WOVEN WIRE MESH PROFESSIONAL MANUFACTURER: WEB WIRE MESH CO.,LTD.

Don't wanna be here? Send us removal request.

Text

Copper wire mesh quality control from web wire mesh Web Wire Mesh has a professional inspection team that checks the quality of copper wire mesh before delivery. We test the material, wire diameter, hole size, mesh width, length, and other details. The copper wire mesh is 100% tested in our factory.

#web wire mesh#wiremesh#wire mesh#woven mesh#wire cloth#woven wire mesh#filter mesh#wirecloth#stainless steel mesh#copper wire mesh

0 notes

Text

As market demand changes, wire mesh companies are moving from "weaving" to "smart manufacturing." Wire mesh companies adopt smart production lines. Using IoT and big data, we can fully digitize production control. This will greatly improve efficiency and product quality. Smart weaving machines accurately control mesh size, and AI inspection systems detect defects in real time.

0 notes

Text

At the 14th International Bio-Fermentation Exhibition 2025 in Jinan, Web Wire Mesh proudly display a range of wire meshes and filtration products. With the excellent performance and innovative design, these wire mesh products attracted great attention from industry experts and potential customers.

0 notes

Text

How is sieve bend screen works

The sieve bend screen is an effective solution in size classification and dewatering.

Slurries are directed to the feed box, where they overflow onto the sieve bend screen. Here, the separation process unfolds, with water and smaller particles being separated from larger ones. These larger particles then proceed along the screen surface until the liquid is sufficiently removed.

The sieve bend screen provides greater capacity than flat wedge screens due to increased gravitational forces on material flowing against the curve, offering higher material throughputs.

#web wire mesh#wedge wire screen#wirescreen#sievebendscreen#sieve bend screen#stainless steel sieve bend screen

0 notes

Text

A customer from New Zealand inquired Web Wire Mesh seeking assistance with a specialized project. After some discussions, Web Wire Mesh successfully meets the customer's requirements

At Web Wire Mesh, we take pride in delivering exceptional service and ensuring customer satisfaction. We are dedicated to providing tailored solutions that meet our customers' unique requirements.

0 notes

Text

Why choose copper wire mesh

Copper mesh is a square weave mesh that is woven together by copper wires, which helps provide a good electrical and thermal conductivity. Copper is a very malleable and soft material which makes it easy to shape for many different applications.

Application for copper wire mesh including

EMI & RFI shielding industry,shielded room, enclosure box, faraday cage and laboratory shielded testing

Architectural & decorative industry

Petrochemical & chemical industry

Battery industry, as an current collectors part of fuel cells.

Filtration and separation applications

Fireplace screen

Insect screens & security mesh

0 notes

Text

Copper wire mesh compare

Pure copper is a material which is made of natural copper, there are also trace amounts of other elements so it cannot be said that pure copper is 100% copper. The approximation of natural copper in pure copper is 99.98%.

We stock a wide range of copper wire meshes.

Copper wire mesh compare

0 notes

Text

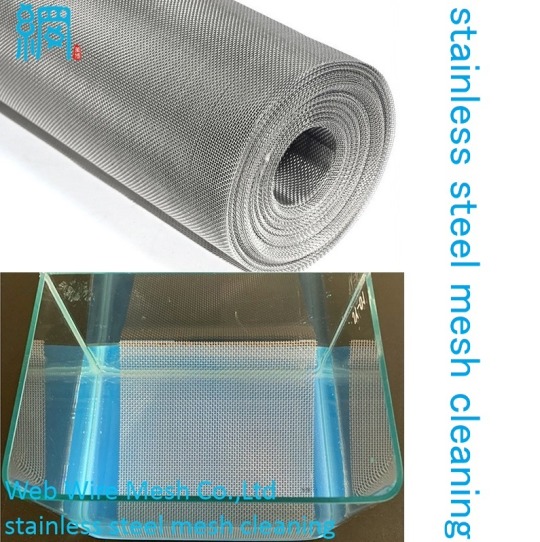

Stainless steel mesh quality control

0 notes

Text

How to test the stainless steel mesh is grade 304?

Generally speaking, it is impossible to identify the chemical composition of a stainless steel by visual check. We will hold a handheld analyzer used to determine the elemental composition of materials. This instrument is a non-destructive tester which has a 98.7% alloy grade identification accuracy.

We are also able to supply a mill certificate for the stainless steel mesh, if required.

0 notes

Text

Tips On How To Clean Stainless Steel Wire Mesh

As a leading manufacturer of stainless steel wire mesh, we know more than just a thing or two about how you can keep your supply of stainless steel wire mesh in good condition.

Generally speaking, stainless steel wire mesh should be cleaned using the following mesh cleaning solutions.

submerge stainless steel mesh in a water tank filled with mild detergent & warm water.

rinse it with clean water.

In addition, please pay more attention to the following three points

ensure gently scrubthe wire mesh with soft nylon brushes, while it is submerged in the detergent tank that helps to remove more stubborn contaminants.

Be sure to use commercial cleaners that contain phosphates.

After use cleaning methods & chemicals, the wire mesh should be rinsed thoroughly with clean water and gently blown dry.

0 notes

Text

Demister Pad Components

Demister pads also known as mist eliminator, they are made of knitted wire mesh pads with supports grids by welding processing.

The demister pad can be separated into several parts for easy installation and transportation. The component quantity will change according to the diameter of demister pad and equipment types.

Component numbers: 1 piece, 2 pieces, 3 pieces, multiple pieces.

0 notes

Text

The Common Classification of Knitted Wire Mesh

Classification by material: The knitted wire mesh can be made of various materials including steel wire, copper wire, brass wire, stainless steel wire, Monel wire, Nickel wire, polypropylene wire, polyethylene wire and others.

Classification by wire types: flattened wires or round wires.

Classification by form: flattened or crimped form.

Classification by filament:mono-filament and multi-filament wire.

Classification by technology: The knitted mesh is produced in rolls. For some applications,they can be compressed into different shapes, such as rectangular, round, ring etc

0 notes

Text

Which one is right for woven mesh vs welded mesh? Generally speaking, the application will determine whether you should use woven wire mesh or welded mesh. If the mesh is for filtration needs, the woven wire mesh is right for you. If the mesh is for shielding field, the woven mesh is best for you. As woven wire mesh is produced predominantly with stainless steel, which is too resistant to corrosive material, the fact that it often has smaller hole sizes than welded mesh should also be considered. If you are working with rugged material that requires a mesh that is sturdy and durable, welded wire mesh may be a good fit. Welded mesh is also a good fit for extremely corrosive conditions as it can be galvanized for extra protection.

0 notes

Text

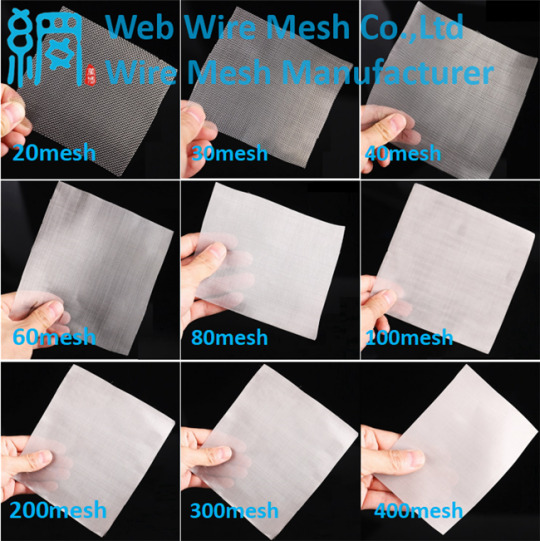

How to choose the woven wire mesh for making filter discs Generally, the 20mesh to 500mesh (the number of wires per inch) woven wire mesh is the commonly used mesh for making filter discs The 20 mesh to 40mesh is much heavy mesh for filter discs; The 40mesh to 200 mesh is light mesh for filter discs; The 200mesh to 500 mesh is much finer mesh for filter discs.

#woven mesh#woven wire mesh#wirecloth#web wire mesh#wiremesh#stainless steel mesh#filter mesh#filter discs

0 notes

Text

www.webwirecloth.com

0 notes

Text

https://www.webwovenmesh.com

0 notes

Text

What are the applications of wire mesh

Common wire mesh applications are:

In the architectural & decorative industries, for the screen of window, door, fireplace and ceiling,facade etc.

In the EMI & RFI shielding industries, for shielded room, enclosure box, faraday cage and laboratory shielded testing.

In the water, oil & gas industries, for the raw material of filter element.

In the petrochemical & chemical industries, for test sieve and structured packing.

In battery industries, as an electrode substrates or current collectors part of fuel cells.

In the filtration and separation industries, for manufacturing filter discs, drum filters, leaf filters and cartridge filters.

In the automobile industries, for airbags, anti vibration and mufflers & silencers.

In the agricultural & food industries, for barbecue grills and pig raising screens.

In the mining & aggregate industries, for vibrating machine

#wire mesh application#architectural mesh#decorative mesh#EMI & RFI shielding mesh#filter element#battery mesh#filtration and separation mesh#food mesh#mining & aggregate mesh#vibrating screen#filter mesh#stainless steel mesh#copper wire mesh

0 notes