#3d scanning solutions

Explore tagged Tumblr posts

Text

1 note

·

View note

Text

Top providers for 3D printing Services in Malaysia.

Projet Technology : This company provides 3D printing services catering to individuals, industrial, and educational institutions. While they are one of the leading 3D printing service providers in Malaysia, they also provide their services to hobbyists nationwide. They offer prototyping, production, and customization services using a range of materials. Projet is Malaysia’s reliable, one-stop 3D printing service provider. WEBSITE : http://projet.my

Why Choose Projet.my for Rapid Prototyping and 3D Printing in Malaysia?

Cutting-Edge Technology: At Projet.my, we leverage cutting-edge 3D printing technology to deliver unparalleled precision and quality in every prototype. Our state-of-the-art machinery ensures that your designs are brought to life with utmost accuracy, allowing for seamless iterations and improvements.

Custom Solutions:

No two projects are alike, which is why we offer tailor-made solutions to suit your specific needs. Whether you require intricate prototypes for product testing or high-volume production runs, our team at Projet.my is equipped to handle it all with finesse.

Speedy Turnaround:

Time is of the essence in the world of product development. With Projet.my, you can expect swift turnaround times without compromising on quality. Our streamlined processes and efficient workflows ensure that your prototypes are delivered promptly, giving you the edge in today’s competitive market.

Rapid Prototyping & 3D Printing Service Malaysia | Projet.my

Cost-Effective Solutions: We understand the importance of cost-effectiveness in every project. That’s why we offer competitive pricing options without compromising on the quality of our services. With Projet.my, you can achieve cost-effective solutions that meet your budgetary requirements without sacrificing on excellence.

Expert Guidance:

Navigating the world of rapid prototyping and 3D printing can be daunting, but fear not — our team of experts at Projet.my is here to guide you every step of the way. From initial concept to final production, we provide comprehensive support and expertise to ensure your project’s success.

Rapid Prototyping:

From concept to prototype, we specialize in rapid prototyping services that help you iterate quickly and efficiently. Whether you’re testing new designs or refining existing ones, our rapid prototyping solutions are designed to accelerate your product development process.

3D Printing:

Our advanced 3D printing capabilities allow for unparalleled precision and detail in every print. Whether you need functional prototypes or intricate models, our 3D printing services deliver exceptional results that exceed expectations.

Customization:

We understand that every project is unique, which is why we offer customizable solutions to meet your specific requirements. Whether you need bespoke materials, finishes, or design modifications, our team at Projet.my is dedicated to bringing your vision to life with precision and care.

#3d printing#3dprintingservice#additivemanufacturing#malaysia#penang#3d scanning services#3d printing service#rapid prototyping#fabrication#solution

2 notes

·

View notes

Text

Revolutionizing Quality Control with Robotic Inspections: The Dynalog Difference

In a manufacturing world that moves faster than ever, achieving precision, quality, and efficiency is no longer optional; it is mandatory. As industries gain automation and production lines gain speed, the need for innovative solutions such as robotic inspection has grown exponentially. This is why Dynalog-US has a significant role in the industry by coming to the forefront with unique robotic inspection systems that will change the framework of how businesses keep their production consistent and quality maintained.

What is Robotic Inspection?

Robotic inspection is using automated robots to inspect, measure, and validate parts or products before or after the production process. These robots will have sensors, cameras, and software that can detect minor defects, deviations, or inaccuracies that human inspectors may overlook.

Unlike traditional inspection processes, robotic inspection provides various elements such as consistent, high speed, and extremely accurate capabilities to make sure every product meets exact specifications. Robotic inspections are rapidly becoming important aspects of the manufacturing process in automotive, aerospace, electronics, or heavy machinery.

Why Choose Dynalog for Robotic Inspection?

Dynalog-US is far more than a robotics company. For decades, we have led the way in robot calibration, robot performance testing, and now into robotic inspection. The systems are engineered to not just find defects but also give actionable data to help manufactures improve their overall production method and process.

Here are some of the reasons Dynalog is different:

1. True Accuracy

At Dynalog we have developed robotic inspection solutions that are designed to be exact. Using technologies such as 3D laser scanning and enhanced vision systems, we can find defects to a fraction of a millimeter. This data helps manufacturers confirm that each component is built exactly to specifications to avoid the consequences of recalls and warranty claims.

2. Real Time Data Feedback

Dynalog robotic inspection excels in providing real time inspection feedback. Our robotic inspection systems are capable of not only finding defects, they can evaluate them instantly and report them to the operators, or manufacturing execution systems (MES). This instantaneous feedback allows manufacturing teams to correct the defect immediately while the robot is still inspecting, thus avoiding downtime, and preventing any defective products from continuing down the manufacturing process.

3. Flexibility In Manufacturing

Every industry has different challenges, whether it's challenging aerospace components, sensitive medical devices, or rugged automotive and electronics-derived components, they all have difficulties in meeting specifications. Robotic inspection is rapidly becoming the answer to not only inspection but preventative quality failure.

The Future of Robotic Inspection

As manufacturing technology advances, it will also place new and different demands and challenges on inspection systems. The future clearly points to more automation in the robotic inspection process, more integrated and smarter AI, and better systems for identifying defects and defects types.

Dynalog is already ahead of these trends- we have invested heavily in R&D so our robotic inspection solutions are at the forefront of emerging technology. Our mission is straightforward: we want to help companies maintain the highest quality product standards while improving efficiency and reducing costs.

There are trends already shaping the future of robotic inspection like:

AI-Driven Defect Recognition: Using machine learning to help robots better recognize complex or rare defects.

Better 3D Scanning: Work will be done to increase the speed and resolution of 3D scans for better inspections.

Predictive Maintenance: As robotic inspection technologies will be looking for defects and determining quality, our robotic inspectors may also be suggesting when machines on the line are in need of maintenance.

Simply put, when working with Dynalog because they are creating tomorrow’s solutions, today!

Uses of Dynalog's Robotic Inspection Systems

Dynalog's systems are utilized in a diverse range of industries.

Here are some examples: Automotive: Inspecting car bodies, engines and transmission components for dimensional accuracy and surface imperfections.

Aerospace: Verifying the requirements of critical components are satisfied meeting the strictest tolerances.

Electronics: Inspecting PCB assemblies and electronic enclosures for microscopic defects.

Medical Devices: Ensuring the careful manufacturing of life-saving equipment.

Heavy Equipment: Ensuring alignment and integrity of large complex parts.

These examples illustrate the importance of robotic inspection in safeguarding brand reputation and providing reliability to users.

Why Robotic Inspection Makes Sense Financially

The implementation of robotic inspection isn't only about achieving higher quality — it is also financially beneficial. The major financial advantages are:Decreased Labor Costs: By employing an automated system, costly manual inspection teams can be avoided.Reduced Time to Market: With robotic inspection time in inspection is reduced which translates into shorter inspection and manufacturing cycles.Decreased Risk of Product Defects: Early detection of defects can prevent significant recalls or liability disputes.Increased Customer Satisfaction: By consistently manufacturing high-quality products, trust with customers is established and enhanced.

As the demands of modern manufacturing continue to increase robotic inspection has moved from a privileged option to an unquestioned requirement as a manufacturing partner. Companies that realize this will be better off in the long run.

#Robotic Inspection#Dynalog-US#Automated Quality Control#Industrial Robotics#Robot Inspection Systems#Precision Manufacturing#Automation in Manufacturing#Robot Calibration#Manufacturing Innovation#Quality Assurance Robotics#Robotic Vision Systems#Industrial Automation Solutions#Smart Manufacturing#3D Scanning Inspection

0 notes

Text

The Growing Importance of BIM Services in Modern Construction

BIM (Building Information Modeling) enhances project efficiency, accuracy, and collaboration. BIM modeling services, scan to BIM services, BIM outsourcing services, and BIM clash detection services made it easier for construction people to streamline their workflow and enhance project outcomes.

Here, architects, engineers, and contractors can perceive, analyze, and optimize building designs before the construction process starts.

What Are BIM Modeling Services?

BIM modeling services are expected to encompass the detailed and 3D development of representations of building projects. The models contain all the fundamental information, such as measurements, materials, and building components, making it easier to plan and execute the construction project. It also serves as a look into the lifecycle of a building from the design to demolition stages, where stakeholders can make informed decisions at each stage.

Teams can identify problems early in the process, and collaboration between architects, engineers, and contractors is simplified, which ultimately leads to fewer costly errors.

Scan to BIM Services: Digitizing Existing Structures

Scan to BIM or Point-Cloud to BIM services involves the application of 3D laser scanning technology to collect precise data of the physical space, which is then converted into a BIM model. Such models contain all the details of an existing building in all its structural elements, walls, and its mechanical systems.

Scan to BIM services is crucial when dealing with older buildings, whose documentation may be incomplete or old. This helps designers and engineers to come up with renovation or retrofitting plans.

BIM Outsourcing Services: Access Expert Talent

To most construction firms, outsourcing is the best cost benefit to accessing expert talent without maintaining in-house resources. BIM outsourcing services allow companies to outsource tasks such as modeling, drafting, and clash detection to specialized teams. Not only does this reduce costs, but it also enables construction firms to stay focused on core business activities while experts handle technical BIM aspects.

BIM services outsourcing can also help firms honor tight deadlines, improve the quality of the project, and take on more complex projects without a rise in staff. This flexibility holds special significance for smaller firms looking to keep their position in the competitive arena of a fast-changing industry.

Role of BIM Clash Detection Services

One of the main benefits of BIM is the ability to detect conflicts in building system clashes and correct them at the design stage. Detection of "clashes" or conflicts between structural, mechanical, electrical, and plumbing systems within a BIM model, for example, is performed by advanced software in BIM clash detection services. Before construction happens, finding clashes saves project teams from costly rework and delays.

With BIM clash detection services, many of the potential conflicts can already be visualized and resolved at the planning stage, thus setting up constructions for even smoother processes and lowering the risk of project overruns.

The incorporation of BIM modeling services, scan to BIM services, BIM outsourcing services, and BIM clash detection services has, therefore, driven the change in the construction industry. Increased accuracy of projects, cost-cutting, and efficient collaboration of teams are some the result benefits that come from the incorporation of BIM technologies in the construction arena. Construction professionals can deliver quality projects on time and on budget with the use of BIM technologies.

#BIM Modeling Services#BIM Clash Detection Services#BIM outsourcing services#Scan to BIM services#cad solution#3d cad solution#indovance inc

0 notes

Text

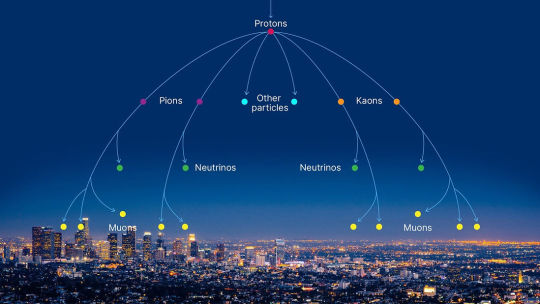

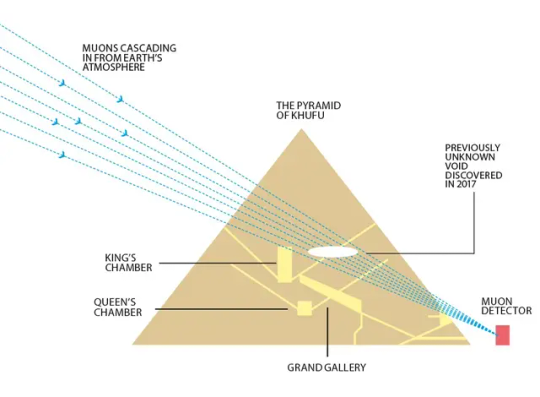

Okay so a guy in my solid state physics class was telling us about this muon scanning startup he worked at, GScan, and I'm going insane. I don't work there and I have no stake in the company, financial or otherwise, I just need to tell you about it.

Muons are short-lived subatomic particles, same charge as an electron but ~200 times more massive. On Earth, they're produced by cosmic rays colliding with the upper atmosphere, and they hit the ground at a rate of about ten thousand per minute per square meter.

They're moving extremely fast at ground level, like 0.99 c. So they careen right through matter, deflecting only very slightly around heavy atomic nuclei – they'll penetrate like a hundred meters into solid rock.

What do you do with this continuous shower of deep-penetrating charged particles, constantly blanketing every square inch of the Earth's surface?

(source)

The classic thing is use them to image the inside of massive structures, like we use x-rays to look inside living tissue – except instead of generating them yourself, you just use atmospheric muons. Muon archeology is a whole thing, they've used it to find hidden chambers in pyramids and stuff. Neat!

But this one Estonian company is doing some crazy bullshit and I love it.

Sandwich anything between a pair of portable muon detectors and get full 3D imaging of the interior, with sub-millimeter accuracy, by tracking the minute deflection of muons between them. Samples that are WAY too thick for x-rays, made of literally anything. Just put some muon detectors on some two by fours in a warehouse and call it a day.

You can just. Image anything??? Anything you want?? Completely passively!! Just detectors! No particle source! Put them anywhere. The detectors themselves are a mature technology, the company's tech is in the algorithms they use to get this level of spatial and elemental resolution.

You can detect failures inside cable-reinforced concrete bridges without cutting open the bridges.

Decommissioned Soviet nuclear submarine filled with concrete, with no drawings or documentation, that may or may not have spent fuel canisters in it? And you need to cut it up for storage? Just look at the muons.

One of the wackiest ideas is to put one detector under your bed and one on the ceiling, so you get a full 3D scan of your body every night, passively. I want one.

7K notes

·

View notes

Text

Expert Scan to BMI & 3D Modeling Services - ASC Technology Solutions

Get affordable laser scan/point clouds transformed into precise 3D models with ASC's Point Cloud to Revit Modeling/3D Modeling Services. We provide scan-to-BIM modeling and outsourcing services using advanced software to create point cloud to 3D modeling Services and BIM software to develop detailed models that meet our clients' specifications. Contact us for more information on our Scan to 3D Modeling Services.

#Scan to 3D Modeling Services#Scan to 3D Modeling#bim services#asc technology solutions#bimrevolution#asctechno

1 note

·

View note

Text

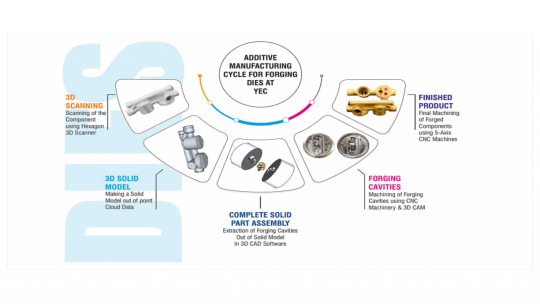

Unveiling the Potential of 3D Scanning in Reverse Engineering

In the realm of engineering innovation, the advent of 3D scanning has revolutionized traditional methodologies. Among its myriad applications, one particularly noteworthy domain is reverse engineering.

Enterprises worldwide are leveraging 3D scanning technologies to dissect and recreate intricate designs, breathing new life into legacy components and machinery. The process involves capturing detailed digital renderings of physical objects, which serve as blueprints for replication or enhancement.

In the heart of technological advancements, Yamunanagar Engineering Cluster stands as a beacon of ingenuity. Employing cutting-edge 3D scanning techniques, the cluster pioneers the restoration and optimization of industrial assets with unparalleled precision and efficiency.

Beyond restoration, 3D scanning facilitates product innovation, enabling engineers to analyze and enhance existing designs swiftly. It expedites prototyping, reduces time-to-market, and fosters a culture of continuous improvement.

As industries evolve, the fusion of 3D scanning reverse engineering propels progress, ushering in a new era of limitless possibilities and unparalleled innovation.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

Portable 3D Scanning Solution

A portable 3D scanning solution typically involves hardware and software components that allow you to capture three-dimensional data of real-world objects or environments. Here's a general overview of what a portable 3D scanning solution might include:

3D Scanner Hardware:

Handheld Scanners: These are compact and easy to use, allowing you to move around the object or scene to capture data from various angles.

Structured Light Scanners: These project a pattern of light onto the object and use a camera to capture the deformation of the pattern, creating a 3D model.

Laser Scanners: Utilize laser beams to measure distances and create a 3D point cloud of the object.

Portable Power Supply:

Since the solution is portable, it's essential to have a power source that can support the 3D scanner. This could be a rechargeable battery or another portable power solution.

Computer or Tablet: A device to run the 3D scanning software and process the captured data. This could be a laptop, tablet, or even a specialized computing unit provided by the scanner manufacturer.

3D Scanning Software: The software is crucial for controlling the scanner, processing captured data, and generating a 3D model. It should have user-friendly interfaces and support various export formats for the generated models.

Alignment and Calibration Tools:

Tools or features within the software that help align and calibrate the scanner to ensure accurate and precise 3D data capture.

Carrying Case or Bag:

A protective case or bag to transport the 3D scanner and its accessories safely.

Training and Documentation:

Comprehensive documentation or training materials to help users understand how to set up, operate, and troubleshoot the portable 3D scanning solution.

Post-Processing Software:

Depending on the application, you might need additional software for further refining and editing the 3D models generated by the scanner. Optional Accessories:

Depending on the specific needs, additional accessories like tripods, targets, or stabilizing equipment might be useful for certain scanning scenarios.

Popular manufacturers in the 3D scanning industry include FARO, Artec 3D, Creaform, and Trimble, among others. When choosing a portable 3D scanning solution, consider factors such as scanning accuracy, resolution, ease of use, and the intended application (e.g., industrial inspection, reverse engineering, cultural heritage preservation, etc.).

0 notes

Text

Virtual Reality Software Development Company | 360 Degree Service Provider | TechVoyager

Best Virtual Reality Development Company

Utilize technology to feed your content and provide your end users with the finest content experience possible.

Virtual reality (VR) and augmented reality (AR), combined with artificial intelligence (AI) and automation, have altered content strategies and revolutionized the way organizations create information.

Matterport Service Provider In India

AR/VR services, Virtual Commerce for Business have been used in products, processes, and, most significantly, training content to provide a more contextual and visual experience to end users. AR/VR content provides consumers with a tactile experience, allowing them to better understand and learn. Today, AR/VR applications are used across sectors and companies to improve content user experience.

Virtual Walkthrough Solutions

TechVoyager provides a wide range of Virtual Reality Services India across industries, with competence in computer vision, machine learning, deep learning, and 3D Virtual Reality Walkthrough Service. We assist in the creation of rich, immersive, and interactive user experiences using AR-triggered content. Personalized content is tailored to a user's personal requirements and is adapted to distinct user roles. Users can fully connect with the released material thanks to the interactive experiences.

End to End 3D Scanning Service

TechVoyager also provides 3D Services in India. Users can visualize the equipment or hardware, examine it in 360 Degree 3D Animation Company in India, and learn how to use and troubleshoot it as a result. The solution is highly customizable, allowing it to be fitted to any sector or purpose.

Here are some of the benefits we provide to consumers with our AR-based content offerings:

Creating immersive and interactive VR-based walkthroughs by converting input product information into 3D.

Integration of solutions with existing CRM/ERP systems.

Creating virtual reality locations/scenarios to increase customer interaction.

Creating single and numerous product visualizations in augmented reality.

TechVoyager

Address

No. 66, Thiruvengadam Nagar

Thanjavur 613005

Contact

+91 7010108633

Our Services : matterport 3d virtual tours | 3d designing & printing | 3d scanning and printing service | 3d design and modeling service in india | virtual store development | 360 Product Photography Service | 360 drone photography

#virtual reality solution provider#best virtual reality development company#virtual reality app development#matterport 3d virtual tours#Matterport Service Provider In India#virtual reality software development company#virtual reality services india#best 3d scanning services in india#3d animation company in india#3d services in india#3d designing & printing#3d modeling services india#3d design and modeling service in india#3d scanning and printing service#3d printing services in india#end to end 3d scanning service#best 3d scanning company#virtual commerce for business#virtual reality in e-commerce#virtual store development#virtual reality online store development#VR Real Estate Solutions#360 virtual tours for business#Real Estate Virtual Tour Services#3D Virtual Tour Service for Real Estate#3D Virtual Reality Walkthrough Service#Virtual Walkthrough Services#Virtual Reality Architectural Walkthrough#Virtual Walkthrough Solutions#360 degree service provider

0 notes

Note

Hi!! First, I'd love to say that I'm absolutely in love with your art. I've been a Les Mis fan since I was 9 or 10, and Enjolras was always my favorite character, and Grantaire my close second. i never I shipped ExR until I saw your art. I've read your fanfics and literally clicked through all your art since when you started posting (somehow I found the time), and it is so fun to see your art progress! I gratefully came across your art recently when I was in a huge art block for 2D hand-drawn art, having transferred to 3D CGI art several years go. You really inspired me to draw again (and to listen to and watch Les Mis again...)

Anyways, I've started trying to sketch in my sketchbook almost every day. I've always had one problem, and that would be the size of the drawings. I usually draw like these teeny tiny full body characters that are like at most 3 inches tall, and their heads are like less than an inch. (and it's so frustrating when i try to erase a tiny detail and end up erasing half of the head). And I have trouble drawing a consistent size for multiple characters in a scene. Do you have any advice on drawing size or any sort of guidelines or like base shapes (idk what they're called when you do that type of blocking, I never took legit drawing classes)?

Thank you soooooo muuchchhhh!! Your art is a blessing to the Les Mis community. :DDDD (sorry I wrote so much)

Hi there! First of all thank you so much!!!! I'm so glad you enjoy my work and enjoyed seeing my growth over the years. I am happy it helped inspire you too!!! I have some advice that is not useful and maybe some that is more useful.

My non-useful advice is I'm an ipad girlie, meaning I currently am mostly only digital sketches, and the advantage of that is you can change the size of anything at any time, which is extremely helpful because I, like you, also end up drawing things in the wrong size all the time and need to adjust that. Unfortunately though having the ease of that does not apply to your situation. Something you could do, but is still roundabout, is back when I was drawing traditional all the time, I would save my major edits for proportions and sizes for photoshop when I got home, so I would scan and make a bunch of digital edits rather than undoing what I did on the paper if I liked most of what was there already, since detail was easier to fix when you can blow it up on the comp. This would also be what I would do when I have characters that are two different sizes, I would fix them gently in photoshop when I got a chance to scan in the sketch. I should add if you are able to do that I think it's a great solution and not 'cheating' in anyway if the paper version isn't the finished product.

However maybe my more useful advice is to get a bigger sketchbook. Bigger paper can help you getting used to working bigger. If you have a tiny sketchbook you'll get used to drawing tiny and I really don't rec that, because I think the reason why my hands are so messed up is because I got used to drawing small and tight. In art school they really stress drawing loosely and bigger. When I say bigger I mean like printer paper sized (8.5x11) or more? I got used to these travel sketchbooks and I don't think they did me any favors.

I would rec drawing the head at least maybe an inch tall if not more? I think maybe when you first are drawing and you put down the little skeletal bits of drawing (the first thing I always draw is like the circle and jaw shape for the head), make sure that it doesn't get smaller than that. A full body at 3 inches sounds incredibly painful for your hands to draw! I don't feel like I'm sounding very helpful right now but I do think that it will be much healthier for your hands to learn to draw bigger or you'll end up with tendinosis like me (sadness.) But yes, I think challenge yourself when you're first putting down your skeletal structure to go bigger. Get bigger paper, and try to do a full body that fills the page. You'll also be able to fit in more detail. Now that's not to say that I don't draw small still, but I don't go under an inch with my heads, so at least try that! As for characters sizes, make sure that you do have a base structure in place for them before you start any details, compare their sizes, measure with your eyes, and make sure you're happy with the way they look next to each other before you finalize, if you're not going to digitally edit anything later. I hope that helps a little? I feel like I might be just saying things you've already tried but hopefully I might have said something useful.

Anyway thank you again for your nice compliments!!

8 notes

·

View notes

Text

Visualize, Analyze, Innovate: 3D Laser Scanning Solutions Unleashed : Harness the power of visualization and innovation with our 3D laser scanning solutions, providing in-depth data for strategic analysis.

#3d laser scanning services#3d laser scanning services near me#how much does 3d laser scanning cost#laser scanning company industrial 3d solutions

1 note

·

View note

Text

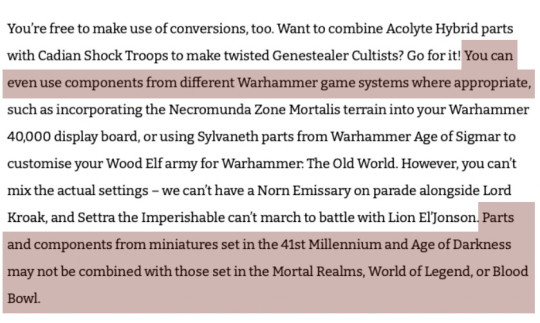

Watching the Warhammer community melt down over some rules regarding a painting competition because so many of them are primed to think that GW will unhinge its jaw and eat their models in front of them if they glue the wrong thing onto them.

It's especially funny because it's partly the community's fault this happened and the rules they're mad about almost certainly exist because of how much of a little fit was thrown over being creative in the hobby by some of the more toxic people in it.

To explain, Armies on Parade, an annual competition which involves you painting an entire army and a diorama board for them released rules prohibiting you from mixing parts from different GW games

We'll come back to that in a second, but I have to talk about Golden Daemon, GW's other painting competition and the fact that last year was extremely controversial on the US side of it.

Firstly, there was a winner with the AI background, and how the painter went on to be incredibly rude to critics in the usual ways (he would go on to have a model win in the UK side without an AI background, and GW went on to modify its rules to prohibit its usage).

(Note, I'm posting this image to both identify what the model was and also to admittedly showcase that the miniature and plinth sculpting was actually of high technical finesse. While I disagree with his use of AI for the background, I don't want it said that I'm implying that the person won by only using AI or whatever game of telephone might occur when sharing this story)

In the same competition the final winner went with this stunning model which used a 3d print of the model flipped to provide a reflection effect.

This is where you saw some members of the community start to shout that 3d prints or scans shouldn't be allowed (even though this competition makes heavy use of sculpting), which was eventually added to the 2025 rules.

While I'm very much in the camp that agrees with AI's exclusion (especially since there is no generative AI that I know of that utilizes a completely opt in system and even if it did, it's still using someone else's artwork which is not GW's for this type of competition), this does show that the painting competitions were under extensive scrutiny to make "fair" rules.

So we arrive at Armies on Parade, where one obvious thing of note is that your army should be, well, the army you've chosen. The first obvious rule here is that you shouldn't have characters from other factions or universes running around in them.

But then comes the big moment of truth that I'm 95% sure is responsible for this:

"If we're banning characters, and we're setting those restrictions by lore, then our fantasy lines shouldn't have sci fi bits in them, right?"

Well easy solution, we'll just say "no recognizable 40k bits in AoS/Old World and that stops anyone from slapping a bolter on an Peasant Militia man.

Nope, because you've got the community primed to rules lawyer now. So they will say "Even though you've shaved off all the pipes and wires, I can tell this sword is from Lion El'Jonson because of the details on it!" or they'll say "I can tell that armor, even with all the details filed off is a Space Marine/Votann/Eldar because it's got that exact silhouette!".

And in the middle of figuring out how you have to word it exactly, someone speaks up and says "Hey, if we're banning 40k stuff from AoS and Old World, doesn't that mean 40K players have a much wider bits bin to pick from than they do? Is that unfair?"

And even though you've had Ork painters grabbing Orruk stuff, Eldar painters grabbing Lumineth and Seraphon stuff, and Space Marine painters grabbing Stormcast stuff for years, you've now got to write out fair rules. Because if someone complains this year about how the new rules force you to pick from 40k or work at a disadvantage then that'll be all over the headlines for a bit and might even get twisted to say "GW prioritizes 40k over its fantasy line as PROVEN by these rules".

So you blanket ban cross system kitbashes in general from the competition in an article only on the painting competition.

But then that gets picked up by the usual people who hear that GW is banning kitbashes and the sky is falling again, without a shred of irony that this decision was almost certainly made because of drama being made into absolute drama.

I should state, I actually think the rule is dumb and shouldn't be in there because this competition is solely for people who spend a lot on hobbying and aren't the average painter or kitbasher anyways. I do feel like the rules about mash up armies like having Nagash in a necrons army or Guilliman at the head of a Cities of Sigmar is actually fine to exclude, especially since the competition still tries to have individual categories for specific games and how in the hell would you deal with that if there's no attempt to commit to one of them? The competition does still need rules to it after all.

Anyways, that's your drama for people who haven't been peeking in and are wondering why their WH players are freaking out this half of the week

8 notes

·

View notes

Text

Welcome to Rakuen,

After the earth (now known as Narak) was made uninhabitable from a radiation disaster thousands of years ago, humanity fled to the stars. Now living upon a mothership known as Rakuen, citizens live in a dystopian world masquerading as a Utopia. An AI known as Sibyl System runs cymatic scans on all inhabitants to assess citizens whether they're safe, a potential danger to society, or outright dangerous to society.

There are also space witches and non- who pilot mecha to search the universe; genetically modified SOLDIER who keep Rakuen safe; arena battlers for entertainment, and more. The story is what you make of it: SoL, action-based, other--?

Features,

• Read the wiki and join via the Google Forms, link provided below, • Only reviewed apps are player apps regarding themselves; character apps aren't reviewed, • Applications are almost entirely optional, • No need to wait for staff. Everything's autonomous: tracking threads, face claims, and even moving your own threads, • Use 3D anime-style art, or illustrated anime-style art as face claims/play-bys, • Create organisations, lineages, and lore by contributing to our members-only wiki, • No admins, just a game master like in DnD., • Rating ESRB Teen, though we're a 21+ group • An open, member-driven semi-private RP where there's no bullshit, no nonsense,

Fandoms included,

• Psycho-Pass • Ghost in the Shell • Cyberpunk 2077/Edgerunners • NieR: Automata • .hack//GU (The World in particular) • Final Fantasy VII • Final Fantasy XIV's Solution 9 • Gundam: Witch of Mercury • Knights of Sidonia • Chobits

How to Join,

• Visit our Rulebook; join link inside (google forms) • Site link & Discord invite given upon player app approval.

#manga rp#anime rp#animanga rp#cyberpunk#cybernoir#cyberpunk rp#cybernoir rp#forum rp#rp#forumrp#multifandom rp#play by post#play by post rp#jcink#jcink rp#ghost in the shell#psycho-pass#cyberpunk 2077#cyberpunk edgerunners#.hack//gu#theworld#final fantasy vii#final fantasy xiv solution 9#gundam witch of mercury#knights of sidonia#chobits

5 notes

·

View notes

Text

Laser-based 3D printing: A powerful tool to advance optical microscopy

Today, optical microscopy is one of the most widely used methods in various multidisciplinary fields for inspecting objects, organisms, or surfaces on a small scale. However, its lateral resolution is fundamentally limited by the diffraction of light—a constraint that, with the use of conventional lenses, has become increasingly critical as the demand for higher resolutions grows. The integration of a dielectric micro-sphere behind the last imaging lens of an optical microscope offers a promising solution to significantly enhance lateral resolution, a research area known as micro-sphere-assisted microscopy. However, in practice, the use of commercially available dielectric micro-spheres comes with substantial limitations. Cumbersome workflows are required for proper handling of the micro-spheres, and the sizes of commercially available dielectric micro-spheres are also limited. These challenges hinder the widespread application of micro-sphere-assisted microscopy as a cost-effective alternative to expensive microscopy solutions, such as scanning electron microscopy or atomic force microscopy.

Read more.

#Materials Science#Science#3D printing#Lasers#Optical microscopy#Materials characterization#Dielectric#Lithography

17 notes

·

View notes

Text

Favorite Games of 2023 Part 5: Dragon Warrior 1+2

I now after having played Dragon Warrior 1+2 (now commonly referred to as Dragon Quest 1 and 2) for the Gameboy Color completely understand why this series became the massive cultural juggernaut that it is now. I played these two games as a complete spur of the moment thing during the last two weeks of the year due to being totally surprised by how pretty the Gameboy Color remake of Dragon Quest 1 looked while watching a Gigaboots stream ( https://youtu.be/1ELg0p31zZI?feature=shared ) of it. I really could not get over how pretty the battle backgrounds looked and how many unique locations they had, it made a limitation of the game (battles only having one enemy per encounter) one of it’s strongest aspects to me. This is of course is in addition to the really fun character and enemy sprites all being distinct and memorable as well. I didn’t even approach this game expecting to want to finish it let alone finish both but the way the games felt like they were always moving forward (DQ1 more than 2 in that regard) kept me interested all the way to the end.

Dragon Quest 1’s combat is as simple as it always appeared to be, a game entirely consisting of one versus one matches of trying to out damage the other. It was a game of breaking new ground in terms of video game genre so it has an excuse at least and even then as with the GBC remake, it’s still decently fun. As a result though, jumping over to Dragon Quest 2 immediately afterwards with its introduction of party members for both you and your opponents felt world changing. Being ganged up on was scary and learning spells that hit multiple enemies felt like a massive upgrade in power. What made the battle systems in both games really click was just how snappy they felt. Random encounters were almost always over within a minute at maximum, attacks are quick, menuing feels immediate, and enemies are felled within one or two rounds. It’s a popcorn like approach to combat, small tasty satisfying bites, easily consumed and never distracting.

What made it more fun to me was trying to find the most optimal way to finish encounters in Dragon Quest 2 in the most efficient way possible (least rounds taken, without wasting unnecessary amounts of magic points). The enemies were all really easily identifiable as to what they’ll do in an encounter (be tanky, heavy hitters, poison appliers) and what made them interesting was the variety of ways they were grouped up with other enemies. Playing through these encounters in manner of quickly reading the situation and giving a fast response in turn eventually made me associate the game with that of Tetris. In both, you’re given the capability to read your current issue at hand and come to a best possible solution in split second timing. In both, you’re never made to feel like theres only ever one way to solve this problem but instead given the freedom to utilize improvisation. This fast, responsive setup to its gameplay always just clicked well with me in creating a flow state that gave a good feeling of thinking without having to think about it.

I totally played both of these with guides and with a good amount of use with the 3DS’s virtual console save state feature. In Dragon Quest 1 it was mainly just always having a map open the whole time so I could know where to go and what town/dungeon was where. In Dragon Quest 2, I don’t think I would have liked that game anywhere near as much as I do currently if I attempted to do it’s convoluted, worldwide search for trinkets that are only hinted at. A friend gave me a PDF of a scanned Prima strategy guide made for the games when they were originally released, it felt like the most appropriate, nostalgic way to play this sort of game. I even did what I always did as a kid and flipped through the whole thing looking for cool art of your characters, one of my favorite parts of my dad always buying the strategy guides for Zelda games or looking at my cousin’s Final Fantasy guides. I attempted to minimize the direct following of the guides and try to figure most things out on my own but after spending what felt like an appropriate amount of time with Dragon Quest 2’s fetch quests, I just did what the guide told me to the end. As for save states, I mainly just used them as a more modern means of saving the game AND a means of trapping any and every metal slime i found in a time loop hell until they gave me the tons of experience that I desired. As a result of that, I found grinding enjoyable and being powerful to just crush everyone afterwards satisfying.

Something I kept joking with my friends while playing through Dragon Quest 2 was the idea that ‘if I can finish Dragon Quest 2 before the end of 2023, then that announced remake of Dragon Quest 3 has to come out in 2024!’ Over the week of playing it the joke became more of a self imposed challenge. This resulted with spending all day December 31st finishing the game up (though partially that was because I just could not put the game down, I was just really enjoying the game at that point). So I accomplished my goal and now the curse of that Dragon Quest 3 remake is lifted and will absolutely come out this year and if it does it’s entirely because of me, you’re welcome. Now though my issue is I really want to play DQ3 right now and now I feel like I should wait out for that remake. I got the want for more Dragon Quest and now I gotta hold it off for the time being (or I can just play that GBC remake of 3, have you seen the enemy animations in that they’re incredible!)

39 notes

·

View notes

Text

It seems to me that computers and automation pose a real crisis for capitalism, at least as it exists today, and I kind of don't understand why other people don't feel the same way.

The cost of reproducing a piece of art has dropped so low that people will reproduce and distribute pieces of art simply out of charity, whether we're talking non-profits like Wikipedia or Project Gutenberg or just randos hosting files on Peer to Peer networks because their computer is on anyway so why not.

So we can, and in practice essentially do have all digitized art available for free to anybody with a computer and internet connection.

The problem with this is that the whole art market is based on selling reproductions, but with the supply of reproductions being essentially infinite the price would not stay high enough except for the fact that there is a legal regime dedicated to creating artificial scarcity in order to inflate the price.

This is, you know, bad.

And now similar things are starting to happen with physical objects thanks to 3d printing.

The other thing is automation of labor. I keep saying this but in a situation where laborers sell their labor on the market and the price at which they sell their labor is based on supply and demand, anything that makes it easier to supply labor is going to be seen as a detriment by the people in the existing labor pool.

I have a friend who complains every time we go to the grocery store about how those self-checkout kiosks are just there so that the grocery store can pay less for staff. Scanning groceries is a rather tedious process but those kiosks don't free former grocery store workers to engage in a life of leisure, they just mean that those workers don't get paid for a bit and then have to find a different job at which they will work just as hard.

And I guess I don't understand how or why market economies would solve either of these problems. Again, in the actually existing capitalist economies, the solution has been having the government impose artificial scarcities on art reproduction, and in labor terms the solution has been... no solution. If your labor suddenly sells for a lot less money you can eat shit, because that's your fault for not being in a market that was less susceptible to automation, which I think we can all agree is a personal moral failing that ought to be punished.

48 notes

·

View notes