowell like Socket weld thermowell, Threaded Thermowell, Flanged Thermowell, Bar Stock Thermowell. Our thermowells, are designed for precision and durability, ensuring accurate temperature measurements in industrial processes. Discover a range of materials and styles to suit your specific needs. Trust Our Brand for reliable thermowell solutions that meet the highest standards of quality and performance. Enhance your temperature sensing with our expertly crafted thermowells – the perfect choice for industrial applications. Shop now for exceptional accuracy and long-lasting reliability our Product services are supply all over India, Mumbai, Delhi, Thane, Kolkata, Lucknow, UP.

#thermowell#threaded thermowell#socket weld thermowell#flanged thermowell#bar stock thermowell#fabricated thermowell

1 note

·

View note

Text

IBR socket weld fittings

Ibr Socket Weld Fittings by Tubefit Industries: Discover high-quality IBR socket weld fittings designed for seamless performance in various industrial applications. Tubefit Industries offers a wide range of fittings that adhere to IBR standards, ensuring durability and reliability. Ideal for high-pressure systems, these socket weld fittings are precision-engineered for secure connections. Explore the collection and find the perfect fit for your piping requirements."

0 notes

Text

SSP Alloys, the top choice for butt-weld fittings in India, specializes in manufacturing

SSP Alloys: Leading Manufacturer of Butt-weld and Socket Weld Fittings, Specializing in 304 & 316 Weld Fittings. Trusted Supplier of Socket Weld Tube Fittings and Manufacturer of Welded Tubes SS409. We serving major cities like Mumbai, Delhi, Bangalore, Karnataka, Hyderabad, Andhra Pradesh, Pune, Faridabad, Aurangabad, Tamil Nadu, Ankleshwer, Punjab, and Chennai.

#304 buttweld fittings manufacturer#Buttweld 304 fittings stockiest#Buttweld Fitting 316 stockist#Welded Tubes SS409 Manufacturer#socket weld tube fittings supplier

0 notes

Text

#thermowell#Threaded Thermowell#Socket Weld Thermowell#Flanged Thermowell#Fabricated Thermowell#Bar Stock Thermowell

0 notes

Text

Carbon Steel Socket Weld flanges Supplier, Stockist in Saudi Arabia | Metalforgeindia

Socket weld flanges are crucial additives in various business piping systems. Designed to provide stable and leak-proof connections, they beautify the integrity of the piping gadget. Among the various types, carbon metal socket weld flanges stand out for his or her sturdiness and reliability. We are a leading supplier and stockist of those flanges in Saudi Arabia, providing awesome products that meet international standards.

What are Socket Weld Flanges?

Socket weld flanges are designed for use in small-diameter, excessive-pressure piping structures. They characteristic a socket into which the pipe is inserted after which filet welded across the outside. This layout presents a clean bore and ensures a stronger, more dependable connection compared to other sorts of flanges. They are ideal for packages wherein high strain and robust connections are paramount.

Advantages of Carbon Steel Socket Weld Flanges

Durability and Strength: Carbon steel is thought for its awesome energy and sturdiness, making it a favored material for socket weld flanges. These flanges can face up to excessive pressures and temperatures, making them appropriate for an extensive range of business packages.

Corrosion Resistance: Carbon metallic socket weld flanges offer great resistance to corrosion, crucial in industries together with oil and gas, petrochemicals, and water remedy. The corrosion resistance ensures an extended lifespan and decreases maintenance fees.

Cost-Effectiveness: Compared to other substances, carbon steel is fairly price-effective, imparting a high-quality balance between performance and rate. This makes carbon metallic socket weld flanges a fee-efficient choice for many industries.

Applications of Socket Weld Flanges

Oil and Gas Industry: In the oil and fuel enterprise, socket weld flanges are utilized in high-stress systems to move oil, gas, and other fluids. Their potential to resist harsh conditions and high pressures makes them ideal for this quarter.

Chemical and Petrochemical Industry: The chemical and petrochemical industries require flanges that could deal with corrosive materials and high temperatures. Carbon metallic socket weld flanges are ideal for those environments, imparting sturdiness and resistance to chemical reactions.

Water Treatment Plants: Water remedy flora use socket weld flanges to make sure stable and leak-proof connections of their piping structures. The corrosion resistance of carbon steel flanges is specially useful on this software.

Why Choose Us for Socket Weld Flanges?

High-Quality Products: We are devoted to presenting wonderful carbon steel socket weld flanges that meet worldwide requirements. Their products go through rigorous testing to ensure they could face up to the demanding conditions of various industries.

Extensive Stock: As a main stockist in Saudi Arabia, our company continues an intensive stock of socket weld flanges. This guarantees short availability and reduces lead times for customers, assisting them meet project time limits successfully.

Custom Solutions: Understanding that specific tasks have precise necessities, we offer custom designed answers for his or her clients. Whether it's a particular size, fabric grade, or layout, they can offer flanges tailored in your wishes.

Competitive Pricing: We give aggressive pricing without compromising on pleasantness. Their price-effective solutions lead them to a favored supplier for many industries looking for dependable socket weld flanges.

Quality Assurance

We guarantee that all their carbon steel socket weld flanges are synthetic to the best requirements. They adhere to stringent pleasant management tactics and worldwide requirements together with ASME, ASTM, and API. This dedication to pleasant guarantees that their products are secure, reliable, and in shape for purpose.

Customer Support

Excellent customer support is a hallmark of Metalforgeindia. Their informed and experienced team is constantly prepared to help customers with their inquiries, provide technical advice, and ensure that they get hold of the proper merchandise for their packages.

Conclusion

When it comes to sourcing superb carbon metallic socket weld flanges in Saudi Arabia, Metalforgeindia is the pass-to supplier and stockist. Their sizable variety of products, commitment to exceptional, and aggressive pricing cause them to depend on partners for industries throughout the region. Whether you're in the oil and fuel, chemical, or water remedy enterprise, Metalforgeindia has the right solutions to meet your needs.

0 notes