#Cross-Linked Polyethylene Demand

Explore tagged Tumblr posts

Text

Cross-Linked Polyethylene Market Report: Trends Analysis, and Growth Forecasts | P&S Intelligence

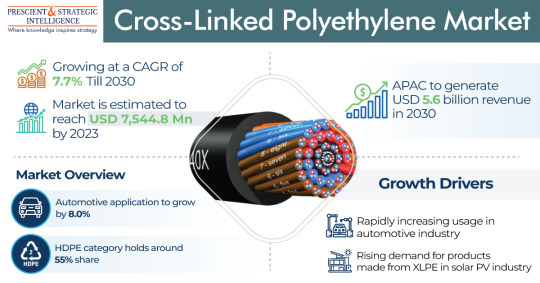

The cross-linked polyethylene market is anticipated to achieve a revenue of USD 7,544.8 million by the conclusion of 2023. It is projected to experience a compound annual growth rate (CAGR) of 7.7% from 2024 to 2030, reaching a total of USD 12,587.5 million by 2030. During the projection period, the automotive is projected to be the fastest-growing category, with a CAGR of 8.0%, on the basis of…

View On WordPress

#analysis#Competitive Analysis#Cross-Linked Polyethylene Demand#Cross-Linked Polyethylene Market#Global Cross-Linked Polyethylene Market#Growth Forecasts#Industry Overview#industry trends#Market dynamics#Market Insights#market outlook#Market Report#Market Research#P&S Intelligence#Polyethylene Industry#regional analysis

0 notes

Text

Leading Solar Cable Manufacturers in India: Why Ambica Cables Deserves Your Attention

India’s renewable energy revolution is well underway, with solar energy at its forefront. As solar installations continue to rise across residential, commercial, and utility-scale projects, the demand for high-quality solar cables manufacturers in india is soaring. These specialized cables are the backbone of solar photovoltaic (PV) systems, designed to withstand harsh weather, UV exposure, and high temperatures — all while ensuring efficient and safe energy transmission.

In this fast-growing sector, several manufacturers have stepped up to provide reliable solar cable solutions. Among them, Ambica Cables stands out as a trusted and innovative name.

Ambica Cables: Powering the Solar Movement

With a strong track record in the cable manufacturing industry, Ambica Cables has earned recognition for delivering high-quality, durable, and cost-effective solar cables suited for Indian climatic conditions. The company combines technical expertise with a commitment to green energy, offering solar cables that meet global standards and safety certifications.

Why Choose Ambica Cables for Solar Installations?

UV & Weather Resistance: Ambica’s solar cables are made with cross-linked polyethylene (XLPE) or similar compounds that are UV-resistant and ideal for outdoor installations.

High Temperature Endurance: Designed to operate efficiently under extreme temperatures, ensuring system reliability.

Low Power Loss: Manufactured using high-purity copper conductors, the cables ensure minimal transmission loss, boosting system efficiency.

IS/IEC Certified: Adheres to international safety and performance standards like IS 694, TUV, and IEC 60228.

Whether it's rooftop solar panels for homes or large-scale solar farms, Ambica Cables delivers products that match the diverse needs of India's solar energy sector.

Final Word

As India marches toward its ambitious solar energy goals, selecting the right cable manufacturer becomes more crucial than ever. A poor-quality cable can compromise the entire solar system’s performance and safety.

That’s why Ambica Cables is gaining ground as a preferred partner for reliable, long-lasting solar cables. Their blend of engineering precision, quality materials, and customer-first approach makes them a smart choice for installers, developers, and EPC contractors alike.

Visit:- https://www.ambicacables.com/solar-cable.html

0 notes

Text

Market Outlook for Fire Resistant Cable Materials: Forecasts and Competitive Landscape

The global fire resistant cable materials market was valued at USD 509.3 million in 2019 projected to reach USD 718.8 billion by 2027 growing at a compound annual growth rate (CAGR) of 4.4% from 2020 to 2027. The increasing need for enhanced fire safety measures in buildings and manufacturing facilities is a key driver behind this growth. As the risk of fire-related incidents rises, the demand for insulating electric channels capable of withstanding extreme heat and fire has grown significantly.

Stringent green building regulations in North America and Europe have accelerated the use of sustainable and fire-resistant construction materials, further boosting the demand for fire-resistant cable materials. The ongoing trend of installing complex electric systems in modern residential and commercial infrastructure also contributes to market expansion.

In the U.S., demand is particularly strong due to the rising emphasis on fire-safe construction practices, supported by an abundance of raw materials, established distribution channels, and a strong presence of leading manufacturers. Meanwhile, global growth in the construction industry—particularly in the commercial sector—has reinforced the need for fire-resistant electric systems compliant with modern safety standards.

Manufacturing facilities across North America, Europe, and Asia Pacific are increasingly prioritizing workplace safety, with secure electrical installations becoming a top concern to prevent fire hazards. This trend is expected to positively influence market demand.

Technological advancements in wire jacketing have led to the development of next-generation cables that offer superior heat and fire resistance. Innovation in raw material composition has further enhanced product durability and high-voltage compatibility, driving deeper market penetration.

Key Market Trends & Insights

Asia Pacific emerged as the largest regional market in 2019, accounting for 31.6% of the global share. Countries such as China, India, Japan, South Korea, and Australia are witnessing high demand for fire-resistant cables due to heightened awareness of fire safety in urban developments. Growth in automotive and electrical equipment production is also fueling market expansion.

China led the regional demand owing to its booming construction sector and a well-established electrical and electronics industry. The country’s growing manufacturing base further supports consistent product consumption.

Cross-linked Polyethylene (XLPE) was the dominant material segment in 2019, holding a 41.2% market share. Known for its high-grade insulation and excellent conductor properties, XLPE is anticipated to continue witnessing robust growth through 2027.

Building and construction was the leading end-use industry in 2019, accounting for 35.5% of the market share. This segment is expected to remain the fastest-growing sector as demand for fire-safe, sustainable construction materials rises.

Order a free sample PDF of the Fire Resistant Cable Materials Market Intelligence Study, published by Grand View Research.

Market Size & Forecast

2023 Market Size: USD 35 Billion

2030 Projected Market Size: USD 14 Billion

CAGR (2024-2030): 90%

North America: Largest market in 2023

Asia Pacific: Fastest growing market

Key Companies & Market Share Insights

Prominent players in the industry are focusing on the introduction of enhanced materials that can sustain the extreme heat and fire flames for a longer duration. Key industry participants are engaged in strategic activities including mergers & acquisitions, joint ventures, and third party manufacturing to expand their geographical reach and enhance their product offerings.

Key Players

Universal Cable (M) Berhad

Tratos Limited

General Cable Corporation

Prysmian Group

LS Cable & System Ltd.

Conclusion

The global fire resistant cable materials market is poised for steady growth, driven by increasing fire safety requirements, evolving building codes, and rising infrastructure investments. The combination of technological innovation, regulatory pressure, and growing urbanization—especially in Asia Pacific—continues to fuel market expansion. As industries and governments prioritize safety and sustainability, fire resistant cable materials will play a vital role in the future of construction and manufacturing sectors.

0 notes

Text

How Plastic Pipes Are Shaping the Future of Construction

Plastic pipes have become a cornerstone of modern construction, plumbing, and industrial systems due to their affordability, versatility, and long-lasting performance. From residential housing to agricultural irrigation, these pipes offer a range of advantages that have led to their widespread adoption over traditional materials like metal and concrete.Get more news about plastic pipe,you can vist our website!

Materials and Types

Plastic pipes are typically manufactured from synthetic polymers such as polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyethylene (PE), and cross-linked polyethylene (PEX). Each type is tailored to specific use cases. For instance, PVC is ideal for cold-water plumbing and drainage, while PEX is prized for hot and cold water systems due to its flexibility and thermal resistance. Polyethylene pipes are commonly used in gas distribution and irrigation because of their strength and corrosion resistance.

Advantages Over Traditional Materials

One of the main reasons plastic pipes have surged in popularity is their resistance to rust and corrosion. Unlike metal pipes, which can degrade over time due to moisture and chemical exposure, plastic pipes retain their integrity for decades. This characteristic not only extends their lifespan but also reduces the need for frequent maintenance or replacements.

Plastic pipes are also significantly lighter than metal alternatives, making transportation and installation easier and more cost-effective. Contractors appreciate the reduced labor time and the ability to manipulate the pipes without specialized tools. Their flexibility allows them to be installed in a variety of configurations, even in tight or awkward spaces.

Applications Across Industries

The uses of plastic piping systems span multiple industries. In residential and commercial buildings, they are used extensively for water supply lines, waste management systems, and HVAC systems. In agriculture, plastic pipes facilitate large-scale irrigation networks that increase crop yield and water efficiency. In the oil and gas sector, high-density polyethylene (HDPE) pipes are used to transport natural gas safely.

Municipal infrastructure also benefits from the scalability and affordability of plastic piping. Sewage systems, stormwater management networks, and potable water distribution increasingly rely on plastic due to its resilience and low installation costs.

Environmental Considerations

While plastic pipes are often criticized for their association with non-biodegradable plastics, they offer sustainability benefits in terms of lifecycle and energy consumption. Many plastic piping materials are recyclable, and their longer lifespan reduces the frequency of replacement, resulting in fewer resources consumed over time. Additionally, the energy required to manufacture and transport plastic pipes is considerably lower than that of metal or concrete pipes.

New innovations are also emerging, such as bio-based plastics and more efficient recycling systems, helping to improve the environmental profile of plastic piping.

Challenges and Future Outlook

Despite their advantages, plastic pipes are not without challenges. Exposure to UV radiation can degrade certain types over time, and poor installation practices can lead to cracking or joint failure. However, with proper handling and continuous innovation in materials science, these issues can be mitigated.

Looking ahead, the demand for sustainable, cost-effective infrastructure solutions suggests that plastic pipes will remain at the forefront of construction and development. As global urbanization continues, and the need for efficient water and energy systems grows, plastic pipes will play an increasingly vital role in shaping the way we build and live.

0 notes

Text

The Afterlife of High Voltage Cables: Where Do They Go?

High voltage (HV) cables are the cornerstone of India’s electrical networks; from grids and metros to renewables and industrial installations. But ever spared a thought about what happens when these cables reach their retirement age?

These high voltage cable wires are made of copper and aluminum cores wrapped in thick, protective layers, usually made from material known as cross-linked polyethylene (XLPE) or other speciality insulation.

It is a material prized for its thermal stability, mechanical strength, and insulation performance in high-voltage applications. That is why it is the global standard across the industry, including in our own triple-layer extruded cable products.

Copper and aluminum cores are still recyclable. However, XLPE’s same qualities that make it robust also make it difficult to recycle using conventional means. It is like an indestructible skin which can neither be easily broken down nor recycled using traditional methods.

Unfortunately, the practical reality is not ideal. As per the industry data, a significant 30–40% of a cable’s mass consists of insulation materials. These polymeric sheathings are either burned or buried, harming the environment.

Are Thermoplastics the Answer to Cable Insulation Recoverability?

India’s cable and wire market is approximately projected to reach over $17 billion, raising demands for collective innovation. Around the world, companies are testing new materials such as thermoplastic alternatives to XLPE.

But why thermoplastic? Because it is easier to recycle and reuse while retaining the electrical performance. Some Asian and European research groups are piloting methods such as mechanical grinding of cable scrap and microwave pyrolysis to recover polymers and metals cleanly.

How as a Responsible Industry Should We Respond?

It is time to innovate around the challenge and create systems that extend these cables’ value beyond first use.

For example, at DICABS, we manufacture HV cables using high-purity XLPE insulation with triple-layer extrusion that ensures long service life, minimal maintenance, and reduced risk of early failure.

This extends the replacement cycle and helps our clients reduce their overall waste generation over time. Looking for HV cables with optimal electrical and mechanical performance, minimal breakdowns, and a longer lifespan? Please visit us here: https://dicabs.com.

1 note

·

View note

Text

Hyphen Cables: A Reliable Name Among LT XLPE Power Cables Manufacturers in India

As infrastructure and industrial growth continue to accelerate across India, the need for robust and high-performance power distribution systems becomes increasingly critical. Low Tension Cross-Linked Polyethylene (LT XLPE) Power Cables Manufacturers have emerged as the preferred choice for reliable and efficient low-voltage electrical transmission. Among the top manufacturers meeting this demand, Hyphen Cables has built a reputation for delivering high-quality LT XLPE power cables designed to meet the evolving needs of modern electrical networks.

Precision Engineering and Compliance with Global Standards Hyphen Cables is known for its engineering excellence and stringent quality control in the production of LT XLPE Power Cables. These cables are insulated with cross-linked polyethylene, offering superior thermal, mechanical, and dielectric properties compared to conventional PVC-insulated cables. The result is a safer, longer-lasting, and more efficient cable solution for low-voltage power transmission.

Manufactured in state-of-the-art facilities, Hyphen's LT XLPE cables adhere to key national and international standards, including IS 7098 (Part 1), IEC, and BS specifications. Available in both aluminum and copper conductor variants, these cables are designed for single-core and multi-core configurations with optional armouring, depending on the application.

Hyphen's LT XLPE cables are widely used in residential, commercial, and industrial installations, as well as in utility-based power networks. Their excellent resistance to heat, moisture, chemicals, and mechanical stress makes them ideal for challenging environments and continuous duty operations.

Serving Key Sectors with Reliability and Customization Hyphen Cables supplies LT XLPE power cables to a diverse range of sectors including construction, manufacturing, energy, transport, and infrastructure development. What differentiates Hyphen from its competitors is not only the product quality but also its customer-centric approach—offering tailored cable solutions, technical support, and dependable logistics.

With a deep understanding of application-specific needs, Hyphen works closely with project managers, contractors, and engineers to ensure that every cable installation meets performance and safety expectations. The company also offers cables with enhanced fire resistance, oil resistance, and UV protection, ensuring reliable performance under extreme conditions.

Backed by a robust R&D team and modern testing facilities, Hyphen conducts thorough inspections and tests on every batch to ensure product consistency and durability. This commitment to excellence has earned Hyphen long-standing trust among clients and a growing footprint in domestic and export markets.

Conclusion In today’s fast-evolving electrical landscape, Hyphen Cables stands as a dependable name among LT XLPE Power Cable manufacturers in India. Combining engineering precision, quality assurance, and a strong focus on customer satisfaction, Hyphen continues to deliver high-performance cable solutions for diverse industry needs. Whether for industrial plants, infrastructure projects, or utility networks, Hyphen’s LT XLPE power cables offer a perfect balance of reliability, safety, and efficiency—making them the go-to choice for forward-looking energy solutions.

Visit:- https://www.hyphencables.com/lt-xlpe-pvc-power-and-control-cables.html

0 notes

Text

Cross-Linked Polyethylene Market Driven by Infrastructure, Energy, and Innovation Surge

The Cross-Linked Polyethylene market has witnessed a significant upswing in recent years, driven by increasing demand across diverse sectors including plumbing, automotive, and electrical. The material’s enhanced heat resistance, mechanical strength, and chemical resistance have made it a preferred choice over traditional polyethylene. These advantages, along with favorable regulatory initiatives and rising infrastructure investment, continue to act as strong market drivers. This article explores the main growth drivers of the cross-linked polyethylene market, outlining how technological, regulatory, and industrial trends are fueling its expansion globally.

Rising Demand in Plumbing and HVAC Applications One of the most prominent drivers of the cross-linked polyethylene market is the growing adoption of PEX in plumbing and HVAC applications. Its flexibility, resistance to high temperatures and pressures, and cost-effectiveness compared to traditional metal piping systems have significantly increased its usage. PEX is now widely used in residential and commercial water distribution systems. According to recent industry insights, over 70% of new residential constructions in North America opt for PEX piping over traditional copper or PVC systems. This shift is largely due to PEX's resistance to corrosion and scale buildup, along with easier installation and lower labor costs.

Expansion of Infrastructure and Construction Activities Infrastructure development across emerging economies, especially in Asia-Pacific and Latin America, plays a pivotal role in driving the cross-linked polyethylene market. Rapid urbanization and government investments in water and sewage systems, power distribution networks, and public housing projects have created robust demand for durable and cost-efficient materials like PEX. Countries such as China and India are witnessing massive infrastructure expansion under government initiatives such as China’s Belt and Road Initiative and India’s Smart Cities Mission, which significantly boosts demand for cross-linked polyethylene in piping, tubing, and cable insulation.

Electrification and Growth in Renewable Energy The increased deployment of renewable energy projects and electrification trends globally are contributing to the growing demand for cross-linked polyethylene as a reliable insulation material for electrical cables. XLPE cables are highly favored in high-voltage applications due to their ability to withstand elevated thermal and electrical stress. The power sector’s transition towards smart grids and underground cabling systems is another crucial driver. According to International Energy Agency (IEA) data, global investment in electricity grids reached nearly $300 billion in 2023, a portion of which is driving demand for advanced materials like XLPE that enhance grid reliability and safety.

Automotive Industry Evolution and Lightweighting Trend The automotive sector is increasingly turning to cross-linked polyethylene to improve fuel efficiency and reduce vehicle weight. PEX tubing is used in automotive fuel systems, coolant lines, and brake systems, thanks to its excellent chemical resistance and temperature tolerance. With global regulations pushing for reduced emissions, the trend toward lightweighting in vehicles is accelerating. Cross-linked polyethylene offers the ideal balance of performance and weight, which aligns with automotive manufacturers’ sustainability goals and electric vehicle (EV) development strategies.

Technological Innovations in Manufacturing Advancements in cross-linking techniques such as silane grafting, electron beam, and peroxide methods have enhanced product performance and diversified application potential. These innovations allow for improved customization based on end-user requirements and offer better control over density, cross-linking degree, and structural integrity. As a result, manufacturers are able to cater to emerging sectors like medical tubing and underfloor heating systems, creating new avenues for market expansion. The ability to tailor the material properties to specific needs is becoming a strong competitive driver.

Environmental Compliance and Sustainability Trends Environmental regulations and the global shift toward sustainable building practices are also propelling the cross-linked polyethylene market. PEX products are recyclable and offer longer lifespans, reducing overall environmental impact. Additionally, governments and industry organizations are encouraging the adoption of energy-efficient materials, especially in green building certifications such as LEED. The push for eco-friendly infrastructure is likely to remain a significant growth driver for XLPE materials in the foreseeable future.

Conclusion In summary, the cross-linked polyethylene market is witnessing robust growth, underpinned by a series of converging drivers—ranging from infrastructure expansion and energy sector modernization to automotive innovation and environmental regulation. As industries seek high-performance, durable, and sustainable materials, the advantages of cross-linked polyethylene are coming into sharper focus. The market is poised for continued expansion, especially in emerging economies and technologically progressive sectors. Manufacturers who invest in innovation and align with green construction and energy trends are expected to lead the market trajectory in the years ahead.

0 notes

Text

Everything You Need to Know About XLPE Insulation and the Best XLPE Suppliers in UAE

Introduction In the world of modern construction and electrical engineering, XLPE insulation (Cross-Linked Polyethylene) stands out as a revolutionary material. Known for its superior thermal, mechanical, and chemical resistance, XLPE is widely used across industries such as electrical wiring, HVAC, plumbing, and infrastructure projects. With the UAE leading the way in infrastructure development, finding reliable XLPE suppliers in UAE and XLPE insulation manufacturers has never been more important.

What is XLPE Insulation?

XLPE, or Cross-Linked Polyethylene, is a type of polyethylene with cross-links that change the thermoplastic into a thermoset material. This cross-linking enhances the thermal and mechanical properties of the material, making XLPE insulation highly durable, heat-resistant, and suitable for high-voltage applications.

Key Benefits of XLPE Insulation

High Thermal Resistance: Ideal for high-temperature environments.

Electrical Strength: Perfect for cable insulation and wiring.

Chemical Resistance: Suitable for chemical plants and industrial applications.

Flexibility: Easy to install in complex layouts and conduits.

Moisture Resistance: Great for underground and underwater applications.

Why XLPE is Popular in the UAE Market

The UAE’s hot climate and high-demand infrastructure projects make XLPE insulation a preferred choice. Whether for high-rise buildings in Dubai or industrial zones in Abu Dhabi, XLPE insulation suppliers in UAE cater to a wide array of commercial and industrial needs.

Leading XLPE Suppliers in UAE

Finding trustworthy XLPE suppliers in UAE is crucial for ensuring quality and compliance with international standards. Top XLPE insulation suppliers UAE offer:

ISO-certified manufacturing

Custom insulation sizes

Quick delivery and project support

Competitive pricing for bulk orders

If you're looking for durability, reliability, and long-term performance, it's essential to work with the best XLPE suppliers in UAE who offer both local expertise and global standards.

Top XLPE Insulation Manufacturers

Many XLPE insulation manufacturers in the UAE operate state-of-the-art facilities and are known for innovation, environmental compliance, and bulk production capabilities. Some of these manufacturers also supply internationally, offering premium-quality XLPE foam insulation and tubes for HVAC and construction sectors.

XLPE Foam Manufacturers in UAE

XLPE foam manufacturers play a key role in supplying thermal insulation solutions. This type of foam is extensively used in:

Duct insulation

Pipe insulation

Acoustic panels

Protective packaging

The UAE has emerged as a hub for high-performance XLPE foam manufacturers, catering to both domestic and export markets.

Choosing the Best XLPE Suppliers in UAE

Here’s what to look for when choosing the best XLPE suppliers in UAE:

Proven track record and industry certifications

Full compliance with DEWA and other regional standards

Wide range of insulation products including rolls, tubes, and sheets

Excellent after-sales support and custom order handling

Conclusion

As the demand for efficient and durable insulation solutions continues to rise, XLPE insulation has solidified its position as the go-to material across the UAE’s thriving construction and industrial sectors. By sourcing from trusted XLPE insulation manufacturers and XLPE foam manufacturers, businesses can ensure long-term value and performance.

0 notes

Text

Power Cable Market Future Outlook Shows Technological Expansion and Rising Global Infrastructure Development Demand

The power cable market future outlook is defined by dynamic trends that reflect a rapidly changing global energy landscape. Driven by increasing urbanization, a shift toward renewable energy sources, and the expansion of smart grid infrastructure, power cables are playing a crucial role in powering modern economies. As demand for electricity continues to grow, so does the need for efficient, reliable, and high-capacity power transmission solutions.

In recent years, governments and private stakeholders have significantly ramped up investments in power infrastructure. From electrification projects in rural areas to the deployment of advanced smart grid systems in urban centers, power cables are fundamental components that enable seamless energy transmission and distribution. These cables, including low, medium, and high-voltage types, are tailored to meet diverse applications, from residential wiring to large-scale industrial and utility-scale projects.

One of the most prominent factors shaping the power cable market’s future is the increasing focus on renewable energy integration. Wind farms, solar parks, and hydroelectric facilities require robust cable systems to transmit power to the grid efficiently. Submarine power cables, in particular, are gaining popularity as offshore wind energy becomes more widespread. These underwater cables allow energy generated offshore to be transferred to mainland grids, ensuring minimal energy loss and stable supply.

Moreover, the growing electrification of transportation is influencing the demand for specialized power cables. Electric vehicles (EVs), electric trains, and charging infrastructure are all powered by systems reliant on high-performance cabling. As nations move towards greener mobility solutions, manufacturers are developing advanced cables that offer higher conductivity, improved insulation, and longer life spans. This segment is expected to significantly contribute to the growth of the power cable market in the coming years.

Technological advancements are another key driver of future market development. Innovations such as superconducting cables, which can transmit electricity with nearly zero resistance, are poised to revolutionize energy distribution. Though currently expensive and in the early stages of deployment, these technologies offer enormous potential for reducing transmission losses and improving grid efficiency. Meanwhile, improvements in materials—such as the use of cross-linked polyethylene (XLPE)—enhance durability, flexibility, and thermal resistance, making cables more reliable in harsh environmental conditions.

Geographically, the Asia-Pacific region is expected to dominate the future of the power cable market. Countries like China, India, and Southeast Asian nations are experiencing rapid industrialization and urban expansion, creating a surging demand for electricity. These nations are also investing heavily in renewable energy and grid modernization, which further boosts demand for efficient power transmission systems. Similarly, Africa and the Middle East are emerging as new markets, especially as energy access initiatives and infrastructure development projects gain momentum.

Europe and North America, while more mature markets, are focusing on upgrading aging electrical infrastructure and expanding smart grid systems. This includes replacing outdated overhead lines with underground power cables, which offer better reliability and safety, especially in areas prone to extreme weather. Moreover, government initiatives supporting carbon neutrality and energy efficiency will continue to fuel demand for advanced power cable technologies across these regions.

Despite strong growth prospects, the industry also faces several challenges. Volatility in raw material prices, such as copper and aluminum, can affect production costs and profit margins. Additionally, the complexity of installation, maintenance, and regulatory compliance—especially in cross-border and undersea projects—may slow down implementation. Nonetheless, continued innovation, supportive government policies, and growing demand from emerging sectors are expected to offset these hurdles.

Sustainability is another central theme in the market’s future outlook. Manufacturers are increasingly focusing on eco-friendly practices, including the development of recyclable cables and reduction of harmful emissions during production. The rise of green building standards and sustainable infrastructure projects further emphasizes the need for low-impact, energy-efficient cabling solutions.

In conclusion, the future outlook of the power cable market is promising and multifaceted. With rising electricity demand, increasing adoption of renewable energy, and growing investment in smart infrastructure, the industry is on a strong upward trajectory. Technological innovation, coupled with a global push toward sustainability and electrification, will continue to redefine the role of power cables in the global energy ecosystem. As such, stakeholders across the supply chain—from manufacturers to energy providers—are well-positioned to benefit from the emerging opportunities in this essential and evolving sector.

#PowerCableMarket#EnergyInfrastructure#SmartGridSolutions#RenewableEnergyIntegration#ElectricPowerTransmission

0 notes

Text

Cable Unleashed: Singapore’s Ultimate Industrial Cable Guide for Technicians & Engineers

Cables are the unsung backbone of Singapore’s modern infrastructure, powering everything from towering skyscrapers to high-speed data networks. Whether you’re a budding technician or an experienced engineer, mastering the fundamentals of cable construction, materials, and applications is essential. In this all-encompassing guide, we’ll take you from the basics of conductor and insulation types, through industry-specific cable solutions for transport, oil & gas, and data centres, all the way to cutting-edge trends like smart cable monitoring and eco-friendly designs. Tailored to Singapore’s strict safety standards and diverse industrial needs, this article equips you with practical insights and best practices to select, install, and maintain the right cable for every project. Let’s plug into the world of cables and power up your expertise.

Introduction: What Is a Cable?

A cable is an assembly of one or more conductors, each individually insulated, and collectively protected by an outer sheath. Cables transmit electrical power, signals, or data between devices and across distances. Unlike simple wiring, industrial cables incorporate multiple layers—insulation, fillers, armouring—to ensure mechanical strength, chemical resistance, and safe operation in demanding environments.

Fundamentals of Cable Construction

Conductors

Copper: High conductivity (≈58 MS/m), ductile, reliable.

Aluminium: Lower cost, lighter weight, moderate conductivity (≈36 MS/m), used in high-voltage overhead lines.

Insulation, Sheath & Armouring

Insulation: Prevents short-circuits and dielectric breakdown (materials detailed later).

Sheath: Protects against moisture, chemicals, UV (e.g., PVC, PE).

Armour (optional): Steel tape or wire for mechanical protection, required in underground or high-stress installations.

Types of Industrial Cables

1. Power Cables (LV, MV, HV)

Low Voltage (LV): ≤1 kV, for building distribution (lighting, sockets).

Medium Voltage (MV): 1 kV–35 kV, for substations and feeder lines.

High Voltage (HV): >35 kV, for grid interconnects and long-distance transmission.

2. Control & Instrumentation Cables

Control Cables: Multi-core cores for motor control, relay logic.

Instrumentation Cables: Shielded pairs/triples for sensor signals, 4–20 mA loops.

3. Fiber-Optic & Data Cables

Copper Data Cables: Cat 5e/6/6A for Ethernet (1 Gbps–10 Gbps).

Fibre-Optic Cables: Single-mode (SM) for long haul; multi-mode (MM) OM-3/OM-4 for data centres.

4. Special-Purpose Cables

Fire-Resistant (FR): Maintain circuit integrity under fire (e.g., IEC 60332-1).

Halogen-Free (LSZH): Low Smoke Zero Halogen for enclosed spaces (airports, tunnels).

5. Marine & Subsea Cables

Shipboard Cables: Flexible, oil-resistant, meets DNV-GL approval.

Subsea Power Cables: XLPE insulated, steel-armoured, for offshore platforms and inter-island links.

Materials Used in Cables

1. Conductor Materials: Copper vs. Aluminium

PropertyCopperAluminiumConductivity≈100% IACS≈61% IACSDensity (g/cm³)8.962.70Cost per kg (SGD)High30–40% lowerMechanical StrengthHighModerate

2. Insulation Materials

PVC (Polyvinyl Chloride): Inexpensive, flame-retardant, moderate temperature (−15 °C to +70 °C).

XLPE (Cross-Linked Polyethylene): Higher temperature (−40 °C to +90 °C), better dielectric strength.

EPR (Ethylene Propylene Rubber): Flexible, excellent cold-temperature performance.

LSZH (Low Smoke Zero Halogen): Emission-safe in fires.

3. Sheathing & Armour

PE (Polyethylene): UV-resistant, used for outdoor telecom cables.

PU (Polyurethane): Abrasion-resistant, used in robotics/machine tool cables.

Steel Tape / Wire Armour: Adds mechanical strength against impact, rodents, digging.

Applications by Industry (Focus on Singapore)

1. Transport & Rail

MRT Signalling Cables: Fibre-optic and data cables for SCADA and voice/data.

Wayside Power Cables: XLPE-insulated MV cables for feeder stations.

2. Infrastructure & Buildings

LV Power Distribution: 3-core copper XLPE armoured for switchboards.

HVAC Control Cables: Multi-core instrumentation cables for BMS systems.

3. Oil & Gas / Petrochemical

Instrumentation Cables: Hydrocarbon-resistant sheaths for refineries (DNV-GL DP-1).

Fire Survival Cables: FR cables for emergency shut-down circuits.

4. Data Centres & Telecommunications

Cat 6A Unshielded Twisted Pair (UTP): Up to 10 Gbps for local networks.

OM-4 Fibre Optic: High-density, low-attenuation for rack-to-rack links.

5. Marine & Port Facilities

Shipboard Cables: IEC 60092-350 approved, oil-resistant and flame-retardant.

Submarine Inter-Island Cables: XLPE insulated, steel-armoured, buried under seabed.

6. Manufacturing & Automation

Robotics Cables: PUR sheath, high flex life (>10 million cycles).

Machine Tool Cables: Shielded for EMC compliance, oil- and coolant-resistant.

Safety Precautions & Regulatory Standards

1. Singapore Standards

BCA CP5: Code of Practice for Fire Precautions in Buildings.

SCDF: Fire safety requirements; LSZH cables in public enclaves.

2. International Standards

IEC 60332: Flame propagation tests.

IEC 60502: Power cables ≤35 kV.

IEC 60754 / 61034: Halogen acid gas & smoke density tests.

3. Installation Best Practices

Segregation: Keep power, control and data cables apart to avoid interference.

Bending Radius: Observe minimum bend radius (×10 × cable diameter).

Support & Clamping: Use cable trays, ladders, and glands to relieve mechanical stress.

Cost-Benefit Analysis of Cable Choices

1. Copper vs. Aluminium

Up-front: Aluminium is ~30–40% cheaper per kg.

Lifecycle: Copper’s superior conductivity reduces resistive losses and cooling costs.

2. PVC vs. XLPE vs. LSZH

MaterialCapital CostTemperature RatingFire-SafetyLongevityPVCLow+70 °CModerateModerateXLPEModerate+90 °CModerateHighLSZHHigh+90 °CExcellentHigh

3. Armoured vs. Unarmoured

Armoured: Higher material & installation cost; essential for underground, outdoor, or high-mechanical-risk areas.

Unarmoured: Lower cost and weight; used in protected indoor routes.

Cables & Technology Trends

1. Smart Cables & Condition Monitoring

Embedded fiber-optic sensors for real-time temperature and strain monitoring, reducing downtime.

2. High-Speed Data & 5G-Ready Fiber

Deployment of bend-insensitive OM-5 and G.657.A2 fibers for ultra-low-latency 5G and enterprise networks.

3. Eco-Friendly & Recyclable Cable Designs

Use of recyclable polymers and bio-based insulations to meet Singapore’s Green Plan targets.

Guidance for Technicians & Engineers

1. Selection Criteria & Sizing

Voltage Rating: Match to system voltage + safety margin.

Current-Carrying Capacity: Based on conductor cross-section and ambient temperature.

Derating Factors: Account for grouping, soil thermal resistivity, high ambient.

2. Testing & Commissioning

Insulation Resistance (IR) Test: ≥1 GΩ for power cables.

High-Pot (Dielectric) Test: Verify dielectric withstand.

Continuity & Loop Testing: Ensure correct wiring and no opens.

3. Maintenance & Troubleshooting

Thermographic Scanning: Detect hotspots in energised cables.

Partial Discharge Monitoring: For MV/HV cables to predict insulation faults.

Visual Inspections: Check glands, sheaths, and terminations for wear or damage.

Conclusion & Recommendations

Selecting the right cable involves balancing performance, safety, and cost. For Singapore’s demanding environments—tropical climate, strict fire codes, space constraints—LSZH and XLPE-insulated armoured cables often represent the optimum blend of safety and longevity, despite higher upfront costs. Copper conductors remain the gold standard for power and control due to superior conductivity and mechanical durability. Fiber-optic solutions are indispensable for today’s high-speed data and telecom networks, especially in mission-critical installations such as data centres, MRT signalling, and 5G infrastructure.

For technicians and engineers, adhere strictly to standards (BCA CP5, IEC series) and best practices—proper sizing, installation, and regular condition monitoring—to ensure cable life expectancy and system reliability. Embrace emerging technologies like smart cable monitoring and eco-friendly materials to future-proof installations and contribute to Singapore’s sustainability goals.

By understanding the fundamentals—from conductor choice to sheath materials, installation practices to cost-benefit trade-offs—you’ll equip your projects with cable solutions that are safe, efficient, and fit for every industry’s unique demands.

Power cables are essential components of our modern world, silently connecting us to energy sources and powering our lives. From the sophisticated systems that light up our homes to the heavy-duty cable required for industrial machinery, understanding the different types of power cables, their specific uses, and the crucial safety tips associated with them is vital. Whether you’re an electrician, a DIY enthusiast, or simply curious about how your devices get their power, navigating the realm of power cables can be daunting. This comprehensive guide will demystify the various cable types, explore their applications in everyday life and industry, and arm you with essential safety knowledge. Join us as we delve into everything you need to know about power cables to ensure you can use them safely and effectively, keeping your projects powered up and in good hands.

Everything You Need to Know About Power Cables: Types, Uses, and Safety Tips

Power cables are essential components of our modern world, silently connecting us to energy sources and powering our lives. From the sophisticated systems that light up our homes to the heavy-duty cable required for industrial machinery, understanding the different types of power cables, their specific uses, and the crucial safety tips associated with them is vital. Whether you’re an electrician, a DIY enthusiast, or simply curious about how your devices get their power, navigating the realm of power cables can be daunting. This comprehensive guide will demystify the various cable types, explore their applications in everyday life and industry, and arm you with essential safety knowledge. Join us as we delve into everything you need to know about power cables to ensure you can use them safely and effectively, keeping your projects powered up and in good hands.

Types of Power Cables

Power cables come in various types, each designed to meet specific needs and applications. The most common types include coaxial cables, twisted pair cables, and fiber optic cables. Coaxial cables are widely used for transmitting television signals and internet data due to their high-frequency capabilities and shielding that reduces signal interference. Twisted pair cables, such as Ethernet cables, consist of pairs of wires twisted together to minimize electromagnetic interference, making them ideal for networking and telecommunications. Fiber optic cables, on the other hand, use light to transmit data, offering unparalleled speed and bandwidth for internet and communication applications.

Another important category of power cables is electrical power cables, which are used to transmit electrical energy from one point to another. These include low voltage, medium voltage, and high voltage cables, each suited for different power transmission and distribution requirements. Low voltage cables, typically rated up to 1,000 volts, are used in residential and commercial buildings to power appliances, lighting, and electrical outlets. Medium voltage cables, rated between 1,000 volts and 35,000 volts, are commonly used in industrial settings and for distributing electricity within large facilities. High voltage cables, rated above 35,000 volts, are used for long-distance power transmission, connecting power plants to substations and the electrical grid.

Specialized power cables also exist for specific applications, such as armored cables for underground or underwater installations, heat-resistant cables for high-temperature environments, and flexible cables for applications requiring frequent bending and movement. Armored cables are designed with a protective layer of steel or aluminum to withstand physical damage and environmental conditions, making them suitable for harsh environments. Heat-resistant cables are made with materials that can withstand high temperatures without degrading, ensuring reliable performance in industrial processes, ovens, and other high-heat applications. Flexible cables, often used in robotics and machinery, are designed to endure repeated bending and flexing without breaking or losing conductivity.

Common Uses of Power Cables

Power cables are ubiquitous in our daily lives, enabling the operation of countless devices and systems. In residential settings, power cables are used to connect appliances, lighting fixtures, and electronic devices to electrical outlets, providing the necessary power for their operation. Extension cords and power strips are common examples of power cables that allow multiple devices to be connected to a single outlet, offering convenience and flexibility in home and office environments. Additionally, power cables are used in home entertainment systems, connecting televisions, audio equipment, and gaming consoles to power sources and each other.

In commercial and industrial settings, power cables play a crucial role in powering machinery, equipment, and infrastructure. Heavy-duty power cables are used to connect large machinery and equipment to electrical panels and power sources, ensuring reliable and efficient operation. These cables are designed to handle high current loads and are often reinforced with protective sheathing to withstand harsh conditions and mechanical stress. Power cables are also used in data centers and server rooms to connect and power servers, network equipment, and cooling systems, ensuring uninterrupted operation and data integrity.

Power cables are essential for the operation of public infrastructure and utilities, such as street lighting, traffic signals, and public transportation systems. Underground power cables are used to distribute electricity to communities, reducing the visual impact of overhead lines and improving safety by minimizing the risk of accidental contact. In renewable energy systems, power cables connect solar panels, wind turbines, and other energy sources to inverters and the electrical grid, facilitating the generation and distribution of clean energy. Additionally, power cables are used in marine and offshore applications, providing power to ships, oil rigs, and underwater equipment.

Understanding Cable Ratings and Specifications

Understanding cable ratings and specifications is crucial for selecting the right power cable for a given application. Cable ratings provide information about the cable’s electrical and mechanical properties, ensuring safe and reliable performance. One of the most important ratings is the voltage rating, which indicates the maximum voltage the cable can safely carry. Voltage ratings are typically expressed in volts (V) or kilovolts (kV) and are used to categorize cables as low voltage, medium voltage, or high voltage. Selecting a cable with an appropriate voltage rating is essential to prevent insulation breakdown and electrical hazards.

Current rating, also known as ampacity, is another critical specification that indicates the maximum current the cable can carry without overheating. Ampacity is influenced by factors such as conductor size, insulation type, and installation conditions. It is typically expressed in amperes (A) and is essential for ensuring that the cable can handle the electrical load without overheating or causing damage to the insulation. Selecting a cable with the appropriate current rating is crucial for preventing electrical fires and ensuring the safety of the electrical system.

Other important cable specifications include temperature rating, insulation type, and environmental ratings. The temperature rating indicates the maximum operating temperature the cable can withstand without degrading, which is important for applications in high-temperature environments. Insulation type refers to the material used to insulate the conductors, which affects the cable’s electrical properties and suitability for different applications. Environmental ratings, such as Ingress Protection (IP) ratings, indicate the cable’s resistance to water, dust, and other environmental factors, ensuring reliable performance in challenging conditions. Understanding these specifications is essential for selecting the right power cable for a given application and ensuring safe and efficient operation.

Safety Tips for Handling Power Cables

Safety is paramount when handling power cables, as improper use or installation can lead to electrical hazards, injuries, and equipment damage. One of the most important safety tips is to always turn off the power before working on electrical systems or handling power cables. This reduces the risk of electric shock and ensures a safe working environment. Additionally, using insulated tools and wearing protective gear, such as rubber gloves and safety glasses, can provide an extra layer of protection when working with power cables.

Proper cable management is essential for maintaining a safe and organized workspace. Avoid overloading power outlets and extension cords, as this can lead to overheating and potential fire hazards. Ensure that power cables are properly routed and secured to prevent tripping hazards and mechanical damage. Use cable ties, clips, and conduits to organize and protect cables, and avoid running cables under carpets or through doorways, as this can cause wear and tear over time. Regularly inspect power cables for signs of damage, such as fraying, cuts, or exposed wires, and replace damaged cables immediately to prevent electrical hazards.

When working with high voltage or industrial power cables, additional safety precautions are necessary. Ensure that all personnel handling high voltage cables are properly trained and qualified, and follow industry standards and regulations for safe installation and maintenance. Use appropriate personal protective equipment (PPE), such as arc flash suits and insulated tools, when working with high voltage systems. Implement lockout/tagout (LOTO) procedures to ensure that power sources are de-energized and locked out before performing maintenance or repairs. Additionally, always follow manufacturer guidelines and industry best practices for handling, installing, and maintaining power cables to ensure safety and reliability.

Installation Best Practices for Power Cables

Proper installation of power cables is essential for ensuring safe and reliable operation. One of the key best practices is to follow manufacturer guidelines and industry standards for cable installation. This includes using the correct tools and equipment, as well as adhering to recommended installation procedures. Properly preparing the installation site, such as ensuring that conduits and cable trays are clean and free of obstructions, can help prevent damage to the cables during installation and ensure a smooth and efficient process.

When installing power cables, it is important to consider factors such as cable bending radius, tension, and support. Avoid bending cables beyond their recommended minimum bending radius, as this can cause damage to the insulation and conductors, leading to potential electrical hazards. Use appropriate cable supports, such as clamps and brackets, to prevent sagging and mechanical stress on the cables. Additionally, avoid excessive pulling tension during installation, as this can stretch and damage the conductors. Using cable lubricants and pulling tools can help reduce friction and tension during installation, ensuring a smooth and safe process.

Proper termination and connection of power cables are crucial for ensuring reliable electrical connections and preventing electrical hazards. Use appropriate connectors and terminals that are compatible with the cable type and size, and follow manufacturer guidelines for proper crimping and termination techniques. Ensure that all connections are secure and free of corrosion, and use insulating materials, such as heat shrink tubing or electrical tape, to protect exposed conductors. Additionally, label all cables and connections to ensure easy identification and troubleshooting in the future.

Maintenance and Troubleshooting of Power Cables

Regular maintenance and troubleshooting are essential for ensuring the longevity and reliability of power cables. One of the key maintenance practices is to perform regular visual inspections of power cables to identify signs of wear and damage. Look for issues such as frayed insulation, exposed conductors, and corrosion, and address any problems immediately to prevent electrical hazards and equipment failure. Additionally, check for signs of overheating, such as discoloration or melting, which can indicate excessive current or poor connections.

Another important maintenance practice is to test the electrical performance of power cables using appropriate testing equipment. Insulation resistance testing, for example, can help identify degradation in the insulation material, which can lead to electrical leakage and short circuits. Continuity testing can verify that the conductors are intact and free of breaks or faults. Performing these tests regularly can help identify potential issues before they lead to equipment failure or safety hazards. Additionally, keeping detailed records of maintenance activities and test results can help track the condition of power cables over time and inform future maintenance decisions.

When troubleshooting power cables, it is important to follow a systematic approach to identify and address the root cause of the problem. Start by verifying the power source and connections, ensuring that all cables are properly connected and that there are no loose or corroded terminals. Use appropriate diagnostic tools, such as multimeters and cable testers, to measure voltage, current, and resistance, and compare the readings to expected values. If a fault is detected, isolate the affected section of the cable and perform further testing to pinpoint the exact location of the issue. Once the problem is identified, take appropriate corrective actions, such as repairing or replacing the damaged cable, to restore normal operation.

Environmental Considerations for Power Cables

Environmental considerations play a significant role in the selection and installation of power cables, as they can impact the performance and longevity of the cables. One of the key environmental factors to consider is temperature, as extreme temperatures can affect the insulation and conductors of power cables. High temperatures can cause the insulation to degrade, leading to electrical leakage and short circuits, while low temperatures can make the insulation brittle and prone to cracking. Selecting power cables with appropriate temperature ratings and using protective measures, such as thermal insulation or cooling systems, can help mitigate the effects of extreme temperatures.

Moisture and water exposure are other important environmental factors that can impact power cables. Water ingress can cause corrosion of the conductors and degradation of the insulation, leading to electrical faults and equipment failure. Using power cables with appropriate moisture resistance ratings, such as those with water-resistant or waterproof insulation, can help protect against water damage. Additionally, proper sealing of cable joints and connections, as well as using protective conduits and enclosures, can further prevent moisture ingress and ensure reliable performance in wet environments.

Chemical exposure is another environmental consideration that can affect power cables, particularly in industrial settings where cables may be exposed to corrosive chemicals or solvents. Chemical exposure can cause the insulation and sheathing of power cables to degrade, leading to electrical hazards and equipment failure. Selecting power cables with chemical-resistant insulation and using protective measures, such as chemical-resistant conduits and enclosures, can help mitigate the effects of chemical exposure. Additionally, regular inspections and maintenance can help identify and address any chemical-related damage before it leads to equipment failure.

Innovations in Power Cable Technology

Power cable technology has seen significant advancements in recent years, driven by the need for higher performance, increased efficiency, and improved safety. One of the key innovations in power cable technology is the development of high-temperature superconducting (HTS) cables. HTS cables use superconducting materials that can carry much higher current densities than traditional copper or aluminum conductors, resulting in lower energy losses and improved efficiency. These cables are being used in power transmission and distribution systems to increase capacity and reduce energy losses, particularly in urban areas where space is limited.

Another important innovation is the development of smart power cables, which incorporate sensors and monitoring systems to provide real-time data on cable performance and condition. These smart cables can detect issues such as overheating, electrical faults, and mechanical damage, allowing for early intervention and preventive maintenance. The use of smart power cables can improve the reliability and safety of electrical systems, reduce downtime, and extend the lifespan of the cables. Additionally, the data collected by smart power cables can be used to optimize power distribution and improve energy efficiency.

Advancements in materials science have also led to the development of new insulation and sheathing materials that offer improved performance and durability. For example, cross-linked polyethylene (XLPE) is a widely used insulation material that offers excellent electrical properties, high-temperature resistance, and good mechanical strength. New materials, such as nanocomposite insulations, are being developed to offer even better performance, with improved resistance to electrical, thermal, and mechanical stresses. These advancements in materials technology are helping to improve the reliability and longevity of power cables, making them more suitable for demanding applications and environments.

Conclusion and Key Takeaways

In conclusion, power cables are indispensable components of our modern world, enabling the operation of countless devices and systems. Understanding the different types of power cables, their specific uses, and the crucial safety tips associated with them is essential for ensuring safe and reliable operation. From residential and commercial applications to industrial and public infrastructure, power cables play a vital role in powering our lives and connecting us to energy sources.

When selecting and installing power cables, it is important to consider factors such as cable ratings and specifications, environmental conditions, and best practices for installation and maintenance. Regular inspections and testing, along with proper cable management and safety precautions, can help prevent electrical hazards and ensure the longevity and reliability of power cables. Additionally, staying informed about the latest innovations in power cable technology can help you take advantage of new advancements that offer improved performance, efficiency, and safety.

By following the guidelines and best practices outlined in this comprehensive guide, you can navigate the realm of power cables with confidence, ensuring that your projects are powered up and in good hands. Whether you are an electrician, a DIY enthusiast, or simply curious about how your devices get their power, understanding power cables is crucial for keeping your electrical systems safe and efficient.

0 notes

Text

Cross-Linked Polyethylene Market Will Reach USD 12,587.5 Million by 2030

The cross-linked polyethylene market is anticipated to achieve a revenue of USD 7,544.8 million by the conclusion of 2023. It is projected to experience a compound annual growth rate (CAGR) of 7.7% from 2024 to 2030, reaching a total of USD 12,587.5 million by 2030. This growth of the market can be credited to the utilization of this material is quickly growing in the automotive sector, for…

View On WordPress

#Cross-Linked Polyethylene Market#Cross-Linked Polyethylene Market Demand#Cross-Linked Polyethylene Market Growth#Cross-Linked Polyethylene Market Outlook#Cross-Linked Polyethylene Market Share#Cross-Linked Polyethylene Market Size

0 notes

Text

Top Quality Solar cable manufacturers in India

Top Quality Solar Cable Manufacturers in India: Spotlight on Ambica Cable

With the rise in sustainable energy initiatives across the globe, India has emerged as one of the largest markets for solar energy. As the country rapidly adopts solar power in residential, commercial, and industrial sectors, the demand for high-quality solar components, particularly solar cables, has surged. Solar cables form the backbone of any solar installation, ensuring efficient power transmission and long-term performance under challenging environmental conditions. In this fast-growing sector, Ambica Cable is recognized as one of the leading manufacturers of reliable, high-performance solar cables in India.

What are Solar Cables?

Solar cables are specially designed electrical cables used to interconnect solar panels and other components of a photovoltaic (PV) system. Unlike conventional cables, solar cables are engineered to withstand extreme temperatures, UV radiation, and varying weather conditions. They are typically made with tinned copper conductors and insulated with cross-linked polyethylene (XLPE) or similar materials to ensure longevity and minimal energy loss.

Key features of top-quality solar cables include:

UV and weather resistance

High flexibility for easy installation

Fire retardant properties

Low smoke emission and halogen-free

Resistance to moisture, oil, and chemicals

Compliance with international standards like TUV, IEC, and UL

Why Quality Matters in Solar Cables

Using substandard or poorly insulated cables in solar installations can lead to major safety hazards, including short circuits, fire, and significant power losses. That’s why it’s essential to choose solar cables from reputable manufacturers that follow strict quality control and industry certifications.

Leading Solar Cable Manufacturers in India

India’s solar cable manufacturing sector has seen impressive growth, with several players leading the way in innovation and product quality. Here are some of the top manufacturers, with a spotlight on Ambica Cable:

1. Ambica Cable

Ambica Cable has built a solid reputation in the Indian cable industry for producing high-performance, durable, and cost-effective solar cables. The company’s solar cable range is specifically designed for harsh Indian climates, ensuring long service life and high electrical efficiency.

Why Ambica Cable Stands Out:

Superior Material Quality: Ambica uses high-grade tinned copper conductors and robust XLPO/XLPE insulation that resists UV, heat, and abrasion.

Certified Manufacturing: Their solar cables are manufactured in compliance with global standards such as TUV, IS/IEC 62930, and EN 50618.

Customization and Scalability: Whether for a small rooftop system or a large-scale solar farm, Ambica Cable provides tailored cable solutions to meet specific customer needs.

Customer Trust: Known for excellent service and product reliability, Ambica has established strong relationships with installers, EPC contractors, and solar developers across India.

2. Polycab

A household name in India’s electrical industry, Polycab offers a comprehensive range of solar cables with global certifications. Their cables are known for excellent heat resistance and long operational life.

3. KEI Industries

KEI Industries manufactures a wide range of solar cables suitable for utility-scale and rooftop applications. Their products are trusted for consistent performance and quality assurance.

4. Finolex Cables

With a longstanding presence in the Indian cable market, Finolex delivers solar cables known for durability, safety, and reliability in tough weather conditions.

5. RR Kabel

RR Kabel offers solar cables that are halogen-free, flame-retardant, and compliant with international solar standards. Their manufacturing facilities and R&D centers help them stay ahead in innovation.

Conclusion

As India accelerates toward its clean energy goals, the importance of choosing the right components for solar installations cannot be overstated. Among the many players in the market, Ambica Cable has proven itself as a reliable and quality-driven manufacturer of solar cables. With a commitment to safety, performance, and customer satisfaction, Ambica continues to power India's solar future—one installation at a time.

For project developers, EPC contractors, and solar integrators looking for trustworthy cable partners, Ambica Cable offers the perfect blend of quality, affordability, and service excellence.

Visit:- https://www.ambicacables.com/solar-cable.html

0 notes

Text

Why Oil & Gas Infrastructure is Boosting Marine Cable Demand

The global E-beam Cross-Linked Marine Cables Market is on a promising trajectory, poised to more than double from US$ 6.3 Bn in 2023 to US$ 13.6 Bn by 2034, growing at a compound annual growth rate (CAGR) of 7.3%. This steady rise is powered by the need for safe maritime navigation, expanding offshore infrastructure, and emerging technological innovations in polymer cross-linking.

Request a Sample Report Copy

What Are E-beam Cross-Linked Marine Cables?

Electron-beam (e-beam) cross-linked marine cables are specially designed for the harsh marine environment. They are manufactured using a unique three-step process: extrusion of the matrix, electron beam irradiation to achieve crosslinking, and foaming in an oven. This method significantly improves the thermal, mechanical, electrical, and environmental resistance of cable insulation.

These cables are essential in powering, controlling, and supporting communication systems aboard ships, submarines, and offshore drilling platforms. As maritime operations grow increasingly complex and digitally integrated, the need for resilient and high-performance cable systems becomes vital.

Key Market Drivers

1. Focus on Marine Safety and Communication

Modern marine navigation relies heavily on integrated systems like GPS, radar, sonar, and satellite communications. These mission-critical technologies depend on durable, fire-resistant, and corrosion-resistant cabling to perform consistently. With increasing incidents of electrical hazards at sea, the marine industry is adopting high-performance e-beam cross-linked cables that minimize the risk of electrical failures and fires.

The rising focus on operational safety, especially for long-distance and military vessels, is fueling demand for these robust cables. Governments and private maritime organizations are emphasizing the upgrade of legacy electrical systems with advanced cabling infrastructure to enhance onboard safety and efficiency.

2. Surge in Oil & Gas Infrastructure Development

As energy security becomes a strategic priority globally, nations are increasing investments in oil & gas exploration and extraction—much of which takes place offshore. E-beam cross-linked marine cables are crucial for powering and automating offshore platforms, where extreme conditions demand high thermal stability and corrosion resistance.

For instance, in February 2024, India’s Vedanta announced a US$ 4 Bn investment to double its oil & gas output, further bolstering demand for heavy-duty marine cables. As offshore drilling rigs expand in number and complexity, so will the requirement for cables that can withstand extreme pressure, salinity, and temperature variations.

Technological Trends Shaping the Market

One of the latest developments in the field is the blending of High-Density Polyethylene (HDPE) with Ethylene Vinyl Acetate (EVA). This composite offers a strong yet flexible solution for marine cable insulation. HDPE provides tensile strength and resistance to chemical attack, while EVA enhances impact resistance and flexibility.

These advanced formulations, coupled with electron-beam irradiation, result in cables that are more durable, lighter, and energy-efficient, meeting the evolving needs of modern marine infrastructure.

Regional Insights: Asia Pacific Leads the Wave

In 2023, Asia Pacific dominated the global market, thanks to the region’s expanding maritime trade and increasing offshore energy projects. According to Invest India, the country consumed 233.3 MMT of petroleum products and 66.6 BCM of natural gas in FY 2023–24, showcasing growing energy demands.

Additionally, trade statistics from UNCTAD reveal East Asia’s significant trade volume growth in 2022, with China’s exports to ASEAN and India rising by 17% and 21%, respectively. These factors drive the region’s investment in advanced marine infrastructure, thereby contributing to increased demand for e-beam cross-linked cables.

Competitive Landscape and Strategic Developments

Several global players are expanding their production capabilities to cater to rising demand. Companies like Eaton, Belden, LEONI AG, and Eland Cables are not only innovating in materials but also extending their regional footprints.

Belden Inc. recently expanded its manufacturing facility in Pune, India, investing US$ 40 Mn and adding 19,000 square meters of production space.

Ravicab Cables Pvt. Ltd. acquired Elegar Kepen, formerly Leoni Cable Solutions India, in a strategic move to enhance its product offerings.

These investments reflect a growing emphasis on local manufacturing, sustainability, and innovation.

Outlook Through 2034

As the maritime industry evolves with digital technologies, sustainable practices, and automation, the role of robust electrical infrastructure will become more central. E-beam cross-linked marine cables offer unmatched resilience and longevity, making them ideal for modern marine applications.

With emerging regions like Asia Pacific setting the pace and major players ramping up production and R&D, the market is set for a transformative decade ahead. From naval defense to offshore oil platforms and commercial shipping, the demand for safe, high-performance cables will be a consistent growth lever.

0 notes

Text

Pigeon Safety Nets Bangalore – Protect Your Home from Bird Infestation

Keep Your Home Bird-Free with Pigeon Safety Nets Bangalore

Sponsored by Prestige Safety Nets

Introduction: A Growing Need in Urban Bangalore

Bangalore’s expanding skyline brings with it a hidden issue—pigeon infestation. With their increasing presence in apartment balconies, ventilation ducts, and open windows, pigeons have become a major urban nuisance. This has led to rising demand for effective bird control solutions like Pigeon Safety Nets Bangalore, which offer a safe, humane, and long-term remedy.

Why Are Pigeons a Problem in Bangalore?

Pigeons might look harmless, but they carry several hidden problems:

Health Hazards: Pigeons can transmit diseases such as histoplasmosis and psittacosis.

Structural Damage: Their acidic droppings can corrode buildings and dirty living spaces.

Noise & Nesting Issues: Pigeons often nest in hard-to-reach places, causing noise and hygiene concerns.

How Pigeon Safety Nets Bangalore Can Help

Installing Pigeon Safety Nets Bangalore is the most effective way to combat pigeon-related issues. These nets prevent birds from entering your private space without harming them, making it an ethical and practical solution.

Features and Benefits of Pigeon Safety Nets

✅ High-Quality Material

Made from UV-stabilized polyethylene or nylon, the nets are designed to withstand Bangalore’s variable climate.

✅ Custom Installation

Professionals measure and fit nets perfectly in balconies, windows, AC ducts, and shafts.

✅ Aesthetic Design

Transparent or color-blended nets are barely visible and don’t affect the look of your home or office.

✅ Low Maintenance

Once installed, they require little upkeep and can be cleaned easily with water spray or a cloth.

Why Choose Prestige Safety Nets?

As the trusted sponsor of this article, Prestige Safety Nets brings years of expertise in bird control solutions. Their team offers:

Prompt and professional service

Free site inspection and measurement

Competitive pricing

Durable, weather-resistant nets

Warranty on installation

Final Thoughts

Whether it’s a home, office, or public building, pigeon problems can’t be ignored. By choosing Pigeon Safety Nets Bangalore from Prestige Safety Nets, you're not just solving a problem—you’re investing in safety, cleanliness, and peace of mind.

For More Information

Contact No: 091089 74473

Website: https://www.prestigesafetynetsbangalore.com/

Link: https://www.prestigesafetynetsbangalore.com/pigeon-safety-nets-in-bangalore.html

Email: [email protected]

Address: D, 72, 2nd Cross St, Sri Satya Sai Baba Layout, Bethel Nagar, Krishnarajapuram, Bengaluru, Karnataka 560036

#PigeonSafetyNetsBangalore#BirdNettingBangalore#BalconyNetting#AntiPigeonNet#PrestigeSafetyNets#PigeonControl#BirdProofing#HomeSafetyBangalore#ApartmentNetting#UrbanBirdControl

0 notes

Text

Hyphen Cables – Trusted LT XLPE Power Cables Manufacturers in India

When it comes to reliable and efficient power distribution, Low Tension (LT) XLPE Power Cables have become the standard for a wide range of industrial, commercial, and infrastructure projects. Among the top LT XLPE Power Cable manufacturers in India, Hyphen Cables stands out for its unwavering commitment to quality, performance, and customer satisfaction.

LT XLPE (Cross-Linked Polyethylene) cables are widely used for low-voltage power transmission (up to 1.1 kV). These cables offer several advantages over conventional PVC cables, including superior thermal stability, higher current carrying capacity, better resistance to chemicals and moisture, and longer service life. Recognizing these benefits, Hyphen Cables has invested in cutting-edge manufacturing technology to produce high-grade LT XLPE Power Cables that meet the evolving needs of the power sector.

Hyphen Cables uses high-conductivity aluminum or copper conductors and premium XLPE insulation, designed to perform in the most demanding conditions. Whether it's for industrial installations, utilities, residential complexes, or infrastructure development, their LT XLPE power cables manufacturers deliver consistent power with minimal losses and excellent protection against short circuits and voltage fluctuations.

All cables manufactured by Hyphen undergo stringent quality checks and comply with industry standards such as IS 7098 (Part 1) and relevant IEC specifications. Their advanced manufacturing facilities are equipped with modern extrusion lines, high-precision testing equipment, and a skilled engineering team that ensures every meter of cable meets the highest quality benchmarks.

What truly sets Hyphen Cables apart is its customer-centric approach and focus on innovation. They offer customized solutions based on client requirements, including various conductor configurations, insulation thickness, and armoring options. Their technical team provides end-to-end support, from cable selection and design to installation guidelines and after-sales service.

Additionally, Hyphen Cables emphasizes environmental responsibility and safety compliance, making their products suitable for sustainable and long-term power infrastructure projects.

With a strong presence across India and a growing portfolio of satisfied clients in sectors such as power distribution, construction, real estate, and manufacturing, Hyphen Cables has earned its reputation as a dependable partner in energy solutions.

For top-quality, durable, and efficient LT XLPE Power Cables Manufacturers, Hyphen Cables remains a leading name trusted by engineers, contractors, and developers alike.

Visit:- https://www.hyphencables.com/lt-xlpe-pvc-power-and-control-cables.html

0 notes

Text

Cross-Linked Polyethylene Market: Key Drivers Behind Its Rapid Growth in Construction and Plumbing

The Cross-Linked Polyethylene market has been experiencing steady growth due to its various applications in plumbing, heating, and electrical industries. Cross-linked polyethylene, commonly known as PEX, is a high-performance thermoplastic material that undergoes a chemical process to enhance its strength and thermal stability. This unique polymer material has become a preferred choice in numerous industries owing to its durability, flexibility, and resistance to chemicals and heat. Several drivers contribute to the growth of the Cross-Linked Polyethylene market, including increased demand for efficient plumbing systems, advancements in construction technologies, environmental sustainability concerns, and expanding application in the automotive industry.

Growing Demand for PEX in Plumbing and Heating Systems