#FactoryEfficiency

Explore tagged Tumblr posts

Text

Boost Factory Productivity with Expert In-Plant Logistics

Abhi Impact Logistics optimizes your shopfloor operations with precision-driven in-plant logistics. From real-time material movement to inventory coordination, we ensure streamlined workflows, reduced downtime, and maximum efficiency all within your factory gates.

#logisticsindia#InPlantLogistics#FactoryEfficiency#ShopfloorSolutions#SmartLogistics#AbhiImpactLogistics#IndustrialLogistics#ManufacturingSupport#bestlogisticscompanyindia

0 notes

Text

Building Operational Excellence: Lean Manufacturing Consulting by Seicho Consulting

In today’s competitive manufacturing world, doing more with less isn’t just an option — it’s a necessity. Lean Manufacturing empowers organizations to maximize productivity, minimize waste, and deliver consistent quality — all while improving worker satisfaction and reducing costs.

At Seicho Consulting, our Lean Manufacturing Consulting Services are designed to implement operational excellence at every level of your factory floor. From layout design to daily improvement systems, we help manufacturers transform operations through Lean principles.

🔧 Key Offerings:

Process Flow Optimization: Eliminate bottlenecks and improve production speed.

5S & Visual Workplace Setup: Create clean, organized, and efficient workspaces.

Value Stream Mapping (VSM): Understand where value is added—and where it’s lost.

Kaizen Programs: Cultivate a culture of continuous improvement through employee engagement.

Standard Work & Error Proofing (Poka-Yoke): Minimize variation and human error.

Lean Layout Redesign: Enhance space utilization and material flow.

📈 Benefits of Lean Implementation:

Higher productivity and throughput

Reduced inventory and faster delivery

Better product quality and fewer defects

Improved worker safety and morale

Significant cost savings

🏭 Who We Serve:

Automotive & Ancillary Units

FMCG & Packaging Plants

Chemical & Pharma Manufacturers

Textile & Engineering Setups

SMEs & Export-Oriented Units

With over 50+ successful Lean projects, our team understands the ground reality of factories and production units. We don’t just teach Lean tools — we help your people adopt Lean culture. Plus, our approach integrates smoothly with TPM, Six Sigma, TQM, and ERP systems, making your business more agile and scalable.

💡 Ready to make your factory future-ready with Lean? Reach out to Seicho Consulting — let’s build sustainable excellence together.

#LeanManufacturing#SeichoConsulting#OperationalExcellence#ManufacturingConsulting#5S#Kaizen#PokaYoke#LeanProduction#FactoryEfficiency#IndustrialConsulting#ValueStreamMapping#ProcessImprovement#ContinuousImprovement#TPM#SixSigma#EngineeringConsulting#TextileManufacturing#FMCGManufacturing#AutomotiveIndustry#LeanTransformation#SMEConsulting

0 notes

Text

Discover the top 10 manufacturing workflows you can automate with Odoo ERP—boost productivity, streamline MRP, and cut down manual operations.

#OdooERP#ManufacturingAutomation#SmartManufacturing#WorkflowAutomation#OdooManufacturing#ERPForManufacturing#FactoryEfficiency#AutomationSolutions

0 notes

Text

Dynemech Mac Level, DML Series is suitable for high speed rotating machines having small or no axial forces. Dynemech Anti-Vibration Technology provides the MAC Level Mounts-DML Series, the best Anti-Vibration Solution meant specifically for high-speed rotating machines with limited axial forces in industrial environments where accuracy, stability, and Vibration Control. Dynemech Mac Level Mounts, meant to high machine performance, lengthen lifespan, and increase output quality, were designed using modern Vibration Isolation Technologies. Created for deliberate performance - Dynemech Anti-Vibration Technology Dynemech Anti-Vibration Technology DML Series was developed especially for machines requiring extraordinary balance and little motion. Dynemech Anti-Vibration Technology offer consistent Vibration Isolation across a large frequency range with a strong iron body and premium elastomeric materials. Presses, blowers, turbine machines, CNC Machine, high-speed rotating equipment, lab spindles, and other delicate machinery.

Apart from guaranteeing better product accuracy, their capacity to lower vibrations at the source shields the machine and surrounding equipment from too much wear and damage. Important Characteristics of the DML Series Dynemech Anti-Vibration Technology MAC Level Mounts Made for High Speeds Rotating Machines Dynemech Anti-Vibration Technology-DML series performs best with machinery featuring high RPM and rotating components. Controlling undesired vibrations helps to stabilize the operational performance of the mounts and lower oscillation-related mistakes. Perfect for uses requiring small axial loads- Dynemech Anti-Vibration Technology Conventional mounts may not provide the optimum support in cases when machines generate minimal or none axial load. Designed especially to preserve performance and balance even in low axial stress environments, the Dynemech MAC Level Mounts. Levelling Mechanism- Dynemech Anti-Vibration Technology Crucially, every mount features a built-in Dynemech Anti-Vibration Mounts that lets you rapidly and precisely change height—a necessary ability to keep machine alignment on uneven surfaces. Once set, the locking mechanism guarantees rigidity and removes drift. Durable and maintenance-free - Dynemech Anti-Vibration Technology The Dynemech Mac Levelling Mounts are designed to resist in industrial conditions corrosion, wear, and chemicals. Their strong construction lets one accommodate a range of industrial weights without sacrificing vibration control. Applications in several sectors - Dynemech Anti-Vibration Technology The Dynemech Anti-Vibration Technology -DML Series offers companies trying to stabilize their equipment a flexible solution without sacrificing adaptability. The Mac Levelling Mounts enable you to keep tighter tolerances, improve production quality, and prolong the life of machinery whether your field of expertise is aerospace, automotive, electronics, or light engineering. Dynemech Anti-Vibration Technology has designed, engineered and developed the most extensive line of Anti Vibration Pads, silent blocks, shock and noise control products. We are also specializing in manufacturing of anti-vibration controlling pad, machinery mounts, spring mounts, and variety of anti-vibration pads.

Dynemech Anti-Vibration Technology manufactures world-renowned anti-vibration pads. Dynemech Systems offers an ideal solution in Anti Vibration Pad. Made from a combination of high quality rubber polymers and cork, this ideal combination ends up to make up a product that has excellent resistance to ageing, compression set, water and oil.

Dynemech’s Anti Vibration Pads are widely used in: Refrigeration Plants, Compressors, Conveyors, Air Conditioning Plants, Diesel Generators, Business Machines, Fans, Motors, Power / Impact Presses, Pumps, CNC Machines etc. Our range of silent block are ideal for controlling machine vibration. Our rubber based products are ideal in controlling both active and passive vibrations coming from various industrial machines.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#MACLevelMounts, #Dynemech, #AntiVibrationMounts, #DMLSeries, #VibrationControl, #MachineLeveling, #IndustrialMounts, #PrecisionMounting, #CNCStability, #HighSpeedMachines, #ManufacturingSolutions, #MachinerySupport, #AutomationEquipment, #FactoryEfficiency, #MachineSetup, #IndustrialSolutions, #SmartManufacturing, #MadeInIndia,

Get in Touch for Load Calculations

📞 Call Us: +91-9810760131 📧 Email: [email protected] 🌐 Website: www.vibrationmountsindia.com

#MACLevelMounts#Dynemech#AntiVibrationMounts#DMLSeries#VibrationControl#MachineLeveling#IndustrialMounts#PrecisionMounting#CNCStability#HighSpeedMachines#ManufacturingSolutions#MachinerySupport#AutomationEquipment#FactoryEfficiency#MachineSetup#IndustrialSolutions#SmartManufacturing#MadeInIndia

0 notes

Text

The future of manufacturing is here — and it’s smarter than ever. Discover how Odoo’s Manufacturing Module is helping factories plan better, track materials, ensure quality, and boost efficiency. From small workshops to large factories, Odoo makes production easy.

#OdooManufacturing#SmartManufacturing#DigitalFactories#FutureOfManufacturing#OdooERP#BusinessAutomation#Industry40#FactoryEfficiency#ManufacturingSolutions#ProductivityBoost#ManufacturingExcellence#TechForBusiness#FactoryManagement#BusinessGrowth#MadeInKenya

0 notes

Text

Wall Traveling Cranes from Cubuilt are designed to offer maximum flexibility and precision in material handling. These cranes travel along a wall-mounted track, providing smooth, efficient movement for heavy loads. Ideal for applications in factories, warehouses, and manufacturing units, Wall Traveling Cranes are perfect for optimizing space and improving operational efficiency. With customizable designs, including various lifting capacities and track configurations, these cranes ensure that your material handling tasks are completed with ease, safety, and reliability. Whether for assembly lines, machine shops, or other industrial applications, Cubuilt’s Wall Traveling Cranes deliver exceptional performance and cost-effectiveness.

#WallTravelingCranes#MaterialHandling#IndustrialCranes#AutomationSolutions#Cranes#LiftingEquipment#FactoryEfficiency#IndustrialMachinery#WarehouseSolutions#PrecisionLifting#CranesForIndustry#HeavyLifting#ManufacturingExcellence#CranesAndHoists#EngineeringSolutions#SpaceOptimization#MaterialHandlingSolutions#WorkplaceEfficiency#CustomCranes#IndustrialAutomation#AutomationTechnology#MadeInIndia#ManufacturingInnovation#ProductionEfficiency#LoadHandling#SteelIndustry

0 notes

Text

Predictive Maintenance in Smart Factories: Combining AI, IoT, and Blockchain for Transparent Operations ⚙️🤖

In the era of Industry 4.0, smart factories are rapidly transforming the manufacturing landscape. By integrating advanced technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and Blockchain, predictive maintenance is taking operational efficiency to new heights. Here’s how these technologies work together to optimize manufacturing processes and ensure transparency:

1. AI-Driven Predictive Analytics 🧠🔍

AI algorithms analyze vast amounts of sensor data from machines to predict potential equipment failures before they occur. By detecting patterns and anomalies, AI enables maintenance teams to address issues proactively, reducing downtime and minimizing disruptions.

2. IoT-Connected Devices for Real-Time Monitoring 📡⚙️

IoT sensors are embedded into machinery to continuously monitor equipment health. These devices collect real-time data on temperature, vibration, pressure, and more, providing actionable insights. This constant monitoring allows for timely interventions, ensuring that maintenance is performed exactly when needed.

3. Blockchain for Transparency and Trust 🔗🔐

Blockchain technology adds a layer of security and transparency to maintenance records. Every action taken on a machine, from repairs to software updates, is recorded in an immutable ledger. This ensures that all stakeholders have access to a trusted, tamper-proof history of equipment performance, maintenance activities, and warranties.

4. Cost Efficiency and Extended Equipment Lifespan 💡💸

Predictive maintenance reduces unnecessary repairs and extends the life of expensive machinery by ensuring that it’s serviced based on actual conditions rather than fixed schedules. This minimizes costs related to breakdowns and parts replacement, making factory operations more cost-efficient.

5. Enhanced Productivity and Reduced Downtime ⏳🔧

By predicting potential equipment failures, factories can schedule maintenance during off-peak times, avoiding costly shutdowns. This proactive approach keeps production lines running smoothly, boosting productivity and optimizing operational efficiency.

#PredictiveMaintenance#SmartFactories#AI#IoT#Blockchain#Industry40#ManufacturingInnovation#SMT#FactoryEfficiency#IndustrialIoT#TechInManufacturing

0 notes

Text

ERP solutions for factories

In today's fast-paced manufacturing industry, efficiency and precision are paramount. SIMPLIRP, a leading ERP software solution for manufacturing in India, is designed to meet the unique needs of factories, helping them optimize operations, reduce costs, and enhance productivity.

Located at G2, Aishwaryam Flats, 4th Street LIC Nagar Madipakkam, Chennai 600 091, Tamil Nadu, SIMPLIRP offers a comprehensive suite of tools tailored for the manufacturing sector. Our software integrates various facets of manufacturing processes, including inventory management, production planning, quality control, and supply chain management, into a single, user-friendly platform.

Why Choose SIMPLIRP ERP Software?

Customizable Solutions: SIMPLIRP provides customizable ERP solutions to fit the specific requirements of your factory, ensuring that all aspects of your operations are seamlessly integrated.

Enhanced Productivity: Automate routine tasks and streamline processes to increase efficiency and reduce human error.

Real-Time Data: Gain access to real-time data and analytics to make informed decisions quickly and accurately.

Scalability: As your business grows, our ERP software can easily scale to accommodate your expanding operations.

Cost-Effective: Implementing SIMPLIRP can significantly reduce operational costs by improving resource management and minimizing waste.

Key Features of SIMPLIRP ERP Software

Inventory Management: Track and manage inventory levels with precision, ensuring you always have the right materials at the right time.

Production Planning: Optimize your production schedules and reduce downtime with effective planning and scheduling tools.

Quality Control: Maintain high standards of quality with integrated quality control modules.

Supply Chain Management: Enhance your supply chain operations for better coordination with suppliers and distributors.

Financial Management: Manage your finances with comprehensive accounting and financial reporting features.

Get in Touch

Ready to transform your manufacturing operations? Contact us today to learn more about how SIMPLIRP ERP Software can help your business thrive.

Contact Information:

Address: G2, Aishwaryam Flats, 4th Street LIC Nagar Madipakkam, Chennai 600 091, Tamil Nadu

Phone: +91 9962073741

Website: https://simplirp.com

#ERPSoftware#ManufacturingERP#SIMPLIRP#ManufacturingSolutions#ProductivityBoost#InventoryManagement#ProductionPlanning#QualityControl#SupplyChainManagement#BusinessGrowth#FactoryEfficiency

0 notes

Text

Ribbon mixer thriving in South Africa's detergent production! 🌍💪 #ManufacturingSuccess #DetergentInnovation #FactoryEfficiency #IndustrialEquipment #LiveMachineryVideos

#atommachinerymfgco#atomsoapmachine#atomsoapplodder#atomsoapsigmamixer#atomtriplerollmill#india#http://atomgroups.trustpass.alibaba.com#technology#health#nutrition

0 notes

Text

Kenya’s manufacturing industry is growing fast, but are your systems keeping up? Discover how businesses are using Odoo’s Manufacturing Module to reduce waste, improve planning, and deliver faster. From Nairobi workshops to industrial plants, digital tools like Odoo are changing the game.

#OdooKenya#SmartManufacturing#DigitalAfrica#MadeInKenya#FactoryEfficiency#OdooERP#ManufacturingSolutions#KenyaBusinessGrowth#TechInAfrica#OdooManufacturing#BusinessAutomation#FutureOfFactories#ProductivityTools#LocalIndustryMatters#AfricanInnovation

0 notes

Text

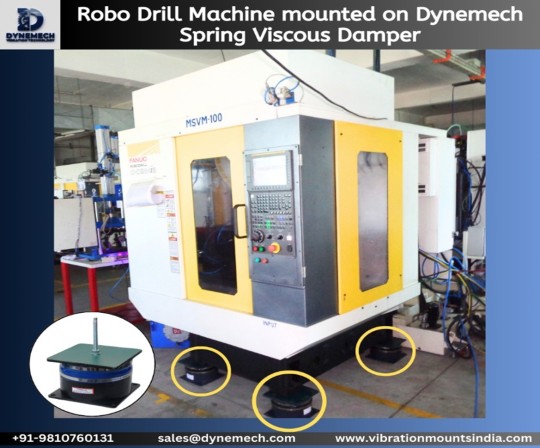

Optimising Precision, Stability, and Production Excellence: Robo Drill Machines Mounted on Dynemech Spring Viscous Dampers

In today's world of advanced manufacturing, high-speed machining, and micron accuracy are part of the norm, not the exception, and the operation of each piece of equipment has a direct impact on producing good results.

A key ingredient to this world of manufacturing are the versatile Robo Drill Machines providing drilling, tapping and milling applications in the automotive, aerospace, electronics, and precision engineering arenas.

Nevertheless, even the best-producing technology can be hampered by its installation base. If you consider the ramifications of uncontrolled vibrations, irregular floors, and unstable foundation throughout the robotics operational cycle, the ability to maintain machining tolerance, etc., for a variety of metrics like surface finish quality, component integrity and machine life may be severely compromised all because of the foundation it was built on. As well, the nature of robotic tools are for repetitive operations with high frequency and dynamic cutting forces present with high spindle speeds, which is where the most harmful vibrations appear, which can make problems with lower output quality, but causes premature machine wear and reliability issues.

Considering the same implications of machining in precision manufacturing for decades, Dynemech Systems has designed a custom solution - the Spring Viscous Damper - specifically to combat and address issues relating to dynamic vibration and needs to meet the standard of performance requirements to deliver reliable excellence to Robo Drill Machines.

How Dynemech Spring Viscous Dampers Optimise Robo Drill Machine Performance

Enhanced Vibration Isolation:

Dynemech’s Spring Viscous Dampers and the associated hybrid system provide natural frequency isolation similar to a high-quality spring and provide viscosity damping and energy-dissipating characteristics to suppress multiple vibrations. This is especially critical during high-speed and high-frequency Machining operations where minimizing vibrations is extremely important.

Improved Machine Stability:

The Spring Viscous Damper will reduce the amount of movement of the machine during operation, enabling the Robo Drill to produce holes in the workpiece with extreme accuracy with least amount of deflection of the machine during operation. This guarantees better hole position, improved thread quality, and better repeatability in production.

Fine Tuning for Accuracy to Achieve Clean Vertical Machining:

The Robo Drill - Spring Viscous Damper design allows almost perfect fine tuning to obtain the precise levelling required to maintain machining tolerances with consistency between batches. Processors will appreciate the accordingly adjusted variables, even when using the Robo Drill in long and high-speed operations.

Greater Machine Life:

One of the most significant advantages is that any vibrations not introduced into the machined workpiece are eliminated from the Robo Drill machine’s structural elements whilst some damped elements protect critical and sensitive internal mechanisms(notably spindle bearings harm and drive motors) from damage-with the overall result is still lowering ongoing maintenance costs with the added benefit of extended machine life.

Greater Throughput Speed and Quality as no interference from vibration:

When vibration is substantially reduced, users can:

1. Improved speed of cutting

2. Higher overall material to remove

3. Superior surface finish

Without degrading part quality which directly results in higher productivity and lower rejection rates.

Why Choose Dynemech Systems?

With over two decades of experience in vibration control technology, Dynemech Systems is recognized as an industry leader offering advanced vibration isolation and machine levelling solutions. Our expertise enables us to create innovative, application-specific products for CNC machines, injection moulding machines, compressors, test equipment, precision measuring machines, and heavy industrial equipment.

Dynemech Spring Viscous Dampers are the result of meticulous engineering, exhaustive real-world testing, and a deep understanding of machine dynamics. They are trusted by manufacturers globally to enhance precision, extend machine life, and optimise factory efficiency.

When you choose Dynemech, you are partnering with a team committed to elevating your manufacturing standards with solutions that deliver measurable results.

Experience the Dynemech Advantage

Empower your Robo Drill Machines with the strength of Dynemech Spring Viscous Dampers, ensuring ultimate stability, enhanced precision, and improved operational excellence in every cycle.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #SpringViscousDamper, #RoboDrill, #MachiningStability, #VibrationControl, #MachineLevelling, #PrecisionMachining, #ManufacturingExcellence, #FactoryEfficiency, #CNCPrecision, #MachinePerformance, #IndustrialSolutions, #EngineeringSupport, #VibrationIsolation, #DynemechSolutions,

Contact Us: +91-9810760131 Email: [email protected] Explore Our Solutions: vibrationmountsindia.com

#Dynemech#SpringViscousDamper#RoboDrill#MachiningStability#VibrationControl#MachineLevelling#PrecisionMachining#ManufacturingExcellence#FactoryEfficiency#CNCPrecision#MachinePerformance#IndustrialSolutions#EngineeringSupport#VibrationIsolation#DynemechSolutions

0 notes

Text

Optimising Precision, Stability, and Production Excellence: Plastic Injection Moulding Machines Mounted on Dynemech Wedge Mounts

In today’s manufacturing environment, with a demand for a specific, zero-defect output that is always repeatable, the performance of every piece of production equipment is of its utmost importance. Among the many critical players in this ecosystem, which ultimately provides high levels of precision and repeatability, are Plastic Injection Moulding Machines, ensuring the right components are manufactured within industries like automotive, electronics, packaging and consumer goods.

For example, these machines can only be effective on their base. The effects of vibration, unlevel installation, and machine instability can all contribute to dimensional inconsistency, increased rejects and premature wear to the machines. Knowing these challenges exist within the industry, Dynemech has designed its high-performance Wedge Mounts as an engineered solution to make sure injection moulding machines are operating in complete stability, accuracy, and efficiency.

Why Dynemech Wedge Mounts Are the Smart Choice for Plastic Injection Moulding Machines

1. In-Place Levelling Adjustments for Accurate Mould Alignment

Achieving a precise alignment of the mould halves is one of the most important aspects of injection moulding. Even small misalignments caused by a lack of levelling can significantly result in part defects such as flash, warpage, and incomplete filling. Dynemech Wedge Mounts is made with a strong three-piece design that incorporates levelling adjustments and uses a screw to assist any post-set requirements. This way, the machine base remains flat and aligned, which will aid in maintaining the geometry of the actual part and a solid engagement of the mould over the long run to allow all production runs.

2. High Vertical and Horizontal Load Capacity

As noted, injection moulding machines (primarily medium to large tonnage machines) create a tremendous force during each cycle of the machine running, not only during injection, but also when clamping up, holding pressure, and ejecting. Dynemech Wedge Mounts are made from high-strength materials specifically designed to deal with vertical and horizontal loads, to moulding machines without deflection while keeping the structural stability of the machine intact. Because of their well-built components, they offer high load-bearing capacity to not only accommodate the heaviest machines when in operation, but aid to avoid settling or sinking over time.

3. Better Vibration Damping to Improve Process Reliability. While these wedge mounts are primarily mechanical devices, they provide better vibrational dampening as a result of their relatively large contact area and firm contact with the floor. By reducing the transfer of operational vibrations between the machine and the shop floor, Dynemech Wedge Mounts can help:

In situations where it is prudent to provide extra damping, Dynemech can supply wedge mounts with damping pads that can further isolate vibration and shock.

4. Increasing Cycle Time and Reducing Rejection Rates.

Stability in a machine has a direct impact on cycle performance. In using Dynemech Wedge Mounts for an injection moulding machine, there will be an improvement in cycle performance that can be measured by:

With this new stable foundation, using the Dynemech wedge mounts, the machining process will produce parts with fewer dimensional variations, better scrap rates and higher productivity on a shift basis.

5. Long-Term Machine Health and Maintenance Efficiency

Over time, even minor variations or vibrations can lead to costly repairs and unplanned downtime. Dynemech Wedge Mounts allow for minimal movement and distortion during machine operation which safeguards bearings, screws, platens and all other important machine components from wear and misalignment. The non-grouted, easy-to-realign installation will make maintenance, moving, and recalibrating quicker and easier.

6. Installation - Not Grouted - Fast and Flexible

In the fast-paced working environment of production, minimising downtime is vital. Dynemech Wedge Mounts are designed to be placed directly underneath the machine with no need for grouting. With the use of simple hand tools, you can level the machine, and an anti-slip bottom on the mount creates a secure grip to the floor surface. A quick, clean and reversible installation is made, especially for the facilities that will expect to undergo layout rearrangements in the future.

Empowering Every Injection Moulding Cycle with Confidence

Whether you are operating vertical moulding presses standalone, or running multi-cavity horizontal injection machines in a fully automated cell, Dynemech Wedge Mounts offer you the solid support your application requires. Wedge mounts maintain the correct alignment of machinery and help absorb operational stresses which can compromise the performance, productivity, and ultimate reliability of your equipment.

Investing in Dynemech Wedge Mounts is an investment in better product quality, lower maintenance costs, and increased operational uptime, which allow you to deliver consistent output in competitive, high-volume business environments.

🔗 To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #WedgeMounts, #PlasticInjectionMoulding, #VibrationControl, #MachineLevelling, #ManufacturingPrecision, #FactoryEfficiency, #InjectionMouldingSolutions, #IndustrialMounts, #EngineeringSupport, #InjectionMouldingStability, #MachinePerformance, #MouldingMachineMounts,

📞 Contact Us: +91-9810760131 📧 Email: [email protected] 🌐 Explore Our Solutions: vibrationmountsindia.com

#dynemech#antivibrationmounts#heavymachinery#precisionengineering#industrialmachinery#vibrationcontrol#industrialefficiency#manufacturingsolutions#machinestability#productivityboost#FactoryEfficiency#IndustrialMounts

0 notes

Text

Jib Cranes.

🚀 Boost Your Material Handling with Cubuilt's Jib Cranes! 💪🔧

Looking for an efficient solution to handle heavy loads and improve productivity? Look no further than Jib Cranes from Cubuilt! Designed for both strength and versatility, these cranes are perfect for tasks like loading/unloading from trucks, machining centers, and assembly stations.

🔧 Why Choose Cubuilt Jib Cranes?

Incredible Strength: Capable of handling heavy loads with ease.

Great Reach: Moves loads to new locations, not just lifting them straight up.

360° Rotation: Offers full rotation, making loading and unloading from trucks quick and easy.

Customization Options: Tailored to your specific needs, with features like motorized rotation and portability.

💡 Upgrade your material handling with Cubuilt’s Jib Cranes today and enhance your operational efficiency!

🔗 Learn More :-https://cubuilt.com/products/jib-cranes/

#JibCranes#MaterialHandling#IndustrialEquipment#LiftingSolutions#CraneSystems#Automation#ManufacturingExcellence#HeavyLifting#LoadingUnloading#FactoryEfficiency#MachiningCenter#AssemblyStation#HoistSystems#LiftingCapacity#EngineeringSolutions#CustomCranes#IndustrialMachinery#WorkplaceEfficiency#CraneTechnology#MadeInIndia#PrecisionLifting#CraneManufacturers#ProductivityBoost#SpaceSaving#CranesForIndustry#AutomationSolutions#WorkshopEquipment

0 notes