Hangzhou Zhiyu Magnetic Technology Co., Ltd. Is China Magnetic Components Factory, SmCo Permanent Magnetic Manufacturers. Custom Aluminum Nickel Cobalt, Magnetic Components.phone: +8619106729372email:[email protected]

Don't wanna be here? Send us removal request.

Text

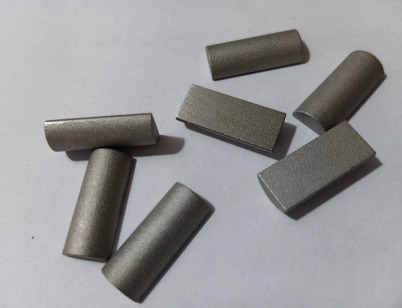

SMCO magnet assembly

We have various specifications of SMCO magnet assembly for magnetic pumps. If you need it, please contact us Contact With Us Send Email: [email protected] Call Anytime: +86 19106729372

0 notes

Text

Samarium Cobalt magnets

Samarium Cobalt magnets are a high-performance permanent magnetic material made of samarium (Sm) and cobalt (Co) as the main components. They have extremely high magnetic energy product and excellent temperature stability, and can maintain their magnetism in high temperature environments up to 350°C. SmCo magnets have excellent magnetic strength and corrosion resistance, so they are widely used in aerospace, military, medical equipment, precision instruments and high-end electronic equipment.

Contact With Us Send Email: [email protected] Call Anytime: +86 19106729372

0 notes

Text

Samarium Cobalt Permanent Magnet Material

Although the room temperature magnetic properties of Samarium Cobalt materials are inferior to those of NdFeB permanent magnet materials, their temperature resistance is more than 10 times that of sintered NdFeB permanent magnet materials. When the operating temperature exceeds 150°C, the magnetic energy product, coercive force and temperature stability of Samarium Cobalt magnets all exceed those of NdFeB magnets, making it the best temperature-resistant permanent magnet material currently available.

Contact With Us Send Email: [email protected] Call Anytime: +86 19106729372

0 notes

Text

Magnet for tooling (cube with ellipsoidal cavity in the middle) - SMCO-Grade33-6×4 (D2)×1.5

Product parameters: Magnet type: SMCO (Samarium Cobalt magnet) Grade: Grade 33 Shape: Cube (with ellipsoidal cavity inside)

Contact With Us Send Email: [email protected] Call Anytime: +86 19106729372

0 notes

Text

Magnetic Rotor Assemblies

The magnetic rotor assembly is one of the representative magnetic assemblies, and the rotor assembly is composed of metal parts and permanent magnets. In fact, depending on the application, motor type and assembly process, sintered neodymium magnets, sintered samarium cobalt magnets, bonded magnets and sintered ferrite magnets can all be used in the rotor assembly. It should be noted that laminated magnets made with magnet segmentation technology can also be used in assemblies to reduce eddy current losses.

Contact With Us Send Email: [email protected] Call Anytime: +86 19106729372

0 notes

Text

Permanent Magnet Motor Assembly Manufacturer

Motor is an electromagnetic device which achieves conversion between mechanical energy and electric energy via the magnetic field. The air gap magnetic field for electromechanical energy conversion can be produced by applying the electric current to excitation winding or utilize permanent magnet. Permanent magnet motor refer to those motor which utilize permanent magnetic field to instead excitation windings.

Contact With Us Send Email: [email protected] Call Anytime: +86 19106729372

0 notes

Text

samarium cobalt magnets

In motor applications, the high coercivity of samarium cobalt magnets means that they can generate a strong magnetic field, which is essential for improving the efficiency and performance of motors. At the same time, samarium cobalt magnets can still maintain good magnetic properties in high temperature environments, which makes them particularly suitable for motors that need to work under high temperature conditions. In addition, samarium cobalt magnets also have good low-temperature stability and corrosion resistance, and can be used for a long time in harsh working environments without affecting their magnetic properties.

Contact With Us Send Email: [email protected] Call Anytime: +86 19106729372

0 notes

Text

Magnetic Stator Assemblies

Magnetic stator assemblies is also a representatives magnetic assembly,consisting of housing and permanent magnet which similar like magnetic rotor assembly. Permanent magnets are mounted on the housing, then housing working as the magnetic yoke to a form a magnetic circuit.

Contact With Us Call Anytime: +86-191 0672 9372 Send Email: [email protected]

0 notes

Text

Sintered NdFeB Magnet

Sintered NdFeB magnet is prepared by the raw materials being melted under vacuum or inert gas atmosphere in an induction melting furnace and processed in the strip caster and thus cooled to form alloy strip. The strips are crushed and pulverized to form a fine powder ranging from 3 to 7 microns in particle size. The powder is subsequently compacted in an aligning field and sintered into dense bodies. The blanks are then machined to the specific shapes, surface treated and magnetized.

Contact With Us Call Anytime: +86-191 0672 9372 Send Email: [email protected]

0 notes

Text

SMCO MAGNET-Grade28-R77×R70×17.94°×L66-Ni Coating

High-performance SMCO (Samarium Cobalt) permanent magnets, with specifications of 28 grades - R77×R70×17.94°×L66, are designed for high-demand application scenarios. The magnet adopts advanced manufacturing technology to ensure excellent and stable magnetic properties, and is covered with a layer of high-quality nickel coating on the surface, which effectively improves its corrosion resistance and environmental adaptability and extends its service life.

Grade and specification: Grade 28, the diameter gradually changes from R77mm to R70mm, the angle is accurate to 17.94°, and the length reaches L66mm. The size is precise and meets the needs of precision assembly. Material characteristics: High-purity Samarium Cobalt material is selected, which has high remanence, high coercivity and excellent temperature stability. It can maintain stable magnetic properties even in high temperature environments and is suitable for a variety of extreme working environments. Surface treatment: The surface is treated with precision nickel coating, which is not only beautiful, but also greatly enhances the anti-oxidation and anti-corrosion capabilities, and is suitable for long-term use in outdoor or humid environments.

Application fields: Widely used in high-tech fields such as motors, sensors, instruments and meters, medical equipment, aerospace, etc., it is a key component to improve equipment performance and ensure stable operation.

0 notes

Text

Arc SmCo magnet

SMCO-Grade24H-R11.3×R10.3×45°×38

Arc SmCo magnet is a high-performance, high-temperature resistant rare earth permanent magnet material, mainly made of samarium (Sm) and cobalt (Co) alloy. Due to its excellent magnetic properties and excellent temperature stability, it is widely used in fields that require high magnetic force and harsh working conditions, such as aerospace, military equipment, automotive industry and high-precision sensors.

This magnet has the following advantages:

High magnetic energy product: The arc SmCo magnet has a high magnetic energy product and can provide strong magnetic force in a small volume.

Excellent temperature stability: It can still maintain stable magnetism in high temperature environment, and the working temperature can reach above 300℃, which is suitable for extreme conditions.

Strong corrosion resistance: Due to the characteristics of the material, it has excellent corrosion resistance and is not easy to oxidize, reducing the need for coating or other protective measures.

0 notes

Text

Magnets for compressor motors

Equipped with our magnets, the compressor motor can respond instantly and output strong and stable power, significantly improving work efficiency. Its characteristics of high remanence and high coercivity ensure that the motor maintains high efficiency during long-term operation, effectively reduces energy consumption, and brings considerable operating cost savings to users.

0 notes

Text

SMCO-Grade32-D20×6

High-performance magnetic materials: high-quality rare earth magnetic materials are selected, which have extremely high magnetic energy product and coercive force, ensuring that the magnet has strong magnetic attraction and stable magnetic field during use. Precision manufacturing process: advanced magnetic material forming technology and precision processing technology are adopted to ensure the dimensional accuracy and surface quality of the magnet, and meet the needs of the fixture for high-precision magnets. Excellent stability: the magnet has been specially treated, has good temperature stability and corrosion resistance, and can maintain stable magnetic properties in various harsh environments. High reliability: after strict quality inspection and performance testing, it is ensured that the magnet has extremely high reliability and safety during use.

High efficiency and energy saving: high-performance magnetic materials ensure that the magnet has higher energy density and lower energy consumption during use. Easy to install: the magnet adopts a standardized design, which is easy to integrate and install with various fixtures and fixtures. Long life: excellent stability and corrosion resistance give the magnet a longer service life and lower maintenance cost.

High-performance magnets for fixtures are high-quality magnet products that integrate high performance, high precision and high stability. Whether you are looking for an efficient magnet that can improve fixture performance, or want to provide strong support for industrial automation and precision manufacturing industries, this magnet is your rare choice.

Contact us: Call Anytime: +86-191 0672 9372 Send Email: [email protected]

0 notes

Text

Automotive SmCo magnets

Automotive magnets are made of advanced rare earth permanent magnet materials, with extremely high magnetic energy product and coercive force, ensuring stable magnetic properties under complex and changing road conditions. The products undergo strict quality control and performance testing to ensure perfect matching with various automotive power systems and escort your driving experience.

High-performance magnetic materials: rare earth permanent magnet materials are used, with extremely high magnetic energy product and coercive force, ensuring that the magnets maintain stable magnetic properties during long-term use. Precise matching: For different models and power systems, we provide customized magnetic steel products to ensure perfect matching with your car and achieve the best power output and stability. Durable: The products undergo strict quality control and durability testing to ensure that they can maintain stable performance and extend their service life in harsh environments.

Safe and reliable: We focus on the safety performance of our products and use advanced production processes and materials to ensure that the magnets will not have adverse effects on other parts of the car during use.

Contact us Email : [email protected] Phone : +86-191 0672 9372

0 notes

Text

About ZHIYU round magnets

🚀 Explore the mystery of magnetism Round magnets, as a symbol of magnetism, contain the wonder and mystery of nature. Every contact with iron products seems to tell a story about attraction. Its magnetism is strong and stable, whether it is used as a teaching tool or a daily necessities, it can bring us endless surprises and fun.

🌀 Diverse functions and wide range of uses Round magnets have a variety of uses. They can not only be used as toy magnets and scientific experiment tools, but can also be used in medical, mechanical, electronic and other fields. Whether it is adsorbing iron objects or serving as the core component of electromagnetic equipment, round magnets play an indispensable role.

💡 Exquisite design and excellent quality We select high-quality magnetic materials, undergo fine processing and strict testing to ensure that each round magnet has excellent magnetic force and stable performance. Its exquisite design and rounded appearance are not only beautiful and elegant, but also easy to hold and operate.

🌱 Environmentally friendly, safe and trustworthy We pay attention to environmental protection and safety. All round magnets are made of non-toxic and harmless materials and comply with international safety standards. You can use it with confidence and enjoy every moment with the magnetism.

0 notes

Text

Cast AlNiCo Magnet

Cast AlNiCo magnets are produced by common casting process. AlNiCo 5 is one of the commonly used grades. Molten alnico alloys with different chemical compositions are melted through an induction furnace and poured into a resin bonded sand mold, then the solidified material with a rough surface will undergo a heat treatment and cooling process.

0 notes

Text

SmCo Arc Magnet

Almost all of arc magnet is served for both rotor and stator in permanent magnet (PM) motor, generators, and magnetic coupling devices.

0 notes