#RoboticsIntegration

Explore tagged Tumblr posts

Text

#FleetManagement#AutonomousRobots#MeiliRobots#WarehouseAutomation#CodeLicense#AMR#RoboticsIntegration#SmartLogistics#VendorAgnostic#FMS#IndustrialAutomation

0 notes

Photo

I imagine future architecture as living systems. Buildings that breathe, adapt, and evolve with their surroundings. Walls that harvest energy, facades that filter air, and structures that predict human behavior will redefine how we live and interact with space. With artificial intelligence and robotics driving this shift, design no longer ends with construction; it begins a continuous dialogue with its environment. Advanced materials and data-driven systems will transform architecture into a discipline where function, aesthetics, and intelligence converge. This future requires architects to unlearn static thinking and embrace a world where adaptability and innovation lead the way.

#futurism#ianfulgar#ai#futurearchitecture#aianddesign#roboticsintegration#adaptivebuildings#parametricinnovation#intelligentmaterials#livingarchitecture#dynamicdesign#sustainabletechnology#progressivearchitecture#urbantransformation#designforchange#nextgenarchitecture#rethinkingdesign#architecturalvision#architecturefactor

0 notes

Text

Articulated Robot Market Strategic Assessment, Strong Revenue by Top Players and Forecast 2030

The qualitative report published by Exactitude Consultancy research on the “Articulated Robot Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Articulated Robot market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Articulated Robot Market from a Global and Regional perspective.

The articulated robot market is expected to grow at 11.5% CAGR from 2023 to 2029. It is expected to reach above USD 46.6 billion by 2029 from USD 17.5 billion in 2023.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/23217/articulated-robot-market/

#ArticulatedRobot#IndustrialRobot#RoboticAutomation#RoboticsTechnology#RoboticArm#RoboticManipulator#RoboticsEngineering#ManufacturingRobot#AutomationSystem#FactoryRobot#RoboticsIndustry#RoboticsInnovation#RoboticAssembly#RoboticControl#RoboticSystem#AIinRobotics#RoboticsDevelopment#RoboticsIntegration#Industry40#FutureOfAutomation

0 notes

Text

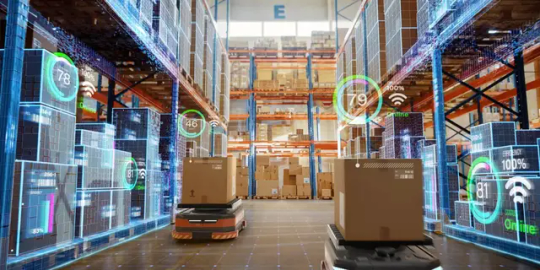

Charting the Growth Path of the Warehouse Robotics Market: Robotic Logistics Revolution

The global warehouse robotics market size is anticipated to reach USD 17.29 billion by 2030, exhibiting a CAGR of 19.6% over the forecast period, according to a new report published by Grand View Research, Inc. The expansion of the e-commerce industry, rising labor costs, and the need for greater efficiency and accuracy in warehouse operations fuel the growth of the market.

The e-commerce sector is witnessing remarkable growth due to technological advancements. Technologies like Virtual Reality (VR), Augmented Reality (AR), blockchain technology, Machine Learning (ML), and Artificial Intelligence (AI) are enhancing the shopping experience. Thus, companies seek new methods to enhance operations and logistics while reducing delivery time and costs.

Warehouse Robotics Market Report Highlights

The cartesian robots are expected to witness a CAGR of approximately 20% in the product segment from 2023 to 2030. The factors such as accuracy, precision, and ability to handle heavy loads is expected to fuel the growth

In terms of function, the transportation segment is anticipated to grow at the fastest CAGR of 20.4% over the forecast period. The growth is attributed to increased demand for sorting, loading, and unloading goods from robots

The 11 kg to 80 kg warehouse robots is likely to witness a CAGR of approximately 20% from 2023 to 2030. The ability to efficiently handle medium and heavy-weight items in manufacturing, healthcare, food, beverages, and other industries is expected to support the growth

The software segment is estimated to experience a CAGR of approximately 21% over the forecast period. The segment is divided into a warehouse management system, a warehouse control system, and a warehouse execution system

The healthcare industry is anticipated to witness the fastest CAGR of approximately 21% in the application segment from 2023 to 2030. The growth is attributed to the continuous developments and increased implementation of robots in the healthcare sector to perform a variety of tasks in healthcare warehouses

For More Details or Sample Copy please visit link @: Warehouse Robotics Market Report

Robots offer a smart, cost-efficient alternative to human labor by automating warehouses catering to the increasing need of the e-commerce sector. The robots help companies to maintain employee safety standards and enhance production quality by performing various tasks such as handling the incoming consignment, picking, packing, slotting, shipping, and asset tracking by saving considerable time and effort.

The COVID-19 pandemic impacted the warehouse robotics industry substantially in terms of the demand for robotics and the supply chain of the robotics industry. However, the need for efficient and contactless order fulfillment and labor shortage due to lockdowns fueled the demand for robots and other automation tools in business operations. The market has shown rising demand and continuously growing as companies invest heavily in research and development activities to improve existing technologies and launch advanced robots.

The initial investment of the robotic set-up into the warehouse is high, creating significant challenges for small and mid-sized companies. Furthermore, implementing robots in warehouse operations is affecting labor jobs. The rising adoption of robots is expected to affect employment and wages, affecting the further growth of the warehouse robotics industry over the forecast period.

#WarehouseRobotics#LogisticsAutomation#RoboticWarehousing#SupplyChainTech#AutomationSolutions#SmartWarehouses#RoboticsInLogistics#Industry40#TechInnovation#EfficientSupplyChain#LogisticsTechnology#RoboticsIntegration#AutomatedStorage#DigitalTransformation#InnovativeLogistics#WarehouseEfficiency#AutonomousWarehousing#RoboticsIndustry#TechInvestment#FutureofLogistics

0 notes

Text

How To Deploy Warehouse Automation System?

Warehouse automation is a solution advised for firms aiming to increase logistics productivity, maximize storage space, and enhance the safety of their personnel, goods, and storage systems. But how exactly does one go about automating a warehouse? What steps should people take? In this blog, let’s discuss the steps to implement warehouse automation.

Rising R&D spending, high labor costs, a shortage of qualified workers, and increasing public awareness of the benefits of the market. Thus, these elements are predicted to boost market growth. In addition, according to a research report by Astute Analytica, the global Warehouse Automation Market is likely to grow at a compound annual growth rate (CAGR) of 15% over the projection period from 2023 to 2031.

Follow This Step-By-Step Guide To Get Started With Warehouse Automation:

Create a committee to oversee the implementation

Create a committee of internal stakeholders with knowledge of current warehouse capabilities, performance, and challenges, as well as an understanding of existing technology gaps; consider bringing in third-party experts who are knowledgeable about supply chain automation and have knowledge of industry and warehouse operations.

Collect essential information

Effective warehouse automation is dependent on data from a person’s existing supply chain and business-critical warehouse operations. Before deploying new automation technology, assess the present data collection method and infrastructure. They should delegate data migration responsibility to qualified IT stakeholders.

Examine inventory controls

Inventory control is crucial to warehouse operations. Determine or refine people inventory control standard operating procedures (SOPs) before using warehouse automation technology. Include standard operating procedures for shipping, purchasing, customer satisfaction, receiving, and inventory loss.

Define the key performance indicators (KPIs) that will be used to assess the effectiveness of automated inventory control procedures and processes. Evaluate the current inventory accounting method (for instance, perpetual or periodic systems) and how automation may affect it.

Set up partnerships with stakeholders

Supply chains can be fairly complicated because they are made up of numerous distinct links. It is beyond a doubt one of the most crucial elements to consider when automating the warehouse because the person must guarantee that the appropriate resources have been engaged.

This entails establishing collaborations with firm stakeholders, who range from funders to technicians, and from their technical assistance team to operations managers. Bringing everyone’s skills and experience together will aid in identifying obstacles, opportunities, and crucial issues at the beginning of the automation process.

Establish a warehouse management system (WMS)

WMS systems include software modules that aid in the control and tracking of inventory, the management of warehouse operations, the reduction of wages associated with manual duties, and the improvement of customer service. A new WMS should aid mobile devices and be compatible with their current enterprise software.

Determine the type of warehouse automation required

Person’s intention to employ automation to cut labor expenses related to back-office warehousing operations and accounting? Or, are they growing their warehouse footprint or opening new locations and believing it’s time to implement advanced physical process automation, like robots and GTP systems? It is critical to identify the type of warehouse automation that corresponds with goals and consumer demand.

Source: How To Deploy Warehouse Automation System?

#Warehouse Automation System#Warehouse Automation Market#Warehouse Automation#WarehouseAutomation#SupplyChainTech#LogisticsSolutions#OperationsManagement#IndustrialEngineering#ManufacturingTech#RoboticsIntegration#BusinessAutomation#TechnologyDeployment#EfficientWarehousing#ProcessOptimization#SmartWarehousing#InventoryManagement#DistributionCenter#AutomatedLogistics

0 notes

Text

Are soft-robotic charging Tech plugging into the future to unleash efficiency?

Soft-robotic charging to unleash efficiency #Robotcharging #EV #electricvehicle #EVcharging

Soft-robotic charging to unleash efficiency? Is it a reality? EV charging with soft-robotic charging is one of the most innovative approaches for enhancing the safety and efficiency of the charging process. Soft-robotic charging to unleash efficiency? Is it a reality? Soft RoboticsIntegration of Charging StationsAutonomous OperationPrecise ManeuveringSafety FeaturesBenefitsThe several…

View On WordPress

0 notes

Text

Bluetooth Low Energy “Beacons” for the Internet of Things (IOT)

Recently the students of IIT revolutionized the markets of Dharavi by using “beacons” to provide customized offers to the people visiting the markets. This illustration of the ability of beacons to change the entire experience of customers underlies the capability of beacon technology to fundamentally alter various processes across different domains in manufacturing and retail. What is a Beacon? In ancient times, beacons were fires lit at different locations and used for signaling purpose. They were used to signal warnings, celebrations, navigation, signify an important location etc. With time and advent of technology, beacons became more sophisticated and their application more widespread and today we typically see a beacon as a very small electronic device typically of the size of buttons of a shirt which emits radio signals in close proximity of varying strengths. How Does a Beacon work? Beacons use technology such as Bluetooth, Wi-Fi or UWB. Most commonly used beacons are equipped with Bluetooth Low Energy (BLE) also called as Bluetooth Smart. BLE allows the beacons to continuously emit radio signals which contain packets of information. These signals are visible to all the Bluetooth enabled devices such as our smartphones and are sent out typically in every 1/10th of a second. In order to emit these signals, beacons have to be connected to a power source such as a battery. BLE requires very less energy as compared to regular Bluetooth and hence the beacons can run even for years with the help of just small button cell. What shall these Beacons do? The Bluetooth enabled devices (smartphones) through the signal are able to identify the beacon, once the phones identify the signal of the beacon it implies that they are within range of the beacon and a predetermined command on the relevant app shall be triggered. Internet connectivity for this stage is necessary for the app to trigger the command. These commands can be discount coupons, navigation option, any new product arrival, register attendance etc. The signals that beacons emit can be used to measure the location of the device around the beacon. The signal strength can be converted into the distance to know that exact location of the device from the beacon. Though one inherent problem that can occur is that beacons emit radio signals and they can be absorbed by objects in between the receiving device thereby altering the strength of the signal and thus affecting the conversion into the distance. With another technology, it is completely possible to address the problem but let us reserve it for another day! Blog Reference: https://addverb.in/Beacon-Whose-Signal-Is-It-Anyway?

#industryautomation#roboticsintegration#warehouseindia#warehouseautomation#industry 4.0#beacon#industryiot

1 note

·

View note

Text

Lighting up your warehouse with Pick-To-Light.

With the rise of E-commerce, the proliferation of SKUs and the expectation of quick deliveries, the intralogistics operations have become quite complex. To cater to today’s customer, both the online and the brick and mortar retailers must maintain an adequate supply of items both in terms of quantity and variability. These competitive pressures prompt companies to have super-fast and highly accurate deliveries, which becomes a daunting task for the warehousing team. To cater to these high service levels and still maintain both the scale and flexibility in their operations, Warehouse Managers should look towards an efficient and accurate order fulfillment solutions. One such solution that ticks the right boxes is a Put-To-Wall solution, which can help in sorting the orders that have been consolidated upstream into individual deliveries before they get dispatched. What is Put-To-Wall? Put-To-Wall system is a part of Goods-To-Person order picking system. This solution mainly comprises of a shelf with individual slots, each slot representing an order. Both sides of the slots are open to facilitate sorting of the orders at one side & collection for the packing on the other side. The Put-To-Wall systems are usually combined with “Wave Picking” process. All the orders that are to be picked are consolidated and processed as a single collective order. The picker collects the items in a tote/crate and sends the crate downstream towards the sortation region which comprises multiple Put-To-Wall stations. How it is used? A Wave is generated by combining the common SKUs, delivery dates, shipping address areas etc. These multiple orders combined are processed together & the individual SKUs for those combined orders are picked in the crates and sent to the sortation area. The operator in the Put-To-Wall area typically has an RF gun which is integrated with the wall. Once the crates from upstream arrive to the Put-To-Wall area, the incoming inventory is scanned at the item level/case level. In case of item level placing, once the item is scanned, the required slot of the Put-To-Wall, where it needs to go illuminates; in case of ‘case level scanning’, all the locations where the items in the case should go illuminate with the quantity getting displayed on the alphanumeric display of the light unit. Upon placing the items into the locations, the operator puts off the light by pressing the acknowledgment button. On the Packing side of the put-wall, another operator packs the orders. The totes/cartons with the consolidated items from upstream are usually carried to the Put-To-Wall station through a conveyor, loop sorter or in some cases by a trolley. Advantages of Put-To-Wall: High Throughput: Wave picking typically reduces the walking time of the picker as walking comprises 50% of the order picking time. This results in a higher order picking rate and subsequently, the Put-To-Wall allows for a very fast and quick sortation. Flexibility: The Put-To-Wall structures can be expanded/contracted by increasing the number of shelves & lighting system to suit the demand fluctuations. Put-To-Wall can be very easily integrated into the existing system without any alterations. It is just an add-on at the end of the order processing line which results in easy, efficient & accurate order handling. Increase employee productivity: As employees standing at one point & sorting the orders, it reduces the travel time and offers a safer and ergonomic work environment. It is easy to train the employees to use a put-wall system that results in higher productivity. Higher accuracy: The Put-To-Wall system involves scanning the items before placing them into the respective slots. The scanning, subsequent light, an alphanumeric display ensure high-quality checks reducing the misplacing of items, quantity errors & increases the order accuracy rates. Efficient Space Utilization: The Put-To-Wall structure has many slots in one shelve and the slots are continuously used for the order processing and packing leading to effective utilization of warehouse space. Environment-friendly: Put-To-Wall is completely paperless, as it involves scanning & light, which makes it environment-friendly & has less scope for errors.

Blog Reference: https://addverb.in/Light-In-The-Wall.html

0 notes

Text

Articulated Robot Market Strategic Assessment, Strong Revenue by Top Players and Forecast 2030

The qualitative report published by Exactitude Consultancy research on the “Articulated Robot Market offers an in-depth examination of the current trends, latest expansions, conditions, market size, various drivers, limitations, and key players along with their profile details. The Articulated Robot market report offers the historical data for 2018 to 2023 and also makes available the forecast data from the year 2024 to 2030 which is based on revenue. With the help of all this information research report helps the Market contributors to expand their market positions. With the benefit of all these explanations, this market research report recommends a business strategy for present market participants to strengthen their role in the market. This report analyzes the impact of the Covid 19 pandemic on the Articulated Robot Market from a Global and Regional perspective.

The articulated robot market is expected to grow at 11.5% CAGR from 2023 to 2029. It is expected to reach above USD 46.6 billion by 2029 from USD 17.5 billion in 2023.

For The Full Report Click here:

https://exactitudeconsultancy.com/reports/23217/articulated-robot-market/

#ArticulatedRobot#IndustrialRobot#RoboticAutomation#RoboticsTechnology#RoboticsEngineering#ManufacturingRobot#RobotArm#RoboticsInnovation#IndustrialAutomation#RoboticsIndustry#RoboticManipulator#AutomationTechnology#RoboticAssembly#RoboticsManufacturing#RoboticsDevelopment#FactoryRobot#RoboticSolutions#RoboticsIntegration#IndustrialRobotics#FutureOfAutomation

0 notes

Text

Pickathon“Order Picking” Productivity in Warehouse Management

Technology has fundamentally altered our lives. It has led to the disruption of business models and the development of innovative products to drive up efficiency. “Industrial Revolution” led to mass manufacturing and an increase in the scale of operation, this led to the creation of big factories followed by large warehouses. Warehouses have become the cornerstone of supply chain management and the warehousing process elements have become the source of the proverbial “Competitive Advantage”.

One of the most pivotal parts of the warehousing process is “Order Picking”. Research has pegged the cost of “Order Picking” process at approximately 55% of the total warehouse operating cost. With such critical importance, it becomes imperative to look at the factors that determine the outcome of the “Order Picking” process. Order Picking primarily depends on the following factors: 1. Level Of Automation: Warehouses can be completely manual, semi-automated or fully automated. The degree of automation involved impacts the service levels of Order Picking. 2. Layout Of Warehouse: Building a warehouse depends on customer demand, economy, products consumption pattern, accessibility and inventory levels. These collectively determine the layout of the warehouse for instance number of aisles, storage locations etc. This, in turn, determines the methodology. 3. Operational Policies: One of the critical factors on which Order Picking depends is operational policies/decisions. They comprise storage patterns, customer demand pattern, routing and order release mode. 4. Methodology: Order Picking methodology can be broadly classified as: Person-To-Item: The person (Picker) goes to different storage locations to collect the items. Item-To-Person: The person (Picker) collects the items from a picking bay. Through equipment such as a sorter, conveyor etc. items are put in picking bay from the storage area. Zone Picking: The entire warehouse storage locations are divided into sub-units (Zones). Each person (Picker) picks only items of the order which fall in his zone. Zones are activated in serial order, one after the other. The order is complete after passing through the last zone. Wave Picking: In this again, the entire warehouse storage locations are divided into sub-units, items from different orders from one zone are picked together and consolidation and final sorting of orders happen later. Key parameters to determine the proficiency of Order Picking are: Delivery Time: This is the time taken from releasing of order to completion of order and final delivery of order for dispatch. A manual system such a Person-To-Item leads to high variability resulting in irregular dispatch and loss of flexibility. Shorter delivery time ensures more bandwidth to handle run-time changes in the order. Minimizing the Delivery time is the primary measure of an Order Picking system. Reliability or Order Integrity: Picking up the correct item is critically important as a wrong order can lead to a disgruntled customer. Correct picking ensures that a company is able to meet the demand of the customer on-time every time. The person-to-item methodology is the most commonly used methodology in warehouses today, typically it involves quite a lot of human interface and leads to a lot of variability in the operation. On an average, a Picker usually spends 70% of his time in traveling and searching. With so much time spent on this activity and only 15% of the time spent in actual picking, the rest of the time is spent in setting up and completing the pick ( validating the checklist). This entire process has a lot of scope for improvement. Add to the fact that the organizations face a lot of attrition at the level of Pickers. Quite a lot of time is wasted in training the new pickers and optimizing their working routes and working pattern. Going ahead, we shall take a look at how Addverb harnesses the technology to automate the Order Picking and address the inefficiencies. Blog Reference: https://addverb.in/Pickathon

0 notes

Text

The economics of robots in industrial iot applications

A robot may not injure a human being or, through inaction, allow a human being to come to harm A robot must obey the orders given it by human beings except where such orders would conflict with the First Law A robot must protect its own existence if such protection does not conflict with the First or Second Law Isaac Asimov, science fiction author, and professor at Boston University postulated the “Three Laws Of Robotics” in his 1942 popular short story “Run-around”. Though these laws appeared fictional at the time of writing, the advent of technology has made humans and Robots work together and these laws more or less, form the crux of the operation in such workplaces. While countries like Germany, Italy, Sweden, France, S. Korea, China, Spain, US, UK have taken to the use of Robots in a big way subsequently driving up productivity and scale, India has somewhat lagged in the adoption of Robots on the shop floor. As the Government pushes on the idea of “Make in India”, it becomes imperative for Indian manufacturers to adopt Robots at the workplace. With increased adoption globally, standard robot models are now mass-produced, and this presents a perfect opportunity for small and medium-sized companies to deploy Robotic Automation in their manufacturing and drive the next wave of value unlocking. A holistic view of the costs involved shall allow them to make the decision to adopt the Robotic Automation. At Addverb, we recommend “FOLDUP” approach to customers to calculate the ROI for Robotic Automation. Flexibility: Robotic Automation is future ready automation, by just re-programming the robot and changing the end tools, the entire production process can be tweaked. This is in stark contrast with the special purpose machines which generally have hard tools which cannot be tweaked. In the case of the manual process, human workforce clubbed with archaic labor laws make the production process very inflexible. Overheads: Once the upfront investment has been made in Robotic Automation, the cost of running the entire system is very less as compared to a manual system. Robotic Automation ensures low or no maintenance and administrative costs, which are quite high while managing a manual workforce. These costs are often not included in the ROI calculation, also the administrative costs (Overheads) generally tend to increase as the number of years of operation increases. Taking this into account results in very low-cost of total ownership for Robotic Automation. Labour: At present, the majority of the jobs that absorbs most of the labour is repetitive in nature, these kinds of jobs do not add any skill to the people who are employed. This in turn results in stagnation of labour which creates a hostile industrial relations scenario. With Robotic Automation, the labour that is required to maintain the robots is highly skilled and as such this provides better employment opportunity, resulting in harmonious industrial relations. Quite a few jobs in manufacturing take place in an environment that is hostile to the human body, using robots for such processes is a great investment which also ensures harmonious Industrial Relations. Dependability: Manual process often results in variability and quality defects. Robotic Automation is highly dependable, and robots often prove to be superior to humans in terms of the quality of the work for most of the production processes. Robotic Automation can drastically reduce the number of defects and improve the quality of inspection. As Robotic Automation displays zero deviation from the production process, the resulting quality of the finished products is quite good. This cost often gets overlooked as a manual process usually results in high-quality defects, affecting the overall brand of the company as well. Usage: This is the most important criteria that must be factored in while implementing Robotic Automation. Robots allow three-shift operations, 7 days a week and 365 days a year without any interruption and stoppage. While comparing with a manual process, this must be compared to an equivalent workforce that shall be required to manage such operations at this scale. Robotic Automation ensures continuous production without any stoppages due to administrative issues. Productivity: Apart from non-stop usage, one of the most neglected aspects of Robotic Automation is the increase in Productivity. Having a Robot is like having a highly skilled resource available, round the clock. Unlike Robots, the human body is susceptible to short-term fatigue, injury, and disability. Many jobs in manufacturing typically either because of the hostile environment or being repetitive in nature result in low productivity after some time. This is not the case with Robotic Automation, which ensures constant productivity throughout. Even with all this, the most important factor that determines the success of Robotic Automation in a factory is an “Integrator”- a company which completely understands the nuances of Robotic Automation and can design complete solution that will maximize the output by selecting the right robot, designing the layout, integrating the vision system etc. Robotic Automation offers a very reliable and efficient production process, robots typically can be refurbished and used again after a period of 10-12 years with ease. All these factors make the ROI on Robotic Automation attractive, a good rule of thumb is to target a minimum of three years for calculating the ROI. After these three years, typically Robotic Automation results in positive cash flow for the company with minimum variability and high-efficiency. That’s the stage when actual value unlocking happens for the organization. It becomes imperative for small and medium enterprises, who aim to grow, to look beyond the near future to truly ascertain the gains obtained from Robotic Automation.

Blog Reference: https://addverb.in/Robonomics

#robotics#roboticsintegration#warehouse automation#storageoptimization#industry4.0#roboticautomation

0 notes