#transmission tower manufacturers

Text

Discover the Innovation in Transmission Line Towers Above and Beyond

In recent times, there has been notable progress and innovation in transmission line towers, which are essential yet frequently disregarded parts of the power transmission system. Industry advancements in efficiency, dependability, and environmental responsibility have been constant goals, ranging from improved designs to sustainable materials.

In this article, we delve into the innovative aspects of transmission line towers, exploring the latest trends and technologies shaping the future of this essential sector.

An Overview of Transmission Line Towers

Transmission line towers are the backbone of energy transmission, transporting power from producing facilities to distribution networks. Their careful location and durable construction are critical to guaranteeing consistent power delivery across long distances.

Importance in Power Transmission Industry

Global industrial growth, urbanization, and technological advancements are driving an increasing need for power. By effectively transporting power over great distances while reducing energy losses, transmission line towers are essential to supply this need.

Transmission Line Tower Evolution

Transmission line towers, which were formerly made of steel, have changed to include strong, lightweight materials like composite fibers and high-strength metals. As a result of these developments, towers can now support higher loads and have a smaller manufacturing and installation impact on the environment.

Innovative Design in Transmission Line Towers

Modern transmission line towers incorporate special designs that make the most of available space, minimize visual effects, and progress auxiliary quality. Lower upkeep costs and speedier arrangements are made conceivable by the utilization of secluded components and modern development forms.

Advanced Materials and Construction Techniques

The use of advanced materials, including carbon fiber-reinforced polymers (CFRP) and galvanized steel, has revolutionized tower design. These materials offer superior strength-to-weight ratios, corrosion resistance, and longevity, ensuring reliable performance even in harsh environmental conditions.

Height and Load-Bearing Capacity Enhancements

In response to the growing demand for higher-capacity transmission lines, engineers have developed towers capable of supporting heavier conductors and increased wind loads. Innovative designs, such as lattice structures and self-supporting towers, maximize strength while minimizing material usage.

Environmental Impact and Sustainability

The transmission line industry is increasingly focused on sustainability, incorporating eco-friendly materials and practices into tower design and construction. Recycled steel, bio-based composites, and modular assembly techniques contribute to reduced carbon footprints and enhanced environmental stewardship.

Eco-friendly Materials and Designs

The adoption of eco-friendly materials, such as bamboo and recycled plastics, reduces the ecological footprint of transmission line towers. Additionally, innovative designs that minimize land use and habitat disruption promote biodiversity conservation in transmission corridor areas.

Integration with Renewable Energy Solutions

Transmission line towers play a vital role in facilitating the integration of renewable energy sources, such as solar and wind power, into the grid. Smart towers equipped with sensors and communication technologies enable efficient energy flow management and grid stability.

Safety and Reliability Features

Ensuring the safety and reliability of transmission line towers is paramount to grid operators and utility companies. Advanced structural analysis tools, real-time monitoring systems, and predictive maintenance techniques enhance tower performance and prevent potential failures.

Enhanced Structural Stability

Innovative tower designs incorporate features like anti-vibration dampers, sway braces, and aerodynamic profiles to enhance structural stability and reduce the risk of oscillations during extreme weather conditions. These measures improve grid resilience and minimize downtime.

Advanced Monitoring and Maintenance Systems

The integration of IoT sensors and data analytics enables proactive maintenance of transmission line towers. Remote monitoring of structural health parameters, such as stress levels and temperature variations, allows for timely interventions and optimal asset management.

Future Trends in Transmission Line Towers

The future of transmission line towers is characterized by integration with smart grid technologies and the adoption of artificial intelligence (AI) solutions. Predictive maintenance algorithms, autonomous inspection drones, and self-healing grid systems are poised to revolutionize the industry.

Smart Grid Integration

Smart transmission line towers equipped with communication interfaces and grid sensors enable real-time data exchange and dynamic load management. This smart grid integration enhances grid resilience, enables demand response capabilities, and supports renewable energy integration.

Incorporation of AI and IoT Technologies

AI-driven predictive analytics and machine learning algorithms are transforming how transmission line towers are monitored and maintained. Predicting equipment failures, optimizing grid performance, and reducing downtime are key benefits of AI and IoT integration in tower management.

Conclusion

Innovation in transmission line towers continues to drive efficiency, sustainability, and reliability in the power transmission sector. Advanced materials, smart grid technologies, and predictive maintenance solutions are shaping the future of this critical infrastructure.

#transmission towers#transmission tower manufacturers#Best Transmission Line Tower Manufacturers#Best Telecom Tower Manufacturers

0 notes

Text

Power Transmission Component Market Analysis Key Trends, Growth Opportunities, Outlook to 2032

Overview of the Power Transmission Component Market:

The power transmission component market involves the manufacturing, distribution, and sales of various components used in power transmission systems. These components are essential for the efficient and reliable transfer of electrical power from power generation sources to end-users. The market encompasses a wide range of products, including transformers, cables, and switchgear, circuit breakers, insulators, and transmission towers.

Power Transmission Component Market size exceeded USD 71 billion in 2021 and is projected to grow at over 4.4% CAGR from 2022 to 2030.

Key Factors Driving the Power Transmission Component Market:

Growing Energy Demand: The increasing global demand for electricity, driven by population growth, industrialization, and urbanization, is a key factor driving the power transmission component market. Power transmission components are crucial for the expansion and upgrade of electrical grids to meet the rising energy demand.

Renewable Energy Integration: The transition to renewable energy sources, such as solar and wind power, requires the integration of these intermittent energy sources into existing power grids. Power transmission components, such as transformers and switchgear, facilitate the efficient integration and transmission of renewable energy.

Grid Modernization and Upgrades: Aging power transmission infrastructure in many countries necessitates grid modernization and upgrades. Governments and utility companies are investing in the refurbishment and expansion of transmission networks, driving the demand for power transmission components.

Rising Investments in T&D Infrastructure: Increasing investments in transmission and distribution (T&D) infrastructure, particularly in developing economies, contribute to the growth of the power transmission component market. These investments aim to improve grid reliability, reduce transmission losses, and expand access to electricity.

Grid Resilience and Stability: Power transmission components play a critical role in ensuring the stability and resilience of electrical grids. Factors such as grid reliability, voltage control, and fault detection and mitigation are driving the demand for advanced power transmission components.

Government Regulations and Standards: Governments and regulatory bodies have implemented standards and regulations related to grid efficiency, reliability, and safety. Compliance with these regulations often requires upgrades and investments in power transmission components.

Technological Advancements: Technological advancements in power transmission components, such as the development of high-voltage direct current (HVDC) transmission systems, advanced materials, and digital monitoring and control systems, drive market growth. These advancements improve efficiency, reliability, and the ability to transmit power over longer distances.

The demand for power transmission components is driven by several factors, including growing electricity consumption, increasing investments in energy infrastructure, renewable energy integration, grid modernization initiatives, and electrification of various sectors. Here are some key aspects influencing the demand for power transmission components:

Growing Electricity Consumption: The rising global population, industrialization, and urbanization have led to increased electricity consumption. This drives the demand for power transmission components to expand and upgrade transmission networks to meet the growing electricity demand.

Infrastructure Investments: Governments and utilities worldwide are investing in the development and expansion of power transmission infrastructure to ensure reliable and efficient electricity transmission. This includes the construction of new transmission lines, substations, and associated power transmission components.

Renewable Energy Integration: The shift towards renewable energy sources, such as wind and solar, necessitates the integration of these intermittent power sources into the grid. Power transmission components, including converters, transformers, and grid interconnections, are in demand to facilitate the efficient integration of renewable energy generation into the existing transmission infrastructure.

Grid Modernization Initiatives: Many countries are focusing on modernizing their electrical grids to enhance reliability, efficiency, and flexibility. This involves the deployment of advanced power transmission components like smart grid technologies, digital control systems, and advanced sensors to monitor and manage the transmission network effectively.

Electrification of Transportation: The increasing adoption of electric vehicles (EVs) and the expansion of charging infrastructure require power transmission components capable of efficiently delivering electricity to charging stations. This includes transformers, cables, and connectors that can handle the high-power demands of EV charging.

Energy Efficiency and Grid Optimization: Energy conservation and efficiency measures drive the demand for power transmission components designed to minimize losses during electricity transmission. Upgrading and replacing aging infrastructure with high-efficiency transformers, conductors, and monitoring systems help improve overall grid efficiency.

Grid Resilience and Reliability: Power transmission components play a crucial role in ensuring grid resilience and reliability, particularly in regions prone to extreme weather events or areas with aging infrastructure. Upgrading transmission lines, substations, and associated components helps enhance the grid's resilience and minimize disruptions.

Cross-Border Interconnections: The establishment of cross-border interconnections between neighboring countries or regions enables efficient power exchange, renewable energy sharing, and grid stability. Power transmission components for interconnections, such as high-capacity transmission lines and interconnectors, experience increased demand to support cross-border electricity transmission.

Decentralized Energy Generation: The increasing adoption of distributed energy resources (DERs), including rooftop solar panels, wind turbines, and energy storage systems, drives the demand for power transmission components that enable the integration of decentralized energy generation into the grid. This involves components like inverters, grid-tie systems, and smart distribution systems.

Upgrades and Replacement of Aging Infrastructure: In many regions, existing power transmission infrastructure is aging and requires upgrades or replacement. This drives the demand for power transmission components to modernize and improve the capacity, efficiency, and reliability of the transmission network.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market. “Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/power-transmission-component-market/11353/

Market Segmentations:

Global Power Transmission Component Market: By Company

• ABB

• Toshiba

• EATON

• Siemens

• Crompton Greaves

• General Electric

• Hitachi

• Schneider Electric

• Mitsubishi

• Hyundai

• BHEL

• Emerson

Global Power Transmission Component Market: By Type

• Transformer

• Circuit Breaker

• Insulator

• Arrestor

• Transmission Line

• Transmission Tower

• Others

Global Power Transmission Component Market: By Application

• Energy

• Industrial

• Military & Defense

• Others

Global Power Transmission Component Market: Regional Analysis

The regional analysis of the global Power Transmission Component market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Power Transmission Component market report are as follows:

North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Power Transmission Component in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product.

Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Power Transmission Component in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors.

Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Power Transmission Component in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction.

Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors.

South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Power Transmission Component in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Click Here, To Purchase Premium Report: https://stringentdatalytics.com/purchase/power-transmission-component-market/11353/?license=single

Reasons to Purchase Power Transmission Component Market Report:

• To gain insights into market trends and dynamics: this reports provide valuable insights into industry trends and dynamics, including market size, growth rates, and key drivers and challenges.

• To identify key players and competitors: this research reports can help businesses identify key players and competitors in their industry, including their market share, strategies, and strengths and weaknesses.

• To understand consumer behavior: this research reports can provide valuable insights into consumer behavior, including their preferences, purchasing habits, and demographics.

• To evaluate market opportunities: this research reports can help businesses evaluate market opportunities, including potential new products or services, new markets, and emerging trends.

• To make informed business decisions: this research reports provide businesses with data-driven insights that can help them make informed business decisions, including strategic planning, product development, and marketing and advertising strategies.

Overall, market research reports provide businesses and organizations with valuable information that can help them make informed decisions and stay competitive in their industry. They can provide a solid foundation for business planning, strategy development, and decision-making.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Power Transmission Component Market Analysis Key Trends#Growth Opportunities#Outlook to 2032#The power transmission component market involves the manufacturing#distribution#and sales of various components used in power transmission systems. These components are essential for the efficient and reliable transfer#including transformers#cables#and switchgear#circuit breakers#insulators#and transmission towers.#Power Transmission Component Market size exceeded USD 71 billion in 2021 and is projected to grow at over 4.4% CAGR from 2022 to 2030.

0 notes

Text

Hansal Steel Tower Manufacturing Bas Is Recognised as " Green Factory"

The Hubei Provincial Department of Industry and Information Technology recently released the Hubei Green Manufacturing List for 2022. Wuhan Tower Factory has been recognized as a provincial-level "green factory", and only 24 manufacturing companies in Wuhan have won the honor. It is understood that the provincial "green factory" is based on the deployment and relevant provisions of the construction of the green manufacturing system in Hubei Province, on the basis of the recommendation of the city, the provincial Department of industry and information technology review and solicit the opinions of the relevant departments for selection, enterprises need to pass the evaluation of more than 80 indicators in 5 categories such as "land intensification, harmless raw materials, clean production, waste resources, energy low-carbon", etc. Selection procedures, standards are very strict.

In recent years, the company continues to improve the level of production technology, the realization of machine instead of artificial exploration, greatly improve the product performance and quality. At the same time, the company attaches great importance to the green development and energy conservation and environmental protection work, established a green factory management organization, continuously improve the green factory management system, dedicated personnel in charge of promoting environmental protection work, in the selection of raw materials, product production process to highlight the concept of ecological environmental protection, product per unit energy consumption, water consumption and pollutant production has decreased year by year, and the indicators are in the advanced level of the industry.

The successful identification of provincial-level "green factory" is highly affirming and encouraging the company to adhere to innovation and transformation, green, low-carbon and sustainable development. In the next step, the company will thoroughly implement the major strategic deployment of promoting new industrialization and accelerating the construction of manufacturing power proposed in the Report of the 20th National Congress, firmly grasp the main direction of intelligent and green manufacturing, stimulate the internal driving force of green manufacturing, actively build a demonstration model of green transformation and upgrading of the manufacturing industry, and promote the high-quality development of the company.

Hansal Group as the window company of Wuhan Tower factory will continue to service our clients with best quality steel tower products in 2023.

0 notes

Text

Chapter 213 Trivia (Part 1)

I guess things were going too well for too long..?

Gen's drawing of Senku here was probably inspired by very early chapter cover images. I don't know why else he'd be holding an exploding container.

We've now got three interpretations of Whyman: the generic one, Luna's, and now Gen's.

I like how Gen's has arms and legs coming out of the skull!

Finally! The Kingdom of Science can watch Dr. Stone together!

As long as someone animates it…

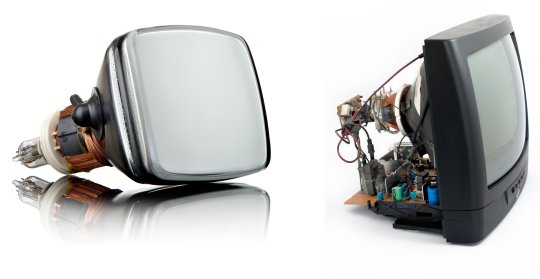

Kenjiro Takayanagi of Shizuoka University is considered one of the main pioneers of television, succeeding in displaying the character イ (i) on his Braun tube display in Dec 1926. Over the next few years, he improved the image allowing more detailed images such as human faces.

By 1939, Japan's first television station began broadcasting from NHK (Japan Broadcasting Corporation). After the war, Takayanagi Sensei's work was used as a foundation for other televisions and related industries around the world.

If everyone thought working on a second cell phone after they'd spent months making one was bad, they're not ready to hear about what they'll need to make for television broadcasts. (Senku also never changes...)

I didn't realize how big their other boat was. I guess things made in the USA really are bigger?

The Perseus not being the biggest ship anymore makes me a little sad :(

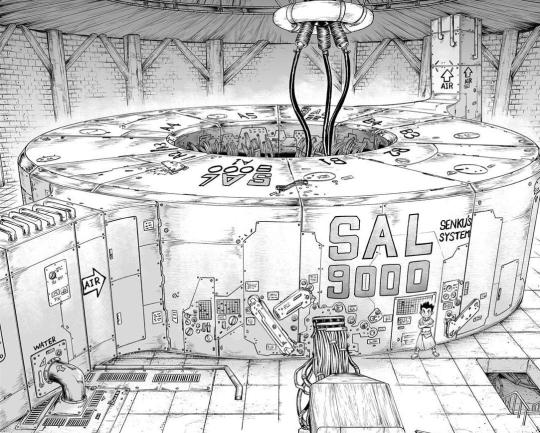

SAL 9000 is a reference to HAL 9000, the AI antagonist from Space Odyssey. It stands for "Heuristically programmed ALgorithmic computer", so in this case it might be "Senku programmed" or even "Sai programmed"!

The "NES" (actually the Famicom again, both in the drawing and Sai's comment in the Japanese version) and SAL 9000 don't have the exact same specifications:

SAL 9000 is specialized for math operations and thus has a longer word length (16 bits vs 8) which allows more significant figures in the numbers. They've also got more RAM (SAL has 16 kB while the NES has 2).

The downside is that because they used parametrons, their clock speed (how fast they can do calculations) is slower than if they'd used transistors.

The large amount of ROM they've also got could imply that they have several built-in programs. Xeno's work, perhaps?

CRT screens only reach a maximum diagonal length of around 40 inches (~101 cm), as a larger screen needs a larger tube, and the thickness of the glass increases with size to handle the vacuum without shattering making it very unwieldy with the added weight and thus not worth manufacturing for sale.

Senku's here is obviously much, much bigger. Possibly even world record; the biggest CRT screens made were 61 inches (~152 cm) on the diagonal.

SAL 9000 has both air and water cooling, probably used depending on what's better for individual parts. Normally you only need one or the other.

It'd be good if they could get the carbonated water maker in there and ferment some alcohol faster too using the computer's heat…

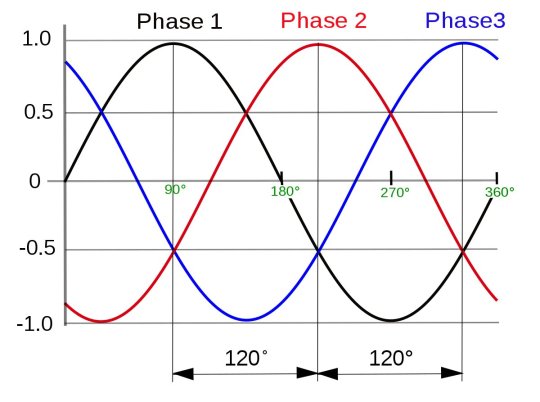

SAL 9000 also has 3 phase power like modern power transmission. They're AC power sources, phase shifted by 120° so that at any point in time, their sum is 0. The advantage to this is that you don't need return lines for the current, so you can use half as many cables.

The games shown are inspired by Tetris (featuring Ishigami Village and Roppongi!), Pacman, a combination game of Gyruss and Tempest, then another combination game of Galaga and Asteroids.

The transmission towers can only be headed towards the dam, so we have an approximate direction for where that is! There's a few rivers nearby in modern Tokyo, but over 3,700 years they've probably changed a lot.

(Next part)

16 notes

·

View notes

Text

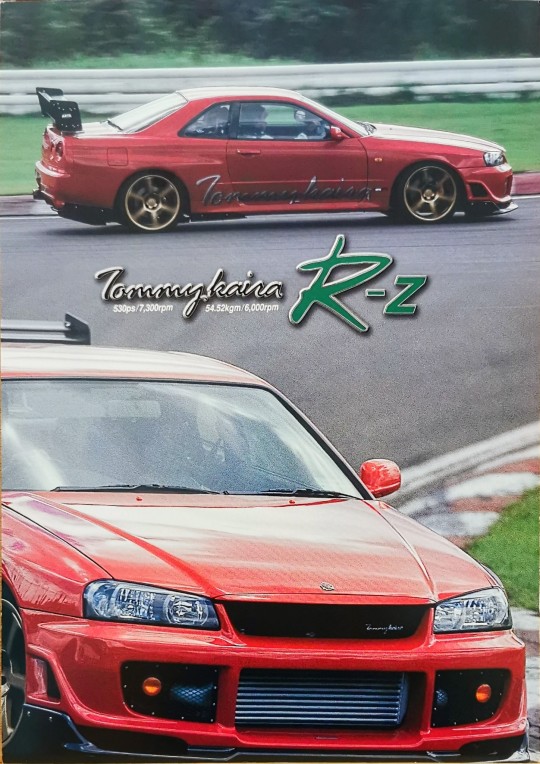

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

17 notes

·

View notes

Text

Types of Insulators in Overhead Lines: The Ultimate Guide

Within the realm of electrical power transmission, overhead wires assume a pivotal function in facilitating the effective conveyance of electricity across extensive distances. The aforementioned lines are upheld by a system of towers and poles, and a crucial element that guarantees their dependable functionality is the insulator. Insulators are specifically engineered to impede the transmission of electrical current between the conductive elements and the supporting frameworks, ensuring the safety of the lines and upholding a consistent electrical provision. Strengthen your electrical networks - Trust the expertly crafted Medium Voltage Support Insulators offered by Radiant Enterprises - one of the leading Medium Voltage Support Insulator manufacturers in India!

This comprehensive reference aims to examine the various classifications of insulators utilised in overhead lines, elucidating their distinctive characteristics and practical implementations.

Pin Insulators:

Pin insulators are widely utilised in overhead lines, making them one of the most prevalent types in use. The components are comprised of a body made of either ceramic or glass, including a spindle located at the bottom that is securely attached to the cross-arm of the supporting structure. The conductors are affixed to the upper groove of the insulator, therefore ensuring electrical isolation. Pin insulators are commonly used due to their simplicity, cost-effectiveness, and capacity to endure mechanical and electrical pressures. Distribution lines and low-voltage transmission lines frequently employ these devices.

Suspension Insulators:

Suspension insulators are utilised in high-voltage transmission lines characterised by elevated tension levels. The design of these units involves a serial connection of insulators, resulting in the formation of an elongated chain. Typically, a unit comprises a ceramic or composite disc accompanied by a metallic cover and an insulating cement joint. Suspension insulators are affixed to the cross-arm through the use of an insulating string, so facilitating the suspension of the conductor beneath the tower. These insulators exhibit exceptional mechanical durability and demonstrate remarkable efficacy in environments characterised by substantial levels of pollution, such as industrial zones.

Strain Insulators:

When a transmission line terminates or a sharp turn is made in the line's direction, strain insulators are employed to securely terminate or anchor the conductors. They are built to endure the mechanical tension of the hung conductor as well as the electrical stress. Strain insulators are often constructed of porcelain or toughened glass and have a long, cylindrical shape. Their major function is to disperse mechanical forces while preventing electrical contact.

Shackle Insulators:

Low-voltage distribution lines typically make use of shackle insulators, which are sometimes known as spool or link insulators. Made of porcelain or polymer, they take the form of a spool. Shackle insulators can be fastened to their support structure with a nut and bolt thanks to the centrally located threaded bolt. The shackle eye is then used to secure the conductor. For low-voltage uses, these insulators are a straightforward and inexpensive option. Experience comfort and energy efficiency - Order high-quality Indoor Insulators manufactured and supplied by Radiant Enterprises - one of the renowned Indoor Insulator manufacturers in India!

Composite Insulators:

In recent years, composite insulators have experienced a surge in popularity owing to their advantageous characteristics, including their lightweight nature, superior mechanical strength, and exceptional pollution resistance. Typically, these objects consist of a core made of fibreglass and a housing made of silicone rubber. Composite insulators possess superior resistance to adverse environmental conditions, hence decreasing the necessity for maintenance. Insulators made of alternative materials are employed in both distribution and transmission lines, serving as a practical substitute for conventional porcelain insulators.

Post Insulators:

Post insulators are commonly utilised in substations and various electrical apparatus. These units are specifically engineered to function as a cohesive entity, effectively insulating the conductors from the earth or supporting structures. Post insulators exhibit a diverse range of shapes and sizes, which are contingent upon the particular application and voltage prerequisites. Crucial elements are present in order to guarantee the safety and effectiveness of electrical power networks within substations.

Final Thoughts:

Insulators play a crucial role in overhead lines, serving as essential components that guarantee the dependable and secure transmission of electrical power. This comprehensive resource provides descriptions of numerous types of insulators that are designed to accommodate varying voltage levels, ambient circumstances, and mechanical specifications. Various types of insulators, ranging from old pin and suspension insulators to contemporary composite insulators, possess distinct advantages and find usage in diverse contexts.

When undertaking the design of overhead lines, it is imperative to take into account many elements such as voltage levels, contamination levels, and mechanical loads in order to make an informed decision regarding the appropriate insulator type. The continuous development of insulators, driven by breakthroughs in materials and manufacturing techniques, has resulted in improved efficiency and increased lifespan of power transmission networks on a global scale. With the continuous advancement of technology, it is anticipated that there will be a proliferation of inventive insulator solutions in the future, which will further enhance the efficiency of overhead lines. Ensure continuous power supply with expertly crafted Outdoor Insulators for your infrastructure supplied by Radiant Enterprises - one of the best Outdoor Insulator manufacturers in India!

#Medium Voltage Support Insulator Manufacturers in India#Indoor Insulator Manufacturers in India#Outdoor Insulator Manufacturers in India

7 notes

·

View notes

Text

Advantages and disadvantages of 5G

5G technology or fifth generation technology offers many features for mobile networks. It is useful for government, students, businesses and professionals. It is a new mobile network designed to connect everyone and everything. It is the new standard in global wireless networks after 1G to 4G. It offers high multi-Gbps data speeds, low latency, large network capacity, and a flexible user experience. As this new technology is deployed, 5G technology should create many new applications.

5G technology features in brief. Speed up to 10 Gbits.

Great app

100 times more device connections

Fast response time

Waste of time

Another software option to upgrade. Great potential

With the proliferation of digital around the world, when live streaming and games, sports, news, movie reviews, social media, etc., the transfer of large amounts of data from one host to another and the Internet of Things (IoT) spurred the development of mobile phone standards. .

However, the 5G technology network has not yet reached its potential because the existing devices and infrastructure are not yet ready to support the 5G technology network. Those who have tested the 5G technology network using it with built-in 4G devices in this application are also called non-stationary 5G technology networks. The full potential of 5G technology will only be realized when independent networks, compatible devices and better communication tower technologies become available.

Advantages of 5G technology

Transfer data faster

The previous generation 4G LTE technology used bands below 3 GHz but in comparison, 5G technology uses bandwidth from 6 GHz in length to 24 GHz. However, it is important to note that 5G technology coverage also requires a base station and a broadcast tower compared to a 4G data network.

Improved network

5G networks are more flexible as they work with different customers, services and market segments. It divides its network in such a way that it will adapt to the needs of the users. It is based on Network Functions Virtualization (NFV) and Software Defined Networking (SDN). It is also called a "network fragment". This provides high data rates, low power consumption, and reliable low latency.

Moving Beamforming

Moving Beamforming refers to a radio signal processing technique that allows for the transmission or reception of a directional network, unlike a passive antenna that beams the signal randomly in all directions. 4G networks also use beamforming to some capacity, but in a growing sense.

Benefits for companies and businesses

It provides improved machine-to-machine communication for automation, real-time communication and guaranteed network availability, digitization of healthcare and agricultural industries.

Benefits for consumers

It provides fast download and download times when you are streaming users. Stable connection to mobile communications, low response time for online or cloud gaming, virtual reality, high quality live TV and 4K video telephony.

A more secure network

5G technology networks offer more security than previous generation networks. It supports protection against data loss, data corruption and theft. The exchange of sensitive and private customer data, such as hospital patient reports, customer data and student information at universities, is more secure in the 5G technology network.

Disadvantages of 5G

Limit coverage

The 5G technology network is a new technology, it requires a large network of ports and transmission towers worldwide, which requires a lot of time, testing, testing and setting up 5G technology towers.

Reduces durability

If the experts are to be believed, the non-standard 5G technology network undermines the performance of 4G network devices. Although a few manufacturers have started to produce 5G technology network devices, R & D believes that due to high data transmission in the largest network, the longevity or service life of mobile phones and other devices will be compromised.

Involvement in aviation

In January, Air India cancled several flights to the United States because they were rolling out 5G technology services in the country. This is a major setback of 5G technology in India as airlines have suffered losses due to ongoing 5G technology deployment projects. It can also be a hindrance in the future if not dealt with quickly. Internet Security Threats

Although the 5G technology network is said to help improve cybersecurity, it also has its limitations as it encourages cloud computing and exposes more data to risk. of hacking due to its lack of privacy and ease of access to network networks. on the other hand. hands

5G technologyin India

India officially launched its 5G technology network in October this year at an event held in New Delhi. Airtel and Jio have started rolling out 5G technology data plans in select state. However, Vodafone Idea is not planning to launch it in the near future.

In case of Airtel, they are currently placed in Tier I to Tier 8 countries. Jio has launched 5G technology services in limited areas. Many telecom operators are also of the opinion that pan-India 5G technology network coverage will take a few years. Jio recently announced after the 5G technology beta test that no SIM card is required to operate Jio's 5G technology network. However, Vodafone Idea has not yet announced its 5G technology network.

The health risks of 5G technology and the disadvantages of 5G technology for the environment

The International Commission on Non-ionizing Radiation Protection (ICNIRP) has stated that increasing radio frequencies above 6 GHz may have biological and health effects. The 5G technology network will increase the amount of electromagnetic radiation in the environment, causing a greater risk of cancer. With the lack of power of 5G technology network devices, there will also be an increase in the collection of electronic waste. The electric current from the cell tower exposed sparrows and other birds to increased egg production and nesting behavior. High rates of energy consumption have also contributed to global warming.

7 notes

·

View notes

Text

What are the benefits of MS Pipe angle and MS Pipe beam?

MS angle, also known as mild steel angle, is a type of L-shaped cross-section that has several applications in the building industry. MS angles, also known as metal angles, are typically used to create right angles with two equal sides with the same width and length. Equal angles are those in which each side is the same length, and unequal angles are those in which one or more of the sides is longer than the other.

While Tube Trading Co. is just one of many MS angle manufacturers in India, it is widely recognized as a leading supplier of MS Pipe angle in Vadodara. MS angles are easy to weld, drill, as well as cut to a desirable size, making them versatile for a wide range of applications. They also have exceptional mechanical qualities.

Applications of MS Angle:

Angles made of mild steel (MS) are produced using two materials, either high-strength low alloy steel or hot-rolled carbon steel, which gives them a great deal of stability for use in a variety of structural applications as well as other general fabrication and maintenance activities. It finds widespread applicability across a variety of engineering fields, including commercial, industrial, and domestic settings.

MS Angle is highly recyclable, and as a result, it is regarded as an economically viable material for the production of a wide variety of tiny and big components in virtually every industry. MS angles have a very broad range of applications since they may be utilized in a variety of contexts to perform a variety of functions to meet your needs.

The construction of bridges, buildings, as well as other types of structures, farm equipment and machinery, precipitators, transmission lines and towers, transportation corners and frames, border frames, as well as a variety of other applications are just some of the common industries that make use of MS angle.

Tube Trading Co. is one of the most reliable sources for all of your requirements if you are looking for a trusted distributor of MS Pipe angle in Vadodara, and if so, you should consider using their services.

Advantages of MS Angles:

In light of what has been discussed thus far, it should come as no surprise that the malleability and high degree of versatility inherent to MS angles confer a plethora of advantages.

The pipe angles made from Mild Steel are also available in a variety of grades, dimensions, as well as surface treatments. It has a lower carbon percentage, which makes it simpler to deal with because it can be easily drilled, cut, and welded to suit a vast range of applications, especially construction because of its tenacity. Additionally, it has a lower carbon content, which makes it more environmentally friendly. MS angles have a superb surface finish, and they are available in mild to high steel, all of which contribute to their popularity as a material for the construction of dependable building frames and structures. It is also quite versatile in nature, and as a result, it is regarded as a "green material" for the fabrication of all construction-related components because of this quality.

Therefore, regardless of the kind of building work you could be doing, you should think about using MS angle because it has such a vast array of different mechanical qualities. When it comes to acquiring items made of mild steel, it is usually suggested to purchase from reputable manufacturers and suppliers.

MS Beams:

Mild steel, often known as MS, is a common and flexible building material that may be found in the construction of large structures like skyscrapers and residential buildings alike. The Mild Steel used in construction is designed to withstand significant weight. MS Pipe beam in Vadodara is available in a variety of dimensions, and its application is determined by the needs of the construction. In order to protect a structure from being damaged by severe weather, it is common practice to make use of MS beams while constructing roof structures and the frames of homes. The ability of MS pipes and beams to be bent and shaped is an important factor in the construction industry's reliance on the usefulness of these materials.

Features of Mild Steel pipes:

● High tensile strength

● Made of a low % of Carbon

● Easily welded

● Budget-friendly

● Long-life

Primary Applications of MS Pipe Beams:

● General engineering purposes

● Mechanical purposes

● Structural purposes

● Water treatment plants

● Chemical processing plants

Advantages of MS Beams:

● Recyclable:

In contrast to the majority of other materials used in construction, structural mild steel may be recycled. This contributes significantly to the reduction of waste produced by construction.

● Durable:

Mild Steel beams and other structural components made of Mild steel are known to have a higher tensile strength that can withstand heavy weight, which contributes to their remarkable durability. It is more resistant to fracture under pressure than a mass of stone or wood of the same volume would be under the same conditions. One of the benefits that make structural mild steel structures ideal for the building of big skyscrapers and bridges is the fact that they can withstand wear and tear for a long time.

● Rust and Corrosion resistance:

The life expectancy of construction materials such as wood is poor because of the increased likelihood that they would rot sooner. Because of the chemical structure of mild steel beams, these components are resistant to rust and corrosion, which are two factors that could otherwise reduce the structure's longevity. Because of this benefit, the life expectancy of structures that are created using mild steel beams supplied by Tube Trading Co. - an excellent supplier and distributor of MS Pipe beam in Vadodara is higher when compared to other construction materials.

#MS Pipe angle in Vadodara#MS Pipe beam in Vadodara#Businss#Industry#MS angle#MS pipe#MS steel#seamless pipe#GI pipe#stainless steel pipe#spiral welded pipe#IBR pipe#ERW pipe#pipes for fire fighting work

7 notes

·

View notes

Text

Figuring out Round Bars' Superiority: An All-Inclusive Guide

Introduction:

Nova Steel Corporation is leading Round Bar Manufacturer in India. Round bars, the unsung heroes of the industrial world, have a significant impact on modern infrastructure and innovation. Despite their simple appearance, round bars are essential components in a variety of industries, including construction, manufacturing, automotive, and aerospace. In this comprehensive tutorial, we will look at the fundamentals of round bars, including their applications, properties, and why they are such important components in engineering and design.

Understanding Round Bars:

Round bars, often called rods or solid bars, are cylindrical metal bars with a circular cross section. They are fabricated from different materials, including steel, stainless steel round bar, High Nickel Alloy Round Bars, XM19/Nitronic Round Bar, LF2 Round Bar, and Alloy Steel 4340 Round Bar, each offering unique properties suited for specific applications. Round bars are manufactured through processes such as hot rolling, cold drawing, or machining, ensuring precise dimensions and consistent quality.

Applications Across Industries:

The versatility of round bars renders them indispensable across a myriad of industries:

1. Construction: Round bars are fundamental components of construction projects; they are used to fabricate building and bridge frameworks, create support beams, and reinforce concrete structures.

2. Manufacturing: Round bars are used in the manufacturing industry to make shafts, axles, fasteners, and precision components for machinery, equipment, and tools.

3. Automotive and Aerospace: Because of their strength, endurance, and resistance to corrosion, round bars are widely used in the automotive and aerospace industries for the fabrication of engine parts, chassis components, landing gear, and structural elements.

4. Energy Sector: Round bars are used in the energy industry to manufacture pipelines, drill rods, and components for power production and transmission equipment.

Key Characteristics:

Several key characteristics make round bars indispensable in engineering and construction:

1. Strength and Durability: Round bars provide structural integrity and endurance because of their great tensile strength and resilience, which allows them to handle large loads and harsh environments.

2. Machinability: Round bars are easily machined and built into unique components, allowing for precision shape and dimensional accuracy to fulfill design specifications.

3. Corrosion Resistance: Because of their superior corrosion resistance, materials such as aluminum and stainless steel are a good choice for outdoor and marine applications where exposure to severe conditions and moisture is common.

4. Thermal Conductivity: Round bars conduct heat well, making them ideal for applications that require heat transmission or dissipation, such as heat exchangers and thermal management systems.

Best Round Bar Manufacturer

Nova Steel Corporation is leading Round Bar Supplier in India. We have substantial expertise in the manufacturing and supplying of all sorts of Round Bars. We are Best Round Bar Manufacturers. Personnel with the necessary qualifications and a wealth of experience handling different kinds of Pipe Fittings and other products supervise the whole manufacturing process.

Finally, round bars represent the pinnacle of versatility, strength, and dependability in the field of engineering and building. From towering skyscrapers to precise machinery, round bars are the foundation of modern infrastructure and innovations, representing human ingenuity and perfection. As technology advances and businesses evolve, the importance of round bars will grow, influencing the landscapes of tomorrow and beyond.

0 notes

Text

5G Towers and Cables Market Outlook 2024-2034: Growth Projections and Emerging Trends

The 5G towers and cables market is projected to experience significant growth between 2024 and 2034 due to the rapid expansion of 5G networks across the globe. As telecommunication providers push for enhanced connectivity and higher data speeds, the infrastructure needed to support these advancements, such as towers and cables, is expected to play a pivotal role.

Growth in usage of IoT-enabled devices is also fueling the 5G towers and cables market progress. The new range of IoT devices and applications rely on 5G infrastructure to collect and exchange data at a rapid pace.

The global 5G Towers and Cables industry, valued at US$ 10.9 billion in 2023, is projected to grow at a robust CAGR of 36.9% from 2024 to 2034, reaching US$ 346.6 billion by the end of the forecast period. This growth is largely driven by increased demand for faster mobile internet and the need to support new-age technologies.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/5g-towers-and-cables-market.html

Market Segmentation: The 5G towers and cables market can be segmented into the following categories:

By Service Type:

Installation services

Maintenance services

Consulting services

By Sourcing Type:

Manufactured in-house

Outsourced manufacturing

By Application:

Urban connectivity

Rural connectivity

Industrial and commercial connectivity

By Industry Vertical:

Telecommunications

IT & Data Centers

Government

Healthcare

Automotive & Transportation

Smart Cities

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis:

North America: North America is a key market for 5G infrastructure due to early 5G deployment in the U.S. and Canada. The region benefits from strong telecom players and significant investment in upgrading infrastructure.

Europe: Europe is witnessing growing adoption of 5G, driven by increased government initiatives and the demand for enhanced connectivity across multiple industries.

Asia-Pacific: This region is expected to lead the 5G towers and cables market due to rapid deployment in countries like China, South Korea, and Japan, where governments are heavily investing in smart city projects and advanced network infrastructure.

Latin America & Middle East & Africa: These regions are still developing 5G capabilities, but rapid urbanization and the growing need for better connectivity are fueling investments in 5G infrastructure.

Market Drivers and Challenges:

Drivers:

Growing Demand for High-speed Data: Increasing consumer and business demands for faster, more reliable internet are driving the deployment of 5G networks.

Expansion of IoT and Smart Cities: The growing adoption of IoT devices and the development of smart cities require robust and widespread 5G infrastructure.

Technological Advancements: Continuous innovations in tower design and fiber-optic cables enhance network performance, fueling demand.

Challenges:

High Capital Expenditure: The significant initial investment required for 5G infrastructure development is a major challenge for telecom operators and service providers.

Regulatory Barriers: Different regions have various regulatory requirements that could delay the deployment of 5G towers and cables.

Environmental Concerns: The construction of new towers may face opposition from local communities and environmental groups concerned about landscape disruption.

Market Trends:

Small Cell Deployments: Increasing focus on small cell deployment to ensure seamless connectivity in urban areas.

Fiber Optic Cables: Rising adoption of fiber optic cables due to their superior data transmission capabilities, which are essential for 5G networks.

Collaborations and Partnerships: Telecom companies are collaborating with equipment manufacturers to develop efficient 5G infrastructure solutions.

Future Outlook: The future of the 5G towers and cables market looks promising, with a forecasted surge in demand driven by the global shift towards digital transformation. Governments and private sector players are expected to invest heavily in 5G infrastructure, and emerging applications such as autonomous vehicles, augmented reality (AR), and virtual reality (VR) will further fuel demand.

Key Market Study Points:

Focus on the role of 5G towers and cables in supporting enhanced mobile broadband, IoT, and industry-specific applications.

Analysis of the impact of 5G deployment on the telecommunications and IT industries.

Exploration of challenges faced by key market players in meeting demand for 5G infrastructure.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=86137<ype=S

Competitive Landscape: The competitive landscape in the 5G towers and cables market is fragmented, with key players focusing on innovation, partnerships, and acquisitions. Major companies in the market include:

Huawei Technologies Co. Ltd.

Ericsson AB

Nokia Corporation

ZTE Corporation

American Tower Corporation

Crown Castle International Corp.

CommScope Holding Company, Inc.

These companies are investing heavily in R&D and forming strategic partnerships to gain a competitive edge.

Recent Developments:

Huawei announced the launch of advanced 5G tower designs aimed at reducing installation time and improving efficiency.

Ericsson entered into a collaboration with telecom companies in Europe to expand 5G coverage in rural areas.

American Tower expanded its portfolio by acquiring several tower sites across the Asia-Pacific region to support the growing 5G market.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Gujarat's Premier Transmission Line Tower Manufacturers

Introduction:

Discover the main transmission line tower manufacturers in Gujarat, renowned for their commitment to great innovation. In this guide, we unveil the top five producers, supplying insights into their notable services and products that set them aside in the enterprise.

Gujarat's Manufacturing Excellence in Transmission Line Towers

Gujarat has emerged as a hub for transmission line tower production, known for its terrific quality and innovation. Learn why those producers stand out in the aggressive landscape, riding advancements in the enterprise.

Excellence in Quality and Innovation

Delve into how those manufacturers excel in excellent and innovation, placing new requirements for transmission line towers. Explore their modern technologies, superior materials, and streamlined techniques that make certain reliability and performance.

Standout Products and Services

Discover the standout services and products supplied by means of every manufacturer, showcasing their particular strengths and competencies. From custom designed tower designs to complete challenge management solutions, learn the way they cater to various consumer desires.

Driving Progress and Sustainability

Explore how these producers pressure development and sustainability inside the transmission line tower industry. From green practices to network engagement tasks, discover their commitment to responsible manufacturing and company citizenship.

Conclusion:

As we finish our exploration of the pinnacle transmission line tower manufacturer in Gujarat, one component turns into clear: excellence knows no bounds in this vibrant enterprise. With a relentless recognition on great, innovation, and sustainability, these manufacturers keep to push the bounds of what is possible, shaping the future of energy transmission infrastructure.

0 notes

Text

Pre-installed Concrete Batching Plants

A pre-installed concrete batching plant, also known as a pre-connected concrete batching plant, is a type of batching plant plant where most of the connecting and commissioning work has already been done before leaving the factory. This design is intended to increase the rapid deliverability of the concrete batching plant and the efficiency of on-site installation, as well as to reduce the failure rate and improve the stability of the concrete batching plant.

Pre-installed concrete batching plant is a kind of pre-assembled concrete mixing equipment, usually consists of concrete mixer, metering system, conveying system, control system, etc., most of the connection and commissioning work has been completed before leaving the factory, the user only needs to carry out simple debugging and installation at the site can be put into use, which greatly shortens the installation time and improves the equipment’s rapid delivery capacity. The output of this kind of concrete batching plant is usually between 25-240 m3/hour, and the equipment can be customized with different specifications according to the needs.

Advantages of pre-installed concrete batching plants are:

– Rapid installation: as most of the connection work has already been done by the manufacturer, users only need to carry out simple commissioning and installation on site, significantly reducing installation time.

– Reduced failure rate: the pre-connection reduces the connection and debugging of the user at the site, reducing failures and accidents caused by improper human operation.

– Improve the stability of the equipment: All parts are connected and debugged by professionals in accordance with certain specifications, so the stability and reliability of the equipment is higher.

– Convenient transportation and movement: all parts of the pre-connected mixing plant form a compact whole, which is easy to be transported and moved, and can be more conveniently transferred from one site to another.

– Increased productivity: due to the short installation and commissioning time, the plant can be put into production faster, thus increasing productivity.

– Reduce cost: Reduces the time and cost for users to install and debug at the site, which reduces the cost of the whole project.

The application scenarios of pre-installed concrete batching plant equipment are very wide, mainly focusing on all kinds of projects that require concrete as building materials, including but not limited to:

– Infrastructure construction: such as the construction of highways, railroads, bridges, tunnels and other transportation facilities.

– Housing construction projects: the main structure and foundation parts of commercial buildings, residential buildings, public buildings (schools, hospitals, gymnasiums, etc.).

– Water conservancy engineering: construction of water conservancy facilities such as reservoirs, embankments, hydroelectric power stations, etc., especially the construction of dams.

– Power engineering: construction of power facilities such as substations, transmission tower foundations, etc.

– Prefabricated component production: for the production of various prefabricated components, such as prefabricated panels, prefabricated beams, prefabricated columns and so on.

– Other projects: port terminals, airport runways, pipeline projects, etc. also need to use concrete.

To summarize, pre-installed concrete batching plant is widely used in all kinds of engineering projects that need concrete with its advantages of quick installation, reduced failure rate, improved equipment stability and production efficiency. Due to its flexibility and high efficiency, it is more and more favored by project builders.

This resource is from https://www.concretebatchplant24.com/pre-installed-concrete-batching-plants.html

Should you be interested in, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

#pre-installed concrete batching plants#pre-installed concrete batching plant#concrete batching plant

0 notes

Text

Salasar Techno Engineering Limited: A Comprehensive Overview of Q1 FY25 Financial Results

Salasar Techno Engineering Limited, a prominent player in the infrastructure sector, recently presented its financial results for the first quarter of the fiscal year 2025. The company, with its diverse operations ranging from telecom towers to power transmission solutions, continues to demonstrate robust performance and strategic growth.

Headquartered in New Delhi with multiple facilities across India, Salasar Techno Engineering is a key enabler in the development of national infrastructure. Their facilities are strategically located to optimize raw material procurement and production efficiency. The company's operations span across three major units, equipped with state-of-the-art machinery including CNC machines, plasma cutting tools, and beam welding equipment.

For the first quarter of FY25, Salasar Techno Engineering reported a revenue of ₹2,940 million, marking a 12.3% increase from the same period last year. This growth reflects the company's successful expansion in its core areas of telecom infrastructure, power transmission, and EPC (Engineering, Procurement, and Construction) projects. The EBITDA for the quarter improved to ₹282 million, showcasing a margin of 9.6%, driven by operational efficiencies and high-margin project execution. However, the PAT (Profit After Tax) saw a modest increase of 3.4%, reaching ₹104.9 million.

The company’s strategic focus on expanding its footprint in telecom and power transmission sectors has bolstered its order book, which stood at ₹24,019 million by the end of Q1 FY25. This strong order book underscores Salasar's market leadership and ability to secure significant projects across diverse segments. Noteworthy orders include projects related to telecom towers, power transmission lines, and renewable energy solutions.

Salasar Techno Engineering's management is optimistic about the company's future, attributing its strong performance to a combination of strategic initiatives and favorable market conditions. The company's vision to contribute significantly to national infrastructure development and its mission to deliver advanced technological solutions remain central to its growth strategy. The emphasis on technological advancements and strategic partnerships, such as the tie-up with Ramboll for manufacturing high-performance tower structures, continues to enhance Salasar’s competitive edge.

The company is also poised to benefit from the substantial investments planned in India's power transmission sector. With the Central Electricity Authority's vision of integrating 500 GW of renewable energy by 2030, Salasar Techno Engineering is well-positioned to capitalize on the opportunities arising from this massive infrastructure upgrade. Additionally, the growth in the telecom sector, with government plans to expand mobile tower infrastructure, presents further opportunities for Salasar.

In conclusion, the first quarter of FY25 has been a period of notable progress for Salasar Techno Engineering Limited. The company’s strategic focus, operational efficiencies, and market expansion efforts have set a solid foundation for continued growth. As Salasar moves forward, it remains committed to leveraging its strengths to drive future success, supported by a strong order book and an optimistic outlook on industry developments. The company expresses gratitude to its stakeholders for their unwavering support and looks forward to building on its achievements in the upcoming quarters.

0 notes

Text

The V SMSR Gearbox: Revolutionizing Power Transmission in Industry

Introduction

In the world of industrial machinery, the efficiency and reliability of power transmission systems are crucial. Among the various types of gearboxes available, the V SMSR Gearbox (Shaft Mounted Speed Reducer) stands out for its innovative design and performance. This article delves into the features, benefits, and applications of the V SMSR Gearbox, highlighting why it is a preferred choice for many industrial applications.

Understanding the V SMSR Gearbox

The V SMSR Gearbox, or Shaft Mounted Speed Reducer, is a compact and efficient gearbox designed to provide speed reduction and increased torque in industrial machinery. Unlike traditional gearboxes that require a base or foundation for mounting, the SMSR gearbox is directly mounted onto the driven shaft, eliminating the need for additional support structures. This design simplifies installation and maintenance, making it a popular choice for various applications.

Key Components and Design Features

Gear Assembly: The core component of the V SMSR Gearbox is the gear assembly, which typically includes helical gears. Helical gears are known for their smooth and quiet operation, thanks to their angled teeth that gradually engage with each other.

Shaft Mounting: The defining feature of the SMSR gearbox is its shaft-mounted design. The gearbox is directly mounted onto the driven shaft, which simplifies the alignment process and reduces the need for additional components.

Torque Arm: The torque arm is an essential part of the SMSR gearbox. It prevents the gearbox from rotating and ensures that the torque is effectively transmitted to the driven equipment. The torque arm is usually adjustable, allowing for flexibility in installation.

Bearings and Seals: High-quality bearings and seals are used to ensure smooth operation and protect the internal components from contaminants. These elements are crucial for maintaining the longevity and performance of the gearbox.

Housing: The housing of the V SMSR Gearbox is typically made from robust materials such as cast iron or aluminum. It provides structural support and protection to the internal components, ensuring the gearbox can withstand harsh industrial environments.

Functionality and Operation

The V SMSR Gearbox operates by reducing the input speed from the motor and increasing the torque transmitted to the driven equipment. The helical gears within the gearbox mesh smoothly, providing efficient power transmission and minimizing energy losses. The shaft-mounted design ensures that the gearbox is directly aligned with the driven shaft, reducing misalignment issues and enhancing overall efficiency.

Applications of V SMSR Gearboxes

The versatility of the V SMSR Gearbox makes it suitable for a wide range of industrial applications. Some of the common applications include:

Conveyors: SMSR gearboxes are widely used in conveyor systems for material handling. Their compact design and efficient power transmission make them ideal for use in industries such as mining, aggregate processing, and manufacturing.

Crushers: In the mining and quarrying industry, SMSR gearboxes are used in crushers to provide the necessary torque for crushing operations. Their robust construction ensures reliable performance even in demanding environments.

Mixers and Agitators: SMSR gearboxes are employed in mixers and agitators used in chemical processing, food production, and wastewater treatment. Their ability to provide precise speed control and high torque is crucial for these applications.

Pumps: In various industrial processes, SMSR gearboxes are used to drive pumps. Their efficient power transmission ensures consistent fluid flow and reliable operation.

Cooling Towers: SMSR gearboxes are used in cooling towers to drive the fans that dissipate heat. Their compact design and reliable performance make them suitable for use in HVAC systems and power plants.

Advantages of V SMSR Gearboxes

Ease of Installation: The shaft-mounted design of the SMSR gearbox eliminates the need for additional support structures, simplifying the installation process. This design also reduces the time and labor required for setup.

Compact Design: The SMSR gearbox is compact and space-saving, making it ideal for applications with limited space. Its streamlined design also reduces the overall weight of the system.

High Efficiency: The use of helical gears in the SMSR gearbox ensures smooth and efficient power transmission. The gradual engagement of the gears reduces energy losses and enhances overall efficiency.

Low Maintenance: The robust construction and high-quality components of the SMSR gearbox result in low maintenance requirements. The direct shaft mounting also reduces the risk of misalignment and associated wear.

Versatility: The adjustable torque arm and flexible mounting options make the SMSR gearbox suitable for a wide range of applications. It can be easily adapted to different setups and operational requirements.

Maintenance and Care

To ensure the optimal performance and longevity of V SMSR Gearboxes, regular maintenance is essential. Here are some maintenance tips:

Lubrication: Regularly check and maintain the appropriate oil levels. Proper lubrication is crucial for reducing friction and wear between the gears and bearings.

Inspection: Periodic inspections of the gearbox can help identify potential issues early. Look for signs of wear, leaks, and unusual noises that may indicate problems.

Cleaning: Keep the gearbox and its surroundings clean to prevent dust and contaminants from entering the gearbox. This can help prevent damage to the gears and bearings.

Alignment: Ensure that the gearbox is properly aligned with the driven shaft during installation. Misalignment can lead to excessive wear and reduced efficiency.

Torque Arm Adjustment: Periodically check and adjust the torque arm to ensure it is properly positioned and securely fastened. This will prevent unnecessary stress on the gearbox and enhance its performance.

Innovations and Future Trends

The field of gearbox technology is continuously evolving, and the V SMSR Gearbox is no exception. Several innovations and trends are shaping the future of these gearboxes:

Advanced Materials: The use of advanced materials, such as composite materials and high-strength alloys, is enhancing the performance and durability of SMSR gearboxes.

Precision Manufacturing: Advances in manufacturing techniques, such as 3D printing and CNC machining, are enabling the production of gears with higher precision and tighter tolerances, resulting in improved performance.

Smart Gearboxes: The integration of sensors and IoT technology is leading to the development of smart gearboxes that can monitor their own performance and provide real-time data for predictive maintenance, reducing downtime and improving efficiency.

Energy Efficiency: As industries strive for greater energy efficiency, gearboxes are being designed to minimize energy losses and improve overall system efficiency. Innovations in lubrication and materials are contributing to this goal.

Conclusion

The V SMSR Gearbox is a vital component in many industrial applications, offering ease of installation, high efficiency, and reliable performance. Its unique shaft-mounted design and robust construction make it suitable for a wide range of uses, from conveyors and crushers to mixers and pumps. By understanding its design, functionality, and applications, industries can leverage the benefits of the V SMSR Gearbox to enhance their operations and achieve greater efficiency.

For more information about the V SMSR Gearbox and to explore our range of products, visit Cherry Belts.

0 notes

Text

Utility Poles Market Poised for Steady Growth in the Future

Utility Poles Industry Overview