#automated visual inspection

Explore tagged Tumblr posts

Text

Intsoft Tech machine vision inspection equipment, optical inspection automatic measuring apply in pharmaceutical manufacturing

#automated visual inspection systems#automated visual inspection#machine vision works#vision screening machine#surface inspection#deep learning for vision systems#an optical inspection system is used to distinguish

1 note

·

View note

Text

Introducing EI-AOI, the cutting-edge solution for automated visual inspection that sets a new standard in precision and efficiency. Our revolutionary software, powered by advanced industrial cameras, transforms the monitoring of various meters, including gas flow meters, chemical meters, and all types of analog meters, across industrial sectors.

#AIO#Automated Visual Inspection#Automated Visual Inspection Solutions#Valve Manifold Panels and Boxes#Valve Manifold Boxes

0 notes

Text

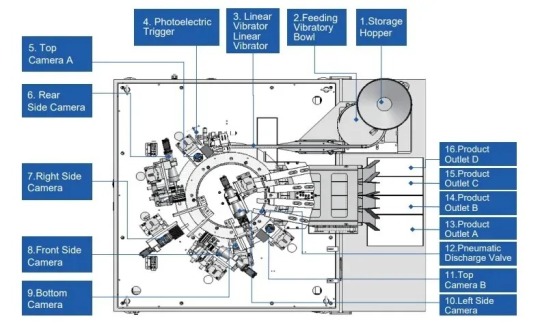

CCD Visual Inspector Manufacturers

CCD visual inspection equipment is a powerful and widely used optical detection equipment. It is mainly used in many fields such as the electronics industry, the automotive industry, and the pharmaceutical industry, playing an important role in improving production efficiency and reducing production costs.

Working Principle

Using optical principles, the product is illuminated clearly with a light source, and the image is taken by a camera, and the image is transmitted to the PC computer vision software for analysis, the analysis results are output, the QR code on the PCBA board is identified, and the image is saved and uploaded to the MES system.

Function and process of CCD visual inspection equipment:

After the product is in place, the stopper stops, and the side camera, top camera, and bottom camera take pictures of the product for analysis. If the product is large, the top camera and bottom camera move once. The equipment has left-in-right-out and right-in-left-out functions, and the inlet and outlet have safety gratings.

CCD inspection content:

Check whether the large components under the product are leaking, deviated more than 10 degrees, or damaged, and save pictures

1. Component size: 3.4*2.7*2.5mm or above 2. Component missing parts must be detected; 3. Component deviation greater than 10 degrees can be detected 4. Component appearance damage and traces can be detected, and the accuracy of appearance damage and traces must be ≤0.2mm; 5. Image storage is saved according to the date, SN, and product code rules

Check the side pin deformation, terminal appearance, damage, and save the image

1. Terminal pin deformation accuracy: 0.25mm; 2. Side component appearance damage and traces can be detected; Terminal appearance damage and trace accuracy ≤0.2mm 3. Image storage is saved according to the date, SN, and product code rules

The gosunm intelligent CCD visual inspection system has high resolution, low distortion in the full field of view, supports -20~50℃ operating temperature, works stably and reliably, and is suitable for various complex industrial visual inspection needs. It displays product images in real time, conducts comparative analysis, and issues an alarm when crimping is poor, and automatically sorts out defective products. Quality monitoring throughout the entire processing process greatly saves labor costs, ensures product quality, and improves production efficiency.

The CCD visual inspection system is the latest visual solution developed by gosunm. The company focuses on technology development and product design in intelligent manufacturing, including non-standard automated production lines, CCD visual inspection labeling solutions, etc. The company's products are widely used in manufacturing industries such as automotive parts, electronics, optical instruments, and special motors. It can customize non-standard automated production lines for various types of processing and assembly for different customers.

#CCD visual inspection equipment#customize non-standard automated production lines#CCD visual inspection labeling solutions#intelligent CCD visual inspection system

0 notes

Text

A manufacturing line that includes a variety of equipment for cleaning, filling, capping, and labeling syrup bottles is known as a pharmaceutical syrup filling line. It’s interesting that it also has an automated syrup production facility. We are a well-known manufacturer of syrup filling lines with uses in the culinary, pharmaceutical, nutraceutical, and herbal industries. Our syrup suspension filling line, which has an elegant appearance, is furnished with state-of-the-art components for production, cleaning, filling, capping, and labeling tasks. The entire suspension fill line functions as a single, integrated system, streamlining the production process.

As one of the top exporters of oral suspension filling lines from India, Adinath has developed both fully automatic and semi-automated oral liquid filling lines. The manufacturing capacity of our filling lines ranges from 500 to 50,000 liters per day.

Let’s have a look on some of the key equipments of our syrup filling line:

Syrup Manufacturing Plant

The pharmaceutical business uses oral liquid manufacturing plants as the best instruments for producing oral liquids. It is specifically made to address two important issues that have a direct impact on the liquids’ quality. Minimal liquid handling by hand and efficient cleanliness throughout production.

youtube

Automatic Bottle Washing Machine

Our bottle washing machine, sometimes called a linear bottle washer, is widely utilized in the pharmaceutical business. It has an all-automatic setup that guarantees hassle-free vial loading on the stainless steel wire mesh conveyor. You can also push them manually from the feed table if you’re comfortable doing things that way. Use this automated machine to save a lot of labor, and you can even opt to have an automatic emptying mechanism when needed. The latter is not required.

youtube

Automatic Bottle Filling Machine

The pharmaceutical business frequently uses bottle filling machines, also referred to as bottle fillers, to pack various liquids into various bottle types. This adaptable device can be used to fill bottles, jars, and containers made of glass, plastic, aluminum, steel, copper, and PET, among other materials. It can also fill aqueous solutions, foamy liquid, and semi-viscous solutions. The machine’s essential components include feeding needles, a piston pump, a quality stainless steel slat conveyor belt, and a robust foundation structure.

youtube

Automatic Bottle Capping Machine

We provide bottle stoppers that are used to cap bottles in a variety of industries, including the manufacturing of chemicals, pharmaceuticals, food and beverage products, pesticides, and alcoholic beverages. Our bottle capping machine is constructed with an M.S. frame and stainless steel enclosures or cladding. An orientation-style cap feeder is included with our ROPP bottle cap sealing machine to ensure smooth cap feeding.

youtube

Bottle Visual Inspection Machine

Adinath International produces and exports a cGMP certified bottle inspection machine with a three track conveyor and hooded lighting configuration. Aside from an inspection table with an SS construction, there is a background that alternates between black and white for a perfect visual inspection. A slat chain made of stainless steel is also a part of it. This machine will last for many years because of its sturdy adjustable bolt support and stainless steel square pipes.

youtube

Automatic Bottle Sticker Labeling Machine

This machine is widely used for labeling PET, aluminum, glass, plastic, and copper bottles, cans, jars, and other containers. With the most advanced microprocessor control label dispensing mechanism available, this linear design machine can detect labels and items with maximum efficiency. Additionally, it features a specially created mechanical and electronic technology that is useful for quickly applying transparent labels on bottles. For the labeling of different bottle types, there are no sections that need to be changed.

youtube

#syrup suspension filling line#oral suspension filling lines#semi-automated oral liquid filling lines#oral liquid manufacturing plants#Automatic Bottle Washing Machine#Automatic Bottle Filling Machine#Automatic Bottle Capping Machine#Bottle Visual Inspection Machine#Automatic Bottle Sticker Labeling Machine#Youtube

0 notes

Text

The Final Click

The video opened with a low mechanical hum, the sound of a workshop alive with quiet, deliberate motion. C9J18 stood on the platform once again, his posture rigid, the sleek black armor now fully integrated with his body. The segmented plates fit seamlessly together, the faint glow of the suit’s internal systems casting a cold light on his skin where it met the edges of the armor. Only his shaved head remained exposed—a temporary state that was about to change.

A Suit Technician stepped forward, fully suited in his own armor, his visor up. His smirk was visible, sharp and cynical, as he held the final piece of C9J18’s transformation: the helmet. The technician turned it in his gloved hands, its polished surface gleaming under the workshop lights.

“Well, here we are,” the technician drawled, his voice filtered slightly through his suit’s comm system. “The crown jewel of your integration. Once this goes on, you’re not just a cadet anymore. You’re part of the system.”

He stepped closer, holding the helmet up for a final inspection. “One size fits all,” he said with a faint chuckle. “Not that it matters. The AI will make it fit... whether you like it or not.”

C9J18 swallowed hard but didn’t respond. He simply stood at attention, his eyes fixed forward as the technician lowered the helmet over his head. The moment it settled into place, there was a sharp click followed by a faint hiss as the seals locked, connecting the helmet to the rest of the suit.

The technician’s smirk widened as he checked his wrist-mounted display. A stream of telemetry data scrolled across the screen, highlighting C9J18’s vitals, neural responses, and suit integration status. “Look at that,” he said with mock admiration. “Perfect fit. Just like it was made for you. Or maybe you were made for it.”

Inside the helmet, everything was dark at first—an all-encompassing blackness that seemed to press against C9J18’s senses. For a moment, there was only the sound of his own breathing, amplified slightly by the helmet’s internal comms. Then, with a faint whir, the visor began to activate. A dim light flickered to life, growing brighter as the system calibrated itself to his neural patterns.

“Welcome to your new world,” the technician said, watching the data streams on his display as the helmet synchronized. “Don’t worry—it’ll all start to make sense soon. Or not. Either way, you’ll adapt.”

The visor fully illuminated, revealing the HUD for the first time. The view was clinical, sterile, and utterly devoid of humanity. Unimportant details in the workshop were greyed out, the AI deeming them irrelevant. Telemetry data crawled across the edges of his vision—heart rate, oxygen levels, suit integrity. A faint overlay marked the positions of nearby personnel, each tagged with their alphanumeric IDs.

The technician gestured at him, his movements highlighted by the HUD. “How’s it feel?” he asked, though his tone suggested he didn’t really care. “Strange at first, isn’t it? Like your head’s full of static. Don’t worry—that’s just the AI integrating with your sensory inputs. Give it a few minutes. You’ll stop noticing soon enough.”

A new menu appeared in the HUD, labeled Calibration, its options faintly glowing. The technician tapped his wrist display, and the menu expanded.

“Let’s get you set up,” he said, his tone laced with sardonic amusement. “We’ll start with the basics. Visual alignment, auditory filtering, neural response thresholds. Don’t worry—we’ll take care of all the hard stuff. You just stand there and let the suit do the thinking.”

The calibration process began. The HUD’s display shifted subtly, adjusting brightness, contrast, and focus. The edges of C9J18’s vision pulsed briefly as the system fine-tuned his peripheral awareness.

“See that?” the technician asked, pointing to a highlighted option in the menu. “That’s your task queue. Automated orders, courtesy of the AI. It’ll tell you what to do, when to do it, and how. You’ll learn to love it—or at least obey it. Either way, it gets the job done.”

Another section of the HUD displayed a comms menu, most of its options greyed out. The technician grinned. “Comms are restricted for now. You’re a cadet. You don’t get to chat unless the system says so. But don’t worry—once you’re authorized, you’ll have the privilege of hearing even more of our delightful voices.”

He tapped another menu labeled Sensory Adjustment. “This one’s fun,” he said, his grin widening. “The AI controls your sensory input. If it thinks something’s irrelevant, it tones it down. If it wants you to focus, it cranks things up. Pain, heat, cold... all dialed to whatever setting keeps you most productive. Efficient, isn’t it?”

C9J18 blinked as the system tested its control, briefly amplifying the sensation of the suit against his skin before dulling it to near imperceptibility. The technician chuckled. “Feels good, doesn’t it? Like a second skin. You’ll forget it’s even there—until you can’t.”

The POV shifted to C9J18’s perspective as the technician stepped back, his figure outlined in faint blue by the HUD. A notification appeared in the corner of the display: Integration Complete. Awaiting Commands.

The technician gave him a mocking salute. “Congratulations, cadet. You’re now a fully integrated asset of the Republic. Welcome to the rest of your life.”

As the feed faded, the Intelligence Conscript’s voice returned, smooth and cold. “The suit isn’t just armor. It’s a system. A tool. A way of life. And now, it’s his reality. Every moment, every thought, every action is guided, monitored, and optimized. He’s not just wearing the suit—he is the suit.”

The final shot lingered on C9J18’s HUD, the unrelenting data streams and greyed-out options framing his vision. The screen faded to black, leaving only the faint hum of the system in the background.

9 notes

·

View notes

Text

A fully automated process, including a brand-new artificial intelligence (AI) tool, has successfully detected, identified and classified its first supernova. Developed by an international collaboration led by Northwestern University, the new system automates the entire search for new supernovae across the night sky—effectively removing humans from the process. Not only does this rapidly accelerate the process of analyzing and classifying new supernova candidates, it also bypasses human error. The team alerted the astronomical community to the launch and success of the new tool, called the Bright Transient Survey Bot (BTSbot), this week. In the past six years, humans have spent an estimated total of 2,200 hours visually inspecting and classifying supernova candidates. With the new tool now officially online, researchers can redirect this precious time toward other responsibilities in order to accelerate the pace of discovery.

Continue Reading.

61 notes

·

View notes

Text

Top Commercial Fence Solutions in Peoria for Business Security and Curb Appeal

When running a business in Peoria, IL, security, privacy, and professional appearance are essential. A well-designed commercial fence not only protects your property but also reinforces your brand’s image. Whether you're managing a construction site, office complex, manufacturing plant, or retail space, the right fencing solution can make a significant difference.

Benefits of Installing a Commercial Fence in Peoria

Business owners in Peoria are increasingly investing in commercial fencing for reasons beyond basic security. Here are some top advantages:

1. Enhanced Security

Protect valuable inventory, equipment, and assets from theft or vandalism. A properly installed fence creates a clear physical barrier and deters unauthorized access.

2. Improved Privacy

Some commercial operations require discretion. Fencing with privacy panels or slats helps shield sensitive areas from public view.

3. Controlled Access

Add automated gates or keypad entry systems to restrict access and monitor who enters and exits your property.

4. Professional Appearance

First impressions matter. A clean, well-maintained commercial fence adds credibility and visual appeal to your property.

5. Compliance with Local Regulations

Many Peoria zoning ordinances require proper enclosures for certain commercial activities. A local fence contractor can ensure your fence meets city codes and guidelines.

Popular Commercial Fence Types in Peoria

Not all fences are created equal. Depending on your industry and property type, one of the following options might be ideal:

Chain Link Fences: Affordable, strong, and widely used for utility yards, factories, and sports complexes.

Ornamental Steel or Aluminum Fences: Stylish and secure — ideal for professional offices, schools, and government buildings.

Vinyl Fencing: Great for commercial plazas and apartment complexes; offers a clean, modern look with minimal upkeep.

Wood Fences: Often used for restaurants, daycare centers, and outdoor venues needing a natural, warm appearance.

Custom Security Fences: High-security fencing with razor wire, anti-climb mesh, or electric gate systems for sensitive facilities.

Working With a Peoria Commercial Fence Contractor

Choosing the right contractor is just as important as selecting the right fence. In Peoria, a top-tier commercial fencing company will offer:

Free on-site evaluations

Customized fencing plans to match your business needs

High-quality materials built to last through Illinois weather

Timely installation with minimal disruption to your operations

Long-term warranties and maintenance support

Be sure to work with a licensed, insured, and locally experienced fencing provider familiar with Peoria’s business zones and regulations.

Keep Your Investment Protected

After installation, routine inspections and repairs are key. Many fencing contractors in Peoria also offer:

Emergency repair services

Gate automation tune-ups

Fence painting, sealing, or cleaning

Replacement of damaged panels or hardware

Regular maintenance extends your fence’s life and keeps your property looking sharp.

Final Thoughts

Your commercial fence is more than just a boundary — it’s part of your business's identity and security infrastructure. From functional chain link fencing to elegant ornamental options, Peoria businesses have access to a wide range of fencing solutions to suit every need.

Ready to Fence In Your Business?

Partner with a trusted commercial fence installer in Peoria and take the first step toward a safer, more polished business property today.

#fence installation#fence contractor#custom fences#peoria fence company#cosma decking and fence#fence

3 notes

·

View notes

Text

IFC to 3DTiles conversion has evolved to this extent with GISBox

Free on-premise cesium ion alternative

As the next generation of spatial information is used in smart cities, digital twins, infrastructure management, etc., the fusion of BIM (Building Information Modeling) and GIS (Geographic Information System) is now an inevitable trend. However, the barrier of interoperability between systems and formats stands between developers and users.

That’s where GISBox comes in. As a new generation 3D spatial data integration platform, it has the industry’s leading IFC to 3DTiles conversion function, and dramatically accelerates data integration and utilization in the fields of architecture, civil engineering, urban planning, and metaverse.

1 | From IFC to 3DTiles: Technology that fills the last step in “BIM x GIS fusion” IFC (Industry Foundation Classes) is an international standard format for BIM that holds geometric information and attribute data (materials, construction history, management numbers, etc.) of architectural structures. On the other hand, 3DTiles is a lightweight format optimized for real-time display that is used in GIS platforms such as Cesium.

There are structural differences between these two, and the following issues frequently occurred in the conventional conversion process:

✅ Missing metadata: BIM attributes such as materials and specifications are lost during conversion

✅ Performance limitations: If IFC is directly loaded into GIS, the display is heavy and it is not suitable for city-level scenes

✅ Compatibility issues: Problems such as display failure and hierarchy collapse due to differences in IFC versions

GISBox tackles these problems head-on, achieving the industry’s first high-precision conversion + attribute preservation + lightweighting at the same time.

2 | No-code & visualization, a conversion experience that is friendly to non-engineers

Conventional conversion tools require specialized knowledge (GLTF, B3DM, etc.), so the reality was that only a limited number of engineers could use them. GISBox provides a UI/UX that anyone can use, such as:

����️ Import IFC files by dragging and dropping

👀 Preview LOD settings, materials, and hierarchy display in real time

🚀 One-click OGC-compliant 3DTiles data output (compatible with Cesium, SuperMap, Mapbox)

🔧 API that can be linked with Python and JavaScript is also provided, allowing developers to automate processing

3 | Supports a wide range of use cases, from architecture to urban scale GISBox’s IFC to 3DTiles conversion is being used in a wide range of fields, from visualization of individual buildings to urban scale:

🏙️ Smart building management Integrate IoT sensor information into BIM models to visualize building interior condition monitoring and maintenance forecasts.

🌇 Urban planning simulation Convert hundreds of IFC building models into 3DTiles at once and use them for evaluations such as visibility analysis and sunshine analysis.

🛤️ Inspection and maintenance of infrastructure facilities

Convert civil engineering structures such as bridges and tunnels into 3DTiles while retaining their construction history. A digital foundation for maintenance.

🕹️ Metaverse construction

By outputting models in lightweight 3DTiles format, they can be quickly deployed in virtual exhibition spaces and virtual factories.

4|GISBox as a common language for spatial information

GISBox’s conversion engine is not just a technical tool.

It is a bridge between the different cultures of BIM and GIS,

and a common language for digital space that connects design, construction, and management.

In Japan’s accelerating smart city concept, architectural digital transformation, and urban disaster prevention and mitigation measures,

GISBox is expected to be the key to realizing the “democratization of spatial data.”

GISBox Official Teams: https://teams.live.com/l/invite/FEAr12sInvEVy4hFQE Official Teams Group: https://teams.live.com/l/invite/FBAFp0pbqhqlpe1BQI

Contact us to get 7-day Team Plan

2 notes

·

View notes

Text

Comprehensive Industrial Solutions by AxisValence: Advancing Productivity, Safety, and Efficiency

In today’s fast-paced manufacturing world, industrial productivity is driven by precision, consistency, safety, and compliance. Whether it’s printing, packaging, converting, textiles, plastics, or pharmaceuticals—modern production lines demand advanced electro-mechanical systems that minimize waste, ensure operational safety, and improve overall efficiency.

AxisValence, a business unit of A.T.E. India, addresses this demand with a complete range of industrial automation and enhancement products. From static elimination to print quality assurance, ink management, and solvent recovery, AxisValence solutions are engineered to optimize each critical point in the production cycle.

This article provides an overview of the key technologies and systems offered by AxisValence across its diverse portfolio:

Electrostatics: Managing Static for Quality and Safety

Electrostatics can compromise product quality, disrupt operations, and pose serious safety hazards, especially in high-speed processes involving films, paper, textiles, or volatile solvents. AxisValence offers a complete suite of static control solutions:

ATEX AC Static Eliminators: Certified for use in explosive or solvent-heavy environments such as rotogravure or flexo printing lines.

AC and DC Static Eliminators: Designed for long-range or close-range static charge neutralization across a range of substrates.

Passive Static Dischargers: Cost-effective, maintenance-free brushes for light-duty static elimination where power isn't available.

Air-based Static Eliminators / Ionisers: Use ionized air streams for dust blow-off and static removal, ideal for hard-to-reach areas.

Static Measurement & Online Monitoring: Includes handheld meters and IoT-enabled monitoring systems for real-time control and diagnostics.

Electrostatic Charging Systems: Generate controlled static charges for bonding or pinning applications in laminating or packaging lines.

Electrostatic Print Assist (ESA): Enhances ink transfer in rotogravure printing by improving ink pickup and registration.

Camera-Based Web Videos for Print Viewing: Real-Time Visual Inspection

High-speed printing applications require instant visibility into print quality. AxisValence’s ViewAXIS systems are high-performance, camera-based web viewing solutions:

ViewAXIS Mega: Entry-level system with high-resolution imaging for real-time visual inspection.

ViewAXIS Giga: Equipped with 14x optical zoom and X-ray vision for deeper inspection of layered prints.

ViewAXIS Tera: Full repeat system with a 55” display, allowing operators to monitor and inspect the complete print layout in real-time.

Camera-Based Web Videos for Print Viewing systems help identify print errors like registration issues, smudging, or color inconsistencies early in the production run—minimizing rework and improving efficiency.

100% Inspection Systems: Intelligent Defect Detection

Modern converters and packaging companies require automated systems that can identify microscopic flaws at high speeds. AxisValence’s DetectAXIS systems use AI-based image processing and line scan cameras for 100% inspection:

DetectAXIS Print: Identifies printing defects such as streaks, misregistration, color deviation, and missing text at speeds up to 750 m/min.

DetectAXIS Surface: Designed for detecting surface anomalies—scratches, gels, holes, fish-eyes—on films, textiles, and nonwovens.

Real-time alerts, digital roll-maps, and adaptive detection improve quality control while reducing material waste and production downtime.

Ink Handling Systems: Consistent Ink Quality and Reduced Waste

Stable ink flow and temperature directly impact print quality and solvent consumption. AxisValence’s Valflow range ensures optimal ink conditioning through:

Ink Filters: Eliminate contaminants like metallic particles, fibers, and dried pigments that can damage cylinders or cause print defects.

Ink Pumps & Tanks: Efficient centrifugal pumps and round stainless-steel tanks designed for continuous ink circulation and minimal ink residue.

Ink Temperature Stabilisers (ITS): Automatically control ink temperature to prevent viscosity drift and reduce solvent evaporation—delivering consistent print shade and odor-free operation.

Valflow Ink handling solutions are ideal for gravure and flexographic printing applications.

Print Register Control Systems: Precision Alignment in Every Print

Maintaining precise print registration control systemis critical in multi-color printing processes. AxisValence offers two specialized systems:

AlygnAXIS: For rotogravure presses, using fiber optic sensors and adaptive algorithms to deliver real-time register accuracy.

UniAXIS: A versatile controller for print-to-mark, coat-to-mark, and cut-to-mark applications—both inline and offline.

These controllers reduce waste, enhance print alignment, and speed up setup during job changes.

Safety and Heat Recovery Systems: Energy Efficiency and Explosion Prevention

Solvent-based processes require strict monitoring of air quality and heat management to meet compliance and reduce operational costs. AxisValence provides:

NIRA Residual Solvent Analyser: Lab-based gas chromatography system for quick analysis of residual solvents in films.

Air-to-Air Heat Exchangers (Lamiflow): Recover and reuse waste heat from drying processes—improving energy efficiency.

LEL Monitoring and Recirculation Systems: Ensure solvent vapor concentrations stay within safe limits in enclosed dryers using flame ionization or infrared detection.

Together, safety and heat recovery systems ensure both environmental safety and process optimization.

Surface Cleaning Systems: Contaminant-Free Production Lines

Particulate contamination can ruin coating, lamination, and printing jobs. AxisValence offers contactless surface cleaning systems that combine airflow and static control:

Non-Contact Web Cleaners: Use air curtains and vacuum to remove dust from moving substrates without physical contact.

Ionising Air Knives: High-velocity ionized air streams neutralize static and clean surfaces entering finishing zones.

Ionising Air Blowers: Cover larger surfaces with ionized air to eliminate static and debris.

Ionising Nozzles & Guns: Handheld or fixed, these tools offer targeted static and dust elimination at workstations.

Waste Solvent Recovery: Sustainable Ink and Solvent Reuse

Reducing solvent consumption and improving environmental compliance is critical for modern converters. AxisValence partners with IRAC (Italy) to offer:

Solvent Distillation Systems: Recover usable solvents from spent ink mixtures, reducing hazardous waste and cutting costs.

Parts Washers: Clean anilox rolls, gravure cylinders, and components through high-pressure, ultrasonic, or brush-based systems.

Waste solvent recovery systems offer a quick ROI and support zero-waste manufacturing goals.

Why Choose AxisValence?

AxisValence combines decades of industrial expertise with innovative product design to deliver reliable, safe, and efficient solutions for manufacturing processes. With a product portfolio spanning:

Electrostatics & Static Control Systems

Web Viewing & Print Inspection Solutions

Ink Handling and Conditioning Equipment

Register Control and Print Automation

Heat Recovery and Air Quality Monitoring

Surface Cleaning Technologies

Waste Solvent Management

…AxisValence serves diverse industries including printing, packaging, plastic and rubber, textile, pharma, and automotive.

From single-device retrofits to complete system integration, AxisValence enables manufacturers to improve output quality, reduce waste, meet safety norms, and gain a competitive edge.

Explore our full product range at www.axisvalence.com or contact our sales network for a customized consultation tailored to your industrial needs.

youtube

2 notes

·

View notes

Text

Intsoft Tech machine vision inspection solution-tablet appearance inspection

#automated optical inspection aoi machine#optical inspection#exact scanning#machine vision works#automated visual inspection#automated visual inspection systems

1 note

·

View note

Text

The Importance of Cable Management in Electrical Panels

In modern electrical installations, particularly in industrial, commercial, and residential applications, cable management in electrical panels plays a critical role. Poor cable organization can lead to inefficiencies, overheating, safety hazards, and costly downtime. Implementing proper cable management is not just a technical necessity — it’s a long-term investment in the performance, safety, and scalability of your electrical system.

What is Cable Management in Electrical Panels?

Cable management refers to the planning, installation, and maintenance of cables within an electrical panel to ensure neatness, organization, and optimal functionality. It includes the use of accessories such as cable ties, ducts, cable trays, wire markers, and labeling systems.

Common Components Used:

· Cable trays and ducts

· Cable ties and clips

· Wire markers and labels

· Conduits and sleeves

· Cable management panels and grommets

Why is Cable Management Important in Electrical Panels?

1. Enhances Electrical Safety

Proper cable routing reduces the risk of:

· Short circuits

· Arc flashes

· Fire hazards due to overheating or overloading

· Accidental disconnections or loose terminals

Safety is non-negotiable in any electrical system, and disorganized wiring is a known contributor to accidents and failures.

2. Improves System Reliability and Performance

A clean layout ensures stable voltage and current flow by minimizing electrical interference (EMI/RFI). It helps in:

· Preventing signal loss

· Reducing cross-talk in data cables

· Maintaining consistency in power distribution

3. Simplifies Maintenance and Troubleshooting

With labeled and properly routed cables:

· Technicians can quickly identify circuits and connections

· Downtime during maintenance is significantly reduced

· Errors due to wrong connections are minimized

4. Optimizes Space and Panel Layout

Efficient cable arrangement allows:

· Better airflow and heat dissipation

· Accommodation of future upgrades or expansions

· Reduced clutter and stress on terminal blocks

5. Compliance with Standards

Organizations such as IEC, NEC, and IEEE provide guidelines on wiring practices. Adhering to these standards not only ensures safety but also legal compliance during audits and inspections.

Best Practices for Cable Management in Electrical Panels

✅ Plan Before You Install

· Design the cable layout during the panel design phase

· Use CAD software for accurate visualization

✅ Use Quality Cable Management Accessories

· Invest in fire-resistant and durable cable trays and ducts

· Use color-coded wire markers for quick identification

✅ Ensure Proper Bending Radius

· Prevent cable damage by maintaining manufacturer-recommended bend radii

✅ Label Everything Clearly

· Use laser-printed or pre-numbered labels for durability and readability

✅ Separate Power and Signal Cables

· Avoid EMI by isolating high-voltage and low-voltage cables

✅ Secure Cables Firmly

· Use cable ties, clamps, or holders to prevent movement or vibration

✅ Regularly Inspect and Maintain

· Schedule routine inspections to spot frayed, loose, or overloaded cables

Industries Where Cable Management is Critical

· Manufacturing Plants — High-voltage systems and automated machinery

· Data Centers — Dense cable infrastructure and sensitive equipment

· Commercial Buildings — Office automation, security systems

· Healthcare — Life-support systems and diagnostic machines

· Renewable Energy — Solar inverters, battery management panels

Conclusion

Cable management in electrical panels is more than just a matter of aesthetics — it’s a critical component of a safe, reliable, and future-proof electrical system. From enhanced safety to easier maintenance and compliance, the benefits far outweigh the costs. Whether you’re an installer, facility manager, or system designer, investing in organized and well-planned cable management is a smart, long-term decision.

#electrical#electrical equipment#electrical supplies#switchgear#911 abc#oman#arcane#artists on tumblr#batman#cats of tumblr

3 notes

·

View notes

Text

360° No-dead-angle And No-bubble Labeling Solution

The core of the visual labeling machine lies in its highly integrated visual recognition system and advanced laminating technology. At present, many factories are manually laminating and manually positioning the auxiliary materials, but there are still bubbles and large laminating accuracy errors. In order to solve this industry pain point, the bubble-free laminating technology ensures the seamless connection between the label and the product surface, improving the overall aesthetics and market competitiveness of the product. The laminating accuracy is as high as ±0.05mm to ±0.15mm, which provides higher efficiency for labeling operations. Gosunm has developed a high-precision visual positioning auxiliary material laminating machine.

Featureds

360° no-dead-angle lamination

gosunm visual labeling machine can handle products of various complex shapes, and can achieve precise lamination no matter which part of the product needs to be labeled.

Bubble-free lamination

By precisely controlling the labeling process, ensure that the label is tightly attached to the product surface without bubbles or wrinkles, thus ensuring the labeling quality

Non-standard customization

In response to the special needs of different customers, gosunm visual labeling machine provides non-standard customization services to meet various specific production needs,

High-precision lamination

The lamination accuracy is as high as ±0.05mm to ±0.15mm, ensuring the high precision of labeling operations and meeting the industry standards with strict requirements on product quality.

Multiple advantages of visual labeling machine

◆Perfect combination of efficiency and precision

The Hardson visual labeling machine greatly improves production efficiency through automated processes. At the same time, its high-precision visual system ensures the accuracy of labeling position, meeting the dual needs of modern production for speed and quality.

◆Strong adaptability and high flexibility

Whether it is regular or irregular product shape, the Hardson visual labeling machine can quickly adapt to different labeling needs through software adjustment, greatly improving the flexibility and adaptability of production.

◆Reduce labor costs and improve safety

Automated visual labeling machines reduce the physical and mental requirements of operators, which not only reduces long-term labor costs, but also reduces errors and safety hazards that may be caused by manual operation.

Application fields and industry impact

Visual labeling machines are widely used in many fields, including but not limited to:

Consumer electronicsMainly used for labeling of structural shell accessories such as mobile phones, laptops, and tablets

Electronic componentsSuitable for laminating operations of electronic components such as cooling fans and foot pads

Emerging fieldsSuch as FPC wireless charging laminating operations, Hardson visual labeling machines meet the strict requirements of emerging technologies for labeling operations with their high precision and high efficiency

As a key component of intelligent manufacturing, the visual labeling machine has promoted the process of industrial automation. It not only significantly improves production efficiency, but also ensures the consistency and accuracy of product labeling, becoming an indispensable "precision eye" in modern manufacturing. With the continuous advancement of technology, we have every reason to believe that CCD visual labeling machines will play a more important role in intelligent production.

#visual labeling machine#gosunm#CCD visual labeling machines#visual positioning auxiliary material laminating machine#Automated visual labeling machine#visual inspection

0 notes

Text

Smart Switchgear in 2025: What Electrical Engineers Need to Know

In the fast-evolving world of electrical infrastructure, smart switchgear is no longer a futuristic concept — it’s the new standard. As we move through 2025, the integration of intelligent systems into traditional switchgear is redefining how engineers design, monitor, and maintain power distribution networks.

This shift is particularly crucial for electrical engineers, who are at the heart of innovation in sectors like manufacturing, utilities, data centers, commercial construction, and renewable energy.

In this article, we’ll break down what smart switchgear means in 2025, the technologies behind it, its benefits, and what every electrical engineer should keep in mind.

What is Smart Switchgear?

Smart switchgear refers to traditional switchgear (devices used for controlling, protecting, and isolating electrical equipment) enhanced with digital technologies, sensors, and communication modules that allow:

Real-time monitoring

Predictive maintenance

Remote operation and control

Data-driven diagnostics and performance analytics

This transformation is powered by IoT (Internet of Things), AI, cloud computing, and edge devices, which work together to improve reliability, safety, and efficiency in electrical networks.

Key Innovations in Smart Switchgear (2025 Edition)

1. IoT Integration

Smart switchgear is equipped with intelligent sensors that collect data on temperature, current, voltage, humidity, and insulation. These sensors communicate wirelessly with central systems to provide real-time status and alerts.

2. AI-Based Predictive Maintenance

Instead of traditional scheduled inspections, AI algorithms can now predict component failure based on usage trends and environmental data. This helps avoid downtime and reduces maintenance costs.

3. Cloud Connectivity

Cloud platforms allow engineers to remotely access switchgear data from any location. With user-friendly dashboards, they can visualize key metrics, monitor health conditions, and set thresholds for automated alerts.

4. Cybersecurity Enhancements

As devices get connected to networks, cybersecurity becomes crucial. In 2025, smart switchgear is embedded with secure communication protocols, access control layers, and encrypted data streams to prevent unauthorized access.

5. Digital Twin Technology

Some manufacturers now offer a digital twin of the switchgear — a virtual replica that updates in real-time. Engineers can simulate fault conditions, test load responses, and plan future expansions without touching the physical system.

Benefits for Electrical Engineers

1. Operational Efficiency

Smart switchgear reduces manual inspections and allows remote diagnostics, leading to faster response times and reduced human error.

2. Enhanced Safety

Early detection of overload, arc flash risks, or abnormal temperatures enhances on-site safety, especially in high-voltage environments.

3. Data-Driven Decisions

Real-time analytics help engineers understand load patterns and optimize distribution for efficiency and cost savings.

4. Seamless Scalability

Modular smart systems allow for quick expansion of power infrastructure, particularly useful in growing industrial or smart city projects.

Applications Across Industries

Manufacturing Plants — Monitor energy use per production line

Data Centers — Ensure uninterrupted uptime and cooling load balance

Commercial Buildings — Integrate with BMS (Building Management Systems)

Renewable Energy Projects — Balance grid load from solar or wind sources

Oil & Gas Facilities — Improve safety and compliance through monitoring

What Engineers Need to Know Moving Forward

1. Stay Updated with IEC & IEEE Standards

Smart switchgear must comply with global standards. Engineers need to be familiar with updates related to IEC 62271, IEC 61850, and IEEE C37 series.

2. Learn Communication Protocols

Proficiency in Modbus, DNP3, IEC 61850, and OPC UA is essential to integrating and troubleshooting intelligent systems.

3. Understand Lifecycle Costing

Smart switchgear might have a higher upfront cost but offers significant savings in maintenance, energy efficiency, and downtime over its lifespan.

4. Collaborate with IT Teams

The line between electrical and IT is blurring. Engineers should work closely with cybersecurity and cloud teams for seamless, secure integration.

Conclusion

Smart switchgear is reshaping the way electrical systems are built and managed in 2025. For electrical engineers, embracing this innovation isn’t just an option — it’s a career necessity.

At Blitz Bahrain, we specialize in providing cutting-edge switchgear solutions built for the smart, digital future. Whether you’re an engineer designing the next big project or a facility manager looking to upgrade existing systems, we’re here to power your progress.

#switchgear#panel#manufacturer#bahrain25#electrical supplies#electrical equipment#electrical engineers#electrical

6 notes

·

View notes

Text

Video as a Sensor Market Report: Opportunities, Challenges & Projections

Accelerating Intelligence: The Rise of Video as a Sensor Technology

We are witnessing a transformation in how machines perceive the world. The global Video as a Sensor market is advancing rapidly, driven by breakthroughs in edge computing, machine learning, and real-time video analytics. video as a sensor market is no longer confined to traditional video surveillance; it now serves as a dynamic, sensor-based system for intelligent decision-making across diverse industries. From optimizing urban traffic to enabling autonomous navigation, VaaS is a foundational layer of next-generation intelligent infrastructure.

By 2031, the Video as a Sensor market is projected to soar to USD 101.91 billion, growing at a robust CAGR of 8%, up from USD 69.72 billion in 2023. This trajectory is fueled by the demand for automation, real-time analytics, and safer environments.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40562-global-video-as-a-sensor-market

Intelligent Video Analytics: Enabling Real-Time Situational Awareness

VaaS leverages video streams as rich data sources. Through embedded AI algorithms, these systems detect and analyze objects, behaviors, and environments—eliminating the need for additional sensor hardware. This shift towards intelligent visual perception is enhancing operations in mission-critical industries such as:

Public Safety: Automated threat recognition and proactive alert systems.

Retail: Heat mapping, customer journey tracking, and loss prevention.

Healthcare: Patient monitoring, anomaly detection, and contactless diagnostics.

Transportation: Traffic flow optimization, vehicle classification, and pedestrian safety.

Manufacturing: Equipment monitoring, quality inspection, and workplace safety.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40562-global-video-as-a-sensor-market

Video as a Sensor Market Segmentation and Strategic Insights

By Type: Standalone vs. Integrated Video Sensors

Standalone Video Sensors offer edge-based intelligence, allowing immediate processing without dependence on centralized systems. Their advantages include:

Reduced latency

Lower bandwidth usage

Enhanced privacy

Ideal for retail stores, small-scale surveillance, and localized analytics

Integrated Video Sensors incorporate multi-modal data inputs. They combine visual data with thermal, motion, acoustic, and even LiDAR sensors to provide a more comprehensive picture. Applications include:

Autonomous Vehicles: Real-time fusion of vision and radar data

Industrial Automation: Hazard detection and predictive maintenance

Smart Cities: Integrated environment and crowd monitoring

By Material: Components Driving Performance and Durability

High-performance materials play a pivotal role in ensuring the reliability and longevity of video sensors. The key components include:

Camera Lenses: Engineered from precision optical glass or polycarbonate for clarity and high zoom capabilities.

Semiconductor Materials: CMOS sensors dominate due to their power efficiency and speed, supporting high-frame-rate video and integration with AI accelerators.

Plastic & Metal Casings: Rugged enclosures designed for outdoor and industrial environments, supporting IP67/IP68 ratings and thermal regulation.

These innovations not only enhance video quality but also reduce device footprint and operational costs.

By End-User: Sector-Wide Transformation Through Video as a Sensor Market

1. Security and Surveillance

Automatic license plate recognition (ALPR)

Biometric identification (face, gait, posture)

Perimeter breach detection

Crowd density analysis

2. Retail

Queue management systems

Shopper intent prediction

Stock-out alerts and planogram compliance

Behavioral segmentation

3. Automotive

Adaptive cruise control and lane-keeping

360-degree situational awareness

Driver monitoring systems (DMS)

Smart parking automation

4. Healthcare

Non-intrusive patient surveillance

Elderly fall detection

Remote surgery and diagnostic imaging

Infection control via contact tracing

5. Smart Cities

Traffic light optimization

Illegal dumping and graffiti detection

Air quality monitoring via visual indicators

Emergency response coordination

Regional Video as a Sensor Market Outlook: A Global Wave of Adoption

North America

With a mature tech ecosystem and strong surveillance infrastructure, North America remains a leader in adopting advanced VaaS systems, especially for homeland security, smart policing, and industrial automation.

Asia-Pacific

Rapid urbanization and significant investments in smart city projects across China, Japan, and India position this region as the fastest-growing VaaS market. Automotive and manufacturing sectors serve as major adoption verticals.

Europe

Driven by stringent GDPR compliance and sustainability goals, Europe emphasizes privacy-focused AI video analytics. Intelligent transportation systems (ITS) and energy-efficient smart buildings are driving demand.

Middle East and Africa

Massive infrastructure initiatives and security upgrades are propelling demand. VaaS is gaining traction in oil facilities, public safety, and tourism hubs.

South America

Emerging VaaS applications in agriculture (precision farming), logistics, and crime detection are gaining momentum as governments and enterprises modernize legacy systems.

Competitive Landscape: Leaders in Video Intelligence

The competitive environment is shaped by innovation in AI chips, edge processors, and scalable cloud architectures. Major players include:

Hikvision – AI-powered surveillance and edge computing

Bosch Security Systems – Integrated security platforms

Axis Communications – Smart network cameras with in-built analytics

Honeywell International – Industrial-grade video intelligence

FLIR Systems – Thermal and multi-sensor fusion

Sony & Samsung Electronics – High-resolution CMOS sensors

Qualcomm, Intel, NVIDIA – AI chipsets and embedded vision

Google Cloud & AWS – VaaS via scalable, cloud-native platforms

Smaller innovators and startups are also disrupting the field with niche capabilities in facial recognition, retail analytics, and edge-AI chipsets.

Future Outlook: Pathways to Intelligent Automation

The future of the Video as a Sensor market is shaped by convergence and miniaturization. We anticipate:

Edge-AI Proliferation: Microprocessors integrated directly into cameras

5G-Enabled Real-Time Processing: Enabling ultra-low latency video transmission

Privacy-Preserving AI: Federated learning and on-device encryption

Autonomous Monitoring: Drones and mobile robots using vision as their primary sense

These trends position video as not just a sensor but as a strategic tool for perception, prediction, and control in an increasingly automated world.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40562-global-video-as-a-sensor-market

Conclusion

The evolution of Video as a Sensor technology is redefining how industries sense, interpret, and act. As AI-driven video analysis becomes a core enabler of digital transformation, the Video as a Sensor market is poised to be one of the most impactful sectors of the coming decade. Enterprises and governments that invest early in scalable, intelligent video infrastructure will gain unprecedented advantages in efficiency, security, and operational agility.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

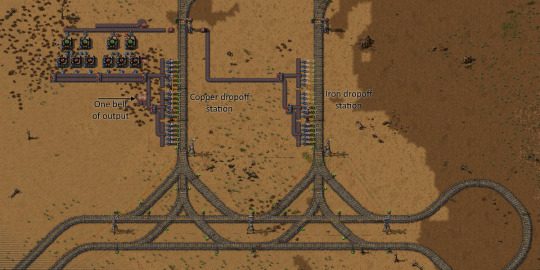

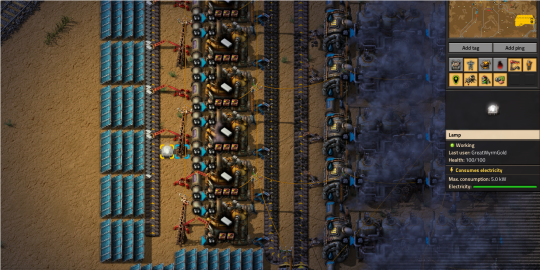

Back to Factorio. Last time, I came within one inserter of setting up nuclear power before noticing that my other solutions had finally brought the factory to a decent equilibrium. This time, I'm making green chips. After some uneventful building, I throw together this prototype.

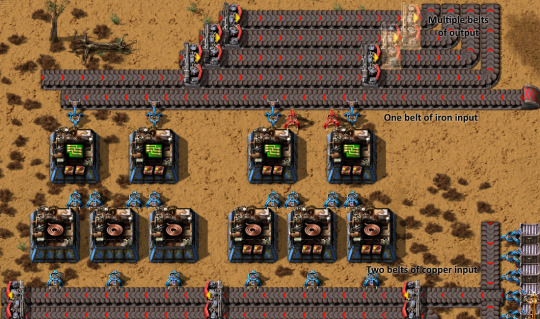

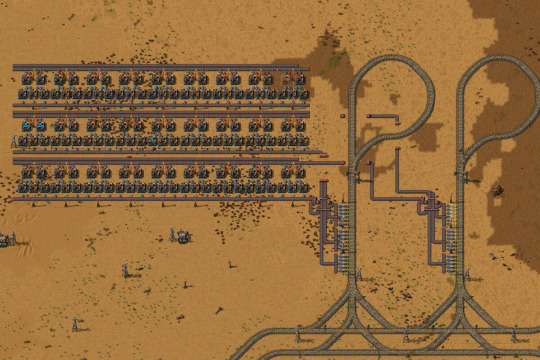

Very simple; separate train stations for the two inputs, and a belt of output that would go to its own separate station. But that single belt of output is kind of a problem. It can only carry a couple dozen assemblers' worth of green circuits, and if I want this one outpost to make a significant fraction of the circuits I'll need once I start plowing down the tech tree, I need way more. I think I'll aim for four belts of green chips.

Cool, but new problem: Input. Four belts of chips require four belts of iron and six belts of copper. Well, a little less with productivity modules, but not whole belts less. I can't build this as one big line. I have to build it as three little lines.

Well, "little" is perhaps not the right word here. Three sets of eighteen chip assemblers, compared to the five I had in my starter base. My bots are busy.

Wait a second. That's a lot of bots.

Oh, there goes my power again. But on closer inspection, this has less to do with bots charging than it does with coal vanishing, due to the coal train getting stuck at the mines.

After like an hour of messing around with train signals, redesigning intersections trying to figure out what screwed-up rail code is causing these problems...I realize a couple of rail segments in a curve are missing. Pretty much invisible to human eyes. Ugh.

...

That's where I logged off for the night, and thank goodness for this self-inflicted log forcing me to keep track of what I was doing, because a bunch of real-life stuff kept me from playing Factorio for several months. But now I'm back, and I have a log of what I was trying to do back in March. I started by making sure the coal-fired boilers were back online (getting there), and I noticed something I'm pretty sure is a visual bug.

I think the solar panels are casting shadows on the belt despite A. the presence of a light source on the other side of the belt and B. the fact that it's the middle of the night. Also the shadowed plastic looks too dark either way, especially with the normal plastic next to it.

Anyways, just two paragraphs after thanking March Me for his brilliant foresight, I have to curse him for his stupidity. Apparently he either never set up automated long-handed inserters and assembling machines, or tore it down when he started disassembling the starter base. Foolish either way.

Once I rectified that with a bit of spaghetti stapled onto the starter base, I realized I needed a lot of power poles for the new chip build, and also that I only automated the big ones. But that means I had everything for medium poles in one spot, and I just needed a little spaghetti to get everything into place.

Word of advice: Don't play with the Renai Transportation mod if you don't want to face constant spaghetti temptation. And if you do, make sure not to power thrower inserters until they're set properly.

Anyways, in the time it took to set that up and take the provided poles to power the new build, all the assemblers and inserters were pretty much produced. And in the time it took to figure out the Screenshot Toolkit, they were delivered.

All I need to do is get the trains set up.

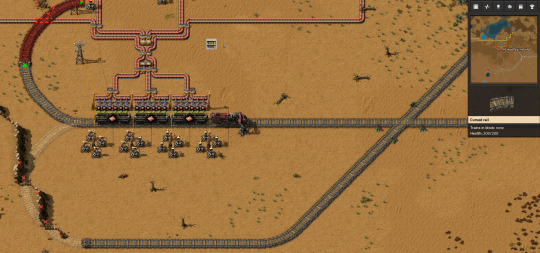

Iron is easy enough; I've already got an iron train running from the iron mines to the starter base, so I just tweak its schedule so it switches between supplying the starter base and the circuit station.

I don't have anything like that for copper; the starter base is still running off the, um, two mining drills which still have ore. About 5,000 between them when I checked, one of which should last a bit less than an hour, the other almost two hours. Hm. Maybe I should have set up something for getting copper to the starter base.

I didn't, though. I didn't even get copper delivered to the circuits. That's because of a terrible mistake I made when setting up the copper mine's loading station.

Whichever way I curve this track, it runs into cliffs. That's what cliff explosives are for, but I never researched cliff explosives. And I tore down my starter base's labs ages ago.

Next time, I will do one of three things:

Find some fortuitous route between cliffs that gets me out of this mess

Set up temporary labs to research cliff explosives, and also temporary cliff explosives production

Move the station five meters to the right

I should probably also do something about our copper situation.

3 notes

·

View notes

Text

Behind the Scenes: A Day in the Life of a Hot Sauce Producer

Morning: Sourcing the Best Ingredients

The day starts early at Modern Food Products with the sourcing of fresh ingredients. As a leading hot sauce supplier in KSA, the company emphasizes quality and consistency. The procurement team works closely with local farmers to ensure a steady supply of high-quality peppers, garlic, and other essential ingredients. The team conducts thorough inspections to ensure that only the best produce makes it into their sauces.

Farm Inspections and Quality Control

Farm Visits: Regular visits to farms are essential to maintain strong relationships with farmers and to ensure sustainable farming practices.

Quality Checks: Each batch of peppers is inspected for color, size, and heat level. Only the peppers that meet the strict standards are approved for processing.

Late Morning: Production Begins

Once the ingredients arrive at the production facility, the real magic begins. The production process at Modern Food Products is a well-oiled machine, designed to maximize efficiency while maintaining the highest standards of quality.

Washing and Preparing Ingredients

Cleaning: All ingredients undergo a rigorous cleaning process to remove any dirt, pesticides, or contaminants. This step is crucial for maintaining the purity and safety of the hot sauce.

Preparation: Peppers are sorted, and stems are removed. Garlic is peeled, and other ingredients are prepped according to the recipe specifications.

Mixing and Cooking

Recipe Formulation: Modern Food Products prides itself on its proprietary recipes, which are carefully guarded secrets. Each recipe is a precise blend of ingredients designed to deliver a unique flavor profile.

Cooking: The ingredients are then cooked in large vats. The cooking process is closely monitored to ensure that the flavors meld perfectly and that the sauce achieves the desired consistency. Temperature control is critical, as overheating can alter the flavor and texture of the sauce.

Afternoon: Bottling and Packaging

After cooking, the hot sauce is ready to be bottled. This stage is as crucial as the preparation and cooking stages, involving stringent hygiene and quality control measures.

Bottling Process

Sterilization: Bottles are sterilized to prevent any contamination. This is a key step in ensuring the shelf stability of the hot sauce.

Filling: The hot sauce is poured into bottles using automated machines that ensure uniformity and prevent spillage. Each bottle is filled to the exact level to maintain consistency across batches.

Labeling and Packaging

Labeling: Bottles are labeled with the brand’s distinctive design. For clients interested in hot sauce private labelling in Saudi Arabia, Modern Food Products offers customization options to create unique labels that reflect their brand identity.

Packaging: The labeled bottles are packed into boxes for distribution. Packaging is designed to protect the bottles during transit and storage, ensuring that the product reaches consumers in perfect condition.

Late Afternoon: Quality Assurance and Testing

Quality assurance is a cornerstone of Modern Food Products' operations. Throughout the day, samples from each batch are tested to ensure they meet the company’s high standards.

Sensory Evaluation

Taste Testing: A team of experienced tasters evaluates the flavor, heat level, and consistency of the hot sauce. This step ensures that every batch delivers the expected taste experience.

Visual Inspection: The color and texture of the sauce are inspected to ensure they align with the product specifications.

Laboratory Testing

Microbial Testing: Samples are tested for microbial contamination to ensure the hot sauce is safe for consumption.

Chemical Analysis: The pH levels and other chemical properties are analyzed to ensure the sauce’s stability and shelf life.

Evening: Logistics and Distribution

As the day winds down, the focus shifts to logistics and distribution. Modern Food Products, being a prominent hot sauce producer in the Kingdom of Saudi Arabia, has a well-established distribution network that ensures timely delivery to retailers and customers.

Inventory Management

Stock Monitoring: Inventory levels are monitored in real-time to ensure there is always enough stock to meet demand.

Order Fulfillment: Orders from retailers and private label clients are processed and prepared for shipping.

Shipping and Delivery

Distribution: The packed hot sauce bottles are loaded onto trucks for delivery to various locations across KSA. The logistics team ensures that the products are delivered on time and in perfect condition.

Export: For international clients, including those looking for a hot sauce supplier in KSA, the export team handles all the necessary documentation and logistics to ensure smooth international shipping.

Conclusion: The Passion Behind the Spice

The journey of hot sauce from farm to bottle is a testament to the dedication and passion of the team at Modern Food Products. As a leading hot sauce producer in the Kingdom of Saudi Arabia, the company’s commitment to quality, innovation, and customer satisfaction is evident in every bottle they produce. Whether you are enjoying their signature hot sauce or benefiting from their hot sauce private labelling in Saudi Arabia, you can be sure that each drop is crafted with care and expertise.

So, the next time you reach for that bottle of hot sauce, remember the intricate process and the hardworking individuals behind it. From the early morning farm inspections to the late evening logistics operations, every step is a crucial part of bringing that fiery flavor to your table.

#Hot sauce supplier in KSA#Hot sauce private labelling in Saudi Arabia#Hot Sauce producer in Kingdom of Saudi Arabia#Condiments manufacturer#Condiments exporter#Private Labelling services#Food processing company#Food distributors company#Food manufacturing companies#Food product company in India#India#UAE#KSA#Oman

4 notes

·

View notes