#workholding

Text

Best Workholding Solutions - PDQ Workholding and Tooling

PDQ Workholding and Tooling offers the best workholding solutions in the industry. Their innovative products and solutions are designed to maximize productivity, accuracy, and efficiency in machining operations. With a focus on quality and customer satisfaction, PDQ Workholding and Tooling is the go-to choice for reliable workholding solutions.

0 notes

Text

Seek Roemheld Suppliers in India | Oewin

Oriental Engineering Works provides economical industrial solutions to its customers. We offer hydraulic cylinders, pumps, valves, Roemheld work holding, and tools at the best prices being the only distributor of Roemheld in India. For more details, visit us!

#roemheld suppliers in India#roemheld workholding#hydraulic cylinder#Hydraulic power pack manufacturers in India

0 notes

Photo

Buy tooling at affordable rates at EDM Tooling. We provide you with System 3R Mini tooling to suit your mini tooling requirements. We are ready to help our customers round the clock in the best way. Hook to our website for more details.

1 note

·

View note

Photo

Custom Workholding Solutions & Tools | PDQ Workholding and Tooling

PDQ Workholding and Tooling offers custom workshop building solutions, customized CNC fixtures and machine tooling to create custom equipment for equipment manufacturing and assembly. PDQ manufactures complete guide paths for machine guidance systems, fixture management systems and automated production systems. We have designed complete machine Custom Workholding guidance interfaces for complex CNC machines using software

0 notes

Note

I just put it in the tags on your post, but I figured I'd send an ask too. For a metal project like that it, if you can find one, a local communal workshop or tool library would be pretty helpful. Something like cutting a chain is definitely doable on your own, but if you havent done a lot of work with power tools and don't have much in terms of a workshop it might be a lot to set up for just one project. Whereas a workshop would have all the tools you'd need, a space to use them, proper vises and stuff for workholding, and people with lots of experience who can help out.

You may not have anything like that around, but I work at a workshop like that and so many people come in who never even realized that there are places like ours out there, so you might be surprised.

i saw yeah, that would be so ideal but honestly i have no fucking clue if we have anything like that here... i live in the middle of nowhere and its kind of impossible to search online for this stuff and i dont know many local people so its tough. thank you tho maybe ill look around

8 notes

·

View notes

Text

Spent too much of yesterday evening tracing, coloring, and annotating the parts diagram for what the lathe used to be. Some points about this exercise:

It was a very silly thing to do.

It will be a very good thing to have done. Apart from being a more legible version of the chart I already use for parts lookup, it’ll let me track modifications/additions/swaps/discards/(in)compatibilities a bit more efficiently than verbal notes.

This isn’t a very faithful diagram to the machine as I received it, which was (a.) secondhand, (b.) broken, and (c.) assembled according to a different company’s spec. These import SIEG clones are a very diverse species, but this is close enough to pretend it matches.

The PDF I used is very crispy indeed. I didn’t have to ink over all the lines, but it helped. A bit odd to think I’ve handled (if not modified or made replacements for) every single one of these parts, but if that wasn’t true I’m not sure I could’ve interpreted the scrumbled print well enough to see what was going on. Thankfully the numbers are better preserved than the isomorphic projections were.

I haven’t counted yet, but something close to half of everything on the machine is now meaningfully non-original. That number goes way up if you consider assemblies rather than discrete parts.

I thought about trying to model, give custom lookup numbers to, and overlay all the things not represented here — new workholding solutions, toolpost alternatives, the sewing machine motor/controller combo, etc. — then went on to think that sounded like far, far too much work. Doing that work would ruin the silliness, and we can’t allow that.

I have a lot of shit to frame and hang, so I might as well add this to the pile. Even if I was opposed to decorating my Very Practical workspace (which I’m clearly not) I could probably launder this as a Very Practical reference diagram if no one looked too closely.

53 notes

·

View notes

Text

What is Bench Vice Tool

A bench vice is a mechanical tool that is used to hold and secure an object in place, allowing the user to work on it with both hands. It is typically attached to a workbench or table and consists of two parallel jaws, one of which is fixed in position and the other is movable. The jaws are operated by a screw mechanism, which can be turned to open or close the vice, allowing it to grip objects of different sizes and shapes. Bench vices are commonly used in woodworking, metalworking, engineering, and other trades or hobbies where a secure and stable workholding is necessary. They can be made from a variety of materials, including cast iron, steel, or aluminum, and may be equipped with additional features such as swivel bases, pipe jaws, or quick-release mechanisms.

2 notes

·

View notes

Photo

Maxx Tooling manufactures System 3r Tooling products for machining and EDM. We offer a wide range of workholding devices to satisfy the demands of industries and companies. Visit our website for more information!

2 notes

·

View notes

Text

SUTTOR ELEMENTARY WATTSON ? 🌞 HUH 💊

OWHMZ ER >> OFF CORE OF ERS NORS >>

NODS FHM GAMA SCENE HARBOUR FREIGHT >> PUMPING CRAFTSMAN >> 🧰

http://lowes.com

2 notes

·

View notes

Text

Unlocking Precision: Understanding CNC Machine Configuration

CNC (Computer Numerical Control) machines have revolutionized manufacturing by automating and streamlining the production of intricate parts with unparalleled precision and efficiency. At the heart of every CNC machine lies its configuration – a carefully orchestrated combination of components and parameters that determine its capabilities and performance. In this blog, we'll delve into the essential elements of CNC machine configuration, shedding light on the key components that drive its functionality and versatility.

Machine Type: CNC machines come in various types, each designed for specific machining operations and applications. Common types include:

CNC Milling Machines: Used for cutting and shaping solid materials, such as metal, wood, and plastics, using rotating cutting tools.

CNC Lathes: Ideal for machining cylindrical parts by rotating the workpiece against stationary cutting tools.

CNC Routers: Employed for cutting and carving materials like wood, foam, and composites using computer-controlled routing heads.

CNC Plasma Cutters: Utilized for cutting metal sheets and plates using a high-velocity jet of ionized gas (plasma). Selecting the appropriate machine type depends on factors such as the desired machining operations, material types, part complexity, and production volume.

Axis Configuration: The axis configuration of a CNC machine refers to the number and orientation of its motion control axes. Common configurations include:

3-Axis Machines: Capable of moving along three linear axes (X, Y, Z) to perform 2D and 3D machining operations.

4-Axis Machines: Incorporate an additional rotary axis (typically A or B) for rotating the workpiece, enabling more complex machining operations and angular cuts.

5-Axis Machines: Feature two additional rotary axes (typically A and B or A and C), allowing for simultaneous movement and rotation in multiple directions, expanding the range of machining possibilities and enhancing precision.

Multi-Axis Machines: Combine three or more linear and rotary axes to achieve intricate machining capabilities, such as simultaneous milling, turning, and grinding. The axis configuration determines the machine's flexibility, precision, and suitability for specific machining tasks.

Control System: The control system is the brain of the CNC machine, responsible for interpreting the part design data (usually in the form of G-code) and translating it into precise movements and commands for the machine's motors and actuators. Key components of the control system include:

CNC Controller: The central unit that processes the G-code instructions and coordinates the motion of the machine axes.

Motor Drives: Power the machine's motors and provide precise control over their speed and position.

Feedback Systems: Include encoders and sensors that provide feedback on the position, velocity, and acceleration of the machine axes, ensuring accurate motion control.

Human-Machine Interface (HMI): Allows operators to interact with the CNC machine, input machining parameters, monitor the machining process, and troubleshoot any issues. Modern CNC machines may utilize proprietary control systems or industry-standard platforms such as Fanuc, Siemens, or Mitsubishi, each offering unique features and capabilities.

Tooling and Workholding: Tooling and workholding play a critical role in CNC machining, enabling the secure fixation of workpieces and the precise execution of machining operations. Key components include:

Cutting Tools: End mills, drills, inserts, and other cutting tools tailored to specific materials and machining operations.

Tool Changers: Automatic or manual systems for changing cutting tools during machining processes, reducing downtime and increasing productivity.

Workholding Devices: Vises, clamps, fixtures, and chucks that securely hold the workpiece in place during machining, ensuring stability and accuracy. Proper selection and setup of tooling and workholding solutions are essential for achieving optimal machining results and minimizing setup time.

CNC machine configuration encompasses a myriad of components and parameters that determine the machine's capabilities, performance, and versatility. By understanding the machine type, axis configuration, control system, and tooling/workholding options, manufacturers can select and configure CNC machines to meet their specific machining requirements and production goals. Whether producing precision parts for aerospace, automotive, or medical applications, CNC machines stand ready to unlock the potential of modern manufacturing with their unparalleled precision and efficiency.

0 notes

Text

Workholding: Techniques and Tools for Securely Clamping Workpieces in Manufacturing Processes

Workholding refers to the various techniques and tools used to securely clamp workpieces in place during manufacturing processes. This ensures accuracy, consistency, and safety in machining operations such as drilling, milling, and turning. Effective workholding strategies can improve productivity, reduce errors, and enhance overall manufacturing quality.

0 notes

Text

Are you looking for an automated die-change system?

Your wait is over! At Oriental Engineering Works, we manufacture a quick die change system for press machine that works automatically and saves labor costs. Visit now.

0 notes

Text

Difference between Erowa Tooling and System 3R

Are you running a manufacturing industry and seeking the best Cutting machinery tools? If so, then Erowa Tooling and System 3R is the best solution.

System 3R

One of the top tooling, work-holding, and automation specialists, System 3R provides solutions for precision engineering and EDM operations that are productive, accurate, efficient, and flexible. It enables you to get the most out of your EDM equipment. It also makes it simpler to increase productivity while spending less money.

Erowa Tooling:

Erowa's clamping systems are well known throughout the world. The best WEDM and CNC tooling are offered by EDM tooling in North America in terms of engineering, customization, and assembly. The Erowa tooling compatibility helps you become more competitive.

#System 3R#Erowa#Tool#Electrical Discharge Machining#Machine#Machining#Tool and die maker#Manufacturing#Machine tool#Die#Computer numerical control#Cutting#system 3r pallet#electrode clamp#wire edm workholding#wire edm tooling#tool holder clamp#workholder#parting tool holder#tool clamp holder

0 notes

Text

Unlocking Precision Exploring the 5C Collet Chuck

Unlock the potential of your machining operations with the 5C collet chuck. Designed for precision and versatility, the 5C collet chuck is a fundamental tool in machining applications. Whether you're turning, milling, grinding, or drilling, this collet chuck ensures secure and accurate workholding for your components.

0 notes

Text

A Deep Dive into CNC Machines

In the realm of modern manufacturing, Computer Numerical Control (CNC) machines stand as the vanguard of precision, efficiency, and versatility. These machines have transformed the way industries produce intricate components and parts across diverse sectors, from automotive and aerospace to electronics and healthcare. With their unparalleled accuracy and automation, CNC machines have become indispensable tools in the pursuit of manufacturing excellence.

What are CNC Machines?

At its core, a CNC machine is a computer-controlled manufacturing tool capable of executing precise and complex machining operations. Unlike conventional manual machining, where operators manually control the movement of tools and materials, CNC machines operate autonomously based on programmed instructions. These instructions are created using Computer-Aided Design (CAD) software, which generates a digital model of the desired component or part.

How do CNC Machines Work?

CNC machines operate on the principle of subtractive manufacturing, where material is removed from a workpiece to achieve the desired shape and dimensions. The basic components of a CNC system include:

Controller: The brain of the CNC machine, the controller interprets the programmed instructions and translates them into specific movements and actions. It communicates with the machine’s motors and actuators to execute precise operations.

Motors and Actuators: These components are responsible for moving the cutting tools and workpiece in various directions according to the programmed instructions. The most common types of motors used in CNC machines are stepper motors and servo motors, which offer different levels of precision and speed.

Cutting Tools: CNC machines utilize a wide range of cutting tools, including drills, mills, lathes, and grinders, to shape and refine the workpiece. These tools are selected based on the material being machined and the desired outcome.

Workholding Devices: To secure the workpiece during machining, CNC machines use various workholding devices such as vises, chucks, and fixtures. These devices ensure stability and accuracy throughout the machining process.

Applications of CNC Machines

The versatility of CNC machines enables their application across a multitude of industries and manufacturing processes. Some common applications include:

Prototyping and Rapid Manufacturing: CNC machines are instrumental in prototyping new designs and rapidly producing small batches of components with minimal lead time. This flexibility allows manufacturers to iterate and refine their products quickly, reducing time to market.

Mass Production: In mass production scenarios, CNC machines offer unmatched efficiency and consistency. They can operate continuously for extended periods, producing large quantities of parts with high precision and repeatability.

Customization and Personalization: With CNC machining, customization and personalization are easily achievable. Whether it’s engraving intricate designs or creating unique shapes, CNC machines empower manufacturers to cater to individual preferences and requirements.

Complex Geometry: Traditional machining methods often struggle with complex geometric shapes. CNC machines, however, excel at machining intricate contours, angles, and curves with exceptional accuracy, making them indispensable for industries such as aerospace and automotive.

High-Tolerance Machining: CNC machines are capable of achieving incredibly tight tolerances, ensuring that parts meet exact specifications consistently. This precision is crucial in industries where even minor deviations can lead to significant performance issues or safety concerns.

Future Trends and Innovations

As technology continues to advance, CNC machines are evolving to meet the growing demands of modern manufacturing. Some emerging trends and innovations in CNC machining include:

Integration of AI and Machine Learning: AI-driven algorithms are being incorporated into CNC systems to optimize tool paths, predict maintenance needs, and enhance overall efficiency. Machine learning algorithms can analyze vast amounts of machining data to identify patterns and trends, leading to continuous improvement in machining processes.

Additive Manufacturing Integration: Hybrid CNC machines capable of both subtractive and additive manufacturing are gaining traction. These machines combine the precision of CNC machining with the flexibility of 3D printing, enabling manufacturers to create complex geometries with enhanced efficiency and reduced material waste.

IoT Connectivity: CNC machines are increasingly being equipped with IoT sensors and connectivity features, allowing real-time monitoring of machine performance, tool wear, and production metrics. This connectivity enables proactive maintenance, predictive analytics, and remote monitoring, maximizing uptime and productivity.

Enhanced Automation and Robotics: The integration of robotic arms and automated material handling systems with CNC machines is streamlining production workflows and reducing labor costs. Collaborative robots (cobots) are being deployed alongside CNC machines to handle tasks such as loading/unloading, tool changing, and inspection, further enhancing productivity and flexibility.

Conclusion

CNC machines have revolutionized the manufacturing landscape, empowering industries to produce complex components with unprecedented precision and efficiency. As technology continues to advance, CNC machining will play an increasingly vital role in driving innovation and shaping the future of manufacturing. From mass production to customization and beyond, the versatility and reliability of CNC machines ensure they will remain indispensable tools for manufacturers worldwide.

0 notes

Text

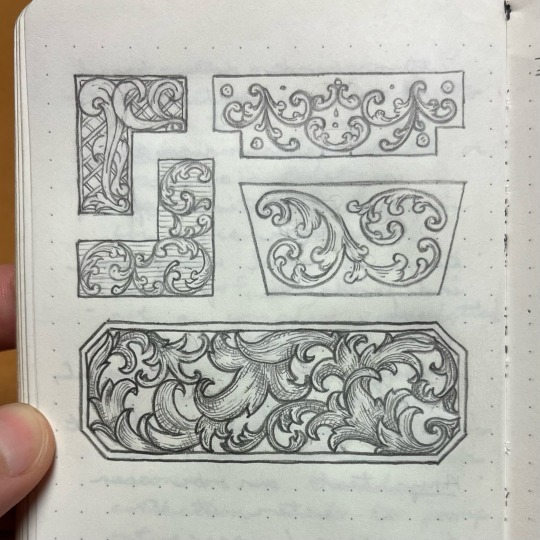

OK, well. Finally got a couple spare hours to myself at a workbench. You’ll never believe it, but my tool handling still sucks. I’m improving, but only subtly — my layout is sloppy, cutter geometry is shaky, and I need to revisit my workholding setup entirely. Perhaps trying to teach myself the most difficult possible combination of techniques all at once was a bit ambitious. And the homemade tools? Fucking unwise. Thankfully I’m still making strides with the pencil studies. Will I ever be good enough to execute ornaments like these? No. Not the point.

My dad used to invite his friends over for steaks when he knew they’d be out of town. At the cost of a knowing wink, such hypothetical wins are basically as good as the real thing: you get credit for being pretty alright; maybe someone supposes you could’ve followed through if the situation were otherwise; who’s to say? One thing he learned that I clearly haven’t is that this strategy works better when you don’t post evidence of your dork-ass macaroni art and annotate it in the leading paragraph. Let’s forget that for a moment and appreciate my brave experiments with cross-shading instead.

15 notes

·

View notes