#Factory Automation Consultants

Explore tagged Tumblr posts

Text

Top Automation Engineers in Illinois | Innovating Industrial Solutions

Automation engineers are specialized professionals who design and implement systems that reduce human intervention in industrial processes. They blend knowledge from multiple fields—mechanical, electrical, software, and control engineering—to create intelligent systems that operate efficiently, reliably, and autonomously.

Their typical responsibilities include:

Designing automation systems from concept to installation

Programming PLCs (Programmable Logic Controllers) and HMIs (Human-Machine Interfaces)

Integrating robotics and motion control

Developing SCADA (Supervisory Control and Data Acquisition) systems

Testing and troubleshooting automated equipment

Ensuring safety and compliance with industrial standards

In Illinois, automation engineers are indispensable to manufacturing, logistics, food processing, energy, and life sciences.

Why Illinois Is a Powerhouse for Automation Engineering

Several key factors contribute to Illinois’s prominence in automation engineering:

1. Diverse Industrial Base: Illinois boasts industries ranging from automotive and agriculture to pharmaceuticals and aerospace. This diversity fuels consistent demand for custom automation solutions.

2. Strong Educational Ecosystem: Top-tier institutions like the University of Illinois, Northwestern University, and Southern Illinois University produce highly skilled engineers with expertise in robotics, AI, and industrial systems.

3. Strategic Location: Illinois's central location offers excellent logistics, making it a favored site for advanced manufacturing, warehousing, and distribution centers—all of which benefit from automation.

4. Innovation-Friendly Climate: The state supports innovation through tech incubators, grants, and public-private partnerships that empower engineers to develop and deploy cutting-edge automation solutions.

Key Services Offered by Automation Engineers in Illinois

Automation engineers in Illinois provide an extensive range of services tailored to the specific needs of businesses across the state. Common services include:

System Integration: Designing and installing complete automation solutions that synchronize machines, robots, and control systems.

PLC & HMI Programming: Writing and testing software that governs system behavior and interfaces.

Robotics Engineering: Installing and configuring robotic arms and automated material handling systems.

Industrial IoT Integration: Connecting machines to networks for real-time data exchange and monitoring.

Retrofitting & Upgrades: Enhancing legacy equipment with modern control technologies.

Safety System Design: Implementing fail-safes, emergency stops, and safety protocols in compliance with OSHA and ISO standards.

Whether working on a small assembly cell or a full-scale production line, Illinois automation engineers prioritize reliability, scalability, and efficiency.

Industries Benefiting from Automation Engineers in Illinois

The work of automation engineers touches nearly every corner of Illinois’s economy. Key sectors include:

Food and Beverage: Automating sorting, bottling, and packaging processes to ensure hygiene and speed.

Pharmaceuticals and Medical Devices: Ensuring precision, compliance, and traceability through automated filling, labeling, and inspection.

Automotive and Aerospace: Deploying robotic arms and motion systems for parts assembly and quality control.

Agriculture and Grain Processing: Integrating automation into storage, sorting, and packaging facilities.

Warehousing and Logistics: Developing conveyor systems, pick-and-place robots, and automated guided vehicles (AGVs).

Energy and Utilities: Implementing SCADA and remote control systems to manage plant operations.

By adopting automation, these industries reduce labor strain, improve accuracy, and increase throughput—critical in today’s competitive global marketplace.

The Future of Automation Engineering in Illinois

As we move further into the age of Industry 4.0, the role of automation engineers is evolving. Engineers in Illinois are not just builders of machines—they are architects of data-driven, intelligent systems. The future will include:

Edge Computing and AI: Allowing systems to make real-time decisions at the source.

Cloud-Connected Automation: Centralized data storage and analysis across multiple plants.

Predictive Maintenance: Using machine learning to anticipate equipment failures before they occur.

Digital Twins: Creating virtual replicas of physical systems for simulation and optimization.

Green Manufacturing: Designing systems that reduce energy use and support sustainability.

Illinois is well-positioned to remain at the forefront of this transformation, with a workforce ready to meet the challenges and opportunities ahead.

Choosing the Right Automation Engineer in Illinois

When selecting an automation engineer or firm, businesses should look for:

Experience Across Industries

Proficiency with Major Platforms (Allen-Bradley, Siemens, Beckhoff, etc.)

Commitment to Safety and Compliance

Strong Project Management and Communication Skills

Local Support and Maintenance Services

A collaborative approach ensures solutions that align with business goals, budget, and operational scale.

Your Automation Engineering Partner: Xtreme Automation LLC

If your Illinois-based business is ready to embrace the future of smart manufacturing, Xtreme Automation LLC is here to help. With decades of experience in automation design, PLC programming, robotics integration, and system retrofitting, Xtreme Automation provides comprehensive engineering solutions tailored to your industry. From planning and development to implementation and support, their team ensures your automation journey delivers real results. Learn more at xtremeautomationllc.com.

#Automation Engineers Illinois#Industrial Automation Services#Robotics Engineering Illinois#Control System Engineers IL#Automation Integration Companies#Smart Manufacturing Illinois#PLC and HMI Programming#Engineering Solutions Illinois#Industrial Robotics Experts#Factory Automation Consultants

0 notes

Text

Top 21 AI Trends in Manufacturing You Must Know in 2025

Understand the newest AI developments in manufacturing, such as Salesforce Einstein GPT integration and predictive maintenance solutions. Discover how Salesforce Manufacturing Cloud implementation services, AI-powered CRM consulting for manufacturers, and Agentforce for Manufacturing integration are transforming smart factory operations.

#AI in Manufacturing#Smart Factory Automation#Salesforce Manufacturing Cloud#Salesforce AI Integration#Agentforce for Manufacturing#Salesforce Einstein GPT#CRM for Manufacturers#PredictiveMaintenanceAI#Salesforce Service Cloud#Salesforce CRM Consulting#Getoncrm

0 notes

Text

Intsoft Tech machine vision inspection solution-deep learning for vision systems

#integrated machine vision solutions for the smart factory#automated visual inspection#robot pick & place#vision manufacturing#manufacturing consulting firms#surface inspection#factory acceptance test

1 note

·

View note

Text

Earlier this week, OpenAI launched its new image generation feature, which is integrated directly into ChatGPT and allows users to input more complex instructions for editing and organizing the presentation of the output. The first big viral trend to come out of the new service was users turning photos of family vacations, historical events, and pop cultural images into animated stills in the style of Studio Ghibli films. (The whole thing was a bit of a throwback to the heady days of 2023 when you would see AI influencers sharing photos of famous figures in the style of Wes Anderson films or whatever.) ChatGPT let users “Ghibilify” the images, so we got Ghiblified Hawk Tuah girl, Ghiblified Elon Musk (obviously), and so on. The issue here should be obvious. I won’t pretend to know exactly how Miyazaki thinks about modern generative AI systems—the tool he was commenting on was a cruder prototype—though one might venture to argue that he’d feel even more strongly about tools that further automate human art with greater ease, and often drive it further into the uncanny valley. Regardless, the man on record with likely the strongest and bluntest disavowal of using AI tools for art, is now the same man whose notoriously painstakingly handcrafted art is being giddily automated by ChatGPT users for what amounts to a promotional campaign for a tech company that’s on the verge of being valued at $300 billion. Sam Altman, OpenAI’s CEO, not only participated, changing his X avatar to a ‘Ghiblified’ self portrait, but insisted that this was the plan all along. Which in turn raises the specter of copyright infringement. Speaking to TechCrunch, a copyright lawyer very diplomatically said that while it’s unlikely infringement to produce images in the style of a studio, it’s “entirely plausible” that OpenAI’s models were trained on millions of frames of Ghibli films. He noted that it’s still an open question whether or not that in fact violates current IP law, or constitutes fair use, as the tech companies argue. On that front, judges recently dealt tech companies a blow, ruling in favor of Thomson Reuters that a pre-ChatGPT AI system was creating images that competed with the original material, and thus was not in fact fair use. OpenAI and Google, meanwhile, are desperately trying to win this battle, appealing to the Trump administration directly, and going so far as to argue that if they’re not allowed to ingest copyrighted works into their training data, China will beat the US in AI. Now, if—and of course this is a whopping if—OpenAI had consulted Studio Ghibli and its artists on all this, if those artists had consented and say reached a licensing deal before the art and frames from their films were ingested into the training data (as is pretty apparently the case), then look, this would indeed be a bout of generally wholesome fun for everyone involved. Instead, it’s an insult.

[...]

OpenAI and the other AI giants are indeed eating away at the livelihoods and dignity of working artists, and this devouring, appropriating, and automation of the production of art, of culture, at a scale truly never seen before, should not be underestimated as a menace—and it is being experienced as such by working artists, right now.

27 March 2025

119 notes

·

View notes

Text

Accurpress at a Glance: Vision, Mission, Core Values & Strategic Roadmap

In today’s rapidly evolving manufacturing landscape, precision, durability and adaptability often set companies apart. Accurpress India Machinery Pvt. Ltd., a recognized leader in machine tool fabrication equipment, has consistently demonstrated how innovation combined with customer focus can shape a global industrial brand. With roots tracing back to North America and strategic expansion into India, Accurpress now stands as a trusted provider of press brakes, shears, turret punch presses, tooling and automation systems.

Operating since 2007 in India and formally established as a subsidiary in 2011, Accurpress India reflects a broader vision of global engineering excellence. The company may not be a household name outside the fabrication sector, but inside workshops and factory floors, Accurpress represents reliability and productivity. This article offers a deep dive into the company's foundational vision, mission, guiding values and strategic journey that defines its long-term roadmap.

A Brand Born with a Vision: The Accurpress Legacy

The foundation of Accurpress began in 1973 when Ted Hilton launched the brand in North America. What started as a modest effort to enhance press brake technology quickly evolved into a revolution in fabrication machinery. The introduction of the AccurShear in 1976 marked a pivotal moment that propelled the company into market leadership. With over 20,000 press brake units operating in North America today, the brand’s commitment to service and value-driven design stands firm.

In India, Accurpress has been active since 2007 and has already surpassed 200 installations, building relationships with industry giants like Godrej, HYVA, Taikisha and Ahura Mazda. Their impression is strongest in Ahmedabad, supported by satellite teams across South India and the Delhi region. This expansion is a testament to the company’s long-term vision of staying accessible and responsive to clients throughout the country.

Vision: Redefining Machine Tool Fabrication in India and Beyond

At the core of Accurpress India’s operational and strategic framework lies a clear vision- to become the benchmark of innovation and precision in the machine tool industry. This vision may seem ambitious, but it's rooted in a history of technical leadership and relentless improvement.

The company envisions a future where automation, accuracy and productivity go hand in hand. Accurpress doesn't just provide machinery - it provides solutions designed to boost its clients’ operational efficiencies. The machines are developed with user-centric design, minimizing complexity while maximizing output. The vision is clear to empower manufacturers with tools that elevate their capabilities without compromising on ease of use or safety.

This aspirational yet practical outlook is evident in their product lines. Whether it’s the Absolute Series press brake or precision-engineered shears, every machine reflects the brand’s commitment to making high-performance technology accessible.

Mission: Innovation, Service and Manufacturing Excellence

A company’s mission can often act as its compass and for Accurpress India, this mission aligns seamlessly with its global heritage. Accurpress operates with a defined mission to deliver high-quality equipment that enhances customer success through innovative engineering and reliable service.

This mission is not just confined to product delivery - it encompasses pre-sales consultation, after-sales support, customized tooling and training. Accurpress may also provide clients with tailored automation solutions that integrate into their existing systems, thereby minimizing transition times and increasing ROI.

Moreover, the company emphasizes close collaboration with clients to ensure that their specific fabrication challenges are addressed. This mission of responsiveness and innovation positions Accurpress not just as a vendor, but as a long-term partner in production.

Core Values: What Drives Accurpress?

At the heart of Accurpress India’s operational culture are the core values that shape both its internal ethos and external commitments. These values act as guiding principles that influence every product, interaction and decision.

Precision with Purpose

Precision is not a catchphrase - it’s a practice. Every machine is engineered with attention to detail, ensuring that tolerances are met consistently. Clients may rely on this precision to meet tight deadlines, reduce rework and maintain quality standards.

Customer-Centric Innovation

The company continually adapts its offerings based on customer feedback. This may include software upgrades, enhanced tooling options or ergonomic designs that simplify operations. The intent is always to make the operator’s job more efficient and effective.

Integrity and Reliability

Accurpress builds trust by standing behind its products. From warranty commitments to service turnaround times, integrity plays a key role in its business relationships.

Knowledge Sharing and Training

The brand invests in operator training and product education. Through demos, workshops and hands-on guidance, Accurpress ensures clients understand how to leverage the full potential of their machinery.

These values are embedded into daily operations, creating a corporate culture that balances performance with purpose.

Strategic Roadmap of Accurpress: Engineering the Future

India’s growth trajectory is no accident - it’s the result of calculated planning and strategic investments. The roadmap ahead focuses on four key pillars:

Expanding Regional Presence

While headquartered in Ahmedabad, the company aims to strengthen its presence in untapped regions across India. This expansion includes establishing local service hubs and stocking spare parts to minimize downtime for customers.

Product Line Diversification

Accurpress continues to refine and broaden its product portfolio. This may involve developing new variants of press brakes with advanced CNC press brake systems or introducing next-gen turret punch presses with better energy efficiency.

Smart Automation Integration

The future of fabrication lies in intelligent automation. Accurpress may integrate more Industry 4.0-compatible features, such as remote diagnostics, real-time monitoring and predictive maintenance alerts, into their machines.

The Accurpress Journey: From North America to South Asia

Looking at the company’s timeline offers valuable insights into how vision and execution covers:

1973: Ted Hilton founds Accurpress in North America, introducing the AccurShear to the product line in 1976.

1998: International expansion begins with the opening of a manufacturing unit in Shanghai, China, under Tim Hilton. Over 3,500 machines now operate across China and Southeast Asia.

2007: Accurpress enters the Indian market, planting its roots through strategic installations.

2011: Establishment of Accurpress India Machinery Pvt. Ltd. as a wholly owned subsidiary, formalizing its commitment to the region.

Each phase of this journey reinforces the company’s growth strategy: identify need, deliver excellence and build trust.

Conclusion: A Trusted Partner in Industrial Evolution

Accurpress India is more than just a machinery provider - it is a trusted partner in the industrial evolution of India. The company’s focus on precision engineering, innovation and customer-centricity continues to shape its success in the fabrication market. With a clear vision, well-defined mission and unwavering values, Accurpress may continue to influence the future of manufacturing both in India and across global markets.

youtube

The strategic roadmap suggests a forward-thinking approach. Whether you’re a business looking to enhance production or an industry professional exploring technology partner, Accurpress India stands as a name you may count on.

2 notes

·

View notes

Text

How Can Tech-Consulting Revitalize the Manufacturing Sector?

Did you ever wonder how manufacturing firms remain at the forefront of an ever-changing technology landscape? As there is growing need for efficiency, quality, and automation, organizations are approaching tech-consulting for manufacturing to maximize operations and implement new technology into operations. Through this strategy, manufacturers are able to improve productivity, optimize processes, and use data-driven decision-making. From intelligent automation to cloud computing, technology-led developments are changing the industry's future.

Understanding Tech-Consulting for Manufacturing

Manufacturing tech-consulting means helping companies adopt technology-enabled solutions in Dubai and globally. It encompasses evaluating existing systems, the scope of improvements needed, and implementing the proper digital tools to drive operations better. With the manufacturing plants desiring greater efficiency, technology consultants assist in embedding leading-edge solutions such as Artificial Intelligence (AI), the Internet of Things (IoT), and enterprise resource planning (ERP) systems.

Technology consultants analyze factory workflows, machine utilization, and supply chain operations to recommend data-backed improvements. Their role is essential in bridging the gap between traditional manufacturing processes and modern digital solutions, ensuring seamless integration that benefits both production and business management.

The Role of Tech-Enabled Solutions in Dubai’s Manufacturing Sector

Dubai is rapidly developing as a smart manufacturing and advanced technology hub at a global level. The adoption of technology-based solutions in Dubai enables companies to enhance automation, minimize the cost of operations, and improve quality checks. With the access to AI-based analytics, cloud computing, and smart factory solutions, Dubai-based manufacturers can achieve improved decision-making and enhance market competitiveness.

From robot process automation to predictive maintenance, all these technologies allow manufacturers the monitoring of the performance of the equipment in real-time, ensuring low downtime and more productivity. By using analytics through AI as well, there are data-driven insights that are enabled to further hone supply chain management and better utilize resources.

Key Benefits of Tech-Consulting for Manufacturing

One of the major benefits of tech-consulting is its capacity to revolutionize production efficiency. Through the use of digital tools, manufacturers can automate routine tasks, freeing their labor to concentrate on more value-added operations. The use of data analytics and IoT in manufacturing also facilitates real-time monitoring, which guarantees accuracy and less error in production lines.

Another advantage is enhanced scalability. When companies increase, they need flexible systems able to accommodate expansion without interfering with day-to-day activities. Tech consultants help institute scalable ERP and cloud solutions harmonized with the company's business goals while promoting cost-effectiveness.

Cybersecurity is also an important area covered by tech-consulting. With growing connectivity in production, data security is a prime concern. Professionals offer advice on network security, safeguarding confidential data, and compliance with industry standards.

Smart Automation and AI-Driven Manufacturing

Automation is redefining the manufacturing scene, enabling corporations to increase productivity while keeping the quality consistent. Tech-consultants assist firms in embracing robotic systems, AI-based analytics, and machine learning algorithms to maximize manufacturing efficiency. AI-based automation helps firms to forecast equipment maintenance needs, minimize downtime, and avoid capital-intensive breakdowns.

In Dubai, there is extensive use of smart manufacturing solutions in order to enhance production efficiency. Right from automated assembly lines to AI-driven quality control systems, companies are able to optimize operational performance and remain competitive in the marketplace.

Cloud-Based Manufacturing Efficiency Solutions

Cloud computing is an essential component of contemporary manufacturing. With cloud ERP and data storage systems, manufacturing companies can simplify operations and access real-time data remotely. Tech-consultants facilitate companies to switch from legacy systems to cloud-based solutions, allowing for efficient integration and optimal efficiency.

Cloud solutions give manufacturers the ability to scale their operations, enhance team collaboration, and streamline supply chain management. The platforms also improve data security through encrypted storage and secure access to business-critical data.

The Future of Tech-Enabled Manufacturing

The future of manufacturing revolves around digital transformation. With industries advancing further, the use of tech-enabled solutions in Dubai will be key to pushing innovation and efficiency. As AI, IoT, and automation technologies improve, manufacturers can look forward to even more improved operational effectiveness and cost reductions.

Implementing digital twin technology, 3D printing, and blockchain supply chain management are some of the trends that will define the future of manufacturing. Tech-consulting is an important aspect that assists companies in navigating these developments and adopting strategies that are compatible with their long-term objectives.

Conclusion

The effect of manufacturing tech-consulting is evident through its ability to enhance efficiency, quality control, and ease of operations. Through the integration of smart automation, AI-driven analytics, and cloud-based platforms, manufacturers are able to compete in a fast-paced industry. With an eye on digital transformation, companies are integrating tech-enabled solutions in dubai for driving innovation and maximizing production procedures.

At Echelon Technology Partners, our team can provide expert guidance in implementing cutting-edge digital solutions tailored to manufacturing needs.

2 notes

·

View notes

Text

Manual to Electric Roller Shutters: Is It Worth Upgrading?

As the demand for improved security, ease of use, and smart automation grows, many property owners are asking: “Should I convert my manual roller shutters to electric?” The short answer—yes, it’s worth it. Whether you’re operating a small shop, managing a commercial warehouse, or securing your home, upgrading to electric roller shutters delivers long-term benefits in security, convenience, and efficiency.

Why Upgrade to Electric Roller Shutters?

Upgrading from manual to electric shutters is more than just a modern convenience. Here’s why many businesses and homeowners are making the switch:

Enhanced Security – Electric shutters offer stronger, more consistent locking mechanisms and can be paired with alarm systems and access control.

Improved Convenience – Open or close your shutters at the touch of a button—no more cranking or struggling with heavy shutters.

Time Efficiency – Especially in commercial settings, automated shutters save time for staff and reduce daily operational friction.

Energy Savings – Many electric shutters come insulated, improving thermal efficiency and reducing heating or cooling loss.

Understanding Electric Shutter Motors

At the heart of every electric roller shutter is the motor—a robust, compact unit designed to handle daily operation smoothly and safely. Depending on the size and weight of your shutter, we offer a range of motor types:

Tube Motors – Common in residential and small commercial shutters.

Industrial Motors – Designed for heavy-duty, high-cycle use in warehouses and factories.

Fire-Rated Motors – Integrated with emergency protocols to respond in the event of a fire.

All motors supplied by UK Doors & Shutters are tested for durability, safety, and compliance with UK regulations.

Control Options: Keypads, Remotes & Smart Integration

One of the biggest advantages of electric shutters is flexible remote control options. You can operate your shutter via:

Wall-Mounted Keypads

Handheld Remotes

Smartphone App Integration

Smart Home or Business Automation Systems

This allows you to operate your shutters remotely, set timers, and monitor access—perfect for businesses looking to improve efficiency and security.

Common Issues & Maintenance Tips

Like any mechanical system, electric roller shutters require occasional maintenance. Common issues include:

Motor Failure or Overheating

Remote Signal Loss

Obstruction Detection Problems

Worn Limit Switches or Gearbox Malfunctions

Roller Shutter Maintenance Tips:

Keep the shutter tracks clean and clear of debris.

Test the manual override function periodically.

Schedule professional servicing at least once a year.

Inspect wiring and control systems for wear or exposure to moisture.

Routine servicing helps avoid costly repairs and extends the life of your electric shutters.

Emergency Shutter Repairs – Fast & Reliable

Shutter stuck? Motor not responding? Whether it’s during business hours or the middle of the night, our emergency repair team is ready to help. We offer 24/7 emergency shutter repair services across Bolton and the North West of England, ensuring you’re never left vulnerable.

Book Your Electric and Manual Roller Shutter Installation, Upgrade, or Repair Online

From manual-to-electric conversions to full installations and fast-response repairs, UK Doors & Shutters is your trusted local expert. We provide:

New electric shutter installations

Manual-to-electric conversions

Shutter motor replacements

Smart access integration

Emergency repair and ongoing maintenance

Contact Us Today

For immediate assistance, call 01204 918991, or book your free site survey, upgrade consultation, or repair service online.

At UK Doors & Shutters, we combine expert engineering with local reliability—giving you peace of mind and powerful protection.

#UK Doors & Shutters#Roller Shutter Repairs#Roller Shutter Installation#Roller Shutter Maintenance#Roller Shutters Warrington#Roller Shutter Installation Warrington#Roller Shutter Servicing#Annual Roller Shutter Servicing#Roller Shutter Services Southport#Roller Shutter Repairs Southport#Garage Door Installation Northwest#Garage Doors Northwest#Insulated Garage Door#Security Grilles#Roller Shutter Repairs Altrincham#Shutter Installers Altrincham#Roller Shutter Repairs Liverpool & Merseyside#Shopfront Repairs Liverpool & Merseyside#Roller Shutter Repairs York#Roller Shutter Installers York#Roller Shutters Manchester#Roller Shutter Repairs Manchester#Roller Shutter Preston#Roller Shutter Repairs Preston#Aluminium Shutters UK#Aluminium Roller ShutterInstallations#Roller Shutter Repairs Oldham#Roller Shutter Installation Wiga#Roller Shutter Repairs Wiga#Roller Shutter Repairs Bradford & West Yorkshire

1 note

·

View note

Text

Edge Computing Market Disruption: 7 Startups to Watch

Edge Computing Market Valuation and Projections

The global edge computing market is undergoing a transformative evolution, with projections estimating an edge computing market size escalation from USD 15.96 billion in 2023 to approximately USD 216.76 billion by 2031, marking a compound annual growth rate (CAGR) of 33.6%. This unprecedented trajectory is being driven by rising demand for real-time data processing, the proliferation of Internet of Things (IoT) devices, and the deployment of 5G infrastructure worldwide.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40540-global-edge-computing-market

Accelerated Demand for Real-Time Data Processing

Edge computing is revolutionizing the digital ecosystem by decentralizing data processing, shifting it from core data centers to the edge of the network—closer to the point of data generation. This architectural transformation is enabling instantaneous insights, reduced latency, and optimized bandwidth usage, which are critical in sectors requiring rapid decision-making.

Industries such as automotive, healthcare, telecommunications, and manufacturing are leading adopters of edge technologies to empower smart operations, autonomous functionality, and predictive systems.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40540-global-edge-computing-market

Edge Computing Market Segmentation Analysis:

By Component

Hardware

Edge computing hardware includes edge nodes, routers, micro data centers, servers, and networking gear. These devices are designed to endure harsh environmental conditions while delivering low-latency data processing capabilities. Companies are investing in high-performance edge servers equipped with AI accelerators to support intelligent workloads at the edge.

Software

Software solutions in edge environments include container orchestration tools, real-time analytics engines, AI inference models, and security frameworks. These tools enable seamless integration with cloud systems and support distributed data management, orchestration, and real-time insight generation.

Services

Edge services encompass consulting, deployment, integration, support, and maintenance. With businesses adopting hybrid cloud strategies, service providers are essential for ensuring compatibility, uptime, and scalability of edge deployments.

By Application

Industrial Internet of Things (IIoT)

Edge computing plays a vital role in smart manufacturing and Industry 4.0 initiatives. It facilitates predictive maintenance, asset tracking, process automation, and remote monitoring, ensuring enhanced efficiency and minimized downtime.

Smart Cities

Municipalities are leveraging edge computing to power traffic control systems, surveillance networks, waste management, and public safety infrastructure, enabling scalable and responsive urban development.

Content Delivery

In media and entertainment, edge solutions ensure low-latency content streaming, localized data caching, and real-time audience analytics, thereby optimizing user experience and reducing network congestion.

Remote Monitoring

Critical infrastructure sectors, including energy and utilities, employ edge computing for pipeline monitoring, grid analytics, and remote equipment diagnostics, allowing for proactive threat identification and response.

By Industry Vertical

Manufacturing

Edge solutions in manufacturing contribute to real-time production analytics, defect detection, and logistics automation. With AI-powered edge devices, factories are becoming increasingly autonomous and intelligent.

Healthcare

Hospitals and clinics implement edge computing to support real-time patient monitoring, diagnostic imaging processing, and point-of-care data analysis, enhancing treatment accuracy and responsiveness.

Transportation

The sector is utilizing edge technology in autonomous vehicle systems, smart fleet tracking, and intelligent traffic signals. These systems demand ultra-low latency data processing to function safely and efficiently.

Energy & Utilities

Edge computing enables smart grid optimization, renewable energy integration, and predictive fault detection, allowing utilities to manage resources with greater precision and sustainability.

Retail & Others

Retailers deploy edge devices for personalized marketing, real-time inventory management, and customer behavior analysis, enabling hyper-personalized and responsive shopping experiences.

Key Drivers Behind Edge Computing Market Growth:

1. IoT Proliferation and Data Deluge

With billions of connected devices transmitting real-time data, traditional cloud architectures cannot meet the bandwidth and latency demands. Edge computing solves this by processing data locally, eliminating unnecessary round trips to the cloud.

2. 5G Deployment

5G networks offer ultra-low latency and high throughput, both essential for edge applications. The synergy between 5G and edge computing is pivotal for real-time services like AR/VR, telemedicine, and autonomous navigation.

3. Hybrid and Multi-Cloud Strategies

Enterprises are embracing decentralized IT environments. Edge computing integrates with cloud-native applications to form hybrid infrastructures, offering agility, security, and location-specific computing.

4. Demand for Enhanced Security and Compliance

By localizing sensitive data processing, edge computing reduces exposure to cyber threats and supports data sovereignty in regulated industries like finance and healthcare.

Competitive Landscape

Leading Players Shaping the Edge Computing Market

Amazon Web Services (AWS) – Offers AWS Wavelength and Snowball Edge for low-latency, high-performance edge computing.

Microsoft Azure – Delivers Azure Stack Edge and Azure Percept for AI-powered edge analytics.

Google Cloud – Provides Anthos and Edge TPU for scalable, intelligent edge infrastructure.

IBM – Offers edge-enabled Red Hat OpenShift and hybrid edge computing solutions for enterprise deployment.

NVIDIA – Powers edge AI workloads with Jetson and EGX platforms.

Cisco Systems – Delivers Fog Computing and edge networking solutions tailored to enterprise-grade environments.

Dell Technologies – Supplies ruggedized edge gateways and scalable edge data center modules.

Hewlett Packard Enterprise (HPE) – Delivers HPE Edgeline and GreenLake edge services for data-intensive use cases.

FogHorn Systems & EdgeConneX – Innovators specializing in industrial edge analytics and data center edge infrastructure respectively.

Edge Computing Market Regional Insights

North America

A mature digital infrastructure, coupled with high IoT adoption and strong cloud vendor presence, makes North America the dominant regional edge computing market.

Asia-Pacific

Driven by rapid urbanization, smart city initiatives, and industrial automation in China, India, and Japan, Asia-Pacific is projected to experience the fastest CAGR during the forecast period.

Europe

The region benefits from strong government mandates around data localization, Industry 4.0 initiatives, and investments in telecom infrastructure.

Middle East and Africa

Emerging adoption is evident in smart energy systems, oilfield monitoring, and urban digital transformation projects.

South America

Growth in agritech, mining automation, and public safety systems is propelling the edge market in Brazil, Chile, and Argentina.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40540-global-edge-computing-market

Edge Computing Market Outlook and Conclusion

Edge computing is not just an enabler but a strategic imperative for digital transformation in modern enterprises. As we move deeper into an AI-driven and hyperconnected world, the integration of edge computing with 5G, IoT, AI, and cloud ecosystems will redefine data management paradigms.

Businesses investing in edge infrastructure today are setting the foundation for resilient, intelligent, and real-time operations that will determine industry leadership in the years ahead. The edge is not the future—it is the present frontier of competitive advantage.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

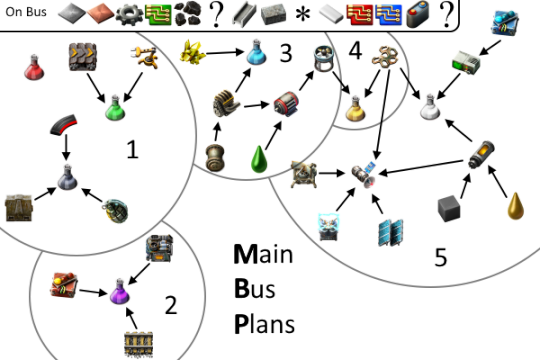

Before I start the next stage of base-building, I need to plan.

No base screenshots this time. Just diagrams and rambling and ratios. But this post forces me to get my thoughts in order and turns them into something I can consult later, and hopefully someone else will find these ideas useful.

This chart, courtesy of Kirk McDonald's Factorio Calculator, shows most of the steps and ratios needed to get about a hundred SPM. That's what a single rocket silo with three productivity modules mark 3 can achieve, so it's a decent benchmark to aim for. (Mining, smelting, oil-cracking, and wire-assembling are over to the left of this part of the graph. But they're less important.

The lines are a mess, but the numbers are clear, especially if I switch back to the list. This requires something like 18 yellow belts of iron and copper, which is absurd. If I switch to red belts, we get a slightly less absurd nine belts of each (plus 3.6 of green circuits, 1.9 of plastic, and basically everything else <1).

Most of the copper and about a third of the iron are in green circuits. Nearly half of the iron goes into steel. Remove that, and I only need 1.2 belts of iron and 3.7 of copper, about half of which goes into low-density structure.

None of this accounts for non-science production, of course (e.g. automating those assembling machine 3's). But even so, that's a lot less resources than I was anticipating. I considered leaving a spot for trains to add more resources to the bus, but it looks like that's basically unnecessary—especially if I ship in green circuits and steel from elsewhere.

I'm still gonna do it, though.

Next, a diagram I made myself.

At the top are things I intend to put on the main bus. Maybe not coal and batteries, and stone bricks are only required for three things (furnaces for purple science, walls for gray, and miscellaneous furnaces/oil refineries) so they'll fall off the bus quickly enough, but the important thing is that they're excluded from the rest of the diagram.

Automation, logistic, and military science are simple enough. Automation is just bus ingredients, while logistic and military science are basic things, half of which I want to mass-produce anyway. At this stage of the bus, I can also build some basic factory stuff, like mining drills and assemblers Mk 2 and more red belts.

This probably sounds weird, but I think it makes sense to put production science next. (Red chips need to go somewhere earlier, but that's fine.) Its three products are disconnected from things made elsewhere, and it lets me get stone bricks off the bus early. Actually, I might just set up that stone unloading station here, to feed rails to purple science and bricks to wall/electric furnace/miscellaneous factory stuff production.

And chemical science is directly linked to utility science, because both use engines. Ideally I'd like one line of engine assemblers that gets split 2:1 between blue science and electric engines, with a few engines of each type getting stashed for making flame turrets and rocket silos and stuff.

Anyways, the rest of chemical science is straightforward, and utility science isn't much harder. The tricky bit will be setting up a circuit system that lets me set how many logistics and construction bots I want in the robot network, which is something I'll definitely do just to the side of the bus.

And then space science. But that's quite a way off.

All that in mind, let's get some figures.

We'll need almost four red belts of green chips, most of which are going into red and blue chip production. This will take something like four belts of iron and six of copper. Yeah, I should just make green chips off-site.

Green chips aside, phase 1 science requires less than a belt of copper and iron, plus coal for the grenades and stone bricks for the walls.

Phase 2 science requires those bricks, a couple belts of iron, half a belt of copper, and plastic. Also advanced circuits.

Phase 3 science requires like half a belt of copper and iron, plus plastic and sulfur.

Phase 4 requires a full belt of iron, a belt and a half of copper, and a bunch of miscellaneous stuff like batteries and plastic and oil.

Phase 5 (Space) requires most of a belt of iron, almost two belts of copper, two belts of green chips, a belt of plastic, and a bunch of other random stuff.

To keep this nice and expandable, I'd say that four belts each of iron and copper with refill stops between phases should be good. Excessive for one rocket, but when I want to run five rocket silos for infinite research I'll thank me.

Likewise, three belts of green chips (which get replaced by red and blue down the bus) sounds good. A belt of steel, one of gears, one or two belts of plastic, maybe a battery belt.

While I'm here, I'll throw together some thoughts about where to produce various factory buildings.

Electric miners, pumpjacks, red belts, chemical plants, power poles, inserters, and assembler 2's can all go in phase 1.

Furnaces and oil refineries need to go with the other stone brick stuff, at the phase 1/2 boundary.

Substations, roboports, and logistics chests can go in phase 2, after the red chips.

Blue belts can go in phase 3, alongside electric engines. They both need lubricant. Getting the red belts to the blue belts to lubricate them is gonna be interesting. Is that a low-volume train job or a long-distance bot job? Or an awkward belt job? Or maybe Renai Transportation has some silly solution?

Not much new in phase 4.

Assembler 3's share speed modules 1 with RCUs, so it makes sense to build them together. Shipping assembler 2's from one end of the bus to the other is like the belt thing, but more.

Explosives need coal, which if it's not on the bus are only going to grenades. But they also need sulfur from blue science. Hm.

Nuclear reactor stuff and rocket silos are best handled in temporary production setups. Or maybe even handcrafted.

Oh yeah, labs need to go somewhere too.

5 notes

·

View notes

Text

The Business Case for Sustainability: Balancing Profitability and Environmental Responsibility

Investors have embraced responsible portfolio management strategies to encourage sustainable enterprises and support socio-economic development. Meanwhile, customers refuse to buy from a brand that fails to curb labor malpractices, pollution, waste generation, and petroleum consumption. This post will describe the business case for sustainability to increase awareness about these trends.

What is Sustainable Business Development?

A company engages in sustainable business development when it revises its operations, product design, and resource allocation to contribute to social and environmental problem resolution. It is not about pretending to be eco-friendly or slowing industrial progress. Instead, sustainability for business ensures companies can thrive without harming social harmony and Earth’s resources.

Today, business leaders leverage sustainability consulting services to navigate modern regulations demanding more responsible corporate approaches. Besides, several pressing matters range from safekeeping consumer data to making workplaces more inclusive.

At the same time, multiple compliance guidelines have overwhelmed managers. So, it is imperative to embrace a tech-led strategy. It will help increase your firm’s compliance across all the major frameworks, like the ones described below.

Environmental, social, and governance (ESG) reporting,

Task force on climate-related financial disclosures (TCFD),

Global Reporting Initiative (GRI),

And the EU taxonomy.

How Can a Business Balance Profitability, Ethics, and Sustainability?

The older the organization, the more challenges you must overcome to go green. An excellent method is multistakeholder brainstorming. Let customers, suppliers, employees, business associates, and investors chime in and provide improvement ideas.

Another indirect approach involves extensive data gathering, insight extraction, and reporting. Using automated computing systems, companies can monitor the policy dynamics in the target markets and improve specific operations in realistic stages.

They do not need to transform all practices and risk productivity loss. Since they will utilize data from authoritative sources, their decisions will also have a sound foundation. Available technologies can involve ESG data solutions tailored for private companies, financial materiality estimates, controversy analytics, and risk forecasting tools.

Finally, leaders, board directors, and the rest must periodically evaluate their business sustainability initiatives. If they notice some strategies becoming obsolete, they must devise appropriate action plans to rectify such issues.

Advantages of Business Sustainability

1| Efficient Resource Consumption

Pollution and carbon risk mitigation require brands to replace conventional energy systems with greener alternatives. This renewable energy transition allows companies to rationalize how they allocate resources to operations. Moreover, they can reduce dependence on public infrastructure for power and water using modern technologies.

Treating and reusing water might not be suitable for all enterprises. However, the scope of these practices encompasses offices, factories, and post-sales product maintenance. In other words, you want to consider the entire product lifecycle to increase your ESG ratings and positive impact potential.

Integrating green technology to fulfill the efficient resource consumption requirements makes you more competitive and attracts more investors. Therefore, business profitability increases thanks to sustainability accounting compliance.

2| Resilient Supply Chains

Socio-economic and ecological threats limit your enterprise’s growth potential. They endanger the well-being of consumers and supply partners. Consider how environmental problems, political chaos, or social issues hinder free transportation, making timely product delivery more arduous.

However, brands can voluntarily work toward building a peaceful, green, tolerant, and resilient community. They must collaborate with employees, educators, policymakers, and local stakeholders. After all, most corporate social responsibility (CSR) projects aimed at literacy increase, women empowerment, and cyber safety awareness create opportunities to create a more stable world.

Aside from social disharmony threats, your supply chain is often vulnerable to fraud, region-specific quality norm inconsistencies, and controversies. You cannot eliminate these risks, but you can reduce the harm they might cause using predictive analysis and contingency plans. Many sustainability frameworks address these aspects in their reporting guidelines.

3| Long-Term Stakeholder Relationships

Responsible consumption and a solid supply chain increase an organization’s reputation. Socially conscious customers prefer companies that realize the cost of human-caused industrial activities. Therefore, they want leaders to embrace business sustainability, transparent communication, and ethical human resource practices.

Simultaneously, social networking sites (SNS) have empowered individuals to voice their disappointment with brands that fail to improve compliance. So, customers will likely stop purchasing from you if you lag behind competitors in sustainable business development.

Conversely, corporations with adequate CSR programs get loyal customers, free press, positive value association, and investor goodwill. They become leaders in establishing new industry norms while others struggle to understand sustainability accounting principles.

Precaution: Greenwashing is Not a Business Case for Sustainability

Consider the following:

What can anyone do if companies manipulate their financial and carbon disclosures?

Will investors, regulators, and customers trust other brands who also report on sustainability or ESG performance metrics?

What types of green claims can an organization include in its marketing campaigns?

How do we verify that a brand’s reported CSR outcomes are genuine and tangible?

Can ESG disclosures backfire and expose your company to controversies and misinformation attacks?

These are legitimate fears expressed by many because of the greenwashing cases. The perpetrators use deceptive verbal and design tactics to boast about on-paper CSR achievements with no on-ground impact. Some claimed they use 100% renewable energy by cunningly omitting crucial reporting elements. Others had suppliers employing child labor in life-threatening working conditions.

Greenwashing hurts stakeholder trust in ESG, TCFD, and GRI documentation. When one company receives greenwashing allegations, others in the same industry also attract criticism. Sooner or later, the media picks up the story, and the hard-earned brand reputation evaporates into infinity.

Avoid greenwashing and disassociate with partners, municipalities, and suppliers doing it.

Conclusion

Leaders who recognize the significance of sustainable business development are visionaries. They know their business can thrive if the consumers, employees, investors, and regulators are happy with their work. So, the world has witnessed a rekindled interest in ethics-driven corporate attitudes and investment strategies.

Reducing byproduct generation, enforcing anti-harassment policies, and adopting practical data governance standards make brands more sustainable. Their supply chain resilience increases while more stakeholders trust them.

Nevertheless, greenwashing risks prevent organizations and investors from unlocking the full potential business sustainability use cases. Therefore, all the stakeholders must be honest with compliance reporting. It is okay if your ESG ratings are low because you can implement initiatives and work with experts to improve them.

In the end, only transparency matters. Without it, sustainability reporting will become a worthless formality. However, with the proper oversight, the opposite will happen, and your organization will surpass all competitors while solving social and environmental problems.

2 notes

·

View notes

Text

Elon Musk hasn’t been sighted at the picket lines in Missouri, Ohio, or Michigan, where autoworkers are striking against the Big Three US carmakers. Yet the influence of Musk and his non-unionized company Tesla have been everywhere since the United Auto Workers called the strike last week. In some ways, Tesla—the world’s most valuable automaker by market capitalization—set the whole thing in motion.

Tesla’s pioneering electric vehicles kicked off a new era that has turned the entire auto industry on its head. In a scramble to compete with Tesla and make that transition, the legacy automakers targeted by the current strike, General Motors, Ford, and Stellantis, have each pledged billions in global investment and have begun dramatically restructuring their operations. For workers, the “green jobs” being created can be scarcer and worse paying. Electric vehicle powertrains have many fewer moving parts than conventional gas-powered ones, and so they require 30 percent fewer vehicle assembly hours, according to one estimate. Plants that make EV batteries are generally outside the core, unionized auto supply chain. The United Auto Workers has seen a dramatic drop in membership due to jobs moving outside the US—it lost 45 percent of its members between 2001 and 2022. A future with more electric vehicles could mean fewer union jobs overall. “This strike is about electrification,” says Mark Barrott, an automotive analyst at the Michigan-based consultancy Plante Moran.

The new assembly plants that the legacy automakers need to pull off the transition have been stood up mostly in US states hostile to union organizing, such as Kentucky, Tennessee, and Alabama. And because many of these plants are joint ventures between automakers and foreign battery companies, they are not subject to previous union contracts.

The UAW did not respond to a request for comment, but UAW president Shawn Fain told CNBC last week that the electric transition can’t leave workers behind. “Workers deserve their share of equity in this economy,” he said.

Tesla’s rise over recent years has also put ever-ratcheting pressure on the legacy automakers to cut costs. Including benefits, Musk’s non-unionized EV company spends $45 per hour on labor, significantly less than the $63 per hour spent in the Big Three, according to industry analysts.

Musk’s willingness to upend auto manufacturing shibboleths has also forced his legacy competitors to seek new efficiencies. Tesla led the way in building large-scale car casts, stamping out very large metal components in one go rather than making a series of small casts that have to be joined together. And it pioneered an automotive chassis building process that can be easily adapted to produce different makes and models.

Tesla’s Silicon Valley roots also helped it become the first automaker to envision the car as a software-first, iPhone-like “platform” that can be modified via over-the-air updates. And the company aims to automate more of its factories, and extract more of the materials it needs to build its batteries itself.

Tesla’s novel production ideas could soon lead the company to put even more pressure on legacy automakers. Musk said earlier this year that Tesla plans to build a new, smaller vehicle that can be made for half the production cost of its most popular (and cheapest) vehicle, the Model 3.

Musk says a lot of things, and many don’t come to pass. (The world is still waiting for the 1 million Tesla robotaxis promised by the end of 2020.) But Tesla has been disruptive enough to leave legacy automakers, including Detroit’s Big Three, “in a quest for capital,” says Marick Masters, who studies labor and workplace issues at Wayne State University's School of Business. Detroit’s automakers have made good money in the past decade—some $250 billion in profits—but also paid a significant chunk of it out in dividends. Pressure from Tesla and the EV transition it catalyzed has left them feeling as if they need every penny they can corral to keep afloat as the industry changes.

“They have little money to concede for union demands,” says Masters. The UAW’s wants include significantly higher wages, especially for workers who have joined the companies since their Great Recession and bankruptcy-era reorganizations, which left some with less pay and reduced pension and health benefits.

So far, the UAW has shown little patience for the idea that the automakers it is pressuring are cash-strapped and under competitive pressure. “Competition is a code word for race to the bottom, and I'm not concerned about Elon Musk building more rocket ships so he can fly into outer space and stuff,” UAW president Fain told CNBC last week when asked about pressure from Tesla. He has argued that production workers should receive the same pay raise received by auto executives over recent years.

When automakers have taken the opposite tack, insisting that they’re well capitalized and making plans to put them ahead of the electric car maker—well, that set up conditions for this strike too. The three American automakers are forecasted to make $32 billion in profits this year, a slight dip from last year’s 10-year high. “The more they toot their own horns about profitability, the more the union looks at them and says, ‘We want our rightful share,’” says Masters.

Tesla did not respond to a request for comment, but Musk has, in typical fashion, chimed in. He posted on X last week to compare working conditions at his companies with the competition, apparently seeking to turn the dispute he helped foment into a recruiting pitch. “Tesla and SpaceX factories have a great vibe. We encourage playing music and having some fun,” he wrote. “We pay more than the UAW btw, but performance expectations are also higher.” A UAW attempt to organize Tesla workers in 2017 and 2018, as the company struggled to produce its Model 3, failed. The National Labor Board ruled that Tesla violated labor laws during the organizing drive; the carmaker has appealed the decision.

5 notes

·

View notes

Text

Carpet Shampooing & Floor Scrubbing Experts in India

When it comes to creating a clean and welcoming environment, floors and carpets make the first impression. At All Services Global Pvt. Ltd., we offer expert Carpet Shampooing and Floor Scrubbing Services for commercial, institutional, and healthcare spaces across India.

With over 30 years of experience, we combine skilled manpower, certified processes, and modern cleaning equipment to ensure every surface is spotless and safe.

Why Our Carpet Shampooing Works

Dust, stains, allergens, and wear-and-tear can damage carpets and affect air quality. Our professional-grade shampooing method removes deep-seated dirt while preserving the fabric and color.

We follow a structured process that includes:

Pre-vacuuming

Foam-based deep shampooing

Water extraction

Quick drying

It not only cleans but also extends the carpet’s life.

Deep Floor Scrubbing That Shines

Whether it's a high-traffic lobby, hospital corridor, or factory floor, our automated floor scrubbers restore shine and safety. Using eco-friendly chemicals, we scrub away grime, grease, and stubborn stains from marble, vinyl, granite, or tile flooring.

Trusted Across Industries

Our cleaning services are trusted by:

Airports

Hospitals

Offices

Pharma companies

Educational institutions

Let’s Clean It Right

Partner with All Services Global to maintain a professional, hygienic, and impressive space. Our expert cleaning ensures long-lasting results with minimal disruption.

For more information or to request a consultation, visit their website: All Services Global Pvt. Ltd..

To stay updated with the latest posts, follow us on social media:

📸 Instagram

📘 Facebook

🐦 Twitter (X)

🔗 Linkedin

📌 Pinterest

🧵 Thread

🥁 Tumblr

❗ Reddit

Contact: All Services Global +91-22 4063 7777 / +91- 22 4063 7788 https://allservicesglobal.com/

Digital Partner:

TVM INFOSOLUTIONS PVT LTD

Contact: TVM Info Solutions Pvt. Ltd.

+91-9004590039

Follow us on Social Media

🌐 Website

📸 Instagram

📘 Facebook

🔗 Linkedin

▶️ Youtube

#CarpetShampooing#FloorScrubbing#FacilityManagementIndia#DeepCleaningServices#CommercialCleaning#AllServicesGlobal

0 notes

Text

Toronto's HVAC Boom: What It Means for Ontario Businesses

Is your commercial property struggling with rising energy bills, poor indoor air quality, or inconsistent climate control? You're not alone. As Toronto’s commercial landscape grows, so does the need for smarter, more efficient HVAC systems — and that’s putting Commercial HVAC Services Toronto in high demand.

The shift isn’t just about comfort. It’s about compliance, cost-efficiency, and long-term sustainability. Businesses across the Greater Toronto Area are now viewing HVAC not as a utility but as an investment. Outdated systems can’t keep up with today’s energy standards — and they often cost more to run and maintain than modern alternatives.

That’s why more organizations are turning to Commercial HVAC Services Toronto for customized solutions. From energy-efficient retrofits to smart automation systems, these services are helping companies reduce energy consumption, meet government regulations, and enhance tenant satisfaction.

Take, for example, the retail sector. With foot traffic fluctuating throughout the day, stores need HVAC systems that can adapt in real time. Smart systems powered by IoT sensors can adjust air flow and temperature based on occupancy — a game-changer for energy savings. And in healthcare facilities, where air quality is mission-critical, advanced filtration and zoning systems ensure that each area maintains the exact conditions it requires.

But the demand goes far beyond the city limits. Across the province, Commercial HVAC Services Ontario are experiencing a surge in business from property managers, schools, manufacturers, and more. In the education sector, clean and well-ventilated classrooms have become a post-pandemic priority. For factories and warehouses, consistent indoor temperatures protect equipment and improve worker safety.

What’s fueling this surge? It's a combination of tighter energy regulations, aging infrastructure, and rising awareness around indoor air quality. Business owners are realizing that proactive HVAC upgrades now can prevent costly downtime later — not to mention reduce operating costs.

Another key driver is smart technology. Modern HVAC systems can now be managed remotely, providing real-time data and diagnostics. Facility managers no longer have to guess where inefficiencies lie. Instead, they receive instant alerts about potential issues, along with detailed reports on performance metrics. This kind of insight helps extend the lifespan of equipment and ensures fewer interruptions to daily operations.

Companies offering Commercial HVAC Services Ontario are adapting quickly to meet this demand. Many are expanding their offerings to include 24/7 emergency response, tailored maintenance packages, and system design consultations. By taking a holistic approach — from installation to ongoing support — they’re helping businesses stay ahead in a competitive, sustainability-driven market.

The financial incentives are significant. Upgrading to an energy-efficient HVAC system can cut utility costs by 20–30%. Regular preventative maintenance further reduces the risk of major repairs. For commercial property owners and business operators, the long-term ROI is clear.

And let’s not forget tenant and employee satisfaction. Comfortable, climate-controlled environments are no longer a luxury — they’re a necessity. In fact, many companies find that improving indoor air quality leads to better productivity, higher tenant retention, and fewer complaints overall.

Now is the time for businesses across Ontario to take control of their indoor environments. Whether you’re managing a retail chain, a school board, or an industrial facility, partnering with experts in Commercial HVAC Services Toronto or Commercial HVAC Services Ontario can give you the performance, efficiency, and peace of mind your operation needs.

0 notes

Text

Popular Commercial RO Plant Manufacturers in Delhi

Delhi essentially needs clean and pure water for commercial premises, industries, and commercial houses. Commercial RO plants have emerged as the most popular and successful water purification solution. Most of the leading manufacturer’s design and develop these important water treatment systems in Delhi. It removes dissolved solids, chemicals, and other impurities by making them safe for various uses of water in the respective commercial institutions. Be it a hotel, a hospital, a factory, or any other business, the right RO plant manufacturer is sought for water purification purposes. In this blog we discuss the Commercial RO Plant Manufacturers in Delhi, highlighting their efficiency, products, and services.

1. Netsol Water

Netsol Water is a major Delhi-based Commercial RO Plant Manufacturer that has more than 15 years of experience providing water treatment solutions. Netsol Water is known for offering industrial quality water purification systems made in its in-house manufacturing unit at Delhi's industrial area.

The company manufactures commercial RO plants in capacities ranging from 100 LPH to 100,000 LPH that are offered for use by various industries. The plants are made of high-grade stainless steel and other premium components sourced from the best brands available in the market. Each plant undergoes a full-fledged test for quality before it is actually delivered so that it offers prime performance and long use.

What sets Netsol Water apart is their comprehensive approach to customer service. They offer free consultation services, helping businesses choose the right RO plant capacity based on their specific requirements. Their team of experienced engineers provides detailed site surveys and water quality analysis before recommending solutions.

The company's commercial RO plants come with advanced features like automatic operation, digital display panels, and remote monitoring capabilities. They use energy-efficient pumps and motors, helping businesses save on electricity costs. All plants include pre-treatment systems like multimedia filters, activated carbon filters, and antiscalant dosing systems for complete water purification.

Netsol Water's after-sales support is particularly noteworthy. They provide annual maintenance contracts, emergency repair services, and regular performance monitoring. Their spare parts inventory ensures quick replacements when needed, minimizing downtime.

The company has successfully installed RO plants in numerous hotels, hospitals, schools, manufacturing units, and residential complexes across Delhi NCR. Their plants are certified by relevant authorities and come with warranties on major components. They also offer flexible payment options and competitive pricing, making quality water treatment solutions accessible to businesses of all sizes.

For businesses considering a commercial RO plant purchase, Netsol Water offers several advantages:

- Extensive experience in water treatment solutions

- Wide range of plant capacities to suit different needs

- High-quality components and durable construction

- Comprehensive pre and post-sale support

- Energy-efficient designs

- Competitive pricing and flexible payment options

- Quick installation and professional maintenance services

- Proven track record with numerous successful installations

- Advanced monitoring and control systems

- Complete water analysis and customized solutions

2. Pure Aqua Technologies

Pure Aqua Technologies has established itself as a reliable Commercial RO Plant Manufacturer in Delhi. With over a decade of experience, they specialize in medium to large-capacity plants suitable for industrial applications. Their systems feature automated operations and come with comprehensive warranty packages. The company offers installation services and regular maintenance support to ensure optimal plant performance.

3. Waterkraft Systems

Waterkraft Systems rounds out the top three manufacturers, known for their innovative approach to water treatment solutions. They focus on energy-efficient designs and user-friendly interfaces in their RO plants. The company provides customized solutions based on input water quality and client requirements. Their after-sales service includes operator training and quarterly maintenance checks.

Bottom-line

When planning to invest in a commercial RO plant, customers should consider factors like water quality requirements, daily consumption needs, available space, and budget constraints. Netsol Water's expert team can help analyze these factors and recommend the most suitable solution. They also provide detailed project proposals including technical specifications, installation requirements, and maintenance schedules, helping customers make informed decisions.

Contact Netsol Water for a free consultation to discuss your commercial water purification needs and find the perfect RO plant solution for your business in Delhi.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#delhi

2 notes

·

View notes

Text

Precision Gear Racks for Industrial Power Transmission: Engineering That Drives Performance

In high-performance industrial machinery, gear racks play a pivotal role in converting rotational motion into linear motion. Whether you're automating assembly lines or engineering transportation systems, precision-engineered gear racks ensure durability, accuracy, and efficiency. At Machinefabriek Krimpen, our commitment to quality and customization makes us a trusted source for premium gear racks across the Netherlands and Europe.

What Are Gear Racks?

A gear rack is a linear gear with straight teeth that mesh with a pinion gear to provide linear movement. The combination is widely used in machine tools, automation systems, elevators, and heavy-duty machinery. The gear rack and pinion system enables consistent linear force over extended distances, making it a preferred choice in many industrial applications.

Our Expertise as a Gear Rack Manufacturer

As a dedicated gear rack production factory, Machinefabriek Krimpen combines decades of experience with cutting-edge CNC technologies. We specialize in:

Custom gear racks (maatwerk tandheugels) tailored to specific mechanical applications.

Standard metric and inch pitch gear racks with tight tolerances.

Heat-treated and hardened gear racks for extreme industrial environments.

Applications of Gear Racks in Modern Industry

Our gear racks are vital in industries that demand precision and reliability:

Automation Systems: Smooth linear movement for robotic arms.

Elevator Shafts: Reliable lifting with reduced wear and tear.

Rail Systems: Controlled positioning over long distances.

Packaging Machinery: High-speed, accurate product handling.

Why Choose Machinefabriek Krimpen?

In-House Engineering & Production We design and produce everything in-house, ensuring complete control over quality, lead times, and specifications.

Tailored to Fit With our expertise in maatwerk tandheugels, every rack is built to meet your specific engineering and operational needs.

High-Strength Materials Our gear racks are manufactured using top-grade alloy steel, carbon steel, or stainless steel to handle different load and environmental conditions.

Precision Finishing From straight cutting to grinding and surface treatments, our finishing processes ensure reduced friction and extended component lifespan.

Buying Industrial Gear Racks: What to Consider

Before you buy industrial gear racks, consider the following:

Load Requirements: Choose a material and tooth profile that matches your operational stress.

Length & Modularity: Longer travel requires seamless modular integration.

Backlash Tolerance: Low-backlash designs ensure smooth motion control.

Maintenance & Repair: Our products are designed for easy maintenance and integration with existing machinery.

Our Complete Gear Rack Solutions

We offer a full gear rack set including pinions, mounting hardware, and optional coatings for corrosion resistance. With detailed technical drawings and consultation, we make your product development cycle smoother and faster.

Sustainability & Innovation

At Machinefabriek Krimpen, sustainability is integrated into every aspect of our gear rack production factory. We use energy-efficient processes, reduce material waste, and continuously invest in greener manufacturing technologies.

Conclusion

Whether you're designing a new industrial system or upgrading existing machinery, Machinefabriek Krimpen is your trusted gear rack supplier. From custom gear racks to ready-to-use gear rack sets, our precision-engineered products deliver reliability, performance, and longevity.

#Gear Racks#gear rack production factory#gear rack supplier#maatwerk tandheugels#custom gear racks#buy industrial gear racks#gear rack set#machinefabriek krimpen#machine factory#machinery factory

0 notes

Text

Protect Your Property with Professional Roller Shutter Installation Services

Roller shutters are an essential security feature for properties, offering protection, convenience, and versatility. At UK Doors & Shutters, we specialize in installing high-quality domestic, industrial, and commercial roller shutters tailored to meet the specific needs of our clients.

Why Choose Roller Shutters?

Roller shutters are ideal for securing a wide range of properties, from homes to industrial premises. Here’s why they are a preferred choice:

1. Enhanced Security

Roller shutters provide a durable barrier against unauthorized access and vandalism, ensuring peace of mind for property owners.

2. Versatility

Available in various configurations, roller shutters cater to residential, commercial, and industrial applications, adapting to different sizes, operations, and control mechanisms.

3. Weather Protection

Designed to withstand harsh weather conditions, roller shutters protect your property from wind, rain, and extreme temperatures.

4. Energy Efficiency

Insulated options help maintain indoor temperatures, reducing energy costs.

5. Custom Control Options

Choose how you want your roller shutters to operate, with a range of manual and automated options available.

Domestic, Industrial, and Commercial Roller Shutters

UK Doors & Shutters offers a comprehensive range of roller shutter solutions for different applications:

1. Domestic Roller Shutters

Ideal for securing garages, patios, and windows.

Available in various colors and finishes to match your home’s aesthetic.

2. Industrial Roller Shutters

Heavy-duty shutters for warehouses and factories.

Suitable for frequent use and large openings, operated manually or with chains for oversized shutters.

3. Commercial Roller Shutters

Perfect for retail stores, offices, and other business premises.

Can be customized with branding, perforations, or vision panels for added functionality.

Operating Options for Roller Shutters

Our roller shutters are designed with flexibility in mind, offering multiple operating methods to suit your preferences:

1. Electrical Operation

Single Phase or 3 Phase Outputs: Suitable for both small and large shutters, providing efficient and reliable operation.

Control Options:

Key Switches: Secure and straightforward operation.

Rocker Switches: Simple and intuitive control.

Push Buttons: Easy-to-use options for quick access.

Remote Control Fobs: Added convenience for remote operation.

2. Manual Operation

Operated by hand or using a crank.

For larger shutters, a chain mechanism ensures smooth and effortless operation.

Customizable Features

Our roller shutters can be tailored to meet your property’s unique requirements:

Size: Made-to-measure solutions for a perfect fit.

Material: Choose from galvanized steel, aluminum, or insulated panels.

Finish: Available in a range of colors and styles to complement your property.

Additional Features: Options for vision panels, perforated designs, or fire-rated materials.

Why Choose UK Doors & Shutters?

At UK Doors & Shutters, we are committed to delivering high-quality roller shutter solutions with unmatched service:

1. Expert Fitters

Our experienced team ensures precise installation for long-lasting performance.

2. Comprehensive Options

We offer a wide range of roller shutter types, control mechanisms, and custom features.

3. Free No-Obligation Quotes

We provide clear pricing and expert advice to help you make the right decision for your property.

4. Reliable Aftercare

From repairs to maintenance, we’re here to support you long after installation.

How to Get Started