#warehouseautomation

Explore tagged Tumblr posts

Text

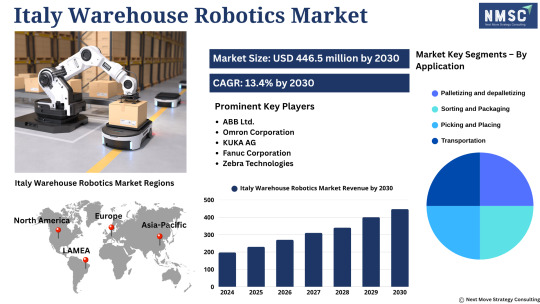

𝗜𝘀 𝗜𝘁𝗮𝗹𝘆 𝗕𝗲𝗰𝗼𝗺𝗶𝗻𝗴 𝗘𝘂𝗿𝗼𝗽𝗲’𝘀 𝗡𝗲𝘅𝘁 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗣𝗼𝘄𝗲𝗿𝗵𝗼𝘂𝘀𝗲?

The 𝗜𝘁𝗮𝗹𝘆 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 is picking up serious momentum — and investors are starting to take notice.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

Market size is projected to reach 𝗨𝗦𝗗 𝟰𝟰𝟲.𝟱 𝗺𝗶𝗹𝗹𝗶𝗼𝗻 by 2030, at a 𝗖𝗔𝗚𝗥 𝗼𝗳 𝟭𝟯.𝟰%.

𝗪𝗵𝘆 𝗶𝘀 𝘁𝗵𝗶𝘀 𝗮 𝗯𝗶𝗴 𝗱𝗲𝗮𝗹?

Italy's manufacturing and logistics sectors are undergoing a major digital shift.

With rising labor costs and the pressure for faster, more efficient order fulfillment, businesses are turning to robotics to stay competitive.

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀: ABB Ltd., Omron Corporation, KUKA AG, Fanuc Corporation, JBT Corporation, Teradyne Inc., Geekplus Technology Co., Ltd., GreyOrange, Zebra Technologies, Honeywell International Inc and others.

𝗙𝗿𝗼𝗺 𝗮𝘂𝘁𝗼𝗻𝗼𝗺𝗼𝘂𝘀 𝗺𝗼𝗯𝗶𝗹𝗲 𝗿𝗼𝗯𝗼𝘁𝘀 (𝗔𝗠𝗥𝘀) 𝘁𝗼 𝗿𝗼𝗯𝗼𝘁𝗶𝗰 𝗽𝗶𝗰𝗸𝗶𝗻𝗴 𝘀𝘆𝘀𝘁𝗲𝗺𝘀, 𝘁𝗵𝗲 𝗱𝗲𝗺𝗮𝗻𝗱 𝗶𝘀 𝘀𝘂𝗿𝗴𝗶𝗻𝗴 — 𝗲𝘀𝗽𝗲𝗰𝗶𝗮𝗹𝗹𝘆 𝗶𝗻 𝗲-𝗰𝗼𝗺𝗺𝗲𝗿𝗰𝗲, 𝗳𝗼𝗼𝗱 & 𝗯𝗲𝘃𝗲𝗿𝗮𝗴𝗲, 𝗮𝗻𝗱 𝗶𝗻𝗱𝘂𝘀𝘁𝗿𝗶𝗮𝗹 𝘀𝘂𝗽𝗽𝗹𝘆 𝗰𝗵𝗮𝗶𝗻𝘀.

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

𝗙𝗼𝗿 𝗶𝗻𝘃𝗲𝘀𝘁𝗼𝗿𝘀, 𝘁𝗵𝗶𝘀 𝗶𝘀𝗻’𝘁 𝗷𝘂𝘀𝘁 𝗮 𝘁𝗲𝗰𝗵 𝘁𝗿𝗲𝗻𝗱. 𝗜𝘁’𝘀 𝗮 𝘀𝘁𝗿𝗮𝘁𝗲𝗴𝗶𝗰 𝗲𝗻𝘁𝗿𝘆 𝗽𝗼𝗶𝗻𝘁 𝗶𝗻𝘁𝗼 𝘁𝗵𝗲 𝗱𝗶𝗴𝗶𝘁𝗮𝗹 𝘁𝗿𝗮𝗻𝘀𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻 𝗼𝗳 𝗼𝗻𝗲 𝗼𝗳 𝗘𝘂𝗿𝗼𝗽𝗲’𝘀 𝗺𝗼𝘀𝘁 𝘃𝗶𝘁𝗮𝗹 𝗹𝗼𝗴𝗶𝘀𝘁𝗶𝗰𝘀 𝗵𝘂𝗯𝘀.

#WarehouseRobotics#ItalyLogistics#Automation#SmartWarehousing#SupplyChainInnovation#RoboticsInvestment#LogisticsTech#InvestInInnovation#CAGR#WarehouseAutomation#ItalyMarketInsights

0 notes

Link

0 notes

Text

Automated Storage and Retrieval Systems Market Growth Driven by Labor Shortages and Warehouse Automation Demands

The global Automated Storage and Retrieval Systems market is witnessing a robust expansion, powered by the continuous evolution in supply chain and warehouse automation. ASRS are a key solution in optimizing storage density, improving inventory control, and enhancing picking accuracy in warehouses and manufacturing facilities. These systems, including unit load, mini load, carousel-based, and shuttle-based ASRS, are enabling companies to increase operational efficiency and reduce labor dependency. The market growth is being driven by a range of significant factors, which are accelerating their adoption across sectors such as e-commerce, food & beverage, pharmaceuticals, automotive, and retail.

Growing Demand for Warehouse Automation One of the primary drivers of the ASRS market is the escalating demand for warehouse automation. With the global boom in e-commerce and omnichannel retailing, businesses are pressured to manage complex and high-volume order fulfillment operations. ASRS offer an automated solution to these challenges by optimizing inventory management, increasing throughput rates, and reducing operational costs. Companies are increasingly deploying ASRS to stay competitive and meet the rising expectations for rapid and accurate order deliveries. Automation also provides real-time inventory visibility, an essential requirement in modern warehousing.

Labor Shortages and Rising Labor Costs Another critical market driver is the global labor shortage, particularly in logistics and warehousing roles. As finding and retaining skilled warehouse staff becomes more difficult, businesses are turning to automated systems to fill the gap. Moreover, rising labor costs in developed economies are prompting companies to adopt ASRS as a cost-saving measure. By reducing the reliance on manual labor, these systems not only ensure consistent productivity but also improve workplace safety and reduce human error. This trend is particularly strong in regions like North America and Europe, where wages are higher and labor availability is declining.

Increased Need for Space Optimization Space utilization is a vital consideration for modern warehouses, especially in high-cost urban areas. ASRS enable high-density storage and allow vertical use of space, thereby reducing the overall warehouse footprint. This is particularly beneficial for businesses operating in cities where real estate costs are a significant burden. Space optimization through automated systems helps maximize storage capacity without the need for warehouse expansion, contributing to significant cost savings in the long run.

Technological Advancements and Integration with Industry 4.0 Technological innovation is another strong driver behind the ASRS market growth. The integration of ASRS with advanced technologies such as IoT, AI, machine learning, and data analytics has enhanced their functionality and appeal. These technologies enable predictive maintenance, performance monitoring, and smart decision-making in real-time. The emergence of Industry 4.0 has encouraged the adoption of intelligent automation solutions, and ASRS are a cornerstone of this digital transformation in logistics. As technology becomes more accessible and affordable, more small and medium enterprises are expected to adopt ASRS to stay technologically relevant.

Growth in E-commerce and Omnichannel Retailing The rapid expansion of e-commerce is significantly contributing to the adoption of ASRS globally. Online retailers deal with high order volumes, frequent returns, and a wide range of SKUs, all of which demand advanced storage and retrieval capabilities. ASRS enable e-commerce companies to manage inventory dynamically, streamline picking and packing processes, and meet tight delivery schedules. The trend of omnichannel retailing, which requires synchronization between online and offline channels, further strengthens the need for efficient warehouse solutions, propelling the ASRS market.

Government Initiatives and Supportive Regulations Governments in various countries are promoting the adoption of automation technologies through subsidies, incentives, and favorable regulations. These initiatives aim to enhance manufacturing and logistics infrastructure, increase industrial productivity, and create smart cities. Such policies are encouraging more companies to invest in ASRS and related technologies. For instance, government-backed initiatives in countries like China, Germany, and Japan are promoting smart manufacturing and digital logistics, thereby indirectly fueling the ASRS market growth.

Resilience in Times of Disruption The COVID-19 pandemic highlighted the vulnerability of supply chains that relied heavily on human labor. In response, many companies began investing in ASRS to increase operational resilience and reduce dependence on workforce availability. Automated systems are capable of maintaining operations even during periods of labor shortages, lockdowns, or health-related disruptions. This long-term shift towards resilient and flexible supply chains is expected to continue, with ASRS playing a vital role.

Conclusion The Automated Storage and Retrieval Systems market is being driven by a confluence of technological, economic, and social factors. The need for efficiency, speed, and resilience in logistics and warehousing is accelerating the adoption of ASRS across diverse industries. As businesses look to future-proof their operations and navigate an increasingly competitive landscape, the deployment of these systems is set to rise, positioning the market for substantial growth in the coming years.

0 notes

Text

How to Fix stock issue with e-commerce inventory management?

Multi-channel E-Commerce inventory management helps businesses sell on many platforms, meet customer needs, and grow their sales easily.

Managing stock across multiple platforms without real-time integration can lead to overselling, stockouts, and lost revenue. This is where a robust multi-channel E-commerce inventory management service becomes essential.

Let us know how businesses can simplify their inventory, the tools that make it possible, and why this strategy is important for success in today’s retail landscape.

What Is Multi channel E-commerce Inventory Management?

Multi channel E-commerce inventory management is the process of tracking and managing inventory across multiple sales channels in real time. Instead of relying on stock records, this approach integrates all selling platforms—online stores, marketplaces, and physical outlets—into a centralized system.

This unified visibility ensures accurate stock levels, timely restocking, and improved customer satisfaction. It also prevents errors such as double-selling or order cancellations due to incorrect inventory data.

The Growing Complexity of Inventory Across Channels

Retailers today are not bound to a single platform. Without a retail inventory system, keeping track of stock becomes very complicated.

By adopting a multi channel E-commerce inventory management solution, businesses can automate, track sales, and manage orders across platforms. Integration with your warehouse inventory management system ensures physical stock and digital listings are always aligned.

Why Warehouse Inventory Management Matters

An effective warehouse inventory management strategy is critical to supporting multi-channel retailing. Centralized warehousing with cloud technology, allows real-time stock updates, order routing, and demand forecasting.

Pairing multi channel E-commerce inventory management with a cloud based warehouse management system enables better space utilization, faster order picking, and reduced operational costs. It is a smart way to scale operations without complexities.

Product Inventory Management

Accurate product inventory management ensures that your listings are never out of sync with physical stock. Automated tools update stock levels instantly when a purchase is made on any channel.

Moreover, robust multi channel E-commerce inventory management software allows SKU mapping, batch tracking, and even expiry monitoring.

The Role of Barcode Scanning and Automation

One of the most effective tools in today’s inventory management is inventory management with barcode scanning. By implementing a simple barcode inventory system, businesses can scan items.

Barcode-enabled store inventory control significantly reduces manual errors. When integrated with a multi channel E-commerce inventory management system, it enables real-time stock visibility from procurement to delivery.

The Best Way to Track Inventory Across Channels

What’s the best way to track inventory when you have dozens of SKUs spread across platforms and warehouses? The answer lies in automation.

A cloud based inventory management system that supports multiple sales channels, warehouse locations, and barcode scanning is the best solution. Not only does it simplify operations, but it also helps identify fast-moving products, slow sellers, and stock discrepancies with ease.

Store Inventory Management for Omnichannel Retailers

Retailers with both physical stores and e-commerce platforms face the added challenge of coordinating in-store and online inventory. A good store inventory management system bridges this gap by connecting POS terminals with central inventory.

This ensures that in-store purchases update your overall stock in real time, contributing to more accurate multi channel E-commerce inventory management. It also helps employees manage shelf restocking, returns, and inter-store transfers.

The Need for Inventory

Manufacturers must manage raw materials, work-in-progress goods, and finished products. A manufacturing inventory system enables the tracking of all inventory types throughout the production cycle.

When integrated with a multi channel E-commerce inventory management system, manufacturers can sell directly to customers or B2B buyers across platforms while maintaining visibility into production and stock levels.

Stock Control Systems for Small Businesses

Small businesses often struggle with inventory due to limited resources. However, investing in a stock control system for small business operations can prevent financial loss and customer dissatisfaction.

An easy-to-use multi channel E-commerce inventory management tool, ideally with barcode scanning and cloud access, can simplify operations for small retailers. These systems offer dashboards, low stock alerts, and channel-specific reporting—all essential for growth.

POS and Inventory

An efficient point of sale and inventory system ensures that in-store transactions instantly reflect in the central inventory system. This eliminates discrepancies and supports smarter restocking decisions.

When POS data is integrated with multi channel E-commerce inventory management, businesses gain control over stock movement, sales analytics, and customer trends.

Why Cloud Technology Is Transforming Inventory

Cloud platforms offer scalability, data security, and remote access. A cloud based inventory management solution can be accessed from any device and automatically syncs updates across all users and systems.

For businesses with multiple warehouses, combining cloud with multi channel E-commerce inventory management ensures everyone is working with up-to-date information at all times.

Shopaver: Your Partner in Inventory Management

Shopaver is a platform designed to simplify multi-channel E-commerce inventory management for businesses. It integrates with major marketplaces and POS systems, allowing retailers to manage their entire inventory from a single dashboard. Whether you are in fashion retail, electronics, or healthcare, Shopaver ensures that your inventory works for you.

#InventoryManagement#StockManagement#WarehouseManagement#InventoryControl#SupplyChain#InventorySystem#InventoryTracking#InventorySoftware#WarehouseAutomation#RetailInventory

0 notes

Text

Struggling to manage your stock across multiple locations?

SAP Business One simplifies inventory management — giving you complete visibility and control.

📦 Track stock in real time

📊 Automate reordering and reduce overstock

📍 Manage warehouses with precision

📉 Minimize losses and stock discrepancies

From raw materials to finished goods, SAP B1 makes inventory smarter, faster, and more efficient.

👉 Let SAP B1 streamline your inventory — so you can focus on scaling your business.

📞 Contact Averlon: +91 9892440788

🌐 www.averlonworld.com

#SAPBusinessOne#InventoryManagement#WarehouseAutomation#ERPForSMEs#StockControl#AverlonERP#SupplyChainSolutions#DigitalTransformation#SAPB1#ERPSoftware

1 note

·

View note

Text

Warehouse Automation Market Growth Driven by E-commerce Expansion and Smart Logistics Integration Globally

In recent years, warehouse automation has emerged as a critical component of modern supply chain management. With global commerce expanding and customer expectations rising, businesses are under increasing pressure to enhance efficiency, reduce errors, and streamline operations. The warehouse automation market has responded to this demand with innovative technologies that are reshaping the way goods are stored, sorted, picked, and shipped.

The Driving Forces Behind Warehouse Automation

The surge in e-commerce has been one of the most significant catalysts for warehouse automation. Consumers now expect rapid order fulfillment and real-time tracking, which necessitates precise inventory management and faster logistics. Manual processes, while still common in many warehouses, can no longer keep pace with the volume and speed of modern retail. Automation technologies fill this gap by providing scalable, data-driven solutions that improve accuracy and throughput.

Labor shortages have also played a role in accelerating automation adoption. Warehousing jobs often involve repetitive tasks and physically demanding work, leading to high turnover rates and recruitment challenges. Automated systems such as robotic arms, automated guided vehicles (AGVs), and autonomous mobile robots (AMRs) can handle these tasks efficiently while reducing the dependency on human labor.

Moreover, the increasing availability of affordable sensors, AI-driven software, and cloud-based warehouse management systems (WMS) has made automation more accessible to businesses of all sizes. Even small and mid-sized companies are now exploring automation solutions to remain competitive in a rapidly changing marketplace.

Key Technologies Shaping the Market

Several technologies are central to the transformation of warehouse operations:

Robotics: Robotic systems are being widely used for picking, packing, and transporting goods within warehouses. These systems use machine learning and computer vision to navigate and perform tasks with high precision.

Automated Storage and Retrieval Systems (AS/RS): AS/RS use cranes, shuttles, and conveyors to store and retrieve products efficiently. These systems are especially beneficial in high-density storage environments.

Conveyor and Sortation Systems: These enable rapid sorting of packages based on size, weight, destination, or priority, which is essential in high-volume distribution centers.

Warehouse Management Software (WMS): A robust WMS integrates with hardware systems to provide real-time visibility into inventory, order status, and workforce productivity.

Internet of Things (IoT): Sensors and connected devices provide data on equipment performance, warehouse temperature, and stock levels, allowing predictive maintenance and better resource management.

Market Outlook and Growth Trends

According to market analysts, the warehouse automation market is expected to continue its robust growth trajectory over the next decade. Valued at approximately $22 billion in 2024, it is projected to surpass $60 billion by 2030, growing at a compound annual growth rate (CAGR) of over 14%.

Geographically, North America and Europe have been early adopters of warehouse automation, driven by well-established logistics infrastructure and high labor costs. However, Asia-Pacific is rapidly catching up, fueled by booming e-commerce sectors in countries like China and India, as well as a strong push toward industrial modernization.

Industries beyond retail are also embracing automation. Sectors such as pharmaceuticals, food and beverage, and electronics are increasingly investing in warehouse technologies to meet stringent quality standards and ensure traceability throughout the supply chain.

Challenges to Implementation

Despite its benefits, warehouse automation is not without challenges. High upfront investment remains a significant barrier for many companies, particularly in emerging markets. Additionally, the complexity of integrating new technologies into existing systems can lead to downtime and operational disruptions during the transition phase.

There is also the issue of workforce displacement. While automation reduces the need for manual labor, it also necessitates upskilling workers to manage and maintain automated systems. Companies must invest in training and change management to ensure a smooth technological transition.

Cybersecurity is another growing concern. As warehouses become more digitally connected, the risk of cyberattacks increases. Ensuring robust data protection and system security is critical for preventing operational disruptions and safeguarding sensitive information.

The Road Ahead

The warehouse automation market is at a pivotal juncture. As technological capabilities expand and the cost of automation continues to decline, its adoption will become increasingly widespread. Businesses that embrace automation early stand to gain a competitive edge through improved efficiency, reduced operational costs, and enhanced customer satisfaction.

However, success in this space requires more than just investment in hardware and software. It demands a holistic strategy that includes employee training, supply chain integration, and a commitment to continuous innovation. By reimagining warehouse operations through the lens of automation, companies can not only meet today’s demands but also build a more agile and resilient logistics ecosystem for the future.

0 notes

Text

#manufacturing units#AGV#SmartLogistics#WarehouseAutomation#IndustrialRobotics#EcommerceGrowth#Intralogistics#ManufacturingTech#FactViewResearch#AutoEVTimes#SupplyChainInnovation#Industry40#AutomationRevolution#FutureOfWork#RoboticsTech#electricvehiclesnews#evtimes#evbusines

0 notes

Text

Truck Loading Belt Conveyors for Industrial Use – Faridabad Experts

Upgrade your material handling with high-performance truck loading belt conveyors manufactured by Faridabad-based experts, including Vashnavi Conveyor Industry. These conveyors are designed to streamline the loading and unloading of trucks, containers, and trailers in warehouses, factories, and logistics hubs. With customizable lengths, adjustable heights, and durable belts, they provide safe, fast, and efficient transfer of goods—reducing labor costs and turnaround time. Ideal for industries like e-commerce, FMCG, manufacturing, and more.

#TruckLoadingConveyor#BeltConveyor#FaridabadManufacturer#MaterialHandling#IndustrialConveyors#LoadingSolutions#VashnaviConveyor#WarehouseAutomation#TelescopicConveyor

0 notes

Text

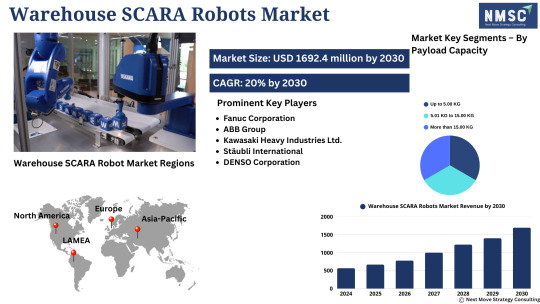

𝗗𝗶𝗱 𝗬𝗼𝘂 𝗞𝗻𝗼𝘄? The 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗦𝗖𝗔𝗥𝗔 𝗥𝗼𝗯𝗼𝘁𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 Is Set to Soar!

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲 𝗡𝗼𝘄! Did you know that SCARA robots (Selective Compliance Articulated Robot Arm) are becoming essential to warehouse automation worldwide?

The global SCARA robot market in logistics and warehousing is projected to grow at a 𝗨𝗦𝗗 𝟭𝟲𝟵𝟮.𝟰 𝗺𝗶𝗹𝗹𝗶𝗼𝗻 𝗯𝘆 𝟮𝟬𝟯𝟬 𝘄𝗶𝘁𝗵 𝗮 𝗖𝗔𝗚𝗥 𝗼𝗳 𝟮𝟬% by 2030. As e-commerce and 24-hour delivery models expand, so does the need for speed, accuracy, and scalable automation.

𝗪𝗵𝘆 𝗦𝗖𝗔𝗥𝗔 𝗿𝗼𝗯𝗼𝘁𝘀?

Ultra-fast pick-and-place capability

Precision in tight spaces

Compact design = minimal floor space needed

High ROI in high-throughput environments

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁 𝗕𝗶𝗴 𝗽𝗹𝗮𝘆𝗲𝗿𝘀 like Fanuc Corporation,ABB Group,Kawasaki Heavy Industries Ltd.,Stäubli International,DENSO Corporationare and others are aggressively investing in robotic automation. SCARA robots are key in their fulfillment centers for sorting, packaging, and material handling.

Did you know some SCARA robot manufacturers are reporting backlogs due to explosive demand from logistics firms upgrading their warehouses?

As digital transformation accelerates, early investors in warehouse robotics are poised to benefit from the next wave of smart infrastructure.

Are you positioning your portfolio for the rise of intelligent automation? SCARA robots might just be your next high-growth frontier.

#SCARARobots#WarehouseAutomation#SmartLogistics#InvestingTrends#FutureOfWork#RoboticsMarket#SupplyChainInnovation#IndustrialAutomation

1 note

·

View note

Text

LG extended fixed dock levelers are now in use across logistics centers, manufacturing sites, and cold storage facilities. Clients choose us for: ✔️ Durable steel construction ✔️ Reliable hydraulic system ✔️ Custom sizes available on request We're proud to support global supply chains with stable loading equipment.

https://lglifter.com/loading-ramp/ Email: [email protected] WhatsApp: https://wa.me/8618615633168

#dockleveler#loadingdock#industrialequipment#warehouseequipment#hydraulicdockleveler#docksolutions#logistics#materialhandling#warehouselogistics#loadingandunloading#heavyloadhandling#docklevellers#warehouseautomation#loadingdocksolutions#forkliftsupport#lglift

0 notes

Text

𝗗𝗶𝗱 𝗬𝗼𝘂 𝗞𝗻𝗼𝘄?

𝗧𝗵𝗲 𝗠𝗲𝘅𝗶𝗰𝗼 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 𝗜𝘀 𝗦𝗲𝘁 𝘁𝗼 𝗘𝘅𝗽𝗹𝗼𝗱𝗲!

By 2030, 𝗠𝗲𝘅𝗶𝗰𝗼 𝗪𝗮𝗿𝗲𝗵𝗼𝘂𝘀𝗲 𝗥𝗼𝗯𝗼𝘁𝗶𝗰𝘀 𝗠𝗮𝗿𝗸𝗲𝘁 is projected to skyrocket — driven by booming e-commerce, nearshoring trends, and the automation wave sweeping Latin America.

𝗗𝗼𝘄𝗻𝗹𝗼𝗮𝗱 𝗙𝗥𝗘𝗘 𝗦𝗮𝗺𝗽𝗹𝗲

𝗛𝗲𝗿𝗲’𝘀 𝘄𝗵𝘆 𝘀𝗺𝗮𝗿𝘁 𝗶𝗻𝘃𝗲𝘀𝘁𝗼𝗿𝘀 𝗮𝗿𝗲 𝗽𝗮𝘆𝗶𝗻𝗴 𝗮𝘁𝘁𝗲𝗻𝘁𝗶𝗼𝗻:

𝗔𝘂𝘁��𝗺𝗮𝘁𝗶𝗼𝗻 𝗶𝘀𝗻’𝘁 𝗼𝗽𝘁𝗶𝗼𝗻𝗮𝗹 𝗮𝗻𝘆𝗺𝗼𝗿𝗲 — With labor costs rising and supply chain efficiency becoming a competitive edge, Mexican warehouses are turning to robotics fast.

𝗠𝗲𝘅𝗶𝗰𝗼 = 𝗧𝗵𝗲 𝗻𝗲𝘄 𝗴𝗹𝗼𝗯𝗮𝗹 𝗵𝘂𝗯 — As companies shift production closer to the U.S., Mexico is becoming a hotbed for logistics and fulfillment centers. Guess what’s at the center? Robots.

𝗖𝗼𝘀𝘁-𝗲𝗳𝗳𝗲𝗰𝘁𝗶𝘃𝗲 𝗶𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝗼𝗻 — Mexico offers lower deployment costs for robotics compared to the U.S., but with similar ROI timelines. That’s a huge win for scalability.

𝗘-𝗰𝗼𝗺𝗺𝗲𝗿𝗰𝗲 𝘀𝘂𝗿𝗴𝗲 — With platforms like Mercado Libre and Amazon Mexico expanding aggressively, fulfillment centers are investing heavily in robotics to keep up with demand.

𝗞𝗲𝘆 𝗣𝗹𝗮𝘆𝗲𝗿𝘀: ABB Ltd., Omron Corporation, KUKA AG, Fanuc Corporation, JBT Corporation, GreyOrange, Bastian Solutions, LLC, Zebra Technologies, Dematic and others.

𝗦𝗺𝗮𝗿𝘁 𝗰𝗮𝗽𝗶𝘁𝗮𝗹 𝗶𝘀 𝗮𝗹𝗿𝗲𝗮𝗱𝘆 𝗺𝗼𝘃𝗶𝗻𝗴 𝗶𝗻 — 𝗧𝗵𝗲 𝗾𝘂𝗲𝘀𝘁𝗶𝗼𝗻 𝗶𝘀: 𝗔𝗿𝗲 𝘆𝗼𝘂 𝗮𝗵𝗲𝗮𝗱 𝗼𝗳 𝘁𝗵𝗲 𝗰𝘂𝗿𝘃𝗲 𝗼𝗿 𝗮𝗯𝗼𝘂𝘁 𝘁𝗼 𝗴𝗲𝘁 𝗹𝗲𝗳𝘁 𝗯𝗲𝗵𝗶𝗻𝗱?

The window of early advantage is closing fast.

𝗔𝗰𝗰𝗲𝘀𝘀 𝗙𝘂𝗹𝗹 𝗥𝗲𝗽𝗼𝗿𝘁

If you’re watching trends that will shape the next decade of supply chain innovation, you should be watching the warehouse robotics wave in Mexico.

#InvestSmart#MexicoMarket#WarehouseAutomation#RoboticsRevolution#EmergingMarkets#LogisticsTech#Nearshoring#EcommerceBoom

0 notes

Text

Automated Material Handling Solutions for Warehouses in UK

Warehousing is changing fast in the UK. Rising demands, tight deadlines, and labour shortages make automation more essential than ever. Automated material handling solutions for warehouses in UK are no longer a luxury. They are becoming the backbone of modern supply chains. These systems offer speed, accuracy, and reduced human error. From conveyors and robots to AGVs and AS/RS, automation is transforming how goods move in and out of UK warehouses.

Automated Material Handling Solutions for Warehouses in UK Let's explore how these solutions work, their benefits, and what makes them vital for warehouse operations across the UK.

Importance of Automated Material Handling Solutions for Warehouses in UK

Manual processes are slow and error-prone. In large warehouses, this leads to delays, bottlenecks, and damaged goods. Automated material handling solutions for warehouses in UK help solve these problems. They move materials quickly, with precision. They reduce the need for manual labour. This boosts efficiency, especially in sectors like e-commerce, retail, and third-party logistics. Automation also helps warehouses meet growing expectations. Customers want faster deliveries. Retailers want lower costs. Automation makes both possible.

Components of Automated Material Handling Solutions for Warehouses in UK

Conveyor Systems Conveyors transport goods across various zones of the warehouse. They come in different types—roller, belt, and chain conveyors. In UK warehouses, powered conveyors are often used in pick-and-pack areas. They are fast and ideal for repetitive movement of items. Automated Guided Vehicles (AGVs) AGVs are driverless transport systems. They follow pre-set paths or use sensors to navigate. They are useful in large UK distribution centres. They reduce walking time for staff. They are also safer, as they avoid collisions and follow strict routes. Automated Storage and Retrieval Systems (AS/RS) AS/RS systems are robotic arms or shuttles that place or pick goods from storage racks. They use vertical space better than manual systems. In urban UK warehouses with limited space, AS/RS help save floor area. They also allow 24/7 operation. Robotic Picking Systems These systems use robotic arms with grippers or suction cups. They pick items from bins and place them into totes or boxes. They often work with AI to recognize items. In the UK, where online shopping is massive, robotic pickers help with fast order fulfillment. Warehouse Management Systems (WMS) A WMS controls all automation in the warehouse. It manages inventory, coordinates machines, and tracks goods. It connects with ERP systems for better control. WMS also helps reduce human oversight by automating tasks like stock counts and reorder alerts.#AutomatedMaterialHandling, #WarehouseAutomationUK, #LogisticsSolutions, #MaterialHandlingEquipment, #SmartWarehousing, #AutomationInLogistics, #UKWarehouses, #IndustrialAutomation, #WarehouseEfficiency, #RoboticsInWarehousing, #SupplyChainInnovation, #AutomationTechnology, #WarehouseSolutions, #HandlingSystems, #FutureOfWarehousing Read the full article

#AutomationSystems#IndustrialTechnology#Logistics#MaterialHandling#OperationalEfficiency#Robotics#SmartLogistics#SupplyChain#UKWarehousing#WarehouseAutomation

0 notes

Text

The automated material handling equipment market has been rapidly growing, driven by a host of factors that have revolutionized the logistics and manufacturing industries. From e-commerce expansion to labor shortage solutions, automated material handling (AMH) systems are transforming the way materials are stored, retrieved, and transported across industries.

Technological Advancements Powering Growth One of the main drivers of the AMH market is the continuous innovation in technology. The integration of robotics, artificial intelligence (AI), and Internet of Things (IoT) into automated material handling systems has elevated operational efficiency to new heights. Smart sensors and real-time data analytics enable precise tracking and reduce operational errors, leading to increased productivity and reduced downtime. These technological enhancements are propelling the adoption of AMH equipment in warehouses and distribution centers worldwide.

E-Commerce Boom Fueling Demand The exponential growth of the e-commerce sector has significantly boosted the demand for automated material handling solutions. Consumers expect faster delivery times and seamless order fulfillment, prompting e-commerce giants and retailers to invest in advanced AMH systems. Automated storage and retrieval systems (AS/RS), conveyor systems, and autonomous guided vehicles (AGVs) are becoming critical components in ensuring speedy and efficient logistics operations. As e-commerce continues to thrive, the AMH market is poised to witness sustained growth in the coming years.

Labor Shortages and Cost Reduction as Key Drivers Labor shortages in various industries, especially post-pandemic, have further accelerated the adoption of AMH equipment. With a limited workforce and rising labor costs, businesses are turning to automation to maintain their operational efficiency. Automated material handling systems reduce reliance on human labor, lower the risk of workplace injuries, and minimize labor-related expenses. This shift not only ensures business continuity but also contributes to significant cost savings in the long run.

Enhancing Workplace Safety and Efficiency Safety concerns in material handling environments have also emerged as strong drivers for the AMH market. Automated systems are designed to handle hazardous tasks, reduce human error, and minimize accidents in warehouses and production facilities. By replacing manual handling with automated solutions, companies can create safer workplaces, comply with stringent safety regulations, and boost overall operational efficiency.

Sustainability and Green Initiatives Pushing Adoption Growing awareness around sustainability and eco-friendly practices is pushing companies to embrace automated material handling systems. These systems optimize energy consumption, reduce carbon footprints, and support green logistics initiatives. Automated equipment ensures precise control of inventory, minimizing waste and maximizing resource utilization. As environmental concerns become a priority for businesses, the demand for energy-efficient AMH solutions is expected to grow steadily.

Expanding Applications Across Diverse Industries The versatility of automated material handling equipment is a key driver behind its growing popularity. While traditionally used in warehouses and logistics centers, AMH solutions are now being deployed in a wide range of industries, including automotive, food and beverage, pharmaceuticals, and electronics. This diversification of applications highlights the adaptability of AMH systems in meeting the unique needs of different sectors, further driving market growth.

Conclusion In conclusion, the automated material handling equipment market is experiencing robust growth due to a combination of factors that act as key drivers. Technological innovation, the e-commerce boom, labor shortages, safety enhancements, sustainability initiatives, and industry diversification are all playing vital roles in shaping the market's future. As companies continue to prioritize efficiency, safety, and environmental responsibility, the demand for automated material handling equipment is expected to reach new heights in the years ahead.

0 notes

Text

Top 7 Inventory Management Challenges—and How to Solve Them?

Efficient Inventory Control is vital for any business that deals with products. Whether it’s a large warehouse or a small retail store, managing stock can be stressful without the right systems in place. Often, businesses face challenges that cause financial losses, customer dissatisfaction, and operational inefficiencies.

If you’ve struggled with out-of-stock products, misplaced items, or inaccurate stock reports, you’re not alone.

These are common issues that businesses across industries encounter every day. Fortunately, with the right approach and tools, these problems can be fixed.

In this blog, we will explore seven major inventory challenges and how to overcome them with practical solutions.

1. Inaccurate Stock Levels

One of the biggest hurdles is having unreliable stock data. This leads to missed sales, overstocking, and frustrated customers.

How to Solve It:

Use a stock management system with real-time tracking.

Conduct regular audits and cycle counts.

Integrate barcode scanning to avoid manual entry errors.

Furthermore, automating this process helps maintain consistency across all channels.

2. Poor Inventory Visibility

When staff can't locate items quickly, it leads to delays and inefficiencies. This issue becomes more complex as your business scales.

How to Solve It:

Adopt a warehouse management system for better layout planning.

Tag each item with a unique ID using RFID or QR codes.

Allow mobile access for remote inventory tracking.

Such systems increase transparency and reduce order fulfillment time.

3. Lack of Integration Across Channels

Many businesses use disconnected platforms for sales, shipping, and inventory. As a result, they face stock mismatches and lost orders.

How to Solve It:

Choose an all-in-one inventory management app.

Integrate your sales, POS, and accounting tools into one platform.

Enable automatic sync across online and offline channels.

With better integration, decision-making becomes quicker and more accurate.

4. Overstocking and Understocking

Holding too much or too little stock affects both profitability and customer satisfaction.

How to Solve It:

Analyze past trends and seasonal demand.

Use an inventory control system with forecasting features.

Set minimum and maximum stock thresholds.

Also, set up auto-replenishment alerts to restock efficiently.

5. Manual Errors and Outdated Processes

Many small businesses still depend on spreadsheets or handwritten logs. This often results in human errors.

How to Solve It:

Move to a digital inventory management system for small businesses.

Train your team to use the platform effectively.

Implement barcode or QR code scanning for all products.

Digital tools reduce effort, save time, and enhance accuracy.

6. Limited Scalability

As your business grows, so do your inventory needs. Without scalable systems, you may struggle to manage increasing SKUs and locations.

How to Solve It:

Invest in the best warehouse management system suited for your business size.

opt for cloud-based solutions that allow remote access.

Ensure the system can support multiple users and locations.

Scalability ensures smooth growth without losing control.

7. Industry-Specific Challenges

Different industries have different needs. For instance, restaurant inventory management requires tighter control on expiry dates, while retail needs demand forecasting.

How to Solve It:

Use inventory systems for small businesses tailored to your sector.

Automated stock rotation (FIFO/LIFO) where necessary.

Monitor perishables and high-demand SKUs more frequently

By customizing your inventory process, you can solve niche-specific issues more effectively.

Benefits of a Smart Inventory System

A reliable inventory system doesn’t just fix problems—it unlocks new opportunities. Here are a few key benefits:

Real-time inventory tracking

Reduced stockout and overstock risks

Automated stock updates across channels

Better demand forecasting

Centralized control for multiple locations

Features to Look for in an Inventory Management Solution

Before choosing an inventory management app, ensure it includes:

User-friendly dashboard

Integration with POS and e-commerce

Barcode and QR code support

Multi-location tracking

Cloud-based data access

Automated reorder points

Comprehensive analytics reports

Conclusion

In summary, overcoming inventory-related challenges requires the right mix of tools, training, and automation. Whether you run a warehouse or a small retail outlet, adopting a reliable inventory management system can make a noticeable difference.

Start small but think big. Streamline your inventory process today and pave the way for better profits, happier customers, and a more scalable business tomorrow.

#InventoryManagement#StockManagement#WarehouseManagement#InventoryControl#SupplyChain#InventorySystem#InventoryTracking#InventorySoftware#WarehouseAutomation#RetailInventory

0 notes

Text

Ready to revolutionize your warehouse operations? With our mobile stack solution, you can enjoy paperless operations, path optimization, seamless integration, and real-time analytics—designed to boost efficiency and productivity. Achieve a 25% increase in warehouse productivity, 50% faster picking, and 100% inventory accuracy and visibility across your entire network.

Visit us today for a customized demo and see how our mobile stack solution can transform your business!

For Business need, reach us out at +91-9266426868 or email us at [email protected].

#WarehouseAutomation#SupplyChainSolutions#MobileStack#Daakit#InventoryManagement#WarehouseEfficiency#ecommercelogistics#next day delivery#shippingsolutions#supplychainmanagement#logistics#logisticsaggregator#same day delivery#same day & next day delivery

0 notes