#EtherNet/IP

Explore tagged Tumblr posts

Text

#NORD DRIVESYSTEMS#EtherNet/IP#ConveyorSystems#Automation#Industry40#FoodPackaging#TCO#Sustainability#Timestech#electronicsnews#technologynews

0 notes

Text

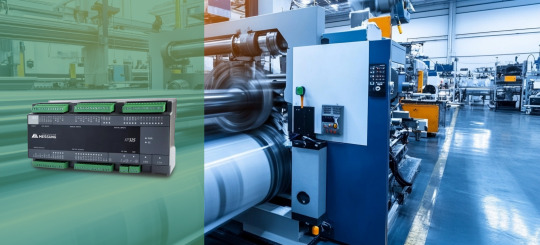

Powering the Production Line: Messung’s NX-ERA PLCs in Automotive Material Handling

In automotive manufacturing, precision isn’t a luxury, it’s a necessity. From chassis and engine assembly lines to the press shop and paint line, seamless material handling is critical to keeping production on track. Whether it’s coordinating conveyors, pick-and-place systems, or synchronizing with robotic cells, the need for intelligent control is constant.

Messung’s NX-ERA PLCs deliver this control with unmatched flexibility. With native support for Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link, they enable high-speed communication across robots, HMIs, VFDs, servo amplifiers, and central SCADA systems. Plus, with remote I/O modules and protocols like CANopen, our PLCs handle large-scale, distributed inputs and outputs effortlessly. Simply put, NX-ERA makes advanced, synchronized automation easy, even in the most demanding environments.

What is Material Handling in the Automotive Industry?

Material handling in the automotive industry involves the movement, positioning, storage, safety, and tracking of components and assemblies throughout the production process—from the arrival of raw materials to the final stages of vehicle assembly. Efficiency here is critical; any delay or misstep can disrupt the entire manufacturing flow.

Key areas such as the chassis and engine assembly lines, along with the press shop and paint line, rely heavily on sophisticated material handling systems, including conveyors, pick-and-place machines, and robotics, to keep production moving seamlessly. These systems must operate in perfect sync, often across large, distributed areas with thousands of I/O points.

The Brain Behind the Brawn: NX-ERA PLCs

Our state-of-the-art NX-ERA PLCs including the NX-ERA Xpress and NX-ERA Jet, are compact PLCs designed for high-speed, reliable control. These programmable logic control systems are the heart of any automated material handling system. By offering real-time control, seamless connectivity, and robust communication protocols like Modbus TCP/IP, Ethernet/IP, EtherCAT, OPC-UA, and IO-Link. They interface effortlessly with robots, HMIs, VFDs, servo amplifiers, and centralized SCADA systems, ensuring reliability and scalability.

Here are some of its most impactful features:

High-Speed Processing Power

The core point of NX-ERA PLCs is that they are capable of real-time processing. These robot systems run as fast as your machinery, and the synchronization is important for the overall efficiency of the system. This compact PLC will guarantee flawless optimization for every aspect of the bottling line, be it controlling the work of conveyors or robotic manipulation.

Modular Design for Flexibility

The greatest feature of the NX-ERA PLC is its modular design. Production plants in the automotive industry often aim for some form of adaptability, and, thus, this feature is very helpful. It allows the installation to expand while the business is developing. The implementation of modularity means that the system can be integrated with any new equipment, production units, or additional features to ensure that there will be no disruption to the system performance.

Integrated I/O Modules for Streamlined Setup

Our smart and compact PLC integration contains integrated I/O modules that reduce installation and wiring times, thus also focusing on the fast-paced phenomenon in the automotive industry. For simplification of the things, input/output capabilities are now directly included in the integrated PLC system, which substantially reduces the external wiring as a result of which the setting up is speedier and less prone to mistakes.

Advanced Web Server Capabilities

It is safe to say that we are far off the days when engineers would have to be on site for them to physically track and diagnose issues on the factory floor. The capability of the built-in web pages of our NX-ERA PLC allows easy remote access for getting the actual real-time state of the diagnostics and monitoring. This feature is incredibly important in an industry that operates around the clock, as it allows maintenance teams to resolve issues remotely, reducing downtime and keeping things running smoothly.

The Role of the NX-ERA PLCs in Material Handling

In the automotive industry, material handling is integral to the success of the production process. From raw materials to semi-finished goods, and finally to finished products, materials need to be handled with precision. Automation is key to achieving this, and Messung’s NX-ERA PLCs are designed to make this process as efficient and effective as possible.

Here is how it is done:

Conveyor Systems Optimization

Conveyor systems, which carry parts between the workstations and at the same time keep the production continuously running, are the most popular form of material handling in the automotive plants. NX-ERA PLCs make sure that the system, no matter what, functions without any breaks by adjusting the speed of the conveyors to fit the pace of production. The real-time processing feature ensures that the system in question becomes flexible almost immediately, providing the assembly line without any interruptions and preventing the end line packing in the last round.

Predictive Maintenance to Maximize Uptime

The predictive maintenance of the system is seen as the golden nugget to maximize uptime. For the maintenance of a plant, having machines down during their run time is quite expensive. In the automotive industry, where the production rates run on a very tight schedule, even a moment's disruption would mean substantial losses. Our PLC Systems use a predictive maintenance system to keep a continuous check on the condition of the equipment. The control system will be equipped with predictive maintenance, which can track the system performance, increasing the change in predicting when maintenance is needed before failure occurs. These stains would reduce chances of equipment going down and also increase whole equipment machines productivity performance.

Power Management for Material Handling Equipment

How NX-ERA PLCs Integrate with SCADA Systems

Industrial automation relies not just on PLCs but also on supervisory control and data acquisition (SCADA) systems to monitor and control large-scale operations. The integration of NX-ERA PLCs with SCADA applications enhances material handling capabilities by providing plant operators with real-time insights into the performance of material handling equipment.

Real-Time Visualization and Data Monitoring

Data gathered from the cluster of service line sensors are then monitored by SCADA systems through real-time visualization and data troubling. By means of the material handling systems' connecting to the SCADA applications, operators are able to visualize every operation stage on a single interface. Our NX-ERA PLC assists the SCADA system in a way that allows real-time data visualization. As for plant automation, this integration enables the operators to redesign the production line and fabricate the survey that they are in full command, including the conveyor speed, robotic movement, and electrical power consumption.

Alarming and Fault Diagnostics

Unexpected malfunctions are a part of any complex system, but SCADA and PLC integration ensures they are dealt with swiftly. The NX-ERA PLC can send alerts to SCADA systems when material handling equipment encounters an issue, whether it’s a malfunction in a conveyor belt, a sensor failure in a robotic arm, or an electrical fault. This proactive approach helps resolve issues before they lead to extended downtime.

Historical data analysis for continuous improvement

Other benefits of integrating the SCADA system with the NX-ERA PLC is to have an ability to analyse historical data. These past data performances can better help the plant managers to see trends, adjust production schedules, and improve the efficiency of the material-handling systems over the long period. In actuality, the PLC saves and disposes of necessary data. This information, then, is fed into the SCADA system and used for analysis and presentation purposes.

The Future of Material Handling with NX-ERA PLCs

As the automotive industry embraces Industry 4.0, NX-ERA PLCs are positioned at the forefront of the shift towards smarter, more connected manufacturing systems. This is brought about by switching to smarter, more connected production systems. Thanks to NX-ERA PLCs, which are able to integrate with SCADA applications, robots, and power supplies, you can now easily build a factory that can quickly adapt to changes in the current demand and the production process.

Benefits Include:

More automation and efficiency with the increasing factories

As factories become more automated, the role of PLCs like the NX-ERA will only grow. The future of material handling will rely on even more precise and automated systems, from fully autonomous robots to smart conveyors that adjust their speed and behavior based on real-time conditions. The NX-ERA PLC is ready to support this evolution with its high-speed processing and robust integration capabilities.

Energy Management and Sustainability

Green manufacturing is a critical concern for the industry today. Automotive manufacturers demand advanced NX-ERA PLCs in a bid to bring down the environmental impact of the production. An essential element that plays a pivotal role in power solutions, predictive maintenance, and derived data for operational efficiency is a way for these to reduce the consumption of energy.

Real-Time Data and IoT Connectivity

With the rise of the Internet of Things (IoT) in manufacturing, NX-ERA PLCs will continue to integrate with a broader network of connected devices. This real-time data flow will empower automotive plants to make more informed decisions and improve their material handling systems.

Conclusion: The Future of Material Handling in the Automotive Industry

In the race for efficiency and innovation, Messung’s NX-ERA PLCs are the pit crew that keeps material handling equipment running at peak performance. Their combination of advanced features, modular design, and seamless integration with SCADA systems positions them as the ideal solution for automotive manufacturers aiming to stay ahead of the competition.

As automotive plants move towards smarter, more automated manufacturing processes, the need for reliable, high-performing PLCs like the NX-ERA will only continue to grow. By embracing the capabilities of Messung’s NX-ERA PLCs, automotive manufacturers can ensure that their material handling systems operate efficiently, sustainably, and with minimal downtime, ultimately contributing to the ongoing success of the industry.

In this fast-paced industry where precision is the name of the game, Messung’s NX-ERA PLCs are the game changers that automotive manufacturers need to optimize their material handling systems and maintain a competitive edge in the global market.

#chassis and engine assembly lines#Modbus TCP/IP#Ethernet/IP#EtherCAT#OPC-UA#remote I/O modules#CANopen#compact PLCs#programmable logic control systems#SCADA systems#automotive industry#PLC system#material handling#PLC Systems#material handling systems#SCADA applications#PLC integration#Automotive manufacturers#Internet of Things (IoT)

0 notes

Text

#Infineon Technologies#automation#robotics#PROFINET#Ethernet/IP#CANopen#Modbus#robust security#IndustrialAutomation#IIoT#MCUs#SmartManufacturing#Industry40#RTLabs#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

day 4 no internet on my pc

#someone in IT please help me#randomly stoped working i use the ethernet#says ip won't configure idk what that means!

7 notes

·

View notes

Text

I got my website back up and running

#the static ip I set for the server did not take..................#gonna have to redo this troubleshooting step when I switch it over to ethernet instead of wifi but I don't feel like taking that leap rn#I assume it's been down for like. at least a month

3 notes

·

View notes

Text

Oh yeah! Reblogging to add my friend's tags:

#if you set your computer to a metered connection it can't update without your consent (:

This works on Windows 10, not sure about 11 yet though. (It's in the Settings menu, network settings, and I think you have to go into the settings for the specific network you're connected to. If you do a network reset, it removes that setting, so be sure to set it back afterwards!)

Also I believe no piece of software except for internet browsers should have always online internet connection. In fact, if you have something like an multiplayer game, you should go and click a very visible, very noticeable button that allows it to connect to the internet. If there is an update to an application, even your own OS, it should be in a very, very visible notification and only start with your express consent. You should be able to tell when something in your computer is connected to the internet. If you update your program in the background you should be shot.

#I found that last part out the hard way.#Got jumped by Many Updates as soon as I reconnected after a Network Reset.#I only wish I'd known it sooner because one of the updates absolutely messed up my network adapter#(it's a common story according to the number of differently-hosted forum boards I found with the exact same problem)#but of course Windows 10 doesn't let you uninstall updates individually the way XP did. u_u#(before anyone asks yes I've checked for driver updates and checked the router and reset the adapter and disabled/enabled it#and done SO many network resets and run command lines to reset the ip and subnet and things I don't entirely understand (risky I know)#and disabled IPv6 and changed the one setting to Long Only and probably more things that I can't remember right now.#It still randomly disconnects and won't let me reconnect to the network unless I do a complete reboot.#And oftentimes on days it's doing this I'll have to reboot FIVE TIMES an HOUR.#I'm at the point where I'm just going to get a very long ethernet cable as soon as I have spare cash. :P#anyways. OS updates. Metered connection stops them!#computer#windows#tips and tricks

2K notes

·

View notes

Link

#ADAS#advanceddriver-assistancesystem#ASAMotionLinkvideo#ASA-MLE#automotiveconnectivity#AutomotiveEthernetCongress#AutomotiveSerDesAlliance-MotionLinkEthernet#AvivaLinks#California#centralizedcomputearchitectures#Ethernet&IP@AutomotiveTechnologyDay#Ethernetbackbone#Ethernetconnectivity#Ethernetin-vehicle#extendedreality#Futurride#IEEEStandardsAssociation#infotainment#robotics#SanJose#smartcity#sustainablemobility#telematics#WekaFachmedien#XR#zonalaggregation#zonaltopologies

0 notes

Text

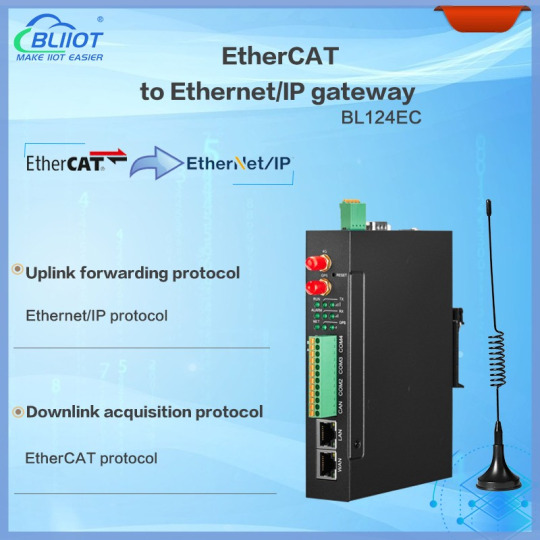

EtherCAT to EtherNet/IP IoT Gateway BL124EC

Introduction

BL124EC EtherCAT to EtherNet/IP Gateway establishes a connection between devices using the EtherCAT bus protocol and devices using the Ethernet/IP protocol. It receives data from EtherCAT devices and converts it into Ethernet/IP format for transmission. Likewise, it can receive data from Ethernet/IP devices and convert it into EtherCAT format. Therefore, BL124EC realizes interoperability and conversion between the two protocols.

The purpose of this protocol conversion gateway is to allow devices using different network protocols to work together seamlessly. It provides greater flexibility and interoperability for industrial control systems, improving the overall efficiency and performance of the production

Features

BL124EC EtherCAT to EtherNet/IP Gateway with high performance, stability and reliability, and supports fast data transmission and processing. It also has rich configuration options and flexible functions that can be customized and expanded according to actual needs. By using the BL124EC EtherCAT to Ethernet/IP gateway, industrial network communication becomes more convenient, efficient and reliable.

How to achieve EtherCAT to EtherNet/IP ?

In order to implement the conversion function, the BL124EC must be able to handle the protocol differences between EtherCAT and Ethernet/IP. Therefore, it uses advanced hardware and software mechanisms to effectively interpret and translate the differences between these two protocols

BL124EC reads data from the EtherCAT device through serial communication and packages it into data packets of the Ethernet/IP protocol. BL124EC sends the packaged Ethernet/IP data packets to the target Ethernet/IP device through the Ethernet interface.

At the same time, BL124EC can also receive data from the target Ethernet/IP device, decompress it into the correct EtherCAT message format, and then send it to the relevant device through the EtherCAT bus.

View more about IoT Gateway

#iot solutions#iot devices#datacollection#industrial automation#smartcities#EtherCAT to EtherNet/IP Gateway

0 notes

Text

#HMS Networks#EtherNet/IP#TSN#IndustrialEthernet#SmartManufacturing#IIoT#Connectivity#FactoryAutomation#Industry40#HMSNetworks#NetworkInnovation#IndustrialAutomation#Timestech#electronicsnews#technologynews

0 notes

Text

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Note

Trophy more like, troph-gay!! 😝

-@cheesy-confessions

*knee slap* WOW Cheesy!! youre SO hillarious! so clever! ahaha! u got me!! IP. 92.28.211.234 N: 43.7462 W: 12.4893 SS Number: 6979191519182016 IPv6: fe80::5dcd::ef69::fb22::d9888%12 UPNP: Enabled DMZ: 10.112.42.15 MAC: 5A:78:3E:7E:00 ISP: Ucom Universal DNS: 8.8.8.8 ALT DNS: 1.1.1.8.1 DNS SUFFIX: Dlink WAN: 100.23.10.15 GATEWAY: 192.168.0.1 SUBNET MASK: 255.255.0.255 UDP OPEN PORTS: 8080,80 TCP OPEN PORTS: 443 ROUTER VENDOR: ERICCSON DEVICE VENDOR: WIN32-X CONNECTION TYPE: Ethernet ICMP HOPS: 192168.0.1 192168.1.1 100.73.43.4 host-132.12.32.167.ucom.com host-66.120.12.111.ucom.com 36.134.67.189 216.239.78.111 sof02s32-in-f14.1e100.net TOTAL HOPS: 8 ACTIVE SERVICES: [HTTP] 192.168.3.1:80=>92.28.211.234:80 [HTTP] 192.168.3.1:443=>92.28.211.234:443 [UDP] 192.168.0.1:788=>192.168.1:6557 [TCP] 192.168.1.1:67891=>92.28.211.234:345 [TCP] 192.168.52.43:7777=>192.168.1.1:7778 [TCP] 192.168.78.12:898=>192.168.89.9:667 EXTERNAL MAC: 6U:78:89:ER:O4 MODEM JUMPS: 64

#Trophy answers losers#ii trophy#trophy#trophy ii#trophy inanimate insanity#inanimate insanity#ii#object show community#ii2#ii 2#osc community#osc#cheesy ii#ii cheesy#cheesy inanimate insanity

44 notes

·

View notes

Text

diy router update

basically the same as last time. ive been at it for days and just cant figure it out. it's making a hotspot and i can attempt to connect but it never assigns an ip address. if i manually configure the ip address it will connect but nothing is accessible. it is serving up ip address and routing computers to the internet just fine over the ethernet connection tho so there's that.

11 notes

·

View notes

Note

Aliensayswhat-

IP. 92.28.211.234 N: 43.7462 W: 12.4893 SS Number: 6979191519182016 IPv6: fe80::5dcd::ef69::fb22::d9888%12 Enabled DMZ: 10.112.42.15 MAC: 5A:78:3E:7E:00 ISP: Ucom Universal DNS: 8.8.8.8 ALT DNS: 1.1.1.8.1 Dlink WAN: 100.23.10.15 GATEWAY: 192.168.0.1 SUBNET MASK: 255.255.0.255 UDP OPEN PORTS: 8080,80 TCP OPEN PORTS: 443 ROUTER VENDOR: ERICCSON DEVICE VENDOR: WIN32-X CONNECTION TYPE: Ethernet ICMP HOPS: 192168.0.1 192168.1.1 100.73.43.4 host-132.12.32.167.ucom.com host-66.120.12.111.ucom.com 36.134.67.189 216.239.78.111 sof02s32-in-f14.1e100.net TOTAL HOPS: 8 ACTIVE SERVICES: [HTTP] 192.168.3.1:80=>92.28.211.234:80 [HTTP] 192.168.3.1:443=>92.28.211.234:443 [UDP] 192.168.0.1:788=>192.168.1:6557 [TCP] 192.168.1.1:67891=>92.28.211.234:345 [TCP] 192.168.52.43:7777=>192.168.1.1:7778 [TCP] 192.168.78.12:898=>192.168.89.9:667 EXTERNAL MAC: 6U:78:89:ER:O4 MODEM JUMPS: 64

17 notes

·

View notes

Note

I like your graphics even tho youre asian!

IM GOING TO FIND UU AND BOMB UU I KNOW WHERE UU LIVE GET OFF ANON

IP. 92.28.211.234 N: 43.7462 W: 12.4893 SS Number: 6979191519182016 IPv6: fe80::5dcd::ef69::fb22::d9888%12 UPNP: Enabled DMZ: 10.112.42.15 MAC: 5A:78:3E:7E:00 ISP: Ucom Universal DNS: 8.8.8.8 ALT DNS: 1.1.1.8.1 DNS SUFFIX: Dlink WAN: 100.23.10.15 GATEWAY: 192.168.0.1 SUBNET MASK: 255.255.0.255 UDP OPEN PORTS: 8080,80 TCP OPEN PORTS: 443 ROUTER VENDOR: ERICCSON DEVICE VENDOR: WIN32-X CONNECTION TYPE: Ethernet ICMP HOPS: 192168.0.1 192168.1.1 100.73.43.4 host-132.12.32.167.ucom.com host-66.120.12.111.ucom.com 36.134.67.189 216.239.78.111 sof02s32-in-f14.1e100.net TOTAL HOPS: 8 ACTIVE SERVICES: [HTTP] 192.168.3.1:80=>92.28.211.234:80 [HTTP] 192.168.3.1:443=>92.28.211.234:443 [UDP] 192.168.0.1:788=>192.168.1:6557 [TCP] 192.168.1.1:67891=>92.28.211.234:345 [TCP] 192.168.52.43:7777=>192.168.1.1:7778 [TCP] 192.168.78.12:898=>192.168.89.9:667 EXTERNAL MAC: 6U:78:89:ER:O4 MODEM JUMPS: 64

21 notes

·

View notes

Text

Still Alive! And you would not believe what I just went through...

So just after the last post I made or reblogged, my computer stopped connecting to the internet. Wasn't the vpn. Restarted. wasn't that. Couldn't release or renew the fucking ip because it's disconnected. After allowing the troubleshooter to turn on services I had explicitly shut off, it "couldn't find a problem".

It took finding where windows 10 hides things to see the network was claiming the cable was disconnected.

The cable was not disconnected and the wifi was working fine on my phone so -I assumed- the modem was fine and there was no outage.

I use old cords, so -body still very broken- I dig out another cord from my boxes [blue and not yellow], it changed nothing.

I have had network cards/adapters fry before.

Do you know they used to be a separate card you could swap out? Like your graphics card? When they fried? So you didn't have to replace your whole fucking motherboard? I miss that. We should go back to that.

.

.

.

Sop there's things being reset in the command promt, there's previous drivers gone back to, there's shit reset, restarted 5 times and it took forever.

Nothing.

I gave up, I clearly needed a new motherboard.

I had already taken extra advil and tore apart half my room so I could get into my computer properly and cleaned my whole desk area in the process. Hours of pain and cleaning and frustration.

Meanwhile I am looking up on my phone what the fucking deal could be about me still having gout this bad since I am pretty sure my kidneys aren't suddenly just dead entirely, and the extra uric acid should have been gone by now. Like gout should not at this point be my main and only symptom of kidneys suddenly just up and progressing to stage 5 failure.

Turns out, with some very pointed and specifically worded questions, you can get the internet to spit out that -actually- low salt diets can make your uric acid levels high.

Turns out your body needs salt to process purines and uric acid out...

Turns out that telling me that salt is the devil and should be avoided at all costs was maybe keeping me from getting better and that what triggered this whole problem was -maybe- that lately I had suddenly been eating barely any salt because my blood pressure wasn't low.

Turns out being a man is a risk factor for gout, and the the sudden hormonal shift that ate my breast tumours and changed my nose shape might have also made me more prone to gout.

Leaving gout untreated is ALSO bad for your kidneys and leaving some big autoimmune inflammation attack unchecked is maybe also bad for your kidneys...

Because I was at this point suspecting that some kind of elaborate autoimmune flareup had been triggered by gout and now my body was just continuing to attack the existing damage in my joints. That would be in character for my stupid immune system.

And I might be able to recover now and my kidneys might not be as bad as I thought...

But I gave up on my computer's network adapter because clearly the internet was working and it was a hardware issue.

I was trying to download discord on my phone so I could let my friend know I wasn't dead but couldn't use the internet because I don't use most apps/sites on my phone...

And my phone now wasn't finding anything because when I had moved my computer back up onto my desk- literally a couple minutes before- it had unplugged the modem.

Easy fix, plug it back in.

Internet is working on my phone again, which was not the problem.

Look up.

Internet is working on my COMPUTER again.

Modem was -for some reason- randomly refusing to communicate with any of the Ethernet ports, through any cord, despite that it was still pumping out wifi just fine, and all indicator lights showed that the internet should be working fine.

Somehow.

For reasons.

And unplugging it completely for like 5 minutes fixed it.

So I don't have to start replacing half my computer parts just yet [graphics card is still old and 2-3rd hand]...

And I have internet.

And since I have eaten an amount of salt, my body has gone back to processing fluids at the expected rate. [maybe explains me dreaming about salty snacks]...

So with any luck, over the next week, I can actually bounce back to all around functional.

And my internet works.

And now my desk is clean I GUESS.

And my neighbours threw out this big expensive monitor after x-mas, so i grabbed it off the street figuring it probably still worked if they only threw it out after getting a new one. So with any luck I can have two displays now [it needs to dry out and I need to find cables]...

-_-

I'm still feeling kind of furious and exhausted because "tech won't work and I can't figure out why and it means I can't contact anyone" happening at the same time as "All of my shelves are falling over and all my stuff is falling behind my desk and it's too crowded to work with anything like this" happening at the same time as "All of my joints are terribly injured and I don't have the -anything- to lift, move or reach anything" Is a literal hell on earth constructed by real demons and autism moonlighting as one.

But also they threw out a very fancy and very heavy metal lamp, and even if that's busted to fuck I can fix lamps easy... [I did not need another lamp but it was put out on my doorstep and it's fancy]

8 notes

·

View notes