#DynemechSolutions

Explore tagged Tumblr posts

Text

Dynemech DLPM Pneumatic Anti-Vibration Mounts – Precision Levelling & Vibration Isolation

Dynemech DLPM Anti-Vibration Technology is a cutting-edge Pneumatic Levelling and Vibration Isolation System designed specifically for precision machinery.

In terms of Machine Vibration Control and Precision Levelling, the Dynemech DLPM (Dynemech Levelling Pneumatic Mount) system is considered to be the mostAadvanced Technology currently available.

The DLPM series is optimized to Isolate Vibrations, automatically level the machinery, and provide stability during dynamic working circumstances. Both of these features were specifically created for delicate machinery and high-precision applications. The Complete Levelling System with Three Points In order to achieve a standard for balancing support on equipment bases, a complete DLPM system is comprised of three master Pneumatic Isolators that operate on a three-point Precision Levelling arrangement. Because of the design, swaying is eliminated, and the accuracy of the equipment is improved, particularly in applications such as:

• Presses in high-speed mode Devices that use lasers

• Manufacturing of semiconductors and electronic components Adjustable Height and Load Compensation Automatically Additionally, each isolator is equipped with an integrated levelling valve that serves two purposes: Load-sensing is a feature that detects changes in weight while the machine is operating.

• Controlling the height: Allows for the machine to maintain a constant level through the use of automatic regulation.

This dynamic technology ensures that the machine is exactly level at all times, even when the load circumstances are fluctuating. As a result, the process quality remains consistent, and the productive capacity of the machine increases.

Installation that is Plug-and-Play Mounts for DLPM are designed to be provided as a fully assembled system that can be installed immediately. Each individual unit is outfitted with the following:

It is easy to install and does not require any specific grouting or foundation, which reduces the amount of time and money required for startup.

Principal Aspects of Performance One of the benefits of fast stabilization is that it reduces the amount of time spent in downtime and gives quick operating capability.

This feature, known as Superior Vibration Isolation, prevents the propagation of low-frequency vibrations that originate from either external sources or inside machine components. Accurate Levelling: This feature ensures that sensitive processes are aligned with the machine in a precise manner.

If there are fewer mechanical parts, there will be less wear and a longer service life. This will result in less maintenance.

The design is both compact and durable. Ideal for use in industrial applications that require both light and heavy-duty work.

Various Requests The following are some of the applications that are ideal for Dynemech DLPM systems: metrology and testing laboratories; electronic and precision component production; CNC machines and grinders; packaging machinery; and any other application that requires zero vibration and absolute stability. Opt for Dynemech DLPM Mounts instead.

Dynemech DLPM Anti-Vibration Mounts offer unparalleled performance in situations when precision, dependability, and high-end dampening are of the utmost importance. Engineered to achieve excellence, industrial sectors have faith in it.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#DynemechDLPM, #AntiVibrationMounts, #PrecisionLevelling, #PneumaticMounts, #MachineStability, #VibrationIsolation, #DLPMTechnology, #DynemechSolutions, #IndustrialAutomation, #MachinerySupport, #CNCStability, #ZeroVibration, #ManufacturingExcellence, #SmartMountingSystems

Contact Dynemech Systems Pvt. Ltd.

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#DynemechDLPM#AntiVibrationMounts#PrecisionLevelling#PneumaticMounts#MachineStability#VibrationIsolation#DLPMTechnology#DynemechSolutions#IndustrialAutomation#MachinerySupport#CNCStability#ZeroVibration#ManufacturingExcellence#SmartMountingSystems

0 notes

Text

Dynemech Vibration Isolation Solutions – Insulation Plates for Industrial Excellence

Engineered Precision for Vibration-Free Performance-Dynemech Anti-Vibration Technology

Dynemech Anti-Vibration Insulation Plates are a specialized solution developed to eliminate unwanted vibrations and improve the operational stability of industrial machinery.

Dynemech Anti-Vibration Insulation Sheet is made from high grade synthetic composite material. This sheet is resistant to water, oils, lubricating oils, fuels etc. used in the shop floor. This sheet has defined stress value and can be placed directly under the machine as per the weight of the machine and no. of mounting positions. This plate will not deform plastically, if the weight of machine does not exceed maximum load value of this Insulation plate.

Manufactured using high-grade synthetic composite materials, these plates are designed to endure the demanding conditions of modern shop floors—providing reliable, long-lasting performance in applications where precision and durability are essential.

Advanced Synthetic Composite Construction- Dynemech Anti-Vibration Technology

Each Insulation Plate is constructed from specially formulated synthetic composites known for their excellent mechanical strength, resilience, and resistance to wear and tear. These materials maintain their structural integrity under continuous vibration and are resistant to oils, coolants, fuels, and water, ensuring a long service life in even the harshest industrial environments.

Engineered Load Distribution- Dynemech Anti-Vibration Technology

Dynemech plates come with a predefined stress tolerance, making it easy to match the plate to the specific weight and configuration of any machine. Based on the machine’s load and number of mounting positions, the plates are installed to evenly distribute weight and mitigate the effects of dynamic and impact forces.

No Plastic Deformation- Dynemech Anti-Vibration Technology

Provided the applied machine load remains within the recommended limits, the Insulation Plates will not deform plastically over time. This ensures that the machine remains level and isolated from structural vibrations, enhancing accuracy, performance, and longevity.

Quick & Direct Installation- Dynemech Anti-Vibration Technology

Dynemech Insulation Plates are designed for easy and direct installation under machines. They require no grouting, anchoring, or bolting, saving both time and installation costs. This feature also makes them ideal for machine relocation and layout changes on the production floor.

Applications Across Industries

Dynemech Anti-Vibration Insulation Plates are widely used across various industries where machines generate high levels of vibration or axial forces. Suitable for both static and dynamic machine loads, they are ideal for:

Tool Room Machinery

Plastic Injection Moulding Machines

Pressure Die Casting Machines

Printing Machinery

Textile Machinery

CNC Machines

Metal Cutting and Forming Equipment

Packaging Equipment

By isolating the machine from the floor, these plates help improve machining accuracy, minimize component wear, and prevent vibration transmission to surrounding equipment and structures.

Benefits:

Superior Vibration Damping and Isolation

Protects machinery and improves precision

Resistant to industrial chemicals and fluids

No maintenance or periodic adjustment required

Enhances operator comfort and workplace safety

Cost-effective alternative to conventional anchoring or grouting

Why Choose Dynemech Anti-Vibration Technology?

Dynemech Systems Pvt. Ltd. has designed, engineered and developed the most extensive line of Dynemech Anti Vibration Pads, silent blocks, shock and noise control products. We are also specializing in manufacturing of Anti-Vibration Controlling Pad, Machinery Mounts, Spring Mounts, and variety of Anti-Vibration Pads Dynemech Systems Pvt. Ltd.

Manufactures world-renowned Anti-Vibration Pads. Dynemech Systems Pvt. Ltd. offers an ideal solution in Dynemech Anti Vibration Pad. Made from a combination of high quality rubber polymers and cork, this ideal combination ends up to make up a product that has excellent resistance to ageing, compression set, water and oil.

Dynemech’s Anti Vibration Pads are widely used in: Refrigeration Plants, Compressors, Conveyors, Air Conditioning Plants, Diesel Generators, Business Machines, Fans, Motors, Power / Impact Presses, Pumps, CNC Machines etc. Our range of silent block are ideal for controlling machine vibration. Our rubber based products are ideal in controlling both active and passive vibrations coming from various industrial machines.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#AntiVibration, #VibrationIsolation, #MachineMounting, #IndustrialInsulation, #VibrationControl, #MachineStability, #FactorySolutions, #InjectionMoldingSupport, #Dynemech, #DynemechTechnology, #DynemechInsulation, #DynemechSolutions, #DynemechPlates, #IndustrialSolutions, #SmartManufacturing, #EngineeringInnovation, #IndustrialEquipment, #MadeForIndustry, #PrecisionEngineering

Call Us: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#AntiVibration#VibrationIsolation#MachineMounting#IndustrialInsulation#VibrationControl#MachineStability#FactorySolutions#InjectionMoldingSupport#Dynemech#DynemechTechnology#DynemechInsulation#DynemechSolutions#DynemechPlates#IndustrialSolutions#SmartManufacturing#EngineeringInnovation#IndustrialEquipment#MadeForIndustry#PrecisionEngineering

0 notes

Text

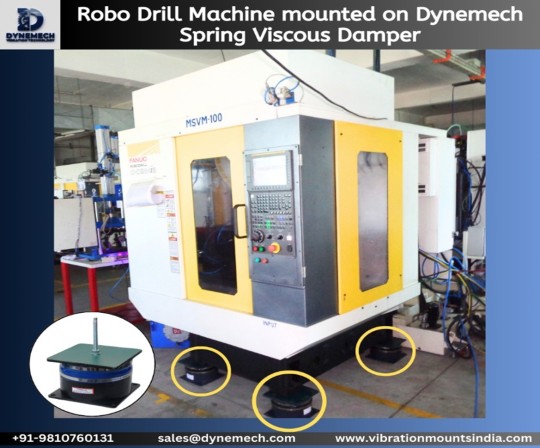

Optimising Precision, Stability, and Production Excellence: Robo Drill Machines Mounted on Dynemech Spring Viscous Dampers

In today's world of advanced manufacturing, high-speed machining, and micron accuracy are part of the norm, not the exception, and the operation of each piece of equipment has a direct impact on producing good results.

A key ingredient to this world of manufacturing are the versatile Robo Drill Machines providing drilling, tapping and milling applications in the automotive, aerospace, electronics, and precision engineering arenas.

Nevertheless, even the best-producing technology can be hampered by its installation base. If you consider the ramifications of uncontrolled vibrations, irregular floors, and unstable foundation throughout the robotics operational cycle, the ability to maintain machining tolerance, etc., for a variety of metrics like surface finish quality, component integrity and machine life may be severely compromised all because of the foundation it was built on. As well, the nature of robotic tools are for repetitive operations with high frequency and dynamic cutting forces present with high spindle speeds, which is where the most harmful vibrations appear, which can make problems with lower output quality, but causes premature machine wear and reliability issues.

Considering the same implications of machining in precision manufacturing for decades, Dynemech Systems has designed a custom solution - the Spring Viscous Damper - specifically to combat and address issues relating to dynamic vibration and needs to meet the standard of performance requirements to deliver reliable excellence to Robo Drill Machines.

How Dynemech Spring Viscous Dampers Optimise Robo Drill Machine Performance

Enhanced Vibration Isolation:

Dynemech’s Spring Viscous Dampers and the associated hybrid system provide natural frequency isolation similar to a high-quality spring and provide viscosity damping and energy-dissipating characteristics to suppress multiple vibrations. This is especially critical during high-speed and high-frequency Machining operations where minimizing vibrations is extremely important.

Improved Machine Stability:

The Spring Viscous Damper will reduce the amount of movement of the machine during operation, enabling the Robo Drill to produce holes in the workpiece with extreme accuracy with least amount of deflection of the machine during operation. This guarantees better hole position, improved thread quality, and better repeatability in production.

Fine Tuning for Accuracy to Achieve Clean Vertical Machining:

The Robo Drill - Spring Viscous Damper design allows almost perfect fine tuning to obtain the precise levelling required to maintain machining tolerances with consistency between batches. Processors will appreciate the accordingly adjusted variables, even when using the Robo Drill in long and high-speed operations.

Greater Machine Life:

One of the most significant advantages is that any vibrations not introduced into the machined workpiece are eliminated from the Robo Drill machine’s structural elements whilst some damped elements protect critical and sensitive internal mechanisms(notably spindle bearings harm and drive motors) from damage-with the overall result is still lowering ongoing maintenance costs with the added benefit of extended machine life.

Greater Throughput Speed and Quality as no interference from vibration:

When vibration is substantially reduced, users can:

1. Improved speed of cutting

2. Higher overall material to remove

3. Superior surface finish

Without degrading part quality which directly results in higher productivity and lower rejection rates.

Why Choose Dynemech Systems?

With over two decades of experience in vibration control technology, Dynemech Systems is recognized as an industry leader offering advanced vibration isolation and machine levelling solutions. Our expertise enables us to create innovative, application-specific products for CNC machines, injection moulding machines, compressors, test equipment, precision measuring machines, and heavy industrial equipment.

Dynemech Spring Viscous Dampers are the result of meticulous engineering, exhaustive real-world testing, and a deep understanding of machine dynamics. They are trusted by manufacturers globally to enhance precision, extend machine life, and optimise factory efficiency.

When you choose Dynemech, you are partnering with a team committed to elevating your manufacturing standards with solutions that deliver measurable results.

Experience the Dynemech Advantage

Empower your Robo Drill Machines with the strength of Dynemech Spring Viscous Dampers, ensuring ultimate stability, enhanced precision, and improved operational excellence in every cycle.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #SpringViscousDamper, #RoboDrill, #MachiningStability, #VibrationControl, #MachineLevelling, #PrecisionMachining, #ManufacturingExcellence, #FactoryEfficiency, #CNCPrecision, #MachinePerformance, #IndustrialSolutions, #EngineeringSupport, #VibrationIsolation, #DynemechSolutions,

Contact Us: +91-9810760131 Email: [email protected] Explore Our Solutions: vibrationmountsindia.com

#Dynemech#SpringViscousDamper#RoboDrill#MachiningStability#VibrationControl#MachineLevelling#PrecisionMachining#ManufacturingExcellence#FactoryEfficiency#CNCPrecision#MachinePerformance#IndustrialSolutions#EngineeringSupport#VibrationIsolation#DynemechSolutions

0 notes