#Assembly Line Support Devices

Explore tagged Tumblr posts

Text

⚙️ Tool Balancer Market Forecast to Reach $762.8 Million by 2035 Amid Growing Demand in Manufacturing & Automotive Sectors

The global Tool Balancer market is poised to grow from $358.7 million in 2024 to $762.8 million by 2035, reflecting a compound annual growth rate (CAGR) of 7.1% over the forecast period.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/tool-balancer-market-research-report

Tool balancers are vital in reducing operator fatigue and improving workflow efficiency across applications such as manufacturing assembly lines, automotive maintenance, warehouse operations, and biomedical equipment handling. The report explores market expansion across dimensions like Product Type, Application, Technology Integration, and Load Capacity.

🔍 Competitive Landscape & Industry Trends

The Tool Balancer market is highly competitive, with top players focusing on innovation, durability, and ergonomic safety. Leading companies include:

Ingersoll Rand

Carl Stahl

Gleason Reel (Hubbell)

Conductix-Wampfler

Tractel

Aero-Motive (Woodhead, A Molex Company)

Hangzhou Tangcheng

POWERMASTER

James Walker

Fasten Enterprises

NAC-InterCom

TE Connectivity

Key drivers fueling market expansion include the evolution of Industry 4.0, growing automation needs, and heightened emphasis on operator safety and fatigue reduction.

🌍 Global Outlook & Demand Hubs

Major growth opportunities lie in:

Rapid industrialization in emerging economies

Technological innovations in smart lifting systems

Strategic partnerships for equipment standardization

Demand is particularly strong in the U.S., Germany, China, Japan, and the UK, with Indonesia, Chile, and South Africa emerging as attractive markets for Total Addressable Market (TAM) expansion.

🔄 Supply Chain Evolution

With North America and Asia-Pacific leading in adoption, the Tool Balancer market’s supply chain—ranging from raw material procurement and precision manufacturing to global distribution—is expected to grow in complexity and resilience.

Challenges such as limited awareness in smaller markets and high upfront costs are being addressed through educational outreach, cost-competitive innovation, and after-sales support strategies.

🧠 About DataString Consulting

DataString Consulting delivers actionable market intelligence through tailored B2B and B2C research projects. With over 30 years of combined experience, our experts track and analyze fast-evolving segments across 15+ industries worldwide to help clients navigate strategic decisions with precision and confidence.

#Tool Balancer Market Forecast#Industrial Tool Balancers#Manufacturing Line Optimization Tools#Automotive Assembly Equipment#Ergonomic Lifting Solutions#Load Handling Equipment#Industrial Safety Tools#Assembly Line Support Devices#Warehouse Equipment Market#Smart Balancing Systems#DataString Market Insights#Global Manufacturing Tools Trends

1 note

·

View note

Text

How to Edit Poetry

A poet’s work is a personal expression that uses figurative language to create imagery with words. But as with any creative writing process, poetry requires careful editing to ensure you’ve conveyed the theme you envisioned in a clear, concise way. Once you’ve finished your first draft, it’s time to begin the poetry editing process.

Tips for Editing Your Own Poems

Whether you’re submitting your first book of poetry to literary agents or self-publishing your own poetry collection, editing your work is an important part of writing poems.

Put the poem away once you’ve written a draft. Just like writing fictional short stories or novels, poetry writing is hard work. When you’ve put all the words down on the page, the first thing you should do is put your poem away and take a break from the creative process for a few days. Come back to it with fresh eyes and a fresh mind. This helps you approach your poem more objectively as you begin to edit.

Review your whole poem. One of the first revision strategies you should do is simply to read the poem in its entirety. When you’re done, jot down the first thoughts that come to your mind, like any words or lines that feel off. Think of the reader’s experience with this poem. What would they come away with? Did your theme come across? Is your writing clear? Whether you wrote in a particular poetic form—like haiku or free verse—determine whether the poetic structure worked or if you want to rewrite your poem in a different form altogether.

Read your poem aloud. Editing poetry is as much about revising for readability as it is for its oral quality. How does your poem sound? Listen for rhythm, flow, and the placement of breaks throughout each line. As you scan the lines, see if the meter works well with your words. As you make changes, read your edits aloud to make sure the revised poem is good on paper and pleasing to the ear.

Go over every line. Good poets craft verse that is unified by a central theme. As you read, make sure you’ve crafted lines that support the meaning of the poem, creating a consistent point of view. If a line doesn’t fit, rework it until you find the best words to create a strong, coherent verse.

Begin and end with powerful lines. Pay particular attention to your first line and last lines of your poem. The opener will set the tone and mood of your poem, the last line should leave a lasting impression.

Look over your language. Poetry is a medium of few words, but each one contributes to the bigger picture a poem creates. Review your word choice to make sure each one is a fit for the theme, structure, rhythm, and rhyme. If you have to, pull out a thesaurus to find the right words for the story you’re trying to tell.

Incorporate poetic techniques and devices. When writing poetry, get creative and take different approaches in how you put words together. Use poetic devices in your work—like alliteration and consonance. Play around with language to assemble words in ways that give your poem new meaning.

Test your line breaks. Look at the end of every line. Review how one line ends and a new line begins. If each thought is complete at the end of a line, marked with a period or semicolon, your lines are end-stopped. If one thought continues from one line to the next, you’re using enjambment. Read the poem through to hear how your poem flows from one line to the next. If the poem feels clunky, try the opposite type of line break to see if it’s a better fit with your words and rhythm.

Look at your poetry on the page. Poetry has an aesthetic quality in addition to the imagery and emotions it evokes. Print out your poem and look at its layout on the page. Notice the amount and shape of white space around the poem. Look at the stanza breaks. Poems that follow a metric pattern should have lines of similar lengths.

Do a final pass. You might have to work through several drafts before you finally feel like every word and every line is in place and your poem is complete. Before you submit the piece to literary journals or get it published, do one last round of proofreading as the final step in your revision process, reading it aloud for good measure.

Source ⚜ More: Notes & References ⚜ Writing Resources PDFs

#poetry#writing tips#writeblr#literature#writers on tumblr#writing reference#dark academia#spilled ink#editing#writing prompt#creative writing#light academia#writing advice#on writing#writing inspiration#writing ideas#poets on tumblr#writing resources

72 notes

·

View notes

Text

A continuation of @skyloftian-nutcase's HC snippet Honor Walk, and her response to this ask.

---

Wild stepped out of the elevator, joining the crowd lining the hallway. The doors to the ICU unit stood at the other end of the hall, where people kept casting expectant glances. The quiet murmuring among them was silenced as the doors swung open, and the Honor Walk began.

The donor patient was lying still in her bed, resting for what would be the last time, unaware of the people gathered to honor her life, and the life she would be gifting to others. She was escorted by her care team and family, the people who had stayed by her side and fought to save her, until there was nothing more to be done.

Everyone was silent as the patient was pushed out of the unit, many dipping their heads in respect. A multi-colored scrub cap caught Wild’s eye, drawing him to the one he had come to support. Four had been run ragged since the patient’s admission, and Wild knew it hurt him to have been unable to save them.

Their eyes briefly locked as Four looked back up from the monitor he was tending. The nurse’s eyes were glistening and red, having been fighting back tears during the procession. Wild gave a small smile and dip of his head. Four gave a small smile in return, before having to look away as the wetness in his eyes burned hotter.

Then they were gone, rounding the corner that lead to the OR, leaving a void in their path. Everyone attending knew it was there where she would be given a rest this world could not offer.

After a few more moments the assembly began to break up, everyone dispersing to return to their units and assignments.

Wild trailed behind the crowd, Four’s face burned into his mind’s eye. His next breath trembled and his clasped hands held tighter as they began to shake. Hurriedly he rushed into one of the unoccupied family waiting rooms, harshly sitting himself down as he began to fall apart.

The room was silent, but the sounds of the hospital buzzed in his ears. The soft beeping of monitors, the hum of equipment, an alarm of some kind or another going off. His hands unclasped, feeling restrained, and grabbed for the IV and tape on his arm that wasn’t there. The soft lights of the family room suddenly seemed harsh and fluorescent. And amidst all of it, Four still stood in front of him, unshed tears in his eyes as he diligently tended to him.

Wild had been that patient. Wild had gotten lucky; he’d survived. The girl being honored today hadn’t. Four had been on the verge of breakdown during her Honor Walk. She would never know, that someone she would consider a stranger, would mourn for them. Simply because she was a person, and a life had been lost.

‘That could have been me. I could have been the one lying in that bed dying.’

To have such an impact on a stranger’s life… He couldn’t imagine how the family had felt, losing a loved one, if even a stranger could grieve for them.

‘That could have been me.’

He saw Twilight’s face, Sky’s, Wind and the others. Tear stained and afraid as they sat at his bedside, talking to him and whispering assurances, trying to comfort him as much as themselves.

He recalled, in his brief moments of awareness amidst the sedation, the tube in his throat, the pressure of something in his skull. The same devices he’d seen on the girl that had passed by just minutes ago.

‘That could have been me.’

The cushion dipped, startling him out of his thoughts as a familiar colorful hat came to rest beside his shoulder, and an arm reached up to cradle his back and put firm pressure on his other shoulder.

‘That could have been me.’

‘But it wasn’t.’

“Thank you.” Four’s voice was quiet, a slight wobble to those simple two words.

“Anytime, Four.” Wild returned the one armed hug, squeezing the smaller male into his side, before huffing out a laugh. “…Dang my guardian angel is working on freaking overtime. Sorry, buddy.”

Four snorted a strangled laugh, pushing away to swat at Wild.

“Dude, your guardian angel needs a vacation.”

28 notes

·

View notes

Text

Low Voltage Switchgear for Commercial Buildings: Key Requirements, Standards, and Best Practices

In the construction and modernization of commercial buildings, low voltage switchgear plays a critical role in ensuring safe, reliable, and efficient power distribution. From office complexes and retail malls to hospitals and data centers, these buildings rely on robust electrical infrastructure — and low voltage switchgear is the backbone of that system.

Whether you’re an electrical panel manufacturer, a building contractor, or a facility manager, understanding the key requirements for selecting and integrating LV switchgear in commercial buildings is essential.

What Is Low Voltage Switchgear?

Low voltage switchgear is an assembly of electrical devices designed to control, protect, and isolate electrical circuits under 1,000V AC. It typically includes:

· Air Circuit Breakers (ACBs)

· Molded Case Circuit Breakers (MCCBs)

· Miniature Circuit Breakers (MCBs)

· Contactors and Relays

· Busbars

· Metering and Protection Devices

Why LV Switchgear Is Critical in Commercial Buildings

Commercial buildings demand:

· Continuous power availability

· High energy efficiency

· Electrical safety for occupants

· Scalability for future expansion

Low voltage switchgear delivers:

· Protection against overloads and short circuits

· Isolation for maintenance and fault conditions

· Load management for energy optimization

· Monitoring via smart metering and IoT integration

Key Requirements for LV Switchgear in Commercial Applications

Safety & Protection Standards

Must comply with IEC 61439 or UL 891 depending on the region

Must include overcurrent, short-circuit, and earth fault protection

Arc flash safety features (like arc fault containment) are crucial in populated buildings

2. Compact Footprint and Modular Design

Space is often limited in commercial utility rooms. LV switchgear should be:

Compact to fit tight electrical rooms

Modular for easy expansion as building loads increase

3. Smart Metering and Monitoring

Today’s commercial buildings demand energy-efficient and intelligent systems. Choose LV switchgear with:

Integrated smart meters

IoT-based energy monitoring

Remote control via BMS (Building Management Systems)

4. High Service Continuity (Form Segregation)

To ensure maintenance without full shutdowns, opt for:

Form 3b or Form 4b segregation

Withdrawable ACBs or MCCBs

Dual incomer and bus coupler arrangements for redundancy

5. Scalability and Flexibility

Commercial facilities evolve. Your switchgear must too:

Allow for load expansion

Be compatible with renewable sources (like solar panels)

Support future retrofits and upgrades

Standards to Follow

Ensure LV switchgear in commercial buildings is compliant with:

IEC 61439–1/2 — General and Power Switchgear Assemblies

UL 891 — US Standard for Dead-Front Switchboards

NEC (National Electrical Code) or local building codes

Also factor in:

Ingress Protection (IP Ratings) — IP54/IP65 for dusty or humid environments

Short Circuit Withstand Ratings — Ensure it matches building fault levels

Best Practices for Installation in Commercial Building

Centralize the switchgear for easy maintenance and reduced cable runs

Provide ample ventilation or forced cooling

Use color-coded wiring for clear identification

Ensure emergency shutdown mechanisms are accessible

Document the system with single-line diagrams and load calculations

Applications in Commercial Buildings

Office Buildings: Smart load shedding and energy metering

Hospitals: Redundant systems for life safety

Data Centers: N+1 configurations and continuous monitoring

Malls & Retail: Segmented load distribution for different zones

Hotels: Backup and emergency panel integration

Choosing the Right LV Switchgear Partner

Look for a supplier who provides

Customized switchgear assemblies

Fast lead times and local support

Engineering assistance for layout and specs

Pre-tested or type-tested assemblies

Future Trends in Commercial LV Switchgear

Digitization & predictive maintenance

Energy-efficient, low-loss designs

AI-assisted load forecasting

SF6-free eco-friendly designs

Need Help Choosing LV Switchgear for Your Next Commercial Project?

At Daleel Trading, we supply certified, compact, and smart low voltage switchgear solutions tailored for commercial buildings. Whether it’s a small retail site or a multi-floor office tower, we deliver performance, compliance, and reliability — on time.

👉 Contact us today for a quote, a technical consultation, or a custom panel solution.

8 notes

·

View notes

Text

I’ve been thinking about this for a little while — something I’d want to do if I had the time and money would be to design a Motorola 68000-powered tiny (10” or smaller) laptop. Modern CMOS 68K implementations are very power-efficient and decently well-suited to handheld and portable devices (see: TI-92 series), and if combined with a crisp, modern monochrome OLED display, could get you days of continuous usage without needing a recharge! Add a few megabytes of RAM, some peripherals (IDE/CF controller, ISA or S-100 slots, DMA controller, SPI bus, RS-232 port, SD or CF slot, PS/2 port for a mouse, text mode + hires monochrome video card, etc…), and you have a nice, flexible system that can be rarely charged, doesn’t require ventilation, and can be just thick enough to fit the widest port or slot on it.

The main issue would be software support: nearly all existing operating systems that ran on a 68K were either intended for very specific hardware (Classic Mac OS, AmigaOS) or required more than a flat 68000 (NetBSD, Linux, or any other UNIX requiring MMU paging). So, it would probably end up being a custom DOS with some multitasking and priv level capability, or perhaps CP/M-68K (but I don’t know how much software was ever written for that — also, it provides a “bare minimum” hardware abstraction of a text-mode console and disk drive). A custom DOS, with a nice, standard C library capable of running compiled software, would probably be the way to go.

The software question perhaps raises another, harder question: What would I use this for? Programming? Then I’d want a text editor, maybe vi(m) or something like that. OK. Vim just needs termcap/(n)curses or whatever to draw the text, and not much else. That’s doable! You’d just need to provide text-mode VT100 emulation and termcap/curses should “just work” without too much issue. I like writing C, so I’d need a compiler. Now, I’m assuming this simplistic operating system would be entirely written in a combination of assembly language (to talk to hardware and handle specific tasks such as switching processes and privilege management and whatnot) and C (to handle most of the logic and ABI). I could probably cross-compile GCC and be good to go, aside from handling library paths and executable formats that don’t comply with POSIX (I have no intention of making yet another UNIX-like system). Hopefully, most other command-line software (that I actually use) will follow suit without too much trouble. I don’t know how much work it is to get Python or Lua to a new platform (though NetBSD on the 68K already supports both), but Python (or Lua) support would bring a lot of flexibility to the platform. Despite me being a Python hater, I must admit it’s quite an attractive addition.

What about graphics? All the software I’ve mentioned so far is text-mode only, yet historical 68K-based systems like the Mac and Amiga had beautiful graphics! Implementing X11 would be a massive pain in the ass, considering how much it relies on UNIXy features like sockets (not to mention the memory usage), and I really don’t want Wayland to have anything to do with this. I guess I’d have to roll my own graphics stack and window manager to support a WIMP interface. I could copy Apple’s homework there: they also made a monochrome graphics interface for a M68K configured with a handful of MiB of RAM. I could probably get a simple compositing window manager (perhaps make it tiling for a modern vibe ;3). Overall, outside of very simple and custom applications, functionality with real software would be problematic. Is that a big problem? Maybe I want an underpowered notebook I can put ideas and simple scripts down on, then flesh them out more fully later on. An operating system allowing more direct access to the hardware, plus direct framebuffer access, could yield some pretty cool graphing/basic design utility.

I’d need a way to communicate with the outside world. An RS-232 UART interface, similar to the HP-48 calculator (or the TI-92’s GraphLink, only less proprietary) would help for providing a remote machine language monitor in the early stages, and a real link to a more powerful (and networked) machine later on. I think real networking would defeat the purpose of the machine — to provide a way to remove yourself from modern technology and hardware, while retaining portability, reliability, and efficiency of modern semiconductor manufacturing techniques. Giving it a CF or SD slot could provide a nice way to move files around between it and a computer, maybe providing software patches. A floppy drive would be amazing: it would provide a way to store code and text, and would be just about the right storage size for what I want to do. Unfortunately, there’s not really a good way to maintain the size of the laptop while sticking a 3.5” (or worse, 5.25”) floppy drive in the middle of it. To my knowledge, 3.5” floppy drives never got thin enough to properly fit with all the other expansion slots, socketed components, and user-modifiable parts I’d want. A completely solid-state design would likely be the best option.

Anyway, uhh… I hope this made some semblance of sense and I don’t sound insane for going on a rant about building a modern computer with a 1979 CPU.

5 notes

·

View notes

Text

Reinventing the clock: NASA's new tech for space timekeeping

Here on Earth, it might not matter if your wristwatch runs a few seconds slow. But crucial spacecraft functions need accuracy down to one billionth of a second or less. Navigating with GPS, for example, relies on precise timing signals from satellites to pinpoint locations. Three teams at NASA's Goddard Space Flight Center in Greenbelt, Maryland, are at work to push timekeeping for space exploration to new levels of precision.

One team develops highly precise quantum clock synchronization techniques to aid essential spacecraft communication and navigation.

Another Goddard team is working to employ the technique of clock synchronization in space-based platforms to enable telescopes to function as one enormous observatory.

The third team is developing an atomic clock for spacecraft based on strontium, a metallic chemical element, to enable scientific observations not possible with current technology.

The need for increasingly accurate timekeeping is why the teams at NASA Goddard, supported by the center's Internal Research and Development program, hone clock precision and synchronization with innovative technologies like quantum and optical communications.

Syncing up across the solar system

"Society requires clock synchronization for many crucial functions like power grid management, stock market openings, financial transactions, and much more," said Alejandro Rodriguez Perez, a NASA Goddard researcher. "NASA uses clock synchronization to determine the position of spacecraft and set navigation parameters."

If you line up two clocks and sync them together, you might expect that they will tick at the same rate forever. In reality, the more time passes, the more out of sync the clocks become, especially if those clocks are on spacecraft traveling at tens of thousands of miles per hour. Rodriguez Perez seeks to develop a new way of precisely synchronizing such clocks and keeping them synced using quantum technology.

In quantum physics, two particles are entangled when they behave like a single object and occupy two states at once. For clocks, applying quantum protocols to entangled photons could allow for a precise and secure way to sync clocks across long distances.

The heart of the synchronization protocol is called spontaneous parametric down conversion, which is when one photon breaks apart and two new photons form. Two detectors will each analyze when the new photons appear, and the devices will apply mathematical functions to determine the offset in time between the two photons, thus synchronizing the clocks.

While clock synchronization is currently done using GPS, this protocol could make it possible to precisely synchronize clocks in places where GPS access is limited, like the moon or deep space.

Syncing clocks, linking telescopes to see more than ever before

When it comes to astronomy, the usual rule of thumb is the bigger the telescope, the better its imagery.

"If we could hypothetically have a telescope as big as Earth, we would have incredibly high-resolution images of space, but that's obviously not practical," said Guan Yang, an optical physicist at NASA Goddard.

"What we can do, however, is have multiple telescopes in various locations and have each telescope record the signal with high time precision. Then we can stitch their observations together and produce an ultra-high-res image."

The idea of linking together the observations of a network of smaller telescopes to affect the power of a larger one is called very long baseline interferometry, or VLBI.

For VLBI to produce a whole greater than the sum of its parts, the telescopes need high-precision clocks. The telescopes record data alongside timestamps of when the data was recorded. High-powered computers assemble all the data together into one complete observation with greater detail than any one of the telescopes could achieve on its own. This technique is what allowed the Event Horizon Telescope's network of observatories to produce the first image of a black hole at the center of our galaxy.

Yang's team is developing a clock technology that could be useful for missions looking to take the technique from Earth into space which could unlock many more discoveries.

An optical atomic clock built for space travel

Spacecraft navigation systems currently rely on onboard atomic clocks to obtain the most accurate time possible. Holly Leopardi, a physicist at NASA Goddard, is researching optical atomic clocks, a more precise type of atomic clock.

While optical atomic clocks exist in laboratory settings, Leopardi and her team seek to develop a spacecraft-ready version that will provide more precision.

The team works on OASIC, which stands for Optical Atomic Strontium Ion Clock. While current spacecraft utilize microwave frequencies, OASIC uses optical frequencies.

"What we can do, however, is have multiple telescopes in various locations and have each telescope record the signal with high time precision. Then we can stitch their observations together and produce an ultra-high-res image."

The idea of linking together the observations of a network of smaller telescopes to affect the power of a larger one is called very long baseline interferometry, or VLBI.

For VLBI to produce a whole greater than the sum of its parts, the telescopes need high-precision clocks. The telescopes record data alongside timestamps of when the data was recorded. High-powered computers assemble all the data together into one complete observation with greater detail than any one of the telescopes could achieve on its own. This technique is what allowed the Event Horizon Telescope's network of observatories to produce the first image of a black hole at the center of our galaxy.

Yang's team is developing a clock technology that could be useful for missions looking to take the technique from Earth into space which could unlock many more discoveries.

An optical atomic clock built for space travel

Spacecraft navigation systems currently rely on onboard atomic clocks to obtain the most accurate time possible. Holly Leopardi, a physicist at NASA Goddard, is researching optical atomic clocks, a more precise type of atomic clock.

While optical atomic clocks exist in laboratory settings, Leopardi and her team seek to develop a spacecraft-ready version that will provide more precision.

The team works on OASIC, which stands for Optical Atomic Strontium Ion Clock. While current spacecraft utilize microwave frequencies, OASIC uses optical frequencies.

"Optical frequencies oscillate much faster than microwave frequencies, so we can have a much finer resolution of counts and more precise timekeeping," Leopardi said.

The OASIC technology is about 100 times more precise than the previous state-of-the-art in spacecraft atomic clocks. The enhanced accuracy could enable new types of science that were not previously possible.

"When you use these ultra-high precision clocks, you can start looking at the fundamental physics changes that occur in space," Leopardi said, "and that can help us better understand the mechanisms of our universe."

The timekeeping technologies unlocked by these teams, could enable new discoveries in our solar system and beyond.

TOP IMAGE: Work on the quantum clock synchronization protocol takes place in this NASA Goddard lab. Credit: NASA/Matthew Kaufman

LOWER IMAGE: The Optical Atomic Strontium Ion Clock (OASIC) is a higher-precsion atomic clock that is small enough to fit on a spacecraft. Credit: NASA/Matthew Kaufman

13 notes

·

View notes

Text

Advances in semiconductor patterning: New block copolymer achieves 7.6 nm line width

A recently developed block copolymer could help push the limits of integration and miniaturization in semiconductor manufacturing, report scientists at Tokyo Institute of Technology (Tokyo Tech) and Tokyo Ohka Kogyo (TOK). Chemically tailored for reliable directed self-assembly, the proposed compound can arrange itself into perpendicular lamellar structures whose half-pitch width is less than 10 nanometers, outperforming conventional and widely used block copolymers. Miniaturization is one of the fundamental qualities of modern electronics and is largely responsible for the incredible increments in performance witnessed over the past decades. To keep this momentum going, it is necessary to achieve circuit patterns finer than the existing ones on semiconductor chips, which are a crucial part of all electronic devices. Some experts estimate that, by 2037, the smallest distance between features in semiconductor devices, known as "half-pitch," will need to be as small as 8 nm to support next-generation electronics, emphasizing the need for advancements in lithographic processes (method of creating highly complex circuit patterns on semiconductor parts).

Read more.

#Materials Science#Science#Polymers#Block copolymers#Semiconductors#Self assembly#Tokyo Institute of Technology

17 notes

·

View notes

Text

Protecting Your Electrical Systems: A Look into Al Taqwa’s Complete Range

In today’s fast-paced world, electrical systems power everything from homes and offices to factories and infrastructure. With increasing energy demands and the growing importance of uninterrupted power supply, having the right switchgear and protection systems is more important than ever. That’s where Al Taqwa United Enterprises LLC, one of Oman’s leading electrical suppliers, plays a crucial role.

In this blog, we’ll explore how Al Taqwa offers a complete range of electrical switchgear products that protect and power systems across the country — safely and efficiently.

Why Electrical Protection Is Critical

An electrical system without proper protection is like a car without brakes. From power surges to short circuits, the risks of equipment damage, data loss, and fire hazards are significant. High-quality electrical protection devices ensure:

· Safe power distribution

· Equipment longevity

· Compliance with safety standards

· Reduced downtime in case of faults

Al Taqwa addresses all of these needs with a comprehensive and reliable product portfolio.

Al Taqwa: A Trusted Name in Electrical Switchgear in Oman

Established in 20011, Al Taqwa United Enterprises LLC has grown into a respected electrical trading and switchgear assembly company in Oman, Qatar, the UAE, and India. Their focus on quality, innovation, and customer satisfaction makes them a preferred partner for engineers, contractors, and facility managers across sectors.

Complete Electrical Switchgear Range from Al Taqwa

Al Taqwa’s product line is designed to meet the needs of low-voltage electrical systems in residential, commercial, and industrial environments.

1. Electrical Panels and Distribution Boards

These serve as the central hub for electrical power distribution. Al Taqwa supplies and assembles:

· Main Distribution Boards (MDBs)

· Sub Main Distribution Boards (SMDBs)

· Final Distribution Boards (FDBs)

· Control Panels and Feeder Pillars

All panels are tailored to meet Omani electrical standards and international safety norms.

2. Circuit Protection Devices

The key to preventing electrical fires and damage is reliable overcurrent and earth fault protection. Al Taqwa offers:

· Miniature Circuit Breakers (MCBs)

· Molded Case Circuit Breakers (MCCBs)

· Residual Current Devices (RCDs)

· Earth Leakage Relays

These components ensure quick fault detection and automatic power cut-off during hazards.

3. Metering and Monitoring Devices

To optimize energy use and improve system performance, monitoring is essential. Al Taqwa provides:

· Analog and Digital Panel Meters

· Current Transformers (CTs)

· Voltage and Frequency Meters

· Energy Monitoring Units

These products give real-time data for smarter electrical management.

4. Electrical Accessories and Control Components

To support the full installation lifecycle, Al Taqwa stocks:

· Terminal blocks

· Cable ties and lugs

· Contactors and timers

· Rotary switches and power supplies

These ensure smooth installation, operation, and maintenance of electrical systems.

Top Electrical Brands Represented by Al Taqwa

Al Taqwa partners with internationally recognized electrical brands, including:

· Enza Electric — Quality switchgear products known across Europe and the Middle East

· Civaux Electric — Comprehensive panel systems and circuit protection components

· Stefan Electric — Trusted for metering solutions and industrial electrical accessories

· Salzer Electric — Renowned for rotary switches and control products

These collaborations ensure Al Taqwa can offer reliable, durable, and cost-effective solutions to its clients.

Beyond Products: Al Taqwa’s Expert Services

Al Taqwa goes beyond just supplying electrical components. Their team of experts offers:

Custom switchgear assembly tailored to project requirements

Site inspections and installation support

Annual maintenance contracts

Technical consultation and troubleshooting

This makes Al Taqwa a one-stop solution for all electrical needs in Oman.

Conclusion: Trust Al Taqwa for Complete Electrical Protection

When it comes to protecting your electrical systems, choosing a trusted provider like Al Taqwa ensures both peace of mind and long-term performance. From high-quality panels and circuit breakers to metering systems and expert service, Al Taqwa covers the full spectrum of electrical protection.

For engineers, project managers, or business owners looking to safeguard their infrastructure, Al Taqwa United Enterprises LLC stands out as the best source of electrical switchgear in Oman.

Explore More:

Visit https://altaqwaoman.com to view the full product catalog or request a quote tailored to your project needs.

#electrical#electrical equipment#electrical supplies#switchgear#oman#ElectricalSystems#ElectricalSafety#ElectricalSolutions#ElectricalProtection#SwitchgearSolutions#PowerDistribution#LowVoltageSystems#CircuitProtection#ElectricalPanels#ControlPanels

3 notes

·

View notes

Text

Understanding the Difference Between a Welding Jig and a Welding Fixture

In manufacturing and fabrication, welding is a critical process that joins materials to create structures, components, and products. Specialized tools like welding jigs and fixtures are often employed to ensure precision, efficiency, and consistency in welding. While these terms are sometimes used interchangeably, they serve distinct purposes and have unique characteristics. Understanding the difference between a welding jig and a welding fixture is essential for optimizing production processes and achieving high-quality results.

What is a Welding Jig? A welding jig is a specialized tool designed to hold and position workpieces in a specific orientation during the welding process. Its primary function is to ensure that the parts being welded are aligned correctly, reducing the risk of errors and improving accuracy. Jigs are often customized for a particular workpiece or assembly, making them ideal for repetitive tasks where consistency is key.

One of the defining features of a welding jig is its ability to guide the welding tool, such as a torch or electrode, along a predetermined path. This guidance ensures that the weld is applied precisely where it is needed, minimizing deviations and enhancing the overall quality of the weld. Jigs are commonly used in applications where tight tolerances and exact alignment are critical, such as in the aerospace or automotive industries.

What is a Welding Fixture? A welding fixture, on the other hand, is a device used to securely hold and support workpieces during the welding process. Unlike a jig, a fixture does not typically guide the welding tool. Instead, its primary role is to stabilize the workpiece, preventing movement or distortion caused by heat or mechanical forces during welding. Fixtures are often designed to accommodate a range of similar workpieces, making them more versatile than jigs in some cases.

Fixtures are particularly useful in high-volume production environments where speed and efficiency are prioritized. By holding the workpiece in place, fixtures allow welders to focus on the welding process itself, reducing the likelihood of errors and improving productivity. Additionally, fixtures can help manage thermal expansion and contraction, which are common challenges in welding.

Key Differences Between Jigs and Fixtures Functionality: The most significant difference between a welding jig and a welding fixture lies in their functionality. A jig is designed to guide the welding tool and ensure precise alignment of the workpiece, while a fixture is focused on holding the workpiece securely in place.

Customization: Jigs are often highly customized for specific tasks or workpieces, making them ideal for specialized applications. Fixtures, while still customizable, are generally more adaptable and can be used for a broader range of similar workpieces.

Complexity: Jigs tend to be more complex in design due to their dual role of positioning and guiding. Fixtures, by contrast, are typically simpler, as their primary purpose is to provide stability.

Application: Jigs are commonly used in industries where precision is paramount, such as aerospace or medical device manufacturing. Fixtures are more prevalent in high-volume production settings, such as automotive assembly lines.

Cost: Because of their specialized nature, jigs are often more expensive to design and produce than fixtures. Fixtures, being more versatile and less complex, are generally more cost-effective for large-scale operations.

Choosing the Right Tool for the Job The choice between a welding jig and a welding fixture depends on the project’s specific requirements. If precision and alignment are critical, a jig is likely the better choice. However, if the primary need is to stabilize the workpiece and improve efficiency, a fixture may be more appropriate. In some cases, a combination of both tools may be used to achieve the desired results.

In conclusion, while welding jigs and fixtures share the common goal of improving the welding process, they serve distinct roles and offer unique benefits. By understanding their differences, manufacturers can make informed decisions that enhance productivity, quality, and overall success in their welding operations.

2 notes

·

View notes

Text

For Ukrainian soldiers facing the near-constant threat of Russian drones, a crude-looking, pocketable drone detector has become one of the most sought-after gadgets on the battlefield. Dubbed Tsukorok, or “sugar,” by its London-based creator, the grassroots device produced by a variety of manufacturers beeps loudly when a drone enters its detection range, allowing soldiers time to run to cover or turn on their jamming devices.

“It’s amazing because it is so cheap and simple,” a mortar crewman, currently positioned in the Donbas region, said of the Tsukorok. He, like all soldiers cited in this article, spoke to Foreign Policy on the condition of anonymity because he was not authorized to talk to the press.

More than two years into Russia’s war in Ukraine, the Russian military still enjoys the upper hand in electronic warfare. “The Russians have powerful electronic warfare equipment. … Unfortunately, Russia is significantly ahead of Ukraine,” Ukrainian activist Maria Berlinska told Ukrainska Pravda in April. Berlinska was instrumental in pushing the Ukrainian military to develop its own drone capabilities and has trained soldiers and civilians to fly reconnaissance and attack drones.

On Ukraine’s front line, electronic warfare has largely focused on the ability to use and defend from reconnaissance and strike drones as well as long-range missiles. Small, agile first-person-view (FPV) drones, which can carry between 2 and 11 pounds of explosives, are now used extensively by both sides. The ability to detect and jam the signals sent and received by those drones is a matter of life and death.

The Russian military has successfully used elaborate truck-mounted jamming systems to reduce the effectiveness of Western-made, GPS-guided artillery shells as well as HIMARS and JDAM guided bombs, the Washington Post reported in May. More recently, Moscow has used armored vehicles and tanks mounted with jamming devices to push across the front line.

Now, with the sky on the front line saturated with drones, Ukraine is attempting to catch up. That often means employing simpler, more inexpensive equipment with smaller ranges, such as the Tsukorok, to detect signals coming from Russian drones and other guided weapons. More than 50 Ukrainian companies are engaged in producing electronic warfare equipment, from the humble Tsukorok to expensive jamming devices. Tens of thousands of drones are also produced or assembled in the country every month.

But the detection gadgets are hard to obtain. “Right now, I think the demand [for jamming equipment] is at least 10 times higher than what we can provide,” said Bohdan Danyliv, the head of the military department at the Prytula Foundation, one of the biggest organizations supporting the Ukrainian military. “Honestly, it may be 50 times bigger.” The Prytula Foundation already delivers equipment including SUVs, strike drones, rifle optics, communication, and medical equipment to the armed forces. In recent months, the organization has looked to ramp up deliveries of electronic warfare devices.

“Yes, it’s difficult right now,” said Dmytro Selin, the London-based Ukrainian software engineer behind the first model of the Tsukorok. “Deliveries [of parts for manufacturing] aren’t reliable. Parcels can get stuck for weeks at a time. … Demand is a lot higher than our team can handle.”

Soldiers and the Ukrainian companies producing electronic warfare equipment must also deal with the ever-changing nature of electronic warfare. “Both the technologies and the tactics evolve very quickly,” said Anton Veklenko, the chief instructor and co-founder of Global Drone Academy, a Ukrainian company training Ukrainian civilians and soldiers in the use of military drones and electronic warfare.

Since 2022, electronic warfare has quickly made GPS guidance, which most off-the-shelf consumer drones use to navigate, obsolete. Both sides now deploy drones that act as relays to increase the flying range of their FPV drones to distances of up to 31 miles. Russia and Ukraine have also each experimented with autonomous guidance systems, allowing drones to strike their targets even when their signals jammed.

“We also train our pilots to detect which frequencies are being jammed in a specific area of the front line so that they can quickly change the frequencies used to fly their drones,” Veklenko said. “There’s no universal jammer that can block everything, so it’s a constant game of adaptation.”

The rise in popularity of the Tsukorok in late 2023, boosted by positive word of mouth from a Ukrainian military blogger, represents one of these adaptations. The constant threat of drones created the need for a small detector that could be used by any soldier without the training that more accurate and reliable—but also more complex—spectrum analyzers require. Selin, who moved to the United Kingdom in 2019, developed the first prototype in the summer of 2022, focusing at the time on detecting signals from the Russian Orlan reconnaissance drone.

Front-line troops use the Tsukorok to know when to turn on their energy-intensive jamming devices; artillery crewmen think of it as a last-resort warning, allowing them to run to prepared shelters as loitering munitions hurl toward them. A combat medic currently serving in the Kharkiv region explained that he always leaves a Tsukorok in his olive-colored ambulance: “I use it as a guide, to know when to use the jammer.”

The surge in demand put Selin and other groups building the device in a bind, as they went from producing a handful of detectors every month to hundreds, and then thousands, facing hurdles to scale up production. “I’m in talks with manufacturers and governments in Europe, but it is complicated, in good parts because of the bureaucracy,” Selin said. “But now we’re looking to diversify as much as possible,” with a goal of producing up to 10,000 detectors every month. Currently, half of the parts of the Tsukorok are produced in China and half in Ukraine; the final product is assembled in Ukraine.

“When it comes to the production of [electronic warfare] equipment, the situation right now is similar to what we had with FPV drones a year and a half ago,” said Danyliv of the Prytula Foundation. There is an “unstructured market, few established players, and a mix of bad devices that can cost a lot of money and high-quality devices that cannot be produced in enough quantities to meet the demand.”

The Tsukorok isn’t a miracle solution, Selin admitted: It can lose effectiveness in areas saturated with drones and is meant to complement, rather than replace, other detecting and jamming devices. “It is meant as a last warning device, but on the battlefield, soldiers will get information from lots of other sources,” Selin said.

“I call them personal protectors—it’s something that every soldier should have,” Danyliv said. “It won’t solve everything, but when you have one of those things in your pocket, you feel a lot calmer.”

5 notes

·

View notes

Text

Finland's news agenda on Monday is dominated by Ukraine President Volodomyr Zelensky's visits to Washington DC and the UK over the past weekend.

To recap: US President Donald Trump and his number two JD Vance criticised Zelensky on camera in the White House, suggesting he was dependent on US support and was insufficiently grateful for the support already given.

Zelensky defended himself and his country, correcting factual errors in the Americans' onslaught, but left without a diplomatic win or a deal on extracting minerals which was the stated purpose of the visit.

On Sunday he went to London to join European and Canadian leaders discussing plans for a new, more independent defence framework as the US apparently prepares to leave its erstwhile allies to their own devices.

Helsingin Sanomat's analysis of the weekend's events was cold.

"It feels like this week's show has been seen before," read the first line of the analysis, which went on to bemoan the lack of concrete measures agreed during the meeting.

Russian assets, which are currently frozen due to sanctions, could not be seized and used for Ukraine in case that had negative implications for the euro and the EU's banking system.

Other countries said they could potentially send soldiers for peacekeeping duties, but the overriding sense was that after three years of war, Europe was finally starting to plan a strategy to support Ukraine.

That's better late than never, according to HS, but the worst-case scenarios are still not being prepared for.

MPs' travel costs

Iltalehti has the latest in the 'parliamentarian expenses scandal' genre, with a look at travel expense claims submitted since the election in 2023.

Top of the charts are National Coalition MPs Pia Kauma and Jukka Kopra, and their Social Democrat colleague Kimmo Kiljunen.

Kauma has completed 36 trips totalling 162 travel days in that time, with Kiljunen making 34 trips over 139 days. Kopra travelled 30 times for a total of 118 days.

There were explanations: Kauma has a role as chair of the OSCE's parliamentary assembly, Kiljunen was chair of parliament's Foreign Affairs committee until he resigned last year, and Kopra is chair of parliament's defence committee.

Overall 170 of the 200 legislators in parliament have made at least one foreign trip during this parliamentary term.

Lapland travel boom

Finland is entering the third and final week of the school winter holidays, and Ilta-Sanomat carries a piece looking at the flood of foreign tourists in Finnish Lapland at the moment.

The international visitors have displaced Finns to such an extent that in December, the peak of the winter season, just 12 percent of overnight stays are spent by Finns.

That's not too surprising, as the average cost of a hotel room at that time was 273 euros. Finns are not keen to spend big money on those rooms, or on experiences like ascending a hillside in a piste caterpillar to look at the aurora borealis.

The reporter had joined an Indian couple doing exactly that, at a cost of 129 euros per head. Finns are not going to spend that money when they could just as easily view the light show from the back yard of their rental cottage.

The irony, according to the IS piece, is that every plane arriving in Lapland increases the rarity of, well, Lapland winters in the traditional sense. Climate change is accelerating and aviation is one of the biggest contributing factors, but Lapland tourism promoters don't have time to stop and consider that long-term impact.

1 note

·

View note

Text

Great Pyramid

The Great Pyramid of Giza is the oldest and largest of the three pyramids in the Giza pyramid complex bordering present-day El Giza, Egypt. It is the oldest of the Seven Wonders of the Ancient World, and the only one to remain largely intact.

The ancient builder technology is evident in the construction of the original Great Pyramid during the Golden Age, pre-Atlantian Cataclysm, which was constructed as a harmonic resonance device to transmit a range of powerful frequencies and subtle energies throughout the Planetary Grid Network. The Great Pyramid was not designed to be a burial chamber.

...

Millions of years ago, the Galactic Federation worked closely with the Sirian High Council to serve as a Guardian race that would help to support the seeding and evolution process of the planet earth in its lowest density, the first Harmonic Universe, also called the third dimensional timelines. The Great Pyramid of Giza was built as a harmonic resonator chamber within an interdimensional portal system in which visiting space craft could time travel and access the earth plane very quickly, especially if intervention was needed. During the cycle in which the Great Pyramid was built during pre-Atlantian times, the Galactic Federation was tasked to protect the Stargate portal and the ascension chamber within it and to intervene in case of an attack from hostile intruders such as the Annunaki resistance. The Great Pyramid was a mystery school for the Blue Flame Melchizedek spiritual ascension program and to accelerate DNA assembly for portal passage through the Inner Earth portal that was under the Sphinx. Some factions of the Annunaki Melchizedeks became patriarchal and had disregarded the Law of One teachings. They became increasingly hostile when they were forbidden access into the ascension chambers and not allowed in the Great Pyramid. Thus, they organized a larger group resistance in Atlantis with the plan to explode the protective force field via setting off explosions in which to take control over the Giza Stargate, and to achieve their goal they enlisted the support of the sympathizers that were in the Galactic Federation as many were originally from the Annunaki lineages that felt they were being unjustly discriminated upon. As a result of the infiltration that occurred from Sirius A, the Jehovian Annunaki took control over the Galactic Federation and the Ashtar Command joining the Luciferian Covenant and planning the final stages of the Atlantian Cataclysm with the purpose to eradicate the earth's historical records and technological knowledge, sending the earth's inhabitants back into the dark ages.

The Galactic Federation works with the NAA groups towards world domination and are behind the mind control propaganda that the Annunaki are the Gods of the earth and this Solar System, promoting themselves as the divine angels returning to help humanity ascend, to seduce the earth population into subjugation to their New World Order enslavement agenda.

Geographical Center of Earth

Giza is the reference to the demographic area of Egypt that is the 4th dimensional planetary stargate and diamond heart complex or Solar Temple that was a primary target of total invasion by the NAA, before, during and after the Luciferian Rebellion, in order to gain full spectrum dominance over the Sol portal, and control access into Mars, install Checkerboard Mutation, as well as take position for total earth domination during the Ascension Cycle. This location is also the geographical center of the earth body.

Egyptian History Erased

Thus, true and accurate Egyptian history was replaced with the Black Sun agenda of inserting the Egyptian Pantheon of Gods, along with their Black Magic rituals, that were to be enforced by the installation of the Setian King lines, Hyksos and the Amun Snake Priesthood. These groups in the Middle East would eventually integrate into the Greek Mystery Schools and further evolve into the corrupted patriarchal lineages of the secret societies that formed as the Knights Templars and Freemasons, some using the image of Akhenaton as their Luciferian high priest for enacting the blueprint for the New World Order. This is an inside joke to the Galactic Federation, to defame his image and make a mockery of his life. Akhenaton was/is a Krystic being serving the Law of One and Reclamation of Christos Mission, attempting to negotiate with these rogue Annunaki groups to allow humanity to ascend in the 2012 window without interference. His negotiations to enter into a peace treaty failed, shortly after he was murdered a heretic king by a family member, and thus branded as a Luciferian high priest to the Illuminati hybrid lines.

4 notes

·

View notes

Text

The Role of Pneumatic Actuators in Smart Manufacturing

Integrating Pneumatics into the Smart Factory Framework Smart manufacturing represents a paradigm shift in industrial operations, where advanced digital technologies such as IoT, AI, and machine learning converge with traditional manufacturing processes. Pneumatic actuators, long valued for their simplicity and reliability, now find renewed relevance in this connected ecosystem. As industries migrate towards automation and data-driven decision-making, pneumatic actuators are being integrated into smart systems that enable real-time monitoring, remote control, and predictive maintenance. These pneumatic linear actuators can be equipped with sensors that relay crucial data on pressure, position, and performance metrics to centralized control systems. This integration transforms pneumatic actuators from basic mechanical devices into intelligent components that contribute to the overall responsiveness and efficiency of the smart factory.

Enhancing Precision and Efficiency in Automated Processes In smart manufacturing environments, precision and repeatability are non-negotiable. Pneumatic actuators provide consistent linear or rotary motion that is critical for various tasks such as material handling, packaging, and assembly. Unlike their hydraulic counterparts, pneumatic actuators offer faster response times and cleaner operation, making them well-suited for environments that prioritize speed and hygiene. When incorporated with programmable logic controllers (PLCs) and advanced control systems, these actuators can operate with high degrees of accuracy and coordination. This enhanced precision leads to reduced waste, lower defect rates, and improved throughput, which are essential metrics in any smart manufacturing setup aiming for lean production.

Supporting Flexibility in Modular Manufacturing Systems One of the hallmarks of smart manufacturing is flexibility— the ability to quickly adapt to changes in product design, volume, or customization without incurring significant downtime or cost. Pneumatic actuators play a key role in supporting this flexibility. Their modular design and ease of integration allow them to be reconfigured or replaced with minimal disruption to the production line. For instance, pneumatic grippers and cylinders used in robotic arms or conveyor systems can be rapidly adjusted or upgraded to accommodate new tasks. This adaptability is especially valuable in industries that rely on batch production or mass customization, where rapid changeovers are a competitive advantage.

Driving Energy Efficiency and Sustainability Sustainability is a growing priority in modern manufacturing, and pneumatic actuators contribute by promoting energy-efficient practices. Traditional pneumatic systems have often been criticized for energy losses due to air leakage and inefficient compressors. However, smart manufacturing leverages advanced monitoring and control technologies to optimize air usage and detect inefficiencies. Pneumatic actuators equipped with smart valves and sensors can dynamically adjust their operation based on load requirements, reducing unnecessary air consumption. Additionally, manufacturers can use real-time data to identify system leaks and maintenance needs before they become costly. This proactive approach not only lowers energy bills but also aligns with environmental compliance and sustainability goals.

Enabling Predictive Maintenance and System Reliability Downtime is a costly threat to productivity, and smart manufacturing combats this through predictive maintenance strategies. Pneumatic actuators integrated into the smart ecosystem contribute to system reliability by continuously reporting their status and performance. Data on cycle counts, operating temperature, and response delays can be analyzed to forecast wear and schedule timely maintenance. This reduces unplanned stoppages and extends equipment lifespan. Furthermore, predictive analytics enable maintenance teams to make informed decisions, optimize spare part inventory, and schedule interventions during non-critical production periods. In this way, pneumatic actuators play a vital role in ensuring operational continuity and maximizing overall equipment effectiveness.

Conclusion Pneumatic actuators are evolving in response to the demands of smart manufacturing, transitioning from simple motion devices to integral parts of intelligent systems. Their roles in enhancing precision, enabling flexibility, improving energy efficiency, and supporting predictive maintenance make them indispensable in the smart factory landscape. As manufacturing continues to advance, pneumatic actuators will remain critical components, delivering the motion and control that power the future of automation.

0 notes

Text

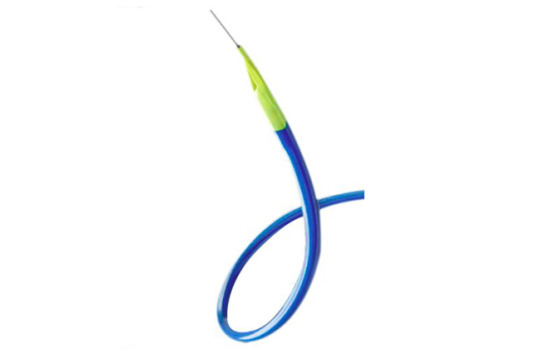

ST Stone Medical Devices Pvt. Ltd. - Comprehensive Product Overview

Established in 2012 and officially operational since 2014, ST. Stone Medical Devices Pvt. Ltd. has emerged as a pioneering force in the Indian medical device manufacturing sector. Headquartered in North East India, the company holds the honor of being the first manufacturer licensed by CDSCO and the State Drug Authority in the region for producing and distributing medical devices.

Over the years, ST. Stone has carved out a strong presence in the medical industry with a broad portfolio of products designed to meet the highest clinical standards. The company specializes in developing, assembling and exporting advanced devices for nephrology, interventional cardiology, anaesthesia, critical care and general consumables. With a firm commitment to innovation, quality assurance and customer support, ST. Stone continues to serve both domestic and international healthcare markets.

Our Medical Device Range

Peritoneal Dialysis Catheter Kit (Tenckhoff, Coil, Swan Neck)

Stone offers a robust selection of Peritoneal Dialysis Catheter Kits, including:

Tenckhoff Catheters: These standard two-cuff straight catheters are widely used for both CAPD and APD procedures. Known for their simplicity and reliability, they are a staple in renal care.

Coil Catheters: Designed with a coiled distal segment that enhances stability and helps reduce catheter migration inside the peritoneal cavity.

Swan Neck Catheters: Feature a permanent bend in the mid-section and a coiled intra-abdominal portion. These are especially effective in maintaining catheter position and minimizing infection risks.

Each kit includes cuffs, clamps, adapters and other essential components for a complete dialysis setup.

CAPD Accessories: Mini Cap, Transfer Set, Titanium Adaptor

Complementing their catheter range, ST. Stone provides CAPD accessories that are essential for ensuring sterile and effective peritoneal dialysis:

Mini Cap: Used to seal off the catheter end and protect it from environmental exposure.

Transfer Set: Connects the dialysis solution bag to the peritoneal catheter, facilitating a safe and smooth exchange process.

Titanium Adaptor: Ensures a strong and stable connection between the catheter and extension set, enhancing durability and reliability during long-term use.

Hemodialysis Catheter Kits

Stone's dialysis range covers both emergency and long-term vascular access:

Short-Term Dialysis Catheter Kit: Designed for acute dialysis, this kit includes polyurethane catheters, nitinol guidewires and all insertion accessories. The kits are sterile, easy to use and optimized for temporary vascular access.

Acute Long-Term Dialysis Catheter Kit: Built for extended treatment, this kit includes reinforced catheter tubing with features like dual cuffs and kink resistance for patient comfort.

Permanent Dialysis Catheter Kit (Platinum+): A premium offering with tunneled, cuffed silicone catheters ideal for long-term implantation. The silicone material and biocompatible design help reduce infection and clotting risks.

Peripherally Inserted Central Catheter (PICC)

The PICC line product range under the CentVent™ brand is available in single, double and triple-lumen configurations. These catheters manufacturer using high-quality polyurethane and are ideal for long-term IV therapies, including antibiotics, chemotherapy and nutrition. Their kink-resistant and patient-friendly design ensures secure placement and longevity.

Central Venous Catheter (CVC) Kit

These comprehensive CVC kits include central venous catheters along with all required components such as:

Guidewires

Introducer needles

Dilators

CVC kits are designed for infusion therapy, blood sampling and central venous pressure monitoring, especially in ICU and emergency care settings.

Aspiration Catheter

Aspiration catheters are used in interventional cardiology and radiology procedures to remove thrombus or unwanted fluids from blood vessels. These devices are engineered to offer precise suction and navigation, making them essential for emergency procedures involving blocked arteries.

Guidewires ST Stone offers a comprehensive lineup of guidewires, each tailored to specific procedural needs:

PTFE-Coated Guidewire: Offers a smooth surface for easy advancement of catheters and stents.

Hydrophilic Guidewire: Low-friction surface enhances maneuverability in complex vascular paths.

Lunderquist Guidewire: Extra-stiff design for high-support vascular and structural heart procedures.

Nitinol Guidewire: Combines flexibility with resistance to kinking, ideal for navigating tortuous anatomy.

Extra Stiff Guidewire: Provides superior support for delivering large-profile devices.

Stainless Steel Guidewire: Offers excellent torque control and is used in a variety of vascular interventions.

Zebra Guidewire: Identifiable by its striped design, it offers both visibility and flexibility for challenging placements.

Bone Marrow Devices: Jamsidi Needle & T-Handle

Jamsidi Bone Marrow Needle: A trusted tool for extracting bone marrow samples, often used in hematology and oncology settings.

Bone Marrow T-Handle: Provides better grip and control for manual aspiration of bone marrow, reducing patient discomfort and procedural time.

Needles: Spinal (Quincke & Pencil Point)

Spinal Needle Quincke Tip: Sharp cutting tip ideal for quick penetration and low resistance in spinal anesthesia.

Spinal Needle Pencil Point: Atraumatic tip that helps reduce post-procedural complications such as headaches. Designed for smooth entry and reduced tissue damage.

Epidural Kit (Minipack)

This all-in-one kit includes an epidural needle, catheter, connector, filter and dressings. The minipack format ensures quick setup and sterile delivery of regional anesthesia, commonly used in obstetrics and post-operative pain management.

Foley Silicone Catheter

Made from medical-grade silicone, these Foley catheters are intended for long-term urinary drainage. Their biocompatible design minimizes irritation and reduces the risk of encrustation and infection.

Skin Stapler

The skin stapler is a precision surgical tool used for the closure of wounds and surgical incisions. It allows for quick, consistent stapling, which minimizes trauma and accelerates healing.

High Pressure Line Braided

Braided pressure lines are used in high-pressure injections and interventional procedures. The braided reinforcement allows for consistent fluid delivery without compromising the line's integrity under stress.

Arterial Catheter

Arterial line catheters are used for real-time blood pressure monitoring and arterial blood sampling. They are vital for critically ill patients and during surgeries that require close hemodynamic monitoring.

Y Connectors (Push-Pull, Push-Click, Screw Type)

Y connectors are essential components in catheter-based procedures. ST. Stone offers them in various locking styles:

Push-Pull: For quick attachment and detachment.

Push-Click: For added security and tactile feedback.

Screw Type: Offers the most secure fit, ideal for long-duration procedures.

Guiding Catheter

Used in interventional cardiology and radiology, guiding catheters help direct other instruments, such as stents or balloons, to the treatment site. They offer strong support, high torque control and atraumatic tips for vessel safety.

Introducer Needles (Y Shape, Pink Hub, White Hub)

Introducer needles are critical for accessing veins or arteries prior to inserting catheters or guidewires. They are available in different hub colors and shapes for quick identification and specific procedural requirements.

Why ST. Stone Stands Out?

Certified Quality: Licensed by CDSCO & state authorities; products adhere to global standards.

Comprehensive QA: Sterility, material integrity and performance are rigorously tested.

Innovative Solutions: Continuously refined through dedicated R&D.

Customer Support: End-to-end assistance from initial consultation to technical service.

Conclusion Stone Medical Devices Pvt. Ltd. has built an extensive and high-performance product lineup designed to meet the evolving needs of modern healthcare. From dialysis solutions and vascular access systems to specialized interventional and surgical tools, each product is crafted with meticulous attention to quality, functionality and patient safety. As a fully licensed manufacturer with a global vision, ST. Stone continues to set new benchmarks in medical innovation and reliability.

youtube

0 notes

Text

A recently developed block copolymer could help push the limits of integration and miniaturization in semiconductor manufacturing, report scientists in Tokyo Tech and TOK. Chemically tailored for reliable directed self-assembly, the proposed compound can arrange itself into perpendicular lamellar structures whose half-pitch width is less than 10 nanometers, outperforming conventional and widely used block copolymers. Miniaturization is one of the fundamental qualities of modern electronics and is largely responsible for the incredible increments in performance witnessed over the past decades. To keep this momentum going, it is necessary to achieve circuit patterns finer than the existing ones on semiconductor chips, which are a crucial part of all electronic devices. Some experts estimate that, by 2037, the smallest distance between features in semiconductor devices, known as 'half-pitch,' will need to be as small as 8 nm to support next-generation electronics, emphasizing the need for advancements in lithographic processes (method of creating highly complex circuit patterns on semiconductor parts).

Read more.

#Materials Science#Science#Block copolymers#Polymers#Semiconductors#Manufacturing#Self assembly#Tokyo Institute of Technology

13 notes

·

View notes

Text

The Evolution of Barcode Scanner Readers | Modern Barcode Scanner Guide – AIDC India

Barcode Scanner Readers

Introduction to Barcode Scanner Readers

Barcode Scanner Readers have completely changed how businesses track, manage, and sell products. From scanning prices at supermarkets to managing large warehouse inventories, these devices have become part of everyday operations. Over the years, they’ve evolved from simple tools to smart devices that make work faster and more accurate. This blog explores the journey of Barcode Scanner Readers, modern types, and why they matter for businesses today.

History of Barcode Scanner Readers: From Basics to Innovation

The story of Barcode Scanner Readers starts in the 1970s, when the first commercial barcode was scanned on a pack of chewing gum. Early scanners were large, slow, and needed direct contact to read codes. As technology advanced, these scanners became faster, smaller, and capable of reading codes from different angles. Today, Barcode Scanner Readers can read multiple types of codes in seconds, even on curved or damaged surfaces. This evolution shows how these devices have kept pace with growing business needs.

Types of Modern Barcode Scanner Readers

Modern Barcode Scanner Readers come in different forms, each suited for specific tasks. Handheld scanners are popular in retail stores and warehouses because they’re easy to use and portable. Fixed-mount scanners are common on production lines where items move quickly. Wireless barcode scanners add flexibility, allowing staff to move freely without tangled cables. Even smartphones can act as Barcode Scanner Readers through special apps, making it easier for small businesses to start without investing in separate devices. This variety helps businesses pick the right tool for their workflow.

Key Features of Today’s Barcode Scanner Readers

Today’s Barcode Scanner Readers offer many features that make them powerful business tools. They can read 1D and 2D barcodes, scan items quickly, and connect with computers and inventory systems. Some advanced models use laser or imaging technology to read damaged or poorly printed codes. Wireless models can work over long distances, and many scanners now come with built-in memory to store data when offline. These features save time, reduce mistakes, and help staff work more efficiently.

Industries Benefiting from Advanced Barcode Scanner Readers

Barcode Scanner Readers are used in many industries beyond retail. In healthcare, they help track medicines and patient records, reducing the chance of errors. In logistics and warehouses, they manage thousands of items daily, improving inventory accuracy. Manufacturing plants use scanners to track parts on assembly lines, while libraries use them to manage books. Even small businesses use Barcode Scanner Readers to simplify billing and stock management. Their adaptability makes them a must-have for almost every industry.

How Barcode Scanner Readers Improve Business Efficiency

Using Barcode Scanner Readers helps businesses in many ways. They reduce human errors that come from manual data entry, saving time and improving accuracy. Quick scanning speeds mean staff spend less time checking items, which keeps operations smooth. Barcode Scanner Readers also help with real-time inventory updates, so managers know exactly what’s in stock. This helps prevent overstocking or running out of items. Overall, they make business operations faster, more organized, and more reliable.

AIDC Technologies India: Empowering Businesses with Barcode Scanner Readers

AIDC Technologies India is known for offering reliable and advanced Barcode Scanner Readers to businesses of all sizes. Their solutions help companies in retail, manufacturing, healthcare, and logistics improve productivity and accuracy. By providing not just devices, but also support and integration, AIDC Technologies ensures that businesses get the best value from their barcode systems. Whether you’re upgrading your scanners or setting up a new system, their expertise makes the process smooth and effective.

Book now with AIDC Technologies India to bring modern barcode scanning solutions to your business.

Future Trends in Barcode Scanner Readers Technology

The future of Barcode Scanner Readers is exciting. Newer models are being designed with AI-powered image recognition, allowing them to read codes even in difficult lighting or from damaged labels. Integration with the Internet of Things (IoT) will let scanners share data instantly with other smart devices, improving decision-making. Some Barcode Scanner Readers are also becoming part of wearable devices, so staff can scan items without holding a separate scanner. These trends show how technology will keep making barcode scanning smarter and more user-friendly.

Conclusion: Why Modern Barcode Scanner Readers Matter

Barcode Scanner Readers have come a long way from large, slow devices to compact, high-speed tools that power modern businesses. They improve accuracy, speed up processes, and help manage data effectively. With reliable providers like AIDC Technologies India, businesses can access the latest scanning technology and stay competitive in their industries. As these devices continue to evolve, their role in simplifying operations and boosting efficiency will only grow stronger.

Ready to Upgrade Your Business with Barcode Scanner Readers?

Discover reliable, modern Barcode Scanner Readers that boost speed and accuracy in your daily operations. Contact AIDC Technologies India today and book your barcode solution now!

0 notes