#steam boiler maintenance

Text

If you want to keep your family safe, save money and keep the warranty valid then boiler maintenance is very important. Booking regular boiler services is beneficial to you. To maintain a home or business at a suitable temperature, your residential or commercial boiler is essential. It’s normal to anticipate that your boiler will endure for several years, but if you use it regularly throughout the year, that may not always be the case.

0 notes

Text

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

For more details please visit our website -

0 notes

Text

Autoclave Machine Maintenance Services in Singapore

Gaia Science, a pinnacle in autoclave machine maintenance services in Singapore, assures top-tier expertise in ensuring the optimal performance of your equipment. With a commitment to precision and reliability, our skilled technicians deliver comprehensive maintenance solutions, extending the lifespan of autoclaves. Rely on Gaia Science for unmatched service excellence, safeguarding the efficiency and functionality of your critical laboratory equipment.

In Order To Find Out More Details On Autoclave Maintenance Services Please Be Touch With Us Today Onwards..!

#Autoclave#Autoclave Machines#Autoclave Maintenance Services#Benchtop Autoclave#Front Loading Autoclave#Vertical Autoclave#Air Compressor#Steam Boiler

0 notes

Text

1 note

·

View note

Text

The Importance Of Training Boiler Operators To Handle the Boilers

Modern boilers are harmless to the ecosystem. But they can be risky if they are not well maintained or kept up to be productive. Subsequently, your workers should be prepared for boiler well-being to figure out the expected dangers. An unattended boiler training from O'Brien is something you need the most.

Just like any other modern machine, boilers can break down. Severe issues might result from damaged boilers, poor upkeep, or rare examinations. Numerous boiler blasts could be avoided if the workers prepare enough for boiler wellbeing.

Modern boilers are utilized worldwide by different industries and plants to produce energy. They are utilized in different enterprises, for example, development, petroleum treatment facilities, fabricating plants, and food handling plants. Because they are so common, employees must be familiar with boiler safety to properly maintain their boilers.

Organizations should put resources into steam boiler training for their representatives to keep the risks that come about because of dismissing boiler upkeep. Comprehending that boiler security preparation isn't finished surprisingly fast is basic.

The main boiler well-being concerns incorporated, however are not restricted to:

Representatives should know that even non-warmed surfaces might be unsafely hot and prepare how to securely work around boiler frameworks.

Boilers might have pivoting parts that represent a risk to workers. Free attire might be trapped in the risky hardware, and the mind should be taken close to boilers.

Boiler frameworks have electrical parts that can deliver hazardous electrical flows.

The most effective way to protect your representatives and guarantee they have the information and abilities to protect themselves as well as other people is through boiler safety training.

An intensive comprehension of boiler parts, development, and how they work can be learned with boiler maintenance training. So, you should not miss the comprehensive instructions on operating boilers safely, effectively, and efficiently.

0 notes

Text

Steam Boiler for Oil Mill: Efficient Heating Solution

In the oil mill industry, a reliable and efficient heating system is essential for various processes, such as seed preparation, oil extraction, and refining. That’s where a steam boiler comes into play. A steam boiler is a versatile and powerful heating solution that ensures optimal performance and productivity in oil mills.

There are several types of boilers commonly used in various industries…

View On WordPress

#Boiler Efficiency#Boiler for Oil Mill#Boiler Maintenance#Energy Efficiency#Industrial Boiler#Oil Mill Boiler#Oil Mill Equipment#Steam Distribution#Steam Generation

0 notes

Text

The Cost of Electric Steam Boilers in India

Thermodyne has a good reputation on the Indian market when it comes to electric steam boilers. Their products are reliable and efficient, and they offer boilers of high quality at affordable prices. The price of electric steam boilers can vary in India depending on many factors, including the brand, the size, the features and the capacity. Electric steam boilers for different budget categories. The products are made with high-quality materials and designed to reduce energy consumption. This makes them cost-effective over time. For more information contact us at https://www.thermodyneboilers.com/electra-electrode-type-boilers/

#Electric steam boiler#Price#affordability#efficiency#industrial applications#capacity#maintenance costs

0 notes

Link

Commercial boiler installers have always told landlords and homeowners about the significance of maintaining the systems regularly and what can go wrong if the same thing isn’t done by a professional or if it isn’t done regularly.

Technicians that are responsible for Commercial Boiler Installation are also the ones you call up when you want the system to be serviced.

#commercial boiler repair#gas boiler maintenance#Boiler Maintenance Services#High Pressure Steam Boiler

0 notes

Text

Disney World Railroad – Orlando

(Thema Park Magic Kingdom)

Dampflokomotive - No.2 - Lilly Belle

Die hier fahrenden echten Schmalspur-Dampflokomotiven (Spurbreite 914 mm) wurden gebraucht in Mexiko auf einem Boneyard gekauft und in Florida überholt bzw. umgebaut. Dabei wurden sie von Kohle auf Heizöl umgerüstet, mit neuen Kesseln und neuen Führerhäusern versehen. Auf den originalen Fahrwerken wurden bei den Schlepptendern ebenfalls neue Aufbauten errichtet. Alle vier in Betrieb befindlichen Lokomotiven wurden Lokomotiven von Baldwin Locomotive Works gebaut.

Zu meinem Besuch im Februar 2024 waren nur zwei Maschinen

No.1, “Walter E. Disney”, Achsfolge 4-6-0, Baujahr 1925, Fabriknummer 58444

No.2, “Lilly Belle”, Achsfolge 2-6-0, Baujahr 1928, Fabriknummer 60589

im Parallelbetrieb. Die anderen beiden Lokomotiven

No.3, „Roger E. Broggie“, Achsfolge 4-6-0, Baujahr 1925, Fabriknummer 58445

No.4, „Roy O. Disney“, Achsfolge 4-4-0, Baujahr 1916, Fabriknummer 42915

waren gerade in Wartung.

Disney World Railroad - Orlando

(Magic Kingdom theme park)

Steam locomotive - No.2 - Lilly Belle

The real narrow-gauge steam locomotives running here (gauge 914 mm) were bought second-hand in Mexico at a boneyard and overhauled or rebuilt in Florida. They were converted from coal to fuel oil, fitted with new boilers and new driver's cabs. New bodies were also built on the original bogies of the locomotive tenders. All four locomotives in operation were built by Baldwin Locomotive Works.

At the time of my visit in February 2024, only two machines

No.1, "Walter E. Disney", axle arrangement 4-6-0, year of construction 1925, serial number 58444

No.2, "Lilly Belle", axle arrangement 2-6-0, year of construction 1928, serial number 60589

in parallel operation. The other two locomotives

No.3, "Roger E. Broggie", wheel arrangement 4-6-0, year of construction 1925, serial number 58445

No.4, "Roy O. Disney", axle arrangement 4-4-0, year of construction 1916, serial number 42915

were currently undergoing maintenance.

Translated with DeepL.com (free version)

#dampflokblog.de#Walt Disney Railroad#steam train#railway#dampflok#stoom locomotief#eisenbahn#steam locomotive#Lilly Belle#Baldwin Locomotive Works#Schmalspurbahn#локомотив#lokomotywa#locomotive à vapeur#鉄道#locomotora a vapor#stoomtrein#Steam train#locomotora#locomotive#schmalspurbahn#narrow gauge

45 notes

·

View notes

Text

Bulleid's Proposed Locomotives

So it turns out Bulleid had so many of his designs dropped for one reason or another, and since I can't stick with a single project for more than a few seconds, I wrote up histories for all of them!

Enjoy the ramblings of a madman who spent a good long while finding free number slots for them.

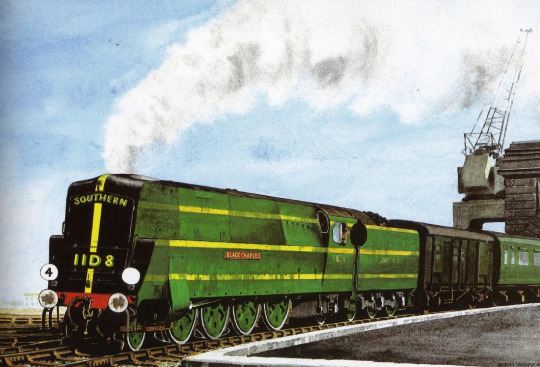

Southern Railway Warship Class

The Southern Railway was the most financially successful of the "Big Four", but this was largely based on investment in suburban and main line electrification. After the successful introduction of the SR Schools class in 1930, the railway had lagged behind the others in terms of modernizing its aging fleet of steam locomotives, as they were more focused on Electrification. Following the retirement of the general manager of the Southern Railway Sir Herbert Walker and Richard Maunsell the Chief Mechanical Engineer (CME) in 1937, their successors considered that the time had come to change this situation. In March 1938 the new general manager Gilbert Szlumper authorized Oliver Bulleid, Maunsell's replacement, to prepare designs for twenty express passenger locomotives. The deteriorating international situation prior to the Second World War was an additional factor in this decision.

Originally, Bulleid had wanted a 4-8-2 Mountain Type, but the Civil Engineering department had resisted this based on size and weight, so a 2-8-2 was chosen instead. Bulleid had worked with Gresley on his P2 2-8-2 express engines, so he already had some background knowledge, especially with the P2’s problems and ideas on how to solve them. Of course, due to the war, they were classified as heavy mixed-traffic engines to get around wartime regulations.

They were built with high-pressure 280 PSI boilers and three 18inx26in cylinders, as well as being the first engines to use Bulleid’s chain-driven valve gear, though the middle cylinder had to be inclined steeply to clear the first driven axle. The boiler was partly welded to save on cost, and the inner firebox was made of steel. The Southern had no facilities to build these boilers, so it was subcontracted to the North British Locomotive Co., as well as Beyer Peacock. They were also fitted with Bulleid’s Air-Smooth Casing. Unlike later designs that utilized this, the casing on the Warships both served their function purpose as labor saving as well as being able to be passed off as some sort of streamlining. How Bulleid got that one through during the war is a mystery! The Warship’s were also the first to use Bulleid’s Firth-Brown Wheels.

10 of these engines were constructed in 1940. More were set to be produced, but once again, the Civil Engineering Department expressed their discomfort at such a large engine running at high speeds with only a single pony-truck in front, despite other engines of a similar design getting on fine elsewhere. This would lead Bulleid to designing and building 30 of his well-known Merchant Navy Class 4-6-2s.

They were named after Warships as a way to increase morale, with 11D1 being officially named “Dreadnought” in April 1940. They performed well in service, hauling heavy passenger and express goods, though the Chain-Driven valve gear was sensitive and required high maintenance, as well as the oil-bath having leaking problems, contributing to wheel-slips(Though the extra wheel helped negate this as well). The casing, while it did save on labor during cleaning, and the more streamlined appearance helped with publicity, it made maintenance hard to carry out. Surprisingly, thanks to their different front ends, they never really experienced drifting smoke like Bulleid’s Pacifics.

All 10 of the engines would be passed into British Railways, numbered 37001-37010, where their duties mostly stayed the same. 11D8 “Black Charles'' took part in the 1948 locomotive exchange trials, where it was compared to LMS Duchess pacifics and LNER A4’s and A2/2s, where it performed favorably, though the chain driven valve gear and its oil bath still caused headaches. After the Crewkerne incident, BR chose a rebuilding program of any engines that still used Bulleid’s Chain Driven motion, however, as the Warships had required far less modifications that the Pacifics, they were on the bottom of the list in the rebuilding program. In the end, only 37003 “Triumph”, 37009 “Warspite”, and 37010 “Exeter” were rebuilt in 1956, 1957, and 1959.

Despite their status as a class with very few engines, all ten would survive until the end of southern steam, going between 1965-1966.

Two are preserved, both being rescued from Barry Scrapyard in Wales. These examples are Class Pioneer 11D1 “Dreadnought”, as well as 11D3 “Triumph”.

Stats

Power Classification - 8MT

Built - 1940 to 1941

Boiler Pressure - 280 PSI

Cylinders (3) - 18in x 26in

Wheels (Driven) - 6ft 2in

Wheels (Leading) - 3ft 1in

Wheels (Trailing) - 3ft 7in

Wheels (Tender) 3ft 7in

Tractive Effort - 40,640 lbf

Total Length - 74ft 8in

Fleet

11D1 (37001) - Dreadnought

11D2 (37002) - Anson

11D3 (37003) - Triumph

11D4 (37004) - Vanguard

11D5 (37005) - Ark Royal

11D6 (37006) - Audacity

11D7 (37007) - Valiant

11D8 (37008) - Black Charles

11D9 (37009) - Warspite

11D10 (37010) - Exeter

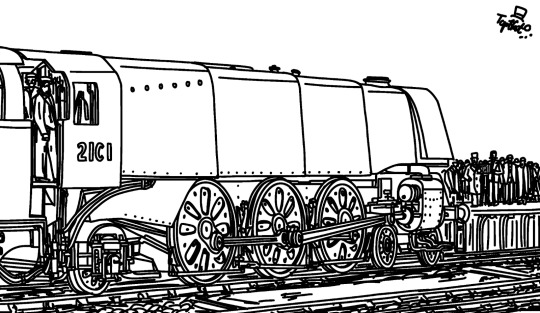

Southern Railway Prototype Light Pacific

(Pic by Sttophat on twitter)

In 1941, Bulleid had introduced his Warship Mikado's and Merchant Navy Pacific's to become the main motive power for the Southern Railway’s Express passenger trains, though while they performed well, they were restricted by their weight, especially since the condition of the rails were hampered by the Second World War. Initially, trains on the lighter sections were handled by the Q1 0-6-0 freight engines and other, older engines, but they couldn’t handle the faster trains that were anticipated after the war. There was also the planned electrification of certain areas after the war, so the new design also needed to handle freight traffic as well, fast enough to not impede electric services.

What was decided on in the end was a downsized version of the Merchant Navy’s, fitted with the same design theory of the Q1’s to create a “Light Pacific”. The Locomotive was completed in 1942 alongside the Q1’s, and was trialed for a short time before entering service. It was deemed a success, and numbered 21C201. It was powerful enough to handle fast, heavy trains, as well as having an extremely light axle loading for a pacific at 16.5 Tons, enabling it to be used on almost every part of the UK Network as a whole. However, Bulleid decided to go with a different approach, creating simply a downsized Merchant Navy with no Q1 elements. This would increase the axle load, though this wasn’t much of an issue, as the Battle of Britain and West Country Class Light Pacifics still had a high enough route availability for the work they were assigned. Thus, the “Q1 Light Pacific'' would remain a one-off.

During the war, No.21C201 would actually travel a fair amount, and would regularly venture out of Southern territory, its light axle-load coming in handy. After the war however, it would mostly stay in the South. Performance-wise, it seemed to inherit all of the good qualities from the Q1’s and the pacific’s. The light-weight was already a plus, coupled with a great, free-steaming boiler and additions that made the driver and fireman’s life easier. However, it also inherited the bad aspects as well. The chain-driven valve gear was a well-known headache on bulleid locomotives, but there was also the issue that its light-weight caused. The regular Light Pacifics had trouble starting heavy trains thanks to their weight, but No.21C201 had it worse, especially with the well-known issues with the oil bath the valve gear was situated in. The light weight would also affect braking power as well, making unfitted trains harder to stop, a trait inherited from the Q1’s.

No.21C201 (Now Renumbered 34000) was not considered for rebuilding like the other Bulleid Pacifics due to its one-off status. It would be given a general repair in 1960 before spending the rest of its life at Nine-Elms, mainly working express and semi-fast goods trains and the occasional passenger turn during peak period and summer excursions. It was withdrawn from service in 1966 and broken up at Eastleigh.

Stats

Power Classification - 6MT

Built - 1942

Wheels (Driven) - 6ft 2in

Wheels (Leading) 3ft 1in

Wheels (Trailing) - 3ft 7in

Wheels (Tender) - 3ft 7in

Boiler Pressure - 250 psi

Cylinders (3) - 16.5in x 24in

Tractive Effort - 28,145lbf

Total Built - 1

Southern Railway L1 Class

Bulleid designed these locomotives during the Second World War, but construction didn’t begin until 1946. They shared many components with Bulleid’s Q1 0-6-0 goods engines, and were essentially the Q1’s with an Air-Smoothed Casing and a bigger boiler (though the firebox was identical with that of a Q1’s).

Twelve of these engines would be constructed between 1946 and 1948, with the final 3 being built by British Railways. They were originally numbered 22C1 to 22C12, though they were renumbered in 1949 to 36101 to 36112. They were originally meant for short distance goods and passenger services, though they never really found their footing in this role. The passenger trains that usually necessitated big tank engines were already being handled by electric engines, and everything else usually required smaller and lighter engines, which meant that, despite inheriting the power and efficiency of the Q1, the added weight and size meant that they were barred from where they could be most effective. The goods work they were meant for were also in the care of both Q1’s and Maunsell’s Q Class, as well as the many N class moguls already in service. In the end they spent their time hopping from shed-to-shed before settling on ex-LSWR territory, and even venturing into Western Region territory.

They were withdrawn between 1962-1964. Only one survives, 22C9 (36109) on the Bluebell Railway.

Stats

Power Classification - 5F 4P

Built - 1946 to 1948

Boiler Pressure - 230 PSI

Cylinders (2) - 19in x 26in

Wheels (Driven) - 5ft 1in

Wheels (Bogies) - 3ft 1in

Tractive Effort - 30,080 lbf

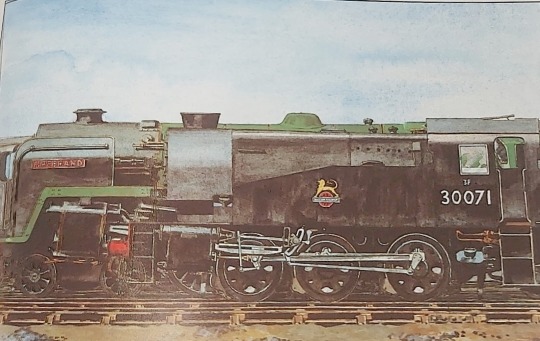

Southern Railway Dock Class

After the Second World War, many of the Southern Railway’s shunters (mainly those at Southampton) inherited from pre-grouping companies were worn out and needed overhauling. As such, Bulleid opted to replace them outright with his own design of 0-6-0T, with a short wheelbase of 10 feet to enable it to negotiate the tight curves. Like many of Bulleid’s designs, he equipped it with a relatively high boiler pressure.

Six would enter service in 1946, and while a total of 18 were planned, this would never come to be, as Eastleigh works was not in a position to build new locomotives with the backlog from the war. In the end, the southern found it cheaper to purchase ex-USATC S100 dock shunters, as they fulfilled most of the requirements needed.

They were numbered C201 to C206, and were renumbered to 30071 to 30076 in British Railways days. The first, 30071, was built with the Idaglass boiler lagging and casing as used in the Q1 class, while the other 5 were built with conventional boiler lagging and tanks. 30071 would be rebuilt like the others in 1953.

The class would lead uninteresting lives as dock shunters in Southampton and Dover until their withdrawal between 1961-1962. One was initially purchased for preservation but the deal fell through. None are preserved.

Stats

Power Classification - 3F

Built - 1946

Boiler Pressure - 220 PSI

Cylinders (2) - 16in x 24in

Wheels (Driven) - 4ft 6in

Tractive Effort - 21,276 lbf

#oliver bulleid#what-if engines#train#I have way more of these if you guys want to see them#or maybe I'll just do it anyways lol

50 notes

·

View notes

Text

Traintober 2023: Day 24 - Odd Jobs

Rusty's Duties Have Always Been Odd Jobs:

Rusty’s duties have always been odd jobs.

It begins, as always, with Rusty being started up early in the morning by their driver, with Mr Hugh close behind. The little diesel is not the first out of the shed – that honour goes to Duke, who always pulls the first train of the day. Rusty quietly wonders if it’s so the others get some extra rest. Whatever the answer is, the heat from Duke’s boiler always warms the shed wonderfully, meaning the little diesel’s engine turns over on command, rather than coughing and spluttering in the cool of the early morning.

From there, Rusty’s first job every morning is to help Mr Hugh inspect the coaches and trucks in the yard. They check that they’re all in their proper places, that the brakes haven’t frozen solid (especially in the winter), that they’ve recently had their joints greased. It’s not a difficult task, nor is it a long one – but it’s enough to help Rusty wake up. The little diesel can’t drink coffee after all, so this has to suffice.

After the trucks and coaches have been checked, the pair inspect the points, and then Rusty is free to shunt trains until the track crew call.

The little diesel doesn’t always pull maintenance trains – it’s just not needed – but that’s alright. There are plenty of other jobs that need doing. Rusty’s roll on the railway – when the little diesel isn’t working on the track – is to act as the ‘relief’. This is a very important job. Whenever one of the other engines breaks down, has an accident, or is delayed, the ‘relief’ is called to cover for them. Rusty takes this job very seriously. It means that the little diesel has to be prepared at any moment to race up the line to help.

But Rusty loves the maintenance trains the most. These trains run up and down the line, and fix the track before there can be a problem. Rusty thinks there isn’t a job in the world more rewarding! Maintenance trains run most often in the autumn and spring – in the winter, it’s almost impossible to see the trackbed for the snow that coats it, and in the summer every engine is needed for the tourist trains. This leaves just the cold, wet month of November for maintenance trains in the autumn, and windy, wet March for maintenance trains in the spring.

Which was rather annoying, for the amount of rain that could fall and cause issues everywhere. Snow melted into torrents that threatened to wash away the line, but that never deterred Rusty. The little diesel dutifully trekked up and down the line, keeping their friends safe in their own way.

When not pulling maintenance trains or acting as the ‘relief’, Rusty could be found shunting trucks and coaches, or delivering coal to the villages in the mountains, or working the inclines. The little diesel did a million things in a day, and they wouldn’t have it any other way.

And as night fell, as the stars began to illuminate the night sky with their twinkling light, Rusty returns to the shed. The little diesel is not the first to return – Sir Handel came off the rails earlier after yet another argument with the coaches – and the little diesel is certainly not the last to return – Rheneas has the mail run – but everyone agrees that Rusty deserves a place in the shed beside Duke. Because in the morning, Duke will be the first engine to get up steam, with his boiler warming Rusty’s engine so the little diesel can do it all again, continuously doing the odd jobs behind the scenes to keep the Skarloey Railway running.

Back to Master Post

#fanfiction writer#railway series#weirdowithaquill#thomas the tank engine#railways#traintober 2023#traintober#ttte rusty#skarloey railway#ttte fandom#odd jobs#Rusty is best diesel

44 notes

·

View notes

Text

I made a slightly cursed au involving a Demon train.-

The gang are souls bound to the train. they are being punished for the bad things they did in life. It is not an eternal punishment but it is still really long. THeir job is to transport escaped demons hunters have caught back to the underworld. As expected this is NOT a pleasant job. The gang has to be on constant lookout, not to make sure the demons don't escape.. it‘s to know when they inevitably will. It WILL happen every night.They just need to know how to recapture the ones who escape.

Dust is the one who keeps track of demon types and how to recapture them. He has a journal of those in the same job as him before and adds any discoveries he finds in order to help the next soul that will inevitably be punished with the position. He knows a lot… needless to say he sleeps the least out of all of the gang. (he writes down the all the types of demons in the train that night as well)

Horror is a mechanic and general maintenance worker for the train. (hey even demon trains need some repairs every once in a while) he can cook but doesn't get any real ingredients very often. Also there are all ghosts so they don't really eat :^ Even though he can't cook anything for him or the gang he is able to cook demon foods.This is a surprisingly good motivator. It seems everyone likes food…

Killer is the conductor you could say. He makes most decisions and is in charge most of the time. Despite his recklessness and general goblinry he is actually a rather good conductor. He is also good with knives. But Killer has a problem making deals with demons… he needs to stop- he can't sell his soul for the fifth time this week- it is not physically possible- Nightmare has to break any connections Killer might have formed with demons because of deals he’s made.

Cross is the weapons master. He is in charge of the weapons and can use a variety. He also has to make sure none of the gang's weapons are swapped for fakes without them noticing. A fake weapon is next to useless against a demon and Cross knows that could be a very painful mistake. Demons will try and swap weapons whenever possible.

Nightmare is not a member of the crew on the train. He IS THE TRAIN. >:D for the most part manages himself and does not need “fuel” . He is a demon who has been punished by being bound to the train. This allows for travel between realities possible in the first place. Without him the train would not run or portal to the underworld in the first place. (in short he’s a cursed eldritch horror train boi)

Dream is a demon hunter (a non mortal that hunts demons that have escaped.)

He is friends with Ink,Blue,and Stretch who are paranormal investigators and ghost hunters. They don't know about Dream being well.. Not mortal and they keep wondering why all their ghosts seem to disappear.

They have a van that they drive around. Stretch is the main Driver and technology guy but doesn’t really go into any of the haunted places. Ink and Blue had been friends since they were little and so they decided to become paranormal investigators. They later found Dream who wished to join them and have been traveling together since.

Dream disguised himself as a mortal in order to Join Blue,Ink, and Stretch. He simultaneously is able to locate demons and Keep The rest of his friends safe from the demons and spirits they are hunting. Though Blue is rather frustrated all the demons keep disappearing soon after they show up.

Dream then Takes any demons to the nearest “train station” which is not visible or tangible to mortals.

if you have any questions about this au then i would enjoy answering any of them.

i am attempting to find the post that inspired this. it was one about steam engines and what they looked like if their boiler exploded or something...

#herrings rambles#nightmare sans#undertale au#bad sanses#killer sans#dust sans#horror sans#Phantom Train au#star sanses#dream sans#swap sans#underswap papyrus

33 notes

·

View notes

Text

Boilers And Chillers Erection Services In India

We have decades of experience servicing boilers and chillers for multiple commercial and industrial facilities as well as servicing other mechanical, electrical and plumbing systems.we provide Magnetic bearing chillers,Screw & scroll chillers,Reciprocating chillers,Steam & hot water boilers,Reciprocating chillers,Steam & hot water boilers,Chiller & boiler controls, System pumps and Cooling tower.

For more details please visit our website

0 notes

Text

Image 1: a typical modern electric slime tram, with adorable "streamlining" and an Advanced Steam commuter train.

The steam engine is an Advanced steam engine with the gas generator boiler fired automatically using microcontrollers, with compound cylinders, steam super heaters, etc. The driver controls the locomotive electronically from a cab at either end of the train.

Advanced steam engines were developed due to skyrocketing oil prices which drove up the price of electricity and made diesel hydraulics much less cost effective to operate. Old style steam locomotives would not have been considered up to snuff and the maintenance facilities for them had dwindled, but Advanced Steam sought to solve the maintenance and servicing problems. Most advanced steam was utilized for very large scale applications like freight hauls and migration trains, but the concepts could also be employed on smaller scales.

Image 2: Locomotives of the Slaibgloth Coal Mine. These comprise about 30 2-8-0+0-8-2 Garrats, 5 Shays, and 5 "easy" (non-articulated) locomotives utilizing spare engine sets from the Garrats and spare boilers from the Shays.

The Garrats were built in 2346 A.D. and retired in 2379 A.D. (two years ago) for service bringing coal carriages from the coal pits up to the interchange at the Glooiw & North Eastern. It is unusual for a coal burning steam engine to remain in revenue service--the majority that remained in use after the development of Diesel-Hydraulics were decommissioned with railway electrification and the ones that remained were mostly converted to oil burning. The Slaibsgloth steam engines meanwhile persisted right up until the closure of the coal mine. Glooiw & North Eastern has acquired the 40 locomotives. Their fates are uncertain but railway preservation groups remain optimistic.

#Mellanoid Slime Worldbuilding#Train#Steam train#steam engine#tram#trolley#railway#railroad#steam locomotive#steam train#Mellanoid slime worm

8 notes

·

View notes

Note

As a Guy who Fixes Machines for a living, but unfortunately doesn't have Much experience with engines, *but* has read a Ton about them: please tell me about steam engines and/or their Repair Quirks and Logistics. Infodump Away :chinhands:

I'm going to be honest with you - this is one of the most flattering asks I've ever received in my 14+ years on this website.

Steam locomotives seem pretty overwhelming at first because, as you'd expect, there's a lot of moving parts, and they're actually huge. Like many large animals, people often don't realize how big they can actually get until they're in the presence of one. The one I drove, Strasburg #90, weighs in at 212,000 lbs - and she's smaller than a lot of the active steam locomotives operating today. 106 tons is nothing to sneeze at, and she's still considered smaller.

You probably don't need this in layman's terms, but I'm going to try to keep the explanations easy to understand in case anyone who doesn't work with machines reads this.

How do the beasts run?

Continuing the metaphor of these things basically being really large animals, you have to feed and water them. Early steam locomotives ran on wood, but as time went on the most common fuels became coal and oil, and today some can even run clean on vegetable oil or torrefied biomass. The fact that they need to be fed and watered fairly regularly is why there's always at least two people in the locomotive cab - you've got an engineer driving and a fireman keeping the beast fed and monitoring the water levels in the boiler.

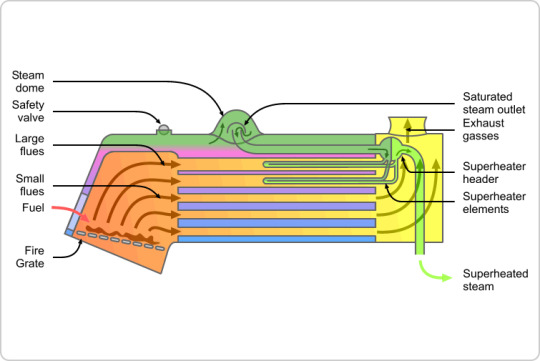

This is a diagram of a fire tube boiler from Wikipedia. Steam locomotives generally use this type of boiler, which gives them their familiar shape. The fuel is thrown into the firebox on the left of the diagram, and the heat from the fire flows up to the tubes in the boiler. The water in the boiler becomes steam (specifically what's called "wet steam" because it's saturated). The steam rises to the highest point in the boiler, the steam dome at the top. From here, the steam is sent down into a superheater, which dries it out and produces superheated steam, and that's what's directed down to the cylinders to get everything moving. The smokestack on the right of the diagram is where the exhaust gasses are released, giving off that plume of smoke everyone expects to see.

Now that the steam is at the cylinders, the pistons can start pumping and moving the driving rods on the driving wheels (the big ones). Here's an animated gif of that process, again from Wikipedia.

At this point, it's basically like any other engine with pistons - the pistons get pumping and the machine starts operating. This whole section of the locomotive is referred to as the running gear, and includes the valve gear, connecting rods, brake gear, wheelsets, axleboxes, and springing.

Essentially, it's a steam engine with wheels that is capable of pulling incredible amounts of weight if everything is done correctly. Your average steam locomotive is still stronger than your average diesel or electric locomotive is. Depending on what you needed your steam locomotive to do, the size of the driving wheels would differ - locomotives built for high speed tend to have really large drive wheels, whilst locomotives designed to go slower but pull more weight have smaller drivers for better adhesion and traction.

Maintenance?

As expected, since they have a lot of moving parts, steam locomotives need a lot of active maintenance. They're checked frequently, have mandated annual inspections, and are required by the Federal Railroad Administration in the United States to have a more thorough inspection every 1,472 days of active service - so it's basically 15 years or 1,472 days of operation, whichever comes first. 90, the locomotive I drove at Strasburg, is currently undergoing her 1,472-day inspection as I write this post and she'll hopefully be back in operation for her 100th birthday next year.

One of the things that's unique about steam locomotive maintenance is that the boiler regularly has to be cleaned out, which is why the boilerplate on the front has hinges - that thing's a door! This job was more dangerous historically because boilers were often insulated with asbestos, but pretty much anything operating today has had any asbestos removed or wasn't built with it in the first place. This website has a really good explanation of the process of cleaning out and fixing up a locomotive boiler for a 1,472 day inspection, complete with photos!

In terms of steam locomotive shops, I'm biased towards Strasburg because I grew up going there all the time, but they really do perform incredible work. Late last year, one of their locomotives, #475, had a run-in with a crane left on the track due to a misthrown switch, and her smokebox took some damage. Fortunately, the damage was minor, and they were able to get her repaired in a mere 96 hours.

She now looks like this:

They opted to braze weld her and didn't smooth it out as a reminder to crews to stay vigilant, so she now has some really cool battle scars.

I'm not as well-versed in repair since I don't have hands-on experience with it (yet), but once I can start volunteering I'll hopefully have some more stuff to talk about since I'm hoping to learn to work with these machines more closely! (And drive. Drive all the time. Drive forever.)

40 notes

·

View notes

Text

Broadway, New York City

Steam Heating in the Concrete Jungle: A Comprehensive Analysis of New York City's Historic and Sustainable Heating Infrastructure

Introduction

1.1 Historical Overview of Steam Heating

Steam heating has a storied history in New York City, dating back to the mid-1800s. Before steam heating, buildings relied on individual coal-burning stoves or fireplaces for warmth, resulting in uneven heating and numerous health hazards. The advent of steam heating, pioneered by engineer Stephen Gold in the 1850s, marked a significant advancement in heating technology. It offered a centralized heating solution, where steam generated in large plants could be distributed efficiently through a network of underground pipes to individual buildings, providing consistent and reliable heat throughout the city.

1.2 Advantages and Disadvantages of Steam Heating

The adoption of steam heating brought several advantages to New York City. It allowed for the elimination of individual heating units in each building, reducing maintenance costs and fire risks. Steam heating systems operate quietly, without the noise associated with forced-air systems, contributing to a more peaceful urban environment. Additionally, steam heating radiators became architectural features, adding a distinctive charm to buildings' interiors.

However, steam heating also presented challenges. One of the primary concerns was heat loss during steam transportation through the extensive underground pipe network. Proper insulation became crucial to mitigate energy waste and ensure efficient heat distribution. Additionally, as the steam system aged, it became susceptible to leaks, and repairing the aging infrastructure posed logistical and financial hurdles.

1.3 Comparison with Other Heating Systems

Compared to forced air and electric heating systems, steam heating offered unique benefits. Forced air systems, prevalent in modern construction, tend to create drafts and circulate dust, potentially exacerbating respiratory issues. Steam heating's ability to deliver consistent warmth without air movement was preferred in many buildings. Electric heating, while convenient and clean, often proved less efficient and costlier, especially for larger buildings served by the steam system.

How Steam Heating Works in New York

2.1 Steam Generation in Centralized Plants

The heart of the New York City steam heating system lies in its centralized plants. These large facilities, situated strategically throughout the city, house powerful boilers that generate steam from various energy sources, including natural gas, oil, and coal. In recent years, efforts have been made to transition towards cleaner fuels and renewable energy options, aligning with the city's sustainability goals.

2.2 Distribution of Steam in Underground Pipes

Once steam is produced, it is conveyed through an extensive network of underground pipes, known as steam mains. These mains crisscross the city, providing steam to thousands of buildings. The pipes are insulated to minimize heat loss, maximizing the efficiency of the distribution process.

2.3 Steam Radiators and Heat Exchange

Upon reaching individual buildings, the steam is directed to steam radiators or heat exchangers, depending on the building's size and heating requirements. Steam radiators are common in residential buildings, where the steam enters the unit and releases its latent heat as it condenses back into water, effectively warming the surrounding air. Heat exchangers are prevalent in commercial and industrial settings, where the steam's heat is transferred to the building's air or water distribution systems.

2.4 Steam Traps and Venting

Steam traps are essential components of the steam heating system. They are designed to remove condensate, the water formed when steam cools down, from the system. Proper venting is equally crucial, as it releases air and non-condensable gases from the pipes, preventing air locks and ensuring efficient steam flow. Specialized venting devices, such as air vents and steam traps, are installed throughout the system to maintain its optimal performance.

New York City Steam Heating System

3.1 Overview of NYC Steam System

The New York City steam heating system stands as one of the largest and oldest in the world. The responsibility for its operation and maintenance lies with private utility companies, which have historically managed the network's intricate web of steam mains, radiators, and heat exchangers.

3.2 Steam Plants in New York City

New York City's steam plants are strategically located to serve the varying heating demands of different neighborhoods. These plants are equipped with modern boilers and state-of-the-art emission control technologies to reduce environmental impacts. Efforts to further improve air quality and sustainability are continuously underway.

3.3 Steam Distribution Network

The steam distribution network encompasses over 100 miles of steam mains, which interconnect and branch to supply steam to individual buildings. The network's design considers factors such as pressure requirements, building density, and historical demand patterns to ensure an efficient and consistent supply of heat throughout the city.

3.4 Maintenance and Upgrades of NYC Steam System

Maintaining such an extensive steam heating system requires regular inspections and maintenance. The aging infrastructure presents challenges, making ongoing upgrades essential to ensure the system's longevity and continued efficiency. Modernization efforts include replacing older pipes with more robust materials, improving insulation, and upgrading boiler technologies to enhance energy efficiency.

Heating Buildings with Steam

4.1 Steam Heating in Residential Buildings

Steam heating systems are a common sight in older residential buildings across New York City. The iconic steam radiators, often found beneath large windows, have become cherished architectural elements. Residents appreciate the steady and cozy heat these systems provide during the harsh winter months.

4.2 Steam Heating in Commercial and Industrial Buildings

Commercial and industrial buildings extensively utilize steam heating due to its ability to meet the substantial heating demands of such structures. Heat exchangers play a crucial role in these settings, where steam heat can be efficiently transferred to large air or water distribution systems, catering to diverse heating requirements.

4.3 Steam Heat vs. Forced Air: Considerations and Comparisons

In the perennial debate between steam heating and forced air systems, each has its merits. While steam heating boasts even heat distribution, quiet operation, and a lack of airborne dust circulation, forced-air systems can also provide air conditioning and ventilation, adding flexibility to building comfort. The choice between these heating methods depends on the specific needs and priorities of each building owner or occupant.

Efficiency and Sustainability of New York City Steam Heating

5.1 Assessing the Efficiency of Steam Systems

Efficiency is a critical aspect of the steam heating system, as it directly affects operating costs and environmental impacts. Regular assessments of individual steam systems and the overall distribution network are conducted to identify opportunities for improvement. Efforts are focused on reducing heat loss, optimizing boiler performance, and upgrading insulation to maximize energy efficiency.

5.2 Environmental Considerations and Emissions

Given the environmental challenges of fossil fuel-based energy sources, New York City is actively exploring ways to reduce emissions associated with steam heating. Increased reliance on cleaner fuels, as well as integration with renewable energy sources, is being pursued to lower the system's carbon footprint and align with the city's commitment to sustainability.

5.3 Energy-Saving Measures and Upgrades

To further enhance the efficiency and sustainability of the steam heating system, energy-saving measures and technological upgrades are continually implemented. These may include installing advanced control systems for better operational management, adopting waste heat recovery techniques, and exploring the integration of renewable energy into steam generation.

Operation and Maintenance of New York City Steam Heating Systems

6.1 Proper Operation and Control of Steam Systems

Operating steam heating systems requires skilled personnel who are well-versed in the complexities of steam distribution and radiator control. Proper monitoring and adjustments to steam pressure and temperature are essential to maintain efficient heat distribution and prevent energy wastage.

6.2 Common Issues and Troubleshooting

Despite rigorous maintenance practices, steam heating systems can encounter occasional issues, such as leaks in underground pipes, uneven heating in specific areas, or water hammer (the loud noise resulting from sudden condensate contact with steam). Timely detection and troubleshooting are vital to minimize disruptions and ensure a comfortable indoor environment.

6.3 Safety Considerations and Maintenance Practices

The safe operation of steam heating systems is paramount, considering the high temperatures and pressures involved. Regular safety inspections and adherence to strict maintenance protocols are essential to prevent accidents, protect occupants and workers, and maintain the integrity of the entire steam heating infrastructure.

Future Trends and Alternatives to New York City Steam Heating

7.1 Innovations in Steam Heating Technology

As technology continues to advance, innovations in steam heating are expected to improve the efficiency and sustainability of the system. These may include advancements in boiler design, better insulation materials, and smart technologies that optimize steam generation and distribution, ultimately enhancing overall system performance.

7.2 District Energy Systems and Combined Heat and Power

District energy systems, also known as district heating or cooling, involve the sharing of heat and cooling resources among neighboring buildings. Such systems can enhance the efficiency of energy use and reduce overall emissions by utilizing waste heat from one building to serve the needs of another. Similarly, Combined Heat and Power (CHP) systems integrate power generation with steam generation, maximizing the utilization of energy resources and reducing greenhouse gas emissions.

7.3 Exploration of Alternative Heating Methods

In pursuit of greater sustainability, New York City is exploring alternative heating methods that can complement or replace steam heating where feasible. Geothermal heating, solar thermal systems, and heat pumps are among the technologies under consideration. These systems harness renewable energy sources to provide heating, potentially reducing reliance on fossil fuels and contributing to a cleaner urban environment.

Conclusion

The New York City steam heating system has left an indelible mark on the city's history, revolutionizing how buildings are heated and providing comfort to millions of residents and workers. The network's robust infrastructure, combined with ongoing efforts to improve efficiency and sustainability, reflects the city's commitment to maintaining a reliable, efficient, and environmentally responsible heating system. As the future unfolds, advancements in technology and the exploration of alternative heating methods will further shape the destiny of steam heating in New York City, ensuring its relevance and resilience for generations to come.

#broadway#New York City#new york#newyork#New-York#nyc#ny#manhattan#urban#city#usa#buildings#visit-new-york.tumblr.com#New York City Steam

202 notes

·

View notes