#BIM for reuse projects

Explore tagged Tumblr posts

Text

The Role of a Construction Estimating Service in Urban Redevelopment and Adaptive Reuse

Introduction: Breathing New Life into Old Structures

Urban redevelopment and adaptive reuse projects are reshaping city landscapes by revitalizing aging infrastructure and underused buildings. These projects are often more complex than new construction due to the need to evaluate existing conditions, comply with evolving regulations, and preserve historical features. A construction estimating service plays a critical role in providing cost clarity, identifying potential risks, and ensuring project feasibility from the outset.

Unique Cost Challenges of Urban Redevelopment

Unlike greenfield projects, urban redevelopment involves variables that are often hidden until construction begins. These may include outdated building systems, structural deficiencies, hazardous materials, or non-compliant layouts. A construction estimating service must thoroughly assess these unknowns during the preconstruction phase, allocating contingencies and documenting assumptions based on site investigations and historical data.

Detailed Scope Analysis and Phasing

Urban redevelopment often requires phased construction to manage occupancy, utility disruptions, or zoning limitations. For adaptive reuse, construction may need to occur while parts of the building remain operational. A construction estimating service helps plan each phase with precision, ensuring that logistics, sequencing, and access constraints are reflected in labor costs, equipment rentals, and schedule impacts.

Dealing with Historical Preservation Requirements

When adaptive reuse involves heritage buildings, compliance with historical preservation standards can increase costs significantly. Specialized materials, traditional construction techniques, and additional permits may be required. Estimators must understand these requirements and consult with preservation experts to ensure budgets are both realistic and sensitive to the historical integrity of the project.

Estimating for Environmental Remediation

Urban sites often have legacy environmental issues such as asbestos, lead paint, or contaminated soil. A construction estimating service collaborates with environmental consultants to price remediation efforts. These costs can be substantial, especially in older industrial or commercial buildings being converted into modern residential or mixed-use developments.

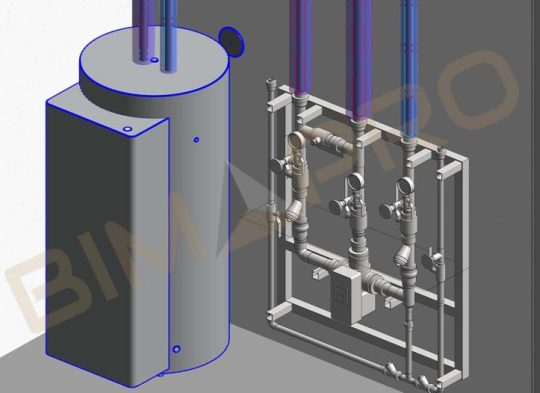

Integration of Modern Systems into Old Structures

Adaptive reuse demands retrofitting new mechanical, electrical, plumbing (MEP), and fire protection systems into outdated frameworks. This often requires custom solutions, selective demolition, or rerouting infrastructure. Estimators must account for higher labor costs and the challenges of fitting standardized systems into non-standard conditions, which can impact timelines and budgets.

Navigating Incentives and Funding Requirements

Urban redevelopment projects are frequently supported by government incentives such as tax credits, grants, or low-interest financing. Many of these incentives have cost-reporting or compliance requirements. A construction estimating service helps developers meet these criteria by providing detailed cost breakdowns and documentation that align with funding rules, particularly in affordable housing or sustainability-focused projects.

Supporting Sustainability and Resilience Goals

Many adaptive reuse projects aim for sustainability certifications like LEED or WELL. A construction estimating service assesses the cost impact of energy-efficient upgrades, low-emission materials, and improved building envelopes. In urban redevelopment, resilience against floods, heat, or seismic risks may also factor into estimates, especially in cities with updated codes to address climate change.

Managing Stakeholder Expectations

Redevelopment projects often face heightened scrutiny from communities, planners, and investors. A construction estimating service brings transparency to the cost implications of design decisions and regulatory mandates. Clear, itemized estimates support stakeholder buy-in, enabling informed decision-making throughout the project's lifecycle.

Technology and Site Intelligence Tools

To improve accuracy, estimators use tools like laser scanning, point cloud data, and Building Information Modeling (BIM) to analyze existing conditions. These technologies help convert outdated or incomplete building documentation into reliable inputs for cost modeling, reducing the risk of major surprises during construction.

Conclusion: Turning Complexity into Opportunity

Urban redevelopment and adaptive reuse projects offer environmental, cultural, and economic benefits—but only if budgets are accurately planned. A construction estimating service serves as a strategic advisor, helping project teams navigate the complexity of existing structures, permitting hurdles, and historical constraints. With detailed cost insights and contingency planning, estimators transform redevelopment challenges into viable, forward-looking projects that reinvigorate cities and preserve architectural legacy.

#urban redevelopment estimating#adaptive reuse cost#estimating old buildings#redevelopment construction service#cost estimate historic building#building retrofit cost#asbestos removal cost#phased construction estimate#urban zoning cost#legacy building systems#code upgrade estimate#adaptive reuse estimator#BIM for reuse projects#historical preservation cost#affordable housing cost estimate#grant compliance estimate#contaminated site cost#seismic upgrade estimating#LEED retrofit estimate#utility rerouting cost#estimating with unknowns#stakeholder budget planning#community housing estimate#fire system retrofit cost#sustainability upgrade cost#resilience planning estimate#estimating with point cloud#downtown redevelopment cost#mixed-use conversion budget#city infill estimator

0 notes

Text

Revit Drafting: The Complete Guide to 2D Detailing

When we think of Revit, the first thing that usually comes to mind is 3D modeling — smart walls, floors, roofs, and intelligent building components. But behind every beautiful model lies a foundation of 2D drawings and details that bring the design to life on-site. That’s where Revit Drafting comes in — a critical but often overlooked aspect of BIM.

In this guide, we’ll explore everything you need to know about Revit drafting — from the basics to best practices — and how it fits into your workflow whether you’re an architect, designer, or construction professional.

What is Revit Drafting?

So, you’ve probably heard that Revit is used to create 3D models of buildings. You can model everything — walls, floors, roofs, windows — pretty much the whole structure. It’s like building a virtual version of your project on the computer.

But here’s the thing: even after the 3D model is done, you still need to explain how to actually build it in real life. You can’t just send a contractor a 3D file and say, “Here you go, build this.” That’s not how it works. Builders need proper construction drawings — like floor plans, sections, and detailed views that clearly show how different parts come together.

This is where Revit Drafting Services comes into play.

Think of it like the old-school hand-drawing architects used to do, but now it’s done digitally inside Revit. You use drafting tools in Revit to create neat and accurate 2D drawings — especially the little details, like how a window fits into a wall or how a roof edge is waterproofed. It’s quick, smart, and much cleaner than drawing by hand. And it helps make sure everyone on site knows exactly what to do.

Two Ways You Can Do Drafting in Revit

When you’re working in Revit, there are two main ways to do drafting, and each one has its own purpose depending on what you’re trying to show.

Drafting That’s Connected to Your Model

This first type of drafting comes straight from your 3D model. As you build your model — walls, doors, floors, roofs — Revit automatically creates views like floor plans, sections, and elevations based on what you’ve modeled.

For example, if you draw a wall in 3D, Revit will automatically show that wall in the floor plan. And here’s the cool part: if you change something — like make the wall taller or switch its material — Revit updates all the related views automatically. No need to redraw anything.

These views are smart and stay in sync with your model. So, when the model changes, your drawings change too. It saves a lot of time and keeps things accurate. These are called “live views“, and they’re great for showing real-time progress and construction info directly tied to your design.

Drafting Views (Like Sketching from Scratch)

The second way is called a drafting view, and it’s more like sketching on a blank sheet of paper. These views aren’t connected to the model. They’re just clean, empty 2D spaces where you can draw details from scratch.

Let’s say you need to show a typical wall section that you use on every project, or a flashing detail around a window — something you already know and don’t need to model every time. In that case, you just open a drafting view and start drawing using lines, hatch patterns, text notes, and detail components.

It’s like you’re freehand drawing a familiar detail — but doing it digitally, in a way you can reuse again and again across different projects.

Tools You’ll Use for Drafting in Revit

When it comes to drafting in Revit, there are some really handy tools that make your work easier and your drawings look clean and professional. Let’s go through them one by one :

Detail Lines – These are your go-to lines for drawing things manually. You can use them to sketch edges, outlines, shapes — basically anything you want to show in 2D that isn’t coming directly from the model. It’s kind of like using a pencil to draw something on paper, but now it’s all digital. Filled Regions – Imagine you’re shading in part of your drawing to show different materials — like concrete, insulation, or soil. That’s what filled regions are for. You can apply different hatch patterns to areas, making your details easy to understand at a glance. It’s like coloring inside the lines with patterns instead of colors. Detail Components – These are ready-made 2D parts that you can just drop into your drafting views. Think of things like steel bolts, wall ties, anchors, or insulation batts. Instead of drawing each tiny piece from scratch every time, you just pick one from the library and place it in your view. Saves time and keeps things looking neat and consistent. Text Notes & Leaders – Need to explain something on your drawing? You’ll use text notes. Add simple labels like “Install flashing here” or “Provide waterproofing.” You can also attach leaders — those little arrows or lines that point from your note to the exact spot you’re talking about. It makes your details clear and easy to follow. Dimensions – To show how far things are from one another, you’ll use dimensions. The best part? They’re smart — if you move something, the dimension updates automatically. No more re-checking measurements or redrawing when things shift. Keynotes – These are like smart labels. Instead of typing out full notes every time, you can use keynotes to tag elements with pre-written descriptions — like “Wall Type B” or “Steel Beam W10x30.” It helps keep your notes short, standardized, and consistent across the whole drawing set.

Know More:- https://www.bimprous.com/revit-drafting-guide-to-2d-detailing/

#RevitDraftingServices#RevitDraftingforArchitects#RevitDraftingforMEPEngineers#RevitDraftingforContractors#RevitDraftingforCivilEngineers

1 note

·

View note

Text

I3S × OSGB! Interoperability of 3D city models

Free on-premise cesium ion alternative

A new era of 3D city data As demand for digital twins and smart cities grows, the development and use of 3D city models is progressing rapidly. At the heart of this is a 3D tile format that can efficiently visualize and distribute buildings, terrain, and more.

Among them, the “Indexed 3D Scene Layer (I3S)” format, which is widely used in Esri’s ArcGIS platform, has become a standard, especially for local governments and large-scale GIS projects.

What are the benefits of the I3S format?

I3S is an advanced 3D data format with the following features:

🌍 **Multiple hierarchies and LOD (Level of Detail) support** enable lightweight display

🏢 Supports multiple types such as buildings, point clouds, and meshes

🔄 High compatibility with ArcGIS Online and ArcGIS Pro

🌐 Strong in real-time display via web browsers

However, on the other hand, there is also the issue of “low compatibility with other 3D platforms.” For example, interoperability with Cesium, FME, OSGB (tilt photography), etc. is limited, and many people have trouble centrally managing and reusing 3D assets.

GISBox considering I3S conversion support?

In light of this background, the 3D geospatial management platform “GISBox” is expected to add support for the I3S format and a conversion function to OSGB/3D Tiles in the future.

GISBox is currently a SaaS-based 3D spatial tile generation and distribution solution that supports major formats such as S3M, OSGB, and 3D Tiles, and can integrate multiple data such as point clouds, tilt photos, and BIM models.

If automatic conversion, preview, and distribution of I3S to 3D Tiles, I3S to OSGB, etc. were to be realized,

✅ Assets built with ArcGIS can be used in other engines (Cesium, Unreal, Unity, etc.)

✅ Web distribution and API integration of I3S format data is possible

✅ Improved reusability of 3D data between different projects and companies and other great benefits would be created.

Expected future prospects

Currently, GISBox is used by many public institutions and construction and civil engineering companies, and requests for “Is I3S support available?” are increasing. This truly represents the market need to effectively utilize I3S data outside the Esri platform.

If “I3S conversion and import” is realized in a future update, it will be a major opportunity for not only ArcGIS users but also a wide range of industries to switch to GISBox.

🔖Summary

The era of 3D geospatial data is evolving beyond the barriers of format. The I3S format is no exception, and our next step is to make its rich structure available for other 3D platforms. Please keep an eye on the future evolution of GISBox.

GISBox Official Teams: https://teams.live.com/l/invite/FEAr12sInvEVy4hFQE Official Teams Group: https://teams.live.com/l/invite/FBAFp0pbqhqlpe1BQI

Contact us to get 7-day Team Plan

0 notes

Text

How Smart Technology Is Transforming Basement Excavation Projects

Sustainable Basement Excavation Methods in 2025

As environmental concerns grow and construction practices evolve, sustainability has become a key focus in basement excavation projects. In 2025, homeowners, developers, and contractors are increasingly turning to eco-friendly methods to minimize environmental impact, reduce waste, and conserve energy all while maintaining the quality and durability of the build.

This blog explores the most effective and widely adopted sustainable basement excavation methods in 2025, along with their benefits and future potential.

1. Low-Impact Excavation Techniques

Conventional excavation practices typically rely on fuel-intensive machinery, leading to significant carbon emissions and environmental strain. In 2025, low-impact excavation equipment powered by electricity or hybrid engines is reducing the carbon footprint on-site. These machines operate more quietly, use less energy, and cause minimal disruption to the surrounding soil and structures.

2. Soil Reuse and On-Site Recycling

Instead of hauling away excavated soil, many projects now adopt on-site soil reuse practices. After testing and treatment, suitable soil is repurposed for landscaping, backfilling, or grading. Similarly, concrete and rubble from demolished structures are crushed and reused as base material, drastically cutting down landfill waste.

3. Green Material Selection for Retaining Walls and Foundations

Eco-conscious contractors are choosing recycled concrete blocks, sustainable steel, and low-carbon cement for retaining walls and foundational work. These materials offer the same strength and durability but significantly lower the embodied energy in construction.

4. Water Management and Rainwater Harvesting Systems

Digging and soil disturbance during excavation can alter natural drainage patterns, often causing runoff and increased soil erosion. In 2025, sustainable drainage systems (SuDS) and rainwater harvesting setups are integrated into basement designs. These systems capture, filter, and reuse rainwater for gardening, flushing, or cooling, making efficient use of natural resources.

5. Smart Planning with Digital Tools

Building Information Modelling (BIM) and Geographic Information Systems (GIS) help plan basement excavations with precision, reducing waste and avoiding unnecessary digging. These digital tools ensure every cut is calculated, avoiding over-excavation and conserving energy and materials throughout the process.

6. Use of Geotextiles and Natural Barriers

Instead of using chemical barriers for soil stability and water control, many sites now use biodegradable geotextiles and natural clay linings. These solutions stabilize soil, prevent erosion, and are safe for the environment.

7. Noise and Dust Control Measures

Eco-friendly excavation in 2025 means keeping noise and air pollution to a minimum. Projects now use dust suppression systems, soundproof barriers, and low-noise machinery, creating cleaner and safer conditions for both workers and nearby residents.

8. Energy-Efficient Site Lighting and Power

Temporary site infrastructure is becoming greener too. Solar-powered lighting, LED setups, and battery storage systems now replace diesel generators, further reducing emissions during excavation and construction.

Conclusion

Sustainable basement excavation in 2025 is not just about reducing environmental harm. it's about building smarter, cleaner, and more responsibly. By using modern technologies, recycling resources, and planning thoughtfully, contractors and homeowners can ensure their basement projects are both future-ready and environmentally sound.

The future of excavation lies not only in going deeper but also in building better for the planet..

0 notes

Text

Smart Manufacturing Techniques Precast Concrete Suppliers Are Embracing

The construction industry is witnessing a major shift as precast concrete suppliers embrace smart manufacturing techniques to improve efficiency, reduce costs, and enhance product quality. With the demand for faster, sustainable, and high-precision building solutions at an all-time high, these suppliers are turning to advanced technologies to stay competitive. Let’s explore the smart manufacturing techniques that are transforming precast concrete production.

1. Automation and Robotics

Precast concrete suppliers are increasingly using automation and robotics to streamline production processes. Automated batching systems ensure accurate mix designs every time, while robotic arms can quickly and precisely handle heavy lifting, demolding, and finishing tasks. This enhances productivity, reduces labor dependency, and eliminates the inconsistencies associated with manual processes.

By minimizing human error and enabling continuous production cycles, automation allows suppliers to deliver high-quality concrete components on a predictable schedule — a crucial factor for large-scale projects.

2. Building Information Modeling (BIM) Integration

BIM is revolutionizing the design, coordination, and execution of precast concrete projects. Suppliers can now create digital 3D models of each concrete panel before casting, allowing architects and engineers to visualize every detail. From design optimization to clash detection and accurate quantity estimations, BIM improves project accuracy and communication across teams.

With integrated BIM data flowing into the manufacturing floor, precast suppliers can produce tailor-made components with the exact required dimensions, embeds, and finishes — all verified digitally before physical fabrication.

3. Sensors and Internet of Things (IoT)

More and more precast concrete facilities are utilizing IoT-enabled devices to monitor their production lines in real time. Sensors installed in molds and machinery can track concrete curing rates, ambient temperature, humidity, and machine performance. This continuous data flow allows managers to optimize process parameters, reduce energy consumption, and predict maintenance before equipment breakdowns occur.

IoT also provides traceability — every batch of concrete can be tracked digitally from raw material intake to delivery at the jobsite. This traceability simplifies quality assurance and improves customer confidence.

4. 3D Printing and Prefabrication

Although still evolving, 3D printing is making waves in the precast industry. This additive manufacturing technique enables suppliers to create intricate molds and custom shapes that would be difficult or impossible to achieve through traditional casting. 3D-printed molds also reduce production lead time and material waste.

Additionally, advanced prefabrication techniques such as modular precast components allow entire sections of a structure — like walls, stairs, or façades — to be assembled off-site in a controlled environment. This minimizes on-site labor, speeds up installation, and improves site safety.

5. Green Manufacturing and Circularity

Sustainability is top of mind for today’s precast concrete suppliers. Many are investing in eco-friendly processes like using recycled aggregates, incorporating supplementary cementitious materials (SCMs) like fly ash, and harnessing solar energy for production. Some suppliers also embrace closed-loop water recycling systems, capturing and reusing water that would otherwise go to waste.

By implementing these green manufacturing techniques, suppliers reduce their carbon footprint and contribute to more environmentally responsible construction practices.

6. Advanced Quality Control Systems

Smart manufacturing enables automated quality control checks at every stage of production. Precast plants use laser scanning and computer-vision-based inspections to detect cracks, dimensional deviations, or surface defects. These systems ensure that only panels meeting strict tolerance levels reach the construction site, enhancing durability and aesthetics.

In some cases, suppliers are also leveraging artificial intelligence (AI) to predict and prevent potential defects by analyzing historical data. This level of predictive maintenance minimizes rework and costly delays.

Conclusion

Smart manufacturing is paving the way for a more efficient, sustainable, and precision-driven precast concrete industry. Techniques like automation, BIM, IoT, and green practices enable suppliers to optimize their processes while reducing waste and delivering superior quality. The result? Faster project timelines, improved safety, and long-term value for clients across all sectors of construction.

By embracing these smart manufacturing techniques, precast concrete suppliers can position themselves at the forefront of innovation — and help build a smarter, greener future.

Ready to Partner with a Leading Precast Concrete Supplier?

At DC Kerckhoff Company, we leverage the latest smart manufacturing techniques to deliver precision-crafted, sustainable precast concrete solutions as trusted precast concrete manufacturers for your next project. Whether you need custom components or full-service support, our experienced team is here to help you build smarter, faster, and more efficiently.Contact us today to learn more about our capabilities and discover how DC Kerckhoff Company can help bring your vision to life!

0 notes

Text

Coimbatore’s New Wave of Design Education: How the City Is Shaping India’s Next‑Gen Architects

Unlike bigger metros where learners are often confined to classroom theory, Coimbatore’s compact urban fabric lets studios spill into the streets. Students regularly map heritage precincts near Race Course, document green roofs in Kovaipudur, and prototype climate‑responsive facades that can handle the summer highs of Tamil Nadu. This “city‑as‑campus” model turns every semester into a portfolio of real‑world case studies.

2. Intersections of Tech and Craft

With several precision‑manufacturing parks on the city’s outskirts, architecture programs here lean heavily on digital fabrication. Workshops in CNC milling, 3‑D printing, and parametric design sit right beside clay‑model studios and vernacular building labs, giving learners both code and craft fluency — an edge recruiters increasingly demand.

3. Spotlight on Bumblebee’s Studio‑First Approach

Among the institutes championing this hybrid philosophy, Bumblebee stands out for its tightly mentored design studios, industry‑backed juries, and semester‑long community projects. Prospective students looking for an evidence‑based curriculum can explore Bumblebee’s detailed syllabus, admission criteria, and studio culture in this comprehensive guide to the best architecture courses in Coimbatore.

Best Architecture Courses in Coimbatore Tamil Nadu — Bumblebee

Career Trajectories Beyond the Drafting Table

A solid architectural education in Coimbatore opens doors well beyond the traditional “licensed architect” track:

Sustainable Design Consultant — Tackle net‑zero mandates for IT parks along Avinashi Road.

Urban Regeneration Specialist — Revive historic pockets like RS Puram while meeting smart‑city KPIs

Data‑Driven Space Planner — Use GIS and BIM to craft pandemic‑resilient campuses.

Design‑Tech Entrepreneur — Spin off start‑ups in modular housing or adaptive reuse.

Successful alumni cite the city’s maker culture, peer collaboration, and exposure to live projects as catalysts for their rapid ascent.

Choosing the Right Program: A Quick Checklist

Visit the Campus Studio: Does it buzz with iterative models or just rows of drafting tables?

Review the Portfolio Requirements: Look for balanced emphasis on concept, context, and constructability.

Speak to Current Students: Ask about mentorship hours, crit frequency, and software access.

Evaluate Industry Links: A pipeline to construction-tech firms or design consultancies is invaluable.

Assess Community Impact Projects: These show how theory translates to grassroots change.

Final Thoughts

For students seeking the best architecture courses in Coimbatore, Tamil Nadu, the city’s institutions — particularly innovators like Bumblebee — offer an environment where design curiosity meets technological prowess. With thoughtfully crafted curricula, hands‑on studios, and a city that doubles as an urban laboratory, Coimbatore is poised to sculpt India’s next generation of architecture leaders.

Ready to sketch your future? Start your exploration with the in‑depth program breakdown linked above, schedule a campus tour, and discover how Coimbatore can turn your design aspirations into built reality.

0 notes

Text

The Shift Toward Circular Economy in the Building Industry

The construction industry, traditionally reliant on linear consumption models, is undergoing a fundamental transformation. In response to growing environmental concerns, the sector is increasingly embracing the principles of the circular economy. These principles aim to redefine how resources are used, reducing waste and enhancing sustainability from the initial design to the end of a building's lifecycle. This article explores the key principles of circular economy in construction and how they can reshape the industry's future.

Understanding the Circular Economy in Construction At its core, the circular economy focuses on minimizing waste and maximizing resource use by creating closed-loop systems. In the context of construction, this means shifting away from the take-make-dispose model toward processes that preserve resources, maintain materials at their highest value, and reduce environmental impact. This approach transforms construction into a regenerative process rather than a consumptive one.

Design for Longevity and Adaptability One of the foundational principles of circular economy in construction is designing buildings that last longer and can adapt to changing needs. This involves choosing durable materials, modular design elements, and flexible layouts that support future modifications, thereby reducing the need for demolition and new construction.

Resource Efficiency and Material Recovery Optimizing the use of resources is critical in circular construction. This includes efficient sourcing of materials, reducing embodied carbon, and using renewable or recycled content. Material recovery strategies, such as deconstruction and selective dismantling, ensure components can be reused or recycled at the end of a building’s life.

Waste Minimization through Reuse and Recycling Instead of sending construction and demolition debris to landfills, circular principles advocate for repurposing existing materials. Salvaged wood, recycled steel, and reclaimed bricks can be reintroduced into new projects. Innovative recycling technologies also help convert waste into new construction inputs, minimizing environmental damage.

Lifecycle Thinking and Systemic Innovation Circular economy principles demand a full-lifecycle perspective. This means considering environmental and economic impacts from the design stage to construction, operation, renovation, and eventual demolition or repurposing. Systemic innovation includes digital tools like Building Information Modeling (BIM), which enables accurate tracking and management of materials throughout their lifecycle.

Collaboration Across the Value Chain Effective circular practices require collaboration between architects, engineers, contractors, suppliers, and policymakers. Shared responsibility and open communication ensure that circular objectives are embedded into every stage of the construction process. By aligning goals, stakeholders can support more sustainable outcomes.

Regulatory Support and Market Incentives Policy frameworks and financial incentives play a crucial role in encouraging circular practices. Governments can support adoption through green building codes, tax credits, and certification programs that reward sustainability. Market demand for eco-friendly buildings also drives innovation and adoption of circular strategies.

Technological Integration for Circular Practices Emerging technologies are enabling the shift to circular construction. Smart sensors, AI, and IoT devices can monitor resource use and predict maintenance needs, extending the life of structures. Digital twins and blockchain help ensure transparency in material sourcing and traceability, reinforcing trust in recycled materials.

Challenges and the Road Ahead Despite its potential, the transition to a circular economy in construction faces challenges such as high upfront costs, lack of standardized practices, and limited awareness. However, growing environmental regulations, client demand for sustainable buildings, and technological advancements are accelerating progress. Industry leaders who embrace circularity are likely to gain a competitive edge while contributing to global sustainability goals.

For More Info : https://bi-journal.com/what-are-the-principles-of-circular-economy-in-construction/

Conclusion The principles of circular economy in construction present a transformative path forward for a traditionally resource-intensive industry. By prioritizing sustainability, efficiency, and innovation, stakeholders can reduce environmental impacts and build for future resilience. The shift requires a holistic commitment, but the benefits—economic, environmental, and social—make it a direction worth pursuing.

#Circular Economy#Sustainable Construction#Green Building#BI Journal#BI Journal news#Business Insights articles

0 notes

Text

High-Precision Architectural Laser Scanning Services for Accurate As-Built Documentation

Our architectural laser scanning services provide accurate and detailed 3D point cloud data for your renovation, restoration, and construction projects. Using advanced LiDAR and 3D scanning technology, we capture existing building conditions with millimeter-level precision—ideal for architects, engineers, and contractors seeking reliable as-built documentation. Whether you're planning adaptive reuse or historic preservation, our scans ensure efficiency and minimize rework.

✅ BIM-ready models ✅ Accurate floor plans & elevations ✅ Fast turnaround with Leica RTC360

📍 Serving clients across the USA.

#construction#architecture#laser scanning#3d scanning#architectural laser scanning#3d laser scanning#bim

0 notes

Link

0 notes

Text

How 3D Map Illustration Renovation Projects

Renovation Projects of 3D Map Illustration

In today’s fast-paced world of urban development and architectural innovation, adaptive reuse and renovation projects are gaining ground. Rather than demolishing historic or outdated buildings, developers are now transforming them into modern, functional spaces. Let’s explore how these visual technologies support architects, planners, and developers in breathing new life into existing structures.

Understanding Adaptive Reuse and Renovation

Adaptive reuse refers to the process of repurposing buildings for uses other than those originally intended, like converting an old church into a library or an abandoned warehouse into a co-working space. Renovation, on the other hand, focuses on updating and repairing structures to make them more functional and appealing.

Both approaches require a deep understanding of existing layouts, infrastructure, and historical details—elements that can be challenging to manage with traditional blueprints alone.

Why 3D Map Illustration is a Game-Changer

1. Accurate Visualization of Existing Conditions

Unlike 2D blueprints, these illustrations depict depth, elevation, and spatial relationships, allowing teams to identify structural constraints or unique architectural features that must be preserved.

In adaptive reuse, where respecting the original character of the building is essential, this type of visual aid is invaluable. With Architecture Illustration, architects can showcase a building’s current state and proposed changes in a single frame.

2. Enhancing Stakeholder Communication

Whether you're dealing with investors, city planners, or preservation boards, 3D Vector Maps make complex plans easier to understand. These clean, scalable visuals can communicate structural layouts, design updates, or infrastructure modifications in a way that non-experts can easily grasp.

Clear communication leads to faster approvals and stronger buy-in from stakeholders.

3. Facilitating Design Iteration and Decision-Making

With 3D Map Illustration, design teams can quickly visualize alternative solutions and iterate in real-time.

Architects can layer multiple options onto a 3D Vector Map, exploring how new elements integrate with the existing framework.

How 3D Vector Maps Optimize Renovation Planning

3D Vector Maps are especially useful during the planning phase of reuse projects. Mapping out utility lines and mechanical systems.

Defining zoning boundaries and property lines.

Planning interior layout changes.

Documenting phased renovation schedules.

Vector maps also integrate seamlessly with GIS data, CAD systems, and BIM platforms, creating a holistic view of the building’s data-rich environment.

Supporting Historic Preservation with Architecture Illustration

Adaptive reuse projects often involve historically significant buildings. In such cases, detailed Architecture Illustration helps ensure preservation guidelines are followed without compromising functionality.

By producing highly stylized, photorealistic or freehand illustrations of the existing structure, architects can highlight intricate design features, such as cornices, arches, or moldings. These visuals not only guide preservation but also serve as powerful storytelling tools for grant applications and community presentations.

Sustainability and Compliance Made Simpler

Green building codes and energy efficiency standards are now integral to most renovation projects. 3D Map Illustration can incorporate data layers that show insulation, HVAC systems, and natural lighting flows, making it easier to plan eco-friendly upgrades.

They also assist in compliance reviews by providing visual documentation of how updates align with building codes and safety regulations. The ability to simulate environmental impact using 3D Vector Maps is a bonus for developers seeking LEED certification or other sustainability accreditations.

Real-World Example: From Factory to Residential Complex

Consider a case study where an old textile factory was converted into a high-end apartment complex. They used 3D Vector Maps to map fire exits, HVAC systems, and new plumbing routes.

The result? Faster city approvals, smoother contractor execution, and a design that preserved the building’s industrial charm while accommodating modern living standards.

The Future of Architecture Lies in Visualization

As urban space becomes more limited, the value of adaptive reuse and renovation continues to rise. Tools like 3D map illustration, 3D Vector Maps, and architecture illustration are not just nice-to-haves—they are essential for modern architecture workflows.

They support sustainable development, reduce project risk, and improve communication at every stage. Whether you're redesigning a school, repurposing an old hospital, or renovating a historic theater, these visual technologies can help you build smarter, faster, and more beautifully.

Conclusion

Adaptive reuse is about honoring the past while building for the future. And with the help of 3D Map Illustration, 3D Vector Maps, and Architecture Illustration, architects and planners are empowered to do just that—transforming outdated structures into vibrant, functional spaces.

These tools don't just make designs look better—they make the entire renovation process more efficient, collaborative, and sustainable. As the demand for green construction and heritage preservation continues to grow, visual technologies will remain at the forefront of architectural innovation.

0 notes

Text

Singapore’s Sustainable Construction Revolution: Building for a Greener Tomorrow

As Singapore moves toward a more sustainable future, the construction industry plays a critical role in reducing environmental impact and promoting green living. Increasingly, builders and developers are adopting eco-friendly construction methods to align with national goals. Industry leaders like Xing Fu Construction are helping reshape Singapore’s urban landscape through innovative, sustainable practices that balance modern design with environmental responsibility.

Why Sustainable Construction Matters in Singapore

Singapore's unique geographic and economic challenges—such as limited natural resources, dense urbanization, and high energy demands—have made sustainability a top priority. The Singapore Green Plan 2030 is a nationwide strategy aimed at addressing climate change, reducing carbon emissions, and ensuring environmental resilience.

As part of this initiative, the Building and Construction Authority (BCA) has set ambitious targets to green 80% of buildings across the island. This plan has become a catalyst for transforming how buildings are designed, constructed, and operated.

Core Elements of Sustainable Building

Sustainable construction refers to designing and constructing buildings that are energy-efficient, environmentally friendly, and resource-conscious throughout their life cycles. Here are the main features:

1. Energy Efficiency

Green buildings are designed to consume less power. This includes:

Installing energy-efficient lighting and appliances

Utilizing solar panels

Optimizing insulation and building orientation

Using natural lighting and ventilation whenever possible

2. Water Conservation

Eco-friendly projects often incorporate:

Rainwater harvesting systems

Water-efficient plumbing fixtures

Greywater recycling for landscaping and flushing

3. Sustainable Materials

Choosing the right materials significantly impacts a building’s environmental footprint. Sustainable options include:

Recycled or reclaimed wood

Bamboo, cork, or other rapidly renewable materials

Low-VOC paints and sealants

4. Waste Reduction

Construction sites are known for high waste output. Green practices focus on:

Modular construction to reduce excess

Reusing building components

Sorting and recycling materials on-site

5. Improved Durability

Long-lasting materials reduce the need for frequent repairs or replacements, saving both money and resources over time.

Advancing Sustainability Through Technology

Cutting-edge technology is playing a pivotal role in transforming construction practices. Examples include:

Building Information Modeling (BIM): Enables accurate planning to minimize errors and material waste.

Prefabrication: Produces components in controlled environments, reducing on-site waste and speeding up timelines.

IoT Integration: Smart systems monitor energy usage and improve building performance in real time.

Vertical Gardens and Green Roofs: Improve air quality, reduce urban heat, and contribute to biodiversity.

Benefits for Developers and Occupants

Sustainable buildings aren't just good for the planet—they're also beneficial for property owners and tenants:

Lower Operating Costs: Efficient buildings reduce energy and water bills.

Healthier Living Spaces: Non-toxic materials and improved air quality enhance occupant well-being.

Stronger Property Values: Green buildings often enjoy higher market demand and resale prices.

Eligibility for Incentives: Government grants and rebates help offset initial investment costs.

Growing Demand for Green Homes

More Singaporean homeowners are embracing sustainable design in residential properties. Popular features include:

Energy-efficient windows and insulation

Smart thermostats and lighting systems

Solar energy panels

Eco-conscious flooring and cabinetry

These features not only reduce monthly costs but also align with the city-state’s broader environmental goals.

Overcoming the Challenges of Sustainable Construction

Despite the clear benefits, there are still some challenges to overcome:

Upfront Costs: Green technologies and materials can be more expensive initially.

Resource Availability: Some sustainable materials may be limited or costlier due to demand.

Specialized Knowledge: Sustainable construction requires skilled teams familiar with green building standards and regulations.

However, increased government support and greater awareness among consumers are helping bridge these gaps.

Government Support Driving Green Innovation

Singapore’s government has introduced several programs to facilitate the adoption of sustainable practices:

BCA Green Mark Scheme: Encourages sustainability in building design and performance.

Skyrise Greenery Incentive Scheme: Offers financial support for rooftop gardens and vertical landscaping.

Sustainable Construction Masterplan: Promotes use of recycled materials and efficient construction practices.

These initiatives reduce the financial and logistical barriers to sustainable development.

Choosing the Right Construction Partner

A successful green project begins with choosing an experienced and reliable construction partner. The right team will:

Recommend eco-friendly materials

Maximize energy and water efficiency

Ensure compliance with regulatory frameworks

Deliver long-term value through thoughtful, sustainable design

Look for firms that demonstrate a deep commitment to sustainability and a solid portfolio of completed projects.

Conclusion: Building Toward a Better Future

Sustainable construction is reshaping the way we think about our buildings and our cities. In a forward-thinking nation like Singapore, green construction isn’t just an option—it’s becoming the standard. Developers, homeowners, and businesses that embrace these principles will benefit from long-term savings, healthier environments, and increased property value.

By collaborating with trusted experts such as Xing Fu Construction, you can turn your vision for a sustainable and future-ready space into a reality—one that supports both your goals and the planet’s well-being.

0 notes

Text

Sustainable Strategies Driving the Future of Construction Waste Management

Key Market Drivers & Trends

The construction waste management market is gaining momentum globally, largely propelled by several strong market drivers. Chief among these is the implementation of stringent government regulations surrounding waste disposal, aimed at reducing environmental degradation and promoting responsible construction practices. Alongside these regulatory pressures, there’s a growing focus on achieving green building certifications, which require strict adherence to sustainable material usage and waste management protocols.

Rapid urbanization and the corresponding surge in infrastructure development have further fueled the need for efficient construction waste management solutions. With expanding cities and increasing construction activities, there is a rising volume of construction and demolition debris that must be managed effectively. Technological advancements are also playing a pivotal role. Waste sorting and recycling processes have become more efficient with the help of modern equipment and AI-driven systems.

On-site waste sorting and processing is rapidly transforming the construction landscape by allowing immediate waste categorization and recycling, which reduces hauling costs and landfill reliance. Meanwhile, prefabrication techniques are becoming increasingly popular as they inherently reduce material waste by emphasizing precision and planning during construction. Cutting-edge solutions like blockchain-based waste chain-of-custody systems are also emerging, offering traceability and transparency in the handling of construction debris. Furthermore, integrating waste data with Building Information Modeling (BIM) is streamlining waste tracking, particularly in complex construction environments in regions such as North America and Europe.

Get Sample Copy @ https://www.meticulousresearch.com/download-sample-report/cp_id=6171?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=08-05-2025

Key Challenges

Despite these drivers, the construction waste management market is not without its challenges. One major barrier to widespread adoption is the high initial cost of implementing comprehensive waste management systems. These costs include equipment investment, workforce training, and operational overheads, which can be significant for smaller firms and projects in developing regions.

There is also a persistent lack of awareness about sustainable construction practices in many parts of the world. This gap in knowledge often results in inefficient waste handling and missed opportunities for recycling and reuse. In dense urban settings, logistical challenges complicate waste collection and sorting, especially when dealing with large-scale demolition or tight construction zones.

Additionally, mixed construction waste is often contaminated, making recycling more difficult and less cost-effective. Balancing sustainability goals with tight project budgets presents another layer of complexity. Regulatory standards also vary widely from region to region, further complicating compliance for multinational firms. Finally, there remains a limited market for recycled construction materials, which restricts the financial incentive for companies to invest in waste recovery.

Growth Opportunities

Despite these obstacles, there are numerous growth opportunities within the construction waste management sector. The rise of circular economy initiatives in the construction industry is creating new avenues for innovation and sustainability. These initiatives promote the reuse and repurposing of materials, reducing overall waste and resource consumption.

Digital waste tracking and management systems are another area with high growth potential. These systems enable companies to monitor waste generation in real time, optimize collection and disposal routes, and ensure regulatory compliance. They also help identify patterns and inefficiencies, leading to continuous process improvement.

Resource recovery from construction and demolition waste is emerging as a lucrative opportunity as well. By extracting reusable materials such as metals, wood, and plastics from waste streams, companies can reduce disposal costs while creating new revenue channels. This approach not only benefits businesses financially but also aligns with broader sustainability objectives.

Market Segmentation Highlights

By Service Type

Among the various service types, construction waste collection is projected to command the largest market share by 2025. This segment plays a crucial role in any construction project, encompassing services like providing containers, dumpsters, and transportation of debris to disposal or recycling facilities.

Construction waste recycling is also gaining prominence, particularly as regulations surrounding sustainability become more rigorous. Recycling not only diverts waste from landfills but also recovers valuable materials that can be reused or sold.

The Waste Minimization Planning segment, while currently smaller in scale, is expected to register the fastest growth during the forecast period. This growth is driven by the increasing adoption of pre-construction waste reduction strategies. As more organizations seek specialized consulting services, including waste audits and compliance reporting, this segment is poised for rapid expansion.

Get Full Report @ https://www.meticulousresearch.com/product/construction-waste-management-market-6171?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=08-05-2025

By Waste Type

Inert waste—including materials such as soil, bricks, concrete, stones, and gravel—is expected to dominate the construction waste management market in 2025. These materials are produced in large volumes during both construction and demolition activities, making their management a priority.

However, the Plastic Waste segment is projected to grow at the highest rate through 2032. Growing regulatory pressure to mitigate plastic pollution and the push for enhanced recycling practices are key contributors to this trend. Technological innovations in plastic processing are also enabling more effective recovery and reuse of this material type, further boosting segment growth.

By Source

The Residential Construction Waste segment is set to hold the largest market share in 2025. Housing developments, home renovations, and demolitions collectively contribute to significant volumes of construction debris that necessitate organized waste management.

Commercial construction, encompassing sectors like retail, offices, healthcare, and education, is also a significant contributor and is increasingly adopting comprehensive waste handling solutions to meet corporate sustainability targets.

That said, the Infrastructure and Public Works segment is expected to grow the fastest over the forecast period. Government-led initiatives to build sustainable infrastructure and the growing scale of public works projects are amplifying the need for efficient construction waste solutions. Furthermore, public funding often mandates stringent compliance with waste disposal and recycling protocols.

By Geography

North America is forecasted to lead the global construction waste management market in 2025, driven by rigorous regulations, a strong focus on green building certifications, and substantial investments in advanced recycling technologies. Major construction firms in this region are also making strong commitments to sustainability, reinforcing market dominance.

Europe will follow as the second-largest market, benefiting from mature circular economy frameworks and a highly environmentally conscious public. Stringent EU directives and national regulations in countries like Germany, France, and the Nordics further support market growth.

Asia-Pacific, however, is set to experience the fastest growth rate during the forecast period. Rapid urban expansion, booming construction activity in emerging economies, and progressively tightening waste regulations in countries such as China and India are key contributors to this growth. The increasing adoption of green construction practices in the region further supports the upward trend.

Competitive Landscape

The construction waste management landscape features a mix of global giants and specialized solution providers. These include waste management companies, recycling technology developers, heavy equipment manufacturers, and digital innovators offering end-to-end solutions.

Players in the market can be grouped into industry leaders, market differentiators, vanguards, and contemporary stalwarts. Each of these categories leverages different strengths, such as scale, innovation, service diversity, or technological integration, to maintain a competitive edge.

Leading companies are investing heavily in integrated platforms that combine traditional waste removal services with digital tracking systems and data-driven sustainability solutions. These integrated strategies enable them to address complex challenges while catering to diverse client needs across various construction verticals.

Key players dominating the global construction waste management market include Waste Management, Inc., Republic Services, Inc., Veolia Environment S.A., Caterpillar Inc., Hitachi Construction Machinery Co., Ltd., Terex Corporation, Komptech GmbH, Rubble Master HMH GmbH, Metso Outotec Corporation, Doppstadt GmbH, HAAS Recycling Systems, BHS-Sonthofen GmbH, and ARJES GmbH.Get Sample Copy @https://www.meticulousresearch.com/download-sample-report/cp_id=6171?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=08-05-2025

0 notes

Text

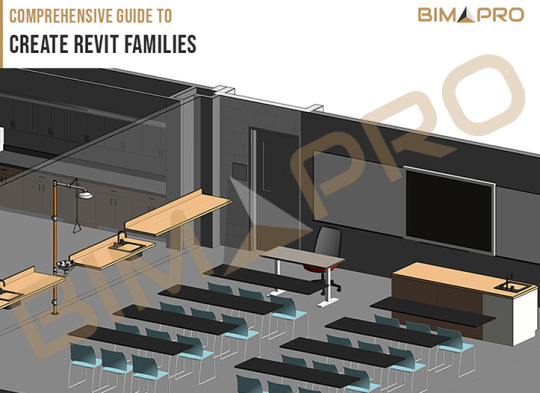

A Comprehensive Guide to Create Revit Families

A Comprehensive Guide to Revit Family Creation is the perfect go-to for anyone looking to get comfortable with making custom families in Revit. Creating Revit Families is a crucial skill for anyone involved in Building Information Modeling (BIM), as it lays the foundation for accurate and efficient project workflows. At its core, a Revit Family is more than just a visual representation of an object—it’s a data-rich element designed to be adaptable and reusable across projects. Whether it’s a door, window, furniture piece, or custom element, each family is crafted using a combination of geometry, parameters, and embedded information to meet specific design needs. By mastering Revit Family creation services, designers can enhance project consistency, streamline collaboration, and unlock new levels of design precision. For those looking to maximize efficiency, outsourcing family creation to experts ensures access to high-quality, standardized components while saving time and costs.

What Are Revit Families?

Revit Families are an integral part of Autodesk Revit, a software used for BIM modeling services. To understand Revit Families, imagine them as digital representations of real-world building components—like windows, doors, furniture, beams, or even plumbing fixtures. They are essentially templates for creating BIM objects that will appear in a Revit model. These objects are not just shapes; they contain crucial data about the objects they represent, such as dimensions, materials, and functional properties, making them a key component in creating an accurate and detailed digital model of a building.

Types of Revit Families

Each Revit Family consists of various “types,” which are different variations of the same basic object. For example, a “window family” might include types for a 3-foot by 5-foot window, a 4-foot by 6-foot window, and so on. These types allow designers to create multiple variations of the same object without needing to start from scratch each time. This level of customization ensures that the model is tailored to the specific design needs of a project.

There are three main types of Revit Families: System Families, Loadable Families, and In-Place Families. Each serves a different purpose within the Revit environment.

1. System Families

These families are predefined within the Revit software and cannot be created or modified in the same way as other families. System Families include basic architectural, structural, and MEP elements like: Walls, Floors, Roofs, Ceilings, Columns, Foundation elements, etc.

These families are essential building blocks that form the structure of the model. They are typically modified using Revit’s built-in tools (like the Wall tool or Floor tool) but cannot be saved separately or loaded into other projects like Loadable Families.

2. Loadable Families

Loadable Families are custom objects that users can create and load into any Revit project. These families are highly versatile and include things like: Doors, Windows, Furniture (chairs, tables), Fixtures (lighting, plumbing), Equipment (HVAC units, appliances).

The beauty of Loadable Families is their reusability—once created, you can save them in a library and use them across multiple projects, ensuring consistency and reducing repetitive work. These families are created from scratch or by modifying existing templates.

3. In-Place Families

In-Place Families are unique to a specific project. These are created when you need a custom element that doesn’t fit into the typical category of a Loadable Family. They are designed directly within the project and cannot be reused across other projects unless they are manually recreated. These families are often used for highly specialized, one-off components, like: Custom sculptures, Special structural elements, Complex and unique building features.

In-Place Families are flexible and can be modified directly within the project, but their lack of reusability makes them less efficient for large-scale BIM operations.

LOD and Its Impact on Revit Family Creation

The LOD directly affects the creation of Revit families, as it determines the amount of detail a family should contain and how it will be used in the broader BIM model. Here’s a breakdown of how LOD influences family creation in Revit:

1. LOD 100: Basic Conceptual Families

At LOD 100, Revit families are created for the purpose of demonstrating the concept or massing of the design. The family models in this stage have minimal geometry and are typically represented as simple placeholders or volumes. The primary goal is to provide an overview of the building’s form and function rather than precise specifications.

Usage: LOD 100 families are useful in early design stages where the primary focus is on massing studies and spatial relationships.

Impact on Family Creation: Families created at this level are not intended for detailed analysis. The geometry is typically low, often represented by basic shapes like boxes, spheres, or simple extrusions.

2. LOD 200: Generic Geometry and Systems Families

At LOD 200, families start to take on more geometric detail. Revit families at this level contain approximate dimensions and may include some additional attributes that help define the size, shape, and location of objects within the model.

Usage: LOD 200 families are useful for schematic design, where the project begins to define key elements more precisely, but without full detailing.

Impact on Family Creation: Families at this stage include more refined geometry and may also include rough system connections and placeholders for MEP (Mechanical, Electrical, and Plumbing) systems.

3. LOD 300: Detailed and Accurate Families

LOD 300 is where Revit families become fully detailed with accurate geometry and embedded data. Families at this level are typically used for coordination and design development. At this stage, the Revit families contain more complex geometry, material specifications, and dimensions that align closely with the design intent.

Usage: LOD 300 families are used for detailed design work, ensuring that all stakeholders can visualize and coordinate with a high level of precision.

Impact on Family Creation: These families are created with detailed dimensions, materials, and attributes that can be used for construction documentation. They include elements such as door hardware, fixtures, and structural connections.

4. LOD 400: Fabrication-Ready Families

When a Revit family reaches LOD 400, it is fully detailed and ready for fabrication. These families contain all the necessary information for actual construction, including accurate geometry, material specifications, and installation details. This is the most detailed level before the final as-built model.

Usage: LOD 400 families are used in the construction phase, where all elements are fully defined and ready for manufacturing or assembly.

Impact on Family Creation: At this level, Revit families contain specific fabrication information, such as detailed part numbers, vendor data, and installation instructions. These families are designed with high precision to ensure that the construction team can use them directly for building.

5. LOD 500: As-Built Families

LOD 500 represents the final, as-built condition of the project. The Revit families at this level are used to document the final construction details after the building has been completed. They reflect the actual materials, dimensions, and components used in the building, and serve as a record for maintenance and operations.

Usage: LOD 500 families are used for facility management, operations, and future renovations. They provide a precise representation of the completed structure.

Impact on Family Creation: Families at LOD 500 are created with extreme accuracy, reflecting the true dimensions and conditions of the as-built elements, including changes made during construction that may not have been present in earlier models.

How Do Revit Families Work?

Revit Families are not just visual representations of objects—they contain embedded data that defines their properties, behavior, and relationships with other elements in the model. There is a stramline process to create Revit family. First, you create the geometry, which defines the shape and size of the object in 2D and 3D space. This could be a simple shape, like a rectangular door, or a more complex shape, like a custom light fixture. Once the geometry is defined, you assign parameters to control the object’s behavior. Parameters are like instructions that define how the object should respond to changes. For instance, a door might have parameters to control its width, height, material, or swing direction. These parameters make the family flexible and adaptable to changes in the design.

The next step is adding data to the family. This is where the real power of BIM comes in. Revit Families are not just graphical elements—they are full of embedded information. For example, a piece of furniture might have data about its weight, material, manufacturer, and cost. This data can be used for scheduling, cost estimation, and energy analysis, among other things. It ensures that the entire project is well-coordinated, with accurate data flowing seamlessly between design, construction, and operations.

1.Geometry

Geometry refers to the 3D shape of the family. This is the visual part of the family that you can see in the model. For example, the geometry of a door family includes the door’s width, height, and shape. Geometry can be simple (like a rectangular window) or complex (like a custom lighting fixture). The geometry is typically created in Revit’s Family Editor, where you can design the object’s 2D and 3D forms.

2. Parameters

Parameters are the key to Revit’s parametric design, which allows families to adapt based on user input. These are the dimensions or properties that define how an object behaves and responds to changes in the model. For example:

Dimensional Parameters: Controls the size of the object, such as the width, height, and depth of a window or door.

Material Parameters: Allows you to assign materials like wood, metal, or glass to your family.

Visibility Parameters: Controls whether certain elements of the family appear at different view scales or in different views (e.g., a door might have a different appearance in a floor plan versus a 3D view).

Instance vs. Type Parameters: Instance parameters apply to individual instances of the family (e.g., a single window in the project), while Type parameters apply to all instances of a specific type of family (e.g., a specific style of window).

By using these parameters, families become dynamic. When you change one parameter (like the width of a door), all related aspects of the family (such as its size or material) automatically adjust according to the rules defined in the family.

3. Data (Embedded Information)

Revit Families are rich in data. Along with the geometry, families contain detailed information that is crucial for project coordination. This might include:

Manufacturer Information: Details about the supplier or manufacturer of a product.

Cost Data: Information on the cost of the object, which can be used for budget analysis.

Performance Data: Specifications such as load-bearing capacity for structural elements or energy performance for windows and insulation.

Scheduling: When a family is placed into the model, Revit can automatically generate schedules to track quantities, dimensions, materials, and other characteristics of the object. This is useful for planning, cost estimation, and logistics.

This data allows teams to work more efficiently, as it automatically populates schedules, helps in procurement, and ensures that the model contains all necessary details for construction.

How to Create Parametric Families in Revit: Step-by-Step

Creating a Revit Family requires knowledge of parametric design and understanding how to structure the family’s geometry, behavior, and data. Parametric design refers to using parameters to control an object’s size, shape, and relationships with other objects. For instance, you might create a table family with parameters for height, width, and leg style, so that if the table’s size changes, the design and proportions automatically adjust.

Once a Revit Family is created, it can be saved in a library for reuse across different projects. This ensures consistency, improves efficiency, and reduces errors in future projects. For example, once you’ve created a custom door family, you can reuse it in multiple building designs, adjusting the sizes or materials as needed, but maintaining the same basic design.

Creating Revit Families is a detailed process that involves several stages. Here’s an overview of how you can create a basic Revit Family:

1. Open the Family Editor

The Family Editor is the environment in Revit where you create and modify families. You can access it by creating a new family file. From there, you can start building your family by defining its geometry and parameters.

2. Create Geometry

Start by creating the 2D and 3D shapes that define your family. This can be done using Revit’s drawing tools like lines, arcs, and extrusion commands. For instance, if you’re creating a door family, you’d start by drawing the door panel’s 2D shape and then extrude it into 3D.

3. Assign Parameters

Next, define the parameters that control your family. This includes setting dimensional parameters (e.g., width, height), material parameters (e.g., wood, glass), and any other properties that will make your family flexible.

4. Add Data

If necessary, you can also embed data into the family, such as manufacturer info, cost, and energy performance. This data is important for project coordination and analysis.

5. Load into Project

Once your family is created, you can save it to a library for reuse. You can then load it into any Revit project. When you place the family into the project, you can adjust the instance or type parameters to customize it for your specific needs.

Benefits of Using Revit Families in BIM

One of the biggest benefits of Revit Families is how they support collaboration in a BIM environment. Since Revit is a multi-disciplinary tool, all team members—from architects to structural engineers to MEP specialists—can work with the same families, ensuring that the design is consistent across all disciplines. This reduces errors and miscommunications and helps with coordination, as any changes made to a family (such as changing the material or dimensions of a door) will automatically update in the entire model.

Using Revit Families offers several benefits within the BIM workflow:

1. Consistency: Families ensure that all components in the model are uniform, reducing errors and discrepancies.

2. Efficiency: Once created, families can be reused across multiple projects, saving time and effort.

3. Data Integration: Families contain embedded data that can be used for scheduling, analysis, and cost estimation, making the BIM model a comprehensive source of information.

4. Collaboration: Since families are standardized, all team members—whether architects, engineers, or contractors—can work with the same components, ensuring better coordination and fewer misunderstandings.

Conclusion

For beginners, learning how to create Revit Families can be challenging but is an essential skill to master in BIM. Once you get the hang of it, it opens up many possibilities for creating customized, reusable, and highly detailed BIM content. It also ensures that the model is both accurate and efficient, providing valuable data for everything from construction to facilities management. As you progress, you’ll be able to create more advanced families, optimize your designs, and streamline your workflow, ultimately contributing to better project outcomes and faster delivery times.

Understanding and mastering Revit Families is crucial for anyone working in BIM. Families are not just graphical elements; they are rich with data and designed to be flexible, dynamic, and reusable. By learning how to create, modify, and utilize Revit Families effectively, you’ll be able to create detailed, accurate models that enhance design, construction, and collaboration, ultimately leading to better project outcomes. Whether you’re an architect, engineer, or contractor, mastering Revit Families will elevate your ability to work efficiently in a BIM environment.

#BIMmodelingservices#RevitFamilycreationservices#BIMcontentcreationServices#RevitFamilyModeling#RevitFamilyDevelopment#RevitMEPFamilyCreation

0 notes

Text

How to Speed Up Your Work in AutoCAD, Revit, and 3ds Max

Introduction

In today's fast-paced design and architecture industries, efficiency is key. Whether you are working on AutoCAD, Revit, or 3ds Max, mastering these tools efficiently can save time and boost productivity. Many students and professionals struggle with slow workflows, which can hinder project deadlines. In this blog, we will explore time-saving tips and tricks to enhance your workflow in AutoCAD, Revit, and 3ds Max while maintaining high-quality designs.

1. Speeding Up Your Workflow in AutoCAD

AutoCAD is widely used for 2D drafting and 3D modeling, but working with it can be time-consuming if not optimized. Here’s how you can enhance your productivity:

Use Keyboard Shortcuts Efficiently

Instead of navigating through multiple menus, use shortcuts like:

L – Line

C – Circle

M – Move

TR – Trim

Mastering these will make your work smoother and faster. If you're looking for an AutoCAD Training Institute, learning these shortcuts is a crucial step in becoming proficient.

Customize Your Workspace

AutoCAD allows customization of the interface for a personalized workflow. Arranging toolbars and palettes as per your project needs reduces unnecessary clicks.

Utilize Blocks and Templates

Creating and using blocks can help avoid repetitive work. Blocks are pre-designed components like doors, windows, or furniture that can be reused in different drawings. AutoCAD Courses cover such features to enhance drafting efficiency.

2. Enhancing Productivity in Revit

Revit is a powerful BIM (Building Information Modeling) software used for architectural design. Here’s how you can make your workflow more efficient:

Leverage Revit Families

Revit families allow designers to create pre-defined elements such as windows, doors, and furniture, which can be reused in multiple projects. If you are taking a Revit Training Course, focusing on families will be beneficial.

Use View Templates

Managing views manually can be time-consuming. Instead, view templates can help standardize visual styles and streamline workflows.

Master Work-sharing & Collaboration Tools

Revit offers collaboration features allowing multiple users to work on the same project. Cloud-based work-sharing ensures efficiency when working in teams.

If you want to develop expertise in Revit Training, focusing on these time-saving techniques can give you an edge in architectural design.

3. Accelerating Work in 3ds Max

3ds Max is a powerful 3D modeling and rendering software widely used in interior design, gaming, and animation. Here’s how to work efficiently:

Utilize Hotkeys and Custom Scripts

Much like AutoCAD, 3ds Max also has keyboard shortcuts to perform actions quickly. Learning hotkeys while attending a 3Ds Max Course can significantly improve your speed.

Optimize Scene Management

Use layers and groups to organize your models.

Hide unnecessary objects while working to improve software performance.

Leverage Rendering Presets

Rendering can be time-consuming, but using preset render settings can help speed up the process. 3Ds Max Training teaches efficient rendering techniques for faster project completion.

4. General Tips to Improve Workflow in All Three Software

Regardless of whether you are using AutoCAD, Revit, or 3ds Max, the following strategies can help improve your efficiency:

Upgrade Your Hardware: Ensure you have a powerful PC with sufficient RAM and a strong graphics card for smooth performance.

Use Cloud Storage: Save your files on the cloud to prevent data loss and access them anywhere.

Stay Updated with New Features: Autodesk frequently updates its software with new tools and shortcuts that enhance productivity.

Practice Regularly: Taking up AutoCAD Classes, Revit Classes, or 3Ds Max Classes ensures you stay updated with industry trends and techniques.

Conclusion

Speeding up your work in AutoCAD, Revit, and 3ds Max requires mastering shortcuts, utilizing built-in tools, and following best practices. Whether you are a student or a professional, continuously improving your workflow can boost productivity and efficiency.

For those who wish to gain in-depth knowledge and hands-on training, enrolling in an AutoCAD Training Institute or 3Ds Max Coaching Centre can help develop expertise. Practical training in these tools ensures better project execution and career growth.

By implementing these tips and learning from a professional training center, you can become proficient in these essential design tools and enhance your career in architecture, interior design, and 3D modeling. Visit us:

Suggested Links:

AutoCAD Mechanical Training

Architecture & Interior Designing

Revit Architecture Training

#autocad#autocad basics#autocad skills#autocad tips#what is autocad#autodesk sketchbook#autocad course in yamuna vihar#autoCAD course in uttam nagar#autocad training

0 notes

Text

Innovations in Mining and Construction: Revolutionizing the Industry with Cutting-Edge Products

The mining and construction industries are integral to global economic growth, providing the raw materials and infrastructure necessary for modern civilization. As these sectors face increasing demands for efficiency, sustainability, and safety, the development of innovative products and technologies has become critical. From advanced machinery to digital solutions, the industry is undergoing a transformation that is reshaping how mining and construction projects are executed.

1. Advanced Machinery and Equipment

The backbone of mining and construction lies in the machinery and equipment used to extract resources and build structures. Recent advancements in this area have significantly improved productivity, safety, and environmental impact.

Autonomous and Remote-Controlled Equipment: Autonomous haul trucks, drill rigs, and bulldozers are now commonplace in mining operations. These machines use GPS, LiDAR, and AI to navigate and perform tasks with minimal human intervention. In construction, remote-controlled excavators and cranes are being used in hazardous environments, reducing the risk to workers.