#variablefrequencydrives

Explore tagged Tumblr posts

Text

⚓ Marine Power Control Made Smarter with Variable Frequency Drives ⚓

From bow thrusters and winches to onboard pumps, cranes, and ventilation systems, modern variable frequency drives (VFDs) provide precise control over motor speed, torque, and load in demanding marine environments. These systems are engineered to deliver up to 200% torque from zero speed, with rugged designs capable of operating in ambient temperatures up to 122°F (50°C), making them ideal for ship engine rooms, docks, and offshore platforms. With dynamic motor control, noise reduction, and enhanced efficiency, VFDs help vessels and ports reduce fuel use, extend equipment life, and lower CO₂ emissions.

Features like conformal-coated electronics, low harmonic performance, built-in EMC/RFI filters, and compatibility with IT shipboard power grids ensure seamless integration and long-term reliability. Whether managing mooring winches, anchor systems, HVAC fans, or ballast pumps, VFDs support both variable and constant torque applications, enabling fine-tuned operation across a wide speed range. As marine operations evolve toward energy efficiency and reliability, VFDs are essential for optimizing vessel performance while cutting operational costs.

The VFD Exchange

#vfdcontrol#variablefrequencydrives#vfds#marineefficiency#portapplications#bowthruster#marinepumps#maritime#automation#controls#winches#ventilation#anchorsystems

0 notes

Text

#VFDMarket#VariableFrequencyDrives#VFDSystems#VFDTechnology#IndustrialAutomation#DriveSolutions#ElectricDrives#MotorControl#USIndustrialMarket#VFDNA#VFDTechnologyEU#IndustrialAutomationEU#VFDAPAC#ManufacturingGrowthAPAC#MEAIndustries#EnergyEfficiencyMEA#LATAMIndustry#VFDMarketLATAM

0 notes

Text

https://www.industryarc.com/Report/19869/us-industrial-vfd-market.html?utm_source=tumbler&utm_medium=social&utm_campaign=Raghavarao

0 notes

Text

IEC Standards for Variable Frequency Drives (VFDs)

Variable Frequency Drives (VFDs) are essential for modern industrial automation and energy efficiency. They control motor speed and torque by varying the input frequency and voltage. But to ensure their safe, efficient, and compatible operation, global standards are needed. This is where IEC standards play a vital role.

IEC Standards for Variable Frequency Drives (VFDs) The International Electrotechnical Commission (IEC) sets the global benchmarks for electrical, electronic, and related technologies. When it comes to Variable Frequency Drives (VFDs), IEC standards define design, performance, safety, EMC, and testing protocols. In this article, we’ll dive deep into the IEC standards for Variable Frequency Drives (VFDs), how they influence VFD design and use, and why adhering to them is crucial for safe and efficient systems. Know more about Components of VFD

Importance of IEC Standards for Variable Frequency Drives (VFDs)

IEC standards bring uniformity and trust. Manufacturers follow them to design safe, efficient, and globally accepted VFDs. Buyers and users benefit from consistent performance and safety. Here are key benefits of using IEC-compliant VFDs: - Assured safety for users and equipment - High energy efficiency and reliability - Smooth integration with automation systems - Compliance with local and international regulations

Key IEC Standards for Variable Frequency Drives (VFDs)

Many IEC standards are directly or indirectly associated with VFDs. Some define general electrical safety, while others focus on drive-specific aspects. Let’s explore the major ones. IEC 61800 Series – The Core for Variable Frequency Drives (VFDs) The IEC 61800 series is the primary standard for adjustable speed electrical power drive systems (PDS), including Variable Frequency Drives (VFDs). PartTitleFocusIEC 61800-1General requirementsTerminology, ratings, and basic frameworkIEC 61800-2General performance requirementsPerformance expectations under standard conditionsIEC 61800-3EMC requirementsElectromagnetic compatibility, emissions and immunityIEC 61800-4System architecture and interfacesInterfacing of components, power and controlIEC 61800-5-1Safety requirementsElectrical safety, insulation, thermal limitsIEC 61800-5-2Functional safetySafety related to motion control and failuresIEC 61800-7Generic interface and profileStandardized drive profiles for communicationIEC 61800-9Energy efficiencyEco-design and loss calculation methods Each part focuses on a different aspect of Variable Frequency Drives (VFDs), ensuring a complete and robust regulatory framework. Know more about Benefits of VFD in HVAC Systems#IECStandards, #VariableFrequencyDrive, #VFDStandards, #IECVFD, #IndustrialAutomation, #MotorDrives, #ElectricalEngineering, #VFDCompliance, #PowerElectronics, #EnergyEfficiency, #DriveSystems, #VFDInstallation, #SmartDrives, #IndustrialStandards, #ElectricalSafety Read the full article

#DriveSystems#ElectricalDrives#ElectricalStandards#energyefficiency#IECStandards#IndustrialAutomation#MotorControl#powerelectronics#VariableFrequencyDrive#VFD

0 notes

Text

Boost Your Industrial Efficiency with Siemens Sinamics G130 MV VFD

Boost Your Industrial Efficiency with Siemens Sinamics G130 MV VFD

Post: Looking for a reliable way to improve your industrial compressor or fan performance? The Siemens Sinamics G130 Medium Voltage Variable Frequency Drive (MV VFD) is designed for heavy-duty applications like Atlas Copco compressors and bypass fans — powering up to 2800 kW!

Why choose Sinamics G130?

Energy savings with precise motor speed control

Reduced maintenance thanks to smooth startups and stops

Enhanced process control for better system reliability

Installed on Atlas Copco compressors, these MV drives help plants save energy and extend equipment life.

Want to learn more? Check out our MV VFD solutions

0 notes

Text

Variable Frequency Drive

Variable frequency drives enable vacuum pumps to operate at a speed tailored to your application, delivering quick results. Explore the visuals to discover the ultimate control with the finest frequency drives.

0 notes

Video

youtube

Variable Frequency Drives Explained - Darwin Motion VFD Basics

Variable Frequency Drives Explained - Darwin Motion VFD Basics

A variable frequency drive (VFD) is a type of motor controller that changes the frequency and voltage of an electric motor's power source. The VFD may also control the ramp-up and ramp-down of the motor during startup and shutdown.

Check out our drives:

Micro Drive- Matrix 900 DR Matrix 350 / Solar Drive DR Matrix 500 DR Matrix 680 DR Matrix 880

VFD Servo Drive High Frequency Drives Profinet Comunication Drives EtherCAT Communication Drives

Call/WhatsApp: +91 8956113099 , +61432112288 E-mail: [email protected]

#youtube#VFD ACDRIVE VARIABLEFREQUENCYDRIVE SERVODRIVE SOLARDRIVE SOLARVFD vsd inverter converter darwinmotion microdrive regenerativedrive highfrequ

0 notes

Text

🌟 Optimizing #FlowControl (Q) in Pumps: Efficiency Matters

Controlling flow rate (Q) is a key factor in optimizing pump efficiency and minimizing energy consumption.

🔷️While there are multiple methods to regulate flow, not all of them deliver the same level of efficiency. Below is a breakdown of the most common approaches, along with an expert evaluation of their effectiveness in real-world applications.

1️⃣ Throttling Valve Control: This method restricts flow by partially closing a valve, creating additional resistance in the system. While simple, it is highly inefficient as it dissipates energy as heat and increases system pressure. Energy losses can reach up to 30%, making this approach suboptimal for energy-conscious operations.

2️⃣ Variable Frequency Drive (#VFD) Control: This is the most energy-efficient solution, as it directly adjusts the pump speed to match demand. By precisely regulating motor RPM, VFDs can reduce energy consumption by up to 50% compared to throttling valves, according to industry studies.

3️⃣ Bypass Line Control: In this approach, excess flow is diverted through a bypass line instead of reaching the main system. However, the pump continues running at full capacity, leading to unnecessary energy consumption. Energy losses can exceed 40%, making this an inefficient choice in most cases.

4️⃣ Impeller Trimming: This method involves physically reducing the impeller diameter to limit flow, providing a more permanent solution. While effective in some scenarios, it lacks flexibility for systems with varying demand, as the impeller cannot be adjusted dynamically.

✅ What’s the Best Choice? Without a doubt, VFD technology stands out as the most efficient solution. At #AdvancedPumps, we integrate VFD-driven systems that dynamically adjust pump speed based on real-time demand. This approach not only optimizes energy use but also reduces mechanical wear, extending pump lifespan and lowering maintenance costs.

📌 Real-World Example: In central water supply systems for buildings, studies have shown that VFD implementation leads to 40-50% energy savings compared to traditional throttling control. Additionally, VFDs enhance system stability by maintaining consistent pressure and reducing operational costs.

Final Takeaway:

When selecting a flow control method, efficiency and sustainability should be top priorities. VFDs aren’t just an upgrade—they’re a strategic investment that drives long-term cost savings and enhances system reliability.

⭕ With the continuous evolution of smart pump technologies, the real question isn’t just how to regulate flow—but how to do it with maximum efficiency.

#EnergyEfficiency #pumps #Sustainability #Innovation #PumpingSystems #VariableFrequencyDrive #SustainableEngineering

#WaterManagement #WaterSolutions

0 notes

Photo

Our Service Team gets units in to work on that has come from many different environments. All our VFDs are NEMA 3R compliant to protect from the weather and bugs. So the bugs, dirt and critters stay on the outside where they belong. The Phase Perfect Digital Phase Comverters have the option of NEMA 1 (Indoor) and NEMA 3R ) outdoor. #serviceteam #phasetechnologies #phaseperfect #nema3r #nema1 #nobugs #vfds #variablespeeddrives #variablefrequencydrives #instamachinist #practicalmachinist #phaseconverter #phaseconversion #phaseinverters #digitalphaseconverter #rapidcity #southdakota #southdakotabusiness #electricalengineering #oem #powerelectronics (at Phase Technologies LLC) https://www.instagram.com/p/B2z2IBtpDGN/?igshid=zgrqzu11oupt

#serviceteam#phasetechnologies#phaseperfect#nema3r#nema1#nobugs#vfds#variablespeeddrives#variablefrequencydrives#instamachinist#practicalmachinist#phaseconverter#phaseconversion#phaseinverters#digitalphaseconverter#rapidcity#southdakota#southdakotabusiness#electricalengineering#oem#powerelectronics

1 note

·

View note

Text

Boost Efficiency in HVAC & Fan Systems with Variable Frequency Drives

Across commercial and industrial facilities, variable frequency drives (VFDs) are key to optimizing HVAC and fan performance by offering precise speed, torque, and airflow regulation. Instead of running at full speed constantly, VFDs adjust motor output to match building demand in real-time, delivering significant energy savings and lower operating costs. Built-in features like sensorless vector control, PID feedback, and automatic sleep/wake functions allow HVAC systems to perform efficiently across all load conditions.

Modern VFDs support a wide range of motors, including induction, permanent magnet, and synchronous reluctance, and typically offer BACnet and Modbus RTU communication as standard, enabling seamless BMS integration. With low harmonic design, internal EMC filtering, and high switching frequencies for quiet operation, VFDs ensure optimal comfort and system reliability. We help facility managers and contractors unlock energy efficiency and operational excellence in their air handling and ventilation systems.

#variablefrequencydrives#vfd#acdrives#industrial#commerical#hvac#controls#automation#airhandling#fans#pumps#motorcontrols#bmsintegration

0 notes

Link

TSCA Electrical Supply Group Of Company Inc. https://tsca.com.ph/

Read more: https://tsca.com.ph/blog-post/variable-frequency-drives-vfd-theory-and-troubleshooting/

0 notes

Photo

UNICO variable frequency drives provide production optimization, equipment protection and energy efficiency. Our Drives are reliable and safe. Embedded controls eliminate the need for an external controller.

0 notes

Text

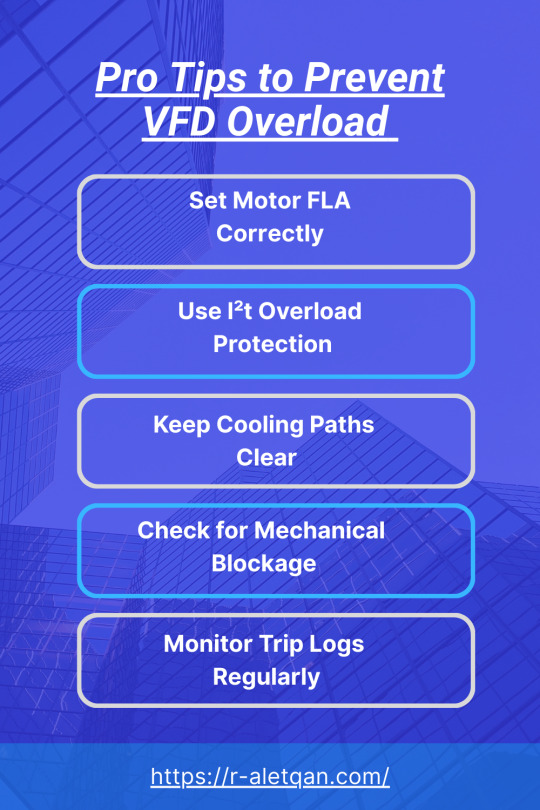

How to Prevent VFD Overload – Quick Pro Tips

Overload trips in VFDs can lead to unexpected shutdowns and equipment damage. Here’s how to prevent them:

Set Motor FLA Correctly – Ensure the drive is programmed with the correct Full Load Amps to avoid false overload trips.

Enable I²t Protection – This offers time-current based protection, reducing the risk of motor overheating.

Keep Cooling Paths Clear – Dust and blockage restrict airflow. Clean vents and fans regularly.

Check for Mechanical Blockage – Misalignment, stuck bearings, or process jams can overload the motor.

Review Trip Logs – VFD logs help you identify patterns and act before failure happens.

✅ Apply these tips to increase drive life and reduce downtime. VFD downtime costing you money? Discover how we help industries prevent failures: r-aletqan.com

VFD #VariableFrequencyDrive #MotorControl #IndustrialAutomation

ElectricalMaintenance #DriveSolutions #PreventiveMaintenance

IndustrialEquipment #ControlSystems #DriveProtection

0 notes

Text

Invertek hits 3.000.000 Milestone of Variable Frequency Drive (VFD)

Adrian Ellam, CEO of Invertek Drives Ltd, with Rhydian Welson, Sales and Marketing Director, and Glyn Jones, Technical Director (left to right) Invertek Drives Ltd arrives this landmark just three years after the two-million milestone. These VFDs are used in applications across a broad spectrum of industries worldwide. These include manufacturing to optimise production line efficiency in processes like pumps, fans, and conveyors; HVAC building services to regulate ventilation, air conditioning, and water pumps in commercial and industrial buildings; water and wastewater to improve efficiency in water treatment plants and pumping stations; renewable energy to control wind turbines and solar tracking systems; to HVAC-R for optimising performance of heating, ventilation, air conditioning, and refrigeration systems. Its Optidrive VFDs play a crucial role in reducing energy consumption of up to 50 per cent in some applications and associated emissions. By precisely controlling electric motors, they ensure they only use the power needed for the specific task, significantly reducing wasted energy. This technology is particularly impactful considering estimates suggest over 80 million electric motors operate globally without VFD control. Designed and manufactured at the company's headquarters near Welshpool, UK, the production of the three millionth VFD represents Invertek Drives' ongoing commitment to innovation and sustainability. “Tackling energy waste and emissions is a global priority," said Adrian Ellam, CEO of Invertek Drives Ltd. "Our VFDs provide a powerful and proven solution. Expanding their use will significantly impact environmental sustainability. We innovate relentlessly, ensuring our technology remains at the forefront of efficiency.” www.invertekdrives.com Read the full article

0 notes

Text

What is the Right Pump VFD for You?

If you're looking for a pump VFD, it's important to know what's the right one for you. There are a lot of different factors to consider, such as the type of pump, the motor, and the application. In CM Industry Supply Automation blog post, we'll help you figure out which VFD such as Lenze VFD or Lenze Drive, KEB Drive, Darwin Motion VFD is right for your pump.

What factors should you consider when purchasing a VFD?

When purchasing a VFD, there are several factors you should consider. The type of motor you are controlling, the voltage, and the horsepower are all important factors to consider. You should also consider the environment where the VFD will be used. If it will be used in a dirty or dusty environment, you will need to make sure the VFD is sealed properly.

#vfd#variablefrequencydrive#lenze#acdrive#inverter#keb#siemens#darwinmotion#lenzedrive#kebdrive#siemensdrive#vsd#variablespeedrive#abb#motor#motorcontrol#automation#industrialautomation#solarpump#pump

0 notes