#steel warehouse building

Text

A Step-by-Step Guide: Building Brilliance in Steel Warehouse Installations

Steel warehouse buildings have become increasingly popular. It has happened as a result of the growing need for durable and advanced storage solutions. These buildings are an incredible option. They work wonders in different sectors because they are affordable, flexible, and long-lasting.

So, a systematic and thorough strategy is essential to guarantee the robust construction of a steel warehouse structure.

Today, we will discuss the essential phases of creating brilliance in steel warehouse installations in this article below.

Best Steps You Can Take For Advanced Steel Warehouse Installations

These are some of the top steps you can take for robust steel warehouse buildings-

Project Preparation and Design

A state-of-the-art steel warehouse building project starts with careful planning. It also needs deliberate design and graphics. Work with skilled architects for this. Take help from engineers to develop a comprehensive plan that suits your company's requirements. Consider things like storage needs, operational workflows, and potential future expansion. A well-designed steel warehouse will maximize space utilization and improve overall functionality.

Setting Up the Site

Site preparation comes next after the design is complete. It entails providing appropriate drainage, leveling the land, and removing the chosen area. The stability and endurance of the steel warehouse structure depend on a well-prepared site. The installation crew should carry out a comprehensive evaluation to handle any possible issues and modify the design as needed.

Building the Foundation

Any structure, including steel warehouse buildings, is anchored by its foundation. Select the best foundation based on the building specifications and soil conditions. Pier or concrete slab foundations often get used for steel warehouses. Confirm that the foundation is strong enough to hold the weight of the stored items and the steel construction.

Fabrication of Steel Structures

The steel warehouse's structure is its main component. Collaborate with trustworthy steel fabricators who can fulfill project demands while producing top-notch components. Precision in production is essential. Accuracy and efficiency are enhanced using modern fabrication processes like computer-aided design (CAD) and computer numerical control (CNC) machining.

Delivery and Transportation

The steel parts must be delivered to the construction site after production. Communication between the logistics staff and the fabrication plant is crucial. It helps in prompt and secure delivery. Proper handling and packaging practices should be in place to prevent any damage during shipment to ensure that the components reach the site in ideal shape.

On-Site Constructing

The assembly stage starts once the steel components are on location. Throughout the installation procedure, competent construction teams should adhere to safety regulations and the comprehensive blueprints. Large steel parts may need to be lifted and placed using heavy machinery and specialist equipment. Any deviations from the plan should be quickly remedied. It ensures the warehouse's structural integrity, and precise assembly is essential.

Roofing and System Integration

The steel warehouse's cladding and roofing are essential elements that enhance its appearance and usefulness. Select cladding and roofing materials of the highest caliber that meet the unique needs of the warehouse environment. Following the installation of the structural components, the focus shifts to the interior finishing and system integration. Safety and accessibility should be prioritized. Organize the interior space to allow for advanced product storage and retrieval.

Wrapping Up This Here

A systematic and well-thought-out approach is a must-have to create brilliant steel warehouse installations. Every stage of the project, from the initial concept and planning to the last details of interior finishing, is vital to its success.

Businesses may guarantee steel warehouse buildings that satisfy their present demands. They also lay the groundwork for future growth and efficiency by devoting time and attention to each stage.

Lastly, contact TSSC - Technical Supplies and Services Co LLC for solid steel warehouse installation materials and cladding solutions. Check out their digital assets and call them right now!

0 notes

Text

youtube

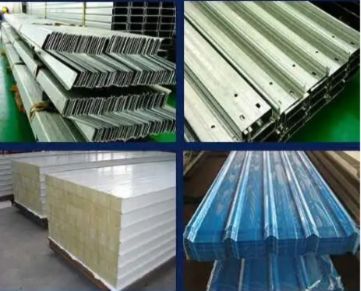

steel building supplier from China, Qingdao Sincere Steel Structure.

3 notes

·

View notes

Text

Steel frame prefabrication long span warehouse building prefabrication workshop

0 notes

Text

Steel warehouses and Hangers in UAE

Steel warehouses and Hangers in the UAE offer sturdy storage solutions for a range of industries. Built to handle tough weather conditions, they provide ample room for storing inventory, equipping, and managing logistics. These structures balance sturdiness with adaptability, catering to diverse storage needs while meeting stringent quality standards and regulatory guidelines.

#Steel warehouses and Hangers in UAE#rmwae#fencing companies in uae#aluminium and glass companies in uae#pre engineered steel buildings uae

0 notes

Text

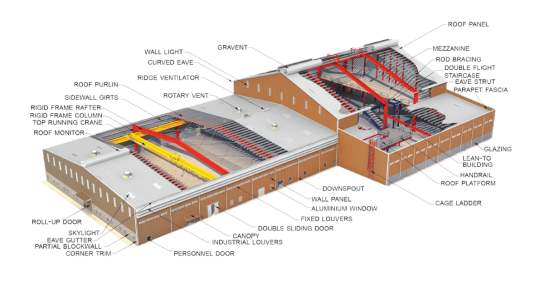

Essential Components that Define a Pre-engineered Warehouse

Introduction :

In the dynamic landscape of industrial construction, the emergence of Pre-engineered Buildings (PEB) has revolutionized the way warehouses are designed and constructed. Blueladder EPC Solutions Pvt Ltd, a leading player in the PEB industry, has been at the forefront of providing cutting-edge solutions that redefine the standards of warehouse construction. In this blog post, we will delve into the essential components that define a pre-engineered warehouse and highlight the myriad benefits associated with each.

1. Structural Framework :

The backbone of any pre-engineered warehouse is its structural framework. Blueladder EPC Solutions employs advanced engineering techniques and high-quality materials to create robust frameworks that ensure structural stability. The use of optimized steel sections enhances the strength-to-weight ratio, allowing for larger spans and minimizing the need for excessive columns. This not only accelerates the construction process but also optimizes the utilization of space within the warehouse.

2. Roofing Systems :

Blueladder EPC Solutions prioritizes state-of-the-art roofing systems to ensure the longevity and sustainability of their pre-engineered warehouses. Utilizing insulated metal panels for roofing not only provides superior insulation, reducing energy consumption for temperature control, but also offers excellent resistance to adverse weather conditions. This results in a more comfortable working environment within the warehouse and substantial energy savings over time.

3. Crane Systems :

Efficient material handling is a hallmark of well-designed warehouses, and Blueladder EPC Solutions integrates advanced crane systems into their pre-engineered structures. These systems are customized to meet the specific needs of the client, allowing for seamless movement and storage of goods within the warehouse. The incorporation of High-quality crane systems enhances operational efficiency, reduces labor costs, and minimizes the risk of accidents. The incorporation of crane systems enhances operational efficiency, reduces labor costs, and minimizes the risk of accidents.

4. Ventilation Systems :

Maintaining optimal indoor air quality is essential for the well-being of both personnel and stored goods. Blueladder EPC Solutions integrates advanced natural ventilation systems into their pre-engineered warehouses. This not only reduces the reliance on artificial ventilation but also enhances energy efficiency, resulting in lower operational costs over the lifespan of the warehouse.

5. Integrated Software Solutions :

Pre Engineered Warehouses go beyond traditional construction practices by incorporating advanced Integrated Software Solutions. These solutions facilitate seamless communication and coordination throughout the design and construction process. From 3D modeling to project management, the use of cutting-edge software ensures precision, efficiency, and transparency, resulting in timely project delivery.

The warehouse weight is efficiently optimized through software that assesses the seismic and wind load conditions in the client site zone. This optimization not only enhances the structural integrity but also contributes to cost savings, allowing adjustments to the warehouse weight based on the specific needs of the zone.

6. Energy-Efficient Lighting :

Reducing energy consumption is a key consideration for sustainable warehouse operations. Blueladder EPC Solutions incorporates energy-efficient lighting systems, such as wall lights & sky lights, into their pre-engineered warehouses. This not only contributes to environmental conservation but also translates into substantial long-term cost savings for warehouse operators.

7. Customization Options :

Every client has unique requirements, and Blueladder EPC Solutions recognizes the importance of customization. The company offers a wide range of customization options, allowing clients to tailor their pre-engineered warehouses to meet specific operational needs. This flexibility ensures that the final product aligns seamlessly with the client’s business objectives.

In conclusion, the essential components that define a pre-engineered warehouse are meticulously designed and integrated to maximize efficiency, durability, and sustainability. By utilizing cutting-edge technologies and materials, Blueladder EPC Solutions has positioned itself as a trailblazer in the PEB industry.

As the demand for innovative warehouse solutions continues to grow, the pre-engineered warehouses by Blueladder EPC Solutions stand as a testament to the fusion of technology, efficiency, and sustainability in modern industrial construction.

Visit our website – www.blueladderepc.com Or call us @ +917887414755

and get detailed knowledge and information regarding the services we offer.

#modern pre engineered buildings#Pre Engineered Building (PEB)#PEB#Pre engineered warehouse#peb steel buildings#Peb building manufacturer

0 notes

Text

Unleashing Steel Excellence: Pioneering Metal Facades

Riyadh skyline is transforming, and (metal facades) واجهات معدنية are at the forefront of this revolution. These innovative architectural elements offer a captivating blend of aesthetics and durability. Imagine a steel structure company in Riyadh crafting sleek, modern facades that not only enhance a building’s visual appeal but also boast exceptional weather resistance and fire protection. Metal facades are lightweight yet incredibly strong, allowing for creative designs and expensive structures.

#factory building contractor riyadh#انشاءات حناجر كونتاكتور الرياض#hangars riyadh#contractor saudi arabia#factory building#construction#constructing hangers gyms contractor#contractor throats constructions#gyms#hangars#malls#metal#steel structure#steel#building warehouses

1 note

·

View note

Text

Best Construction Companies In Bangalore | Industrial Shed Construction Companies In Bangalore | Warehouse Contractors | Roofing Shed Contractors In Bangalore

Best Metal Building Contractor | Best Industrial Shed Contractors in Bangalore | Warehouse Manufacturers | Steel Building Construction Companies In Bangalore

BEST PEB Builders | Best PEB Contractors | Best Steel Construction Company | Best Construction Company | Best PEB Companies in Bangalore

Arvind Construction company In Bangalore, Bengaluru, Karnataka is dedicated and specialized in delivering the highest possible standards of Quality Products & Services into all type of construction of Steel Buildings including Designing, Detailing, Fabrication, Erection, Sheeting & Civil Works of Pre-Engineered Building Systems (PEB) on a Turnkey Basis and with the Complete Customer Satisfaction. We make your job easier as a One Stop Solution for the all variety of PEB Building at the Right Price with the Best Quality Products & Services for Industrial and Commercial Applications.

Please check our websites,

https://arvindpebstructure...

https://arvindpeb.com/

https://arvindconstruction...

https://arvindcranes.com/

https://arvindgroups.com/

#arvind#arvindfabricators#construction#steel structure#garage and shed#warehouse#logistics#manufacturing#manufacturer#contractor#peb#pebstructure#structure#structuralcontractors#steelbuildingcontractor#buildingconstruction#columns#fabrication#heavy metal#metal buildings#steel buildings#arvindpebstructure#arvindpeb#arvindconstruction#arvindcranes#arvindgroups#mezzanine#mezzaninefloorcontractors#mezzaninecontractors#mezzaninefabricators

0 notes

Text

#SS structures Manufacturers#Heavy Mild steel fabrication Manufacturers#Factory construction Manufacturers#Pre Engineered buildings Manufacturers#Warehouses Manufacturers#Greenhouses Manufacturers#Industrial shed Manufacturers#Godowns Manufacturers#Poly houses Manufacturers#MS Pergolas Manufacturers#Polycarbonate sheet work Manufacturers#Skylights Manufacturers

0 notes

Text

80 X 150 Ft Metal Building | 80 X 150 Prefab Metal Buildings - Coastal Steel Structures

Horse Arena Builders, uncover the versatile space options provided by our 80 x 150 Ft metal building, designed for use as a steel structure warehouse. Whether for warehousing, storing equipment, or creating a functional workspace, this adaptable structure offers ample flexibility. Connect with us today to discuss customized solutions that perfectly fit your needs and optimize your space utilization.

Know More:https://coastalsteelstructures.com/models/80-x-150-prefab-metal-buildings-capitan

0 notes

Text

Best Industrial plant and steel structure building

Qingdao Omiga Construction Engineering Co., Ltd., as a leading supplier and manufacturer in the field of steel structure construction, specializes in the export of steel structure building materials and related products. The company Located in the beautiful coastal city of Qingdao, with over 20 years of experience in steel structure projects and are a key incubation enterprise in the Qingdao Park of China Science and Technology Development Institute. Omiga is committed to providing high-quality steel structure building solutions for global customers. Our products cover various fields, including industrial plants, commercial buildings, sports arenas, residential buildings, bridges, etc. We have a first-class design team and advanced production equipment, enabling us to provide customized solutions based on customer requirements.

We offer one-stop procurement services, including product design, raw material procurement, production processing, quality control, logistics distribution, and installation guidance. In the field of steel structure building exports, we have established long-term partnerships with well-known domestic steel structure manufacturers. This enables us to meet customer requirements with competitive prices and high-quality products, ensuring the quality and delivery time of our products. We introduce and apply international advanced steel structure building technologies and equipment, strictly implementing quality management systems to ensure that our product quality meets international standards.

Advantages of Steel Structure Buildings:

Exceptional Strength: Steel is renowned for its high strength-to-weight ratio. Steel structure buildings can withstand heavy loads, making them ideal for tall skyscrapers, industrial facilities, and bridges. This strength provides long-lasting durability and structural integrity.

Speedy Construction: Steel structures can be fabricated off-site, allowing for faster construction compared to traditional methods. This reduces construction time, labor costs, and disruptions to nearby areas.

Design Flexibility: Steel allows for creative and flexible architectural designs. The material's ability to span large distances without the need for numerous columns or supports enables open, spacious interiors and innovative aesthetics.

Sustainability: Steel is a recyclable material, making it environmentally friendly. The recycling process does not compromise its structural integrity, making steel structures an eco-conscious choice. Additionally, steel can be repurposed for other construction projects.

Cost-Effective: Despite initial higher material costs steel structure buildings often provide long-term cost savings due to their durability, minimal maintenance, and shorter construction times.

Innovations in Steel Structure Buildings:

Advanced Coatings:Innovations in coatings have enhanced the corrosion resistance of steel structures, increasing their lifespan and reducing maintenance requirements. These coatings also offer aesthetic options and energy-efficient features.

Prefabrication and Modular Construction:

Prefabrication techniques have improved efficiency in steel construction. Components can be manufactured off-site with precision and then assembled on-site, reducing construction time and waste.

High-Strength Steel Alloys: The development of high-strength steel alloys allows for lighter and stronger structural elements, reducing material usage and enabling more sustainable construction.

Building Information Modeling (BIM):

industrial plant BIM technology enables precise planning and coordination of steel structure projects. It helps optimize designs, reduce errors, and improve project management, resulting in cost savings and better project outcomes.

Sustainable Practices: Innovations in steel production have led to more sustainable practices, such as energy-efficient manufacturing processes, reduced emissions, and responsible sourcing of raw materials.

Steel structure buildings continue to be a fundamental part of the construction industry, offering numerous advantages and benefiting from ongoing innovations. Their strength, versatility, sustainability, and cost-effectiveness make them an attractive choice for a wide range of construction projects, from residential buildings to large-scale industrial complexes. As technology and materials continue to evolve, steel structures will likely play an increasingly vital role in shaping the future of modern construction.

Steel warehouses are essential components of the supply chain and industrial infrastructure. These structures provide storage solutions that are durable, cost-effective, and versatile, making them integral to various industries.

Structural Integrity and Durability:

Steel is renowned for its strength and resilience. Steel warehouses can withstand extreme weather conditions, seismic activity, and heavy loads, ensuring the safety and security of stored goods over the long term.

Spacious Interiors: Steel's high strength-to-weight ratio allows for large, open interior spaces without the need for numerous columns or support structures. This design flexibility makes steel warehouses ideal for efficiently storing and accessing goods.

Quick Construction: Prefabrication techniques in steel construction enable rapid assembly. This reduces construction time, minimizes disruptions to operations, and leads to faster ROI for warehouse owners.

Customizable Designs: Steel warehouses can be customized to meet specific storage needs. This includes adjustable shelving, racks, and mezzanines, enabling efficient space utilization and organization.

Cost-Efficiency: While initial construction costs may be higher than other materials, steel's longevity, minimal maintenance requirements, and energy-efficient features make it a cost-effective choice over the long term.

Sustainability: Steel is recyclable and environmentally friendly. Many steel warehouse structures incorporate eco-conscious features such as energy-efficient insulation, lighting, and roofing systems.

Innovations in Steel Warehouses:

Automated Storage and Retrieval Systems (AS/RS): AS/RS technology optimizes warehouse operations by automating the retrieval and storage of goods, reducing labor costs, and increasing efficiency.

Energy-Efficient Design: Innovative designs incorporate natural lighting, solar panels, and energy-efficient HVAC systems to reduce energy consumption and environmental impact.

Security and Surveillance Systems: Modern steel warehouses often feature advanced security systems, including surveillance cameras, access control, and fire suppression systems to safeguard valuable inventory.

Inventory Management Software: Integration of warehouse management software streamlines inventory tracking, order fulfillment, and overall warehouse operations, increasing accuracy and efficiency.

Distributed Warehousing Networks:

Companies are increasingly adopting distributed warehousing networks, strategically locating smaller steel warehouses in proximity to customers to reduce shipping times and costs. Steel warehouses are indispensable assets in today's industrial landscape, providing the durability, flexibility, and efficiency required for modern supply chain management. As technology and sustainability practices continue to evolve, steel warehouses will play an even more crucial role in optimizing storage and distribution processes. Their resilience, cost-effectiveness, and adaptability make steel warehouses a cornerstone of the global logistics industry, supporting economic growth and innovation.

0 notes

Text

Unlocking the Potential: Building Brilliance in Steel Warehouse Installations

The materials choice for warehouse buildings in business design plays a vital role in task efficiency, sturdiness, and usual fulfillment. Among the myriad alternatives to be had, steel sticks out as a beacon of energy and versatility, providing a stable basis for a steel warehouse building that not most effectively meets but exceeds industry standards. We will explore key factors that make steel warehouse buildings the epitome of brilliance in modern industrial installations.

Key factors that make steel warehouse buildings the epitome of brilliance in modern industrial

Following are the Key factors that make steel warehouse buildings the epitome of brilliance in modern industrial Installations

Structural Integrity

The inherent power of steel sets it aside as a material with remarkable structural integrity. In an industrial environment where warehouses often comprise heavy and bulky materials, the capability to support the right loads is of the utmost importance. Steel electricity ensures that warehouses can withstand stresses from heavy equipment, stacked materials, and adverse weather situations. These bendy systems mean durability, lowering the want for frequent maintenance and repairs.

Flexible Design

Steel’s flexibility and versatility make it an ideal material for warehouse construction, allowing architects and engineers to design structures that meet specific needs, Whether businesses need spacious furniture with clear widths to ensure efficient storage or a particular configuration to accommodate specialized equipment, steel offers flexibility so that these configurations come to life with warehouses that can be designed to work with served according to specific requirements.

Speed of Construction

Time is often of the essence in engineering, and the speed of construction offered by steel is a huge advantage. Steel warehouse buildings can be constructed relatively quickly compared to buildings with conventional materials. These efforts not only accelerate project timelines but also translate into cost savings, allowing businesses to start their business in the new facility faster.

Cost-Effective Longevity

While the initial investment in a steel warehouse may seem justified, the long-term cost is key. The steel durability and corrosion resistance for the cost over the life of the building is reduced. Companies can, therefore, achieve cost savings in the form of reduced repairs and replacements, making steel an economical choice for warehouse installations.

Energy Efficiency

The thermal conductivity of steel contributes to the energy efficiency of warehouse buildings. Excellent insulation, reflective ceilings, and the ability to incorporate energy-saving materials such as skylights help optimize indoor temperatures. It eliminates the need for overheating or cooling, reducing energy consumption in the long run. Steel warehouse buildings not only provide sustainable shelter for materials but also contribute to sustainable energy practices.

Recycling and Sustainability

At a time when sustainability needs to be increasingly considered, steel shines as one of the most environmentally friendly materials. It is recyclable, making it a sustainable option in warehouse construction. The steel recycling ability reduces the environmental impact. Corporate choice of steel warehouse buildings is consistent with responsible construction practices, creating a sustainable and environmentally friendly industrial environment.

Reduced Construction Waste

Precision in manufacturing steel components minimizes on-web page waste all through construction. Unlike conventional construction materials that frequently bring about extra waste, steel components are fabricated to specific specs, leading to a reduction in production waste. It aligns with sustainable creation goals, reduces the environmental footprint of the assignment, and underscores the performance of steel warehouse installations.

Technological Advancements

Steel production has advanced appreciably with technological advancements. Computer-aided design (CAD) and building facts modeling (BIM) technologies enable particular planning and execution of steel systems. This advanced engineering contributes to the general brilliance of steel warehouse installations, ensuring accuracy in layout, minimizing mistakes, and improving the efficiency of the construction method.

Conclusion

In the realm of business production, steel warehouse buildings grow to be beacons of brilliance, seamlessly mixing strength, flexibility, and sustainability. Their structural prowess, value-effectiveness, and power efficiency redefine current warehouse installations. As enterprise leaders, TSSC gives modern steel solutions, ensuring your warehouse stands as a testament to sturdiness and efficiency. Choose TSSC, release brilliance, and elevate your industrial infrastructure to new heights.

0 notes

Text

How do PEB Structures protect the Environment?

The traditional method of construction has been accepted norm for a long time. The word traditional means conventional, customary, and established by its very definition. In traditional construction foundations are laid, walls are built, roofs are added and then the interior of the building begins to be created. Finally, before being handed over to the customer, the snag-list is drawn up and tackled – all those minor issues and tasks that need addressing. Then, and only then, is the building officially complete. Modular construction, on the other hand, revolutionizes everything, from cutting time to changing attitudes.

Here we are discussing how Traditional Construction methods degrade our environment?

A mandatory aspect of any construction project is to ensure the preservation of the surrounding environment. In India, it is tough to maintain soil erosion and degradation. The reason is mainly floods, droughts, soil alkalinity, aridity, and salinity. Besides air and water pollution levels are still not within controllable limits in the country. Urbanization in major cities has decreased the soil quality, impacting the environment. Building construction contributes 23% to pollution of the air, 40% to drinking water pollution, and 50% to landfill waste.��For a deeper understanding of this topic, let’s dig deeper into the details.

1. Atmosphere

When it comes to air pollution, every action matters as the production of dioxide gases is one of the main factors causing global warming. The construction sector is responsible for 39% of energy and process-related carbon dioxide emissions.

2. Biodiversity

Think about how construction impacts animals. The first few things that probably came to your mind are loud machines or working on construction sites at night. Noise and light pollution heavily impact wildlife, especially bats, badgers, and birds, by disturbing their natural day cycle.

3. Waste

Traditional construction methods require extra materials because it relies on fast, cheap solutions that need to be replaced every year or even every few months which leads to increased waste.

Different construction processes generate a great deal of this waste. It’s our responsibility to adopt the right tools and technologies to reduce this waste.

Luckily, prefabricated buildings can reduce this pollution percentage and waste.

We believe that the future of construction is sustainable, which is why now is a perfect time to change our approach and take responsibility for our actions. You might not know that these buildings are constructed from factory-made components or units that are transported and assembled on site.They take very little construction time and reduce waste by up to 52%, which helps us protect the environment. Additionally, they often use recycled building materials for their internal walls, insulation, and roofs, making them very eco-friendly. We are MultiDecor India Pvt. Ltd., a leading manufacturer of modular buildings in India, produces all sorts of prefabricated structures, such as prefabricated labour accommodation, prefabricated site offices, portacabins, modular homes, and farmhouses.

Multi Decor India Pvt. Ltd is a top leading pre-engineered buildings manufacturer in India established in the year 1992. We manufacture, design, and deliver a wide range of customized PEB structures constructed specifically per the customer’s requirements. We provide every commercial requirement and being a leading PEB structure manufacturer, guarantee a high-quality construction with quick installation.

Our concept is designed to provide a complete building envelope system that is airtight, energy efficient, optimum in weight, and above all, designed to fit user requirements like a well-fitted glove. PEB (Pre Engineered Buildings ) means that all the components are manufactured at the factory site and shipped to the location site to be assembled and erected at the site with the nuts bolts and anchor bolts. These types of buildings are also known as Pre Engineered Steel Buildings.

Check more at:

#laborcolonies#porta cabin manufacturer#peb manufacturers#prefabricated steel buildings#prefabricatedbuildings#prefabricated warehouse

0 notes

Text

Why Choose Steel Over Traditional Materials for Factory Building and Warehouse?

When constructing a factory or warehouse, durability, versatility, and longevity are essential factors to consider. While conventional materials such as wood or concrete have been reliable, steel stands out as the optimal choice for numerous reasons. Let’s explore why steel structure dominates the world of factory and warehouse construction:

Read More:

#steel structures for factory building#steel warehouse buildings#steel structures for factory buildings

0 notes

Text

Who is the Largest cold storage Building Manufacturers company in India?

Cold Storage Building Manufacturers Steel Structures, Industrial Roofing Sheds, and MS Portable Cabins are some of the things that VEDANSHI INDUSTRIES manufactures. Cold Storage Building Manufacturers Additionally, VEDANSHI INDUSTRIES offers steel fabrication services of the highest caliber.

Secondary Members/Cold Formed Members Cold Storage Building Manufacturers Roof and wall panel Manufacturers C Purlin Suppliers Z Purlin Suppliers Warehouse Manufacturers Multi Storey Steel Building Manufacturers Z Purlin Manufacturers Roofing Sheet Manufacturers

Website – https://www.cpurlin.in/

#c purlin suppliers#primary framing solution#c purlin manufacturers#multi storey steel building manufacturers#secondary members/cold formed members#z purlin manufacturers#roofing sheet manufacturers#cold storage building manufacturers#warehouse manufacturers#roof and wall panel manufacturers

0 notes

Text

Mekark is your Trusted Warehouse Shed Manufacturer and Contractor

Introduction:

Chennai, the bustling metropolitan city, has witnessed a significant transformation in its industrial and logistics sectors over the past few years. With the rapid growth of e-commerce and the expansion of various industries, the demand for state-of-the-art warehousing solutions has never been higher. In this evolving landscape, Mekark emerges as a leading warehouse shed manufacturer and contractor in Chennai, catering to the diverse needs of businesses across the region.

Warehouse Shed Manufacturer: Crafting Excellence

Mekark takes pride in being a pioneer in the realm of warehouse shed manufacturing. Our commitment to excellence, quality, and innovation sets us apart. When it comes to constructing durable, efficient, and cost-effective warehouse structures, we are the go-to choice for businesses in Chennai.

Our Warehouse Steel Construction Expertise:

Warehouse steel construction is at the core of our services. We understand that the strength and durability of your warehouse are paramount. With our advanced construction techniques and skilled workforce, we ensure that every warehouse project we undertake is built to withstand the test of time.

Warehouse Shed Contractors: Your Trusted Partners

As Warehouse Shed Contractors in Chennai, Mekark offers end-to-end solutions, from the initial design concept to the final execution. Our team of experienced professionals works closely with clients to understand their specific requirements, ensuring that every project is tailor-made to meet their needs.

Warehouse Building Contractors: Design and Build Excellence

Mekark's expertise as a Warehouse Building Contractor is not limited to steel construction alone. We excel in designing and building warehouses that maximize space utilization, energy efficiency, and overall functionality. Our designs take into account the unique requirements of your business, whether it's for storage, distribution, or manufacturing purposes.

Warehouse Shed Manufacturer in Chennai: Unmatched Quality

Being a local Warehouse Shed Manufacturer in Chennai, Mekark understands the importance of adapting to the local climate and environmental conditions. Our structures are designed to withstand Chennai's tropical weather, ensuring that your goods are protected year-round.

Conclusion:

In a rapidly evolving business landscape, having a trusted partner like Mekark, who excels as both a warehouse shed manufacturer and contractor, is invaluable. We take pride in being at the forefront of warehouse construction and steel structure technology, offering tailored solutions for businesses in Chennai.

If you're in need of a warehouse shed manufacturer or contractor in Chennai, look no further. Mekark is here to provide you with the highest quality, most cost-effective, and most efficient warehousing solutions that will support your business's growth and success. Choose Mekark for excellence, quality, and innovation in every warehouse project we undertake.

Keywords: Warehouse Shed Manufacturer, Warehouse Shed Manufacturer in Chennai, Warehouse Shed Contractors, Warehouse Shed Contractors in Chennai, Warehouse Building Contractors, Warehouse Steel Construction.

Contact Mekark Today:

✨You can find anything here! Dial right away!

📱 Contact: 9790924754

📧 MailID : [email protected]

📍 Location: No.15, First Floor, 62nd street, Ashok Nagar, Chennai-600083

🌐Visit - For More Details: https://www.mekark.com/warehouse-shed-manufacturer-chennai

#Warehouse Shed Contractors#Warehouse Shed Manufacturer#Warehouse Shed Manufacturer in Chennai#Warehouse Shed Contractors in Chennai#Warehouse Construction Contractors#Warehouse Building Contractors#Warehouse Contractors#Warehouse Steel Construction

0 notes