#3D printed structure

Explore tagged Tumblr posts

Text

The Value of a Residential Estimating Service in 3D Printed Home Construction

The rise of 3D printed homes is revolutionizing the construction industry. By using additive manufacturing technology, builders can create homes with greater precision, less waste, and reduced labor costs. However, while the technology promises cost savings, the unique nature of 3D printed homes requires specialized budgeting and planning to ensure projects are financially viable. A residential estimating service plays a crucial role in this process by helping to forecast accurate costs, accounting for the intricacies and potential challenges that arise in 3D printed home construction.

As 3D printing technology continues to evolve, homeowners and developers need reliable estimating services to navigate the complexities of this innovative construction method. These services help ensure that projects stay within budget while meeting quality standards and project timelines.

Understanding 3D Printed Home Construction

3D printing in home construction involves the use of a printer to create walls, floors, and other structural components layer by layer. The primary materials used in 3D printing for homes include concrete, clay, or composites, with printers capable of creating intricate designs that traditional methods cannot easily replicate.

While 3D printing offers numerous advantages—such as rapid construction, reduced labor, and customization options—its costs can vary significantly. Factors such as material choice, print size, project complexity, and technology specifications all impact the overall cost of a 3D printed home.

Budgeting for 3D Printing Materials

One of the primary considerations in estimating the cost of 3D printed homes is the material used. The quality, type, and quantity of the material play a major role in determining the total cost of the build. Concrete, often used in 3D printing due to its strength and durability, is typically more affordable than other materials, but the cost can still fluctuate depending on the supplier and local availability.

A residential estimating service helps clients understand the cost implications of using various 3D printing materials. The estimator will provide a detailed breakdown of material costs, considering factors such as material waste, transportation, and handling fees. Since the technology is still relatively new, these costs may not always be predictable, making an expert estimator’s role all the more vital in forecasting potential variances.

Labor and Printing Time Considerations

While 3D printing eliminates many manual construction tasks, such as bricklaying and framing, there are still labor costs associated with setup, monitoring the printing process, and post-printing tasks. The process of setting up the printer, maintaining equipment, and overseeing quality control requires skilled labor. The printing itself, although automated, is not instantaneous and can take days or even weeks depending on the complexity of the design.

A residential estimating service accounts for these labor costs and the printing time, which can be significantly different from traditional construction projects. The estimator can calculate labor costs for monitoring, troubleshooting, and finishing tasks, ensuring that these costs are incorporated into the budget. They also take into account any additional time required for material delivery, setup, and calibration.

Design Flexibility and Customization

One of the most attractive aspects of 3D printed homes is their design flexibility. With the ability to create complex, customized shapes and structures, 3D printing allows for architectural freedom that traditional construction methods often cannot achieve.

However, this flexibility can impact the budget. More intricate designs may require more material or longer printing times, leading to higher costs. A residential estimating service evaluates the design’s complexity and integrates these factors into the overall estimate. By balancing custom features with cost constraints, the estimator ensures that the project’s design vision aligns with the budget.

Site Preparation and Foundation Costs

Although 3D printing reduces the amount of manual labor required during construction, site preparation remains a crucial part of the process. Depending on the location, this could involve clearing the land, leveling the site, and ensuring the foundation is properly prepared to support the printed structure.

For a 3D printed home, the foundation typically consists of a reinforced concrete slab, which must be poured and cured before printing can begin. The residential estimating service accounts for these additional costs and provides a clear picture of what needs to be done to prepare the site. This includes evaluating soil conditions, assessing the need for grading, and determining the cost of the foundation installation.

Regulatory and Permit Costs

Like traditional construction, 3D printed homes must comply with local building codes and regulations. In some areas, building codes may not yet address 3D printed structures, making it necessary to consult with local authorities and engineers to ensure that the construction meets safety and code standards.

The residential estimating service plays a key role in navigating these regulatory challenges. The estimator helps identify the necessary permits, certifications, and inspections required for a 3D printed home, and factors these into the overall project budget. This helps avoid costly delays caused by missing permits or non-compliance with regulations.

Maintenance and Long-Term Durability

While 3D printed homes offer a unique and innovative building solution, homeowners and builders must also consider the long-term durability and maintenance of the materials used. 3D printed homes are generally built to last, but depending on the material used, they may require specific maintenance or repairs over time.

A residential estimating service can factor in the cost of maintaining the home in the future. For example, if the home is constructed with concrete or composite materials, the estimator will consider the potential for cracking, erosion, or other wear-and-tear issues. This long-term perspective helps homeowners budget for future repairs or upgrades that may be needed after construction.

Conclusion

The rise of 3D printed homes presents both exciting opportunities and unique challenges. While the technology promises cost savings and design freedom, accurately budgeting for a 3D printed home requires a detailed understanding of the materials, labor, site preparation, and regulatory considerations involved. A residential estimating service offers valuable expertise in these areas, helping homeowners and developers navigate the complexities of 3D printed home construction while staying on budget.

By providing a clear, comprehensive estimate, residential estimators ensure that all aspects of the project—from the initial design to the final finishing touches—are accounted for. With their help, homeowners can confidently embrace this innovative construction method while avoiding unexpected costs or delays.

#residential estimating service#3D printed homes#additive manufacturing#3D printing materials#construction budgeting#customized home design#concrete printing costs#labor for 3D printing#site preparation for 3D homes#3D printing labor#home foundation costs#regulatory compliance#building code for 3D printed homes#printing time budgeting#home design flexibility#customized home construction#printing equipment setup#3D printed structure#material waste costs#home permit fees#architectural freedom#future home maintenance#3D home durability#building with composites#3D printing in construction#site grading costs#local construction regulations#3D printed home foundation#labor for finishing#project timeline costs

0 notes

Text

Nathan Smith

41 notes

·

View notes

Text

not to be continuously stereotypical representation of the nonbinary bisexual community but I am once again working on a fursuit head

#guess the animal#I bought a 3d printed base#previously I've only used foam#idk how to attach the nose???#I guess some serious hardcore glue?#foam is easier#but this is really neat#it's structural without having a ton of thick foam#and the nose is also 3d printed

3 notes

·

View notes

Text

What Is a Bill of Materials?

Bill of Materials (BOM) is a detailed list of all the materials and components needed to complete the pre-engineered building. PEBs are buildings that are manufactured at the factory and assembled and erected at the site. Structural design consultants for factories must provide an accurate, comprehensive BOM for proper, timely procurement, fabrication and erection of the PEB.

3 notes

·

View notes

Text

Bring Your Ideas to Life with Brisbane's Leading 3D Printing Services

As a leader in 3D printing service Brisbane, industrial design Brisbane, and plastic engineering services Brisbane, Red Labs provides a comprehensive suite of services tailored to meet the needs of engineers, designers, and manufacturers. Whether you're working on a complex prototype, a structural framework, or a custom component, our advanced capabilities can bring your ideas to life with unmatched precision and speed.

Comprehensive 3D Printing Service Brisbane

Our 3D printing service in Brisbane is designed to deliver rapid, accurate, and cost-effective solutions. From functional prototypes to high-quality end-use parts, we utilize state-of-the-art additive manufacturing technologies, including Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Our expert team ensures every detail is perfected, from material selection to final finishing.

Benefits of our 3D printing services include:

Rapid prototyping for faster product development

High precision and dimensional accuracy

Cost-effective production with minimal waste

Complex geometries made possible without traditional tooling

Innovative Industrial Design Brisbane

Our industrial design Brisbane team combines creativity with technical expertise to transform your concepts into market-ready products. We focus on ergonomics, aesthetics, and functionality, ensuring that your product not only stands out but also performs exceptionally in real-world conditions.

Services include:

Concept development and sketching

CAD modeling and 3D visualization

Design for manufacturing (DFM) and assembly (DFA)

User experience and usability testing

Precision Sheet Metal Design Brisbane

For projects requiring robust metal components, our sheet metal design Brisbane services are second to none. We handle everything from initial design through to fabrication, using advanced CAD software and precision machining. Our sheet metal solutions are perfect for custom enclosures, brackets, and structural supports.

Advantages of choosing our sheet metal design services:

High strength-to-weight ratios

Versatile material options, including aluminum, stainless steel, and mild steel

Tight tolerances for critical applications

Efficient and repeatable production processes

Expert CAD Drafting Services Brisbane

Accurate technical drawings are the foundation of any successful engineering project. Our CAD drafting services Brisbane ensure that every line, curve, and dimension is meticulously planned and executed. We provide detailed 2D and 3D CAD drawings that are fully compatible with industry standards, ensuring seamless integration into your manufacturing processes.

Key benefits:

Precision designs for complex components

High-quality digital files for CNC machining and 3D printing

Reduced design errors and production delays

Comprehensive support for mechanical and structural designs

Reliable Structural Drafting Brisbane

Structural integrity is crucial for any construction or engineering project. Our structural drafting Brisbane services are tailored to deliver accurate and detailed blueprints for everything from small components to large-scale structures. We work closely with engineers and architects to ensure every detail is structurally sound and compliant with Australian standards.

Services include:

Steel detailing and connection designs

Reinforced concrete detailing

Structural steel layouts and assembly drawings

3D modeling and clash detection

Plastic Fabrication Experts Brisbane

Our plastic fabrication Brisbane services provide bespoke solutions for industries ranging from medical devices to automotive components. We specialize in custom plastic parts, ensuring high durability, chemical resistance, and lightweight designs. Our capabilities include vacuum forming, CNC machining, and precision cutting.

Why choose our plastic fabrication experts Brisbane?

Custom designs to fit exact specifications

Wide range of plastic materials, including acrylic, polycarbonate, and HDPE

Quick turnaround times with competitive pricing

Exceptional quality and durability for demanding applications

Plastic Engineering Services Brisbane

For businesses looking for specialized plastic engineering services Brisbane, we offer comprehensive support from initial design through to final production. Our engineers have extensive experience in plastics, ensuring optimal material selection, strength analysis, and cost-efficient manufacturing processes.

Key advantages:

Innovative solutions for complex challenges

Advanced material knowledge for superior product performance

In-house testing and quality assurance

Cost-effective, scalable production

Why Choose Red Labs for Your Engineering and Manufacturing Needs?

Plastic Fabrication Experts Brisbane- At Red Labs, we pride ourselves on our commitment to quality, precision, and customer satisfaction. With a full range of services, including 3D printing service Brisbane, industrial design Brisbane, sheet metal design Brisbane, CAD drafting services Brisbane, structural drafting Brisbane, plastic fabrication Brisbane, and plastic engineering services Brisbane, we are your one-stop solution for all your design and manufacturing needs.

Contact Us Today

Ready to bring your ideas to life? Contact Red Labs for a consultation and see how we can support your next project with world-class engineering and manufacturing services.

#3d printing service Brisbane#Industrial Design Brisbane#Sheet Metal Design Brisbane#CAD Drafting Services Brisbane#Structural Drafting Brisbane#Plastic Fabrication Brisbane#plastic engineering services brisbane#plastic fabrication experts brisbane

1 note

·

View note

Text

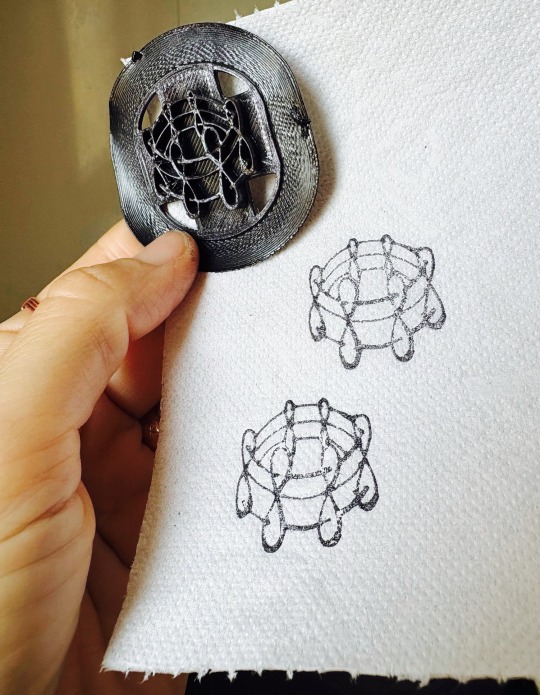

3D Printing Fun: My Benzene Molecule Stamp

As a pharmacist and artist, I love combining chemistry with creative expression. Recently, I took one of my illustrations—a benzene molecule with its ring and p-atomic orbitals—and transformed it into a functional 3D-printed stamp. The process started with vectorizing my original drawing, then bringing it into Blender to create a 3D model. Actually, I designed it as a polymer clay cutter, but I…

View On WordPress

#3d print#3D printed stamp#3D printing with TPU#Benzene molecule illustration#Blender for 3D printing#Chemistry-inspired art#Creative scientific projects#Custom 3D printed stamps#DIY block printing#Experimental printmaking#Handmade chemistry prints#Molecular structure stamp#Science and art fusion#Toilet paper block printing#TPU stamp printing#Vector to 3D print workflow

0 notes

Text

Recyclable Stretchable Plastic created through 3D Printing for Multiple Applications

Researchers have used a 3D printing process to manufacture a novel material that is elastic, flexible, and recyclable. The material, which is composed of thermoplastic elastomers, is believed to provide products adjustable stiffness and flexibility. The method is appropriate for industrial application since it blends scalability and cost-effectiveness. According to studies, these developments are…

#3D printing#featured#medical devices#Nanoscale Structure#prosthetics#sciencenews#soft robotics#wearable electronics

0 notes

Text

Beyond Earth | The Role of a Construction Cost Estimating Service in Lunar and Space Habitat Projects

Introduction

As humanity expands its reach beyond Earth, construction is no longer confined to terrestrial landscapes. Ambitious plans from space agencies and private firms alike aim to establish permanent habitats on the Moon and even Mars. While the science behind these missions often takes the spotlight, one fundamental challenge remains critical: budgeting. In this futuristic context, a construction cost estimating service becomes as vital as propulsion systems and life support. Estimating construction costs for lunar habitats is an emerging discipline, bridging engineering, logistics, and economics in an entirely new domain.

The Challenges of Off-Earth Construction

Unlike conventional building environments, lunar and space habitats face extreme constraints. Materials must survive radiation, microgravity, and vacuum conditions. Transporting building supplies from Earth is immensely expensive, with every kilogram costing thousands of dollars. Labor is automated or conducted by astronauts under high-risk conditions, making precision in planning and budgeting non-negotiable.

Traditional construction cost estimating services cannot simply extend their models to space without modification. New frameworks must address entirely different metrics—launch mass, fabrication in zero gravity, and material behavior in non-Earth atmospheres.

Reimagining Cost Inputs in Space Projects

In terrestrial construction, estimators consider land acquisition, local labor rates, and weather impacts. In space, the variables are starkly different. A specialized construction cost estimating service must adapt to factors such as:

Launch weight penalties: Every extra kilogram impacts rocket fuel costs. Estimators must calculate mass-efficient solutions and include cost-benefit analyses for lighter or in-situ materials.

In-situ resource utilization (ISRU): Using lunar regolith or Martian soil to build structures cuts down transport costs. Estimators must model these savings accurately.

Automation and robotics: Much of space construction will rely on robotic systems. Estimating the cost of custom hardware, maintenance, and redundancy becomes crucial.

Habitat resilience: Structures must withstand radiation, micrometeorites, and thermal extremes. These safety requirements inflate material and engineering costs, demanding specialized forecasting.

Material Considerations and Transport Costs

Earth-based construction has access to a broad array of materials, suppliers, and delivery options. For lunar or Martian projects, the first cost hurdle is transport. A construction cost estimating service operating in this context must begin by assessing:

The cost of launching construction components via existing heavy-lift vehicles

The modular breakdown of prefabricated structures to fit within payload constraints

Opportunities to 3D-print using local materials, which introduces cost advantages but also new maintenance and reliability factors

These estimators must also calculate the cost implications of redundancy. In space, failure is not an option—spare parts and fail-safes must be factored into every budget.

Design and Engineering Collaboration

Close collaboration between cost estimators and aerospace engineers is essential. Every design decision affects cost exponentially. For example, selecting a spherical habitat design for its structural efficiency in resisting external pressure may reduce material volume but increase fabrication complexity.

A construction cost estimating service can simulate different design choices and their cost trajectories under space conditions. This collaborative feedback loop is essential for mission planners aiming to balance safety, performance, and financial feasibility.

Examples from Current Space Programs

NASA’s Artemis program and private initiatives like SpaceX’s Starship project are rapidly advancing the potential for lunar bases. While public estimates exist for mission costs, the actual construction phase of lunar surface infrastructure remains largely theoretical.

However, testbeds such as the Mars Dune Alpha habitat—being built on Earth to simulate Martian conditions—already employ advanced cost estimation to determine long-term feasibility. These prototypes rely on construction cost estimating services that consider both Earth-based costs and extrapolated values for deployment beyond our atmosphere.

Predictive Modeling and Future-Proofing

Because space construction is largely untested, predictive modeling is crucial. Cost estimators use probabilistic modeling to account for unknowns: delays due to solar events, failure rates of equipment, or advances in propulsion that may alter transport costs.

As technology evolves, future cost estimates must also be adaptable. For instance, the development of reusable rockets or on-site robotic assembly could drastically reduce certain costs while introducing others. Construction cost estimating services must remain flexible and continuously update their models as aerospace capabilities advance.

Sustainability and Lifecycle Costing in Space

Even in the vacuum of space, sustainability matters. Space habitats must function autonomously for extended periods. Estimators must assess the full lifecycle costs of structures: how often components need replacement, what energy systems are most efficient, and how waste is managed.

Just as on Earth, lifecycle costing helps mission planners make sustainable, long-term decisions that reduce risk and optimize investment. For space projects, these estimations are even more critical due to the complexity of repair and maintenance operations in extreme environments.

Conclusion

As we push the boundaries of civilization into outer space, the disciplines of architecture and construction must evolve—and with them, the role of cost estimation. A construction cost estimating service tailored to lunar and space habitats isn't just a support function; it's a foundation for feasibility, safety, and sustainability. By integrating mass constraints, ISRU, robotics, and life-support durability into their projections, these services help chart a financially viable path to our off-Earth future.

#lunar construction costs#space architecture#moon base budgeting#space habitat estimates#construction cost estimating#in-situ resource use#rocket payload cost#Mars construction service#space building materials#off-Earth housing#robotic assembly cost#space station budgeting#habitat resilience#micrometeorite protection#zero gravity building#deep space estimation#NASA habitat costs#3D printing in space#cost of lunar regolith#radiation shielding budget#construction logistics in space#Artemis mission budgeting#Starship construction planning#off-planet living costs#orbital structure estimating#astronaut construction safety#future of building#sustainable space design#extraterrestrial housing#space economy planning

0 notes

Text

mit x steelcase

5 notes

·

View notes

Text

Researchers create 3D printed, biodegradable, color-changing conductive material from cellulose

An elastic material that changes color, conducts electricity, can be 3D printed and is also biodegradable? That is not just scientific wishful thinking: Empa researchers from the Cellulose & Wood Materials laboratory in Dübendorf have produced a material with these exact properties on the basis of cellulose and carbon nanotubes. The work is published in the journal Advanced Materials Technologies. The researchers started with hydroxypropyl cellulose (HPC), which is commonly used as an excipient in pharmaceuticals, cosmetics and foodstuffs, among other things. When mixed with water HPC is known to form liquid crystals. These crystals have a remarkable property: Depending on their structure—which itself depends on the concentration of HPC, among other things—they shimmer in different colors, although they themselves have no color or pigment. This phenomenon is called structural coloring and is known to occur in nature: Peacock feathers, butterfly wings and chameleon skin get all or part of their brilliant coloration not from pigments, but from microscopic structures that "split" the (white) daylight into spectral colors and reflect only the wavelengths for specific colors.

Read more.

#Materials Science#Science#Cellulose#3D printing#Biodegradable#Electrical conductivity#Structural color

36 notes

·

View notes

Text

Like part of me still wants to give 3d printing a shot but I can't ignore the part of my brain telling me in the same amount of time it would take to get a 3d print to work I could have sculpted, molded and made several copies of the same thing and I would have enjoyed the process significantly more

#i feel like even if i cheaped out and made hollow resin castings they would still probably be stronger than something with print layers#i know enough about 3d printing to know that 3d printed plastic has terrible shear strength across the print layers#kind of like wood grain#and like with wood grain it impacts what structures are possible or can make certain shapes particularly weak#like maybe im overestimating how fast i can do those steps#but id rather be doing that than sitting for 10 hours just to find out i have to start again and wait another 10 hours#to say nothing of the cost and learning curve and plastic waste#i feel like the speed of these things are overstated by people who dont have other making skills#i would rather be sculpting clay or gluing plastic together and making molds than 3d modeling and wrestling a cnc machine with a Z axis#maybe printers have gotten better lately but generally you dont get a perfect part in the first attempt#you cant just mash go and walk away either prints can fail halfway through#like even if i absolutely had to 3d print a part to make sure it was correct it would still be faster to mold/cast copies#than to repeat a 12 hour print#then you have to deal with smoothing the print lines

0 notes

Text

Structural Engineering Design Services

In UAE

Our Services as Freelance

#structural#3d printing#design#seo services#freelance#sketch#drawing#interiors#animation#urban#home#city#nature#decor

0 notes

Text

This one was a little silly, I bought a vintage Easy Weaver loom on a road trip and it was pre-warped with wool yarn that was slightly disintegrating but I was able to weave with it in the car ^-^; It's not my usual taste but it'll be a good reference as a color gamp.

Finished: ~10/4/24

Warp: ancient wool yarn :l

Weft: terrible terrible yarn

Dent: 8 (i think)

Structure: plain weave

Notes: I love this as a travel loom and I actually want to make some modifications like adding an apron bar (currently just has velcro to hold the yarn in place) and 3d printing more heddles in different dents. I found mine for $20 so definitely a fun little loom to try if you want something small.

3K notes

·

View notes

Text

I love that Bridgerton just went "fuck your historical accuracy, I want to do Art Deco and neon embroidery on a Regency silhouette with a Rococo wig and 3D printed structures inspired by Alexander McQueen- and if you flinch, I'm also adding fairy lights -aaah, excellent, I saw a flinch, bring me my mechanised LED swans"

I'm eating the entire plate, asking for seconds, begging the chef to marry me, and throwing peas at whoever complains

9K notes

·

View notes

Text

love sitting in my couch for an hour and a half distinctly Not Doing my work. why am i listening to no hands by waka flocka flame i need to make a building by noon tomorrow

#i am also Boiling this computer is so hot rn#pray for me !!#im at the point where i cannot edit the structure anymore or else it literally will not be done in time to submit next week.#manifesting i can get my 3d printing to work out my friend said he would help me and i am very much counting on that rn T-T#the thought of having to make this by hand is terrifying <3#lee's bullshit

0 notes