#truck scale load cells

Text

truck scale load cells, also known as Weighbridge load cells, are intended for use with both rail scales and truck scales. The Thames Side line contains alloy tool steel and stainless steel, which meet environmental requirements up to IP68 and are appropriate for usage in muddy and damp conditions.

0 notes

Text

Anatomy

1. If you were composed of something, why?

a. I believe that somewhere really deep, like, really deep, like Hadal deep, or Loubouttin in eye, socket deep, I've got a toms. You know toms?

b. I shall supplicate a categorical imperative derived by my years of primatology research with Bonobos and Britney Spears. F, C, U, K—yes, these four nitrogenous bases supplied with bitter sugars form the cataclysmic pudenda that dilates god's creation algorithm. In Genesis, Adam and Eve were basically a torpedo and a wormhole in oestrus, and in a gaping paroxysm of smoke-belching buses in Manila, created that beautiful face you point at called matter.

c. Apgar scores, eyes closed, zippers open. Soul snow melting, giving me neo-Pavlovian, colonial shivers. During Grade 6, they said I was too good for the Philippines, that I deserved Hong Kong, or Singapore. There I would be tossed the perfume scented dirt from their necks and knighted for non-conformity, profanity and ability to piss in three legs.

d. Tarmac roads of memory foam. Justified by tequila shots anaphasing with Beatniks gargling spoken word. An inch beyond a shoulder, red LED trying out green leather jackets by Zara. Beneath a truck loaded with beer, a pot-bellied man on a hammock rubs his crotch dreaming of quarter-Lebanese rest-human poster Gerbers.

e. Dough placed on arpeggio speakers, mashing me to non-Newtonian fluid with friction blisters. When I rise in a subcutaneous oven, I'd be like steroid pumped with lashes on my wrists, 'you are all batards!'

f. Shanzai Bucherer. Bucher killed by a bucher. Flesh carved from metal not found in any periodic table with a do-it-yourself best before date and kama sutra malleability. Climbing on my palm is the soft woolly corpse of a magenta chick, and I cry; remembering Tuesdays, coconut husks and/or, scrabble tiles.

g. Copy paste Leonardo da Vinci's treatise on water. Not so much architrave, not very cornice. In the extent of dehydration, I would be flattered to be a cell in your sheet #2 dressed in deep blue organza.

h. A welterweight neoplasm champion that has eluded the Richter scale. While I live, some Japanese otaku is ejaculating over Generativity sucks Stagnation. In 3 a.m. news Pacman's sandpapering his fists off neurons with prayers and white-petal flowers.

i. Can I please be partial points? Or at least, supplementary dusks...tears only flow how other tears fell. Just moved in a M-something street cul-de-sac, behind your back a neighbour with two navels, and you go, this ain't no Narnia. Where did the first tear go?

— Mariel Alonzo, from “ Anatomy"’

1 note

·

View note

Text

Sponge Rubber vs Solid Rubber: What’s the difference?

One of the most commonly asked questions is what is the difference between sponge rubber and solid rubber?

The EPDM sponge rubber seal is one of the most used ones. One essential thing to determine between the two is whether these natural, synthetic and elastomers polymers come with elastic properties.

Both sponge rubber and solid rubber undergo vulcanization. Vulcanization is the process that uses chemical agents and heat like sulfur to enhance durability.

These are available in different compounds such as silicone, neoprene, and EPDM. One of the prominent benefits of sponge rubber and solid rubber is that it can be molded into a sponge rubber sheet and can be extruded into different shapes.

The most common difference between the two is air for both sponge rubber and solid rubber.

Sponge rubber has balloon-like cells and interconnected pockets that either allow it to hold air or even contribute to passing it. Nonetheless, solid rubber does not contain any cellular structure.

One of the most common places where sponge rubber and solid rubber is used includes offering insulation and sealing.

Solid Rubber

Solid rubbers are very much different from sponge rubber sheets. The solid rubber cannot be drawn into sheets, unlike the sponge rubber sheet.

Solid rubber is available as hard, soft and medium too. In terms of rubber, a durometer is the measure of hardness, and it is further expressed in terms of the Shore A scale.

The soft rubber used for pencil erasers is in terms of durometer, and the measure is 40. However, those for hockey pucks have a durometer measure of 90. The difference ranges in terms of one type of rubber being harder than the other.

The solid rubbers are used for truck bumpers, shock absorbers, and anti-vibration pads for machinery, equipment and vehicles.

The solid rubber is industrial grade products which eventually reduces the risk of downtime and protects the mechanical parts.

The solid elastomers will eventually absorb the impact for rubber bumpers, and the truck strikes a loading dock. One of the common benefits of solid rubber seals and gaskets is to provide fluid containment and surface protection.

Sponge Rubber

Similar to solid rubber, sponge rubber is also available in various durometer measures. Although sponge rubbers are softer than other rubbers, this will always not be the case.

Although the gradings are different, it will also bring about a difference in the material’s hardness. It will also affect the ability to maintain the thickness of the rubber.

Unlike other rubbers, sponge rubber gasket material can provide a noticeable cushioning impact. Furthermore, these can also be over-compressed so that the sealing fails.

The sponge rubber sheet’s common applications include vibration dampening, weather stripping, shock absorption, cushioning, and soundproofing.

Other areas where sponge rubber is used include filters, custom gaskets, and thermal insulation depending on meeting approvals and standards. Although sponge rubbers can meet these requirements, it is necessary to maintain the standards and approvals.

How is sponge rubber used?

Sponge rubber is made of different elastomeric materials like silicone, neoprene, EPDM and nitrile. The profiles offer shock absorption and can help with good compression and recovery.

The sponge rubber sheets can be used for custom fabrication which can further help with value-added operations like that of gasket taping.

Although sponge rubber is compared to solid rubber, it is generally software and less resistant to compression. Sponge rubber comes with a strength-to-weight ratio.

The sponge rubbers are further used for medical sponges, prosthetic devices, medical filters, sterilization bags and electrocardiogram (ECD) pads.

Most of these sponge rubbers come with elastomeric components that can help with the passage of gases and water. These sponge rubbers can be helped with medical components, thereby helping with sitting up and getting up. The FDA approves the closed sponge rubber.

As the FDA approves these, it can help for medical applications as well as food contact. However, there is a significant difference between being FDA compliant and being FDA approved.

As a result, before beginning to choose a material, you should do proper research. Sponge rubbers can be helpful for hatches, enclosures and bulb seals. The trim seals are made of separate bulbs that can offer retainer sections made of different materials. However, the EPDM sponge rubber seal has the bulb portion.

How is sponge rubber made?

Sponge rubber has different densities because of its variant cellular structure. Depending on the hardness level, sponge rubber is divided into different groups such as soft, medium and firm.

According to experts, there are two types of sponge rubber- the closed-cell rubber and open-cell rubber.

The open-cell material has interconnected and open pockets that can make it easy for air, water and various chemicals to pass through.

This will only be beneficial if the material is not compressed. The closed-cell sponge rubber has balloon-like compartments or cells that can be beneficial for holding nitrogen gas, thereby preventing the passage of various substances across low pressure.

The addition of sodium bicarbonate to different materials in the heated mould helps to provide shape to open-cell sponge rubber.

However, for closed-cell sponge powder production, the chemical powder is decomposed in heat and pressure.

The release of nitrogen gas helps to provide a shape to closed-cell sponge rubber, thereby providing easy recovery and a robust compression setting.

Nitrogen is gas, but it produces no foam like various gaseous blowing agents that are often used in foam rubber.

Unlike others, foam rubber has open-cells which can be used in the production process.

Many foam rubber cells are closed and hence do not qualify for the ASTM test for water absorption, which is a staple requirement across the closed-cell materials.

Uses of sponge and foam rubber sheet

The foam and sponge rubber sheets are used across defence, racing, medical, nautical and aerospace industries.

However, various industries such as packaging, construction and glass companies have been using the foam rubber sheets. Since sponge rubber sheets are flexible, they are mostly used in the automotive industry.

Due to its flexible characteristics, the sponge rubber sheet is also known as porous rubber because of its properties and usage across various industries.

Depending on the selected grade and material, the sponge rubber comes with shock resistance, sealing and oil resistance. Sponge rubber is flexible and durable.

Furthermore, it also contributes to housing inserts, packing and security components across different industries.

What are the benefits of compression moulding in a sponge rubber sheet?

Compression moulding can provide several benefits for sponge rubber sheets. These sponge rubber gasket materials can be folded into large and complex parts irrespective of the use of flat washers.

The compression moulding can be cost-effective, which is more beneficial than other types of moulding. Furthermore, compression moulding can be beneficial for large parts that may be used across different materials.

The materials can turn out across moulded cavities, thereby providing less restriction for various bodyweight parts.

Takeaway

There’s a huge difference between solid and sponge rubber sheets. No matter what type of industry you are in, it is necessary that you pay attention to all the aspects.

The right compound will eventually make a difference, thereby maintaining the balance between cushioning and impacting resistance.

If you need any rubber products for any industry, you can rely on R-Tech Rubber Industries. They provide a variety of Rubber products & are renowned rubber manufacturers in India.

0 notes

Text

Truck Scale Repair in Oregon: Ensuring Accuracy and Longevity

Importance of Truck Scale Repair

Truck scales, also known as weighbridges, are subjected to heavy loads, harsh environmental conditions, and continuous use. Over time, these factors can cause wear and tear, leading to inaccuracies in weight measurements. Inaccurate readings can result in legal issues, fines, and even damage to vehicles or infrastructure. Therefore, timely truck scale repair is vital to avoid costly mistakes and ensure compliance with state and federal regulations.

In Oregon, businesses rely on accurate truck scales for various reasons:

Regulatory Compliance: Oregon has strict regulations regarding vehicle weight to protect its roads and ensure safety. Truck scale repair Oregon Accurate scales are essential for adhering to these regulations and avoiding penalties.

Operational Efficiency: Inaccurate scales can lead to delays, as vehicles may need to be re-weighed or adjusted to meet weight limits. Regular maintenance and repair ensure smooth operations and minimize downtime.

Cost Savings: Regular maintenance and prompt repairs can prevent more significant issues from developing, saving businesses money in the long run. Preventative maintenance can extend the life of a truck scale, reducing the need for costly replacements.

Common Truck Scale Issues

Truck scales, due to their heavy-duty use, can encounter several issues that require professional repair. Some of the most common problems include:

Load Cell Malfunctions: Load cells are the heart of a truck scale, converting weight into a measurable signal. If a load cell fails or becomes damaged, it can lead to inaccurate readings.

Foundation Problems: The foundation of a truck scale must be stable and level. Any shifts or cracks in the foundation can affect the accuracy of the scale.

Electrical Issues: Since truck scales are electronic devices, they can experience wiring issues, sensor malfunctions, or power supply problems.

Debris Buildup: Over time, dirt, debris, and moisture can accumulate on the scale platform, causing inaccurate readings or mechanical issues.

Choosing a Truck Scale Repair Service in Oregon

Selecting a reliable and experienced truck scale repair service in Oregon is crucial for ensuring the longevity and accuracy of your scales. When choosing a repair service, consider the following:

Experience and Expertise: Look for a company with a proven track record in truck scale repair. Experienced technicians will be able to diagnose and fix issues quickly and efficiently.

Availability of Parts: Ensure that the repair service has access to genuine parts and components, Pallet scale repair Washington especially for specific brands and models of truck scales.

Preventative Maintenance Programs: A good repair service will offer preventative maintenance programs to help keep your scales in top condition and reduce the likelihood of unexpected breakdowns.

Compliance with Industry Standards: The repair service should be familiar with industry regulations and standards, ensuring that your scales meet all legal requirements.

0 notes

Text

Top Weighbridge Manufacturer in India

ESSAR WEIGH offers a comprehensive range of export-quality electronic weighbridge solutions tailored to meet the diverse needs of industries worldwide. We are a leading Weighbridge Manufacturer in India.

What is a Weighbridge?

A weighbridge, also known as a truck scale or a vehicle scale, is a large, sturdy platform scale typically mounted on a concrete foundation. Its primary function is to weigh entire vehicles and their contents. These vehicles can range from trucks laden with goods to other heavy equipment used in construction, mining, agriculture, and more.

Types of Weighbridges

Weighbridges come in different types and configurations, tailored to specific needs:

Pit Mounted Weighbridges: These are installed in a pit so that the weighing surface is level with the ground, allowing vehicles to move smoothly onto the scale.

Surface Mounted Weighbridges: Mounted above ground level, these are easier to install and maintain but require ramps for vehicles to access.

Portable Weighbridges: These are modular and can be transported to different locations as needed, offering flexibility for temporary sites or where space is limited.

Importance in Industry

The role of weighbridges extends far beyond simple weight measurement. Here are several reasons why weighbridges are crucial in modern industry:

Logistics and Inventory Management: Weighbridges ensure that trucks are loaded within legal weight limits, preventing overloading which can damage roads and compromise safety. Accurate weight data also helps in managing inventory and ensuring correct billing for transported goods.

Compliance and Safety: Many jurisdictions have strict regulations regarding vehicle weights, especially on public roads. Weighbridges help companies comply with these regulations, avoiding fines and ensuring road safety by preventing overloaded vehicles.

Quality Control: In industries such as mining and agriculture, where bulk materials are transported, weighbridges play a vital role in quality control. Accurate weighing ensures that products meet specified standards and that customers receive the correct quantities.

Efficiency in Operations: Weighbridges facilitate quick turnaround times for vehicles, reducing waiting times at loading and unloading points. This efficiency translates into cost savings and improved customer satisfaction.

Data Collection and Analysis: Modern weighbridges are often equipped with software that allows for automated data collection and integration with other systems such as ERP (Enterprise Resource Planning) software. This data can provide valuable insights into operational efficiency and performance.

Technological Advancements

Advancements in technology have significantly enhanced the capabilities of weighbridges. Today, many weighbridges are equipped with:

Digital Load Cells: These provide precise weight measurements and are more durable than traditional mechanical components.

Remote Monitoring: Allows for real-time monitoring of weighbridge operations, improving efficiency and reducing downtime.

Integration with Software Systems: Enables seamless data flow between weighbridges and other enterprise systems, streamlining operations and enhancing data accuracy.

Conclusion

In conclusion, while weighbridges may seem like simple pieces of equipment, their role in modern industry cannot be overstated. From ensuring compliance with regulations to optimizing logistics and enhancing safety, weighbridges are indispensable in a wide range of industrial applications. As technology continues to evolve, so too will the capabilities of weighbridges, further improving efficiency and accuracy in industrial operations worldwide.

For more details, please contact us!

Website :- https://www.essaarweigh.com/

Contact No. :- 09310648864, 09810648864, 09313051477

Email :- [email protected]

#essaarweigh#weighbridge#electronic weighbridge#weighbridge manufacturer in India#weighbridge supplier in India

1 note

·

View note

Text

Global Top 3 Companies Accounted for 93% of total Automotive Plastic Tailgate market (QYResearch, 2021)

An automotive plastic tailgate refers to the rear door or hatch of a vehicle, typically found in SUVs, hatchbacks, and some trucks, that is made primarily or partially from plastic materials. The tailgate serves as an access point to the cargo area of the vehicle and can be opened and closed to load and unload items.

A plastic tailgate is typically made from high-strength plastics such as reinforced thermoplastics, fiberglass-reinforced composites, or carbon fiber composites. These materials are chosen for their lightweight properties, which can help improve fuel efficiency and reduce overall vehicle weight.

According to the new market research report “Global Automotive Plastic Tailgate Market Report 2023-2029”, published by QYResearch, the global Automotive Plastic Tailgate market size is projected to reach USD 0.79 billion by 2029, at a CAGR of 7.7% during the forecast period.

Figure. Global Automotive Plastic Tailgate Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Automotive Plastic Tailgate Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch..

Figure. Global Automotive Plastic Tailgate Top 6 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Automotive Plastic Tailgate Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Automotive Plastic Tailgate include Plastic Omnium, Magna, etc. In 2022, the global top three players had a share approximately 93.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

FCEVs or BEVs-The Future of Mobility

March 26, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

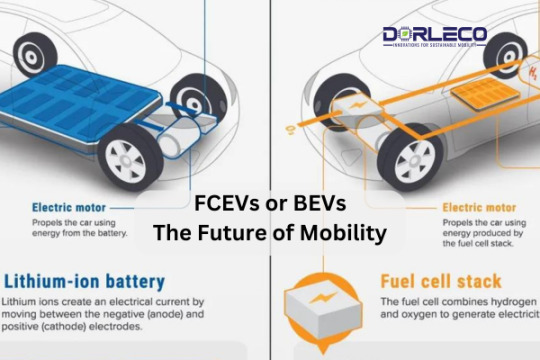

FCEVs or BEVs

Introduction

As we already know, automakers are turning to alternative energy sources to power their vehicles due to the depletion of fossil fuel deposits and the negative environmental effects of their combustion. These energy sources must be varied and sustainable, including fuel cell electric cars (FCEVs) and battery electric vehicles (BEVs).

There is much discussion about whether BEVs should take precedence over FCEVs, even if the automobile industry has already begun to look at sustainable alternatives. This is especially true given the finite supply of lithium, a key component of lithium-ion batteries. As a result, a lot of researchers are supporting the use of fuel cells, which use a redox reaction’s chemical reaction to produce energy. However, most automakers are still cautious about using fuel cells in production vehicles since research and development are still being done on how they behave in automotive batteries.

This article aims to address these concerns about the FCEVs or BEVs debate.

The Relationship between FCEVs or BEVs

In this specific argument, a common misperception is that fuel cells and lithium-ion batteries are rival technologies. It’s critical to realize that batteries, as one of the main energy sources, are here to stay in business for a very long time.

Lithium-ion and fuel cell technologies offer a range of solutions to address issues related to sustainability, pollution, and efficiency. These two substances seek to improve the answers to the electrification dilemma that the sector is now dealing with. Fuel cells are expected to complement batteries rather than replace them as the main component of the electrified solution in the future.

Difficulties in the Current Market

when discussing sustainable mobility, range is often the first factor to be questioned, particularly when discussing heavy-duty transportation. Very high-payload capacity combustion engine vehicles often have a big fuel tank, roughly 200–300 liters (50–80 gallons). This frequently enables them to travel 400 miles (depending on the payload) before needing to halt for a fuel stop. But while fuel cells and lithium-ion cells are still in their infancy, none of the technologies has yet been able to match the range requirements of heavy-duty transportation.

Furthermore, a high-capacity battery is probably going to be hefty, which raises the load and thus the energy requirement. For example, the battery in the Hummer EV is expected to weigh the same as the battery in the Honda Civic. High-energy-density batteries, sometimes known as fuel cells, are one way to break this vicious cycle.

Automotive designers will face a unique issue when it comes to heavy-duty transport because there are a lot of trade-offs when adopting Li-ion cells. The maximum permitted weights on each axle are currently capped at a lower level, which forces designers to decrease battery capacity, which reduces range.

It also reduces the amount of load a vehicle can transport on a given trip when the payload capacity is restricted, which is not exactly good logistical economics. Ultimately, automakers will always have to make a trade-off between efficiency and performance.

It is not exactly ideal logistical economics, as it also lowers the amount of load a truck can transport on a given journey when the payload capacity is limited. In the end, automakers will always have to choose between performance and efficiency.

FCEVs or BEVs

One of the reasons FCEVs presently outperform BEVs is downtime. An internal combustion engine vehicle (ICEV) requires approximately twice as much time to refill as a fuel cell electric vehicle (FCEV), which makes it a desirable option for lengthy road trips.

Creating megawatt-scale charging stations would be the answer to this problem for BEVs. Because drivers can stop as often as necessary for charging, shortening the charging period also enables designers to minimize the size (and weight) of the battery.

The ability to use renewable energy solutions more widely and hasten the adoption of sustainable power sources is another significant benefit of FCEVs. Additionally, they fill in the performance and operational deficiencies in the current batteries. When it comes to driving a style that primarily involves long-distance travel, like commercial vehicles, FCEVs can generally outperform BEVs.

Moreover, fuel cell electric vehicle (FCEV) payload capacity surpasses that of a battery electric vehicle (BEV) due to the fuel cell powertrain’s substantial weight reduction, which permits engineers to enhance the energy capacity without appreciably changing the vehicle’s overall weight. The capacity of a lithium-ion battery to satisfy the powertrain’s dynamic needs is by far its greatest advantage over a fuel cell.

Fuel cells are designed for non-dynamic/static behavior, while numerous combinations for dynamic behavior may be produced at this time. It is hoped that shortly, solid-state cell solutions for mobility will be developed by researchers in the lithium-ion battery business.

So, which is superior in every situation?

The argument over whether BEVs are preferable to FCEVs or vice versa should be seen from a different angle since it comes down to whatever technology is best suited for a certain set of transportation requirements. A greater portion of the industry can be served by BEVs, but sustainable FCEV solutions can address their drawbacks.

FCEVs with lighter powertrains can have greater range since they can hold more energy without adding to their total weight. Fuel cells are an appealing option for heavy-duty and long-distance applications because of their increased payload-bearing capability and faster charging (or refilling) times.

The disadvantage of a fuel cell is that hydrogen requires a lot of energy to produce and store, and fuel cell technology is still in its infancy. This means that fuel cells are more expensive than lithium-ion batteries. Lithium-ion batteries also have far superior dynamic behavior than fuel cells. By no means are BEVs and FCEVs two sides of the same coin. Rather, it is necessary to consider them as two distinct avenues that might be pursued to address the same issue—that is, the difficulties associated with sustainable mobility.

Initiatives for BEV and FCEV at Dorleco

At Dorleco, we create software based on models for battery chemicals and fuel cells. Development-wise, we are focusing on cell balancing algorithms and Kalman filter-based SOC estimate techniques, along with thermal modeling and control of these energy sources.

The focus is on the BMS controller and fuel cell controller integration on a CAN architecture, as well as battery validation and verification using charging and discharging experiments. Using Raptured tools, we can assist you with rapid control prototyping for battery systems as well.

Write to [email protected] to find out more about our software development skills for requirements unique to batteries and explore our best VCU products and services.

0 notes

Text

What does it Cost to Run Your Trucking Company

I love trucking, but let's be honest: I am in this business to make money.

The only thing I like better than making money is keeping it. There are two factors that are in my control and that could destroy my business as an owner-operator: my health, and my ability to cover my expenses. (I am very health-conscious — but I'll save that story for another time.)

This blog post is about the real costs of running a trucking business as an owner-operator, based on my personal experience over seven years. Your costs won't be the same as mine, but it's important to keep track of every dollar you spend. I'm not in the business of giving financial advice, so if you want to apply some of these ideas to your own business, please talk to an accountant or another trusted advisor.

There are two kinds of costs that you need to control in trucking: fixed costs and variable costs.

Fixed Costs Are Predictable. Some Can Be Pre-Paid.Fixed costs are periodic expenses that remain more or less unchanged from month to month. The upside about fixed cost is that you can predict this number as much as a year in advance. Fixed cost is sometimes called "overhead," and I don't like it hanging over my head. So my goal is to pay off as much of that fixed cost as I can, as early as I can, at the beginning of the year. The downside of fixed cost is that you have to pay this expense whether you work or not.

Examples of fixed costs include lease payments and insurance payments on your equipment, annual license and registration fees, software, computers, cell phones, internet service, truck parking near my home, and whatever else you need to run your business. I track every expense, no matter how small. If you maintain an office, or you have employees who are on salary, employee compensation, rent, and utilities would also be counted as fixed costs.

Variable Costs Change With Activity Level, but You Can Economize.A variable cost is a cost that changes in relation to the level of activity in your business. If I don't drive my truck, almost all my variable costs disappears. Variable costs include fuel, maintenance, washouts, scale fees, and parking on the road. This is the easiest place to cut cost. For example, you can drive 55 MPH, reduce out-of-route miles, use an APU at night, or install aerodynamic gear on your trailer to help save fuel, which is one of your biggest variable costs.

Source:- DAT.

AVAAL partners with DAT to offer a special on the TruckersEdge Load Board to its members. Sign up for TruckersEdge today and get your first 30 days free by signing up at https://bit.ly/2IbuHhk. This offer is available to new TruckersEdge subscribers only.

#truckingindustry#truckinglife#avaal#trucking factoring#trucking company#ontario#canada#truck load#trucking#logistics

0 notes

Text

The Evolution of Industrial Scales: From Analog to Digital Precision

In the realm of industrial operations, precision and accuracy are paramount. From manufacturing to logistics, the measurement of weight plays a crucial role in ensuring efficiency and quality control. At the heart of this process lie industrial scales, an indispensable tool that has undergone a remarkable evolution over the years.

Understanding Industrial Scales

Industrial scales are specialized instruments designed to measure and weigh heavy loads accurately. They come in various forms, including bench scales, floor scales, truck scales, and crane scales, each tailored to specific industrial applications. These scales are utilized across diverse sectors, from agriculture and manufacturing to transportation and logistics.

The Analog Era: A Foundation of Reliability

Historically, industrial scales were predominantly analog devices, relying on mechanical components such as springs and levers to measure weight. While these scales provided a foundation of reliability, they were not without limitations. Analog scales were susceptible to wear and tear, calibration issues, and lacked the precision demanded by modern industries.

The Digital Revolution: Enhanced Precision and Efficiency

The advent of digital technology revolutionized the landscape of industrial weighing. Digital industrial scales leverage advanced electronic components, including load cells and microprocessors, to deliver unparalleled accuracy and efficiency. These scales offer features such as digital readouts, tare functions, and connectivity options for data logging and integration with enterprise systems.

Key Advantages of Digital Industrial Scales

Precision: Digital scales offer precise measurements, minimizing errors and ensuring consistency in weight readings.

Versatility: With programmable settings and customizable features, digital scales can adapt to a wide range of industrial applications.

Efficiency: Digital scales streamline weighing processes, enabling faster throughput and enhanced productivity in industrial environments.

Data Management: Integration with software systems allows for seamless data collection, analysis, and reporting, facilitating better decision-making and compliance with industry standards.

The Role of SEO in Promoting Industrial Scales

In today's digital age, the visibility of industrial scale manufacturers and suppliers relies heavily on effective search engine optimization (SEO) strategies. By strategically incorporating relevant keywords such as "industrial scales" into website content, blog posts, and product descriptions, businesses can enhance their online presence and attract organic traffic from potential customers.

Conclusion

Industrial scales represent a critical component of modern industrial processes, facilitating accurate measurement and weight management across diverse sectors. The transition from analog to digital technology has significantly improved the precision, efficiency, and versatility of these essential tools. By embracing digital innovation and leveraging SEO strategies, industrial scale manufacturers and suppliers can effectively reach their target audience and showcase the value of their products in today's competitive marketplace.

FAQ'S

1. What are industrial scales used for?

Industrial scales are used to measure the weight of heavy objects or materials in various industrial settings. They are essential for tasks such as inventory management, quality control, shipping and receiving, and production processes.

2. What types of industrial scales are available?

There are several types of industrial scales available, including:

Bench scales

Floor scales

Truck scales

Crane scales

Platform scales

Counting scales

Pallet scales

Each type is designed for specific applications, with varying weight capacities and features.

3. How accurate are industrial scales?

The accuracy of industrial scales depends on factors such as the type of scale, calibration, and the quality of the components. Digital industrial scales tend to offer higher accuracy compared to their analog counterparts, with some models capable of providing precise measurements down to fractions of a pound or kilogram.

4. How often should industrial scales be calibrated?

Industrial scales should be calibrated regularly to ensure accurate measurements. The frequency of calibration depends on factors such as the usage environment, the level of accuracy required, and any regulatory requirements. Many industries follow calibration schedules recommended by manufacturers or regulatory agencies.

5. Can industrial scales be connected to other systems or devices?

Yes, many modern industrial scales come equipped with connectivity options such as Wi-Fi, Ethernet, or USB ports, allowing them to be connected to computers, printers, barcode scanners, or enterprise systems. This connectivity facilitates data logging, integration with inventory management software, and real-time monitoring of weighing processes.

6. How do I choose the right industrial scale for my application?

Choosing the right industrial scale involves considering factors such as:

Weight capacity: Ensure the scale can accommodate the heaviest objects you need to weigh.

Environment: Consider factors such as temperature, humidity, and exposure to dust or chemicals.

Accuracy requirements: Determine the level of precision needed for your weighing tasks.

Features: Evaluate additional features such as digital readouts, tare functions, and connectivity options based on your specific needs.

7. Are industrial scales subject to any regulations or standards?

Yes, depending on the industry and the intended use of the scales, there may be regulations or standards that govern their design, calibration, and usage. Industries such as manufacturing, pharmaceuticals, and food processing often have specific requirements for weighing equipment to ensure product quality, safety, and compliance.

8. How do I maintain industrial scales for optimal performance?

Regular maintenance is essential to ensure the optimal performance and longevity of industrial scales. This may include:

Cleaning the scale surface and components regularly to prevent buildup of debris or contaminants.

Checking and calibrating the scale according to the manufacturer's recommendations or regulatory requirements.

Inspecting for signs of wear, damage, or malfunction and addressing any issues promptly.

Following proper handling and usage guidelines to prevent damage to sensitive components.

0 notes

Text

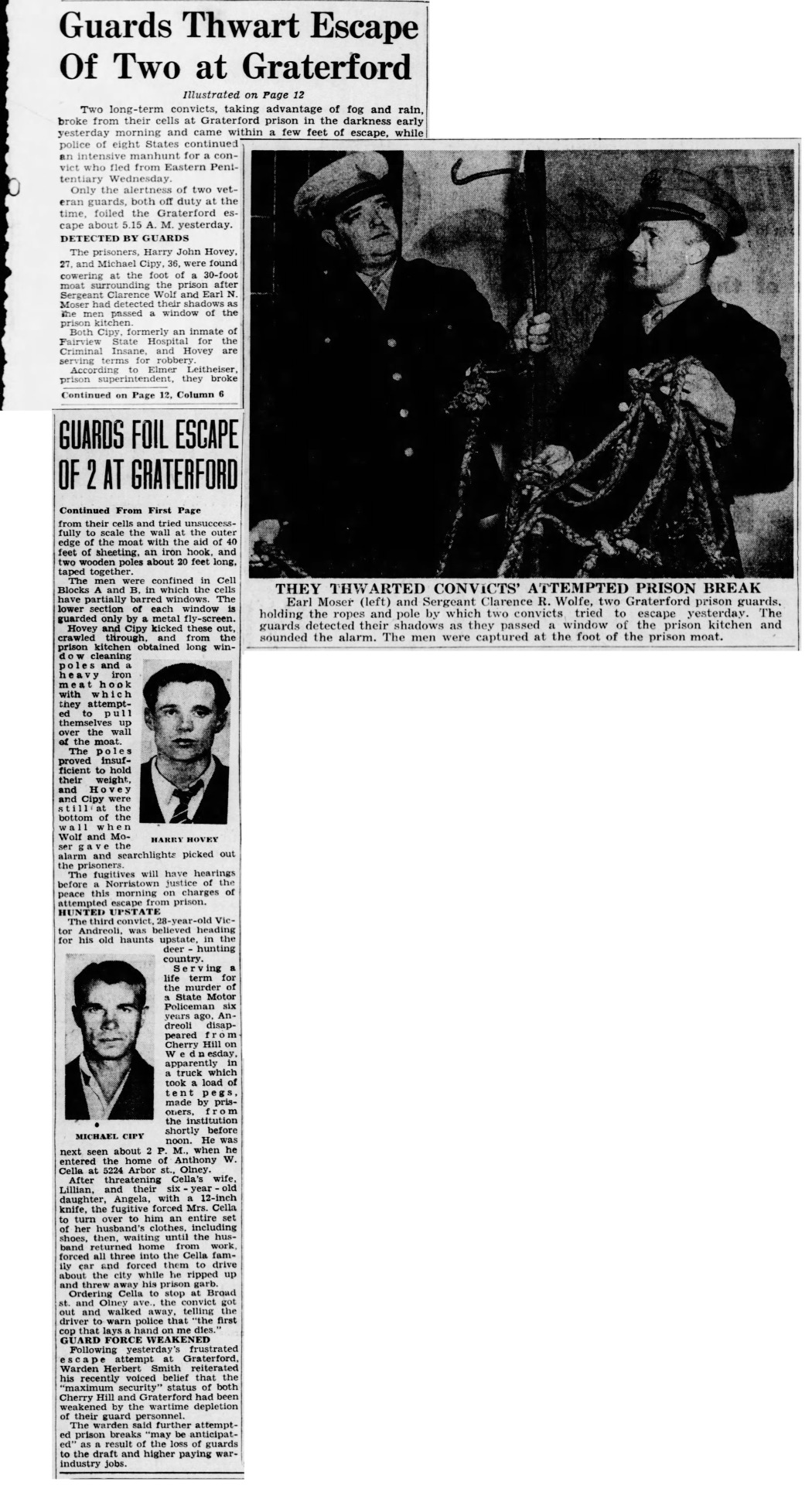

"Guards Thwart Escape Of Two at Graterford," Philadelphia Inquirer. October 29, 1943. Page 1 & 12.

----

Two long-term convicts, taking advantage of fog and rain, broke from their cells at Graterford prison in the darkness early yesterday morning and came within a few feet of escape, while police of eight States continued an intensive manhunt for a convict who fled from Eastern Penitentiary Wednesday.

Only the alertness of two veteran guards, both off duty at the time, foiled the Graterford escape about 5.15 A. M. yesterday.

DETECTED BY GUARDS

The prisoners, Harry John Hovey, 27, and Michael Cipy, 36, were found cowering at the foot of a 30-foot moat surrounding the prison after Sergeant Clarence Wolf and Earl N. Moser had detected their shadows as the men passed a window of the prison kitchen.

Both Cipy, formerly an inmate of Fairview State Hospital for the Criminal Insane, and Hovey are serving terms for robbery.

According to Elmer Leitheiser, prison superintendent, they broke from their cells and tried unsuccessfully to scale the wall at the outer edge of the moat with the aid of 40 feet of sheeting, an iron hook, and two wooden poles about 20 feet long, taped together.

The men were confined in Cell Blocks A and B, in which the cells have partially barred windows. The lower section of each window is guarded only by a metal fly-screen.

Hovey and Cipy kicked these out, crawled through, and from the prison kitchen obtained long window cleaning poles and a heavy iron meat hook with which they attempted to pull themselves up over the wall of the moat.

The poles proved insufficient to hold their weight, and Hovey and Cipy were still at the bottom of the wall when Wolf and Moser gave the alarm and searchlights picked out the prisoners.

The fugitives will have hearings before a Norristown justice of the peace this morning on charges of attempted escape from prison.

HUNTED UPSTATE

The third convict, 28-year-old Victor Andreoli, was believed heading for his old haunts upstate, in the deer hunting country.

Serving a life term for the murder of a State Motor Policeman six years ago. Andreoli disappeared from Cherry Hill on Wednesday, apparently in a truck which took a load of tent pegs, made by prisoners, from the institution next seen entered the shortly before noon. He was about 2 P. M., when he home of Anthony W. Cella at 5224 Arbor st., Olney.

After threatening Cella's wife, Lillian, and their six-year-old daughter, Angela, with a 12-inch knife, the fugitive forced Mrs. Cella to turn over to him an entire set of her husband's clothes, including shoes, then, waiting until the husband returned home from work, forced all three into the Cella family car and forced them to drive about the city while he ripped up and threw away his prison garb.

Ordering Cella to stop at Broad st. and Olney ave., the convict got out and walked away, telling the driver to warn police that "the first cop that lays a hand on me dies."

GUARD FORCE WEAKENED

Following yesterday's frustrated escape attempt at Graterford, Warden Herbert Smith reiterated his recently voiced belief that the "maximum security" status of both Cherry Hill and Graterford had been weakened by the wartime depletion of their guard personnel.

The warden said further attempted prison breaks "may be anticipated" as a result of the loss of guards to the draft and higher paying war-industry jobs.

Picture caption:

THEY THWARTED CONVICTS' ATTEMPTED PRISON BREAK

Earl Moser (left) and Sergeant Clarence R. Wolfe, two Graterford prison guards. holding the ropes and pole by which two convicts tried to escape yesterday. The guards detected their shadows as they passed a window of the prison kitchen and sounded the alarm. The men were captured at the foot of the prison moat.

#graterford pennsylvania#eastern correctional institution#graterford penitentiary#prison break#attempted escape#escape from prison#prison guards#desperate convicts#maximum security institution#history of crime and punishment#pennsylvania prisons#american prison system#world war ii

0 notes

Text

Driving Efficiency: The Critical Role of Truck Scales in Logistics and Beyond

Introduction:

In the intricate dance of goods transportation that defines the modern logistics landscape, accuracy and efficiency reign supreme. At the heart of this precision-driven process lies a seemingly humble yet indispensable tool—the truck scale. These heavy-duty weighing systems play a pivotal role in ensuring the smooth flow of goods, compliance with regulations, and the optimization of resources. In this article, we explore the multifaceted significance of truck scales in logistics and their broader impact on various industries.

The Evolution of Truck Scales:

Truck scales, also known as weighbridges, have come a long way from their manual, mechanical origins. Early iterations relied on mechanical levers and analog systems, while today's truck scales incorporate cutting-edge technologies such as load cells, digital readouts, and sophisticated software integration. This evolution reflects the industry's commitment to accuracy, efficiency, and the ever-growing demands of global supply chains.

Key Components of Modern Truck Scales:

Load Cells and Sensors: Load cells are the unsung heroes of truck scales. Strategically positioned beneath the scale platform, these sensors are responsible for converting the physical weight applied to them into electrical signals. Advanced load cell technology ensures accurate and reliable measurements, even in challenging conditions.

Scale Platforms: The scale platform itself has undergone significant advancements. Constructed from durable materials such as steel or concrete, modern platforms can withstand heavy loads and harsh environmental conditions. Some designs include pit-type installations for a flush surface, while others use above-ground configurations for ease of installation and maintenance.

Weighing Terminals and Software Integration: The user interface of truck scales has evolved into sophisticated weighing terminals. Operators can input data, initiate weighing processes, and access real-time weight readings. Moreover, these terminals often integrate with software systems, allowing for seamless data management, analysis, and integration with broader logistics or enterprise resource planning (ERP) systems.

Applications and Significance in Logistics:

Regulatory Compliance: One of the primary roles of truck scales is to ensure compliance with weight regulations. Overloaded vehicles not only jeopardize road safety but also contribute to infrastructure wear and tear. Truck scales help prevent violations by accurately measuring and monitoring the weight of vehicles, promoting safer roadways.

Optimized Load Planning: Truck scales play a pivotal role in optimizing load planning. By accurately measuring the weight of shipments, logistics operators can maximize load capacities while adhering to legal weight limits. This results in more efficient use of transportation resources and reduced operational costs.

Inventory and Supply Chain Management: In industries dealing with bulk goods, truck scales facilitate precise inventory and supply chain management. Accurate weight measurements contribute to inventory accuracy, aid in demand forecasting, and streamline the overall supply chain process.

Enhanced Financial Transparency: The accuracy provided by truck scales has a direct impact on financial transactions within the logistics sector. From calculating shipping costs to invoicing clients, transparent and precise weight measurements foster fair and reliable financial dealings.

Conclusion:

As the backbone of logistics and transportation, truck scales quietly contribute to the efficiency, safety, and sustainability of supply chains worldwide. The integration of advanced technologies and the commitment to precision weigh heavily on the success of modern logistics operations. Beyond their role in compliance and load optimization, truck scales serve as silent guardians, ensuring that the wheels of industry keep turning smoothly in an increasingly interconnected and fast-paced global economy.

Source Url : - https://sites.google.com/view/loadensecales/home

0 notes

Text

With our superior assortment of truck scales for sale, discover unmatched durability and precision. With cutting-edge load cell technology and dynamic weighing, our truck scales offer unparalleled performance. Boost your company's performance with the certainty of precise weight readings.

0 notes

Text

In-Depth Look: How Public Weighbridges Impact Various Industries

Public weighbridges play a vital role in various industries by ensuring accurate weight measurements and facilitating fair trade practices. In this blog post, we will take an in-depth look at how public weighbridges impact different sectors, including scrap metal recycling, construction, agriculture, and waste management.

By understanding the definition, purpose, and importance of public weighbridge, we can appreciate their positive impact and encourage their utilisation for industry-specific needs.

Definition and Purpose of Public Weighbridges:

Public weighbridges, also known as truck scales or weigh stations, are specialised facilities that are designed to measure the weight of vehicles or goods accurately. They consist of a large weighing platform, often made of concrete or steel, and an integrated weighing system that provides precise weight measurements. The primary purpose of public weighbridges is to ensure fair trade practices by preventing fraud and ensuring accurate weight measurements for commercial transactions.

Public weighbridges function through sensors, load cells, and sophisticated software that captures and calculates the weight of a vehicle or goods placed on the platform. These facilities have high-precision weighing equipment that can handle heavy loads and provide accurate measurements within a specified tolerance. Using public weighbridge Melbourne, businesses can ensure transparency and fairness in their transactions, promoting trust and credibility within their respective industries.

Importance of Public Weighbridges in Scrap Metal Recycling:

The scrap metal recycling industry heavily relies on public weighbridges to ensure accurate measurements and fair transactions. When buying or selling scrap metal, it is crucial to determine the weight accurately to determine its value. Public weighbridges allow both buyers and sellers to have confidence in the weight recorded, preventing disputes and promoting fair pricing.

Using public weighbridge facilities, scrap metal recycling Melbourne companies can improve their operational efficiency and streamline their processes. Knowing the precise weight of the scrap metal enables them to calculate transportation costs accurately, ensuring profitability. Moreover, it helps in reducing waste and optimising recycling processes, leading to a more sustainable approach.

Impact of Public Weighbridges on Various Industries:

A. Construction Industry:

Public weighbridge services play a crucial role in the construction industry by ensuring proper weight distribution for transportation purposes. Construction projects often involve moving heavy equipment, materials, and machinery. Accurate weight measurements are essential to determine the load capacity of vehicles and ensure safe transportation. Public weighbridges provide construction companies with the tools to comply with weight restrictions and regulations, preventing accidents and ensuring site safety.

B. Agriculture Industry:

In the agriculture industry, public weighbridges are instrumental in transporting harvested crops or livestock. Accurate weight measurements allow farmers to determine the yield accurately, manage inventory effectively, and facilitate fair trading. Public weighbridge services enable farmers to calculate the weight of their produce before selling, ensuring transparency and preventing any potential disputes. This promotes proper pricing and enhances trust between farmers and buyers.

C. Waste Management Industry:

Public weighbridges play a crucial role in the waste management industry by accurately measuring waste disposal from residential or commercial areas. Waste management companies rely on public weighbridge facilities to determine appropriate fees for waste disposal services. Accurate measurements also aid in managing landfill resources effectively, ensuring that waste is correctly allocated and promoting environmentally friendly practices. Using public weighbridges, waste management companies can track and monitor waste volumes, enabling them to make informed decisions about waste processing and disposal methods.

Benefits of Utilizing Public Weighbridge Services:

There are several benefits that various industries can gain from utilising public weighbridge services. Firstly, these facilities increase operational efficiency by providing accurate weight measurements quickly and reliably. This saves time and resources for businesses, allowing them to focus on other crucial aspects of their operations.

Secondly, public weighbridge services enhance accuracy in weight measurements, reducing the risk of errors and discrepancies. This accuracy ensures fair trade practices and prevents disputes between buyers and sellers, promoting trust and credibility within the industry.

Furthermore, public weighbridge facilities often offer additional perks such as automated processes and digital records. These features make it more convenient for businesses to manage their weight measurements, track their transactions, and generate reports for analysis and auditing purposes.

Conclusion:

Public weighbridges have a significant impact on various industries, including scrap metal recycling, construction, agriculture, and waste management. By ensuring accurate weight measurements and promoting fair trade practices, public weighbridges contribute to the efficiency, safety, and sustainability of these industries.

Understanding the definition, purpose, and importance of public weighbridges allows us to appreciate their positive impact and encourages their utilisation for industry-specific needs. We encourage readers to explore public weighbridge Melbourne services for their respective industries, benefiting from the increased efficiency, improved accuracy, and enhanced customer trust that these facilities provide.

#Scrap Metal Melbourne#Scrap Metals Melbourne#Scrap Metal#Public Weighbridge Melbourne#Scrap Metal Recycling Melbourne

1 note

·

View note

Text

What are the Importance and Applications of Weighbridge?

Importance and Applications of Weighbridge:

The significance of weighbridges extends across various industries:

Logistics and Transportation: Weighbridges ensure compliance with weight regulations, preventing overloading which can damage roads and endanger safety. They also facilitate accurate billing based on weight.

Mining and Construction: In these sectors, precise measurement of materials such as ores, gravel, and construction materials is crucial for inventory management and cost control.

Agriculture: Weighbridges help farmers and producers accurately measure crop yields, livestock weights, and other agricultural products, aiding in inventory management and fair trading practices.

Waste Management: Weighbridges are used to measure waste collection vehicles, ensuring efficient disposal and appropriate billing based on weight.

Industrial Manufacturing: They play a role in quality control, ensuring that raw materials and finished products meet weight specifications.

What is a Weighbridge?

A weighbridge, also known as a truck scale or a weigh station, is a large, robust platform designed to weigh entire vehicles and their contents. These structures come in various sizes and capacities, accommodating everything from light trucks to heavy-duty haulers transporting massive loads. Weighbridges are typically installed at fixed locations such as factories, ports, mines, and warehouses, where accurate weight measurement is critical for logistical and legal compliance reasons.

Types of Weighbridges:-

Weighbridges are classified based on their structure and method of operation:

Surface-Mounted Weighbridges: These are installed flush with the ground, making them suitable for locations with limited space or where ramps are not practical.

Pit-Mounted Weighbridges: These are installed in a pit, with the weighing platform level with the surrounding ground. They often require ramps for vehicles to access the platform.

Portable Weighbridges: These are modular systems that can be moved and set up quickly at different locations, providing flexibility for temporary or remote operations.

Axle Weighbridges: Designed specifically to weigh individual axles and wheels of vehicles, providing detailed weight distribution data.

Technological Advancements:-

Modern weighbridges are equipped with advanced technology to enhance accuracy and efficiency:

Load Cells: These sensors detect the weight applied to the platform and convert it into an electronic signal, ensuring precise measurement.

Digital Indicators: Display units that provide weight readings and may include additional features such as data logging and connectivity options.

Software Integration: Weighbridges can be integrated with software systems for automated data management, invoicing, and reporting.

Remote Monitoring: Some systems allow for remote access and monitoring, enabling real-time data collection and analysis.

Challenges and Considerations

Despite their reliability, weighbridges require regular maintenance and calibration to ensure accurate readings. Environmental factors such as temperature fluctuations and moisture levels can affect performance, necessitating proper care and upkeep.

Conclusion

In conclusion, weighbridges are indispensable tools in today’s industrial landscape, facilitating efficient operations, ensuring compliance with regulatory standards, and contributing to overall safety and accuracy in weight measurement. As technology continues to evolve, so too will the capabilities of weighbridge systems, further enhancing their role in modern logistics and beyond. Whether at a bustling port or a remote mining site, the weighbridge stands as a testament to the importance of precision in measurement — a cornerstone of effective industrial practice.

Top Weighbridge manufacturer in India

ESSAR WEIGH offers a comprehensive range of export-quality electronic weighbridge solutions tailored to meet the diverse needs of industries worldwide. We are a leading Weighbridge Manufacturer in India.

For more details, please contact us!

Website :- https://www.essaarweigh.com/

Contact No. :- 09310648864, 09810648864, 09313051477

Email :- [email protected]

#weighbridge#electronic weighbridge#weighbridge manufacturer in India#Top weighbridge manufacturer in India#Best weighbridge Manufacturer in India#weighbridge Supplier in India#weighbridge manufacturer in Delhi#weighbridge manufacturer in Ghaziabad#weighbridge manufacturer in Faridabad#Essaarweigh

1 note

·

View note

Text

Reliable Double-Ended Shear Beam Load Cells - Sensomatic Loadcell

Looking for precision and durability in industrial weighing? You've come to the right place! Our Reliable Double Ended Shear Beam Load Cells, branded as Sensomatic Loadcells, are engineered to deliver unparalleled accuracy and resilience in various applications.

🔹 Key Features:

✅ Robust design for challenging environments

✅ Exceptional accuracy, minimizing off-center loading effects

✅ Versatile applications across industries

✅ Easy installation and seamless integration

✅ Compliance with industry standards

Applications:

From truck scales to platform scales and industrial weighing systems, our load cells find utility across diverse industries, ensuring reliable and precise measurements.

Why Choose Us?

🤝 Experience improved efficiency and cost-effectiveness with our load cells.

🛡️ Trust in compliance and certification for peace of mind.

🤝 Partner with us for enhanced customer satisfaction through accurate weighing data. For all your industrial weighing needs,

Choose Reliable Double-Ended Shear Beam Load Cells Reach out today to learn more and optimize your operations!

#Doubleendedshearbeamloadcell#shearbeamloadcell#loadcell#sensomaticloadcell#ReliableDoubleEndedShearBeamLoadCells#shearpinloadcell#Compressionloadcell#Stypeloadcell#Singleendedshearbeamloadcell#WeighbridgeLoadcell#DigitalLoadcell#Balltypeloadcell#Doubleendedballtypeloadcell

0 notes

Text

Leading Weighbridge Load Cell Manufacturer - Thames Side

The load cells for weighbridges, often referred to as load cells for truck scales, are designed for use with both rail scales and truck scales. The alloy tool steel and stainless steel used in the Thames Side line are suitable for use in muddy and damp environments and exceed environmental requirements up to IP68.

0 notes